39 minute read

ASHRAE CAPÍTULO MONTERREY LLEVO A CABO LA SESIÓN TÉCNICA DE FEBRERO 2020

Mejores Prácticas en

Sistemas Híbridos VRF

El pasado 13 de Febrero del 2020 en las instalaciones del Casino Monterrey se llevó a cabo la segunda sesión del año y la séptima sesión técnica del periodo 2019-2020 de ASHRAE Capítulo Monterrey patrocinada por la empresa Carrier; siendo presidente de ASHRAE Capítulo Monterrey el Ing. Ricardo A. Gómez, contando con una audiencia de 43 asistentes.

La sesión inicio con puntualidad a las 19:20 hrs. En ausencia del Ing. Pedro Garza Campa dio la cordial bienvenida a los asistentes el Ing Eleazar Rivera quien bendijo los alimentos para dar inicio a la cena.

En esta ocasión fue noche estudiantil y el Ing. Echeagaray líder de actividades estudiantiles nos compartió que en este mes se otorgarían becas a estudiantes.

También fue noche de elecciones de miembros para formar la mesa directiva de ASHRAE Capítulo Monterrey, siendo

elegidos de manera unánime los miembros propuestos por el comité de nominación, donde es importante mencionar que también fue posible emitir el voto por correo:

Enseguida el Ing. Eleazar Rivera Mata presentó al Ing. Franky Mancilla con el tema: Mejores Prácticas en Sistemas Híbridos VRF; su curriculum es el siguiente: Egresado del Tecnológico de Monterrey de la carrera de Mecatrónica y actualmente se desempeña en el área de ventas en Carrier. Al término de su presentación el Ing. Mancilla contestó las preguntas de los asistentes quienes se mostraron muy interesados en el tema.

En la parte final del evento El Ing. Eleazar Rivera Mata Hizo entrega de un reconocimiento al Ing. Franky Mancilla por su excelente exposición y se entregó otro reconocimiento al patrocinador del evento Carrier recibiéndolo el Ing. Jesús de la Cruz.

Presidente Electo: Francisco Gastelum Camacho. Secretario: Natalia Piñeiro Cárdena. Tesorero: Donald J. Hay Soule. Gobernadores: Ricardo Alberto Gómez Rodríguez Carlos Alberto Cavazos Tamez Eleazar Rivera Mata José Félix Rodríguez Laveaga Pedro Garza Campa.

MÁQUINA DEL TIEMPO Fuente: Archivo Histórico REFRINOTICIAS AL AIRE INAUGURACIÓN Nueva Sucursal De Climaproyectos En Mexicali, B.C. Mayo 2013

Transcurría el día 3 de Mayo del año 2013 y la empresa Climaproyectos llevaba a cabo la inauguración de sus nuevas instalaciones en la ciudad de Mexicali en el estado mexicano de Baja California. En punto de la 7 de la tarde comenzaron a llegar clientes, proveedores y amigos así como representantes de las distintas marcas que comercializa la empresa, entre ellos la Ing. Noelia Ayala, Representante de Ventas de Carrier Enterprise México y el Lic. Federico Fuentes, Gerente de Ventas para la zona norte de Midea México.

Mexicali es una ciudad de vital importancia en el mercado nacional, no solo por su alto volumen de consumo de productos de aire acondicionado y calefacción, sino también por ser un territorio de vanguardia para la industria de ahí la importancia para la empresa de instalarse en esta ciudad icono de innovación ubicada al norte de México.

En esa ocasión el público asistente en su gran mayoría técnicos contratistas y sub distribuidores de la zona, no solo se llevaron una grata impresión confirmando el profesionalismo y capacidad de los anfitriones al conocer el equipo local de operación de la empresa para esta nueva sucursal.

DE ÚLTIMA HORA...

TOYOTA MÉXICO: Nueva Planta de Manufactura En Guanajuato Con Alta Tecnología E Innovación

Durante el pasado mes de enero la empresa Toyota de México informó sobre el inicio de operaciones de su planta de manufactura en Apaseo el Grande, Guanajuato, Toyota Motor Manufacturing de Guanajuato (TMMGT por sus siglas en inglés), para la producción de su emblemática camioneta pick up, Tacoma.

En el comunicado Toyota reitera su compromiso con México para continuar con sus planes de inversión y producción en el país, a través de este proyecto en el cual contó con la colaboración de los gobiernos federal, estatal y municipal. Este plan que inició en 2016 con una inversión de aproximadamente $700 millones de dólares, al día de hoy dará empleo a cerca de mil personas.

Juan Francisco García López, presidente de Toyota Motor Manufacturing de Guanajuato señaló: “Estamos muy contentos por el inicio de operaciones de nuestra planta ya que con ella Toyota contribuye a la generación de empleo y desarrollo para el país. La planta cuenta con la más alta tecnología e innovación para la fabricación de Tacoma, un vehículo de alta calidad que estamos seguros podrá satisfacer la demanda del mercado de Norteamérica y el mercado local, con el orgullo de estar producido por manos mexicanas”.

El directivo señaló que la producción anual de la planta de TMMGT será de 100 mil unidades al año cuando opere a su máxima capacidad, lo que sucederá en el corto plazo.

“Los cerca de 1,000 colaboradores de esta planta estamos muy orgullosos de comenzar la producción y agregar un nuevo capítulo a los 17 años de historia de Toyota en México”, expresó García López. En línea con su filosofía de Pensar Global y Actuar Local, Toyota compromete sus operaciones en favor de las comunidades donde opera y en el caso de Apaseo el Grande, Guanajuato, trabaja de la mano de la comunidad para identificar proyectos y acciones que incidan positivamente en el desarrollo de sus habitantes y vecinos de la planta.

Toyota de México reitera su compromiso con el mercado mexicano y con el desarrollo del país por medio de la generación de empleo que, sin duda, impacta en beneficio de miles de familias.

