THE BUSINESS SIDE OF WOODWORKING WINTER 2022 www.woodindustry.ca PM #40063056 BACK TO THE FUTURE DUE SOUTH WORKING WITH ROBOTS A FEAST FOR THE EYES

The CNC processing center with robot support forms one of the smallest possible cells of the furniture production. In this combination, the FEEDBOT D-300 increases your overall productivity. It does not have to take a break, can work around the clock on the shop floor and ensures consistently high quality. Small and medium-sized companies save a lot of time by using the robot integration FEEDBOT D-300 and reduce the workload for their staff. The resulting flexible manpower organization allows your workforce to be used more for value-added activities and production processes. The result is added value for your plant in terms of quality, availability and performance.

YOUR SOLUTION www.homag.com | info-canada@homag.com | 1-800-797-8231

Safe, Precise, Automatic Handling of Workpieces for More Efficient Production CNC DRILLTEQ V-500 Robot handling FEEDBOT at CNC DRILLTEQ V-500

WINTER 2022 CONTENTS 18 Back to the Future Design trends for 2023 that honour the past and look at emerging sustainability goals 28 Technology with a Human Touch Connected manufacturing—artisanal craftsmanship 38 Folding wood and Bending Minds A deeper dive into kerf cutting for the laser 4 From the Publisher A nod to the past, an eye to the future 40 Product Showcase 42 Stats & Facts COLUMNS DEPARTMENTS Vol. 18, No.4 www.woodindustry.ca THE BUSINESS SIDE OF WOODWORKING www.woodindustry.ca BACK TO THE FUTURE DUE SOUTH WORKING WITH ROBOTS A FEAST FOR THE EYES Photocredit: Peregrine Retail Design Manufacturing 10 He shoots, Brantford Scores A hockey stick institution continues in a new location 14 Due South LUXkbs cabinet door maker growing at home with an eye to the US 22 In the club PEREGRINE’s growing portfolio 22 Harbour City Kitchens Can robots and employees work hand-in-hand? FEATURES

A NOD TO THE PAST. AN EYE TO THE FUTURE

THE END OF ANY YEAR is not only a time to reflect back at accomplishments, successes and challenges, but also a time to look forward at new plans and paths yet untaken.

Despite COVID abating somewhat, and certain parts of life getting back to normal, world and economic events have still taken their toll (as has COVID still). For now, the early part of 2023 may also be difficult as inflation and interest rates remain high, and the labour market remains tight. The economy will definitely weather some kind of storm.

The good news is that many economists feel a recession in Canada could be “mild.” And in a year filled with uneven ups and downs, isn’t it nice to know some industries remain strong and continue to move forward?

Take for example our article on LUXkb. The cabinet door maker expanding its Moncton location. Sales projections are through the roof and the company is planning to triple its workforce.

Another cabinet maker, Cabio&co is also in growth mode. The labour shortage is making that a challenge as it recruits help from abroad. However, the company has invested in technology to help upgrade one of their manufacturing plants. Speaking of labour and technology, take a look at our article on Harbour City Kitchens. The Saanichton, BC-based company has invested in a massive robotic arm from Automatech Robotik to sort, pick up, and cut material. Robots are nice but what about people? This edition of Wood Industry’s article on commercial retail design firm PEREGRINE showcases its work at the Terminal City Club – a Vancouver hotspot. The company was called in to take the club’s restaurant – The Grill – and create a unique interior designs from millwork to custom liquor lockers. An already popular club got a makeover making it even more appealing to customers.

But this wouldn’t be a Canadian Wood Industry magazine without a little hockey. Of course our national past time remains strong through pandemics and other economic challenges, but what of the industries behind it? Heritage Hockey Sticks, formerly made in the southern Ontario town of Hespeler, is strong and continues to supply sticks for the better part of 133 years. The company, has moved locations and has set up shop in Wayne Gretzky’s home town of Brantford, Ontario. The company’s new location is three times the size of its previous one and is still making sticks for future “Great Ones.”

There’s much to be hopeful and thankful for in our industry. Craftsmanship and technology are working in tandem to propel growth and seed businesses for years to come. All of us at Wood Industry/Le monde du bois wish you great joy this holiday season, and continued happiness and prosperity in the New Year.

ART DIRECTOR

PUBLISHER

Mike Neeb miken@mediaedge.ca

EDITOR Joel Kranc joel@kranccomm.com

PRESIDENT Kevin Brown kevinb@mediaedge.ca

PRODUCTION MANAGER

Ines Louis Inesl@mediaedge.ca

Annette Carlucci annettec@mediaedge.ca

GRAPHIC DESIGNER

Thuy Huynh roxyh@mediaedge.ca

CIRCULATION circulation@mediaedge.ca

Wood Industry is published four times an nually, Spring, Summer, Fall, Winter, for the secondary wood products manufacturing and marketing industries in Canada. Subscriptions are free to qualified participants in Canada’s secondary wood processing industry. Subscribe at www. woodindustry.ca. Paid subscriptions rates: $40 to Cana dian addresses, $60 U.S. and foreign, $20 student rate. Please mail payment to Wood Industry, 2001 Sheppard Avenue East, Suite 500, Toronto, Ontario M2J 4Z8 For subscription inquiries, e-mail circulation@mediaedge.ca

© 2022 by MediaEdge Communications All rights reserved. MediaEdge Communications and Wood Industry disclaim any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect to the results of any action taken or not taken in reliance upon information in this publication. The opinions of the columnists and writers are their own and are in no way influenced by or representative of the opinions of Wood Industry or MediaEdge Communications

2001 Sheppard Avenue East, Suite 500 Toronto, Ontario M2J 4Z8

PUBLICATIONS MAIL SALES AGREEMENT #40063056

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: WOOD INDUSTRY 2001 Sheppard Avenue East Suite 500, Toronto, Ontario M2J 4Z8

THE EDITOR

Published by FROM

ISSN 1715-507X

2012

Mike Neeb

MERIVOBOX an innovation by Blum

Offering variety has never been so easy. Discover the many options you have to satisfy your customers’ wishes – with a single box platform. Get a head start and get ready for the exciting challenges that lie ahead.

www.blum.com/merivobox

Pillar Machine acquires Larick Machinery

In an effort to provide clients with more product offerings, Pillar Machine has acquired the Colorado-based Machine Manufacturer–Larick Machinery

“For more than three decades, Larick has manufactured high-quality machinery including profile sanding, shape and sand, wire brush sanders, and more. We couldn’t be more excited to incorporate this new lineup into our offerings,” the company said in a statement.

