4 minute read

Corporatisation of OFB: A Significant Step towards ‘Atmanirbharta

CORPORATISATION OF THE OFB: A SIGNIFICANT STEP TOWARDS ‘ATMANIRBHARTA’

With the government’s announcement that the OFB will be corporatised, there is a need to ensure that functional and oversight mechanisms are not so overbearing as to revert it to a department with a ‘corporate’ avatar

Advertisement

By R CHANDRASHEKHAR

I

n follow-up to the Prime Minister’s call for ‘Atmanirbharta’, the Finance Minister mentioned eight sectors for structural reforms which included defence production. In regard to defence sector, the Finance Minister mentioned some major areas of reform. These are:

(a) the notification of a list of weapons and platforms not to be imported after a specific date, (b) introduction of time-bound procurement processes, (c) raising of FDI limit for foreign firms to participate in manufacture of defence stores and importantly, (d) corporatisation of the

Ordnance Factory Board (OFB).

This article seeks to analyse the functioning of the OFB and the expectations from corporatisation of the OFB towards self-reliance in defence manufacturing.

INDIA’S ORDNANCE FACTORIES

The Indian Ordnance Factories (OFs) trace their origin back to 1787 when a gun powder factory was established at Ishapore. A Gun Carriage Agency established at Cossipore in 1801 exists today as the Gun & Shell Factory. The family of 16 OFs at the time of India’s Independence are now 41 in number and supported by nine Training Institutes, three Regional Marketing Centres and four Regional Controllers of Safety. The OFs take pride, and rightfully so, in their broad and versatile production base, multitechnology capabilities, and their large reservoir of skilled and professionally qualified work force.

EXISTING COMMAND STRUCTURE

The OFB, the apex command and control organisation for the OFs, was constituted in 1979. Based in Kolkata, it is headed by the Director General Ordnance Factories (DGOF) as Chairman with nine members in the rank of Additional DGOF. The OFs are grouped into five ‘Operating Divisions’ based on the type of products and technologies. These are the Ammunition and Explosives (A&E); Weapons, Vehicles & Equipment (WV&E); Materials and Components (M&C); Armoured Vehicle (AV) and the Ordnance Equipment Group of Factories (OEF) Divisions.

OFB PRODUCT RANGE

A list of OFB products for which OFB has indigenous industrial capability to produce are as tabulated below:

Weapons

Military vehicles Ammunition, explosives & propellants Armoured Fighting Vehicles (AFV) Equipment stores Artillery guns (105/155 mm, Tank guns 120/125 mm, Small Arms from 5.56 to 20 mm including Assault Rifles, Protective Carbine, Pistol, Revolver etc, Mortars 51/81/120 mm, Rocket launcher 84 mm, Under Barrel Grenade Launcher 40 mm and Multi Shell Launcher. Mine Protected Vehicles, Military Vehicles Around 150 types of ammunition including state of the art Pinaka Rockets, Bi-modular charge system for 155 mm ammunition, Artillery ammunition, cannon gun ammunition, Signalling and Related stores, Rockets, Bombs, Fuzes, Explosives and Propellants, Detonators and Igniters. Tank T-90, MBT Arjun, Variants of T-72, ICV BMP-II and its variants, AFV engines, NVDs, Sensors and Fire control system.

Brake parachutes, man dropping and supply dropping parachutes, combat uniform, ECC clothing.

The criticality of each of these products for execution of battle needs no emphasis.

OFB ORDER BOOK

The OFB receives orders through five-year roll-on indents from the Indian Army for ammunition items to meet WWR and annual training requirements. It also receives fixed quantity indents in respect of armoured vehicles and their spares. Roll-on indent/ indents are placed by the Defence Services for supply of items with indicated delivery schedules. However, the Services finalise year-wise targets based on budgetary allocations. The present capacity created at the OFB to supply equipment is around Rs 17,000 crores to all indents subject to availability of orders. While capacities are adequate to meet requirements as projected through indents, but indents placed are themselves limited by budgetary constraints and do not reflect operational requirements. Importantly, they do not cover ‘surge capacities’ that become imminent during operations requiring the Services to maintain large quantities of War Wastage Reserves (WWR) with consequent security and storage issues.

In fairness to OFB, it needs to emphasise that OFs have consistently sought to keep pace with contemporary technologies. It has drawn up a Modernisation Plan focussing on renewal and replacement of Plant and Machinery (P&M), augment capacities through acquisition of P&M and develop civil works infrastructure. The Technical and Administrative Cadres that provide managerial leadership to OFs have a spirit of ownership. There have been delays in executing the Modernisation Plan, which are attributed to delays in procurement as the machinery to be installed requires customised special purpose solutions and attract few offers. Also, these plans have not been supported by adequate fiscal allocations – circumstances beyond the scope of the OFB to resolve, leaving it a victim of systemic encumbrances.

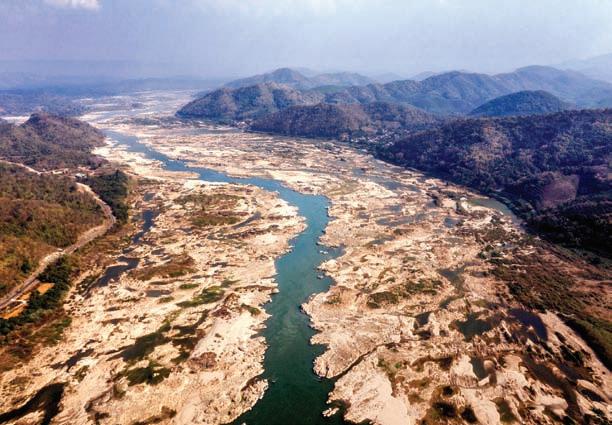

An Ordnance Factory assembly line

TENACIOUS RELATIONSHIP WITH THE DEFENCE SERVICES

In spite of the inevitable long and mutual dependence, there exist low trust and some oft-mentioned fault lines in OFB’s relations with the Defence Services. The major issues being: