AILWAY G E SERVING THE RAILWAY INDU S TR Y S INC E 1856 WWW.RAILWAYAGE.COM OCTOBER 2022 ROLLING INTO ORLANDO Brightline Realizing its Vision TIMEOUT FOR TECH Condition Trending and Predictive Analytics Drama Meter Drops from Red to Yellow DIFFICULTIES MULTI-EDGED

Every day, our high performance fasteners support safe and reliable transportation. Our GE11 e-style clip is produced with an innovative manufacturing process which signi cantly reduces internal stress, improving the fatigue performance beyond that of the legacy eClip. Approved and used by Class I and transit customers, these American-made fasteners are available in both right-handed and left-handed versions. Innovative fastener solutions are just one more way, we keep you rolling.

220057

We keep you rolling.

Railway Age, USPS 449-130, is published monthly by the Simmons-Boardman Publishing Corporation, 1809 Capitol Avenue, Omaha, NE 68102. Tel. (212) 620-7200. Vol. 223, No. 10. Subscriptions: Railway Age is sent without obligation to professionals working in the railroad industry in the United States, Canada, and Mexico. However, the pub lisher reserves the right to limit the number of copies. Subscriptions should be requested on company letterhead. Subscription pricing to others for Print and/or Digital versions: $100.00 per year/$151.00 for two years in the U.S., Canada, and Mexico; $139.00 per year/$197.00 for two years, foreign. Single Copies: $36.00 per copy in the U.S., Canada, and Mexico/$128.00 foreign All subscriptions payable in advance. COPYRIGHT© 2022 Simmons-Boardman Publishing Corporation. All rights reserved. Contents may not be reproduced without permission. For reprint information contact PARS International Corp., 102 W. 38th Street, 6th floor, New York, N.Y. 10018, Tel.: 212-221-9595; Fax: 212-221-9195. Periodicals postage paid at New York, N.Y., and additional mailing offices. Canada Post Cust.#7204564; Agreement #41094515. Bleuchip International, PO Box 25542, London, ON N6C 6B2. Address all subscriptions, change of address forms and correspondence concerning

to Subscription Dept., Railway Age, PO Box 239 Lincolnshire IL 60069-0239 USA; railwayage@omeda.com; or call +1 (402) 346-4740;

October 2022 // Railway Age 1 railwayage.com

FAX

Printed at Cummings Printing,

ISSN

(print); 2161-511X (digital). FEATURES 9 24 28 32 34 38 Financial Desk Book Multi-Edged Difficulties Tech Focus – M/W Fasteners: Hold On Tight! New York MTA The Biggest Bounces Back Tech Focus – C&S Next-Gen Train Control Rolling Into Orlando Brightline Realizes Its Dream Timeout For Tech Tenth in a Series COMMENTARY 2 8 44 From the Editor Watching Washington ASLRRA Perspective DEPARTMENTS 4 6 7 41 42 42 43 Industry Indicators Industry Outlook Market People Professional Directory Classifieds Advertising Index COVER PHOTO An Ontario Southland Railway snowplow train slices through deep drifts on the St. Thomas Subdivision, Gladstone, Ont. Stephen C. Host photo OCTOBER 2022 28 AILWAY GE

subscriptions

+1 (847) 291-4816.

Hooksett, N.H.

0033-8826

Remembering Jim Florio

hose of you who take an interest in rail road history, particu larly the business side, are well aware of the role the 1980 Staggers Rail Act played in shaping our industry as it exists today. But you may not be aware the legislation that enabled partial economic deregulation—I emphasize the adjective “partial” because the noun “deregulation” should never, ever be used without it—wasn’t crafted by the con gressman, Harley O. Staggers (D-W.Va.), for which it was named. The actual author was a young congressman, a Democrat with a working-class background who represented a rather gritty area of “South Jersey” that included Camden (just across the Delaware River from Philadelphia): James J. Florio.

Jim Florio died at 85 last month (p. 41). I knew him best as Governor of my home state, New Jersey, from 1990 to 1994. I think it’s fair to say the Staggers Rail Act was one of his greatest legislative accomplishments, if not the greatest. So why was his name not on the bill?

The simple answer is that Florio put substance before politics, and had the ability to “reach across the aisle” to get things done—something sadly lacking in today’s poisonously partisan, “us vs. them,” environ ment. He also knew that having his name on a bill was far less important than what that bill would actually accomplish.

Railway Age Capitol Hill Contributing Editor Frank N. Wilner, who arguably knows railroad regulation and legislation better than most, interviewed Florio several times for this publication. He explains: “The Staggers Rail Act is named after a longdeceased and now hazily, if at all, remembered West Virginia Democratic lawmaker—Harley O. Staggers—but

TStaggers didn’t even write the bill that carries his name, nor did he manage its successful passage. Much of the bill writing, as well as its majority-vote getting, was accomplished by Rep. James J. Florio (D-N.J.), Chairman of what was then the House Transportation Subcommittee (now the Subcommittee on Railroads, Pipelines and Hazardous Materials). In a last-ditch effort to inch over the finish line what was then the Rail Act of 1980—which was in danger of being rele gated to the dust bin of history—Florio, in a flash of political savvy, renamed it to honor Staggers, about to retire and still the immensely popular Chairman of the House Interstate and Foreign Commerce Committee (now Transportation and Infrastructure Committee). The name change to the “Harley O. Staggers Rail Act” similarly earned for the bill bipartisan support in the Senate.”

Frank Wilner questions “why railroaders speak repeatedly of the increasingly unfamil iar and four-decades-old Staggers Rail Act.” It’s because the legislation “at least provides modern-day opinion leaders and decisionmakers not steeped in railroad history an inkling that the law has to do with railroads.”

We can thank Jim Florio for that.

We can also thank long-time Railway Age Contributing Photographer Joseph M. Calisi, my friend and colleague for 30 years, for his many beautiful railroad images that have appeared in print and online these past three decades. Joe, who had recently retired from the New York MTA, died unexpectedly last month. The New York City Transit photo on pages 1 and 28 is our tribute to him.

Riposa in pace, Jim and Joe.

WILLIAM C. VANTUONO Editor-in-Chief

Railway Age, descended from the American Rail-Road Journal (1832) and the Western Railroad Gazette (1856) and published under its present name since 1876, is indexed by the Business Periodicals Index and the Engineering Index Service. Name registered in U.S. Patent Office and Trade Mark Office in Canada. Now indexed in ABI/Inform.

Change of address should reach us six weeks in advance of next issue date. Send both old and new addresses with address label to Subscription Department, Railway Age, PO Box 239, Lincolnshire IL 60069-0239 USA, or call (US, Canada and International) +1 (402) 346-4740, Fax +1 (847) 291-4816, e-mail railwayage@omeda.com. Post Office will not forward copies unless you provide extra postage.

POSTMASTER: Send changes of address to: Railway Age, PO Box 239, Lincolnshire, IL 60069-0239, USA.

Photocopy rights: Where necessary, permission is granted by the copyright owner for the libraries and others registered with the Copyright Clearance Center (CCC) to photocopy articles herein for the flat fee of $2.00 per copy of each article. Payment should be sent directly to CCC. Copying for other than personal or internal reference use without the express permission of Simmons-Boardman Publishing Corp. is prohibited. Address requests for permission on bulk orders to the Circulation Director. Railway Age welcomes the submission of unsolicited manuscripts and photographs. However, the publishers will not be responsible for safe keeping or return of such material.

Member of:

SUBSCRIPTIONS: 1 (402) 346-4740

EDITORIAL AND EXECUTIVE OFFICES

Simmons-Boardman Publishing Corp. 1809 Capitol Avenue Omaha, NE 68102 (212) 620-7200 www.railwayage.com

ARTHUR J. McGINNIS, Jr. President and Chairman

JONATHAN CHALON Publisher jchalon@sbpub.com

WILLIAM C. VANTUONO

Editor-in-Chief wvantuono@sbpub.com

MARYBETH LUCZAK

Executive Editor mluczak@sbpub.com

CAROLINA WORRELL Senior Editor cworrell@sbpub.com

BILL WILSON

Engineering Editor/Railway Track & Structures Editor-in-Chief wwilson@sbpub.com

DAVID C. LESTER

Managing Editor, Railway Track & Structures dlester@sbpub.com

HEATHER ERVIN

Ports and Intermodal Editor/Marine Log Editor-in-Chief hervin@sbpub.com

Contributing Editors

David Peter Alan, Jim Blaze, Nick Blenkey, Sonia Bot, Peter Diekmeyer, Alfred E. Fazio, Don Itzkoff, Bruce Kelly, Ron Lindsey, David Nahass, Jason H. Seidl, David Thomas, John Thompson, Frank N. Wilner, Tony Zenga Art Director: Nicole D’Antona

Graphic Designer: Hillary Coleman Corporate Production Director: Mary Conyers Production Director: Eduardo Castaner Marketing Director: Erica Hayes Conference Director: Michelle Zolkos Circulation Director: Joann Binz

INTERNATIONAL OFFICES

46 Killigrew Street, Falmouth, Cornwall TR11 3PP, United Kingdom 011-44-1326-313945

International Editors Kevin Smith ks@railjournal.co.uk

David Burroughs dburroughs@railjournal.co.uk David Briginshaw db@railjournal.co.uk Robert Preston rp@railjournal.co.uk Simon Artymiuk sa@railjournal.com

CUSTOMER SERVICE: RAILWAYAGE@OMEDA.COM , OR CALL 1 (402) 346-4740 Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

2 Railway Age // October 2022 railwayage.com FROM THE EDITOR

AILWAY GE

WHEN YOUR BUSINESS RELIES ON RAIL, RELY ON US.

is North America’s leading railcar equipment and services provider. With a comprehensive platform of leasing, manufacturing, maintenance and professional services, you can rely on TrinityRail to fully deliver trusted expertise, innovative solutions and supply chain optimization. Learn more at TrinityRail.com.

