AILWAY G E

SERVING THE RAILWAY INDUSTRY SINCE 1856

ADVANCED-TECH CONVERGENCE

Railroads, Suppliers Propel Innovation

CLEAN TRACK AHEAD

Why Locomotive Emissions

Must Keep Dropping

CYBERSECURITY

PREPAREDNESS

The Case for a Railroad

Defense Budget

WWW.RAILWAYAGE.COM SEPTEMBER 2023

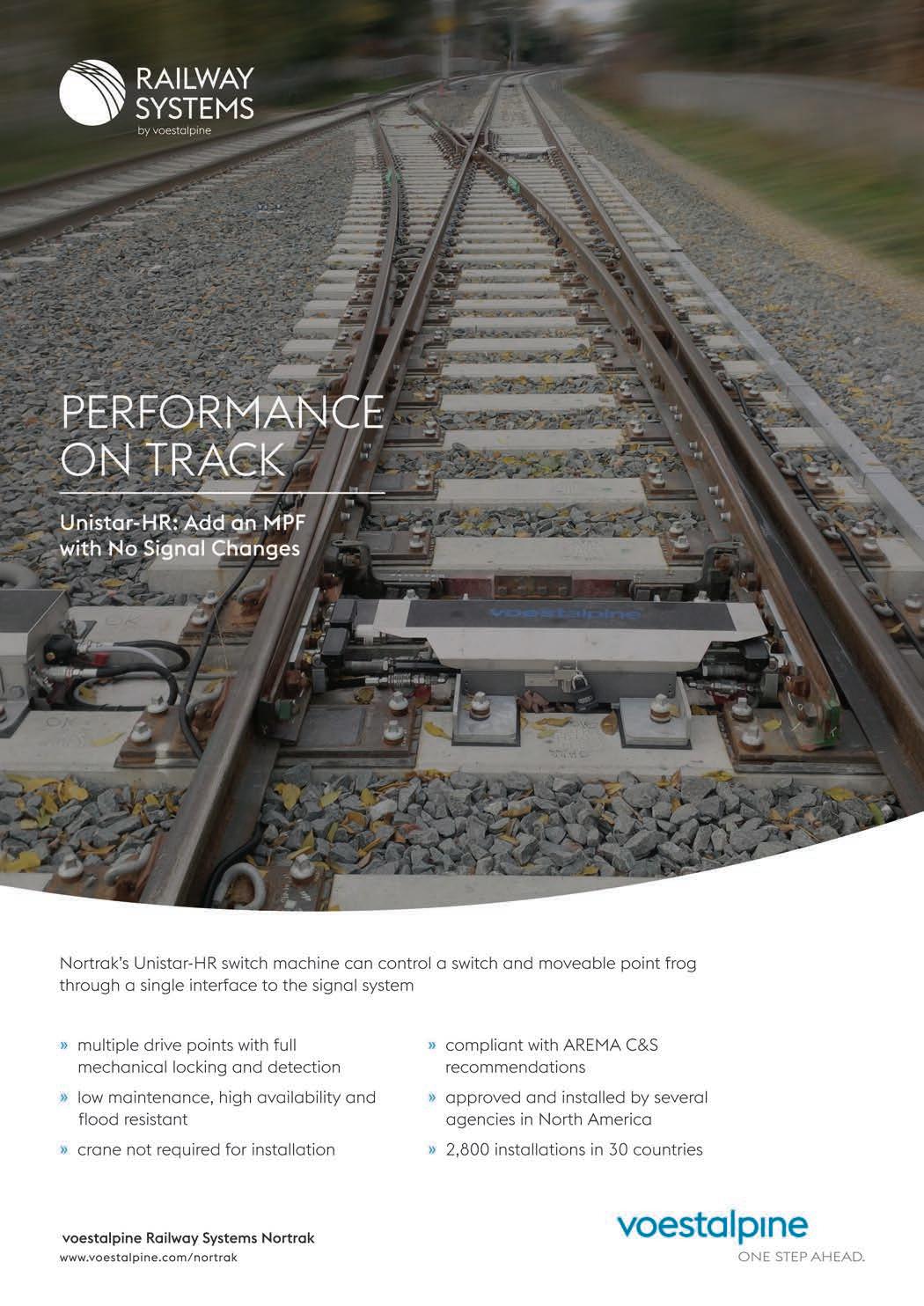

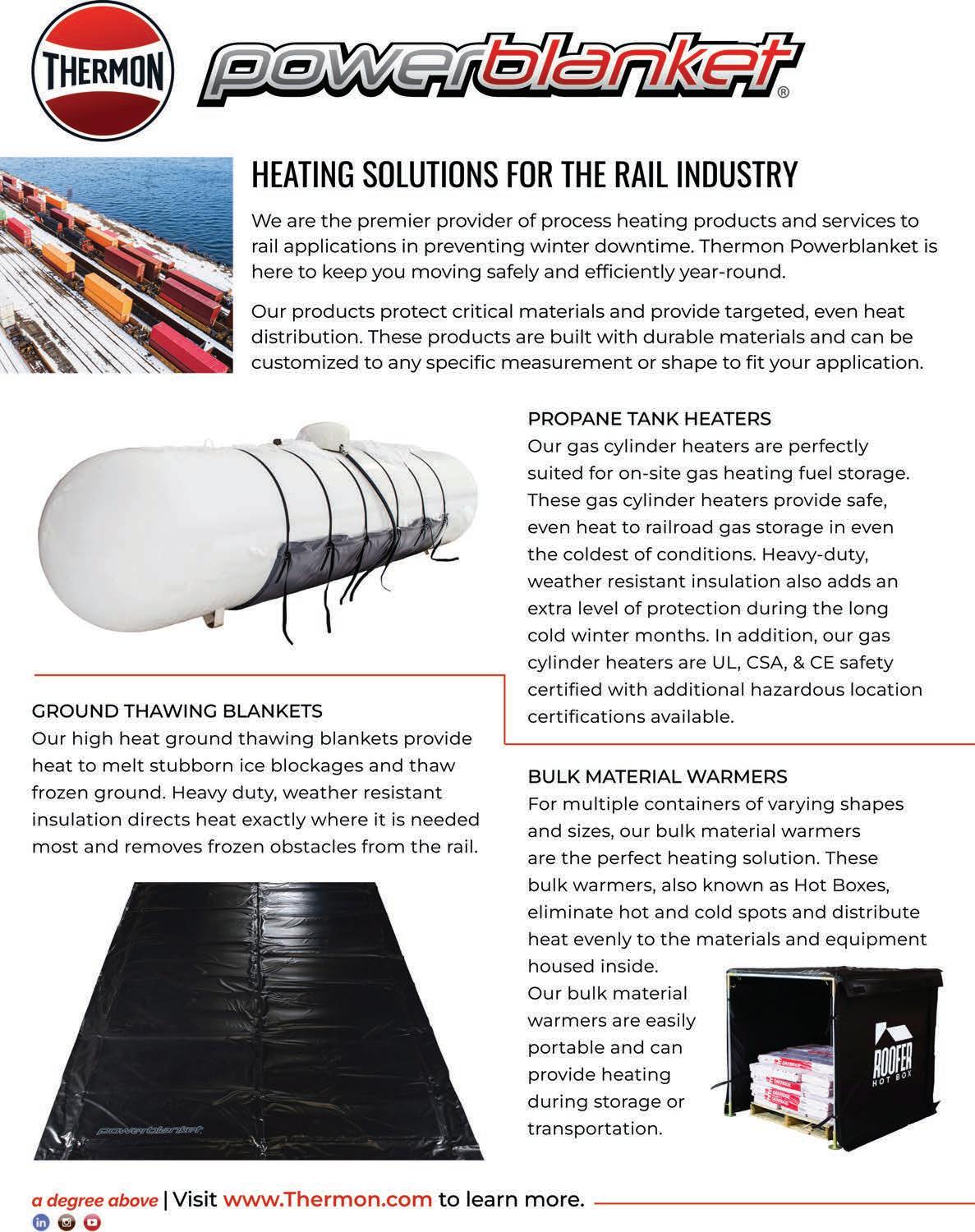

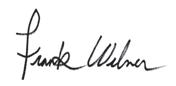

Come see us at booth 3953 at the Railway Interchange and booth 4842 at the APTA Show

Come see us at booth 3953 at the Railway Interchange and booth 4842 at the APTA Show

Railway Age, USPS 449-130, is published monthly by the Simmons-Boardman Publishing Corporation, 1809 Capitol Avenue, Omaha, NE 68102. Tel. (212) 620-7200. Vol. 224, No. 9. Subscriptions: Railway Age is sent without obligation to professionals working in the railroad industry in the United States, Canada, and Mexico. However, the publisher reserves the right to limit the number of copies. Subscriptions should be requested on company letterhead. Subscription pricing to others for Print and/or Digital versions: $100.00 per year/$151.00 for two years in the U.S., Canada, and Mexico; $139.00 per year/$197.00 for two years, foreign. Single Copies: $36.00 per copy in the U.S., Canada, and Mexico/$128.00 foreign All subscriptions payable in advance. COPYRIGHT© 2023 Simmons-Boardman Publishing Corporation. All rights reserved. Contents

September 2023 // Railway Age 1 railwayage.com

be

International Corp., 102 W. 38th Street, 6th floor, New York, N.Y. 10018, Tel.: 212-221-9595; Fax: 212-221-9195. Periodicals

