40 Embodied Carbon Reliable data and identifying the level our timber products contribute to the built environment. 46 Homegrown Timber Growing and specifying the best that British forests have to offer: how hard can it be?

38 Timber is the Way to Go Delivering the Government’s Timber in Construction Policy Roadmap will have profound changes for the UK.

MEDITE SMARTPLY

DESIGN TECHNOLOGY SUSTAINABILITY INTERVIEWS NEWS ANALYSIS CASE STUDIES Issue 35 – Spring 2024 – £4.95 www.structuraltimbermagazine.co.uk

Achieving Airtight Homes and Net Zero with OSB

Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

IFirstly, you’ll see that we have given

nside, we cover some important areas that will be affecting the way we use and think about timber for years to come. Published in December last year, the UK Government’s Timber in Construction Roadmap – with its framework for increasing the use of timber in construction – set out seven key priorities to secure a better future for our forests and timber products. These priorities are all touched on this issue across many of the features on offer.

The Roadmap had some clear messaging about what ‘government’ will do and what ‘industry’ will do. Some of that will live in the ‘work in progress’ realm for quite some time I believe, but it is a commitment from a Conservative administration that has a haphazard approach to its sustainability and decarbonisation aims. But the STA, TDUK and Confor will be acting as a joint Secretariat of a working group leading the development and implementation of solid plans to deliver each of the seven key priorities.

One of those priorities is the creation and distribution of dependable and consistent

data. In case you missed it, TDUK has provided invaluable insights into the embodied carbon data of timber products consumed in the UK. Encompassing over 95% of timber consumed, it is a free resource for design teams to accurately assess the carbon impact of their material choices and paves the way for a heightened sense of what is meant by sustainable construction.

The UK’s position as the second-largest net importer of timber globally – trailing only behind China – underscores the urgent need to re-evaluate our timber consumption patterns. What can be done to expand the market for homegrown timber? By increasing tree planting in England, this promises a more diverse domestic timber supply over the long term, but we must also move away from overspecification of timber and ignoring the grade strength of the timber under our noses. Again, all of this and more inside.

As ever, many thanks to all our contributors, advertisers, and supporters for their help this issue, it is always genuinely appreciated.

3 www.structuraltimbermagazine.co.uk

DEFECTING CROSSCUT SAW

AUTOMATIC OPTIMISING &

to the first issue of Structural Timber Magazine for 2024.

magazine

Pip

01743 290006|

pip.greenroyd@radar-communications.co.uk

produced and published by Structural Timber Media Ltd 101 Longden Road, Shrewsbury, Shropshire, SY3 9PS T: 01743 290001 Subscriptions and back issues visit W: www.structuraltimbermagazine.co.uk Advertising Opportunities For all advertising enquiries contact: Karen Cox, Account Manager Radar Communications Ltd T: 01743 290001 E: karen.cox@radar-communications.co.uk Disclaimer: The content of Structural Timber Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved. Print Printed on FSC Mix paper by Buxton Press Ltd Palace Road, Buxton, Derbyshire, SK17 6AE T: 01298 212000 W: www.buxtonpress.com We are always looking for the latest industry news, people appointments and project case studies using all types of timber systems and products. For use both in print and online please send them to me at the contact email above. Gary Ramsay | Consultant Editor Email: gary.ramsay@structuraltimbermagazine.co.uk

Welcome Welcome

the

a facelift and refreshed the way it looks and feels while still retaining our usual focus on the varied world of timber. Contact Structural Timber Circulation:

Greenroyd T:

E:

Production: Design Team T: 01743 290001 E: design@structuraltimbermagazine.co.uk Accounts: Debra Brooks T: 01743 290016 E: debra.brooks@structuraltimbermagazine.co.uk Structural Timber Magazine is

Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

Cover: MEDITE SMARTPLY

The use of structural timber in both traditional and modern methods of construction will be instrumental in the UK achieving its net zero targets and meeting the Future Homes Standard.

UK Industry News

A quick round-up of some recent news stories from the timber and construction sectors that you may have missed including: Donaldson Timber Systems appointed to the CHIC Newbuild Development Framework, a joint industry Secretariat is formed to drive the Government’s Timber in Construction Policy Roadmap working group and 55 100-year-old Douglas Fir logs help build a new home.

26 Make Double Capacity a Reality

How do you double your manufacturing capacity without increasing your overheads? Machinery specialist Weinig are working with industry partners to prove exactly how it can be done.

28 Healthy Buildings: Healthy Planet

Over 150 delegates from across the construction sector attended the ASBP Healthy Buildings conference recently, which this year focused on biodiversity, forestry and health and wellbeing.

32 Balancing Conservation With Refurbishment

Newson’s Yard is a high-profile design hub featuring top end retail outlets and eateries, located in a reimagined former timber yard with a mass timber solution at its core.

34 Energy Efficiency and Elegance

A contemporary take on a Derbyshire Longhouse has delivered a beautifully designed, multigenerational house using SIP panels to deliver high energy efficiency.

36 Growing Timber Homes

Brooks Dye Works, a regeneration scheme in St. Werburghs, Bristol is one of the latest developments to benefit from an innovative timber frame design, expertise and product innovation.

38 Timber is the Way to Go

Delivering the Government’s Timber in Construction Policy Roadmap will have profound changes for the UK. Andrew Carpenter, Chief Executive of the STA, discusses potential industry impact.

40 Unlocking Timber’s Carbon Credentials

Questions surrounding the levels of embodied carbon in construction are not easily answered but new data on timber products provides new levels of understanding.

46 Branching Out: Using UK Timber

Can the construction industry support the UK timber industry by specifying and procuring responsibly sourced UK grown timber?

48 World of Warmth & Vibrancy

Michelin Scotland Innovation Parc is an ambitious joint venture between Scottish Enterprise, Dundee City Council and Michelin with glulam and CLT a major element of its Innovation Hub.

50 Optimising Our Environmental Resources

Stopping climate change demands bold action and the construction industry is both part of the problem and a potential solution. Chloe Donovan, Managing Director at Natural Building Systems explains more.