TrinityRail®

‘GET USED TO DISAPPOINTMENT’

“If you were expecting August rail traffic to provide a definitive statement regarding the state of the economy, well, get used to disappointment,” the Associa tion of American Railroads reported last month. “As in June and July, rail traffic in August was relatively evenly balanced between categories with carload gains and those with declines. In August, 11 of the 20 carload categories we track had gains. Total carloads were up 2.3% over last year; weekly average total carloads (237,978) were the most since May 2021. Coal and grain led the way, but for neither of those are carloads closely correlated with the state of the economy. Industrial products, carloads of which are closely correlated to the broader economy, saw carloads rise 0.1% in August after small declines the previous three months. Excluding coal, U.S. rail carloads were up 1.2% in August, their first increase in six months. Meanwhile, August was the 12th decline in the past 13 months for intermodal, but August’s 1.2% decline was the smallest percentage decline in those 13 months.”

31,61528,68910.2% Chemicals 163,400162,7520.4% Petroleum & Petroleum Products48,34051,750-6.6% Coal 350,686333,2185.2%

Primary Forest Products 5,8065,23910.8%

Lumber & Wood Products 16,31215,816 3.1%

Pulp & Paper Products 26,89528,944 -7.1%

Metallic Ores 32,16430,6415.0%

Coke 18,064 18,436 -2.0%

Primary Metal Products 40,84947,560-14.1%

Iron & Steel Scrap 20,26821,367-5.1%

Motor Vehicles & Parts 69,157 66,439 4.1%

Crushed Stone, Sand & Gravel 110,171102,844 7.1%

Nonmetallic Minerals 19,37019,448-0.4% Stone, Clay & Glass Products 39,83042,715-6.8% Waste & Nonferrous Scrap 19,03019,806-3.9%

All Other Carloads 26,05630,970-15.9%

4 Railway Age // October 2022 railwayage.com

Indicators

Industry

Source: Rail Time Indicators, Association of American Railroads Intermodal MAJOR U.S. RAILROADS BY COMMODITY AUG. ’22AUG. ’21% CHANGE Trailers 74,896101,917-26.5% Containers 1,260,722 1,249,557 0.9% TOTAL UNITS 1,335,6181,351,474 -1.2% CANADIAN RAILROADS Trailers 0 0 Containers 374,533360,1844.0% TOTAL UNITS 374,533360,1844.0% COMBINED U.S./CANADA RR Trailers 74,896101,917-26.5% Containers 1,635,255 1,609,741 1.6% TOTAL COMBINED UNITS 1,710,151 1,711,658 -0.1% FIVE WEEKS ENDING SEPTEMBER 3, 2022 Railroad employment, Class I linehaul carriers, AUGUST 2022 (% change from AUGUST 2021) Transportation (train and engine) 48,760 (+3.50%) Executives, Officials and Staff Assistants 7,900 (+8.65%) Professional and Administrative 9,791 (-0.63%) Maintenance-of-Way and Structures 28,437 (+0.36%) Maintenance of Equipment and Stores 17,410 (+1.19%) Transportation (other than train & engine) 4,716 (+1.22%) Source: Surface Transportation Board TOTAL EMPLOYEES: 117,014 % CHANGE FROM AUGUST 2021: +2.26%

ORIGINATED CARLOADS

BY COMMODITY AUG. ’22AUG. ’21% CHANGE Grain

Farm Products excl. Grain

Grain Mill Products

Food Products

TRAFFIC

MAJOR U.S. RAILROADS

102,09889,50414.1%

3,707 2,86929.2%

46,07443,8455.1%

CARLOADS 377,251

U.S./CANADA RR 1,567,143

FIVE WEEKS ENDING SEPTEMBER 3, 2022

TOTAL U.S. CARLOADS 1,189,892 1,162,852 2.3% CANADIAN RAILROADS TOTAL CANADIAN

368,9282.3% COMBINED

1,531,780 2.3%

30,351 24,38224.5%

81,529 76,383 6.7%

October 2022 // Railway Age 5 railwayage.com TOTAL U.S. Carloads and intermodal units, 2013-2022 (in millions, year-to-date through august 2022, SIX-WEEK MOVING AVERAGE) TOTAL U.S./Canadian CARLOADS, august 2022 VS. august 2021 1,567,1431,531,780 AUGUST 2022 AUGUST 2021 Copyright © 2022 All rights reserved. Short Line And Regional Traffic Index CARLOADS BY COMMODITY ORIGINATED AUGUST ’22 ORIGINATED AUGUST ’21 % CHANGE Chemicals

Stone, Sand & Gravel

Food & Kindred Products

Carloads

The Insulated Joint Designed To Handle Stress

GET A QUOTE (833) 224-9628 Meets all current AREMA specifications Easy installation, minimum maintenance Rail sizes from 30 - 141 pounds Specialty formulated polyurethane bonded

53,736 52,995 1.4% Coal 19,236 24,654-22.0% Crushed

12,228 10,56415.8% Grain 26,669 21,87921.9% Grain Mill Products 8,526 7,66811.2% Lumber & Wood Products 10,559 9,46111.6% Metallic Ores 2,749 3,338 -17.6% Metals & Products 20,019 18,910 5.9% Motor Vehicles & Equipment 9,390 9,677 -3.0% Nonmetallic Minerals 2,629 2,475 6.2% Petroleum Products 2,169 2,109 2.8% Pulp, Paper & Allied Products 18,753 17,721 5.8% Stone, Clay & Glass Products 16,735 16,364 2.3% Trailers / Containers 46,486 54,475-14.7% Waste & Scrap Materials 12,204 12,088 1.0% All Other

Because of their bonded-tosteel construction, Seneca joints flex as a unit with vertical & horizontal stress. Making them virtually immune to coldflow under the most rugged use & environmental conditions.

Industry Outlook

unions—even those who have ratified tentative agreements—to honor picket lines. While rail labor contracts prohibit so-called “sympathy strikes,” a loophole allows unionized workers to honor picket lines of other unions if members personally feel threatened were they to cross them.

Might Union Chiefs Override Member Vote?

If tentative wages, benefits and work rules agreements reached between rail labor unions and most Class I rail roads (and many smaller ones) fail to be ratified by union members in coming weeks, might leadership of those unions override a majority “no” vote and unilater ally impose the tentative agreement, or, alternatively, submit it to binding arbitra tion rather than pursue further collective bargaining or authorize a strike? It’s currently an unanswered question. And it has happened before.

For example, in 1996, the leadership of the United Transportation Union—now the Transportation Division of the Sheet Metal, Air, Rail and Transportation Workers (SMART-TD)—overrode its members’ rejection of a tentative agreement on wages, benefits and work rules. Rather than return to the negotiating table or order a work stoppage, either of which was sought by members, the union’s leadership made a deal with carriers to send the memberrejected tentative contract to binding arbitration, where a carrier-friendly award was imposed.

What actually lurks in various rail labor union constitutions—especially those provisions’ interpretation by union offi cers—is unknown. The answer will become apparent over the next few weeks.

Fringe factions of rail labor have been

predicting—even urging—“no” votes. Mainstream media, in reporting on those efforts and discontent among rail union members, has provided nattering nabobs of negativism credibility and a pulpit from which to preach against ratification. As the RLA (Railway Labor Act) has run its course, there now is no law keeping even a single rail labor union from striking, or carriers from locking out workers if union members decline to ratify tentative agreements.

Last month, following a 20-hour negoti ating session on the eve of RLA work-stoppage barriers expiring, several Biden Administration cabinet officers brought about tentative agreements with several hold-out unions. Last-minute nego tiated sweeteners conceded by the carriers made the difference.

But the tentative agreements only post pone the threat of a work stoppage, as union member rejection could trigger one. Even a strike against one railroad could cause a nationwide rail shutdown, as occurred in 1992 against CSX. All other major railroads responded by locking out employees, contending the nation’s rail network is so interconnected and interde pendent that a strike against one railroad is a strike against all.