paid at New York, N.Y.,

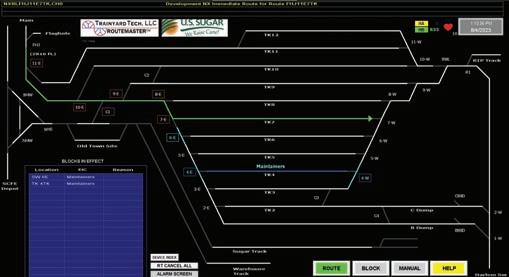

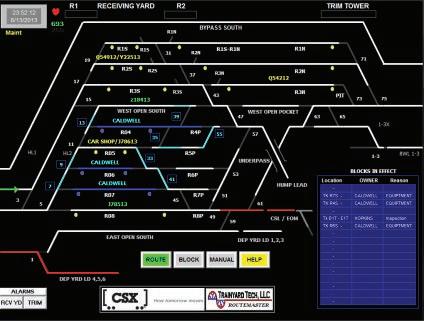

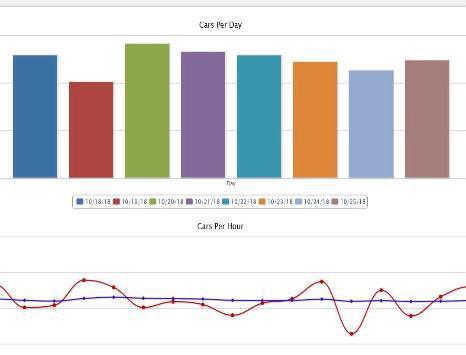

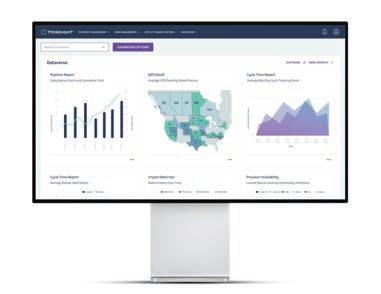

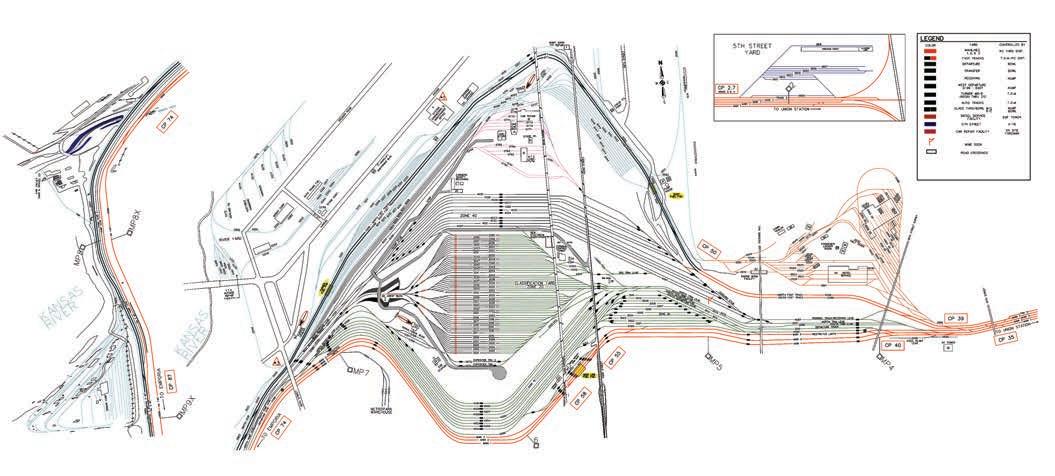

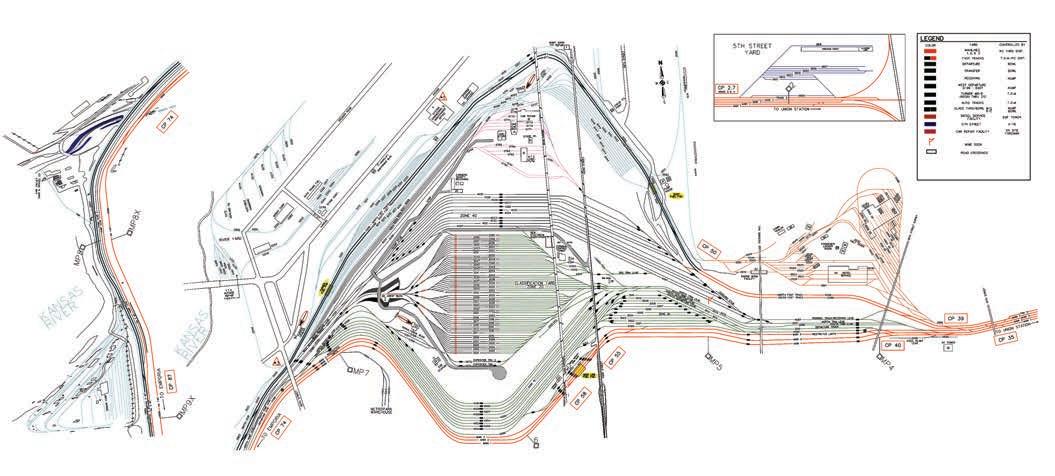

offices. Canada Post Cust.#7204564; Agreement #41094515. Bleuchip International, PO Box 25542, London, ON N6C 6B2. Address all subscriptions, change of address forms and correspondence concerning subscriptions to Subscription Dept., Railway Age, PO Box 239 Lincolnshire IL 60069-0239 USA; railwayage@omeda.com; or call +1 (402) 346-4740; FAX +1 (847) 291-4816. Printed at Cummings Printing, Hooksett, N.H. ISSN 0033-8826 (print); 2161-511X (digital). FEATURES 15 54 60 66 70 74 76 80 83 86 Innovations Showcase State-of-the Art Technology Tech Focus – Locomotives Getting Cleaner, Faster Tech Focus – C&S Controlling BNSF’s Argentine Yard Tech Focus – M/W CSX’s “Team Sport” Approach Rail Cybersecurity Investing in Preparedness Tech Focus – IT Which Intelligence, When? Stop Jack Knife Derailments Using Alignment Control Couplers Microlubrication Benefits of zMAX Application Timeout for Tech Managing Risk of Failure MxV Rail R&D EMAT Update COMMENTARY 2 10 92 From the Editor Watching Washington Financial Edge DEPARTMENTS 4 6 8 88 90 90 91 Industry Indicators Industry Outlook Market Book Review Professional Directory Classifieds Advertising Index COVER PHOTO Shutterstock/Irina Shi September 2023 60 AILWAY

E BNSF

may not

reproduced without permission. For reprint information contact PARS

postage

and additional mailing

G

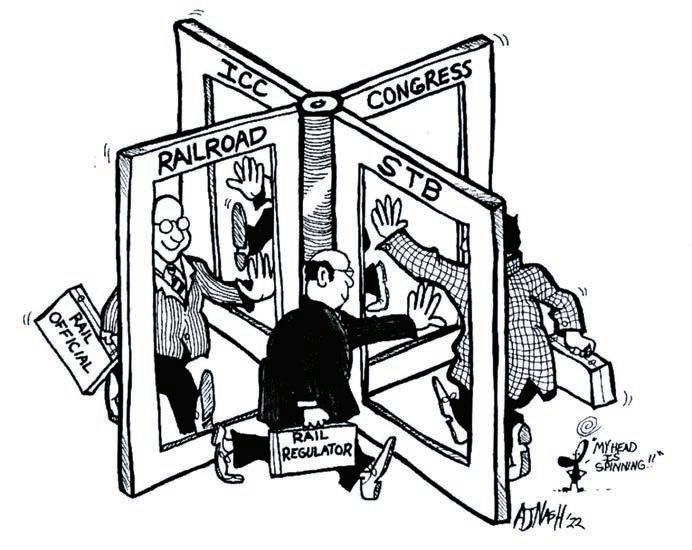

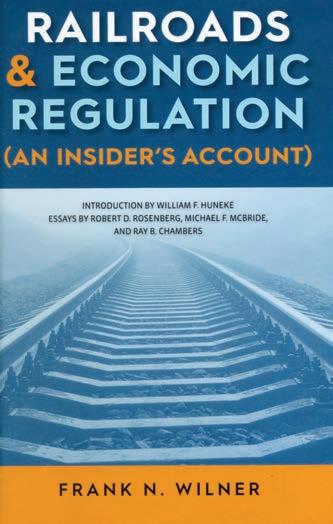

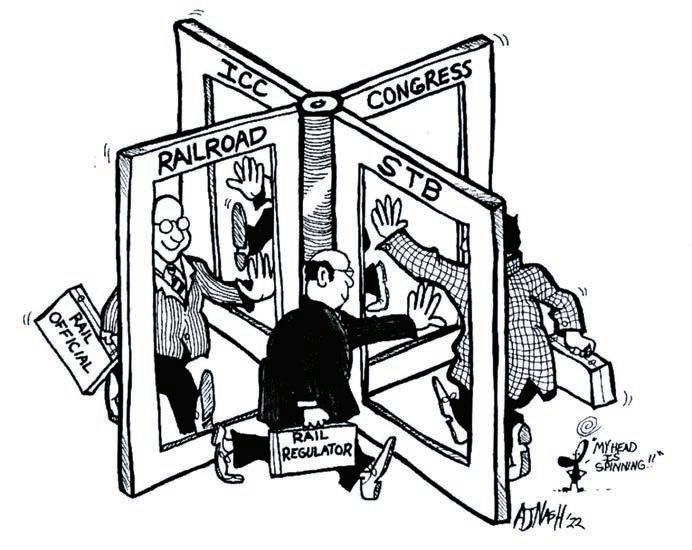

‘Stories are Spirit’

Capitol Hill

Contributing

Editor Frank

N. Wilner’s new book, Railroads & Economic Regulation, An Insider’s Account, reviewed by fellow Contributing

Editor Jim Blaze (pp. 88-89), contains an Appendix, “Stories are Spirit,” that shows the human side of some who have regulated our industry since 1887. As economist George Hilton quipped in 1972, “Regulators are not automatons, but men and women who go to baseball games, advocate their political philosophies, have their gallbladders removed, take their cats to the veterinarian, and otherwise behave like the rest of us.”

Here’s a small sampling—and you can’t make this stuff up:

“This shipper description of railroads appeared in the Jan. 1, 1910, Traffic World: ‘With pilfering clutch they lay a burden on the traffic that I ship, and lo! My profits fail me. Can we be men and suffer such dishonor? Alack, the day I took to merchandising and placed my goods in pawn. Yet there be law to seek, and by this power we’ll tear away the tentacles whereby an octopus does drag us down, and drive the vampire to his cave.’”

“ICC Commissioner Thomas F. Woodlock (1925-1930)—a native of Ireland and one of just three foreign-born members of the ICC or STB—was quoted in the 1941 ICC Practitioners’ Journal: ‘As a junior clerk in a London stockbrokerage firm I heard a good deal about the 1887 Act to Regulate Commerce. It quite convinced me that it would be a catastrophe if it passed and fine if it didn’t. Many, many years later, by a set of curious chances, I found myself a member of the ICC. Often, sitting mute upon the bench, I would, without any

AILWAY GE

SUBSCRIPTIONS: 847-559-7372

EDITORIAL AND EXECUTIVE OFFICES

warning, hear a small voice whispering in my ear, doubtless that of the devil, ‘Maybe you were right.’”

“Printed in the Report of the Second Annual Meeting of the ICC Bar Association in 1935 is a recollection by Commissioner Joseph B. Eastman (1919-1944) of a note sent him in good humor by Pennsylvania Railroad Chief Counsel Henry Wolf Bikle: ‘Having heard from time to time that you are given to Sabbath-breaking by working on Sundays, I began to wonder whether the things you say in your dissenting opinions, which cause your railroad friends so much distress, may not be written on Sunday and are the product of your sinful habits.’”

“The Dec. 29, 1953 New York Times reported: ‘Two attorneys turned an ICC hearing into a brawl yesterday. The session, held in a small room at 346 Broadway, started in formality and ended in invective and a sharp slap administered by the older of the attorneys, Sidney Szerlip, 71. It was received by 43-year-old Sidney Eisen. Later during the hearing, Mr. Szerlip, agile for his age, ran around four desks joined together as one long table and swung at Mr. Eisen. The latter feinted nicely and sidestepped. Mr. Eisen seemed to debate for a second whether to retaliate with a jab. Instead, he countered with a mumbled remark about ethics. Again, the older counselor stepped in. This time, Mr. Eisen forgot to duck and a sharp slap landed against his already reddened left cheek. The opponents were pulled apart. The case was adjourned and the sides settled privately.’”

Again, you can’t make this stuff up. Buy the book! It’s available from Simmons-Boardman Books, www.transalert.com.

Simmons-Boardman Publishing Corp. 1809 Capitol Avenue Omaha, NE 68102 (212) 620-7200 www.railwayage.com

ARTHUR J. McGINNIS, Jr. President and Chairman

JONATHAN CHALON Publisher jchalon@sbpub.com

WILLIAM C. VANTUONO Editor-in-Chief wvantuono@sbpub.com

MARYBETH LUCZAK Executive Editor mluczak@sbpub.com

CAROLINA WORRELL Senior Editor cworrell@sbpub.com

DAVID C. LESTER Engineering Editor/Railway Track & Structures Editor-in-Chief dlester@sbpub.com

JENNIFER McLAWHORN Managing Editor, RT&S jmclawhorn@sbpub.com

HEATHER ERVIN Ports and Intermodal Editor/Marine Log Editor-in-Chief hervin@sbpub.com

Contributing Editors

David Peter Alan, Jim Blaze, Nick Blenkey, Sonia Bot, Bob Cantwell, Peter Diekmeyer, Alfred E. Fazio, Gary Fry, Michael Iden, Don Itzkoff, Bruce Kelly, Ron Lindsey, David Nahass, Jason Seidl, Ron Sucik, David Thomas, John Thompson, Frank N. Wilner, Tony Zenga

Art Director: Nicole D’antona

Graphic Designer: Hillary Coleman

Corporate Production Director: Mary Conyers

Production Director: Eduardo Castaner

Marketing Director: Erica Hayes

Conference Director: Michelle Zolkos

Circulation Director: Joann Binz

INTERNATIONAL OFFICES

46 Killigrew Street, Falmouth, Cornwall TR11 3PP, United Kingdom 011-44-1326-313945

International Editors

Kevin Smith ks@railjournal.co.uk

David Burroughs dburroughs@railjournal.co.uk

David Briginshaw db@railjournal.co.uk

Robert Preston rp@railjournal.co.uk

Payment should be sent directly

herein for the flat fee of $2.00 per copy of each

personal or internal reference use without the express permission of Simmons-Boardman Publishing Corp. is prohibited. Address requests for permission on bulk orders to the Circulation Director. Railway Age welcomes the submission of unsolicited manuscripts and photographs. However, the publishers will not be responsible for safekeeping or return of such material.

Member of:

Simon Artymiuk sa@railjournal.com

CUSTOMER SERVICE: RAILWAYAGE@OMEDA.COM , OR CALL 847-559-7372

Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

2 Railway Age // September 2023 railwayage.com FROM THE EDITOR WILLIAM C. VANTUONO Editor-in-Chief Railway Age, descended from the American Rail-Road Journal (1832) and the Western Railroad Gazette (1856) and published under its present name since 1876, is indexed by the Business Periodicals Index and the Engineering Index Service. Name registered in U.S. Patent Office and Trade Mark Office in Canada. Now indexed in ABI/Inform. Change of address should reach us six weeks in advance of next issue date. Send both old and new addresses with address label to Subscription Department, Railway Age, PO Box 239, Lincolnshire IL 60069-0239 USA, or call (US, Canada and International) 847-559-7372, Fax +1 (847) 291-4816, e-mail railwayage@omeda.com. Post Office

not

copies unless you provide extra postage.