CALENDARIO HVAC/R* Abril 2020

• HVAC+R SYMPOSIUM 2020 EL EVENTO DE LA INDUSTRIA HVACR MÁS IMPORTANTE EN TURQUIA 1 al 3 de Abril de 2020 Marriot Hotel Asia, Estambul. TURQUIA www.ttmd.org.tr • BUILDING INNOVATION 2020 EL EVENTO NORTEAMERICANO DE LA INDUSTRIA DE LA CONSTRUCCIÓN 6 al 9 de Abril de 2020 Renaissance Arlington Capital View Hotel. USA www.buildinginnovation.org • CHINA REFRIGERATION 2020 31 EXPOSICIÓN INTERNACIONAL DE LA INDUSTRIA DE LA REFRIGERACIÓN 8 al 10 de Abril de 2020 Wuhan International Expo Center. CHINA www.cr-expo.com • HVACR & REFRIGERATION LIVE LA CONFERENCIA Y EXPOSICION DE LA INDUSTRIA HVACR EN REINO UNIDO 20 al 22 de Abril de 2020 ExCel Londres. INGLATERRA www.hvacrlive.com • EXPO SEGURIDAD INDUSTRIAL EL EVENTO DE LA SEGURIDAD INDUSTRIAL EN MÉXICO 21 al 23 de Abril de 2020 Centro Citibanamex, Ciudad de México. MÉXICO www.exposeguridadindustrial.com • EE GLOBAL 2020 EL FORO GLOBAL DE LA EFICIENCIA ENERGETICA 28 y 29 de Abril de 2020 TBD Washington D.C. USA eeglobalforum.org *DERIVADO DE LA PANDEMIA GLOBAL CAUSADA POR EL CORONAVIRUS COVID-19 MUCHOS DE LOS EVENTOS Y EXPOS A NIVEL MUNDIAL SE HAN REPROGRAMADO O CANCELADO, POR ELLO DEBE VERIFICAR EL STATUS CON LOS ORGANIZADORES

Magazine

EDITION 110 / VOLUME 13 / MARCH 2020

REFRINOTICIAS Magazine

Staff

PUBLISHER ROBERTO ROJAS JUAREZ direccion@refrinoticias.com

EDITORIAL ROBERTO ROJAS DAMAS

ART & DESIGN JOSE JULIO GARCIA ROCIO ROJAS

ADVERTISING REFRINOTICIAS AL AIRE MEXICO: +52 (55) 5740 4476, 5740 4497, 4430 4447, 4430 4448 USA: +1 (646) 403 4710 cord.editorial@refrinoticias.com

ADMINISTRATION MARTHA D ARAUJO

PUBLISHING OFFICES BURO DE MERCADOTECNIA DEL CENTRO, S.A. Playa Revolcadero 222 Col. Reforma Iztaccihuatl Norte 08810, MEXICO, D.F. MEXICO: +52 (55) 5740 4476 USA: +1 (646) 403 4710 Web site: www.refrinoticias.com/magazine

Article Submissions email proposal to: cord.editorial@refrinoticias.com

REFRINOTICIAS Magazine Supplement is published monthly by BURO DE MERCADOTECNIA DEL CENTRO, S.A. Dedicated to the HVAC/R Global Markets.

Entire Contents © by BURO DE MERCADOTECNIA DEL CENTRO, S.A. Unless otherwise noted on specifc articles. Registration pending.

Table of Contents MARCH 2020

COVER STORY

FEATURE ARTICLE

NEW PRODUCTS

ASHRAE: Resources Available To Address COVID-19 Concerns S10 ARMSTRONG Announces New Booster Systems With Permanent Magnet Motors & Booster S14 DOW A Reimagined Legacy: The New Olympic Stadium For Olympic Games Tokyo 2020 S12

This magazine is printed on paper from sustainable sources. NEWS AND NEW PRODUCTS North America S 4 Asia and Oceania S 6 Europe and Africa S 7 Brazil and Latin America S 8 Middle East S 8 New Products S14 Associations News S14

Our Cover: ASHRAE: Resources Available To Address COVID-19 Concerns. Picture: Dreamstime Cover design: REFRINOTICIAS Magazine

DIGITAL EDITION

Get direct access to our electronic digital edition, access from the comfort of your computer, before anyone else receives the best overall information industry, plus you can download the digital edition, access hot links, keyword search, annotation, highlight and note making. For more details, please access:

http://www.issuu.com/refrinoticias

REFRINOTICIAS Magazine is published monthly by Buro de Mercadotecnia del Centro, S.A. As a supplement with REFRINOTICIAS AL AIRE a publication of Buro de Mercadotecnia del Centro, S.A. Playa Revolcadero 222 Col. Reforma Iztaccihuatl Norte 08810, Mexico, D.F. Roberto Rojas Juarez, Publisher; Roberto Rojas Damas, Editor. Postmaster: Send address changes to REFRINOTICIAS Magazine, Playa Revolcadero 222 Col. Reforma Izztacihuatl Norte 08810, Mexico, D.F. Email: info@refrinoticias.com Printed and edited in Mexico. REFRINOTICAS Magazine does not assume and hereby disclaims any liability to any person for any loss or damage caused by errors or omissions in the material contained here in, regardless of whether such errors result from negligence, accident or any other cause what so ever.

NEWS

North America

VERTIV Announces Addition Of Sheryl Haislet As CIO

Vertiv (NYSE: VRT), a global provider of critical digital infrastructure and continuity solutions, today announced that Sheryl Haislet, an experienced IT leader in the technology and manufacturing sectors, has joined the executive team as CIO.

Haislet will lead the global information technology (IT) organization and be responsible for advancing IT within the organization to support Vertiv initiatives focused on enhancing the customer experience, driving innovation and developing employees. She brings more than 25 years of experience in lean manufacturing environments, engineering and information technology to the Vertiv executive team.

“The CIO role is crucial to Vertiv’s success. Sheryl’s proven ability to inspire teams and manage organizational change will ensure we continue to use IT across our global organization to drive innovation and collaboration,” said Vertiv Chief Executive Officer Rob Johnson.