Moreover, a strike by even a small union could trigger a full-blown nationwide rail shutdown by causing members of all other

Notwithstanding the Biden Administration basking in the political sunlight of tentative agreements being reached, the threat of an economy-jolting nationwide rail shutdown remains—and will be pinned on Biden and Democrats if it occurs prior to mid-term elections in November. Hence, there’s chatter as to whether rail labor leaders, very much invested in Democratic success in mid-term elections, might override a membership rejection of the tentative agreement or, alternatively, seek binding arbitration so as to avoid a work stoppage damaging to Democratic candidates.

Efforts by Congress to craft immediate and economy-saving back-to-work legisla tion in the event of a strike or lockout were unsuccessful. If union members reject ratification, and Congress remains unable to craft back-to-work legislation, the length of a national rail shutdown would be indeterminate.

The sides could agree not to engage in a strike or lockout until after November midterm congressional elections, although Congress would remain as politically divided as it is today—and will remain so at least until a new Congress is seated in January. Moreover, during lame-duck sessions following mid-term elections and before a new Congress is seated, defeated and retiring lawmakers become less concerned with public image or political debts, and mavericks become more embold ened. This festering impending chaos all could have been avoided had the National Mediation Board followed decades of prec edent and held the parties in mediation until after the elections, but it didn’t.

One union officer, asking not to be identified, said, “The RLA is silent as to the ratification process, which is found in each union’s constitution. Some arbitra tors have ruled that the membership lacks the authority to second-guess the agreedupon best efforts of the carriers and union leadership.”

– Frank N. Wilner

6 Railway Age // October 2022 railwayage.com

SMART-TD

SMART-TD President Jeremy Ferguson

California Ramps Up HFC

Stadler, the California State Transportation Agency (CalSTA) and the California Department of Transportation (Caltrans) have signed a Memorandum of Understanding (MOU) for design and delivery of four HFC (hydrogen fuel cell) fourcar FLIRT H2 trainsets. The contract includes options for 25 more units, which would replace existing diesel locomotive-operated push-pull sets used for state-funded Amtrak California services. These trainsets are based upon the initial two-car HFC trainset ordered by San Bernardino County Transportation Authority (SBCTA) from Stadler in 2019, due to enter service in 2024 on the new ninemile SBCTA San Bernardino Transit CenterUniversity of Redlands line alongside newly delivered Arrow low-emission Stadler FLIRT DMUs. Ballard Power Systems will supply six 100 kW FCmove™HD+ fuel cell engines to power the SBCTA train.

WORLDWIDE

WABTEC and KAZAKHSTAN TEMIR ZHOLY have signed a $600 million MOU for 150 FLXdrive™ battery-electric switchers and modernization work to transform the KTZ main line diesel-electric fleet into Next Fuel™ LNG-powered locomotives. The switchers will be 100% battery powered with more than 1.5 MwH of energy. They are claimed to have the ability to reduce the rail road’s yard operations fuel cost by approxi mately $75,000 per unit per year and reduce scheduled maintenance by up to 97%.

NORTH AMERICA

TELEGRAPH, a Chicago-based startup offering a cloud-based operating system for railroads, shippers, logistics service providers and railcar leasing companies, has partnered with WATCO to help shippers with tough logistics challenges, with a focus on rail trans portation. “Telegraph helps railroads, ship pers, logistics providers and railcar lessors work more efficiently via a singular platform,” the company said. Its platform “up-levels the consumer experience, making it easier for businesses to incorporate rail into their pro curement and execution processes. The com bination of Watco’s decades of rail logistics experience and Telegraph software provides customers visibility of their railcars beyond Watco facilities or tracks. Telegraph provides exceptional predictability and visibility for carload and intermodal shipments. Leverag ing EDI, API and telematics integrations, the platform delivers best-in-class forecasting capability and pipeline management. To date, we have saved customers thousands of hours in manual work and millions of dollars in accessorial charges.” Said Telegraph Cofounder Shachar Astor: “We recognized a distinct need for software designed for the rail-centric supply chain.”

A LSTOM last month signed a contract renewal to carry out preventive and cor rective maintenance on 186 locomotives of the FERROCARRIL M ÉXI C ANO (FERROMEX) fleet for a period of five years. Alstom’s commercial relationship with Ferromex began in 2004 and has allowed for “a synergy in favor of rail mobility in Mexico,” the company said. According to Alstom, this service contract, implementing remote monitoring, “con sists of performing preventive and correc tive maintenance on the locomotives, applying condition-based maintenance technologies, and performing predictive maintenance through vibration analysis and oil chemical analysis.” Maintenance work will be carried out at the Ferromex centers located in Torreón, Chihuahua and Guadalajara. “The renewed confidence in Alstom with this additional maintenance contract reaffirms Alstom’s commitment to assisting Ferromex in the optimization of its operations with increased fleet reli ability and availability for a more efficient and sustainable transportation network,” said Maite Ramos Gómez, General Direc tor at Alstom Mexico.

October 2022 // Railway Age 7 railwayage.com Market

Stadler

Can STB Avoid Political Division?

Surface Transportation Board (STB) Chairperson Martin J. Oberman remains as difficult to categorize today as when he arrived in January 2019. In many respects, he brings to mind mythical Roman god Janus, who, in seeing forward and backward, symbolizes change and transition.

Clearly one-of-a-kind, even at age 76, Oberman’s favored ride to work is a bicycle. Likely to roll his eyes when addressed as “Mr. Chairman,” he displays little tolerance for fools and time wasters, a trait retained from his stint as an elected Chicago alderman. Colleagues describe Oberman, who controls the agency’s docket, as consensus driven with inordinate patience to hear contrarian theories, and willing to allow cases to move even when the majority is not on his side.

Not a large man, Oberman’s favored bow ties for office attire cast him as a contempla tive law professor rather than a big-stick, menacing rail regulator, even though his sound bites are more the stuff of the latter:

• “There’s just not real effective competi tion among rail carriers.”

• “Except for intermodal and a handful of other areas, generally speaking, I think shippers have very little bargaining power these days.”

• “If [carriers] need another 400 crews to move trains … pay whatever price you need to get them. I don’t oversee [collective] bargaining, but I do oversee service.”

Railroads haven’t heard such bully pulpit lectures since A. Daniel O’Neal, who chaired STB predecessor Interstate Commerce Commission, walked the plank in 1979 at the urging of economic deregulation advocate President Jimmy Carter, who recruited rail regulators more likely to have on their night stands books by Ayn Rand, Milton Friedman and William F. Buckley than John Maynard Keynes, Ralph Nader and John Kenneth Galbraith.

Oberman is influenced by provisions of National Transportation Policy that include fostering “sound economic conditions,” promoting a rail system “to meet the needs of the public,” allowing to the “maximum extent possible” competition and demand to establish “reasonable” rates, and encour aging “fair wages and safe and suitable

working conditions.” His view is that “if we let railroad share price drive all decisions, we won’t have an economy that can rely on freight rail.”

Clashing with that perspective are rail road shareholders and boards of direc tors expecting CEOs to “right size” plant and work force in advance of approaching economic recessions, a looming cratering of high-margin coal traffic, and the impact on truck-competitive pricing and market share of a collectively bargained 24% unionized employee wage increase.

Oberman’s aggressive use of the bully pulpit is not incompatible with his efforts to encourage better industry behavior voluntarily, thereby facilitating unanimous votes among members with starkly differ ing views and politics. An example was his gaining Board consensus on approving CSX’s acquisition of Pan Am Railways. His use of probing questions and preliminary determinations elicited voluntary agree ments between CSX and concerned parties, avoiding third-party regulatory edicts rarely satisfying to any stakeholder.

Oberman also formed consensus to expand publicly accessible railroadreported service-metrics—again in expec tation that public shaming, including from investors, would lead to voluntary rather than regulatory fixes.

While there are deep political divisions in Congress, there are no Democratic or Republican “gang” colors flashed at the STB. “We have neither idealism nor polar ization,” Oberman says.

“True to his word [when President Biden named him chairperson], Marty has worked indefatigably to achieve consensus on the vast majority of our decisions, spending count less nights listening to members’ concerns and identifying solutions,” says STB Repub lican member Patrick J. Fuchs.

As the Board finalizes pending matters and initiates others—promising indelible impacts on shippers and railroads—colle giality will be tested. Pending decisions may expand access to rate relief for smallervalued cases; develop new rate-reasonable ness methodology; establish minimum standards under the statutory common carrier obligation; require a railroad open its privately owned track to permit two-railroad competition (reciprocal switching); and define revenue adequacy’s relationship to maximum reasonable rates.

Oberman’s fellow Board Democrat Robert Primus, says, “[We all] want rail roads to figure out ways to solve their own problems.” As they do, and with increas ing congressional interest, the question is whether the STB can continue to work collegially and ignore Washington’s politi cal divide and dysfunction.

FRANK N. WILNER Contributing Editor

8 Railway Age // October 2022 railwayage.com Watching Washington

with increasing congressional interest, the question is whether the STB can continue to work collegially and ignore Washington’s political divide and dysfunction.”