5 Structural Timber Magazine www.structuraltimbermagazine.co.uk Contents

6 26 32 36 40 48 28 34 38 46 50 8

Achieving Airtight Homes with OSB

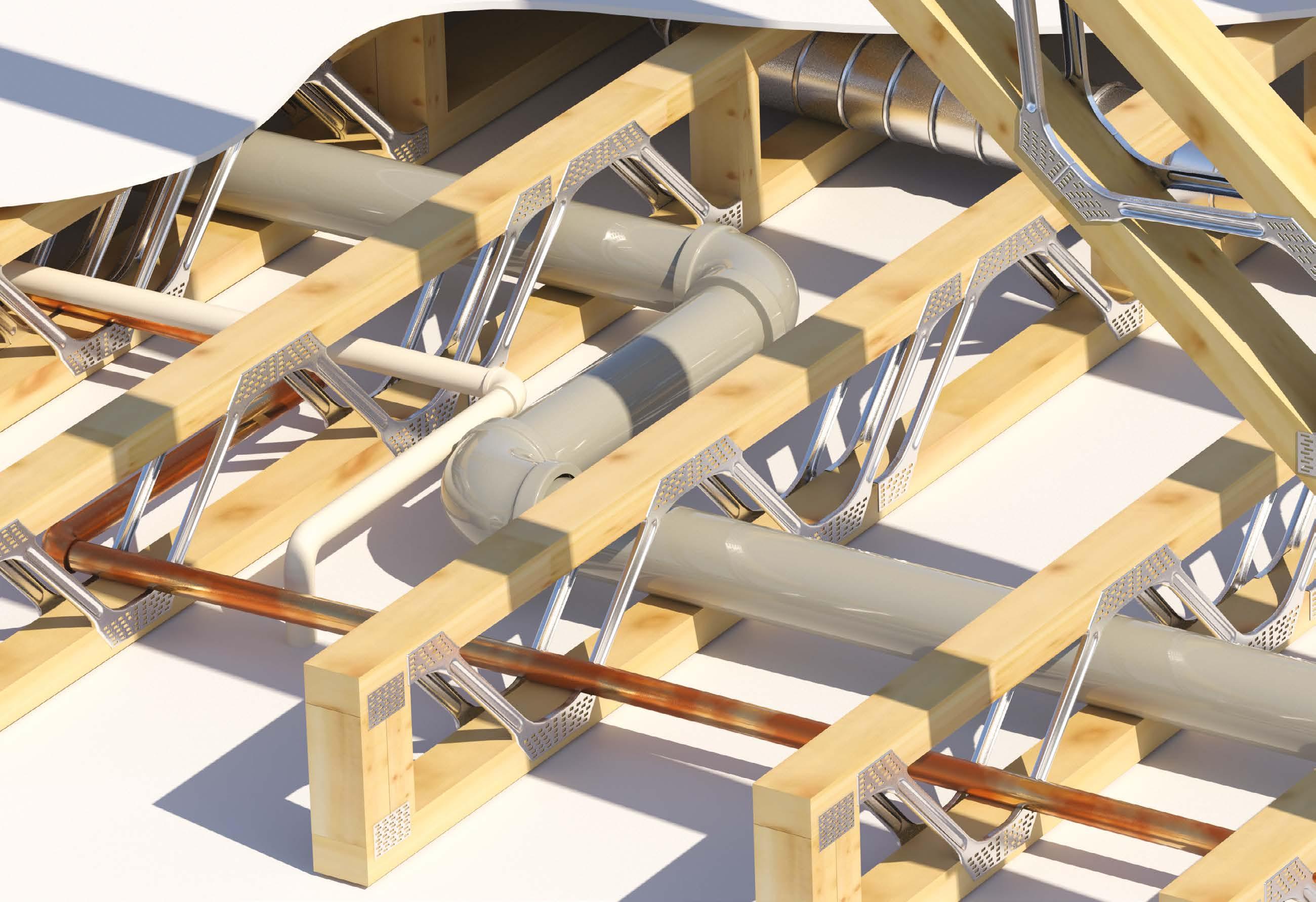

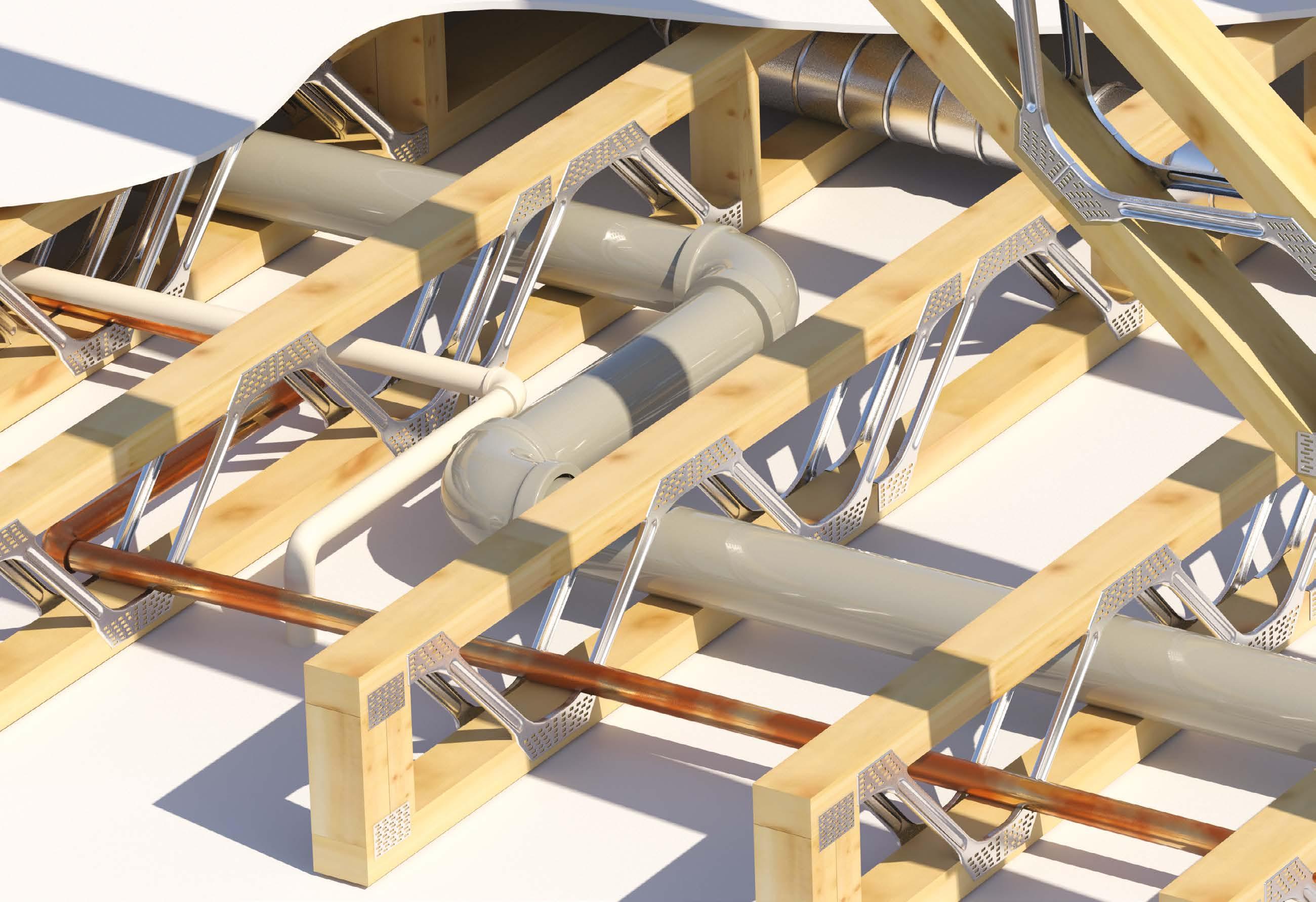

The use of structural timber in both traditional and offsite construction will be instrumental in the UK achieving its net zero targets and meeting the Future Homes Standard – what part can OSB play in making this happen?

The use of structural timber in both traditional and offsite construction will be instrumental in the UK achieving its net zero targets and meeting the Future Homes Standard – what part can OSB play in making this happen?

With new homes expected to produce 75-80% less carbon emissions compared to current levels, OSB with built-in vapour and air barrier properties emerges as a potential game-changer and a robust sheathing solution for timber frame contractors striving to meet the stringent airtightness requirements of this new standard.

With the government’s updated Part F and Part L requirements of the Building Regulations seen as an important stepping-stone to the Future Homes Standard in 2025, there is no escaping the fact there needs to be a clear emphasis on the design of a building’s envelope. This heightened focus on the building fabric presents both challenges and opportunities. As a route to more thermally-efficient building envelopes, it will become critical to ensure buildings are airtight. Timber frame manufacturers that can provide high-performance, airtight envelope solutions will be well-positioned to meet these changing regulations and capitalise on the move towards low-energy construction.

Pushing the envelope

In order to meet the evolving standards, there is an innovation solution to simplify the path to airtight building envelopes. The increasing demand for double sheathed timber frames in both structural applications and the development of offsite closed panels, led to innovation for producing an airtight OSB/3 panel with airtightness engineered into the panel substrate. The panel can be used as the airtight layer on the warm side of the insulation in timber frame construction systems, helping to create an airtight building envelope.

With new homes expected to produce 75-80% less carbon emissions compared to current levels, OSB with built-in vapour and air barrier properties emerges as a potential gamechanger

Each panel features alternating layers of wood strands coated with a high-quality formaldehyde-free resin and wax binder system to deliver outstanding levels of airtightness. A specialist coating is then applied to ensure vapour resistance and provide a premium performance OSB solution for super-insulated and passive buildings and enabling the elimination of a traditional additional vapour control membrane from the construction.

By seamlessly integrating air and vapour barriers into high-performance OSB panels, this streamlines the installation process, minimising the risk of air leakage that often plagues traditional timber frame structures. This cutting-edge solution not only simplifies construction but also ensures a certified, proven approach to creating airtight building envelopes that will pave the way for lowcarbon, energy-efficient homes of the future.

High-quality fresh air

Whilst airtightness is important for avoiding heat loss, an appropriate ventilation strategy should also be considered as without it, a building can potentially suffer from moisture and condensation issues and a reduction in indoor air quality. To maintain a healthy indoor air quality whilst minimising energy loss, controlled

Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

Cover Story – MEDITE SMARTPLY

mechanical ventilation with heat recovery (MVHR) is a requirement in Passivhaus buildings. This involves extracting hot air from wet rooms such as bathrooms and kitchens and supplying fresh air to living areas and bedrooms. The fresh air is filtered and is heated by the extracted air through a heat exchanger. In very cold climates, the fresh air can be heated through ground or air source heat pumps.

Smarter housing

Testament to the benefits of OSB with built-in vapour and air barrier properties is an exciting regeneration project in Cardiff. Lowfield Timber Frames specified SMARTPLY AIRTIGHT panels alongside a supply of their timber kits for a development of 12, twobedroom houses in Heath, Cardiff. Built to strict Passivhaus standards, the homes offer improved health and wellbeing conditions for occupants whilst requiring very low levels of energy for space heating or cooling. Additionally, using timber frame for the construction lowers the carbon footprint of the development. One of the principal benefits of a Passivhaus build is the significant reduction in energy consumption during the operating life of the structure. This will ultimately lead to reduced energy costs, heating bills, and even lower carbon emissions for the planet.