Send changes of address to:

Age,

Box

Photocopy rights: Where necessary, permission is granted

Center

will

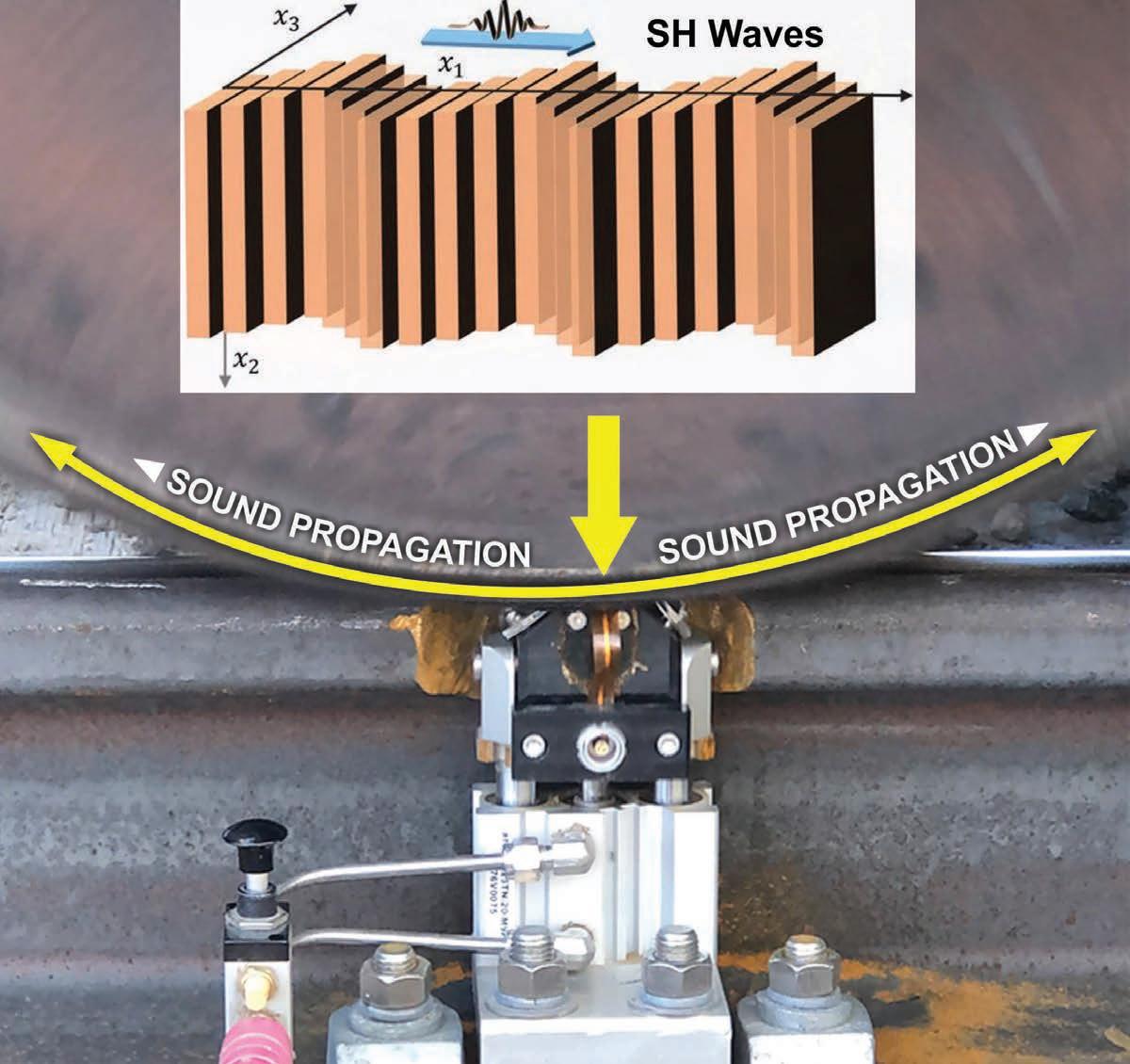

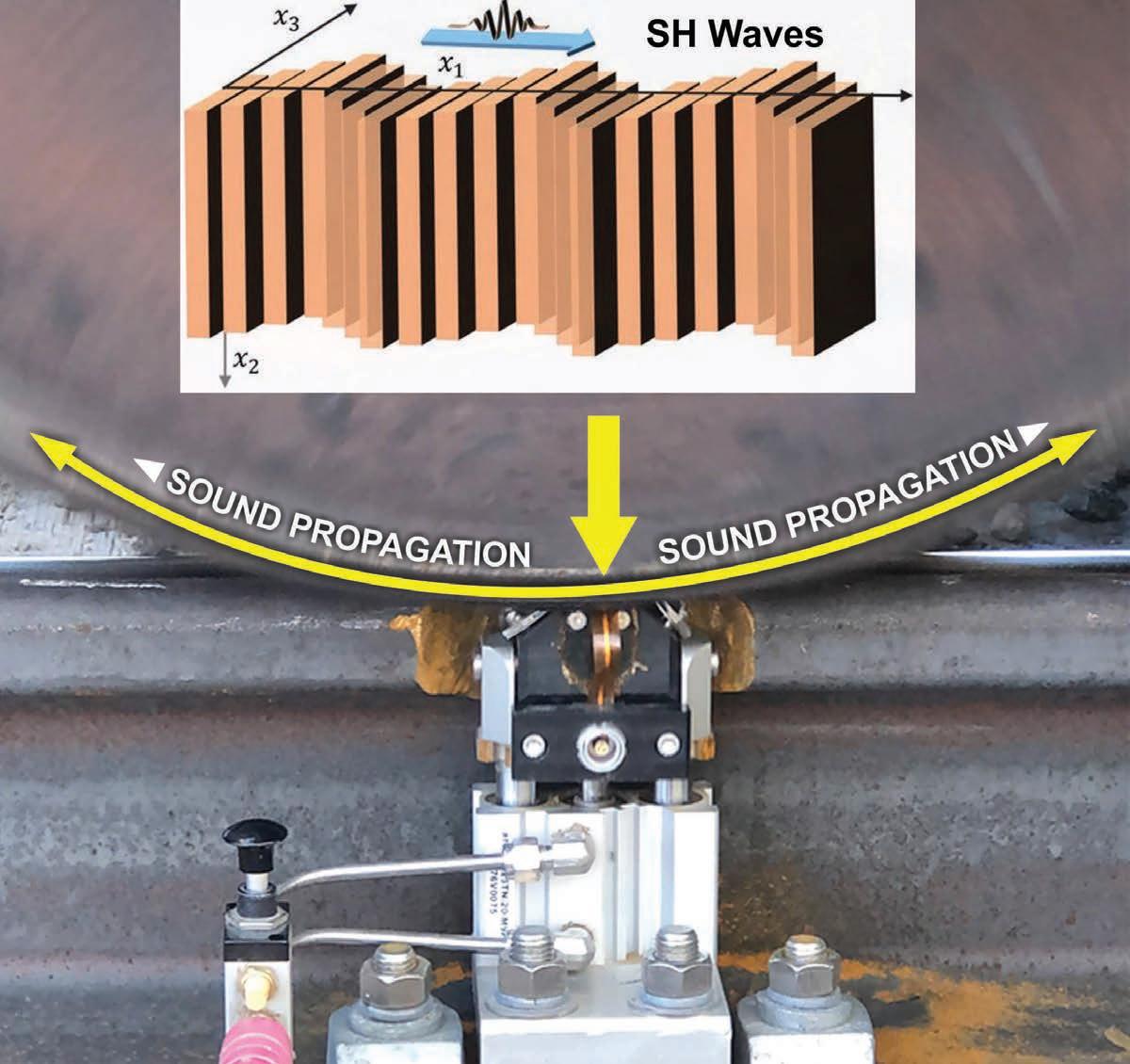

forward

POSTMASTER:

Railway

PO

239, Lincolnshire, IL 60069-0239, USA.

by the copyright owner for the libraries and others registered with the Copyright Clearance

(CCC) to photocopy articles

article.

to CCC. Copying for other than

THE OKONITE COMPANY Okonite Cables...A higher Standard! 102 Hilltop Road, Ramsey, New Jersey 07446 201.825.0300 www.okonite.com OurPremierVitalCircuitSignalCablesare EscortedbySuperiorCustomerService OKONITE Ourformulatokeepyourbusinessontrackisourfleetof6 manufacturingplants,5servicecentersand23localsalesoffices. Ourmultipleplantcapabilityprovidesmanufacturingflexibilityaswe supportyourneedswithourdirectsalesforceandapplication engineeringstaff.Okonitehasbeensettingthestandardsince 1878...andalways100%builtintheU.S.A. We’re Here ForYou!

Industry Indicators

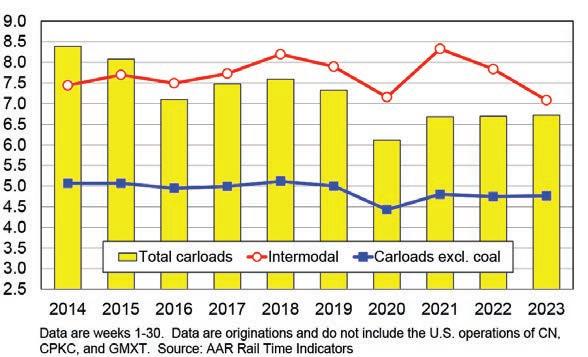

‘SOME ENCOURAGING SIGNS’

“The July 4th holiday complicated an analysis of U.S. rail volumes in July, but there were some encouraging signs,” the Association of American Railroads reported last month. “For example, the three non-July 4 weeks in July were the three highest-volume intermodal weeks of the year for U.S. railroads. Intermodal in July 2023 was still down 5.5% from July 2022, but that’s the smallest percentage decline for any month so far this year. U.S. carloads of chemicals rose in July for the first time in almost a year; carloads of crushed stone and sand rose for the 27th straight month; carloads of motor vehicles and parts rose for the 16th straight month; and carloads of industrial products, which is an aggregation of seven key carload categories and is better correlated with GDP than most other rail traffic categories, were up solidly for the third consecutive month. There was nothing encouraging about grain in July 2023: U.S. grain carloads averaged 14,669 per week, down 21.0% from July 2022 and their lowest weekly average for any month in our data that go back to January 1988. Weak grain exports, especially corn, are mainly to blame. Year-to-date U.S. grain carloads through July were the lowest since 2013. Total originated carloads on U.S. railroads fell 0.6% in July 2023 from July 2022; for the year to date, they were up 0.4%. Excluding coal, carloads were flat in July and up 0.4% for the year to date.”

Railroad employment, Class I linehaul carriers, JULY 2023

(% change from JULY 2022)

TRAFFIC ORIGINATED

Transportation (train and engine)

52,090 (+7.95%)

Executives, Officials and Staff Assistants

8,208 (+4.72%)

10,417 (+5.17%)

Intermodal FOUR WEEKS ENDING JULY 29, 2023

4 Railway

railwayage.com

Age // September 2023

Source: Rail Time Indicators, Association of American Railroads

Professional and Administrative

of

and

Transportation Board TOTAL EMPLOYEES: 122,816 % CHANGE FROM JULY 2022: +5.51%

Maintenance-of-Way and Structures 28,945 (+1.86%) Maintenance

Equipment

Stores 18,280 (+5.52%) Transportation (other than train & engine) 4,876 (+4.39%) Source: Surface

CARLOADS four WEEKS ENDING july 29, 2023 BY COMMODITY JULY ’23JULY ’22% CHANGE Grain 101,792112,236-9.3% Farm Products excl. Grain 12,0556,59382.8% Grain Mill Products 43,274 44,975-3.8% Food Products 43,627 41,7744.4% Chemicals 177,575178,426-0.5% Petroleum & Petroleum Products79,23881,718 -3.0% Coal 288,020291,882-1.3% Primary Forest Products 6,1468,438-27.2% Lumber & Wood Products 22,73925,328-10.2% Pulp & Paper Products 27,80730,536-8.9% Metallic Ores 78,42674,1235.8% Coke 21,353 21,867 -2.4% Primary Metal Products 49,58648,6721.9% Iron & Steel Scrap 21,35922,682-5.8% Motor Vehicles & Parts 92,786 81,45613.9% Crushed Stone, Sand & Gravel 113,110109,151 3.6% Nonmetallic Minerals 18,91220,682-8.6% Stone, Clay & Glass Products 47,32947,046 0.6% Waste & Nonferrous Scrap 17,30317,641-1.9% All Other Carloads 30,37428,6566.0% TOTAL NORTH AMERICAN CARLOADS 1,292,811 1,293,882 -0.1% MAJOR NORTH AMERICAN BY COMMODITY JULY ’23JULY ’22% CHANGE Trailers 52,47863,464-17.3% Containers 1,186,369 1,319,151 -10.1% TOTAL UNITS 1,238,8471,382,615 -10.4% MAJOR NORTH AMERICAN RAILROADS MAJOR NORTH AMERICAN RAILROADS

TOTAL North American CARLOADS, JULY 2023 VS. JULY 2022

1,292,8111,293,882

Short Line And Regional Traffic Index

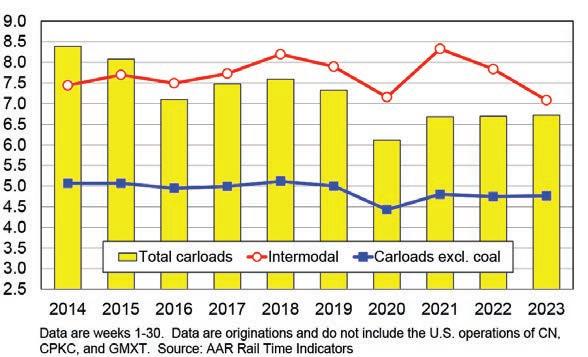

TOTAL U.S. Carloads and intermodal units, 2014-2023 (in millions, year-to-date through july 2023, SIX-WEEK MOVING AVERAGE)

September 2023 // Railway Age 5 railwayage.com

JULY 2023 JULY 2022 Copyright © 2023 All rights reserved.

CARLOADS BY COMMODITY ORIGINATED JULY ’23 ORIGINATED JULY ’22 % CHANGE Chemicals 53,425 47,59512.2% Coal 19,288 17,647 9.3% Crushed Stone, Sand & Gravel 29,562 27,329 8.2% Food & Kindred Products 12,269 10,89712.6% Grain 19,970 24,396-18.1% Grain Mill Products 8,911 7,94612.1% Lumber & Wood Products 9,202 9,586-4.0% Metallic Ores 2,673 3,026 -11.7% Metals & Products 20,209 18,493 9.3% Motor Vehicles & Equipment 11,088 8,76526.5% Nonmetallic Minerals 1,760 2,297-23.4% Petroleum Products 2,438 2,05918.4% Pulp, Paper & Allied Products 15,399 17,133 -10.1% Stone, Clay & Glass Products 15,562 14,520 7.2% Trailers / Containers 41,697 38,828 7.4% Waste & Scrap Materials 11,846 11,672 1.5% All Other Carloads 69,292 74,331-6.8% AILWAY GE Visit http: //bi t.ly/rai l jobs To place a job posting, contact: Jerome Marullo 732-887-5562 jmarullo@sbpub.com ARE YOU A RAILROAD OR SUPPLIER SEARCHING FOR JOB CANDIDATES? RA_JobBoard_1/3Vertical.indd 1 7/27/21 3:02 PM

Court Halts Uinta Basin Railway Project

[Interstate Commerce Commission Termination Act of 1995],” according to the Court. It said STB “failed to weigh the Project’s uncertain financial viability and the full potential for environmental harm against the transportation benefits it identified.”