2023 AILWAY G E SERVING THE RAILWAY INDU S TRY S INCE 1856 COMPANY PROFILES 20 RAILROAD FINANCIAL DESK BOOK M ULTI- E DGED D IFFICULTIES

10

By David Nahass, Financial Editor

MULTI-EDG ED DIFFICULTIES

BY DAVID NAHASS, FINANCIAL EDITOR

elcome to the 2023 Railroad Financial Desk Book. The North American rail drama meter has finally backed off from the red line down to a more tepid level of yellow. Granted, North American rail never approached the hyper-intense drama of a titanic battle like Elon Musk vs. Twitter, but the threat of a nationwide rail strike garnered national news cover age and attention for three or four days. Every industry veteran and transporta tion manager answered the probability question at least a dozen times. Want to talk about lost productivity? Think of the number of hours spent developing and sketching out contingency plans by companies providing essential services or running facilities that “can’t” (whether

Wdue to cost or necessity) be shut down. All for naught! Console yourselves—at least you’re prepared for the next time!

Let’s cut to the bare metal: There never was going to be a strike. Whether you believe the executive branch added value or just grabbed the headlines and the credit, the railroads and the unions would have been sent back to the bargain ing table until they found a way to get along. Two words: midterm elections.

The Biden Administration milked the preparation for rail Armageddon shame lessly, going so far as to suggest that they were looking at contingency plans to transfer freight from rail to other modes (as if, “Okay, Joey, just back up that barge to the edge of this rail yard. Yeah, I know there’s no water—just do it!”). There were rumors that calls were placed to Starfleet Command to see if freight

could be “beamed” from location to location to pick up the slack that would have been created by the strike. Given enough time, a reach out to Dreamworks studios to see if they could get some advanced technology on the flying loco motive from “Back to the Future 3” was probably a likely scenario.

Unfortunately, the soap opera around the labor drama became another oppor tunity for a dog pile on the railroads. Late night talk shows had a field day. Jimmy Fallon weighed in on Biden’s political success, The New York Times joined in, and The Wall Street Journal took issue with the strike and with the publicity grab. It’s tough being the butt of the joke.

Vantuono

Of course, this all assumes that the proposal is ratified by the unions. That is not a guarantee. However, certain circumstances bear considering for the William C.

10 Railway Age // October 2022 railwayage.com 2023 FINANCIAL DESK BOOK

Powering your fleet ahead.

CIT Rail leverages deep experience and one of the youngest, most diversified railcar and locomotive fleets in the industry to help you keep your business on track for success. With a long-standing commitment to providing creative railcar leasing solutions, we can help you free up capital for your growth priorities.

Get started today at citrail.com ©2022 First-Citizens Bank & Trust Company. All rights reserved. CIT and the CIT logo are registered trademarks of First-Citizens Bank & Trust Company. MM#12025

Given enough time, a reach out to Dreamworks studios to see if they could get some advanced technology on the flying locomotive from “Back to the Future 3” was probably a likely scenario.

post-strike look at North American rail. Jason Kuehn, Vice President at Oliver Wyman and perennial Rail Equipment Finance speaker, suggests that North American rail’s labor troubles might not end after ratification.

Start with this: Railroad union employees are set to receive a retroac tive “catch-up” payment of back pay going back to Jan. 1, 2020. The current estimate for that payment is an average of $11,000 per employee, including an immediate wage boost averaging more than 14%, plus $1,000 per year in bonus payments. Kuehn raised the question of how many employees have been hanging on for that catch-up payment, and now that the labor war of attrition has come to a close, he wonders how many of the freshly compensated union employees might step up and take the short walk to the exit.

Don’t act all surprised about this. That result would not separate rail from any other industry in a similar position. The question is how senior are the employ ees that may leave and how many may leave in total. Any statistically relevant number would impact whatever prog ress the railroads have made in resolving their current issues.

Kuehn also points out that a national

wage agreement being proposed between railroad and labor creates another poten tial issue. He notes, “Many of the staff ing issues, as we have heard from the railroads, are not systemwide but are location-specific. A national agreement is not a solution that allows carriers to modify pay locally other than things such as one-time hiring bonuses.”

This is a key issue as it relates to improving service in these areas. Kuehn sees it as a critical factor. From recent presentations at Cowen’s annual Trans portation Conference, he recounts CSX noted “that they are facing challenges in New York state” and that Norfolk Southern “called out specific geographi cal areas where staffing is an issue.” He notes Union Pacific and BNSF have had issues centered in California, which is known for higher-than-average wages and cost of living.

Tired yet? Kuehn is concerned there will still be a disconnect when wages are measured against the cost of living in specific locales. These concerns, he notes, “are increasingly becoming problematic in areas where housing prices (and other cost of living categories) are very high.”

Like with the wage-related inconsisten cies, a national wage agreement is not tooled to handle these idiosyncrasies.

As you contemplate the bumps in the road, console yourselves with the hopes that it may be another four years before the rail industry needs to deal with this again.

RAIL R OADS, RAILCA RS AND I NFLATION

The railcar market is tight, and prices for those that lease cars are, in many cases, higher than they’ve been in the past 20 years (see “Around the Market” in this Desk Book, p. 16). Railcar lease rates are high on everyone’s list of interest ing topics on the fall conference circuit, along with inflation and its impact on new railcar prices.

Another topic of great concern to those that lease and own cars ties back to rail service and the ability of the rail roads to originate more carloadings both to serve more customer needs and to grow revenue and strengthen the role of the rails in North America.

Here’s one double-edged problem created by railroad service issues: On one side, it feels like there aren’t enough cars to meet demand. On the other side, there aren’t enough crews, and service on the railroads isn’t good enough to meet the needs of those customers that want to ship by rail.

12 Railway Age // October 2022 railwayage.com

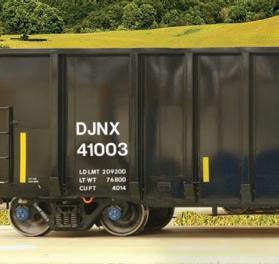

GETTING YOUR SCRAP METAL TO THE MILL DOESN’T HAVE TO BE A GAMBLE With over 135 years of financial strength and stability, DJJ is also known for our creative transportation solutions. Contact us today to discuss private fleet or leasing options. RailGroup@djj.com www.djj.com

Service disruptions are causing some modal shifting of rail loads. It could be a shift to other forms of transportation (most likely truck). In power genera tion, it could cause a decrease in (or put a cap on) the maximum tons of coal that power generators are able to ship by rail. As a result, the volume of coal being burned for consumer or indus trial consumption is being reduced in favor of higher priced (today at least), pipeline-delivered natural gas. These modal shifts create a gap in opportunity cost for a consumer of rail traffic. Ulti mately, that cost gets passed on, directly or indirectly, to the consumer, and that becomes an inflationary pressure.

John Ward, National Coal Transpor tation Association (NCTA) Executive Director and Rail Equipment Finance speaker, notes that in a 2022 NCTA member survey, “More than 80% of respondents reported that they had curtailed power generation to conserve coal; that coal supply commitments for the year were not met; and that coal inventory levels were reduced below target levels.”

For consumer and industrial products

manufacturers, those price increases may not be passed on to their custom ers until six months to a year after the impact starts being felt at the producer level. There is a negative arbitrage period during which the producer carries the additional expense before it gets passed to the next company in the supply chain and on to the consumer. These price impacts might lag inflationary reporting during this negative arbitrage period. In consumer energy markets, the passthrough of lost opportunity is more immediate. On the producer level, the impact is the same timewise as trans portation modal shifts. Congestion on the rails and increasing lease costs due to inefficiency also weigh on these price increases, even as the industry enters its second year of increasing lease costs.

Cost transfer from service disrup tions also happens when facilities that are only rail-served have to temporar ily shut down when they cannot receive feedstock or move product to custom ers. Eamon Monahan, Vice President for Environmental Affairs and Workplace Safety for the Corn Refiners Associa tion (CRA), which represents refiners of

corn that serve the food and animal feed markets (not including ethanol), notes that CRA’s member companies are oper ating at maximum capacity. When railserved facilities are forced to shut down, for however short a duration, that capac ity is lost and is not recoverable. Addi tionally, facilities are not light switches; a shutdown can turn into a multi-day expensive turn of events. Shutdowns stress infrastructure and increase main tenance costs. This additional level of lost opportunity cost is passed down the line and is difficult to measure.

There is no direct measurement of the inflationary impact of these modal shifts that result from railroad-related service disruptions. Clearly this is not the only factor influencing inflation. Its significance rests in the undocumented and unmeasured potential impact. It is important to remember, as Todd Tranausky, Vice President for Rail and Intermodal at FTR Transportation Intel ligence, notes, today’s inflationary cycle was driven first by demand, and that these expenses can’t be passed through as easily when the demand does not exist like it does today.

14 Railway Age // October 2022 railwayage.com

Bruce Kelly

UTLX.COM 855-UTLX-NOW leasinginquiry@utlx.com

In many cases, the individual consumer won’t see the impact of these forces in the CPI (Consumer Price Index) until those prices have been thor oughly incorporated at the retail level (six to even 12 months in some cases). It is one of the challenges behind measur ing the impact.