Showcasing an impressive level of airtightness, the average air test result for the 12 homes in this development came in at below 0.5 ACH. Furthermore, a Larsen truss panel (a lightweight wall extension which creates extra wall space to a house insulation) was also used in the project. It was 330mm deep with the finished wall make-up being closer to 500mm, allowing for thicker insulation.

Darren Jarman, Managing Director of Lowfield Timber Frames, commented:

“The Highfields scheme in Cardiff was just one of several Passivhaus schemes we have completed over the past two years. We now have an external wall build-up that not only meets the Passivhaus standards, but also has extremely low embodied carbon credentials.”

Darren Jarman, Managing Director of Lowfield Timber Frames

“The Highfields scheme in Cardiff was just one of several Passivhaus schemes we have completed over the past two years. We now have an external wall build-up that not only meets the Passivhaus standards, but also has extremely low embodied carbon credentials. Whilst there are other products available which will achieve the airtightness, we feel SMARTPLY AIRTIGHT is the most robust solution available and eliminates the possibility of accidental damage, resulting in a failed test.” For timber frame contractors, OSB that features integrated vapour control and air barrier properties will enable timber frame contractors to consistently achieve the stringent airtightness levels needed and create airtight, high performance building envelopes that surpass the new Future Homes Standard with ease.

www.mdfosb.com/en/products/smartply-osb

7 Structural Timber Magazine www.structuraltimbermagazine.co.uk

Cover Story – MEDITE SMARTPLY

New STE Timber Vehicle Storage Solutions

Scott Timber Engineering (STE) has unveiled a set of standardised timber vehicle storage solutions and porches, aimed at allowing housebuilders to cut down construction time and resources on-site whilst adding value to properties.

Providing alternatives to bricks and mortarbased garages and porches, the Easi-fit range comprises prefabricated components made from engineered timber which are delivered on-site to housebuilders on a just-in-time basis for rapid assembly. STE have focused on developing a set of standardised measurements and configurations that can easily be procured and incorporated into housing developments at scale.

“With Easi-Fit, we have focused on developing an attractive, practical solution for housebuilders looking to add something special to their developments,” said James Scott, Managing Director of the Scotts Group. “We’re taking advantage of timber’s suitability for offsite construction to deliver time and cost savings without compromising on quality or desirability. We are confident our solutions will add significantly to the aesthetics of any housing scheme.”

One of the additional selling points of EasiFit is sustainability replacing mortar or steel solutions for porches and garages with durable timber to help reduce carbon footprint and increase the use of natural materials.

The timber for Easi-Fit is manufactured from a range of PEFC-certified and sustainabilitysourced timbers including Redwood, Whitewood Oak, Douglas Fir, and Accoya.

James Scott continued: “Scotts recently completed our carbon footprint certification to help ensure we can maximise the low carbon benefits of timber products for our customers. For every tonne of timber used in our buildings instead of concrete, another two tonnes of carbon dioxide emissions are saved. Easi-Fit is designed to make it as easy as possible for housebuilders to replace aspects of their builds with timber, so it really is a win-win for our customers in sustainability, costs and speed of installation.”

Scotts Timbers has secured contracts with Miller Homes to deliver Easi-Fit products with several more contracts in the pipeline. All customers will be provided with on-site training to ensure Easi-fit products can be installed as efficiently as possible.

From its manufacturing centres in Thrapston and Redditch, Scotts Timber Engineering works with major volume housebuilders, specialist luxury homebuilders and other developers across the country.

It designs, manufactures, and supplies timber-engineered roof trusses, spandrel panels, metal web joists, porches and canopies, as well as car barns and carports.

www.scottste.co.uk/easi-fit-timber

NEWS IN BRIEF

Phoenix Ready to Rise

Human Nature has secured planning permission for a 685-home riverside estate known as the Phoenix. It will transform a former industrial site in Lewes, East Sussex and is set to be one of the biggest timber developments in the UK. Human Nature was founded by former Greenpeace directors Michael Manolson and Jonathan Smales.

RTE Enhancing Mass Timber Offer

Robertson Timber Engineering (RTE) has announced its boosting its timber solutions in line with customer requirements and combined net zero goals. RTE currently delivers to Scotland’s housing market and recently supplied the timber frame kit to the £27million ONE SeedPod project and Moorpark Primary School in Kilbirnie.

Beesley & Fildes Invests in New Treatment Plant

Beesley & Fildes has invested £300,000 in a new timber treatment plant at its Chester branch. The facility adds to a vast range of timber services offered across the North West. The merchant manufactures engineered timber products from its Widnes branch, including roof trusses, I-joists and Posi-joists.

BSW Chairman Tony Hackney Retires

BSW Group’s UK Chairman, Tony Hackney, has announced his plans to retire at the end of March, following a 30-year career in the timber sector. Tony has been the figurehead of BSW for more than 15 years, having joined as CEO in late 2008 and stepping into the role of UK chairman last year.

TimberTight Looks to Expand

Cleckheaton-based, TimberTight, which designs, makes and erects timber frames plans to grow its workforce and double its production capacity. The family-run business recorded 38% growth during the 12 months from October 2022 to October 2023 – an increase in turnover from £3.75million to £5.2million.

Charley Brentnall 1956-2024

A well-known and admired structural timber pioneer recently passed away. Charley Brentnall along with Roderick James were the original founders of Carpenter Oak & Woodland, that morphed into Carpenter Oak. Charley was also a co-founder of Xylotek Advanced Timber Structures, the timber specialist responsible for many cuttingedge timber projects including the demountable ABBA Arena.

8 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

ACTIS

9 Structural Timber Magazine www.structuraltimbermagazine.co.uk

CERTIFICATE 22/646

Log House Built With 100-Year Old Douglas Fir Logs

Logs the length of a double decker bus, harvested by Forestry Land Scotland (FLS) and supplied to a specialist log cabin builder, are now being used to build a full-scale log house. The house is now being constructed by Bedrock Buildings and erection on-site is expected to begin in the early summer, on a plot of land in the village of Tomich. The finished house will use a total of 55, massive, 100-year-old Douglas Fir logs. Harvested as part of FLS’s A82 steep ground harvesting programme, (designed to remove very large old trees that are now getting too large for the landscape and causing a potential risk), the logs are now being prepared by the Bedrock Buildings team, at their workshop and yard.

The log work (peeling, scribing, cutting and assembly) takes place mostly in the workshop and yard, ahead of a short (2-3 day) assembly on site after which the roof, floors and windows are all added. While the vast majority of FLS timber is sold to a limited number of major sawmillers, who have extensive buying powers, these logs have been supplied to Ross Balharry, owner of Bedrock Buildings as part of FLS’s ‘local marketing strategy’. The strategy allows FLS to engage with SME’s and craftspeople such as furniture makers, who are looking for special timber in small quantities and who would otherwise struggle to purchase timber in the volumes FLS would usually market.

Speaking about the project, Graham Godsman, Marketing

and Sales Business Manager at Forestry and Land Scotland, said: “This is the type of initiative that FLS will be looking to support in future through our local marketing strategy; it’s important we reach out to small and medium sized businesses who may not have the capacity or resources to compete for large scale contracts or who may require to purchase niche products and species from us.”

Ross Balharry founded Bedrock Buildings in 2001 after building his first log cabin with his brother when they were teenagers. He thanked FLS for going the extra mile and being interested in what he is hoping to achieve. Ross explained: “Working with FLS and Calum Duffy has been great: knowing that the requirement was a bespoke order,

for log cabin construction, they helped to find practical solutions throughout, from order to cutting spec, purchase and collection. I was given an opportunity to view and select logs at the felling site, allowing for detailed assessment and measuring up, prior to purchase. This was a huge benefit for me with regards to planning and logistics. The current project is a log house for my mother, - a modest 100m² 1 bedroom build, with mezzanine floor and large veranda. We are still at the beginning of our journey but hope to have four full time employees by the end of the year and aim to construct 2-4 projects like this a year.”

www.forestryandland.gov.scot www.bedrockbuildings.co.uk

10 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

Deeside Timberframe Meet Increased Demand with Hundegger Investment

Responding to a surge in demand and a commitment to leading the timber frame construction industry, Deeside Timberframe has integrated the stateof-the-art Hundegger Saw into their operations.

This strategic move is designed to enhance production efficiencies, enabling the company to accommodate a growing portfolio of projects across residential, commercial, and affordable housing sectors more effectively..

This investment is part of Deeside Timberframe’s broader initiative to expand its product offerings and streamline its manufacturing processes. The introduction of the Hundegger Saw, known for its high precision and fully automatic capabilities, marks a significant step change for the company. It is a clear indicator of the intent to solidify its presence across the UK, aligning with its recent growth trajectory and ambitious expansion plans.