“A transition period is anticipated, moving the operations from Colorado to Utah over the next year, but in the interim we will be offering these high-quality machines to our current and future customers. We’ve also enlisted Larry Schwartz [previous owner of Larick] to help guide the transition and act as a resource for product knowledge and sales support.”

Pillar Machine’s acquisition of Larick Machinery will allow it to remain a lead innovator in the woodworking industry. The company’s focus remains building machinery that makes production lines more efficient.

America,” says Rob Brown, President and CEO of Hardwoods Distribution. “We have significantly transformed our business over the past several years as we organically expanded our product offering and added quality businesses through our acquisition strategy.”

“We believe the new name ADENTRA captures the overall value we have built – our extensive product portfolio, our critical role providing supply chain expertise, and the benefits of scale we deliver to our vast network of customers,” Brown adds. The customer relationships will continue to be managed directly through each brand and the corresponding regional customer service centres in their local markets.

New president at B.C.’s ILMA

The Interior Lumber Manufacturers’ Association (ILMA) has a new president. ILMA hired former Ministry of Forests executive Paul Rasmussen to lead the group, following the retirement of Dan Battistella. Rasmussen, who previously served as an assistant deputy minister for south area operations in the Ministry of Forests, has a long background in the forestry sector.

southern interior to do more of that work.”

Dan Battistella will remain involved in ILMA’s activities during the transition. He will later focus on yet-to-be named projects.

Sherman Williams Buys German Coatings Cos

Sherwin-Williams to Acquire German Wood Coatings Companies, Oskar Nolte GmbH and Klumpp Coatings GmbH

The Sherwin-Williams Company announced an agreement to acquire German-based Specialized Industrial Coatings Holding, a Peter Möhrle Holding and GP Capital UG venture comprised of Oskar Nolte GmbH and Klumpp Coatings GmbH. The business’ portfolio of solutions includes foil coatings as well as radiation-cured and waterbased coatings for the board, furniture and flooring industry. The business has approximately 220 employees and annual sales of more than € 91.5 million (approx. $126 million) and will become part of the Sherwin-Williams Performance Coatings Group reportable segment. The transaction is expected to close by early 2023, pending customary regulatory approvals.

Hardwoods Distribution Inc. to Rebrand as ADENTRA Inc.

Hardwoods Distribution Inc. will rebrand and be known as ADENTRA Inc. The name change will be formally submitted to shareholders for consideration at its special meeting of shareholders on December 2, 2022.

Deriving from the Spanish word ‘dentro’ meaning ‘within,’ ADENTRA represents the company’s modern identity as a diverse supplier of specialty architectural building products used to create spaces where we live, work and play.

“This is an exciting time for the company and our employees throughout North

“My whole career has been in the Kootenays and Southern Interior of B.C., so I’ve got a deep understanding of the issues and opportunities in the ILMA region,” he explains. “The ILMA members have a different relationship with their communities,” Rasmussen adds. “The business isn’t just a business to them; it’s a sustainable way of life that can’t be packed-up and moved to new locale when times are tough.”

According to Rasmussen, First Nations partnerships will be a big part of that future, following the example of ILMA member Vaagen Fibre Canada. “Reconciliation is about more than just recognition. It requires action, meaningful dialogue, and a true partnership, and I think there’s great opportunity across the

NKBA’S Canadian Thirty Under 30

This year, three Canadian women, Yana Rizhova, Mandy Wozniak and Danielle Heath joined the National Kitchen and Bath Association (NKBA’s) Thirty Under 30.

6 WOOD INDUSTRY WINTER 2022

FILINGS

AUTOMATECH Robotik

Every year the NKBA selects 30 young professionals from the industry to join the Thirty Under 30 program, to provide them with opportunities and to help them grow within the industry. Nominees are evaluated on their career or educational achievements, commitment to excellence in the kitchen and bath industry, and leadership within their organizations.

Danielle Heath graduated in 2017 from the Interior Decorating program at London, Ontario’s Fanshawe College, before working for a custom countertop company. In August 2020 she was hired by Casey’s Creative Kitchens as an assistant to two of the company’s top designers. She is now a designer herself.

Yana Rizhova first graduated from of George Brown College in Toronto 2018, where she studied for a paralegal degree. She now works for Ontariobased Canmade Hardware, where she is in charge of business development. As such, her specialty is to find solutions to problems and optimize new and efficient products.

As for Mandy Wozniak, with her Interior Design Technology diploma and her bachelor’s degree in Interior Design in hand, she founded her own interior design business, Salix Studio, based in Alberta. She takes a holistic approach to interior design, focusing on sustainability, physical and mental health.

Operating income prior to restructuring and other items was $4.7 million, compared to income of $53.4 million in the second quarter of 2022, and $53.5 million of income reported in the third quarter of 2021 WMS to return in 2023

The Woodworking Machinery & Supply Conference & Expo (WMS) will return to the Halls 1 and 2 of the International Centre on November 2–4, 2023 after a two-year COVID absence.