An interesting pandemic-era parallel is supply chain shifts that may have come up as a result of port congestion on the West Coast. It is still unknown if freight that was shifted from the West Coast to the South or East Coast or that was nearsourced (vs. being sourced in China, for example) will get returned to previous points of origin and destination once congestion eases. Once modal shift has occurred and those supply chain costs are being recovered from the consumer, will companies prevent a shift back to rail (or back to China)? Generally, memories are short, and profit seems to trump all (geez, where have you heard that before?), so a cycle of opportunis tic offshoring and modal shifting back to rail is probably available again at some time in the future.

AROUND THE M A RKET

Leases rates continue to torture lessees and bring smiles to the faces of lessors. There are so many factors driving what is happening in the lease market. It’s service related; it’s being impacted by raw material pricing; and it’s part of the overall economic demand cycle. However, one factor is quickly becoming the straw that stirs the drink. Interest

rates, backed by the Federal Reserve’s need to rein in inflation, have been on the rise. It’s pretty stratospheric. How crazy is it? In May 2021, the one-year Treasury was 0.05%. On Sept. 22, it hit 4.11%. For the 10-year Treasury, it was 0.67% in May 2021 and on Sept. 22 it hit 3.55%. Ouch! That’s a stinger.

Raw material prices, especially hot rolled coil steel, are trending downward. This may provide some relief on new railcar prices, but plate steel continues to trend at high levels. Component-related supply chain issues, especially those that may have been sourced in Russia, continue to be impact factors that affect pricing on all car types.

With scrap sitting in the mid-$200s per ton ($260 as of this writing), the above-average numbers of cars being scrapped has slowed. Longer term, as service improves, expect this to help push down lease rates when car supply frees up a bit.

Back to interest rates: Even after the September 75-basis-point increase in the federal funds rate, the Federal Reserve continues to remain hawkish on further rate increases, and the end of the road does not seem near. The 10-year Treasury, which hasn’t been above 4% since 2008, seems headed there quickly. There’s no easy metric to determine the impact of rising interest rates on lease pricing, as lease rates are a mélange of several factors, but it would be fair to say that the full impact of rising rates has not yet been felt by railcar users. Table set. Gruel served.

Here is what is going on in the lease market:

Covered Hoppers: Grain shipments are down 4.3% YTD, but you wouldn’t know it from lease rates, which are differ ent degrees of high right now. For 4,750cf cars, expect to pay high-$300s ($400s if you don’t mind making enemies on the way up) full service (f/s). For 5,200cf cars, expect numbers to start with a six. Leases are five years f/s. Looking for super jumbos for DDG service? Expect to pay in the low-$700s right now.

Covered Hoppers for Plastic Pellets: “Good luck finding one,” one lessor noted during a recent conversa tion. High-$600s to low-$700s are likely numbers. New cars are being built and continue to be expensive.

Pressure Differential Covered Hoppers: Looking for newer 5,660cf PDs? Expect to pay mid-$800s f/s with terms of five years. Numbers for more out-of-favor smaller cars of 5,200cf capacity are not much better in the high$600s or low-$700s.

Covered Hoppers for Sand and Cement: The Renaissance continues! The problem with a market with so much extra capacity is that the marginal cost of bringing cars into service can occasion ally thin out the pool of available assets. This could be the case for the divergence of rents heard in the market on these cars. The range is from low-$300s to less than $100 f/s, with the majority landing in the mid-$200s.

Tank Railcars: This is probably the segment showing the weakest impact

16 Railway Age // October 2022 railwayage.com 2023

FINANCIAL DESK BOOK

The Right Cars. The Right Services. The Right Partner.

PNW Railcars is a leader in the North American railcar leasing and management business, providing best-in-class railcar asset availability and fleet management, supported by a uniquely talented team that offers decades of combined experience. Our team is committed to serving you and dedicated to helping your business succeed. Visit us at pnwrailcars.com or email info@pnwrailcars.com

2023 FINANCIAL DESK BOOK

of current market tightness. Pressure tank railcars are still seeing some cars in storage and rate in the high-$500s to low-$600s with a fall pickup expected. 25Mg GP tanks are available in the market, and prices have not moved much above the mid-$600 range f/s. Crude oil tanks (117Js) are the best performers, with rates in the $800s. The May 1, 2023 transition date for using DOT111A cars in Ethanol service is approaching fast. According to the Railway Supply Insti tute, as of Dec. 31, 2021, roughly 7,200 DOT111s remain in ethanol service. So expect some jockeying on that front in the near future.

Mill Gondolas: There’s tightness here as well with the shorter 52-foot cars leasing for mid-$600s f/s. If you’re looking for a 66-foot car, expect to pay $700-plus. Some new cars are being built to address demand, but as this is one of the older fleets, expectations for improvement are marginal, even with

low-scrap rates.

Coiled Steel Gondolas: There’s also some building in this segment. New cars in the $130,000 range have lease rates at higher levels. Expect high-$700s to low-$800s for this car if you can find one available right now. For a smaller total fleet, service-related impacts on car supply are amplified.

Centerbeam Flat Cars: There’s some availability in the market for these cars. There is an expectation that the downturn in housing starts may improve availability, but as Dan Anderson from TrinityRail noted at the FTR conference, cars with risers continue to fall further out of favor, even in this tight market. Expect to pay high-$400 to low-$500 per car f/s.

Coal Cars: Coal loadings although up YOY are not as high as they could be. That hasn’t held down lease rates at all for these cars. Lease rates for alumi num gondolas continue to move in the

$300s f/s. As with small-cube covered hoppers, rates are all over the place, with numbers ranging from high-$300s net to the low-$200s f/s. Car availability is an issue here as well. Looking for rapiddischarge cars? Expect the possibility of a slight premium to gon pricing. That is not guaranteed. Availability is scarce here as well.

Boxcars: Tightness in this market continues with high-$600s to low-$700s for both 50- and 60-foot cars. Cars are few and far between, so don’t expect much inventory available. New cars are in the pipeline, but expensive, so expect new car leases to begin with something that looks more like an eight.

It’s clearly a lessor’s market and it’s expected to remain this way for the remainder of the year into the second half of 2023.

LEASING RESOURCE DIRECTORY FOLLOWS

18 Railway Age // October 2022 railwayage.com

To learn how quickly Infinity Transportation can meet your rail needs, contact: Lee Martini lee.martini@gafg.com VP of Sales & Marketing (678) 904-6315 Brian Ottinger brian.ottinger@gafg.com VP of Sales & Marketing (312) 731-2763 Ken Johnson ken.johnson@gafg.com VP of Sales & Marketing (859) 640-0362 Infinity Transportation provides e cient, coste ective leasing and financing solutions for a wide range of clients in rail and intermodal markets. Infinity Transportation LEASING & EQUIPMENT MANAGEMENT Powered by Global Atlantic Infinity delivers: • A large rail fleet comprising an extensive range in car types • Exceptional customer service and flexibility with leases and modifications • An unwavering commitment to finding the transaction and equipment that meets each customer’s specific needs • A team that delivers over 90 years of combined transportation equipment management experience STAY IN GEAR WITH RAIL GROUP NEWS ROUND-UP RAILWA RAIL GROUP NEWS From Railway Age, RT&S and IRJ https://railwayage.com/newsletters RA_RailGroupNews_Fourth_InGear_2022.indd 1 1/10/22 12:43 PM

SHOULD YOU LEASE OR BUY? Hi-Rail Grapple Truck Nordco TRIPP Mecalac Hi-Rail Mini-Excavator CALL US TODAY. LET’S TALK BUSINESS. 800.962.2902 quotes@RELAMinc.com RELAMinc.com RELAM, Inc. 7695 Bond Street Glenwillow, Ohio 44139 A SIMPLE FRAMEWORK FOR TOUGH DECISIONS • Know the three factors that most impact the lease vs buy decision. • Understand the real cost of ownership vs leasing. • Save capital and invest in innovation. Download the Lease or Buy white paper

2023 FINANCIAL DESK BOOK DIRECTORY

FINANCE COMPANIES

BUNDY GROUP

Bundy Group is a boutique investment bank that specializes in representing business owners and management teams in business sales, capital raises and acquisitions. The firm is a senior-driven orga nization with offices in Charlotte, New York and Virginia. Bundy Group has been a recognized expert in the rail and transportation industry for more than a decade and has numerous successfully closed transactions in the segment. In represent ing a business and its shareholders in exploring a sale or recapitalization, Bundy Group is focused on managing a structured process and delivering premium value for its clients. For more information about Bundy Group’s work in the rail space, please contact Jim Mullens at jim@bundygroup.com or at 540-342-2151. For more information about Bundy Group visit www.bundygroup.com.