David Crawford, Managing Director, Deeside Timberframe, emphasised the importance of this advancement: “Integrating the Hundegger Saw into our production line is a transformative milestone. It significantly boosts our capacity, essential for keeping pace with the increasing demand. This investment not only reflects our commitment to innovation but also our dedication to delivering quality and sustainable solutions in timber frame construction.”

This collaboration between Deeside Timberframe and Hundegger exemplifies the synergy of cutting-edge technology with industry expertise to meet the evolving needs of the construction sector. It is a powerful testament to how strategic investments in technology can propel the industry forward, setting new standards for efficiency, quality, and sustainability.

www.hundegger.com

www.deesidetimberframe.com

HUNDEGGER TURBO-Drive

THE SUPERCHARGED TIMBER COMPONENT CUTTING

Me and my Hundegger!

Never change a winning team!

hundegger.com

Cutting Machine TURBO-Drive

The most versatile truss and frame component cutting machine in the UK market

• Impressive 450 x 160 mm cutting capacity

• Cutt ing timber dimensions in 5 axis

• Exce llent for the high production of roofing trusses,and timber framing

• Seam lessly links to all the main CAD software suppliers

• In b uilt Board-Stretcher

• Yiel ds more and waste less timber

• Fast, accurate, flexible and affordable

Hundegger UK Ltd.

Chris Osborne

Snetterton Park, Harling Road

Snetterton, Norfolk NR16 2JU

Office: +44 (0)1953 660 331

Mobile: +44 (0)7512 155 156

c osborne@hundegger.com

Innovation in timber engineering

11 Structural Timber Magazine www.structuraltimbermagazine.co.uk Advertorial

TD_4c_93x267+3_GB_Daniel Blades 15_03_2021.indd 1 15.03.2021 07:28:43

DC Timber Systems Awarded STA Gold Standard

DC Timber Systems, timber frame kit specialists and a division of The JR Group, has been accredited with a gold status accreditation – the highest rating which can be achieved - by the Structural Timber Association (STA), through its STA Assure scheme.

The STA Assure membership and quality standards program, is designed to benefit both customers and members alike, promoting the differing specialisms and demonstrating a commitment

to the exceptionally top-level standards held by STA members.

The Gold standard is awarded to businesses who can ensure a consistently high quality of structural timber products and offers complete customer assurance in the construction, offsite build and timber frame build sectors.

This is the second accreditation assigned to DC Timber Systems from the STA since its creation in 2020, when they were previously awarded the silver standard, demonstrating that the business

has successfully showcased its commitment towards the highest quality output possible. Based in Dundonald in Ayrshire it specialises in the design and manufacture of structural and full timber frame kits throughout Scotland and the UK.

Ian Samson, managing director of DC Timber Systems, said: “We are delighted to be awarded the highest possible status from the Structural Timber Association, it is a step forward for DC Timber as a company. This accreditation reflects the hard work of the team

in-house in delivering quality procedures, management systems and product performance as well maintaining the high standards already achieved by us.

“Our gold standard demonstrates our calibre and expertise to the market and offers complete reassurance for our customers. We’re hugely grateful for our workforce on operating consistently at this high level to help us achieve this as a team.”

12 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

www.thejrgroup.co.uk

Timber Industry Will Spearhead Key Government Policy

Working in partnership, the Structural Timber Association, Timber Development UK and the Confederation of Forest Industries (Confor) have been appointed joint Secretariat of the Government’s Timber in Construction (TiC) Policy Roadmap working group, in a bid to expedite delivery of this critical industry plan.

The TiC roadmap – published by DEFRA in December last year – is the culmination of many months of collaboration between Government and industry and sets out a framework for increasing the use of timber in construction. Having already worked together as key contributors to the development of the policy document, the three organisations are well placed to bring their shared expertise to its execution. All three organisations were integral to the creation of the policy roadmap and collectively represent the full spectrum of timber industries.

Crucially, the Secretariat role will be tasked with leading the development and implementation of solid plans to deliver each of the seven key priorities identified within the roadmap, which cover demand, supply, building safety, labour and skills, carbon, insurance, and innovation.

Andrew Carpenter, Chief Executive of the Structural Timber Association, commented:

“I am pleased that DEFRA has recognised the importance of ‘boots on the ground’ expertise and has given us this vital opportunity to shape delivery of such a key piece of policy. Drawing on the combined experience and practical knowledge each organisation brings to the table, we have an exciting part to play in driving these policy goals forwards – turning aspirations into action. Through

TRANSPARENT SELF-ADHESIVE PROTECTIVE

the Secretariat role, we also hope to bring other Government bodies and stakeholders together to support and accelerate the roadmap’s implementation, which is crucial to ensuring the UK stays on track to meet our legally binding climate commitments.”

www.structuraltimber.co.uk www.timberdevelopment.uk www.confor.org.uk

13 Structural Timber Magazine www.structuraltimbermagazine.co.uk

DEFENCE ADHESIVE 200 is the self-adhesive membrane that protects timber building elements.

rothoblaas.com Choose efficient and reliable solutions, choose self-adhesive membranes from Rothoblaas.

Extremely transparent and durable, it provides 12-week protection against water, rubbing and dust. It can be repositioned and reapplied in the event of an error, making the work of professionals who install it off-site or on site easier.

Industry News

CCG Celebrates 50 Years of ‘Building Futures’

Glasgow construction and manufacturing group CCG is proud to announce its 50th anniversary in 2024, marking five decades of innovation across the Scottish construction sector.

Founded in 1974 as a small heating and plumbing contractor, CCG has grown into a full-service construction and manufacturing company, one of the largest of its kind in the country, with 738 dedicated employees deployed across eight, fully integrated divisions.

The Group’s annual turnover for construction now exceeds £240million with 90% of business being the delivery of mixed-tenure housing. To commemorate this significant milestone, CCG’s Board of Directors – Alastair Wylie, Chairman and CEO, Bernard Rooney, Financial Director, Managing Director, David Wylie, and Directors Calum Murray, Stephen Ruxton, John Baggley, and Graeme Wylie – were pictured together at the company headquarters in Cambuslang.

Alastair Wylie, who has been CEO since 1994, said: “As we reflect on this remarkable half-century, CCG stands tall as an industry leader—a testament to resilience, adaptability, and unwavering commitment to construction. The Scottish construction landscape has shifted, but alongside our peers, we continue to deliver in the face of ever-changing economic conditions.

“Our own success has been achieved with a clear strategy of investment in our products and people and as we stand here today at our headquarters in the Cambuslang Investment Park which we built 23 years ago, I am immensely proud of our continued, sustainable growth and am thankful for the support of our employees, partners and clients.”

CCG operates principally as a main contractor for new housebuilding with over 2,500 mixed-tenure homes currently on-site across the Central Belt however the majority of projects are now supported by a wide range of additional, in-house services.

The company’s offering includes the manufacture of timber systems and window and doorsets, main utilities, M&E and renewables as well as flooring installation, and plumbing and joinery trades. An entire division dedicated to the planned maintenance of occupied homes under tenancy of RSL’s and councils also forms a large part of the firm’s operations alongside CCG Homes, the firm’s private housing division which is currently marketing two

developments in Glasgow and the West of Scotland.

CCG Managing Director David Wylie has been with the Group for 25 years and credits the continued support and investment of the Board for positioning the business as an industry leader for sustainable housing delivery across the country. He said: “The CCG Group is uniquely placed to address Scotland’s housebuilding and sustainability targets because of our Board’s ongoing commitment to reinvest. The catalyst for developing our product offering began fourteen years ago when we opened CCG Offsite Manufacturing (OSM): a £12million facility that uses a mix of craftmanship and automation to design and fabricate closed panel timber systems.

“It is a more efficient way of constructing new homes and buildings and it has been the blueprint for CCG ever since. We now integrate these timber systems with our own products and once we reach the site, we have our own construction teams to ensure delivery, offering a ‘whole’ service unlike anything in the Scotland.”

Alongside innovation in construction, CCG places a strong emphasis on its people. The company is well known for its approach to youth employment and skills development, something that is evident across its workforce with 55 trade and modern apprentices, 12 trainees, and 25% of all staff aged under 28.

www.c-c-g.co.uk

14 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

15 Structural Timber Magazine www.structuraltimbermagazine.co.uk Industry News Fastening Technologies for Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK. Fastening Technologies for Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK. Fastening Technologies Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices you can depend on from BeA Fastening Fastening Technologies for Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK. Fastening Technologies for Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service and delivery BeA Fastening Systems UK. Fastening Technologies for Future Generations Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK. Fastening Technologies for Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK.

Technologies for Future Generations

Fastening Systems UK. FOR AUTOMATION Fastening Technologies for Future Generations

competitive prices and

kind of service

delivery BeA Fastening Systems UK. Fastening Technologies Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service you can depend on from BeA Fastening Systems UK. Fastening Technologies Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of you can depend on from BeA Fastening Systems UK.

Fastening

Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA

group.com

the

and

Kirkwood Timber Frame Appoints Two New Directors

Aberdeenshire-based Kirkwood Timber Frame has appointed Barbara Massie as business development director and promoted Steven Robbie to technical director designate, following its commitment to expanding its market share and driving advancement to modern methods of construction (MMC).

Leveraging its state-of-theart facility and innovative build systems – including open panel, closed panel, and floor and roof cassettes – the company aims to play a key role in shaping the future of the timber frame industry in the UK.

Barbara Massie, with over 19 years of experience in the construction industry, has established valuable connections and acquired extensive expertise.

She held key roles such as regional director at NorDan UK and trading director for North England and Scotland at Travis Perkins PLC, with a focus on company growth and future development. With a passion for creating vision and strategy, Barbara is joining the team to drive Kirkwood Timber Frame’s market share growth in the UK. Her focus will be on cultivating customer partnerships, building relationships, and ensuring the company remains a leading solution provider.

Barbara commented:

“Throughout my construction career, I have always had a passion for timber frame, and I have followed the growth of Kirkwood Timber Frame as well as celebrated its successes along the way. My primary focus is to deliver strong results and

adapt to the ongoing challenges and shifts within the industry. I am dedicated to promoting, developing, and establishing Kirkwood Timber Frame as a market leader in modern methods of construction (MMC) in both Scotland and England.”

In a significant achievement, Steven Robbie has also been promoted to technical director designate, marking his first directorial role. Joining Kirkwood Timber Frame in 2021 as a technical manager, Steven’s 24 years of experience position him as a vital asset to the company. This promotion reflects Kirkwood Timber Frame’s dedication to nurturing talent and growing its internal expertise. With a critical focus on training and mentoring, Steven’s role will enhance the capabilities of the team, utilising Kirkwood Timber Frame’s

automated production facility to drive efficiencies and contribute to the company’s overall growth.

Managing director of Kirkwood Timber Frame, Malcolm Thomson, emphasised the significance of these appointments, stating: “The new appointments are pivotal for Kirkwood Timber Frame as we expand the business and support the government’s roadmap towards promoting timber as a critical building material and achieving net zero. Timber and offsite manufacturing will play a crucial role in sustainable building, and the growth opportunities here are incredible, supported by Barbara and Steven in their new roles.”

L-R Steven Robbie, Malcolm Thomson, Barbara Massie.

16 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

www.kirkwoodtimberframe.co.uk

Structural Timber Magazine www.structuraltimbermagazine.co.uk

Visually graded

Fully compliant to all

standards*

Third party accreditation*

Available in 25mm x 38mm / 50mm 01623 446 800 | www.sr-timber.co.uk SRTA0324 V1 | © SR Timber 2024. All rights reserved. The information contained in this document is believed to be correct at the date of publication. Images shown are for illustration purposes only Did you know SR Timber can also supply... Cedar Shingles OSB Graded Carcassing Don’t forget to protect your batten end cuts with... BATTEN SHIELD n Makes batten cut ends complaint with BS 5534 n Prevents water damage n 0% VOCs * Relevant standards: BS 8417:2011 (Preservation of Timber) and BS 5534:2014+A2:2018 *Third party accreditation regularly audited by CATG (UKAS Accredited) to ensure continued and consistent application of British Standards. THE FUTURE IS GOLDEN! WITH PREMIUM GOLD BATTEN

n

roofing battens n

relevant

n

n

TDUK Data Highlight Positive Timber

Despite the challenging end to 2023 seen across the construction sector, timber import volumes for the year were actually higher in three of the six product groups, with softwood imports in 2023 just outperforming the volumes seen in 2022 with growth of 0.8%.

Overall, the volume of the main imported timber and panel products ended 2023 a little lower than in 2022, down by 2.2% on the previous 12 months.

The main timber and panel products sectors saw mixed fortunes throughout 2023. After a slow start, softwood imports gained impetus in the second half, to end the year 1% higher. Hardwood, plywood, particleboard and engineered wood products imports were all lower in 2023, but OSB import volumes were significantly higher (up 19.4%) and MDF volumes, too, were 2.2% higher than in 2022.

Volumes in the first half of 2023 trailed those seen during 2022, but modest improvements in the second half of the year made up for much of this lost volume. The scale of the cumulative deficit of all import volumes in 2023 compared to 2022 reduced each month starting from the middle of the year, until the final month when December brought weaker volumes across the board than were seen in December 2022.

Import volumes in the final quarter of 2023 were 1% below the same quarter in 2022. Crucially, the four quarters of 2023 saw a greater stability return to the market, with substantially less volatility in imposrts compared to each of the four quarters of 2020, 2021 and 2022, during which time the timber market fluctuated significantly.

TDUK Head of Technical and Trade, Nick Boulton, said: “Now that we have the full import data for 2023, we can take a longer-term

view of the import performances right across the main timber and panel products sectors. Despite a difficult year in 2023, the growth path for nearly all timber and panel products remains positive.

“As we move into 2024, the outlook for the timber sector is cautiously optimistic for the rest of this year, with indications of modest growth to come as the UK economy begins to recover

Glidevale Protect Supports Zero Carbon Concept House

Glidevale Protect has supplied two of its market leading wall construction membranes for use at the Vistry Innovation Centre – a unique new concept house built in timber frame that signposts the products and technologies which will support the housebuilding industry on the road to net zero.

Developed by housebuilder Vistry Group, the new Vistry Innovation Centre features a flagship property that relies on a fabric first approach mixed with a range of cutting-edge technologies needed to create the homes of the future. Glidevale Protect supplied a combination of its low emissivity products - Protect TF200 Thermo external wall breather membrane and the air and vapour control layer Protect VC Foil Ultra for the internal walls of the concept home.

Both membranes feature a high-quality reflective surface with strong aged thermal resistance that is designed to prevent heat loss, and when used together as a system, they are particularly effective at maximising thermal efficiency. With the two products having recently received independently verified Environmental Product Declarations (EPDs), they are ideally suited for use in the next generation of low carbon homes.

Glidevale Protect is one of a number of innovative product manufacturers to support Vistry Group in the creation of this important

from the technical recession we experienced at the end of 2023. The ability of timber products to weather the instability and adverse influences of the first three years of the 2020’s and emerge with virtually all products remaining on a positive growth path is a testament to the strength and resilience of the UK timber industry.”

www.timberdevelopment.uk

research facility, having worked closely with leading builders’ merchant Jewson, one of the main sponsors on this project, in the supply of its construction membranes.

Jack Brayshaw, Head of Technical Innovation at Vistry Group commented: “Collaboration and support from our supply chain partners has been an integral part of the development of the Vistry Innovation Centre as we brought together more than 50 individual suppliers. The Centre is designed to pave the way for creating ‘next generation’, future-proofed homes so it was crucial to design and develop the property with the most energy efficient products available built on the foundation of a fabric first approach. The products and materials installed at the centre not only work well individually but together provide a holistic, whole house solution and we are pleased to include Glidevale Protect’s construction membranes in this project.”

Located at Vistry Works East Midlands, the housebuilder’s timber frame construction factory in Leicestershire, the Vistry Innovation Centre has been constructed using 18 different trades and 54 suppliers, featuring over 100 different products and smart technologies.

www.glidevaleprotect.com

18 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

Innovative Thinking –Revolutionary Technologies

OFFSITE CONSTRUCTION WEEK shines a spotlight on the transformative digital, material and manufacturing innovations that are advancing the design and application of offsite construction processes.

Become a Host and Run Your Own EventWe Can Help!

If you would like to host an event of your own during Offsite Construction Week* we can utilise our platforms to promote your events.

To give you inspiration, events can include:

FACTORY TOURS

ROUNDTABLE EVENTS

SITE STUDY TOURS

WEBINARS & PODCASTS

BREAKFAST CLUBS

DRINKS RECEPTIONS

... just as long as you are talking about offsite technology!

* We recommend avoiding the 17 & 18 September due to major industry events taking place

All events during OFFSITE CONSTRUCTION WEEK are FREE to attend

Contact the team on 01743 290001 or info@offsiteconstructionweek.co.uk

www.offsiteconstructionweek.co.uk

PARTNERS:

19 Structural Timber Magazine www.structuraltimbermagazine.co.uk

DTS Secures CHIC Framework for Timber Frame

Leading UK offsite timber frame manufacturer, Donaldson Timber Systems (DTS), has been appointed to the Communities and Housing Investment Consortium’s (CHIC) Newbuild Development Framework.