Prior to joining Vertiv, Haislet served as CIO and VP of Digital Office for Adient, a tier-one automotive supplier. She has also served as CIO for Johnson Controls Power Solutions division, where she helped drive commercial excellence programs and an SAP system implementation.

“I’m very excited about the direction of the company and the IT talent that exists within the Vertiv organization,” said Haislet. “Working together, we can help enable Vertiv’s customer-focused strategy through innovative and effective use of information technology.”

Haislet earned a bachelor’s degree from the University of Michigan and a master’s degree in information systems from Grand Valley State University. She also holds a graduate certificate in SAP Business Processes from Central Michigan University. She will complete her executive MBA from Quantic School of Business and Technology in April 2020.”

CARRIER TRANSICOLD Chiquita Completes Successful Trans-Atlantic Shipments Using Carrier Transicold’s New EverFRESH® Technology

Carrier Transicold, with Chiquita, successfully completed live cargo shipments for the new EverFRESH® active controlled atmosphere system, transporting fully loaded containers of bananas from Panama to the Netherlands. Carrier Transicold is a part of Carrier, a leading global provider of innovative heating, ventilating and air conditioning (HVAC), refrigeration, fire, security and building automation technologies.

Chiquita shipped bananas using 40-foot, high-cube containers equipped with Carrier Transicold PrimeLINE® refrigeration units. The EverFRESH systems were programmed to maintain oxygen levels at 5% and carbon dioxide at 4%. Temperature, gas and humidity concentrations were monitored continuously throughout the 17- day shipments.

Significantly, the containers used in the shipments were not new and had some degree of air leakage due to normal wear and tear, making them more representative of typical containers used throughout the global fleet. Positive-pressures generated by the installed EverFRESH system helped offset issues related to leakage from the existing containers.

“Through multiple trials, the EverFRESH system delivered on its promise to create a controlled atmosphere balance that could be sustained throughout the voyage,” said Stefano Di Paolo, president, Great White Fleet, Chiquita. “The speed at which the EverFRESH system reduced oxygen levels to slow ripening and its ability to maintain high humidity were impressive.”

Jim Taeckens, senior product manager, Global Container Refrigeration, Carrier Transicold, said, “In the shipments, container humidity levels were maintained as high as 90%, a feat other active atmosphere control systems can struggle with, which can potentially lead to a loss of fruit moisture content. We are pleased to have had the opportunity to work with Chiquita on this trial, successfully demonstrating the EverFRESH system’s ability to protect and preserve their valuable cargo en route to consumers in Europe.” Introduced in November 2019, Carrier Transicold’s new EverFRESH system builds on the first generation EverFRESH system introduced 25 years ago. Today’s EverFRESH system continues to help preserve the quality of perishables beyond what refrigeration alone can do by actively managing oxygen and carbon dioxide levels to slow respiration and the natural ripening of the commodity inside. Moreover, it does so more affordably than the previous EverFRESH system. As an active system, it generates nitrogen to more quickly and responsively displace oxygen, rather than relying on respiration alone to gradually reduce oxygen levels. The new EverFRESH system will be available in the first quarter for Carrier Transicold PrimeLINE refrigeration systems equipped with the Micro-Link® 5 controller option. www.carrier.com

PENTAIR Engineer Honored By 8th Annual STEP Ahead Awards

Pentair plc (NYSE: PNR), a global water treatment company, announced that the Manufacturing Institute will award Sonal Gola, Smart Products & IoT Delivery Manager at Pentair, with the Women in Manufacturing STEP Ahead Award. The STEP Ahead Awards honor women who have demonstrated excellence and leadership in their careers and represent all levels of the manufacturing industry, from the factory floor to the C-suite. On April 30, the Manufacturing Institute will recognize 130 recipients of the STEP Ahead Awards at a reception in Washington, D.C.

Launched in 2012, the STEP Women’s Initiative is the nation’s marquee program to close the gender gap in manufacturing. STEP works to foster a 21st-century manufacturing workforce by elevating and inspiring women in the manufacturing industry through recognition, research and leadership, as well as by motivating alumnae to pay it forward by mentoring the next generation. www.pentair.com

THYSSENKRUPP Sells Elevator Technology Business For $18.7 Billion

Thyssenkrupp sells its Elevator Technology business entirely to a consortium led by Advent, Cinven and RAG foundation. The respective Executive Board decision was approved on february by the Supervisory Board of thyssenkrupp AG. The purchase agreement has been signed. Closing of the transaction is expected by the end of the current fiscal year. The purchase price is €17.2 billion. thyssenkrupp will reinvest part of the purchase price (€1.25 billion) in a stake in the elevator business. The transaction is subject to merger control approvals, although thyssenkrupp does not expect the competent authorities to have any reservations. The proceeds from the transaction will remain within the company and are to be used to the extent necessary to strengthen the balance sheet. Alongside this, the proceeds shall be used to advance the development of the remaining businesses and the portfolio. As announced at the Annual General Meeting at the end of January, thyssenkrupp is proceeding the analysis phase so that a decision on the concrete use of funds can be taken in May.

The sale of Elevator is a favorable solution not only for the company, its shareholders, customers and employees, but also for the elevator business itself. In the consortium, thyssenkrupp has found new owners for the elevator business who have extensive industrial expertise and offer the workforce a high degree of security. The buyers have a strong track record in profitably growing and nurturing companies to become global champions. In negotiations with employee representatives and the IG Metall trade union, the buyers have committed to far-reaching site and employment guarantees. In addition, it was agreed that the buyers will continue to manage thyssenkrupp Elevator as a global group. The company will also remain based in Germany and employee co-determination will continue. That means the solution is in line with thyssenkrupp’s understanding of corporate and social responsibility. www.thyssenkruppelevator.com

United Technologies Corp., based in Farmington, Connecticut, provides high-technology systems to the building and aerospace industries. By combining a passion for science with precision engineering, the company is creating smart, sustainable solutions the world needs.