ARRANGERS

THE DAVID J. JOSEPH COMPANY

300 Pike Street, Cincinnati, Ohio 45202; Tel.: 513-419-6200; Fax: 513-419-6221; Trey W. Savage, VP Rail Group; Clint Rice, General ManagerRail Equipment Group; Jeff Schmutte, Jeff Blake and Eric Hausfeld, Regional Sales Managers; Dan Dorsey, General Manager-Private Fleet; Steven R. Skeels, Chief Mechanical Officer; and Ann Edwards, Mgr. Retired Rail Assets (502212-7365). The David J. Joseph Company’s Rail Group provides a broad range of transportation services throughout North America: single inves tor, leverage leases, freight cars, portfolio evalua tion, remarketing fleet management, purchases and sales of portfolios, and private fleet manage ment. Other services include freight car inspec tions and engineering services from design of new cars to complete ISL extended life, modifications and analysis; in addition to railcar dismantling for scrapping and parts reclamation.

SEE OUR AD ON PAGE 13

RAILROAD FINANCIAL CORPORATION 676 N. Michigan Avenue, Suite 2800, Chicago, IL 60611; Tel.: 312-222-1383; Fax: 312-222-1470; David G. Nahass, President, Email: dnahass@railfin.com; William J. Geiger, Senior Vice President, Email: wgeiger@railfin.com. RFC represents domestic and international clients in the following areas: debt and lease financing of all railcar types includ ing coal cars, tank cars and covered hopper cars for sand and plastics; railcar and locomotive fleet acquisitions and sales; lease brokerage; mergers and acquisitions; equity and debt financing of rail property acquisitions, fleet and lease restructurings

and/or refinancing. RFC also provides continuing education for the industry.

RR MERGERS & ACQUISITIONS

11 The Pines Court, Suite B, St. Louis, Missouri 63141; Tel: 314 878-1414; Fax: 314-878-1414; Robert Fowler, President, 314 878-1414 x227 Email: robert@rrmergers.com. Jack Sickles, Vice President, 314 878-1414x221 Email: jack@rrmerg ers.com. RR Mergers & Acquisitions has special ized in the sale of rail-focused companies for more than 15 years. Trusted professionals with long-standing relationships in the rail sector, RR Mergers interfaces with strategic and financial buyers finding the right buyer for a Company, to make the best deal happen. While maintaining confidentiality at all times, RR Mergers manages the total process of selling railroad industry suppliers, rail services companies and Short Line Railroads. RR Mergers provides advisory services to prepare the company for acquisition, develop ing a confidential information memorandum, negotiating term sheets, letters of intent and coor dinating the due diligence process.

STRATEGIC RAIL FINANCE

1700 Sansom St., Suite 500, Philadelphia, PA 19103; (215) 564-3122. Michael Sussman, President and CEO. SRF has served for 23 years as trusted advisor to Class I and short line railroads, rail shippers, public sector agencies, and industrial developers. The firm has brought capital, clarity, and velocity to infrastructure development projects in 45 states and Canadian provinces. SRF integrates capital from public programs and private sources with growth marketing strategies and management consulting to position executives toward shortterm objectives and long-term opportunities.

WINTRUST COMMERCIAL FINANCE

3201 Dallas Parkway, Suite 800, Frisco, TX 75034. Tom Forbes, Executive Vice President and Chief Sales Officer. (469) 777-5649 (office); (615) 290-3069 (mobile). Wintrust Commercial Finance (WCF) is Wintrust’s Texas-based, equipmentfocused financing group offering sophisticated loan and lease products to companies through out the United States. Our team offers excep tional customer service and expertise from years of experience providing customers in a variety of industries with innovative capital solutions. WCF funded in excess of $3 billion in equipment-secured loans and leases since our founding in 2015 and has continued to grow into one of the largest equip ment financing companies in the country. WCF is led by an experienced management team with, on

average, 25 years of experience. With the team’s extensive knowledge, we’re prepared to consider all structures, including structured financing and loans; financing for new and used equipment acqui sitions; re-financings and estate planning; capital, operating, synthetic, and TRAC leases; sale/lease back and lease discounting; capital expenditure financing with fixed and floating rates and acqui sitions. For more information, visit http://www. wintrust.com/business-solutions/mid-market/ lending/commercial-finance.html.

LESSORS

THE ANDERSONS RAIL GROUP

1947 Briarfield Blvd., P.O. Box 119, Maumee, OH 43537; Fax: 419-891-2749. Contacts: Joe McNeely, Rail Group President, 419-897-3646; Sean Hankinson, Vice President of Sales, 419-8916352, Sean_Hankinson@andersonsinc.com; Sam Anderson, Vice President of Operations, 419-8914436, Sam_Anderson@andersonsinc.com. The Andersons Rail Group, a part of The Andersons, Inc., has served the rail industry for more than 30 years. The group owns a fleet of nearly 25,000 railcars which it leases to customers handling a wide variety of commodities. It also provides repair, maintenance and component manufac turing services to private railcar owners through its 26 repair shops and steel fabrication facility. With extensive knowledge in taxation, govern ment regulations and railroad requirements, The Andersons Rail Group offers quality products and superior customer service. For more information, visit www.andersonsrail.com.

AMERICAN INDUSTRIAL TRANSPORT INC. (AITX)

100 Clark Street, St. Charles, MO 63301-2075. Tel.: 636-940-6000; Fax: 636-940-6100. Contacts: Sean Hankinson, Chief Commercial Officer, 814-242-6141. shankinson@aitx.com.

American Industrial Transport, Inc. is a leading solutions-provider of railcar services, dedicated to growing our fleet and providing customers a range of options across leasing, fleet management, and repair services. AITX has access to one of the indus try’s most diverse fleets of nearly 60,000 railcars across car-types and commodities-served. Due to their customer service, flexible financing options, and extensive knowledge of taxation, government regulations and railroad requirements, AITX has satisfied leasing customers across freight indus tries. AITX and its subsidiaries operate worldclass railcar repair services through its specialized network spanning across North America. Offering

20 Railway Age // October 2022 railwayage.com

2023 FINANCIAL DESK BOOK DIRECTORY

a range of programs from full to light repair, AITX’s maintenance capabilities include full-service repair facilities, tank car qualifications, a wide footprint of responsive mobile operations, and onsite customer dedicated partnerships. To learn more about AITX’s depth of services and customer commit ment, visit aitx.com.

ATEL LEASING CORPORATION

The Transamerica Pyramid, 600 Montgomery Street, San Francisco, CA 94111; Tel.: 415-6163486; Ken Fosina, Executive Vice President, Email: kfosina@atel.com. Since 1977, ATEL has leased rail assets to America’s largest railroads and shippers. ATEL specializes in the leasing of all types of rail assets, including railcars, locomotives and main tenance-of-way equipment. ATEL targets railcars and locomotives built prior to 2005, but prefers new maintenance-of-way assets. Leases can be full service, but net leases are preferred. ATEL executes lease transactions directly and through its Capital Markets desk. Each year, ATEL’s Portfolio Manage ment will sell rail assets from one of its Funds managing expiration.

CAI RAIL

Steuart Tower, One Market Plaza, 9th Floor, San Francisco, CA 94105. Tel: 415-788-0100; Fax: 415-788-3430. James H. Magee, President, email: jmagee@capps.com; Freddy Fernandez, Vice President-Operations, email: ffernandez@capps. com. CAI Rail is an operating lessor in the new and used railcar space. CAI performs full service, net, per diem and finance leases on all railcar types. We have complete maintenance, engineering, opera tions and field marketing staff. In addition, CAI offers a comprehensive rail car customization and refurbishing program to meet our clients’ specifi cations. Our parent company, CAI International (NYSE: CAI) specializes in container leasing and sales as well as domestic and international intermo dal logistics. So, let’s get moving!

CARMATH, INC.

25965 482nd Ave., Brandon, SD 57005; Walker Carmon, Vice President, Tel.: 605-582-8340; Email: wcarmon@mwrail.com; Website: www. carmathinc.com. At CarMath, we believe every business should have the opportunity to lease quality railcars at a reasonable price. We have the ability to lease both large and small groups of cars with a wide variety of leasing options and will customize a leasing program to best fit your needs.

CIT RAIL 30 South Wacker Drive, Suite 2900, Chicago, IL

60606; Tel.: 312-906-5701. CIT’s Rail division offers a full suite of railcar leasing and equipment financing solutions to rail shippers and carri ers across North America. It manages one of the youngest and most diversified railcar and locomo tive fleets in the industry and leverages its deep experience to empower customers. Contact us to learn how our transportation solutions can power your business. Visit cit.com/rail, call 312-9065701 or follow @CITgroup.

SEE OUR AD ON PAGE 11

C.K. INDUSTRIES, INC. P.O. Box 1029, Lake Zurich, IL 60047-1029; Tel: 847-550-1853; Fax: 847-550-1854; email sales@ ckrail.net. Brian M. Harris. C.K. INDUSTRIES, a privately held corporation, began its U.S. leasing operations in 1980, and offers its services to ship pers, short line, regional and Class I railroads in North America. New investment opportunities up to $10MM of both new and used types of freight cars will be considered. Our existing lease fleet offers a wide variety of car types to meet your lease requirements. We offer mid to long terms, either on a full service or triple net basis.