Tim Fixmer, president and CEO of CCI Canada who organizes the event, is grateful for the mobilized exhibitors. He is hopeful this year’s conference will be on par with the previous year’s events.

Scheduled exhibitors should receive updated information about the 2023 event shortly. CCI Canada also announced its official partnership with Corcoran Expositions, Inc. to manage WMS 2023.

Educational sessions and keynotes are planned, including two events sponsored by the Wood Manufacturing Cluster of Ontario, WMS exhibitors, and other associations.

will present inspirations in the context of central trends of the furniture and interior design industries. For example, the forum on Materials & Nature is dedicated to innovative and pioneering materials, and production technologies, while the forum on Textile & Machinery presents the most important trends and innovations in mattress production, and the related circular economy.

After Four Years of Absence, LIGNA 2023

LIGNA, the international trade fair for the woodworking and wood processing industry jointly organized by Deutsche Messe and VDMA Woodworking Machinery, will be back in 2023 from May 15 to 19, in Hanover, Germany.

The fair, which showcases the entire range of products and services for the primary and secondary industries, will showcase two-thirds of its longstanding exhibitors having confirmed their participation for 2023. Seventy-five per cent of the available exhibition space is already occupied.

Western Announces Third Quarter 2022 Results

Western Forest Products Inc. announced a net income of $6.6 million and adjusted EBITDA of $17.3 million in the third quarter of 2022 as compared to adjusted EBITDA of $66.2 million in the second quarter of 2022, and adjusted EBITDA of $66.3 million in the third quarter of 2021.

Net income in the second quarter of 2022 amounted to $38.6 million; and net income of the third quarter of 2021 represented $42.2 million.

Looking Forward to interzum 2023 interzum will return on May 9, 2023, in Cologne, Germany. The industry event provides the global furniture supplier industry with future-oriented fashion. It is also an opportunity for the global supplier industry to share its innovative capabilities.

More than 70,000 trade visitors and 1,800 exhibitors participated to interzum 2019. interzum considers the changing needs of living and work from a design perspective and incorporates them into an inspiring event program. In three theme-related trend forums, interzum

“This positive trend underscores the importance of LIGNA for the woodworking community as a key networking hub and platform for development and innovation,” comments Dr. Bernhard Dirr, Managing Director of the VDMA Woodworking Machinery Association.

In addition to the presentation of tool and machinery solutions, next year LIGNA visitors can also look forward to discussions of highly relevant industry challenges at the LIGNA.Stage. At the LIGNA.Campus, participants from research and education will present their educational offers and research projects, and at the LIGNA.Future Square powered by VDMA, start-ups from the industry will showcase their business ideas. At LIGNA.Recruiting, professionals and companies will have the opportunity to present themselves in a digital job forum and exchange ideas in person in a matchmaking area onsite.

8 WOOD INDUSTRY WINTER 2022

FILINGS

( R ) EVOLUTION

)

Silentia+

The new-generation of soft close hinges from Salice.

Besides showing no resistance while opening doors, the Silentia+ hinges guarantee an exceptional and consistent deceleration thanks to twin fluid dampers, delivering a perfect soft closing action in all applications and under any temperature condition.

Silentia+ incorporates an innovative switch to adjust the deceleration mechanism. This enables the closing speed of doors of any size or shape to be perfectly adjusted.

30° 10°

(

( )

salicecanada.com

+

HE SHOOTS, BRANTFORD SCORES

A hockey stick institution continues in a new location

By Ambre O. Khiari

The company’s original plant in the former southern Ontario town of Hespeler was one of Canada’s oldest continuous manufacturing operations manufactured this sports equipment from 1887 to 2021.

The company, which is still in business today, was formed when stick manufacturers from several southwestern Ontario communities pooled their knowledge and began to work together in the same building in Hespeler during the 1930s.

That group eventually became the Hespeler Wood Speciality Company.

Fast forward almost three-quarters of a century – and several changes of ownership under brands like Cooper and Nike Bauer – and the operation becomes an employee-owned business in 2004.

The now-independent Heritage Hockey Sticks comes under the leadership of W. Graeme Roustan 15 years later.

Graeme Roustan picked up Heritage Hockey Sticks three years ago

He picks up Heritage Wood Specialties from Mark Fackoury for an undisclosed amount in April, 2019.

A hockey business entrepreneur whose resume includes acquiring Bauer Hockey from Nike in 2008 and a close – but unsuccessful – attempt at buying the Montreal Canadiens in 2009, Roustan adds Heritage to his Christian and Torspo equipment brands.

He also owns The Hockey News, one of the sports’ most popular news outlets.

“I think I’ve touched more pieces of the hockey business than most people I’ve come across,” he has reportedly said.

10 WOOD INDUSTRY WINTER 2022 FEATURE

It’s been 133 years and Heritage Hockey Sticks, a company whose beginnings date back to 30 years before the National Hockey League (NHL), is still making its wooden hockey sticks in its bid to keep Canada’s national sport affordable.

A fan of the sport from an early age, Roustan tarted playing hockey when he was still only a three-year-old boy in the 1960s.

That passion for hockey transformed his life, leading to later acquire companies in the hockey space through his venture capital firm, Roustan Capital.

“(Heritage Hockey Sticks) is the only factory in Canada that makes hockey sticks,” Roustan reportedly told the Toronto Star.

“What’s really important from a Canadian heritage point of view is that our game is supported in Canada and that we can make these products in Canada,”

The businessman picked up Heritage Hockey Sticks after realizing in 2008 when he was sitting at the chairman of the board Bauer Hockey that most hockey equipment is now manufactured in Asia.

“I’ve seen firsthand the skill and tradesmanship of making hockey sticks and equipment,” Roustan told the Toronto Star earlier this year.

“And once you lose the trade you can’t get it back.”

The serial entrepreneur is adamant that the skill needed to make quality hockey sticks must be passed down from one generation to the next.

Goodbye, Cambridge. Hello, Brantford. Moving and expanding to Wayne Gretzky’s hometown

In 2021, the manufacturer of hockey sticks made a big move.

Heritage Hockey Sticks left Hespeler after more than 100 years and moved to an industrial site in Brantford, hockey superstar Wayne Gretzky’s hometown.

His dad, Walter Gretzky, has been a cornerstone of the Heritage Hockey Sticks plant for decades.

He often visited the factory in Cambridge and would always leave with hockey sticks in hand.

The decision to move the company to Brantford was heavily influenced Roustan’s wish to be close to Walter Gretzky’s home so that the sport’s most well-known dad could visit more often.

But that never happened.

Walter Gretzky unfortunately passed away last year at the age of 82 before the project could be completed.

Leaving Hespeler was a bittersweet moment for Heritage Hockey Sticks’ employees.

“We like the history of the building, we like how old the building is and the tradition of making wooden hockey sticks here,” Roustan Hockey’s general manager Bo Crawford reportedly told CTV News. “But, on the other hand, it is old. It’s a little inefficient.”

The 52-year-old woodworker was building kitchen cabinets for a company that went bankrupt and needed to find a new job when he started working at the Cambridge factory.

“It was going to be temporary because I wanted to get back into kitchens,” he said.

Thirty years later, he’s still making hockey sticks. During that time, he’s

made them for NHL greats like Eric Lindros and Wendel Clark.

Crawford calls that “the cool factor.”

Heritage Hockey Sticks’ new home on Spalding Drive in Brantford is three times the size of the Cambridge location, with 75,000 square feet of space.

Canadian-made, wooden sticks are more affordable than those made with space-age materials.

- W. GRAEME ROUSTAN

www.woodindustry.ca 11 FEATURE

Graeme Roustan, owner of Heritage Hockey Sticks

“OUR MISSION IS TO GROW THE GAME OF HOCKEY THROUGH OUR EFFORTS OF MAKING AND SUPPLYING STICKS AT PRICE POINTS THAT ARE MORE AFFORDABLE.”

- W. GRAEME ROUSTAN

The move comes on the heels of a deal with Canadian retailing juggernaut Canadian Tire that approached Roustan in 2019 about selling more Canadian made products and then inked a deal with Heritage Hockey Sticks in 2020.

The company’s wooden hockey sticks are made of multi-ply birch or incredibly strong aircraft veneer, often referred by the acronym ACV, rather than the more expensive materials used by most other manufacturers of these products.

Throughout the years, the cost of the game has soared.

Playing elite-level hockey in Toronto, even for children, can cost up to $10,000 per season, with sticks like the CCM Ribcor Trigger 6 Pro, made of nanolite carbon, retailing at about $370.

“If I were starting out to play hockey now, my parents wouldn’t have been able to afford to put me in the sport,” NHLer “Jumbo Joe Thornton reportedly told The New York Times. “That’s just the reality of it.”

Fighting that elitism and rising costs in the sport with affordable wooden sticks is all part of Roustan’s vision.

“Our mission is to grow the game of hockey through our efforts of making and supplying sticks at price points that are more affordable,” states the Heritage Hockey Sticks website.

With his storied stick brand, factory and hockey magazine Roustan is proud of his company’s made-in-Canada origins.

And it’s still growing.

This year, Roustan Hockey acquired Scarborough’s McKenney Custom Sports, a custom hockey and lacrosse equipment manufacturer for an undisclosed amount to grow Canada’s domestic supply of sports

12 WOOD INDUSTRY WINTER 2022 FEATURE

equipment. PANEL PROCESSING SOLUTIONS

Innovation. Safety. Productivity. HAND GUARD | PANEL SAW The world’s first panel saw with optical safety system developed to detect hazardous situations before they occur. The Hand Guard is not only safe but extremely versatile with a wide range of configurations to suit your needs. www.akhurst.com Delta, BC | Edmonton, AB | Mississauga, ON | Montreal, QC | Dieppe, NB ✔ Early detection of potential danger ✔ No damage to the saw blade when triggered ✔ Ready to run again in seconds ✔ Suitable for all materials and sawblades ✔ No work restrictions ✔ Works with gloves

Building Trust. Creating Together.

SEEN FIRSTHAND THE SKILL AND TRADESMANSHIP OF MAKING HOCKEY STICKS AND EQUIPMENT.”

“I’VE

Hespeler St. Marys’ Wood Specialties

Discover what’s new. biesse.com

is

We simplify your manufacturing process to empower your business.

Everything

evolving.

DUE SOUTH

LUXkbs cabinet door maker growing at home with an eye to the US

By James Risdon, Wood Industry Contributing Writer

By James Risdon, Wood Industry Contributing Writer

ment team. “I’ll hire 20 employees next year,” says Malenfant. “Atlantic Canada is in a growth stage.”

Certainly, Atlantic Canada’s biggest city, Halifax, is booming. It saw an unprecedented spike in new housing starts in 2021, with an annual growth rate of 16.8 per cent and 3,794 housing units built, most of them apartments, according to the Halifax Partnership’s Halifax Index 2022.

This year, housing construction in Halifax is still going strong. In only two days in June, Nova Scotia’s housing minister, John Lohr, approved two developments that alone will mean more than 1,000 new homes in the Halifax Regional Municipality. The old Penhorn Mall property in Dartmouth is being built out with 860 apartments and 45 townhouses, along with commercial space on the ground floor of several apartment buildings.

Fledgling laminate cabinet door maker LUXkbs is already in the black and looking to expand its Moncton operations after busting through its sales projections for the year in less than half that time, says the company’s top exec. “In the last five months, we’ve exceeded our annual projection for sales,” explains LUXkbs president and CEO Paris Malenfant.

The company, founded in 2021, only started selling its products in May this year, hoping to hit $360,000 in sales during its first year of operations, after getting its 7,840-square-foot shop on Halifax Street in New Brunswick’s hub city set up. But by the third week of October, LUXkbs already had roughly $380,000 in sales – and Malenfant is now eyeing

explosive growth in the coming year.

“For next year, we’re looking at $1.2 million in sales,” she says. The entrepreneur is in talks to buy the building in which the business is located.

And the company is in hiring mode, planning to roughly triple its workforce, which now consists of nine people including the owners and rest of the manage-

The other development is an affordable housing project, also in Dartmouth, that will see the construction of 373 apartments. “They are building,” adds Malenfant, “and they need our doors which are generally less expensive than wood doors.” LUXkbs is gaining access to that booming Halifax market through a distribution deal with the Halifax outlet of Würth McFadden’s.

That distributor of melamine, quality knobs, pulls, cabinets, kitchen and closet solutions also has five other outlets located in Ontario, Quebec, the Maritimes and Newfoundland and Labrador and could potentially open the door to other Canadian markets for LUXkbs. In New Brunswick, LUXkbs has been serving the regional market by building relationships directly with cabinet makers.

When Malenfant and her husband – and production and manufacturing

14 WOOD INDUSTRY WINTER 2022 FEATURE

Paris Malenfant President & CEO at LUXkbs & Wesllay Hache Production Manufacturing Manager at Luxkbs

manager – Wesllay Hache, founded LUXkbs – an acronym which stands for “Luxury kitchen bathroom and storage”– last year, they invested an undisclosed amount described only as being under $500,000. They secured a low-interest loan from the Business Development Bank of Canada for $120,000 to get started.

The seed of the idea that would become LUXkbs had taken root prior to the COVID-19 pandemic. The husbandand-wife team of 40-somethings were already entrepreneurs in a steel roofing company in Moncton when Malenfant decided to sell her shares and use that capital to start a new business. “We were going to start a small, home-based business in our garage… and then we were told this would be much bigger than something like that,” she explains.

Not everybody was on board. An advisory group went so far as to tell the serial entrepreneurs to not bother starting the business at all because the market was supposedly already facing a glut of cabinet makers. Unwilling to just throw in the towel, Malenfant did her own market research and discovered roughly half the cabinet makers in Atlantic Canada were buying laminate doors and were eager to be able to order them from a local producer. The couple took the plunge.

After checking to ensure they could get a steady supply of the materials they would need to make their doors from engineered wood products manufacturers Uniboard Canada and Arauco, they leased out a building in an industrial sector in Moncton. Renovating and upgrading the building’s electrical system took a big bite out of the start-up’s capital but the entrepreneurs saved by having their own LUXkbs-branded equipment made to their specifications by machine manufacturers. They also built some of the equipment themselves, including the spray booth.

“Wes made this with flat sheet metal,” explains Malenfant. “It cost us $500 to make and would have cost $15,000 or

more to buy.” Using Mozaik Software to cut the doors out of the sheets of material on the CNC machine, workers at

www.woodindustry.ca 15

FEATURE

TOP: Melissa Langille, Director of Operations

BOTTOM: Timothy Kearney

“THEY ARE BUILDING AND THEY NEED OUR DOORS WHICH ARE GENERALLY LESS EXPENSIVE THAN WOOD DOORS.”

LUXkbs then sand the surfaces and apply a water-based, non-toxic Kleiberit glue ahead of drying the core of the door, and then laminating it.

Malenfant wants to expand the physical space available to the company to include an additional storage area for raw materials and finished products. She sees the company’s competitive edge as being able to precisely match on LUXkbs doors the patterns and colours of customers’ cabinets and to then deliver those doors to cabinet makers more quickly than bigger players outside the region – within a couple of weeks instead of months.

Malenfant is already eyeing the American market. Using Moncton’s strategic location as a transportation hub for the Maritimes, she hopes to expand south of the border. “Moncton is very close to the United States, to Maine and Bangor, and that’s one of the reasons we’re here,” she says. “Our plan is to start expanding into the United States in less than two years.”

16 WOOD INDUSTRY WINTER 2022

FEATURE

LEFT: Lamination rolls

BOTTOM RIGHT: Wesllay Hache

“WE WERE GOING TO START A SMALL, HOME-BASED BUSINESS IN OUR GARAGE… AND THEN WE WERE TOLD THIS WOULD BE MUCH BIGGER THAN SOMETHING LIKE THAT.”

From kitchens and closets to home offices, mudrooms and more, KCD Software has woodworkers covered.

sales

Sell

precision cut-lists for efficient

manufacturing

Manufacture Find the solution just right for you at KCDSoftware.com | 508.760.1140 DESIGNER PROFESSIONAL WORKSHOP CNC COMMANDER

Enjoy unparalleled design flexibility with our comprehensive suite of intuitive and powerful design tools for virtually any cabinet or storage project. Design Get through the

process faster and eliminate re-works with photo-realistic 3-D Renderings, Real-Time Quotes and Built-In Contract generation.

Export

traditional

or send the whole job directly to state-of-the-art CNC Machinery.

BACK TO THE FUTURE

Design trends for 2023 that honour the past and look at emerging sustainability goals

By Clare Tattersall, Coverings Editor and Wood Industry Contributing Writer

Like fashion, interior design trends are vast and varied. But some stand out more than others, partly because they’ve been gaining traction over the past 12 months. As we close out 2022, now is the time to delve into what will be hot in homes for 2023, and how wood products manufacturers can prepare for the coming year.

18 WOOD INDUSTRY WINTER 2022 COLUMN

VINTAGE REVIVAL

Design styles from a bygone era are returning with a new contemporary spin, as people look to incorporate simple comforts from the past into their humble abode to evoke an uplifting and welcoming ambience.

Hard surfaces are taking a softer, curvier turn. Rounded cabinet ends and kitchens islands that were a mainstay in the 1950s are back, but this time with added sophistication, often featuring a textural front like ribbed or reeded wood that’s either painted or left in its natural state. A curved island allows for greater circulation around the space. And with no sharp edges or points, it’s a safer choice for parents with small children. Generally, an island with rounded corners is paired with flat-front 90-degree angled cabinetry (or vice versa) to create a focal point, provide contrast and not overdo the look. This also lends a midcentury flair to modern kitchens.

As seen in the kitchen, where counters and islands are forgoing their clas-

sic straight lines and sharp angles for softer shapes and edges, furniture and case goods with arcs and curves are also being embraced by consumers as they bring lightness into interiors and naturally draw the eye through a room. From rounded sofa backs and fluid style sectionals to curved sideboards, furniture with a circular silhouette will have a heyday.

ECO-FRIENDLY OPTIONS

Designs may be taking inspiration from the past but some trends, like materi-

al choices, are more future-oriented. People are shopping more sustainably, which means buying responsibly sourced and produced items, as well as those that bring as much of the outdoors inside as possible to emphasize the beauty of nature.

Materials like solid wood, rattan, wicker, jute and bamboo cane are increasingly preferred for furniture, as are less toxic glues and fibers used to manufacture these products. In terms of fabric colours, earth tones and soft blues

www.woodindustry.ca 19

COLUMN

“FROM ROUNDED SOFA BACKS AND FLUID STYLE SECTIONALS TO CURVED SIDEBOARDS, FURNITURE WITH A CIRCULAR SILHOUETTE WILL HAVE A HEYDAY.”

and greens are coveted since they add to the people-planet connection.

For cabinetry, the warm look of midtone and dark walnut, and oak sans as well as the 1980s and 1990s honey spice stain, are among customer favourites; however, alternatives like bamboo, lyptus and hemp wood are gaining ground. A grass, bamboo looks most like other woods on the market, making it highly desirable. Where it really stands out is that it grows incredibly rapidly, is generally stronger and harder than other hardwood options, and is touted for improving indoor air quality.

Newer to the cabinetry scene is lyptus, an engineered product from a hybrid of two species of eucalyptus tree that reaches maturity much faster than it takes most hardwood to grow. Its appearance and feel are similar to that of mahogany, red oak and cherry, and it

has a vast colour range from light pink to darker earth tones. Then there’s hemp wood, which is made from the stalks of the hemp plant. It grows in a 90-day cycle, is 20 per cent stronger than American white oak and is naturally non-toxic.

DUAL PURPOSE

As people are still working from home, either full-time or part of a hybrid solution, kitchens and living areas continue to play double-duty.

In the kitchen, an island with generous proportions that stretch more than seven feet provides ample room to accommodate a host of activities. Where space is no object, the most highly coveted kitchen feature can be split into two units. The double island allows for functions to be neatly divided – the first can serve as a food prep station, and the second for seating, whether eating, typing on the computer or tak-

ing part in a Zoom meeting. Either island option is an ideal addition to a home that doesn’t have dedicated office space since both offer a ton of extra counter surface and lots of hidden built-in storage, allowing one (or two) drawers to be turned into a filing cabinet.

Elsewhere in the home, dual-purpose furniture like storage benches, writing desks and lift-top coffee tables are necessary to save space and make the most of a remote or hybrid work model for homeowners. As designs change, consumers and manufacturers are changing with them to meet the growing demand in home renovations, efficient uses of space, and overall home makeovers.

Clare Tattersall is an interior designer and decorator in Toronto, and the editor of Canada’s floor covering magazine, Coverings.

20 WOOD INDUSTRY WINTER 2022

COLUMN

DESIGNS MAY BE TAKING INSPIRATION FROM THE PAST BUT SOME TRENDS, LIKE MATERIAL CHOICES, ARE MORE FUTURE-ORIENTED.

IN THE CLUB

PEREGRINE’s growing portfolio

By Matthew Bradford, Wood Industry Contributing Writer

By Matthew Bradford, Wood Industry Contributing Writer

22 WOOD INDUSTRY WINTER 2022

PEREGRINE Retail Design Manufacturing is enjoying front-of-the-line industry status following its renovation of a popular Vancouver hotspot. In 2021, the Burnaby, BC, firm put the final touches on a revitalization project at the Terminal City Club, capping a showpiece for Peregrine’s awardwinning architectural millwork.

“This was a special one, for sure,” reflects Brian French, president of PEREGRINE. “We were called in by this exclusive club to take its restaurant, The Grill, to the next level in terms of its interior design and food and beverage facilities, and we knew we had a reputation to uphold.”

PEREGRINE was recruited to the project by general contractor BLT Construction, for whom French, and the team had worked before. Alongside designer Kurt Design, PEREGRINE helped transform The Grill,

www.woodindustry.ca 23 PROFILE

The Grill at Terminal City Club - Ema Peter Photography

crafting and installing rift cut white oak features throughout. These included the restaurant’s front and back bars, host and service stations, booth and banquette seating, service columns, private dining credenza, kitchen passthrough, and liquor lockers.

“Everything was unique in its own way, but one of my favourite features was the custom liquor lockers,” says French. “They were made so members could rent them out, get a key, and store their drinks there between visits. What made the space even better, though, was that it contained a hidden door to the private dining area.”