The “normal remedy” is to vacate a rule found to be unlawful, according to the Court, which wrote: “[W]e see no reason to depart from our normal practice here given the lack of argument from the Board, [BiOp producer the Fish and Wildlife] Service, or the [Seven County Infrastructure] Coalition, that vacatur would be disruptive.”

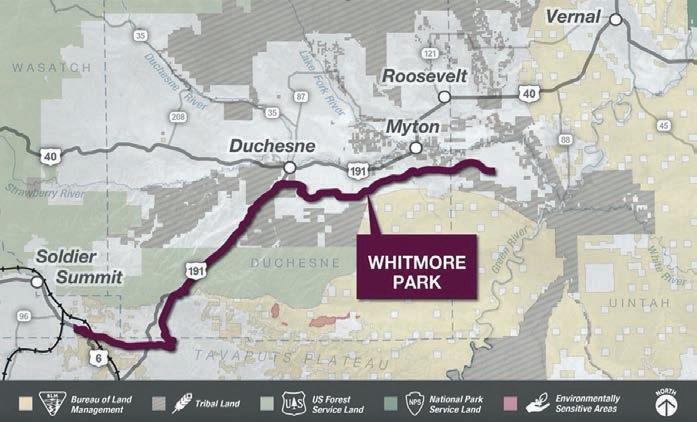

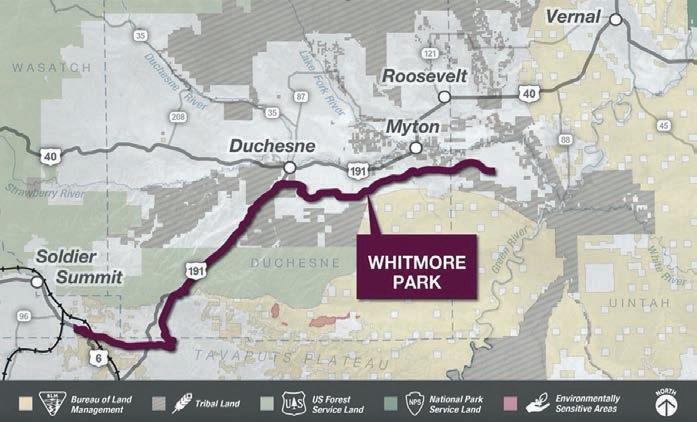

THE SURFACE TRANSPORTATION BOARD’S (STB) DECEMBER 2021 APPROVAL OF THE CONSTRUCTION AND OPERATION OF THE UINTA BASIN RAILWAY WAS STRUCK DOWN BY THE U.S. COURT OF APPEALS FOR THE DISTRICT OF COLUMBIA CIRCUIT, WHICH CALLED IT “ARBITRARY AND CAPRICIOUS.” The 88-mile line would be the first major freight railroad built in the U.S. in the past 30 years.

Behind the project is Utah’s Seven County Infrastructure Coalition, an “independent political subdivision” of the state that sought STB approval for the line, which would primarily haul shale-extracted crude oil. The Coalition joined forces with Drexel Hamilton Infrastructure Partners to raise private capital for the build and with Rio Grande Pacific Corp. to operate and maintain the line once completed. AECOM was chosen to lead the design, and the SkanskaClyde Joint Venture and Obayashi Corporation would help with construction.

The court’s Aug. 18, 2023, decision granted in part the consolidated petitions of Eagle County, Colo., and the Center for Biological Diversity and vacated the STB’s final exemption order as “arbitrary and capricious.” It also vacated in part STB’s Environmental Impact Statement (EIS) outlining the various impacts associated with the railway’s construction and operation, and the Biological Opinion (BiOp) concerning the railway’s potential impacts

on endangered species and critical habitats. The matter was remanded to STB for further proceedings.

The Court explained that the decision to vacate depends on two factors: “the likelihood that ‘deficiencies’ in an order [like STB’s] can be redressed on remand, even if the agency reaches the same result, and the ‘disruptive consequences’” of vacating.

According to the Court, “[T]he deficiencies here are significant. We have found numerous NEPA [National Environmental Policy Act] violations arising from the EIS, including the failures to: 1) quantify reasonably foreseeable upstream and downstream impacts on vegetation and special-status species of increased drilling in the Uinta Basin and increased oil-train traffic along the Union Pacific Line, as well as the effects of oil refining on environmental justice [of] communities [in] the Gulf Coast; 2) take a hard look at wildfire risk as well as impacts on water resources downline; and 3) explain the lack of available information on local accident risk in accordance with 40 C.F.R. § 1502.22(b) (2020). The EIS is further called into question since the BiOp failed to assess impacts on the Colorado River fishes downline.”

The Court wrote that “[t]he poor environmental review alone renders arbitrary the Board’s consideration of the relevant Rail Policies and the final order’s exemption of the Railway.” STB “also failed to conduct a reasoned application of the appropriate Rail Policies as required under the ICCT Act

In an Aug. 18 Facebook post following the ruling, the Seven County Infrastructure Coalition said: “The #UintaBasinRailway team remains committed to the successful planning, construction, and operation of the railway. While we disagree with the D.C. Circuit Court’s recent decision, we respect the authority of the U.S. Court of Appeals. We firmly believe that the railway’s Environmental Impact Statement (EIS) contains appropriate and thorough analysis of the highlighted concerns, as it stands today. Nonetheless, we are ready, willing, and capable of working with the STB to ensure additional reviews and the project’s next steps proceed without further delay. We look forward to bringing this railway to the Basin in a safe and cost-effective way.”

On May 29, 2020, the Seven County Infrastructure Coalition sought STB authority to build and operate the Uinta Basin Railway, which it said would provide Basin shippers a viable alternative to trucking—currently the only available transportation option. The Uinta Basin is an approximately 12,000 square-mile area spanning northeastern Utah and northwestern Colorado that contains mineral deposits, including phosphate, crude oil, natural gas, oil shale, oil sands, gilsonite, natural asphalt, aggregate materials and low-sulfur coal. STB on Jan. 5, 2021, preliminarily approved the project on its transportation merits, subject to completion of environmental review. In August 2021, the STB Office of Environmental Analysis issued a Final EIS for the project, identifying the 88-mile Whitmore Park Alternative as the environmentally preferred route, one of three analyzed.

6 Railway Age // September 2023 railwayage.com Industry Outlook

WE’RE AHEAD OF THE CURVE.

The transportation sector is a pillar of the modern world. It moves people and goods, powers economic growth and a more equitable global society. Rail is a critical component of this global eco-system. From clean diesel to future fuels, we’re making great strides to help rail operators around the world improve efficiency and meet their sustainability goals.

Learn more by scanning the QR code below.

©2023 Cummins Inc.

©2023 Cummins Inc.

WORLDWIDE TRANSPORT FOR LONDON (TFL)

last month began tendering the next franchise agreement for the DOCKLANDS LIGHT RAILWAY (DLR), the 25-mile fully automated light metro network serving 45 stations in east and southeast London. The DLR is currently operated by a joint venture of KEOLIS and AMEY under a franchise agreement that began Dec. 7, 2014, for an initial term of seven years, and that is now due to end on April 1, 2025. The new contract will be for an approximate initial period of eight years, with an option to extend this by up to two years and a separate seven-month extension option. The estimated total value of the contract is £2.3 billion. The franchisee will be responsible for train and passenger service operations, ATC management and all maintenance.

CHSRA Issues Trainset RFQ

The California High-Speed Rail Authority (CHSRA) Board of Directors on Aug. 24, as part of a two-step procurement process, approved the release of a Request for Qualifications (RFQ) to industry for the nation’s first 220-mph electrified high-speed trainsets. CHSRA anticipates receiving Statements of Qualifications (SOQs) from prospective trainset manufacturers in November 2023. Once received, CHSRA will evaluate the SOQs and create a shortlist of qualified teams capable of delivering high-speed trainsets and release a Request for Proposal (RFP) in the first quarter of 2024. The procurement will allow CHSRA to receive six trainsets capable of operating at 220 mph and tested up to 242 mph; two prototypes in 2028 to support static/dynamic testing and trial running; and an additional four trainsets by the end of 2030 to support revenue operations on the 171-mile Merced to Bakersfield section. It also includes a 30-year maintenance contract, including spare parts supply, and Heavy and Light Maintenance Facilities.

NORTH AMERICA

AMTRAK last month executed a contract to order 10 additional Airo™ trainsets “as demand for passenger rail travel exceeds expectations,” bringing the total contract order to 83. The first Amtrak Airo™ trainset is scheduled to debut in 2026 on the railroad’s Casacdes service before eventually operating on routes throughout the country, including Northeast Regional, Empire Service, Virginia Services, Keystone Services, Downeaster, Maple Leaf, New Haven/ Springfield Service, Palmetto, Carolinian, Pennsylvanian, Vermonter, Ethan Allen Express and Adirondack

GULF & ATLANTIC RAILWAYS LLC (G&AR) on Aug. 29 entered into a definitive agreement to acquire PINSLY RAILROAD COMPANY’S Massachusetts short line and warehousing business. The transaction includes the 18-mile PIONEER VALLEY RAILROAD (PVRR) and Pinsly’s RAILROAD DISTRIBUTION SERVICES, INC. (RDS), a rail-served warehousing and distribution business. The purchase is subject to authorization by the Surface Transportation Board. PVRR, which Pinsly acquired in 1982, runs from Westfield to Holyoke, Mass., with interline access to CSX,

including Pan Am Southern. Together with RDS, which Pinsly established in 1985, the short line serves more than 30 diversified customers. RDS operates two rail-served warehouses with 140,000 square feet of indoor storage and 3.5 acres of outdoor storage. The addition of PVRR will expand Jacksonville, Fla.-based G&AR’s portfolio to six small roads. It already operates the 430mile FLORIDA, GULF & ATLANTIC RAILROAD and the 228-mile GRENADA RAILROAD, which received Honorable Mention in Railway Age’s 2021 Short Line and Regional Railroad Awards program. Additionally, earlier this year, G&AR acquired the 15-mile CAMP CHASE RAILROAD, 28-mile CHESAPEAKE & INDIANA RAILROAD, and 10-mile VERMILION VALLEY RAILROAD from MIDWESTERN & BLUEGRASS RAIL.

MARTINUS NORTH AMERICA, INC. on Aug. 28 entered into a purchase agreement to acquire Lee’s Summit, Mo.-based BOTTOM LINE COMPANY LLC. This is the first North American acquisition for Martinus, which operates in Australia, New Zealand and South America and employs more than 1,500 people worldwide.

8 Railway Age // September 2023 railwayage.com Industry Outlook California High-Speed Rail Authority

market

RailBlazer by Trilogical: Revolutionizing Rail Freight Management with Advanced Telematics

Distinguished by an unprecedented blend of proprietary technology, e ciency, and maintenance-free operation, RailBlazer emerges as Trilogical’s groundbreaking IoT solution, reshaping the landscape of intelligent rail freight operations and yielding substantial returns on investment for railroads, eet owners and shippers.

In the realm of rail freight, the escalating demand for dependable and competitively priced railway transportation underscores the need for heightened e ciency and optimized expenditures. E ciency and pro tability synergize by optimizing the utilization of existing assets prior to considering new investments.

The digital transformation of railroads represents a crucial stride toward unlocking untapped potential and capitalizing on opportunities for enhanced e ciency. The capability to analyze and decipher data for informative insights, coupled with the ability to provide asset management and cargo visibility, forms the foundation.

Trilogical’s RailBlazer stands as the vanguard of engineered telematic solutions, directly addressing pivotal concerns at the heart of railroads. Drawing from extensive experience in IoT and remote condition monitoring across diverse industries and based on the outcomes of the rst generation of Trilogical’s railcar telematics, this innovative solution delivers intelligent data without unnecessary complexities, o ering a notably straightforward implementation process.

High-level Bene ts of RailBlazer

Enhancing Railcar Utilization with RailBlazer: With meticulous attention to optimizing railcar utilization, RailBlazer leverages advanced planning and predictive railcar allocation. By seamlessly integrating hybrid communication technologies, RailBlazer empowers tracking of railcar location, including precise positioning in the trainset and on speci c tracks within bustling shunting yards. This realtime monitoring capability serves as the cornerstone of elevated e ciency and revenue generation. By extracting actionable insights from data-driven statistics, rail operators can adeptly synchronize railcar availability with demand, orchestrating smarter operations.

Achieving Advanced Maintenance E ciency with RailBlazer: A central aspiration for railway operators is harnessing advanced IoT devices to monitor, track, and assess railcar health, thereby augmenting maintenance e ciency. RailBlazer’s pioneering technology ingeniously transforms each railcar into an intelligent, digitally traceable entity. Within the domain of maintenance enhancement, RailBlazer streamlines maintenance through the

integration of mileage and smart sensors’ analysis. By astutely analyzing realtime data, railroads and eet owners acquire the ability to strategically plan maintenance activities, culminating in heightened e ciency. Proactive response to maintenance requirements, based on accurate insights, signi cantly enhances responsiveness to health indicators, resulting in extended service intervals. Furthermore, the issuing of immediate alerts pertaining to deviations or potential issues, facilitates swift and precise intervention, proactively preventing downtime and minimizing operational disruptions.