THE DAVID J. JOSEPH COMPANY 300 Pike Street, Cincinnati, Ohio 45202; Tel.: 513-419-6200; Fax: 513-419-6221; Trey W. Savage, VP Rail Group; Dan Dorsey, General ManagerRail Equipment Group; Jeff Schmutte, Jeff Blake and Eric Hausfeld, Regional Sales Managers; Luke Weatherhead, General Manager-Private Fleet; Steven R. Skeels, Chief Mechanical Officer; and Ann Edwards, Mgr. Retired Rail Assets (502212-7365). The David J. Joseph Company’s Rail Group provides a broad range of transportation services throughout North America: single inves tor, leverage leases, freight cars, portfolio evalu ation, remarketing fleet management, purchases and sales of portfolios, and private fleet manage ment. Other services include freight car inspec tions and engineering services from design of new cars to complete ISL extended life, modifications and analysis; in addition to railcar dismantling for scrapping and parts reclamation.

SEE OUR AD ON PAGE 13

GATX CORPORATION

Thomas A. Ellman, President, Rail North America, GATX Corporation, 222 W. Adams Street, Chicago, IL 60606; Tel: 312-621-6200 Fax: 312-621-6546 GATX is a leader in the rail leasing industry with more than a century of experience, preeminent expertise in specialized railcars, and a growing international presence. GATX meets shipper and

railroad needs with one of the largest lease fleets of tank and freight cars and locomotives in the world. We provide our customers with a unique mix of financial (global financing, valuation, structur ing, leasebacks, joint ventures, partnerships) and mechanical (regulatory, maintenance, engineering, cleaning, inspection) services in North America. Contact via www.gatx.com or 1-800-428-8161.

THE GREENBRIER COMPANIES

One Centerpointe Drive, Suite 400, Lake Oswego, OR 97035; 800-343-7188; Fax: 503-968-4383; Email: Marketing.Info@GBRX.com; Website: www.GBRX.com. Tom Jackson, V.P., Market ing. Greenbrier, headquartered in Lake Oswego, Oregon, is a leading international supplier of equipment and services to global freight trans portation markets. Through its wholly owned subsidiaries and joint ventures, Greenbrier designs, builds and markets freight railcars and marine barges in North America, Europe and Brazil. We are a leading provider of freight railcar wheel services, parts, repair, refurbishment and retrofitting services in North America through our wheels, repair and parts business unit. Green brier manages 445,000 railcars and offers railcar management, regulatory compliance services and leasing services to railroads and other railcars owners in North America. GBX Leasing (GBXL) is a special purpose subsidiary that owns and manages a portfolio of leased railcars that origi nate primarily from Greenbrier’s manufacturing operations. Together, GBXL and Greenbrier own a lease fleet of 8,700 railcars. Learn more about Greenbrier at www.gbrx.com.

INFINITY TRANSPORTATION

Powered by Global Atlantic. 1355 Peachtree Street, NE, Suite 750, Atlanta, GA 30309; Website: www.infinitygafg.com. Lee Martini, VP Sales & Marketing; Tel.: 678-904-6315; lee.martini@ gafg.com; Brian Ottinger, VP Sales & Marketing; Tel.: 312-731-2763; brian.ottinger@gafg.com. Ken Johnson, VP Sales & Marketing; Tel.: 859-6400362; ken.johnson@gafg.com Infinity Transpor tation is a private lessor with a fleet of more than 10,000 railcars of varying types. Lease packages are tailored to meet customer needs, including a variety of short-term operating leases and longterm leveraged leases, as well as other assignment and deployment arrangements. Infinity prides itself on exceptional customer service and flexibil ity with regard to leases and railcar modifications to find the transaction and equipment to best serve our customers.

October 2022 // Railway Age 21 railwayage.com

SEE OUR AD ON PAGE 18

2023 FINANCIAL DESK BOOK DIRECTORY

THE INSTAR GROUP, LLC

2001 Route 46, Ste. 506, Parsippany, NJ 07054. (636), 778-0611; (973) 355-6484. Umesh Choksi, CEO. UChoksi@instargrp.com. The InStar Group LLC is a full-service railcar leasing company estab lished in 2016. We are owner operators and/or investors in the railcar business in North America and provide the highest quality railcars on either a full service or net lease to North American shippers and railroads. We invest and offer all railcar types across all industries we deem to be most efficient for the commodities carried with proven track record of consistent cash flow. We are flexible in our approach to investing in railcars and have the ability to own outright, participate in lease in/lease out arrangements, sale-leasebacks, joint ventures or provide structured financial products for our customers. The InStar Group management team is composed of seasoned industry professionals with manufacturing, leasing, railcar portfolio manage ment, and financing expertise. We maintain rela tionships with all major railcar manufacturers, other operating lessors, shippers, railroads, repair and maintenance facilities and financial institu tions within the industry. The InStar Group, LLC is now part of J.P. Morgan Global Alternatives’ Global Transportation Group, the alternative investment arm of J.P. Morgan Asset Management. More infor mation: https://instargrp.com.

MITSUI RAIL CAPITAL, LLC

One South Wacker Drive, Suite 3110, Chicago IL 60606 - Phone: 312-803-8851: Dan Penovich, President; Chris Gerber, Vice President Sales and Marketing. Mitsui Rail Capital is a railcar operat ing lessor that offers some of the youngest railcars in our industry. From tank cars to covered hoppers to a wide variety of other car types, we deploy assets in every industry, including oil, gas, plastics, agri culture and steel. Our proactive approach enables us to know your unique needs and railcar require ments, getting well-structured deals done, faster. MRC has been in business for 20 years and is a joint venture between Mitsui & Co. Ltd. and JA Mitsui Leasing of Tokyo.

PNW RAILCARS INC.

121 SW Morrison St., Suite 1525, Portland, OR 97204. 503-208-9295. sales@pnwrailcars.com. www.pnwrailcars.com. PNW Railcars, Inc. (formerly MUL Railcars) offers a complete railcar leasing solution set with asset management, regu latory support, and specialized services designed to provide customers with the options they need. PNW Railcars has one of the newest and most comprehensive tank car and freight car fleets in rail

leasing, serving several industries including auto motive, chemical, steel, agriculture, aggregates, construction, infrastructure and intermodal.

SEE OUR AD ON PAGE 17

PROGRESS RAIL, A CATERPILLAR COMPANY

Mike MacMahon, Director of Railcar Leasing, mmacmahon@progressrail.com; Jay Hatfield, Director of Business Development, jhhatfield@ progressrail.com; Gary Lawrence, Manager, Loco motive Sales & Leasing, glawrence@progressrail. com. Jacob Creech, Manager, Locomotive Leasing, jcreech@progressrail.com. Progress Rail, a Cater pillar Company, offers through its Freight Car Leasing Division offer a wide variety of freight cars and leasing options to meet our customers’ specific transportation requirements: Full-Service, Net and Per-Diem leases, and Purchase-Leasebacks. Under standing your needs and supplying an optimal solu tion is what we do best. The Locomotive Leasing Division offers Full-Service Leases: Net, Seasonal, Sell-Lease Back, Trade-Ins. All locomotives sold or leased go through an extensive inspection to ensure you are receiving equipment that is ready for service. Refurbishment or upgrades are avail able to ensure the locomotive fits your operation, with work completed in our own shops under our supervision, ensuring the highest level of quality. Through the acquisition of Electro-Motive Diesel, Progress Rail has access to locomotive information other providers cannot supply. Our locomotive inventory is constantly changing, as we strive to be your top supplier of quality and dependable used locomotives.

SEE OUR AD ON THE INSIDE FRONT COVER

RELAM (RAILWAY EQUIPMENT LEASING AND MAINTENANCE) INC.

7695 Bond Street, Glenwillow, OH 44139; (440) 439-7088. John Roberts, CEO, Email: jroberts@ relaminc.com. As a full-service leasing company, we offer complete MOW equipment leasing services. Each of our team members is knowledgeable, professional, prompt and courteous, one reason why our clients stay with us. We understand the importance of making every business transaction easy on the customer. We handle all the paperwork and logistics for every lease, so you can spend your time on more important things. We are commit ted to providing our clients with the highest level of service while remaining competitive in today’s market. RELAM knows railroad operations and the equipment involved.

SEE OUR AD ON PAGE 19

RALTRAC, LLC

200 S. Wacker Drive, Suite 3100, Chicago, IL 60606; tel: 312-674-4742; fax: 312-421-2742; www.raltrac. com. RALTRAC (formerly RALCO) is a privately held, Illinois Limited Liability Company in the business of acquiring, managing and leasing rail road rolling stock on net or full services leases. The Company has the intellectual and financial resources necessary to compete in the small cap lease market where its size and structure provide it with a competitive advantage. RALCO also provides consulting and advisory services to its clients. Contact: Peter Urban, Principal, purban@ raltrac.com, 847-975-3568 (mobile); Richard Johannes, Principal; Jason Urban, Principal.

RELCO LOCOMOTIVES, INC.