As part of CHIC’s new eight-year framework, DTS will sit on the ‘MMC (Modern Methods of Construction) Manufacturer – Frame & Panel’ workstream, delivering timber frame and panels across the UK to create modular new-build homes. The design, manufacture, and installation of timber frame wall panel building systems will meet build speed, fabric performance, building design, and cost requirements.

With a fabric-first approach that achieves net zero operational carbon, DTS’ timber systems will create sustainable, resilient homes that meet the Future Homes Standard 2025.

The CHIC Newbuild Development Framework aspires to establish a new Gold Standard development framework to offer solutions for

development and regeneration schemes of all types and sizes across the UK. As well as a route to market for members, CHIC intends to establish a ‘Framework Core Group’ that shares learning, understanding and ideas and promotes standardisation and collaboration. DTS was involved in competitive tenders based on CHIC’s standard house types and a wide range of rates for all other work. In total, the CHIC framework totals £3.16 billion.

Gemma Darroch, National Partnerships Manager from Donaldson Timber Systems said: “We’re really pleased to have been named as one of the long-term contracts on the CHIC Newbuild Development Framework. For decades we have been championing offsite timber frame systems, which use innovative and sustainable technologies and play a key role in meeting the energy requirements of new homes. We’re proud to be promoting this further via this framework over the coming years.”

Sarah Davey, CHIC’s Head of Development added: “We are excited to have Donaldson Timber

Systems on CHIC’s Newbuild Framework. They will be an instrumental part in helping our members deliver their newbuild development efficiently setting a gold standard for the industry.”

Last year, DTS became one of the first manufacturers to achieve Buildoffsite Property Assurance Scheme Plus (BOPAS Plus) in recognition of the quality and durability of its offsite build systems. With DTS’ state-of-theart open and closed panelised systems – Alpha, Delta, and Sigma ll – works can still be carried out on-site, ensuring that social value potential is reached within the communities served.

The Sigma II closed panel systems offer near-Passivhaus standards of performance and sustainability. The system is being widely used with housing developers, particularly with those driven by whole life costs and fabric performance, contributing positively to fuel poverty challenges.

www.donaldsontimbersystems.com

20 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK Industry News

Deltabeam®: Longer Spans & Open Spaces

Hopealaakso Kindergarten is currently being built in Helsinki, Finland with a frame made of mass timber elements and DELTABEAM®.

The developer of the kindergarten, the City of Helsinki, organised a design and build competition. The frame solution was not specified so each participant suggested a frame of their choice. The winner was decided on price, architecture and environmental issues.

“It became clear that we were the only one of the four finalists to offer a timber-structured option,” recalls Project Manager Janne Manninen. “We assume that a timber-framed option was not more expensive to build than concrete, even though weather protection was included in the tender.”

As the aim of the frame solution was to achieve long spans, open spaces, and slim floors, the DELTABEAM® was a conscious choice. “We used DELTABEAM® to make full-height cross laminated timber (CLT) elements work as floorheight walls. This kept the number of elements and joints much smaller,” adds Janne Manninen.

According to Puurakentajat Rakennus Oy – the sub-contractor for the frame – the hybrid frame solution works well. “When erecting the

DELTABEAM® enables open spaces and slim floors with timber slabs

DELTABEAM® Composite Beam allows combining a renewable and ecological material, wood, with two of the strongest materials, steel and concrete. DELTABEAM® is an excellent solution for creating a slim floor structure with wooden slabs.

DELTABEAM® allows architectural freedom

Open spaces with minimum columns

A smooth ceiling allows straight and easy HVAC installations

Flexible layout and floor plan over the entire life cycle of the building

Integrated fireproofing

Fast and safe erection process

www.peikko.co.uk

frame, the composite beams were mounted on the walls and screwed on. Using wood beams would have left much less room for technical installations,” explains Jyrki Huttunen, CEO of Puurakentajat Rakennus Oy. Another bonus, the timber-concrete intermediate floor provides sound insulation especially suitable for kindergartens.

Puurakentajat used DELTABEAM® for the first time at the Hopealaakso site. The designs had been done so well that there were no problems during the installation. “They are certainly easy to install at the site, since the requirements of building technology have been taken into consideration as regards perforations, for example,” says Jyrki Huttunen. Both Huttunen and Manninen’s future construction sites in Helsinki at Pakilanpuisto school and Verkkosaari kindergarten will be constructed with the same concept.

www.peikko.com

21 Structural Timber Magazine www.structuraltimbermagazine.co.uk

Products

Building

.uk o.c w w i .

BENEFITS OF USING DELTABEAM® WITH WOODEN SLABS

New-look Posi Span Calculator Gets Technical Upgrade

As the uptake of Posi-Joists grows in the UK and Ireland, MiTek has expanded its Posi Span Calculator to help specifiers generate more detailed data. What’s changed and how does it work?

The adoption of Posi-Joists is on an upward trajectory in the UK and Ireland construction sector. Specifiers looking for solutions to help meet the demands of The Future Homes Standard for newbuilds are adopting the versatility and flexibility Posi-Joists offer. Ideal for supporting the integration of services like MVHR, Posi-Joists also offer a lightweight but strong joist option for wide spans, and are precision engineered offsite. In 2022 Posi-Joist and connector plates were Environmental Product Declaration (EPD) verified for the UK market, which quantified the environmental credentials of both products.

On the back of the product’s continued growth and development, MiTek has upgraded its Posi Span Calculator, (www.mitek.co.uk/spancalculator) to make it easier for specifiers to integrate Posi-Joists into their designs. Building on the existing calculator, architects, self-builders and engineers, for example, can now use it to get an instant idea of whether Posi-Joists are right for their project. And, if they are, what technical specs and quantities they’ll need to support the design.

Select your spec, step-by-step

The calculator has been re-designed as a simple to use step-by-step tool. Users will need to select the required joist application, either floor, flat or pitched roof, choose from a list of pre-defined loading configurations, specify the overall length of the joist(s) and the maximum required joist depth. A range of options are then presented, that provides the required information for specification purposes.

“We know the popularity of Posi-Joists continues to grow and we want to help facilitate the interest,” says Adam Williams, Director of Technical and Engineering Services at MiTek UK and Ireland.

The Posi Span Calculator allows users to input measurements and choose from a list of pre-defined configurations to generate the required information needed for their specifications

The adoption of Posi-Joists is on an upward trajectory in the UK and Ireland.

“Upgrading our calculator in the way we have, now gives specifiers the opportunity to identify what products they need themselves. Created by MiTek’s in-house expert design team, thousands of combinations are fed into the calculator to give optimum results for the end user who can then go away with the results and reach out to a manufacturer, armed with information to get them started.”

Once the details have been generated, specifiers can use the ‘Find a manufacturer’ tool on the Posi Span Calculator homepage to search for local timber manufacturing companies to contact and start the PosiJoist journey. If the measurements needed are outside the parameters of the Posi Span Calculator, then the design team at MiTek are available and can help generate specifications for you.

The new-look and upgraded Posi Span Calculator is now available to use – start generating your specifications today. The MiTek design team can help with the most complex of projects. Contact them at: ukdesign@mitek.co.uk or call 01384 451408. More at www.mitek.co.uk/span-calculator

22 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

Building Products

Structural Timber Magazine www.structuraltimbermagazine.co.uk

16.04.2024

30 EUSTON SQUARE - LONDON

DAVID

08:30 REGISTRATION, EXHIBITION VIEWING AND NETWORKING

09:30 CHAIR INTRODUCTION

Andrew Carpenter, Board MemberConfederation of Timber Industries

STRATEGIC INITIATIVES

09:40 KEYNOTE SPEAKER

David Hopkins, Chief Executive OfficerTimber Development UK

Government Timber in Construction Working Group

10:00

Alex Goodfellow, Chief Executive Officer - Donaldson Offsite

Is Now the Time for Timber?