By embracing the RailBlazer solution and capitalizing on its advanced maintenance features, railway operators can signi cantly curtail maintenance expenses, maximize railcar availability, and elevate the overall reliability of their operations.

Safety: Safety constitutes a paramount priority for rail freight operations. RailBlazer operates in real time to detect and alert about railcar health anomalies, unsafe loading practices, and excessive impacts. Monitoring End-of-Train (EOT) events heightens safety standards, safeguarding both personnel and cargo.

Transparency and Enhanced Customer Satisfaction: RailBlazer leverages intelligent data analysis to enhance supply chain transparency. Providing customers with realtime loading status updates, estimated time of arrival (ETA) and cargo status data empowers shippers with the information they need. This fosters improved relationships with customers and opens new business opportunities.

Unmatched Technology and E ciency: RailBlazer transforms railcar telematics with its hybrid communication technology, ensuring seamless realtime data transmission and accurate tracking. Integrated with Trilogical’s cloud-based platform, RailBlazer o ers features like order management, railcar allocation, history, and mileage-based service alerts, boosting operational and maintenance e ciency.

With a focus on precision, e ciency, and reliability, RailBlazer sets a new industry standard. Installation is a breeze, and the device’s up to 6-year battery life ensures hassle-free performance.

Experience the future of rail freight with RailBlazer by Trilogical: https://www.trilogical.com/railblazer

Contact Tatiana Voloshin, our International Business Development Director, for more information or a product demonstration via email tatianav@trilogical.com or LinkedIn:

https://www.linkedin.com/in/tatiana-voloshin

If you are attending the upcoming Railway Interchange 2023 event, we invite you to attend our showcase at the Innovation Theatre within the RSSI Exhibit Hall D on Monday, October 2, at 3:30 pm. Visit our booth - RSSI Hall E, Booth 1308

Budget Hocus Pocus Targets Rail Workers

Deep within the enigma of the federal budget process is a paradoxical scheme to reduce—without actually reducing—red ink. While congressional scal hocus pocus is not new, this nancial absurdity is especially egregious as it adversely impacts rail workers.

Under a guise of reducing federal spending, congressional budget hawks are preventing the payment of a portion of sickness and unemployment bene ts owed rail workers. ey further seek to hobble a federal agency’s ability to process and pay rail worker bene ts claims by cutting its budget, even though the agency is funded entirely by rail employee and/or railroad payroll taxes.

Targeted is the Railroad Retirement Board (RRB), which administers and disburses railroad disability, retirement, sickness, survivor and unemployment bene ts. Under federal law, the RRB is a claims-agent and paymaster—an intermediary whose nancial transactions appear in the federal budget, although not a penny of federal spending can be saved by the scal legerdemain contrived by congressional budget hawks.

e rent on RRB’s Chicago headquarters and 53 eld o ces, as well as wages and fringe bene ts paid the RRB’s 728 employees, is funded entirely by payroll taxes assessed rail employees and railroads. Even the cost of RRB copy machines and their ingredients, computers, telephones and even paper clips, snack room microwaves and co ee makers is funded by these payroll taxes. As for the congressionally slashed sickness and unemployment benets, they are funded entirely by payroll taxes assessed railroads.

Rather than reducing federal spending, these cuts are in icting monetary pain and mental su ering on rail workers and their families. So wicked is this pickpocketing by Congress that it has uncharacteristically caused rail carriers and rail labor to link arms in solidarity to halt it.

Two cunning schemes are at issue—one festering since 2011 and a second a part of current federal budget negotiations.

e 2011 congressional sleight-ofhand expropriated railroad sickness and unemployment bene ts administered and disbursed by the RRB—bene ts funded exclusively by railroads and deposited in a dedicated trust fund separate from the Railroad Retirement Trust Fund. Congress slashed them by 5.7%, reducing the already meager biweekly bene t from $870 to $820.41.

Employees in no other industry endure such inhumane cuts, as non-railroad sickness and unemployment bene ts plans administered by states are exempt from such sequestration. Only because the railroad-funded plans are federally administered—owing to the complex interstate nature of rail operations—do they appear in the federal budget.

(Note that the 2011 bene ts cuts, suspended by Congress for two years during the COVID-19 pandemic, were restored in May 2023. Also, do not confuse RRB administered sickness bene ts with recent collectively bargained sick leave, as eligibility for RRB administered sickness bene ts—intended for longer term medical issues and injury—is delayed when sick leave is taken.)

e second congressional sleight-ofhand, if passed by the House and Senate, would slash 25% of the RRB’s budget, resulting in 168 furloughed RRB employees, cancellation of RRB’s information technology modernization and security upgrades, and delays in the processing and payment of rail employee disability, retirement, sickness, survivor and unemployment claims.

Again, there would be no federal spending reduction as all RRB funding is obtained from railroad and rail employee payroll taxes. Any reduction in the RRB budget or bene ts paid rail workers merely creates an illusion of reduced federal spending.

It is unlikely the 5.7% cuts in sickness and unemployment bene ts will be restored this session of Congress, even though the Railroad Employee Equity and Fairness Act (H.R. 2785 and S. 1274) seeks to do so. Congress repeatedly has rejected abandoning its scal dishonesty here and elsewhere.

Budget hawk Rep. Mike Braun (R-Ind.)

made that clear in dancing around facts and telling Bloomberg Law, “We’re now $32 trillion in debt and everyone’s going to have an issue that’s important.” Optimism remains that the provision slashing 25% of RRB’s scal year 2024 funding can be excised.

Ironically and farcically, railroads are continuing to pay a maximum 12.5% (on each $1,895 of monthly wages) to fund the RRB administered sickness and unemployment plan, plus a 1.5% surcharge to keep the fund’s minimum balance at $100 million, following a spike in furloughs.

(Frank N. Wilner’s new book, Railroads & Economic Regulation, is available from Simmons-Boardman Books at www.transalert.com, 800-228-9670.)

FRANK N. WILNER Contributing Editor

10 Railway Age // September 2023 railwayage.com Watching Washington

this wicked pickpocketing by Congress has uncharacteristically caused rail carriers and rail labor to link arms in solidarity to halt it.”

W OMEN IN RAIL

NOVEMBER 2, 2023

Chicago, IL

CONNECT. INSPIRE. INNOVATE.

Network and collaborate with a diverse group of women and allies who are making a difference in the rail industry. Learn how railroaders can maintain the momentum of inclusion, build strong support networks, and take advantage of ever-broadening career opportunities.

WHY ATTEND:

•Discover career advancement and development opportunities

• Learn about the career paths of women leaders and how today’s railways are supporting them

•Explore DEI (Diversity, Equity and Inclusion) initiatives

• Learn about mentorship best practices—from finding a mentor, to serving as one

•Discover how ERGs (Employee Resource Groups) are established for community building and support

•Connect with your peers—both upcoming talents and accomplished women in rail

SUPPORTING ORGANIZATIONS

AILWAY GE

SPEAKERS INCLUDE REGISTER: www.railwayage.com/womeninrail SPONSORSHIPS: Jonathan Chalon | jchalon@sbpub.com | 212.620.7224 Judy

SVP

Janet

Anacostia

Robert

EVP

Deb

Officer & AVP, Workforce Resources

Sebastian

& Inclusion NJ TRANSIT Marc

Siemens

Ed

R.

K. Carter

& Chief HR Officer BNSF

Drysdale SVP & Chief Stakeholder Relations CN Peter A. Gilbertson President & CEO

Rail Holdings Company

Grasty

& Chief HR Officer Amtrak

Schrampfer Chief Diversity

Union Pacific

Moreno Dir. Diversity

Buncher President & CEO

Mobility North America

Quinn President & CEO

J. Corman Railroad Group Kari Gonzales President & CEO MxV Rail CleLeatha

Shaw Mgr. - Crew Dispatching Metra

Laura Ramirez Head of DEI Trinity Industries

Tom Prendergast EVP AECOM

WHEN YOUR BUSINESS RELIES ON RAIL, RELY ON US.

TrinityRail ® is North America’s leading railcar equipment and services provider. With a comprehensive platform of leasing, manufacturing, maintenance and professional services, you can rely on TrinityRail to fully deliver trusted expertise, innovative solutions and supply chain optimization. Learn more at TrinityRail.com.

AILWAY G E

SERVING THE RAILWAY INDUSTRY SINCE 1856

PRODUCT & INNOVATIONS SHOWCASE 2023

As the industry’s partner for generations, Railway Age recognizes the importance of the supply community continuing to interface with customers. We’re pleased to present our 2023 Product Innovations Showcase, spotlighting dozens of the industry’s top suppliers—innovators all.

4AI SYSTEMS

HORUS A.I. ADVANCED DRIVER ADVISORY SYSTEM

4AI Systems creates arti cial intelligence and machine learning sensor systems for rail. Our mission is to build solutions that empower people and organizations to ultimately make better, data-driven decisions for their rail operations in real-time. Introducing HORUS, 4AI Systems’ all-seeing eye for rail, which is an arti cial intelligence (AI) machine learning system that processes real-time data from an onboard sensor array. e system can be used for: LOCATION ASSURANCE—Accurate location de nition to a speci c track and location in multiple-track territory by fusing imagery and navigational data. TRACK INTRUSION DETECTION—Detection of an unexpected object or hazard on or about the rail track. INFRASTRUCTURE MONITORING—Condition monitoring of selected rail infrastructure for maintenance assessment. SPEED MONITORING—Speed checking against network data and rules. AUTHORITY MONITORING—Static signage or signal lamp post recognition and reading of displayed information/aspect. SPAD emergency braking if required by network rules. To do this, we’ve combined smart sensor tech with machine and deep learning models to provide a comprehensive AI real-time advanced driver advisory system that can be integrated with an existing control system or as a standalone system. It can be applied to metro passenger rail, freight rail, and work trains and is compatible with CBTC, PTC, and other current control systems. To learn more about HORUS, our team will be attending AREMA/Railway Interchange or you can visit our website at www.4aisys.com.

ALSTOM ALSTOM EC6 TRACK CIRCUIT

Track circuits have been around since the late 1800s, helping railroads and transit operators detect the location of trains while providing broken rail protection. In the 1970s, Alstom introduced its Electro Code product line, adding signal aspect communications while extending track circuit length. Now, a er ve versions of Electro Code, Alstom is bringing the track circuit into the digital world, releasing what could be a game changer in track circuit technology with the rollout of Electro Code 6 (EC6). EC6 is the epitome of smart technology. It uses innovative signal processing techniques to provide two-way digital vital communication through the rails. Data is collected and sent in packets to the rail to specify signal aspects and indications (e.g., red to stop, green to proceed, and yellow for caution), allowing more data to be transmitted through the rails, such as exchange of analog data between both ends of the track circuit. e additional data allows EC6 to operate without requiring any adjustments over its life cycle, preventing costly train delays, and avoiding hours of unplanned maintenance. e sharing of information between each end of the track circuit allows EC6 to quantify track conditions (such as ballast and rail resistance) in real time, which are useful diagnostics for both signaling and track departments. EC6 provides bandwidth for the railroad to send its own customized information without installing radios or other cables or interfering with other track-connected devices such as highway grade crossings and cab signal systems, provide longer track circuits than previously possible, and can potentially locate broken rails, crucial information for restoring operations safely and quickly. With more than 40 million EC6 messages sent and decoded, and 10,000 trains detected already during the development, EC6 is on track to be the future of track circuits and train detection.

16 Railway Age // September 2023 railwayage.com 2023 Product

& Innovations showcase

AVANTE INTERNATIONAL TECHNOLOGY, INC. TRACK GEOMETRY MEASUREMENT, TRACK IMAGING, TRACK PROFILE AND RAIL SWITCH SENSOR SYSTEMS

At Avante, we stand as a pioneering U.S. company specializing in the provision of rail and train safety monitoring systems. We utilize the best technology in order to provide our clients with a solution that is safe, e cient and reliable. Real-Time Autonomous Track Geometry Measurement System: Provides real-time information, including buckling, vibration, and temperature, facilitating trend analysis and predictive maintenance for optimal track performance. e system incorporates advanced sensor technologies to o er measurements such as track gauge, cant/cross level, twist, alignment and unevenness. RAIL TRACK INTEGRITY IMAGING SYSTEM: Incorporates high speed imaging cameras that capture continuous images of the rail tracks and bed. It utilizes advanced image processing algorithms, and arti cial intelligence assisted pattern recognition-based image analysis techniques to detect potential defects and missing components, and evaluate the overall integrity and safety of the railway infrastructure. RAIL TRACK REAL-TIME PROFILE MEASUREMENT AND INTEGRITY MONITORING

SYSTEM: A specialized solution designed to accurately measure and analyze the pro le of rail tracks. It uses high speed high-precision laser pro le sensors to capture accurate measurements of the rail pro le to measure and record eld and gage rail pro le, head, web, and base for wear and comparison to standard pro le. It is ideal to detect small rail track defects/wears such as dents and cracks/gaps, as well as rail cant/inclination. RAIL SWITCH POINT POSITION SENSORS: Provides 24/7/365 real-time monitoring of the switch point and its closure integrity. is system operates autonomously and demands minimal installation e orts. It promptly generates real-time alerts, transmitting them to the monitoring center and onboard computer whenever the switch gap exceeds the safe threshold.

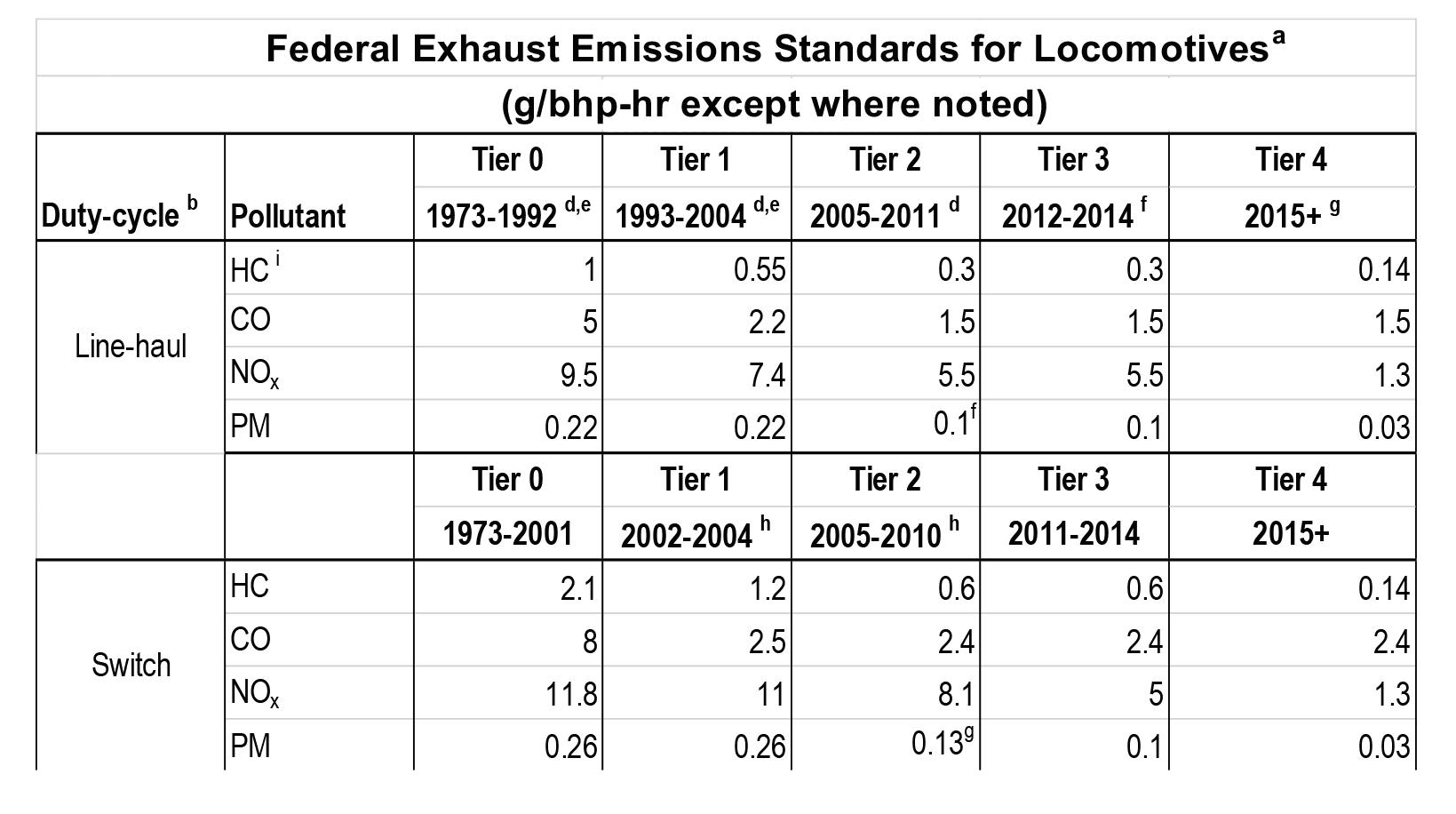

BROOKVILLE EQUIPMENT CORPORATION BROOKVILLE EQUIPMENT TO INSTALL CUMMINS POWER MODULES

With more than 100 years of experience, BROOKVILLE is a world-class American manufacturer of innovative powered transportation solutions including switcher, freight, and passenger locomotives, among other rail products. BROOKVILLE’s products are fully custom designed to the highest engineering standards for quality, safety and environmental responsibility. BROOKVILLE o ers a variety of services to the rail industry, including brand new locomotives, as well as overhauling, restoring, rebuilding, repowering and modernizing existing vehicles. With deep expertise in locomotive manufacturing and remanufacturing, BROOKVILLE can take your Tier 0 locomotive and modernize it with a Tier 3 or 4 certi ed turnkey solution. A recent partnership with Cummins, Inc. focuses on the ability to repower low Tier locomotives by signi cantly reducing exhaust emissions and improving the locomotive’s performance. With grant funding possibly available, BROOKVILLE and Cummins o er an EPA Tier 3 and Tier 4 Locomotive Switch Certi ed package, ranging from 1,000 hp and 2,130 hp. By utilizing Tier 3 and Tier 4 Power Modules, it will reduce emissions up to 80% to 93%, respectively. BROOKVILLE’s long history of high-quality locomotive work, coupled with Cummins Power Modules, will ensure your locomotive is back on the track with high-quality performance and cleaner emissions.

Remanufacture/Modernization FEATURES:

• Engine Replacement, Featuring EPA Certi ed, Fuel E cient, Low Emissions Engines

• Alternator Upgrades and Replacement

• Traction Motor Upgrades and Replacement

• Cab Upgrades, including Anti-Vibration and Climate Control

• Head End Power Replacement or Integration

• Advanced Locomotive Control Systems

18 Railway Age // September 2023 railwayage.com 2023 Product

showcase

& Innovations

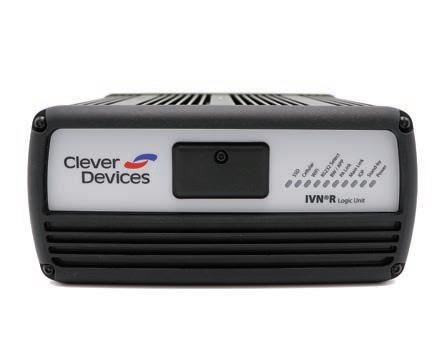

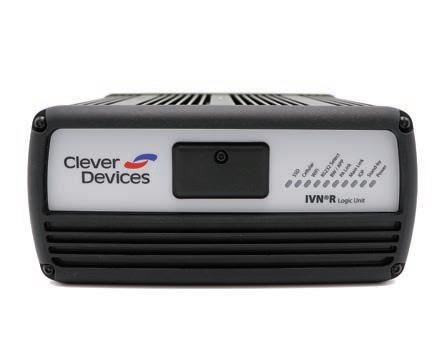

CLEVER DEVICES INTELLIGENT VEHICLE NETWORK FOR RAIL (IVN-R)

IVN-R is the foundation of the Clever Devices onboard rail solution. It is a fully contained, rail certi ed (EN50155, EN61373, EN50121 49 CFR 238), service proven, and reliable solution with enormous processing power.

e IVN-R operates the installed Clever Devices rail system applications as well as other onboard systems and various communications devices.

e IVN-R provides riders with automated audio and visual announcements as well as two-way text messaging between the vehicle operator and train controller and ad-hoc messaging to passengers from the train controller. e IVN-R interfaces with a cellular router or modem for real-time data communications between the IVN-R and the back-end systems. Examples of interfaces include onboard vehicle monitoring and diagnostic data is captured by the IVN-R for transmission to the back o ce for evaluation of vehicle status and overall performance; the ability to manage and control the information on your wayside and onboard communication, signage and infotainment systems; passenger emergency intercoms, crew intercoms, and onboard vehicle alarms supported by IVN-R, keeping you connected to riders and crew; integration with Automatic Passenger Counting (APC) systems to help monitor passenger loads and plan appropriate service levels; various analog or digital discrete inputs; on-board CCTV solutions; and communications through Land Mobile Radio (LMR). e Clever Devices onboard system interface is the Zero Client - Transit Control Head (ZC-TCH), a rail-certi ed interface contained in a rugged housing with a graphical 9-inch screen color backlit display with highly reliable touchscreen technology. e ZC-TCH communicates to the IVN-R using an Ethernet connection and serves as the interface where technical maintenance sta perform diagnostics and testing. Contact us: bit.ly/IVN-R

COMET REDESIGNED REMOTE SITE MONITOR MAKES PROACTIVE AEI MONITORING MORE USER FRIENDLY THAN EVER

Comet’s Remote Site Monitor (RSM) is a web-based monitoring and ticketing so ware that allows you to proactively track your AEI network and address minor issues before they become major.

• Map or list view of your entire AEI site network.

• Each AEI site’s health status is color-coded green (healthy), yellow (minor issue), or red (critical issue).

• When RSM picks up an error code from one of your sites, it sends you an SMS and/or email issue noti cation and auto-generates an issue ticket.

• Comprehensive issue history log for each site.

• Refreshed user interface design.

Track an issue’s status every step of the way, from assigning the ticket to a technician (automatically or manually), to troubleshooting and resolution. Modern railroaders know how important AEI is to their wayside infrastructure: not only for billing and logistics, but also for identifying the cars that HBDs and other critical detection systems ag as unsafe. RSM is the ideal companion so ware for monitoring and keeping your AEI network fully operational. Visit us at cometind.com/ electronics/remote-site-monitor to watch a demo and schedule a consultation.

20 Railway Age // September 2023 railwayage.com 2023 Product &

showcase

Innovations

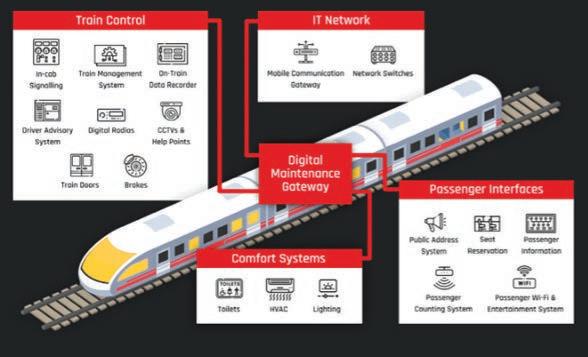

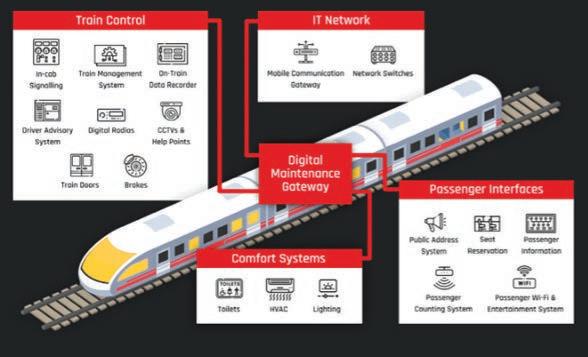

CYLUS RAIL TECH DSECURITY PLATFORM

e rail industry is undergoing a digital revolution, but this transformation presents challenges for cybersecurity and risk management. With increasing risks and attack surfaces, those responsible for securing rail tech environments face new obstacles. Cyber risk is now seen as business risk, and cybersecurity and safety are intertwined. However, rail operators are investing in digitalization faster than they are growing their security budgets, and generic security tools may not serve the strategic need. Companies are increasingly seeking tailored cybersecurity platforms for their speci c vertical market, and by 2026, 76% of operators will demand speci c vertical market knowledge and capabilities, according to Gartner. Cylus, the global leader in rail cybersecurity, is expanding to meet these evolving needs by creating the new expanded Rail Tech Security Platform category. eir platform provides real-time visibility for security and operations teams, deep rail context, and mitigation guidance for every identi ed security situation. With increasing rail tech complexity and widening attack surfaces, rail operators and global regulators are demanding more innovative rail tech security. Cylus is committed to leading the rail transport industry to a cyber-secure future by supporting customers with a holistic and integrated Rail Tech Security Platform to protect their strategic rail operations assets.

DAIRYLAND ELECTRICAL INDUSTRIES OVERWATCH™ HEFPD

Overwatch™ HEFPD is a new class of device, designed using Dairyland’s proven solid-state technology to protect sensitive trackconnected crossing and signaling equipment from high-energy AC faults and lightning. Railroad systems are increasingly required to operate in common corridors with power transmission and distribution lines, presenting new equipment protection challenges. Damaging AC faults caused by failure of power utility equipment on overhead power lines present high-energy, long-duration events that typical lightning surge protective devices are not capable of withstanding. ese events pose a risk to track-connected signaling and crossing warning systems as well as other protective equipment. To address these concerns, Dairyland Electrical Industries has introduced Overwatch HEFPD, a new class of product in the railroad industry. Designed using Dairyland’s decades of experience in high-energy applications, Overwatch HEFPD uses proven solid-state technology that can withstand the powerful, long-duration events caused by AC faults to keep your sensitive track-connected equipment protected.

Benefits of Overwatch HEFPD

• Provides protection from both high-energy AC faults and lightning surges

• Designed and tested to meet AREMA Manual Part 11.3.7, as well as the applicable requirements of primary surge protection as de ned in 11.3.1

• Built to withstand multiple AC fault or lightning surge events without failure

• Dairyland’s proven solid-state design prevents sparks and arcing

• Extensive third-party testing/veri cation

Learn more at Dairyland.com/Overwatch. Visit us in booth 2341

22 Railway Age // September 2023 railwayage.com 2023 Product & Innovations showcase

WHO SAYS LESS IS MORE? MORE IS MORE.

Marmon On-Site Services means one team, one point of contact, and a custom solution for gate-to-gate on-site and mobile rail services. No company o ers more to make your operations more e cient. Together, we keep our world moving forward.

Marmon On-Site Services Companies

Marmon On-Site Services Companies

DEUTA AMERICA

SAFETY-RELEVANT HMIS WITH DUETA TRUST TECHNOLOGIES

Requirements for safety-relevant Human Machine Interfaces (HMIs) for train operators are becoming more common around the world. With the increasing complexity of train control systems, additional functionality requires HMI devices to be safety critical. is includes requirements on information displayed (for example, current train speed), as well as input to the HMI from a human operator (a selection or acknowledgement). e solution: IconTrust® with SelectTrust® function. IconTrust detects display errors and di erentiates between the safety-related input areas on the HMI. e contained SelectTrust® function checks the activation or release of the touch area, or the single or continuous transmission of the activation.

Always safe: display and input.

• Assessment up to SIL 3.

• Safe input and output.

• So ware and hardware from a single source.

• Easy assessment of application changes.

• Cost-e cient.

Deuta’s Trust Technology is the solution for all HMI displays that need to meet safety requirements. is includes train control displays (aspect display units) and train operator displays. As Deuta has already deployed this technology since 2014, the risks of new technology introduction are largely mitigated. Deuta Trust Technologies have an installed base of approximately 12,000 units, deployed in 35 countries and have become a standard in many train control suppliers’ platforms. www.deuta-america.com/us/

DUOS TECHNOLOGIES, INC.

RAILCAR INSPECTION PORTAL (RIP®)

Duos Railcar Inspection Portal (rip®) is transforming the railcar inspection process for Class I and passenger railroads. The average railcar contains hundreds of mechanical parts and components that are critical to the proper functioning of the railcar and must be inspected frequently to ensure safe and reliable operation. The rip® employs advanced optics, purpose-built sensors, and specialized lighting. Combined with specialized image processing technologies, Artificial Intelligence (“AI”) algorithms and advanced presentation software, a Duos rip® enables acquisition and presentation of high-resolution images of passing railcars at operating speeds up to 125 mph. Offering a detailed 360-degree view of each railcar, the rip® enables mechanical inspectors to perform comprehensive inspections using state-of-the-art software. Duos combines Artificial Intelligence/Machine Learning (AI/ML) with the rip® to automatically detect anomalies and mechanical issues in real time with the capability to notify the operator of significant defects. Duos’ highly skilled development staff builds industry-specific machine learning algorithms, developed exclusively for the rip®. Each expertly designed algorithm targets and detects specific problem areas, including those required to maintain compliance with regulatory guidelines, providing a pathway to request inspection waivers if desired. We have scanned more than 2.1 million railcars in a 90-day period. More information on this system and others is available at https://www.duostechnologies.com/

Features & Benefits:

• Increase Safety—Employees, General Public & Customers

• Reduce Cost of Risk—Derailment Prevention & Service Interruption Reduction

• Decrease Dwell Times & Improve Equipment Turns

• Improve Overall Fleet Health by Proactively Managing Car Repair Process

• Accelerate Customer Communications and Regulatory Compliance

24 Railway Age // September 2023 railwayage.com 2023 Product &

showcase

Innovations

TRACK on for

HIGH CAPACITY | PRECISION | RELIABILITY

Some see steel tracks. We see safer connections — trusted pathways maintained by our high performance, American-engineered technology. Because wherever they lead, at the end of the line, everything is riding on quality. plasseramerican.com

tomorrow

ENSCO RAIL URFS: ADDRESSING TODAY’S RAIL INDUSTRY NEEDS AND PIONEERING TOMORROW’S INNOVATIONS

ENSCO Rail is a global leader that addresses rail aw testing needs with services and products. In the dynamic rail technology landscape, ENSCO Rail’s Ultrasonic Rail Flaw System (URFS) sets the standard for accurate, e cient and reliable rail inspection. is integrated URFS solution is a game-changing system that ensures precise aw detection and streamlined inspection processes, making it a standout in the rail aw products industry. In response to industry demands, ENSCO’s URFS seamlessly integrates with visual inspection and thermal imaging o ering a comprehensive track assessment. is empowers maintenance teams to make informed choices by combining technologies e ectively. ENSCO’s dedication to innovation shines through, with so ware engineers adeptly integrating rail surface imaging and rail pro le measurement into URFS, enhancing accuracy while remaining cost-e ective. By harnessing Machine Learning and Arti cial Intelligence (ML/AI), ENSCO Rail leads the charge in technology-driven rail solutions. ML/AI expertise enhances URFS, showcasing our commitment to top-quality products. ENSCO Rail’s passion for progress and leveraging cutting-edge advancements guarantees enduring precision, e ciency and safety in rail transportation. URFS is essential for hi-rails and rail-bound vehicles, detecting and preventing safety risks to avoid derailments. It integrates with technologies like machine vision and rail pro le measurement, o ering bene ts such as pinpoint defect detection and streamlined controls. When combined with ENSCO Rail’s machine vision solutions like Rail Surface Imaging and Joint Bar Imaging, URFS signi cantly enhances rail integrity assessment. Despite the shi to continuous testing, ultrasonic rail aw inspections remain crucial. URFS adds value by reducing false-stops, enhancing automation-driven productivity, improving true-positive detection, and predicting/preventing rail aws.

FRAUSCHER SENSOR TECHNOLOGY RELIABLE AND ROBUST AXLE COUNTING SYSTEMS

For over 35 years, Frauscher has been known globally as the gold standard producer of wheel sensors and axle counters. We are also known for a high level of investment annually in R&D, helping to improve existing products and develop new ones. Most importantly, we actively listen to our customers and encourage them to reach out with speci c pain points and to tell us what they need. Within the past year, this philosophy led to development of the Frauscher Track Vacancy System FTVS. Several of our Class I customers expressed interest in a track vacancy system based on our RSR110 Wheel Sensor. is non-vital solution is appropriate for use in applications where CENELEC SIL4 vitality is not required, such as for switch point protection in yards. Complex switch layouts and distributed control systems found in yards present special challenges for conventional signaling systems, due to space constraints, sub-optimal ballast conditions and high maintenance requirements. e FTVS is perfectly suited for these locations:

• Immune to e ects of snow, water, ice, dirt and changing ballast resistance

• No drilling, joints, or bonds to install and maintain.

• Easy installation—wheel sensors are clamped to the rail in under ve minutes.

• Small footprint required in the wayside signal equipment.

• e ability to determine exact fouling points.

• Minimal maintenance requirements.

• Easy integration with any existing control system.

• Minimal wiring requirements.

Several Class I railroads have implemented FTVS, and the results have been very favorable. We are con dent that additional railroads and transits will utilize this unique and e cient system in the near future. We look forward to the opportunity to demonstrate FTVS and discuss additional details at Railway Interchange and APTA Expo in October. www.frauscher.us

26 Railway Age // September 2023 railwayage.com 2023 Product & Innovations showcase

Harsco Mark IV Production Tamper

Harsco Mark IV Production Tamper

Hi-Rail

SAVE CAPITAL. MAXIMIZE PROFITS. INCLUDE RELAM IN YOUR PROJECT PLANNING CONTACT US TO START PLANNING TODAY. Renting lets you save your capital. Planning ahead ensures accurate operating budgets. Call us before contracts are signed to fill out your fleet with the profits you need. Get accurate rental rates right away. Plan longer rental terms at lower rates. Get the equipment you need when you need it. • • •

Nordco TRIPP Tie Exchanger

Grapple Truck

CONTACT US. LET’S TALK BUSINESS. 800.962.2902 quotes@RELAMinc.com RELAMinc.com RELAM, Inc. 7695 Bond Street Glenwillow, Ohio 44139

Nordco Shuttlewagon Railcar Mover

THE GREENBRIER COMPANIES

HIGH-STRENGTH STEEL GONDOLA

ree of America’s leading industrial and transportation companies—United States Steel Corporation, Norfolk Southern Railway and e Greenbrier Companies—have created a unique partnership to produce a new, more sustainable steel gondola railcar. Using an innovative formula for high-strength, lighter-weight steel developed by U. S. Steel, each gondola’s unloaded weight is reduced by up to 15,000 pounds. ese award-winning gondolas will provide an extended lifecycle, increased sustainability and greater freight capacity. See the railcar revolution at go.gbrx.com/gondola

GREENKOTE®

HIGH-PERFORMANCE ANTICORROSION COATINGS FOR RAIL HARDWARE

Greenkote® anticorrosion metal coatings (greenkote.com) can signi cantly extend the service life of rail fasteners and xtures that have long-term exposure to weather and harsh environments. ese coatings are especially useful in applications with high humidity or wetness, as well as where visual rusting is aesthetically undesirable. e newest, highest-performance Greenkote coating is G5k™ which extends anticorrosion protection to over 5,000 hours of ASTM B117 salt spray testing, to stand up to the most challenging conditions. Employing a patented zinc thermal di usion process, Greenkote coating is physically di used into the surface of metal parts, for an exceptionally strong, permanent metallurgical bond. Its corrosion resistance lasts longer, without chipping or peeling. And with an intrinsically high surface hardness, up to HRC 40-42, Greenkote survives bulk handling, contact with installation tooling and service conditions. Plus, Greenkote coverage is highly conformal and uniform, making it ideal for parts with complex geometries. e Greenkote name derives from its eco-friendliness. Unlike many coating processes, Greenkote uses no hazardous materials, generates no toxic wastes, and is benign to the environment. It passes even the strictest environmental regulations around the globe. Fast-turnaround coating of parts can be scheduled at the Greenkote headquarters facility in Ohio or at many other Greenkote locations internationally. Contact: 1 (440) 243-2865 or contactus@greenkote.com. Greenkote® and G5k™ are trademarks of Greenkote PLC. For additional information: Mark Gore, CEO; Greenkote PLC; 6435 Eastland Road; Brook Park, Ohio 44142; O ce: +1 440.243.2865; Cell: +1 925.719.3573 (preferred); mark.gore@greenkote.com; www.greenkote.com

28 Railway Age // September 2023 railwayage.com 2023 Product & Innovations showcase

Discover all that Stucki and Salco has to offer at the 2023 Railway Interchange Exhibition. October 1-4, 2023 in Indianapolis, IN. Stucki/Salco Booth Number: 3665

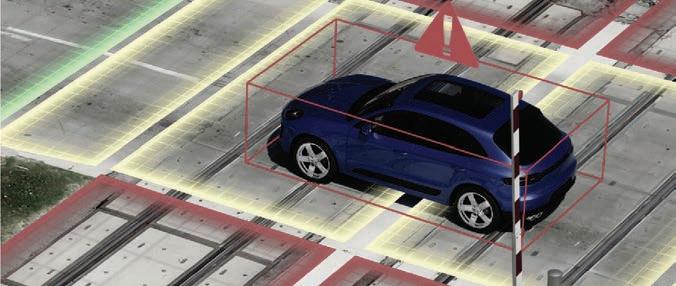

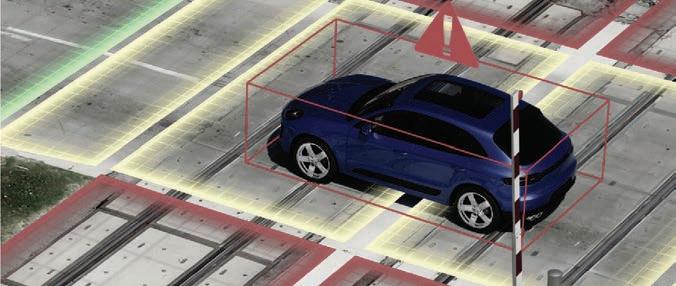

HERZOG RAILSENTRY™: CRITICAL ASSET MONITORING FOR RAILROADS

Experience the future of railroad safety with RailSentry™, Herzog’s cutting-edge object detection and alerting system. RailSentry is an advanced, intelligent solution that mitigates collisions between a train and vehicles, people or other objects. It is the only solution that integrates with Positive Train Control (PTC) and the locomotive onboard unit to notify locomotive engineers of a potential hazard ahead. Harnessing decades of Herzog’s expertise in railroading, RailSentry is poised to rede ne railroad safety. e system is meticulously programmed to emulate the mindset of a seasoned railroader, employing business logic developed and re ned through years of hands-on experience working in rail environments. From trespassers to stalled vehicles to obstructions on track, RailSentry’s advanced sensors detect these threats in real time. Whether positioned at crossings, stations, bridges or other areas of interest along the ROW, RailSentry provides comprehensive sensor and video coverage, ensuring that potential risks are identi ed across these critical locations. RailSentry excels in analyzing and modeling intricate situations, o ering a comprehensive approach to mitigating potential risks. e system’s ability to seamlessly integrate with existing railroad infrastructure enhances its adaptability, ensuring a smooth incorporation process without disrupting operations. With RailSentry, proactive safety takes center stage. e system’s object detection capabilities provide identi cation of potential hazards in real time. e moment an obstacle is detected, RailSentry’s alert system triggers, providing timely noti cations to locomotive engineers, train dispatchers, security personnel or emergency services, through messaging applications or integrated warning devices, such as electronic signage and audible alerts. Herzog’s visionary technology underscores the industry’s progression toward a safer, more secure, and technologically advanced future. Visit with Herzog at Railway Interchange to discover a smarter way to ensure your railroad’s safety with RailSentry.