One Relco Ave, Albia, Iowa 52531. Tel.: 641-9323030; Website: www.relcolocomotives.com. RELCO, as one of North America’s leading locomo tive rebuild, remanufacturing and leasing compa nies, can provide a full range of locomotive leasing and maintenance services. Since 1961, RELCO has developed a reputation for providing the finest motive power and custom maintenance packages to fit any need:

• Full line of both switching and road power available.

• Specifications ranging from qualified to completely custom remanufactured.

• Aftermarket systems upgrades available, including radio remote controls, micropro cessor control systems, fuel management systems, etc.

• Nationwide full-maintenance programs available.

• Net, full-service, financial and sale/leaseback programs.

SMBC RAIL SERVICES LLC

300 South Riverside Plaza, Suite 1925, Chicago, IL 60606; Mike McCarthy, President & CEO (312) 559-4803; Tina Beckberger, Senior Vice President Leasing, (312) 559-4818. SMBC Rail Services is a full-service operating lessor, invested in all tank and freight car types, offering a broad selection of equipment leasing and financing products for the North American rail market. SMBC Rail can struc ture a solution for all your rail equipment needs, short and long term, full-service or net leases, sale/ leasebacks, or portfolio acquisitions. Contact us via www.smbcrail.com or sales@smbcrail.com.

TEALINC, LTD.

1606 Rosebud Creek Road, Forsyth, MT 59327; Tel.: 406-347-5237; Fax: 406-347-5239; www.tealinc.

22 Railway Age // October 2022 railwayage.com

2023 FINANCIAL DESK BOOK DIRECTORY

com; webmail@tealinc.com; Julie Mink, President, 720-733-9922; julie@tealinc.com; Kristen Kempson, Director-Railcar Leasing & Sales; Tel. (708) 854-6307; kristen@tealinc.com; Shannon Rodgers, DirectorOperations; Tel.: (814) 631-9277; shannon@tealinc. com. Tealinc, Ltd. is a boutique private freight railcar lessor, railcar fleet manager and rail transportation consultant. Guided by our Customer-Centric philos ophies, we partner with our customers by leasing, buying, and selling railcars nationally and interna tionally. Our private railcar fleet includes covered hoppers, flatcars, gondolas, open top hoppers, etc. Custom-tailored railcar lease support packages include options such as daily tracing, cycle time reports, preventative maintenance planning, etc. Our rail transportation consulting services enable our customers to have a successful freight-by-rail experi ence. With a combined 80 years providing service and expertise in the freight rail industry, the Tealinc team is dedicated to being a rail partner to novice, interme diate, and expert freight railcar shippers.

TRINITYRAIL®

14221 North Dallas Parkway, Ste. 1100, Dallas, TX 75254. 1-800-631-4420. TrintyRail® provides access to the rail transportation businesses of Trinity Industries, Inc. With an owned and managed fleet of approxi mately 131,000 railcars, Trinity Industries Leasing Company (TILC) provides one of the largest railcar fleets in North America. In addition to comprehensive leasing and management services, our customers have access to extensive manufacturing and engineering resources, railcar maintenance, parts, asset manage ment and advisory services, and on-site field support for operational assistance and training. An overview of our platform of integrated rail products and services is available at www.trinityrail.com.

SEE OUR AD ON PAGE 3

UNION TANK CAR COMPANY

175 W. Jackson Blvd., Suite 2100, Chicago, Illinois 60604; 312-431-3111; leasinginquiry@utlx.com; https://www.utlx.com. Union Tank Car Company (UTLX) supplies general purpose and pressure tank cars, in addition to plastics covered hopper cars, for bulk shippers. Along with Canadian affiliate Procor Limited (PROX), our combined companies own the largest and most diverse tank car fleet in North America, specializing in full-service tank car leasing. We also operate the largest railcar repair network on the continent, and with the acquisition of Transco Railway Prod ucts Inc. in 2019, our repair network now includes 26 full-service shops and more than 100 mini shop and mobile unit installations. UTLX is capable of servicing all fleet management and maintenance

needs for all car types. Our manufacturing opera tion, located in Alexandria, Louisiana, specializes in the fabrication of tank cars. Leveraging an inte grated leasing-repair-manufacturing model with experience cultivated throughout our 130-year history, our talented team provides superior customer service and shapes the future of the highly regulated North American tank car indus try. Union Tank Car Company is a Marmon/ Berkshire Hathaway Company.

SEE OUR AD ON PAGE 15

VTG RAIL INC.

103 West Vandalia, Suite 200, Edwardsville, IL 62025. Bryan Vaughan, Regional Vice President Sales, 630-361-6745, Bryan.Vaughan@vtg.com. Lynn Hayungs, Regional Vice President, Sales, 956-630-2723 ext. 206, Lynn.Hayungs@vtg.com. VTG is a freight and tank railcar lessor offering operating leases and customer structured solutions. VTG also provides fleet management services for its customers and for other private railcar owners and operators. VTG is a customer service oriented leasing company that provides a best in class mix of service, operational and mechanical expertise at competitive lease terms. VTG invests in all freight car types.

WELLS FARGO RAIL

Wells Fargo Rail, 9377 W. Higgins Road, Suite 600, Rosemont, IL 60018; Telephone: 844-459-9664; Fax: 847-318-7588; Web: www.wellsfargo.com/rail. Email: RailAccountServices@wellsfargo.com. Wells Fargo Rail is the largest, most diverse rail equipment operating lessor in North America. Whatever you’re transporting, we’ve got you covered with more than 175,000 railcars and 1,800 locomotives. Our team of experienced rail industry professionals is ready to listen to your needs and structure creative solutions to add value to your business.

PROFESSIONAL SERVICES

RAILROAD APPRAISAL ASSOCIATES

Division of The Occor Company; Management Consultants providing a variety of consulting services to the railroad and urban transportation industries and the financial institutions and leasing companies that serve them: Railcar and Loco motive Appraisal & Inspection Services for New and Used Equipment, Rail Equipment Portfolio Reviews and Valuation, Market Studies, General Consulting. We have more than 20 years of market experience and data. Patrick J. Mazzanti, President; Ronda Lemons, Assistant. Headquarters: 1914 Springdale Drive, Spring Grove, IL 60081, (815) 675-3300; E-mail: pat@railroadappraisals.com.

RAILSOLUTIONS, LLC

1401 Walnut Street, Suite 500, Boulder, CO 80302; (646)258-5812. 2593 Wexford-Bayne Road, Suite 205, Sewickley, PA 15143; (724) 766-6699; Email: mmahoney@railsolutions-llc.com, rblankemeyer@ railsolutions-llc.com; Website: www.railsolutionsllc.com; Michael E Mahoney, President; Robert Blankemeyer, Senior Vice President. RailSolutions LLC provides a broad variety of railroad equipmentrelated consulting, technical and advisory services to financial institutions, railroads, shippers and fleet owners with a primary focus on equipment valua tion and appraisal services. RailSolutions LLC offers two publications on a subscription basis, The Inves tors’ Guide to Railroad Freight Cars and Locomotives and the RailSolutions Railroad Equipment Historical Database. Our firm draws on close to 50 years of rail road industry experience in railcar and locomotive equipment valuations supported by both a sound base of market data and advanced analytical techniques.

SEE OUR AD ON PAGE 16

RR MERGERS & ACQUISITIONS

11 The Pines Court, Suite B, St. Louis, Missouri 63141; Tel: 314 878-1414; Fax: 314-878-1414; Robert Fowler, President, 314 878-1414 x227 Email: robert@ rrmergers.com. Jack Sickles, Vice President, 314 878-1414x221 Email: jack@rrmergers.com. RR Mergers & Acquisitions has specialized in the sale of rail-focused companies for more than 15 years. Trusted professionals with long-standing relation ships in the rail sector, RR Mergers interfaces with strategic and financial buyers finding the right buyer for a Company, to make the best deal happen. While maintaining confidentiality at all times, RR Mergers manages the total process of selling railroad indus try suppliers, rail services companies and Short Line Railroads. RR Mergers provides advisory services to prepare the company for acquisition, developing a confidential information memorandum, negotiat ing term sheets, letters of intent and coordinating the due diligence process.

STRATEGIC RAIL FINANCE

1700 Sansom St., Suite 500, Philadelphia, PA 19103; (215)564-3122. Michael Sussman, President and CEO. SRF has served for 23 years as trusted advisor to Class I and short line railroads, rail shippers, public sector agencies, and industrial developers. The firm has brought capital, clarity, and velocity to infrastructure development projects in 38 states and Canadian provinces. SRF integrates capital from public programs and private sources with growth marketing strategies and management consulting to position executives toward shortterm objectives and long-term opportunities.

October 2022 // Railway Age 23 railwayage.com

HOLD ON TIGHT!

BY CAROLINA WORRELL , SENIOR EDITOR

Rail fastening system suppliers continue to find new ways to deliver a tight hold and longer track life, helping to ensure the safety of heavy-haul, high-speed passen ger rail and transit applications across North America and beyond.