UNITED TECHNOLOGIES Unveils New $40 Million Air Compressor Facility For Pratt & Whitney Engines

United Technologies Corp. (NYSE: UTX) today unveiled a new $40 million 9,000 square-foot compressor facility at United Technologies Research Center (UTRC) in East Hartford, Connecticut. The closed-loop facility is the largest system of its kind known today, and will be used for research, testing and experimentation on engines made by Pratt & Whitney.

The close proximity of the new closed-loop compressor to Pratt & Whitney’s headquarters in East Hartford will allow for a more seamless transition from experimentation to product development, maximizing innovation and efficiency. The compressor facility will extensively benefit the next generations of jet engines being developed by Pratt & Whitney.

“This facility is a significant investment in technology as well as human capital right here in Connecticut, providing Pratt & Whitney engineers with access to full-scale compressor block testing that will fuel their research, innovation and expertise,” said Dr. Andreas Roelofs, Vice President of Research at UTC’s research center, which serves as the global innovation hub for UTC and its business units. “This new $40 million closed-loop compressor facility allows us to better serve our aerospace and defense operations by helping to ensure that our jet engines are cleaner, quieter and more efficient.”

During a ribbon cutting ceremony today which included Governor Ned Lamont, Senator Richard Blumenthal, Congressman John Larson, East Hartford Mayor Marcia Leclerc and members of the East Hartford legislative delegation and Town Council, Dr. Roelofs officially opened the UTRC engine compressor facility.

Air compression is critical to the performance of a jet engine. This facility provides the ability to test and experiment with compressor components. The unique closed-loop system improves test efficiency as it can operate without being impacted by fluctuations in climate or ambient conditions, providing the highest in data quality and test efficiency.

“For 95 years Pratt & Whitney has designed jet engines that have defined and redefined aviation,” said Geoff Hunt, Senior Vice President of Engineering for Pratt & Whitney. “Innovation in jet engines is accomplished by continually investing in cutting-edge technology for our next-generation products. This facility will allow our engineers to continue developing market-leading products, such as the Geared Turbofan engine which powers the Airbus A320neo family aircraft and Embraer’s E2 family of jets, and the F135 propulsion system, which powers the F-35 Joint Strike Fighter.”

This announcement is part of UTC’s efforts to develop new emerging aerospace technologies that will help drive more efficient and sustainable forms of aviation. The compressor facility is one in a series of investments by UTC including a $75 million Additive Manufacturing Center of Expertise (AMCOE) that opened in 2017 in East Hartford, to maximize innovation in the manufacturing and development of its products.

“Connecticut’s workforce is second-to-none, and businesses know that if they want to build the innovative products that are going to be on the cutting edge of their industries, this is where they need to be. This is exactly why UTC continues to expand and invest in Connecticut,” Governor Ned Lamont said. “This company has solidified East Hartford as a global innovation hub and we couldn’t be more proud of the amazing advancements they are doing here.”

“I’m excited to be here today for the ribbon cutting of UTRC’s closed-loop compressor facility. This research center is home to some of the most cutting-edge R&D in the world,” said Rep. John B. Larson (CT-01). “The innovation that happens here powers Connecticut’s unparalleled manufacturing ecosystem and will lead to job growth up and down the supply chain. I applaud United Technologies for their continued investment in East Hartford and look forward to the innovations that this facility will produce.”

www.utc.com

NEWS

Asia & Oceania

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the felds of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the fnished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a joint venture of Mitsubishi Heavy Industries and partners, with around 7,000 employees worldwide.

HITACHI And Chulalongkorn University Agree On A Cooperative Relationship For Social Innovation

Hitachi, Ltd. (TSE: 6501), Hitachi Asia Ltd., and Hitachi Asia (Thailand) Co., Ltd. (collectively “Hitachi”) announced the signing of a Memorandum of Understanding with Chulalongkorn University to cooperate on defining the societal challenges that may affect Thailand’s future society and to identify possible solutions to those challenges. This agreement lays the groundwork for Chulalongkorn University and Hitachi to work together to contribute to the development of human resources in digital and design field, and the advancement of societal infrastructure in Thailand.

With unpredictable and volatile changes occurring in today’s global market, there is increasing uncertainty into what the future may bring. In Thailand, new solutions tailored to the region’s needs are being sought as concerns rise towards risks such as financial decline resulting from an increasingly aging population or structural transformation of industry.

Hitachi and Chulalongkorn University will be using Hitachi’s “Kizashi” methodology to define future trends in Thailand, and how peoples’ values may change, and from there identify opportunities for new business growth that will bring new value to future Thai society.”

www.hitachi.com

JOHNSON CONTROLS Design Panel For 4-Way Cassette Indoor Unit Awarded

Design panel “Silent-Iconic” designed by Hitachi, Ltd. and manufactured by Hitachi-Johnson Controls Air Conditioning was awarded the iF DESIGN AWARD 2020 organized by iF International Forum Design GmbH.

The iF DESIGN AWARD is one of the world’s most prestigious design prizes over more than half a century since 1953, and is consisted of 7 disciplines: Product, Packaging, Communication, Interior Architecture, Service Design, Professional Concept and Architecture. In this year’s iF DESIGN AWARD, 7,298 entries were submitted from 56 nations. The evaluation was comprehensively conducted based on the design features of uniqueness, innovation, functionality such as usability, and environmental friendliness as well as quality. This time, Hitachi and Hitachi-Johnson Controls Air Conditioning’s Silent-Iconic was awarded in the discipline of Product. The awarded SilentIconic panel is an option panel designed

to be inconspicuous in architectural spaces. While architects prefers ducted indoor units which is invisible from architectural spaces, compromise tends to be made due to cost reasons, resulting in the often use of cassette-indoor units. Survey conducted to architects by Hitachi and Hitachi-Johnson Controls Air Conditioning revealed that there is a hidden needs for visually silent cassette-type air conditioner design that harmonize with interiors.

