ailway ge R A

September 2012 | www.railwayage.com

Serving the railway industry since 1856

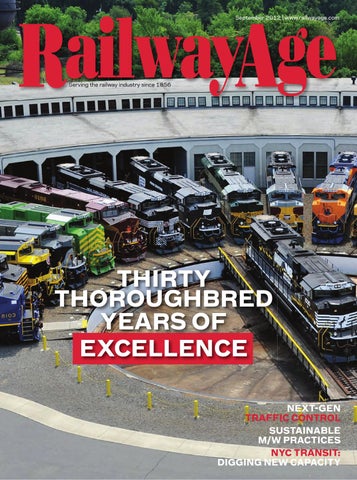

thirtY thoroughbreD YearS of excellence next-gen traffic control SuStainable m/w practiceS nYc tranSit: Digging new capacitY

ailway ge R A

September 2012 | www.railwayage.com

Serving the railway industry since 1856

thirtY thoroughbreD YearS of excellence next-gen traffic control SuStainable m/w practiceS nYc tranSit: Digging new capacitY