HOLLAND SHORT PLUG FLASH-BUTT REPAIR WELDING

For over 50 years, Holland has been performing mobile ash-butt welding around the globe. e newest to Holland’s welding portfolio is Short Plug Flash-Butt Repair Welding. is ash-butt welding process provides higher quality and more cost-e ective defect remediation compared to traditional methods with less equipment and labor needed. Flash-butt welding o ers other bene ts as well including reduced maintenance costs, faster installation, no weld ller material, and a smaller heat-a ected zone. With Holland’s short plug repair welding gang, 5-foot plugs are used with two pieces of equipment and a total of four (railroad and Holland) employees. By using 5-foot plugs out of a 40- or 20-foot piece of rail, there is no scrap. Typical repairs take between 60-75 minutes and a single four-man crew can match the e ciency of three thermite crews. At the heart of our ash-butt welding services is our Intelliweld® Control System which provides superior control over the ashing process and rail consumption. is system provides real-time weld monitoring, control, and diagnostics along with automated data collection. Our customers can access a full production report within 60 minutes of the weld being completed. is weld data is compiled and can be delivered in customer-speci c formats.

30 Railway Age // September 2023 railwayage.com 2023 Product & Innovations showcase

HUMATICS HUMATICS FOCUS™

Enable predictive maintenance with Humatics. Humatics Focus™ is a track and train condition monitoring solution that leverages the onboard sensors of revenue service trains and provides maintenance insights. e sensor data is continuously collected as vehicles run in service without any need to interface with other onboard systems. Track conditions are assessed via proprietary machine-learning algorithms and displayed on userfriendly dashboards that show precise geotagging of track anomalies. e system uses inertial measurement sensors to measure vehicle dynamics fused with positional data to allow accurate geotagging of anomalies. e geotagging is achieved with a variety of sensors based on the environment such as GPS-RTK, traditional onboard odometry, radio-ranging, video, or LiDAR-based solutions for GPS-denied territories. When installed on multiple vehicles, the Humatics Focus™ system will perform cross- eet analytics to predict vehicle maintenance needs. Humatics Focus™ supplements mandatory track inspections performed by specialized track geometry vehicles. e continuous track condition monitoring covers any applications on rail—both transit and freight—transforming any suitable rolling stock unit into a data collection instrument. Earlier this summer, Humatics installed Focus™ systems on two light rail vehicles at New Jersey Transit. Installation was completed in three hours per train. As part of the trials, both onboard systems collected more than 5,000 miles of track data. e track section under monitoring was analyzed and no immediate track issues were identi ed as con rmed by NJT. To get insights from your track and rolling stock, contact us at transit@humatics.com

ICOMERA

VIDEO SURVEILLANCE & ANALYTICS

Icomera’s applied expertise in connected solutions for rail transport delivers a Video Surveillance, Analytics & Monitoring solution allowing operators to remotely view live onboard camera feeds and retrieve footage of any incidents while the vehicle is in service. Once connected, onboard surveillance cameras can live-stream HD video feeds, playback, and download footage regardless of the vehicle’s speed or location. e solution has been designed to integrate the latest advancements in video analytics as they become available, including:

• Monitoring track health, track obstruction, catenary and pantographs.

• Detecting vegetation, smoke, re, objects or aggressive behavior.

• Identifying distracted drivers and relaying that information back to an operations center, without the need to constantly stream video footage o the vehicle or manually monitor onboard.

On-demand access to data like this supports the resilient and reliable “predict and prevent” strategies that are key to creating smarter, safer rail networks.

September 2023 // Railway Age 31 railwayage.com 2023 Product & innovations showcase

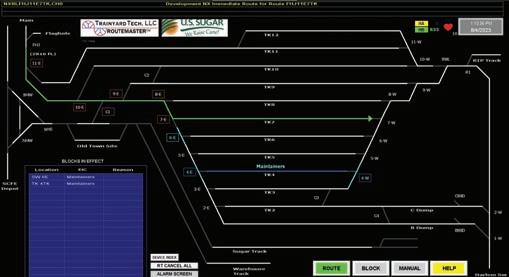

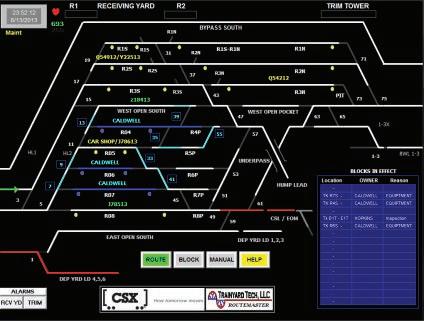

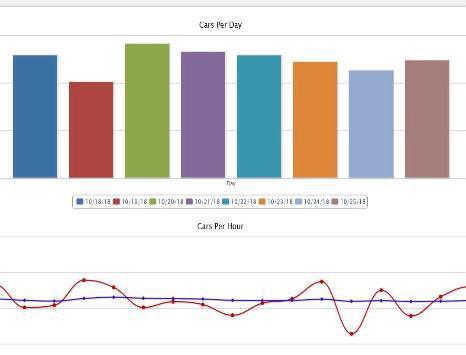

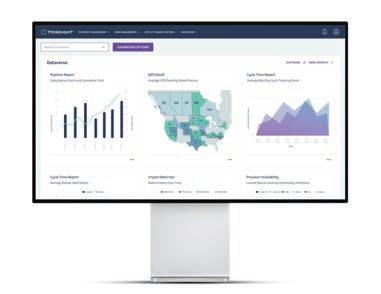

INTELLITRANS INTELLITRANS TMS

IntelliTrans is a leader in managing rail freight, managing 90% of rail freight in the U.S. for mining, coal, lumber/ forestry, food, oil/gas, and other industries. IntelliTrans TMS is the only SaaS-based TMS that provides holistic and seamless shipment visibility and execution across rail, truck, intermodal, barge, and ocean shipments. is comprehensive platform streamlines transportation and logistics management, lowering costs and increasing customers’ satisfaction with shipments. IntelliTrans provides supply chain transparency for bulk and break-bulk shippers, tracking your shipments in realtime across di erent modes of transportation and lowering shipment costs 5-10%. Accessible via an online dashboard, IntelliTrans integrates data from various sources to continuously optimize and improve your shipments. Our system helps automate processes across your operations by providing a holistic data integration platform—pinpointing the most a ordable, reliable carriers in any mode, lowering demurrage rates up to 77%, and alerting transportation delays in real-time for better communication. Multi-modal Transportation Management Solutions have also been proven to reduce total transportation costs 5-10% and deliver an ROI in less than 9 months. IntelliTrans’ Global Control Tower provides high levels of supply chain transparency; aggregates, completes, and enhances data from a variety of sources; o ers visibility into and execution of di erent aspects of the supply chain; and generates data-driven alerts and analytics that ask deeper questions and deliver meaningful insights. By leveraging tracking information, the Global Control Tower provides analytics that measures key performance indicators (KPIs) like eet cycle time, origin/destination dwell time, lane and hauler performance, back orders, freight spend, load optimization, and more. With their rate, equipment, lease, tracking, and invoice data in a central repository that’s accessible 24/7, companies can position themselves for success in any market conditions.

IRIDIUM THALES MISSIONLINK® 200

Iridium proudly keeps railways around the world on track, providing reliable connectivity in areas unreached by cellular, land-based, or even other satellite providers. Delivering mission-critical services through low-cost equipment, Iridium provides consistent performance on-the-move, ensuring valuable telematics, location, and safety information can be reliably sent and received from the train. e ales MissionLINK® 200 powered by Iridium Certus® extends your reach beyond terrestrial coverage with weather-resilient, reliable satellite connectivity. With upload and download speeds up to 176 Kbps, Iridium Certus 200 delivers reliable, truly global coverage through small, lightweight, low-power equipment. From highquality voice calling on-the-move to internet and messaging and critical remote applications, Iridium Certus 200 o ers an a ordable broadband connectivity solution, keeping you on track anywhere in the world. Key applications and features include real-time tracking and tra c management, asset visibility and monitoring, positive train control, engine information, locomotive diagnostics, onboard system condition reporting, unattended sensor reporting, and more. To learn more, visit www.iridium.com/rail.

32 Railway Age // September 2023 railwayage.com 2023 Product &

showcase

Innovations

KAWASAKI RAILCAR – TRACK TECHNOLOGIES

AUTONOMOUS TRACK INSPECTION SYSTEMS

Kawasaki’s latest developing product is an autonomous track component monitoring system. is technology, while installed on a locomotive, will capture high-resolution pictures and provide the necessary data for Kawasaki to utilize machine learning algorithms to identify track fasteners and other track components that need to be inspected and repaired. A er successful testing with railroads in Japan during 2022, testing began with freight railroads in North America earlier this year. Production systems will be available in early 2024. Along with the track component monitoring system and Kawasaki’s locomotive-mounted autonomous track geometry monitoring system in production since 2021, Kawasaki is also developing a so ware platform designed to make track inspection and repair safer and more e cient. Beta testing of the so ware platform will begin this fall. “We are excited to bring locomotive-mounted autonomous inspection technology to the North American marketplace,” said Ryoji Negi, Project Manager at Kawasaki. “With this innovative technology, any time the locomotive is moving and pulling passengers or freight, it is testing track and providing a frequent, valuable, cost-e cient service to our customers. is is another building block for Kawasaki’s vision of providing a complete suite of autonomous track inspection products along with predictive data modeling and platform to provide our customers the ability to be safer and more e cient with their track maintenance spend.” More information at https://www.kawasaki-track.com.

L.B. FOSTER L.B. FOSTER PLACES SAFETY FIRST

L.B. Foster adopts and deploys the latest technological advances to improve safety and reduce accidents by automating processes, reducing human error, reducing trackside maintenance, and providing realtime monitoring and alerts. Our Friction Management (FM) portfolio supports railroads as they continue to look to their FM programs to maximize value in terms of fuel savings, reducing GHG emissions, and extending rail life. In addition, a well-run FM program can reduce the state of stress acting on their track infrastructure which, from a safety perspective, can reduce track spreading and derailments. Our Total Track Monitoring portfolio was created to drive e ciencies, cost-e ectiveness, and, ultimately, enable rail safety for freight, transit, and industrial customers. e WILDIV system remotely monitors rail vehicle wheel health to ensure safe and productive train operations. It allows users to detect wheel defects, reduce the likelihood of wheel and load related derailments, avoid costly transfer penalties, extend wheelset lifespan, and enhance maintenance and operational e ciency. Rockfall Monitoring uses LiDAR technology to scan above the track for rocks and obstacles that pose a risk to trains. If a rock or obstacle of critical size is detected on track, a relay is dropped, and controllers are remotely alerted about the size and location of the obstruction. Our Flood Monitoring is a 24/7 wireless inspection system that detects high water levels in ood-prone areas, helping to detect ooding near rail in real time. We are universally committed to enabling safety and believe that by placing safety rst, we can build trust and con dence in our business and contribute to a safer world.

September 2023 // Railway Age 33 railwayage.com 2023 Product & innovations showcase

Product & Innovations showcase

LORAM RAIL PRO® INFINITY

Loram continues to prioritize the deployment of its advanced so ware technology, Rail Pro® In nity, for production rail grinding. is revolutionary so ware controls the position of grind stones used by Loram’s rail grinders, allowing for precise removal of damaged or fatigued metal and shaping of rails to desired pro les. e implementation of Rail Pro In nity has led to improved conformity to desired rail pro les with less grinding e ort, resulting in reduced energy and fuel consumption for Loram’s rail grinding customers. Loram was recently recognized for these achievements and honored as an Innovation winner at the inaugural Norfolk Southern oroughbred Sustainability Partner Awards. anks to Rail Pro In nity, Loram was able to grind more pass miles for NS than ever before, while helping NS achieve its ESG goals of reducing fuel consumption and reducing its carbon footprint. Additionally, since 2021, Loram customers utilizing Rail Pro In nity helped reduce thousands of gallons of fuel consumption and tons of CO2 emissions. Furthermore, Loram’s customers have bene ted from reduced rail head loss of up to 15%, slowing rail wear and avoiding future CO2 emissions. Rail Pro In nity helps railroads not only improve rail quality but also reduce their carbon footprint.

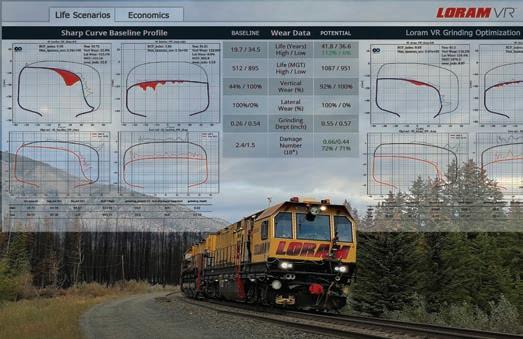

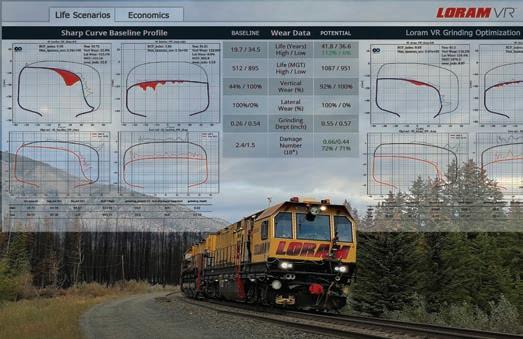

LORAM TECHNOLOGIES INC. LORAM VIRTUAL RAIL

Loram Technologies Inc.