PRIMETALS TECH First Coil Processed At Rourkela Steel Plant Of Sail

At the production facility of India steel maker Rourkela Steel Plant of Steel Authority of India Limited (SAIL), a hot strip mill with an annual production capacity of three million metric tons, processed the first coil on January 31, 2020. The hot strip mill was supplied by Primetals Technologies and produces high quality steel for the automotive industry and API grades. It is equipped with pair cross technology to ensure optimum control of profile and flatness. The first coil was produced within two days of the start of hot trials.

SAIL, in which the Indian state is a majority stockholder, has been engaged in an ambitious expansion program that aims to boost production capacity from 14 to 24 million metric tons of steel a year. The Rourkela Steel Plant, established in 1955 as the first integrated steelworks in India, will increase its production capacity from the current level of 5.6 million tons to 10.8 million tons of steel.

The order was awarded to a consortium of Mitsubishi Corporation (MC) and Larsen & Toubro (L&T). MC was responsible for the project management as a consortium leader, and L&T undertook civil construction, erection and local supply. Primetals Technologies undertook designing and engineering of the hot strip line as well as supply of main mechanical equipment as a main technology supplier. This includes a reheating furnace, a single-stand roughing mill, a seven-stand finishing mill, two down coilers, auxiliary systems and equipment for the roll workshop. Hitachi Limited undertook to design, engineer, and supply electrical equipment/automation system. The hot strip mill, one of the largest of its kind in India, is able to produce coils in thicknesses between 1.2 mm and 25.4 mm and in widths between 725 mm and 2,150 mm. Maximum coil weight is 35 metric tons. The range of products includes carbon steels for the construction industry, low and medium-carbon steels, LPG cylinder steel and API grade steels, including X100, up to high-grade products that meet the requirements of the automotive industry. Four stands of the finishing mill are equipped with pair cross technology. This permits optimum adjustment of the roll gap contour and thus a fine control of the strip profile. Depending on the angle set, the crown of the strip can be varied in a wider range than can be achieved in a conventional 4Hi mill with work roll bending only.

www.primetals.com

Europe & Africa

The Wilo Group is a global leading premium provider of pumps and pump systems for Building Services, Water Management and Industry. Using smart solutions that bring together people, products and services, the Wilo Group is on the path to becoming the digital pioneer in the sector. Around 7,800 employees support the company worldwide.

The Bundesliga football team Borussia Dortmund and the technology specialist Wilo have extended their partnership, which has existed since 2011, by a further four years with effect from the upcoming season. “As partners who have been working together for a while now and have some joint plans for the future, we are united by our love for Dortmund. And as ambitious companies, we’re united by our passion and our resolve to always become a little bit better in every area.” Oliver Hermes, President and CEO of Wilo Group, and Hans-Joachim Watzke, CEO of Borussia Dortmund, are unanimous in providing the reasons for the partnership between the pump and pump system solutions manufacturer and the eight-time German football champions.

What’s more, the partnership is perfectly represented by the football pitch in Germany’s largest stadium: “Wilo supports Borussia Dortmund in the Signal Iduna Park. Amongst other things, our products and technical solutions ensure that the grass on the pitch is always lush and green”, explains Oliver Hermes. Borussia Dortmund’s Managing Director Carsten Cramer agrees. As he points out: “It’s really good news for us to know that we’ll have a great partner from our home town at our side for at least four more years – a partner we can trust and work well with, particularly in the increasingly important field of environmental protection.” It is important for both companies to use forward-looking technologies that help to reduce CO 2 emissions in the Signal Iduna Park as part of their partnership. In terms of sporting achievements during the thus-far successful partnership between Borussia Dortmund and Wilo, the “Schwarzgelben” (referring to the players’ black-andyellow kit) have twice been the champions of the German Bundesliga, won the DFB-Pokal knockout football cup twice and been in the finals of the UEFA Champions League. “Our partnership with Borussia Dortmund gives Wilo a tremendous driving force and a strong appeal amongst our customers and partners. It’s seen as a sign of warmth and authenticity, even internationally – for example, it goes down well in the Asian markets that are very important for us”, Oliver Hermes explains.

As a technology specialist with an international presence and production sites and branches in over 60 countries, Wilo is proud of its roots in Dortmund: “The whole city lives and breathes football, and a considerable number of our employees are also Borussia Dortmund fans. We’re united by the values that the Borussia Dortmund club traditionally represents – motivation, a down-to-earth attitude and a real sense of emotion”, says Oliver Hermes.” wilo.com

A-GAS Announced As Finalist For National Employer Of The Year

A-Gas has been nominated as a finalist at the upcoming Amazon Scale-Up Awards in the Employer of the Year category.

The Employer of the Year award recognises organisations that have created stimulating and supportive work environments and are committed to supporting its employees, resulting in a well-motivated and integrated workforce. Over 400 companies from across the UK entered the awards, which will be held in London on the 20th of March.

A-Gas was founded in the UK in 1993. Over the last 26 years, the company has evolved and grown worldwide with a dedication to maintaining the culture that has been at the core of the business from the beginning. Thanks to the dedication of its team and the commitment to its culture, the company has survived through challenges and thrived in opportunities.

www.agas.com

EBM PAPST The Energy Of The Future

As a clean energy supply, hydrogen could revolutionize the heating technology sector. The first experiments are already on the market and ebm-papst is also prepared for gas condensing boilers featuring climate-neutral fuel with its NRV 118 Hydrogen composite system.

TECHNICAL REQUIREMENTS

Many manufacturers are working on converting their condensing units to clean energy supply with as few technical changes as possible. Hydrogen is the chemical element with the lowest density, which is why components in condensing boilers have to be adapted. The combustion behavior requires special attention. As the flame speed is eight times higher than with methane, the ignition times in the combustion controller have to be checked and adjusted if necessary. Hydrogen has a lower heating value than methane but its Wobbe index, important for the interchangeability of fuel gas, is almost as high. For an optimal mixture in the venturi, the gas/air ratio controls have to be designed correctly. As a result, the interaction between the gas blowers, venturi and gas valve is of great importance.