10:20 RESERVED

10:40 Q&A PANEL DISCUSSION

10:50 PANEL DEBATE:

Building Safety and the Impact of the Building Safety Act

Tim Galloway, Deputy Director Building Safety ProgrammeHealth & Safety Executive

Kelly Harrison, Director - Whitby Wood

Andrew Orriss, Chief Operating Officer - Structural Timber Association

11:10 REFRESHMENT BREAK, EXHIBITION VIEWING AND NETWORKING

SHOWCASING THE BEST OF THE BEST

12:00

12:25

David Lomax, Associate Director - Waugh Thistleton Architects and Duncan Walters, Director - Eckersley O’Callaghan

A Case Study on The Black & White Building

Alex Brock, Pre-Construction Manager - B&K Structures, Ross Barrett, Design Director - HLM Architects, Steve Peet, Associate Engineer - Engenuiti

A Case Study on National Manufacturing Institute Scotland (NMIS)

In partnership with:

24 Structural

Magazine – Issue 35 – Spring 2023 @STMagUK

Timber

PHILIPPA BIRCH-WOOD ROSS BARRETT

ALEX BROCK ANDREW CARPENTER

FINBAR CHARLESON TIM GALLOWAY

CHRIS GAZE ALEX GOODFELLOW

KIRSTEN HAGGART KELLY HARRISON

HOPKINS JESS HRIVNAK

12:50 Steve Wilkinson, Associate - James Gorst Architects

A Case Study on New Temple Complex

13:10 Tim Snelson, Structural Engineer - Arup

A Case Study on Sky Pavilion

13:30 Krzysztof Marcinkiewicz, Associate Director - Heyne Tillett Steel and Lucas Lawrence, Company Director - Studio Egret West

A Case Study on The Arbour, Brent Cross

13:50 Q&A PANEL DISCUSSION

14:00 LUNCH, EXHIBITION VIEWING AND NETWORKING

FUTURE FOCUS – WHAT NEXT FOR TIMBER?

15:00 Chris Gaze, Sustainability Consultant - Structural Timber Association

Timber Construction and Whole Life Carbon

15:20 PANEL DEBATE: Building a Circular Economy with Timber

Philippa Birch-Wood, Local Network CoordinatorUK Green Building Council

Kirsten Haggart, Associate Director - Waugh Thistleton Architects

Charlie Law, Founder & Managing Director - Sustainable Construction Solutions

15:40 Jess Hrivnak, Sustainable Development Adviser - RIBA

Will We Look Back in 2050 and Ask What Went Wrong?

16:00 Finbar Charleson, dRMM

Home-grown Timber, Markets and Opportunities

16:20 Q&A PANEL DISCUSSION

16:30 CHAIRMANS EVENT SUMMARY

16:35 EVENT END

Now is the time to align with industry leaders and strengthen your supply chain, as we ask ‘what next’ for structural timber construction. To learn more about the exhibition & sponsorship opportunities, please contact Karen Cox on 01743 290014 or email karen.cox@radar-communications.co.uk WWW.STRUCTURALTIMBERCONFERENCE.CO.UK

Timber Magazine

25 Structural

www.structuraltimbermagazine.co.uk

LOMAX KRZYSZTOF MARCINKIEWICZ

ORRISS STEVE

SNELSON DUNCAN WALTERS

WILKINSON

CHARLIE LAW LUCAS LAWRENCE DAVID

ANDREW

PEET TIM

STEVE

PROMOTIONAL OPPORTUNITIES AVAILABLE

TICKETS ON SALE NOW

Make Double Capacity a Reality

How do you double your manufacturing capacity without increasing your overheads? This isn’t a trick question with machinery specialist Weinig working with industry partners to prove exactly what can be achieved.

Areal-life example is with London-based external joinery company, Stanbrook & Nicholson. Its recent investment in a Conturex Artis+ CNC single component production system from Weinig has seen the ambitious company introduce new revenue streams and have the capability to complete orders five times larger than ever before.

“In 2010, our company changed direction to become a specialist in external joinery,” says Ben Stanbrook, Director of Stanbrook & Nicholson. “It was at this point we bought our first window line. Since then, the goal has been to own a single component machine that could produce our complete product portfolio – reducing production times and increasing capacity without upping labour costs. In 2022, we found ourselves running at maximum capacity. We knew it was time to put our plans into action.”

In need of a machine that could produce any window component and automatically switch to another in direct sequence while offering zero change-over time on all parts (including profiles and ancillary operations), Ben and his business partner, Simon Nicholson, started investigating Weinig’s offering.

“We’d heard about the Conturex but we presumed it would be out of our financial reach,” says Ben. “Weinig are well known for installing multi-million pound window and door lines into large-scale manufacturing facilities. We didn’t realise a machine like the Conturex

With a maximum tool diameter of 340mm and tool weight up to 12kg, the Conturex allows for mortise and tenon joints to be created with absolute precision

The Conturex offer complete and precise machining in one clamping process thanks to its patented RePos clamping table

26 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

Machinery

would be attainable for a smaller manufacturer like us. When comparing the Conturex to other machines on the market, we knew we were looking at a completely different animal and incorporating this machine into our production would put us on a footing with the big guys.”

Before investing in the Conturex, Stanbrook & Nicolson would batch its machining. “We offer a wide range of products – from windows and doors to roof lanterns and by-fold doors – so our orders are often compiled of multiple parts. Batching items meant we’d be grouping different orders together and having to wait for other parts to be machined before we could complete an order. It made production planning more challenging, often leaving us paying overtime to get jobs done more quickly.

“We’d use a cross-cut saw to start with and move the pieces onto our window line to complete the inner profiles. Then we’d glue up and use a CNC to do the outer profiles. We’d also need to hand finish each piece before painting it. It was a slow process that left room for error and material damages.”

With a three or four-axis 30kW main shaft, profiling on the Conturex can be carried out in a single step, eliminating the need for a CNC and a dedicated operator. “Now, pieces go from the cross-cut saw directly onto the Conturex Artix+ before being painted. We no longer need two people running each machine. One person can now oversee the machining and also have time to support the team in the assembly area. Overtime is a thing of the past, too.”

Adaptive tooling has played a key part in the company’s production figures. Ben explains: “We worked closely with Oertli Tooling to create a tooling solution that would help us get the most out of the Conturex, which included duplicating tooling to speed up production. This has made a huge impact on the time it takes to machine different profiles and the fast rpm on the Conturex offers a much cleaner cut, which means less finishing.”

This has reflected on the company’s order book: “Not only can we confidently work on orders five times bigger than we could before, but we can also incorporate smaller, one-off items into our production schedules thanks to the machine’s quick and easy set-up. We no longer have to wait for a large batch to be completed before we can start work on it or halt production while we manually set-up the machine for a specific order. In fact, it’s so easy to work variations into our production that we now offer an express service to customers.”

The benefits of virtually unlimited design options and quick, precise machining have led to updates in the company’s portfolio. “We’ve change from externally glazed to internally glazed designs and introduced new products, including the Heritage Slim Light – a

As it doesn’t rely on any jigs or fixtures, the Conturex can go from any one window component to another in direct sequence

The Conturex performs five operations in one, replacing the need for several machines, including a drilling machine, mortising machine and/or CNC

traditional sliding sash window that features individual panes of glass. To do this the old way, it would have been painfully slow and unviable financially.”

Ben concludes: “It’s clear to us that the Conturex can double our capacity and we’re expecting to see a return on investment almost immediately. We were maxed out with a turnover of £2-2.5million each year. Thanks to the introduction of the Conturex, we now have the capabilities to reach upwards of £5million per year without any additional staff, bigger premises or more machinery. Our next job is to feed the beast and win larger contracts. Having this kit in our industry sets us at a new level and we’re already feeling the buzz around it. It’s a really exciting time for us and we’re looking forward to the next chapter in our story.”

www.weinig.co.uk

“When comparing the Conturex to other machines on the market, we knew we were looking at a completely different animal and incorporating this machine into our production would put us on a footing with the big guys.”

Ben Stanbrook, Director of Stanbrook & Nicholson

27 Structural Timber Magazine www.structuraltimbermagazine.co.uk

Machinery

Healthy Buildings: Healthy Planet

Over 150 delegates from across the construction sector attended the Alliance for Sustainable Building Products (ASBP) Healthy Buildings conference recently, which this year focused on biodiversity, forestry and health and wellbeing.

One of the reasons people want to commission, design and occupy buildings made with timber is the way wood links us back to nature. The links between timber and nature were a big theme at this years’ conference plus how expanding the use of timber and more bio-based materials across the built environment, can deliver against the core principles of the circular economy.

Giving a keynote talk, DEFRA’s Deputy Director for Trees, Woodlands and Forestry, Bella Murfin, was clear that that the use of timber in construction was good for nature. Referencing the UK Government’s Timber in Construction Roadmap, she outlined the importance of forests and trees for nature and the climate and how the Environment Act is targeting an increase in tree cover in England to 16.5% by 2050.

Ms Murfin challenged the construction industry – particularly in England – to use more timber, pointing out the contrast between England, where timber frame is used in only 9% of newbuild and Scotland, where the figure is 92%. She added that timber construction

St Mary’s Primary, Derby, the UK’s first biophilic school. Courtesy Hawkins/ Brown/Matthew Ling

This was the ASBP’s eighth annual conference

can cut embodied carbon by around 60% - as was demonstrated in calculations carried out for one of the ASBP award-winning projects showcased on the day. Goldfinch Create and Play, a cafe and art space in Bristol used timber throughout. Analysis showed the whole life carbon came in lower than the RIBA 2030 climate challenge levels.