Crafting the liquor lockers proved to be one of the more complex aspects of the job. The team was challenged to source the right materials during the pandemic or, in the event of material

delays and shortages, find alternative solutions that met the owner’s timelines and expectations. Moreover, adds French, installing a hidden door to the private dining area introduced its own unique considerations: “This door is about 10 inches thick and needed a metal frame, but it also had to be fairly lightweight. Between that and sourcing the hardware that would allow it to open and close as intended, it was a welcome engineering challenge.”

In the end, innovation and experience won out. And since re-opening its doors, staff and members of the Terminal City Club have embraced the upgrade. “We recently had lunch with the general manager of the club and he said the feedback has been very, very good,” French reports. “This was a popular venue that was coming due for a renovation, so we’re proud to

be part of making it into this great, revitalized space.”

EXPANDING THE PORTFOLIO

PEREGRINE has been in the business of transforming retail and commercial spaces for nearly a half-century. The company was founded in 1977 as PEREGRINE Plastics, a full-service custom plastic thermoforming and fabrication company. In 2012 it was purchased by French and his business partner Tim Bell, who saw the potential to expand its offerings.

“When we came in, the company was located down in East Vancouver and we had about four employees working out of a 5,000-square-foot plastic fabrication shop,” French recalls. “From there, we just kept building the team and looking for opportunities to expand.”

24 WOOD INDUSTRY WINTER 2022

PROFILE

The Grill at Terminal City Club - Ema Peter Photography

The first expansion came in 2015 when PEREGRINE purchased Stelmark Products after the company entered bankruptcy. The acquisition provided French and Bell with the people, assets, and Stelmar’s expanded facility to make its play in the millwork space. “We went from 14 people to about 40 people kind of overnight, and we also started working for three customers that remained our core business over the next few years,” French notes.

Further growth occurred in 2016 when French and Bell welcomed Ryan Wilcox as a third business partner. One year later, the trio led the purchase of Acorn Wood Design Ltd., a precision architectural millwork provider that had been in the business since 1983 and built four restaurants across North America.

Today, PEREGRINE/Acorn is home to over 75 employees who provide a broad range of engineering, project management, manufacturing, and installation services for retail, restaurants, commercial spaces, and cannabis stores. The company’s combined facilities and technologies provide it with a wealth of internal capabilities, including millwork, metal fabrication, plastics fabrication, paint, digital print, CNC cutting, lighting, glass fabrication, and solid surface fabrication.

“What differentiates us from a typical workshop is we have a lot of the trades in-house,” notes French. “We have our metal shop, we do Corian countertops, LED lighting, sign fabrication, plastic fabrication — all of that

PEREGRINE team

is done in our own workshop and to our high standards.”

BACK TO “NORMAL”

Business changed when the pandemic hit prompting many woodworking companies to change their strategies. And for PEREGRINE, it provided an opportunity for the company to return to its plexiglass roots. “We did a lot of those plexiglass shields for our restaurant and retail customers over the past couple of years, so it was good to draw on the skills we had when we began,” says French. “Now, though, we’re back to our pre-COVID business and focusing on restaurant and retail millwork, with the occasional office install when it comes along.”

ON TO THE NEXT ONE

The past 45 years have been marked by significant growth for

PEREGRINE and its team. Along the way, the company has learned the nuances of building a successful and sustainable woodworking business. “We’ve definitely learned to grow smarter and focus on what we’re good at,” French reflects. “For example, we learned early on that residential just wasn’t our thing, and that our best work was within the retail and restaurant segments.”

Up next, PEREGRINE is on track to add more showpieces to its portfolio with installs across North America. Today, the team is working on projects at Steak 48 in Beverly Hills, California; BC and several locations in the US (e.g. Florida), Bar Oso in Whistler, BC, a yet-to-be-named project in Victoria, BC, among other tasks. “We’re keeping busy these days, which is fine by us,” French adds.

www.woodindustry.ca 25

PROFILE

“WHAT DIFFERENTIATES US FROM A TYPICAL WORKSHOP IS WE HAVE A LOT OF THE TRADES IN-HOUSE.”

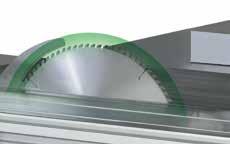

THE FASTEST NON-CONTACT TRIGGERING SAFETY

DEVICE IN THE WORLD!

Felderʼs Preventative Contact System (PCS) prevents accidents at the speed of light.

Every woodworker (and woodworking company) has ten good reasons not to compromise when it comes to working safety - PCS prevents accidents and assures dexterity and a quality handshake forever!

Today, all state-of-the-art saws and panel saws need to have standard safety equipment such as a splitter and an overhead saw guard in accordance with the applicable Ontario Health and Safety accident prevention regulations. For some years, there has also been a technical solution that largely prevents cuts due to instant blockage of the saw blade, but it destroys the saw and unit. The consequential costs for the repair are the price that you have to pay for saving one or more fingers. Until now, because there is a better way:

• If the system detects movement past a certain threshold - which surrounds the saw blade and protects against access from all directions - a safety lowering mechanism is triggered. The system lowers the saw blade below the circular saw bench a few milliseconds after a risk detection. Its extremely fast response time is possible thanks to the principle of electromagnetic repulsion, says Felder.

• The safety lowering mechanism does not cause any damage to the blade or incur extra costs. And the table saw will be ready for reuse at the push of a button.

• The PCS system doesn’t feature any wear partsavoiding the need to adjust or maintain anything beyond regular machine maintenance.

“ “ The system is amazing. No one else has anything comparable to the system. It acts without being touched, it drops down at light speed without causing any damage, and the customer can restart the machine right away.

Tratter, Head of R&D at the Felder Group

SPONSORED CONTENT

Robert

1-866-922-8879 www.felder-group.ca FELDER GROUP CANADA

Surveillance of danger zone with advance approach detection.