NRV 118 READY FOR H2

The established NRV 118 composite system from ebm-papst is already designed for use with a hydrogen content of up to 10% without any changes. Thanks to a few changes, the composite system is even suitable for use with 100% hydrogen. This has now been proven in several investigations and initial field tests. The leak tightness of the gas valve and blower has been increased and the materials used checked for their suitability. Thanks to a special pre-mixing device, the NRV 118 hydrogen is ideally suited for hydrogen use. The “premix” gas blower compensates for the disadvantage of the lower Wobbe index and calorific value of hydrogen, while at the same time increasing burner pressure loss due to the gas/air mixture upstream of the fan. Complex control cables, as for operation in excess pressure, are not required. Furthermore, higher modulations can be run because the gas valve can be optimally controlled by negative pressure.

It will be some time before the clean fuel can be used extensively for heating, but if developments continue in science, politics and industry, this could become reality in the not-too-distant future. www.ebmpapst.com

NEWS

Brazil & Latin America

Founded in 1961, Weg is a global electric-electronic equipment company, operating mainly in the capital goods sector with solutions in electric machines, automation and paints for several sectors, including infrastructure, steel, pulp and paper, oil and gas, mining, among many others. WEG stands out in innovation by constantly developing solutions to meet the major trends in energy effciency, renewable energy and electric mobility.

WEG Takes Part Of Talara Refnery Modernization Project In Peru

WEG participated in the modernization project of a Peruvian oil refinery, supplying two x 62MVA ST41 generators that will be powered by steam turbines, in addition to 2 x 3.125MVA 4.16 / 0.48kV transformers to be used in the desalination process of the said refinery. These transformers were manufactured with a special painting system for this application, resistant to corrosion at the coastal environment.

The ST41 line is a suitable solution for 4-pole WEG turbogenerators, incorporating new technologies with the application of state-of-the-art CAD tools, which has resulted in an innovative concept of the cooling system, optimizing airflow and reducing losses, allowing better power by mass ratio. This generator was developed using virtual prototyping and validated through tests allowing a good balance between mass reduction and structural strength.

Additionally, WEG will also supply medium voltage induction motors from the W50 and W60 lines with powers ranging between 400kW and 3MW, driven by WEG MVW3000 frequency inverters. These machines will drive compressors, blowers and exhaust fans for the auxiliary units and support services in the refinery. The supply of the complete package and the possibility of carrying out integrated performance tests were key factors for the customer to select WEG. The MVW3000 incorporates multilevel technology of voltage source inverters with Cascaded H-bridge (CHB) topology, and has very low levels of harmonic content. Another differential is the use of plastic film capacitors, which guarantees a long lasting operation lifetime for the equipment. In addition, this frequency inverter has built-in automatic cell bypass, which allows continuous operation, even in the case of an unexpected failure event, possibility of input column with disconnect and multi-pulse phase shifting transformer incorporated, being a fully integrated solution, that is, all parts of the medium voltage system are on a single panel. MVW3000 also allows the use of the same solution, components and accessories, for different voltages.

With this modernization project, the refinery intends to increase its production capacity by 30%, in addition to reducing the sulfur content of diesel fuels, gasoline and LPG to a maximum of 50 ppm and increasing the profitability and competitiveness of the refinery by increasing the crude oil processing capacity from 65,000 to 95,000 barrels per day, processing heavy crude oil and converting waste products from processing units into marketable products.” www.weg.net

Middle East

Grundfos develop water solutions for the world. Set the standard in terms of innovation, effciency, reliability and sustainability. Is a pump company connecting with millions and millions of people every day. Grundfos solutions help its partners and customers move water to where it is supposed to go. Providing drinking water for the smallest villages and the highest skyscrapers, treating and removing wastewater and bringing heat and comfort to the world – or cool it down if needed.

GRUNDFOS Organises Cricket Tournament Plumbers In UAE

Grundfos, a global leader in innovative water solutions with sustainability at the core of its business, partnered with MAHY Khoory & Co to arrange a cricket tournament to support the plumbers and installers in the UAE market.

The inaugural Grundfos Cricket Tournament for Installers was open to all plumbers and installers from across the UAE and was held over two consecutive weekends. The tournament featured ten teams of eight players, with five teams registering from Dubai, three from Sharjah, one from Ajman and one from Abu Dhabi. Four teams, PM1, CR, CMBE and SEG, reached the semi-finals, with PM1 from Sharjah coming out on top in a thrilling final win over Dubai team SEG. The winning team shared a

prize of AED10,000, with the runners-up sharing AED8,000 and the beaten semi-finalists picking up AED3,000 each.

Sikander Ejaz, Marketing Lead at Grundfos, said: “At Grundfos and MAHY Khoory, we wanted to create a platform that resonates with the personal interests of plumbers and brings them together as a community. Over the past two weekends we have thoroughly enjoyed hosting the tournament while supporting good health and wellbeing.”

Aside from the on-field action, participants also enjoyed a range of activities including a fastest- bowler competition, an aiming challenge - where bowlers had to hit the middle stump – and a photobooth, while refreshments and food was provided for all.

ASHRAE

Resources Available To Address

COVID-19 Concerns

With information by: ASHRAE. Images: Dreamstime

ASHRAE, a global society advancing human well-being through sustainable technology for the built environment, has developed proactive guidance to help address coronavirus disease 2019 (COVID-19) concerns with respect to the operation and maintenance of heating, ventilating and air-conditioning systems.

The ASHRAE COVID-19 Preparedness Resources webpage, ashrae.org/COVID19, provides easily accessible resources from ASHRAE to building industry professionals.