Bella Murfin also supported the greater requirement for design for deconstruction and re-use. Two of the day’s ASBP prize winners were doing exactly this. The Initiative Category People’s Prize winner Brittany Harris explained: “One of the major obstacles to reusing materials is just knowing where everything is.” Its Qflow materials tracking system creates an electronic record of material flows on and off construction sites, making the reuse of materials much more practicable.

Another ASBP People’s prize winner in the Product Category was the timber-and hemp-based ADEPT modular construction system that goes even further to facilitate deconstruction. The panelised system uses timber with a hemp-based insulation. This fits together with removable timber pegs and tongue and groove fixings so that it can be disassembled easily.

28 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

ASBP p30

29 Structural Timber Magazine www.structuraltimbermagazine.co.uk ASBP

“Architects should think about the implications of their design decisions – go beyond just ‘timber is good’ and think ‘are we enhancing the forest’?”

Jez Ralph, Director of forestry consultancy Evolving Forests

Crawford Wright, Head of Architecture for Schools and Colleges at the Department for Education (DfE), spoke passionately about how important interactions with nature are. “This was really brought home during the pandemic. The impacts of COVID-19 on the mental health of children and young people are still being felt. While we can’t fix that, exploring the potential of biophilic schools – schools that bring students and nature close together – felt like something DfE architects could contribute.”

Crawford Wright’s team at DfE, working with the University of Derby, gathered research and information on biophilic architecture, and this led to the design and construction of St Mary’s Primary School, Derby using a SIP panel design and is the UK’s first purpose built biophilic primary school. The aim of the school design is to create an accessible landscape where planting is brought close to the buildings, to offer play, adventure

Harris Academy, Sutton. The timberbuilt school was visited by DEFRA minister Rebecca Pow along with Bella Murfin, describing it as ‘a wonderful school, beautiful and practical’. Courtesy Architype

The ADEPT demountable construction system is a teaching space at Aldershot Construction College. Courtesy Natural Building Systems

and sanctuary. “The entire external setting encourages nature connectedness.” The school is also acting as a testbed, with intensive research into the experience and impact on students and staff.

The use of more broadleaf timber in construction could also support more biodiverse forests. Jez Ralph, Director of forestry consultancy Evolving Forests stressed the value of mixing tree species in planting, not just to benefit the many species that live in woodland, but to protect the forest itself and offer a fresh resource for construction to utilise.

“Construction is very focused on uniformity,” he said. “But a uniform age, single species stand is not ecologically robust. Climate change means more storms and more disease – what if spruce gets a disease? It’s high risk to have very few species.” Jez Ralph hopes for more use of UK grown broadleaf timber in construction, for example thermally modified poplar and sycamore that are compliant with structural requirements, saying: “Architects should think about the implications of their design decisions – go beyond just ‘timber is good’ and think ‘are we enhancing the forest’?”

The day ended with the announcement of the winners of the sixth annual ASBP Awards. All attendees had the opportunity to vote for their favourite entry in the Project, Product and Initiative categories of the awards, following short presentations from the nine finalists. At the evening awards ceremony and drinks reception hosted by ASBP board member Alex Sparrow, the winners of the Judges’ Award, decided following a series of site visits and interviews, and the People’s Prize were announced. The inaugural winner of a new award, created in memory of Neil May who helped set up ASBP and many other sustainability organisations, was presented to Richard Oxley.

For more information: www.asbp.org.uk

30 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

ASBP

Glidevale Protect Publishes Key EPDs

Leading UK building products manufacturer Glidevale Protect has published third party, independently verified Environmental Product Declarations (EPDs) for three of its construction wall membranes to assist specifiers by providing clear sustainability and life cycle assessment data.

Created by One Click LCA and verified by the EPD Hub in accordance with EN 15804+A2 & ISO 14025/ISO 21930, the product and factory specific EPDs do not contain average calculations and have been assessed cradle to gate with modules A1-A3, C1-C4 and D, with the life cycle analysis (LCA) published in accordance with the reference standards ISO 14040/14044. Detailing key environment impact data including global warming potential (GWP) calculations as well as total energy and water use, the EPDs form a transparent analysis of each product’s carbon footprint to give full reassurance in specification.

The development of EPDs for Protect TF200 Thermo, Protect VC Foil Ultra and Protect TF200 demonstrates Glidevale Protect’s continued commitment to and investment in sustainability. Protect TF200 Thermo is a reflective breather membrane for external walls which can enhance thermal performance and Protect VC Foil Ultra, a reflective

air and vapour control layer (AVCL), offers low emissivity to enhance the thermal performance of internal walls, ceilings and floors. Both can be used together as a system to help maximise the energy efficiency rating of a building and control condensation risk. Protect TF200 is a high-performance breather membrane, offering protection to external walls and minimising the risk of interstitial condensation.

Detailed EPDs help specifiers to understand a product’s sustainability credentials when working to more stringent regulations such as Building Regulations Part L as well as whole building environmental assessment standards like BREEAM. EPDs quantifiably demonstrate the environmental impact of a product and data is independently verified and certified in line with internationally recognised standards, focused on the product’s whole life cycle.

31 Structural Timber Magazine www.structuraltimbermagazine.co.uk

Building Products Safety Storage Efficiency combilift.com 2 5 Safety Storage Efficiency combilift.com

find out how Combilift can help you safely and efficiently handle your loads. Contact Us Today

Combilift range of multidirectional forklifts, straddle carriers and

gantries will allow you to increase the storage, efficiency and

of your warehouse when

construction

Offsite Ad A5 Liz 2023 rev 2.0.indd 4 13/04/2023 14:01:29

To

The

mobile

safety

handling offsite

components.

Balancing Conservation With Refurbishment

Newson’s Yard is a high-profile design hub featuring top end retail outlets and eateries, located in a reimagined former timber yard set amidst the famous Pimlico Road Design District. At the core of the development is a mass timber solution.

Created as a mainly residential extension to Belgravia, the Pimlico district of South-West London is known for its garden squares and Regency architecture, being designated a conservation area in 1968. As befits a former timber yard, timber was a key material for this imaginative refurbishment scheme, and B&K Structures (BKS) – a leading exponent of mass timber and structural steel packages – were instrumental in the delivery of Newson’s Yard.

Newson’s Yard has been developed by Grosvenor, with Stiff + Trevillion as architect and Heyne Tillett Steel (HTS) appointed as structural engineer. BKS provided the offsite-manufactured, hybrid steel and engineered timber package, including the use of cross laminated timber (CLT) panels, which formed part of the new internal structure and created an extensive mezzanine level, which stands at the heart of the development’s identity and commercial success.

Design expertise helped address the technical challenges associated with the heavy refurbishment work of Newson’s Yard. Rob Mills of HTS explained: “We were involved in a very detailed survey of the building prior to beginning the design work, which showed the old timbers were actually in quite good

The use of CLT has given the development a gigantic sustainability boost

condition, but the task of incorporating them, and the retained brickwork, into the new structure was extremely complex. Part of the reason we were able to employ a CLT solution was its inherent fire resistance. Each of the units has its own means of escape so we were only required to achieve 30 minutes protection across the mezzanine: which we could justify with the charring characteristic of the CLT and therefore, installing fire sprinklers was unnecessary.”

“From design to manufacturing, transportation and on-site installation, the team used the latest digital tools collaboratively to ensure the project’s speedy and accurate construction. Prefabricated timber panels meant that all elements and connections were able to be fitted offsite and erected very quickly.”

Craig Robinson, Operations Manager, B&K Structures

32 Structural Timber Magazine – Issue 35 – Spring 2023 @STMagUK

Mass Timber

Sustainability was a heavily emphasised requirement for the project. As such, developers opted for offsite mass timber due to its sustainability benefits and its well-recognised structural capabilities. However, loadbearing requirements sometimes require timber to be married with stronger construction materials – primarily steel – to match specific demands. In the case of Newson’s Yard, a hybrid offsite solution in the form of structural steelwork supporting 700 m2 of CLT floor slabs and the retained frame of the Victorian building, proved the ideal combination.

Michael Polack, Technical Manager at B&K Structures, said: “BKS designed the timber and steel connections. The cantilevering internal balconies, and restrictions on loading of the existing masonry piers, led to the challenge of high moments on the CLT to steel connections. This challenge was overcome by using shot fired connections which optimised constructability on-site.”

Just as important was the conservation of the timber yard’s aesthetic, meaning that a totally bespoke design was required. The inclusion of CLT panels for the floor slabs brings several aesthetic benefits to the project, with the new tenants choosing to keep the visual appeal of exposed timber, rather than lining the units. In fact, the designers specified ‘Industrial Visual’ grade CLT slabs, which means the CLT is of a high enough visual quality to be left exposed, which suits the ambience of the former timber yard and offers a long, robust working lifetime.