“The recent escalation in the spread of coronavirus disease 2019 is alarming on a global scale,” said 2019-20 ASHRAE President Darryl K. Boyce, P.Eng. “While ASHRAE supports expanded research to fully understand how coronavirus is transmitted, we know that healthy buildings are a part of the solution. ASHRAE’s COVID-19 Preparedness Resources are available as guidance to building owners, operators and engineers on how to best protect occupants from exposure to the virus, in particular in relation to airborne particles that might be circulated by HVAC systems.”

Available on the webpage is ASHRAE’s recently approved position document on Airborne Infectious Diseases. The Society’s position is that facilities of all types should follow, as a minimum, the latest practical standards and guidelines.

The following publications are referenced in the position document and on the resources webpage:

• ANSI/ASHRAE Standard 62.1-2019, Ventilation for Acceptable Indoor Air Quality– Outlines minimum ventilation rates and other measures intended to provide IAQ that is acceptable to human occupants and that minimize adverse health effects. • ANSI/ASHRAE Standard 62.2-2019, Ventilation for Acceptable Indoor Air Quality in Residential Buildings– Defines the roles of and minimum requirements for mechanical and natural ventilation systems and the building envelope intended to provide acceptable indoor air quality in low-rise residential buildings.

• ANSI/ASHRAE/ASHE Standard 170-2017, Ventilation of Health Care Facilities – Ventilation guidance, regulation, and mandates to designers of health care facilities. It addresses hospital spaces, outpatient spaces, and nursing home spaces. • ANSI/ASHRAE Standard 52.2-2017, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size – Establishes a method of laboratory testing to measure the performance of general ventilation air-cleaning devices in removing particles of specific diameters. • ANSI/ASHRAE Standard 55-2017, Thermal Environmental Conditions for Human Occupancy – Specifiesconditions for acceptable thermal environments and is intended for use in design, operation, and commissioning of buildings and other occupied spaces. • ANSI/ASHRAE Standard 185.2-2014, Method of Testing Ultraviolet Lamps for Use in HVAC&R Units or Air Ducts to Inactivate Microorganisms on Irradiated Surfaces – Establishes a test method for measuring the intensity of ultraviolet lamps on irradiated surfaces under typical HVAC&R operating conditions. • ANSI/ASHRAE Standard 161-2018, Air Quality within Commercial Aircraft – Definesthe requirements for air quality in air-carrier aircraft and specifies methods for measurement and testing in order to establish compliance with the standard. • ASHRAE Guideline 28-2016, Air Quality within Commercial Aircraft – Serves as a companion to ANSI/ASHRAE Standard 161, Air Quality within Commercial Aircraft. Includes additional research and supporting information for guidance in assessing and assuring good air quality within the aircraft cabin.

The position document also advises that new and existing healthcare intake and waiting areas, crowded shelters, and similar facilities should go beyond the minimum requirements of these documents, using techniques covered in ASHRAE’s Indoor Air Quality Guide to be even better prepared to control airborne infectious disease (including a future pandemic caused by a new infectious agent).

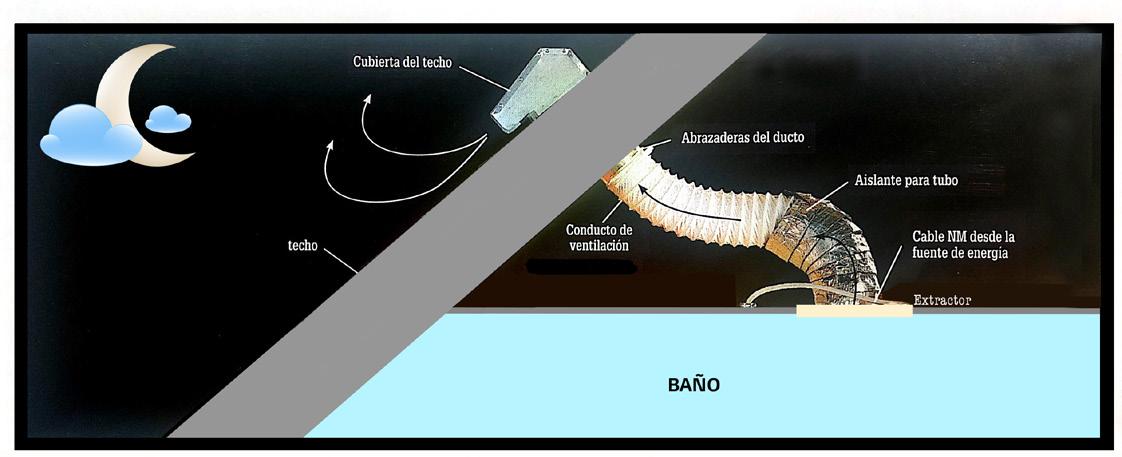

Because small particles remain airborne for some period of time, the design and operation of HVAC systems that move air can affect disease transmission in several ways, such as by the following:

• Supplying clean air to susceptible occupants; • Containing contaminated air and/or exhausting it to the outdoors; • Diluting the air in a space with cleaner air from outdoors and/or by filtering the air; • Cleaning the air within the room.

ASHRAE recommends the following strategies of interest to address disease transmission: dilution ventilation, laminar and other in-room flow regimes, differential room pressurization, personalized ventilation, source capture ventilation, filtration (central or unitary), and UVGI (upper room, in-room, and in the airstream).

Owners, operators, and engineers are encouraged to collaborate with infection prevention specialists knowledgeable about transmission of infection in the community and the workplace and about strategies for prevention and risk mitigation.

DOW

A Reimagined Legacy: The New Olympic Stadium

For Olympic Games Tokyo 2020 Infused With

History, Innovaton And Dow Solutons

With information and images by: Dow

Dow Corporate Headquarters in Midland, Michigan. S erving as the main venue for the Olympic Games Tokyo 1964, Tokyo’s newly-inaugurated Olympic Stadium has been reimagined for the Olympic Games Tokyo 2020 and constructed with multiple Dow (NYSE: DOW) technologies. While the eyes of the world are on the athletes and creative pageantry of the Opening and Closing Ceremonies, as well as other fan-favorite athletic events, Dow’s solutions will be working behind-the-scenes. These technologies will help enable, protect, enhance and maintain the integrity and performance of key infrastructure systems for the 72,400-square-meter Olympic Stadium.

“The Olympic Games symbolize many things—from the thrill of competition to the common threads that unite the world—but for Dow and our customers, the most poignant aspect of the Olympic Movement is the power and possibility of collaboration,” said Mike Reed, vice president of Dow Olympic and Sports Solutions. “In sharing our expertise in materials science and combining that with the know-how of architects, developers and customer partners in Tokyo, we are able to achieve new levels of innovation, sustainability and opportunity for the Olympic Games infrastructure and beyond.”

Designed by architect Kengo Kuma in partnership with Taisei Corporation, the re-envisioned Olympic Stadium serves as an artistic representation of both Japan’s rich history and its vibrant future. With an estimated 60,000 attendees 1 anticipated to descend upon the new Olympic Stadium during the peak of summer heat, VORANOL™ Polyether Polyols—used to produce low- to high-density foams as sealants—fill the gaps between the building materials and are designed to help keep the stadium safe and stable by decreasing the deformation risk caused by the expansion of concrete under high temperatures.

For those viewing the events from the comfort of their homes, AXELERON™ Compounds used in telecommunication wires support the seamless transmission of the thrill of the live atmosphere onto a global digital stage. This wire solution aids in ensuring the stadium’s transmission speeds and signals are as efficient and reliable as possible, reducing the risk of signal loss. AXELERON™ Compounds, and in some cases along with ENGAGE™ Polyolefin Elastomers, are also used as insulation layers for 70 kilometers of low- and medium-voltage cables to help provide reliable power throughout the venue.

Following the Olympic Games, the new Olympic Stadium will play host to countless national and international events. For Tokyo 2020 and beyond, PRIMAL™ Acrylic Emulsions, high-durability binders for interior wall coatings, offer excellent long-term durability and substrate adhesion, while ELASTENE™ Elastomeric Wall Coatings help provide a solution for the exterior with excellent dirt pick up resistance and mechanical property balance. DOWANOL™ Glycol Ethers are used in water-based coating systems to optimize stability and performance of the coatings while meeting low-volatile organic compound (VOC) requirements.

The Olympic Stadium also honors the history of Japan through its structural features, reminiscent of the 1,300-year-old Gojunoto pagoda at Horyuji Temple in Ikaruga. To achieve this, 70,000 cubic feet of larch and cedar wood were leveraged in the intricate steel-lumber roof and sourced from nearly all of Japan’s 47 prefectures 2 . From its nature-inspired architecture to the advanced technologies at play in its construction, the reimagined Olympic Stadium is designed to stand the test of time and leave a legacy of fortitude, environmentalism, heritage and innovation. Picture: Dow

Armstrong Fluid Technology has announced new versions of the Design Envelope 6800 Vertical Multistage Booster with Design Envelope Permanent Magnet motors for increased energy efficiency.

The new Design Envelope 6800 boosters also offer Booster Manager, an innovative cloud-based Performance Management service. Booster Manager delivers industry leading analytics and performance insights including profiles of energy and water consumption. Through continuous performance management, reports and alerts, Booster Manager increases reliability and sustains optimal performance in a booster system.

Working in combination, Booster Manager and the new Ultra-Premium Efficiency IE5 Design Envelope Permanent Magnet motors provide up to 40% additional savings compared to booster systems with Premium efficiency NEMA motors with integrated drives.

Brent Ross, Director, Configured and Standard Building Products with Armstrong comments, “With Design Envelope Permanent Magnet motors and Booster Manager, these new Design Envelope 6800 Booster Systems provide tremendous value for customers through a combination of energy savings and increased reliability.”

Company: Armstrong Fluid Technology More Information: armstrongfluidtechnology.com

ASSOCIATIONS NEWS

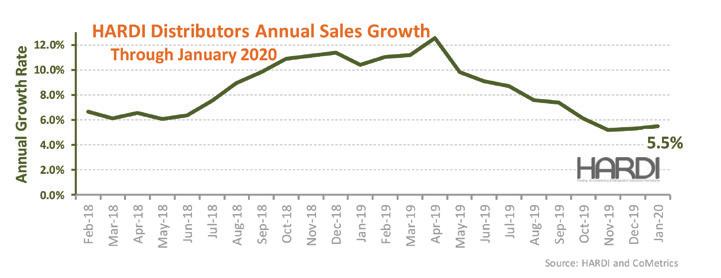

HARDI Distributors Report 0.7% Percent Revenue Growth In January

Heating, Air-conditioning & Refrigeration Distributors International (HARDI) released its monthly TRENDS report, showing the average sales performance by HARDI distributors was an increase of 0.7% percent during January 2020.

The average annual sales growth for the 12 months through January 2020 is 5.5 percent.

“Heating degree days were below normal in 47 of the 48 states,” said HARDI Market Research & Benchmarking Analyst Brian Loftus. “The average sales growth for the month was about flat to start the new year, while the dollar weighted growth was 2.5%. The average annual growth rate ticked up a bit to 5.5%.”

The Days Sales Outstanding (DSO), a measure of how quickly customers pay their bills, is near 51 days. “The DSO was a bit higher than the recent Decembers,” said Loftus. “This is the third consecutive month that the DSO has been about a day or more higher than the prior year.”

“The economy has been growing in the 2% area. The consensus expectation before the impact of COVID-19 was for that pace to ease in the new year,” said Loftus. “The financial markets seem to be indicating those expectations need to be trimmed further. The economic data will begin to reflect our interconnected world, like increasing delivery times and inventory shortages.”

HARDI members do not receive financial compensation in exchange for their monthly sales data and can discontinue their participation without prior notice or penalty. Participation is voluntary, and the depth of market coverage varies from region to region. An independent entity collects and compiles the data that can include products not directly associated with the HVACR industry.