In the case of an unexpected fast approach in the saw blade area the PCS drop-down safety feature is triggered. The area of protection encloses the saw blxade and prevents access from any direction.

2Accident prevention in a matter of milliseconds.

After detecting the risk of an accident, PCS triggers the retraction of the saw blade under the table in few milliseconds. The method used on the electromagnet repulsion principle enables a never before achieved ultrafast action time.

FELDER GROUP MISSISSAUGA, ON 1-866-922-8879 info@felder-group.ca

3Immediately ready for use again. The Panel saw with the PCS retraction is ready for use again at the touch of a button and does not require additional attention or cleaning cycles.

Felderʼs Preventative Contact System is available on the Kappa 550 Emotion

FELDER GROUP CALGARY, AB 1-403-720-8330 info@felder-group.ca

BURNABY, BC Ultimate Tools 1-604-291-WOOD(9663) felder@ultimatetools.ca

FOR ADDITIONAL DEALER LOCATIONS CALL 1-866-922-8879

OAK BLUFF, MB

Wallace Machinery & Tool Co.Ltd. 1-204-788-1199 kevin@wallacemachinery.com

SPONSORED CONTENT

1

TECHNOLOGY WITH A HUMAN TOUCH

Connected

manufacturing—artisanal craftsmanship

By Sandra Wood, Executive Director, CKCA

Cabico&co is one of North America’s leading privately owned custom cabinetry manufacturers. Their team consists of more than 600 specialists and craftsmen with more than 370,000 sq. ft. of manufacturing facilities based in Coaticook, Quebec and St. Catharines, Ontario. Cabico&co has a network of more than 550 dealers across North America and is fuelled by over 35 years of solid growth.

Ouzilleau, President and CEO, CABICO&CO

Ouzilleau, President and CEO, CABICO&CO

There are 330 employees based in Coaticook, while the other 300 are located in St. Catharine’s with approximately two-thirds living locally or about 20 minutes away from the plant.

The company’s business approach is to harness the latest technology while still incorporating an essential human touch into every step of the design and manufacturing process, and every aspect of client and business relationships.

Alain Ouzilleau, President and CEO, CABICO&CO

• Custom cabinetry is no longer a question of choosing inside a catalogue; it’s now taking a dream and making it reality.

• The impact on our employees will be positive as well. Their work will be more rewarding, and they will be able to use their talent and skillsets for customization and craftsmanship, which is what matters most.

• We have been inspired by other great Canadian cabinet manufacturers, and we hope to do the same for others in the industry.

28 WOOD INDUSTRY WINTER 2022 PROFILE

Alain

VALUE PLACED ON THE HUMAN TOUCH

Alain Ouzilleau, President and CEO confirms that he faces the same challenges most in the industry are feeling—a labour shortage. “Some of the ways we have been able to mitigate this challenge is to recruit abroad and hire internationally,” he explains. “We have 36 new employees who will soon be welcomed to Coaticook (12 from Senegal and 24 from the Philippines). We are also hiring an additional 70 individuals from the Philippines, half will work in St. Catharines, and the other half will work in Coaticook. Hiring internationally requires a lot of work and expense with securing housing, immigration, etc. but right now, technology just isn’t enough, we still have a need for employees who can infuse the human touch into our products.”

INVESTING IN TECHNOLOGY

On September 22, Cabico&co unveiled new ultramodern facilities, new equipment, and upgrades to their Coaticook manufacturing plant. Alain told the Canadian Kitchen Cabinet Association (CKCA) that “With nearly $25 million in updates, including major digital and technological transformation, this upgrade now positions Cabico&co as a leading player to increase produc-

tion and growth in domestic and North American markets.”

Cabico&co’s plant optimization strategy meshes automation and robotization technology, connected manufacturing, and the know-how and artisanal approaches of specialists and craftsmen who bring personalized touches to the most complex projects. The design and manufacturing of custom cabinets require seamless communication between people, machines, and systems. Achieving this balance was a significant implementation challenge for the technology teams at Cabico&co and its Quebec partners Dunin Technologies, Nubik (Deloitte), Createch (Talan), PSTOX, and Automatech, which managed to converge, integrate, and synergize a range of software and technologies.

AUTOMATING “CUSTOM”

Cabico&co has a multi-year vision to ease

customer experiences in designing and manufacturing personalized projects. While some may think automation will limit customization, Alain doesn’t see things that way; “This massive transformation has only one purpose—to be at the service of our woodworkers, so they spend more time doing what they’re best at, infusing their craftsmanship into our products.”

He also notes that, “Technology is associated with standard production (i.e., no more custom). Robots and systems free up our talented craftsmen’s time. This helps to increase production capacity and to produce projects of unparalleled quality. The system transformation that is happening right now is influencing the designer’s design because we can take these designs and send them directly to our production system.”

A PLATFORM THAT COMMUNICATES He further states, “Each project contains

www.woodindustry.ca 29

“WHAT OUR TEAM HAS ACCOMPLISHED OVER THE LAST COUPLE OF YEARS IS JUST PARAMOUNT.”

- ALAIN OUZILLEAU, PRESIDENT AND CEO, CABICO&CO

PROFILE

Coaticook expanded and upgraded manufacturing plant in Coaticook

more than 600 parts. All these parts have unique routes inside our systems. These parts converge towards the assembly line, where they are assembled

and shipped to our customers.”

Alain and his team recognized that custom cabinetry brings a significant communication challenge between the

systems, the people, and the machines. Alain says, “It was impossible to find one system that answered all the challenges we had for producing custom cabinetry. So, we had to find one expert system as our solution. We ended up finding one system to join all these systems together.”

COCREATOR PLATFORM

Alain is excited about the Cocreator platform which will become the cornerstone of the communication between Cabico&co and their partners. The idea behind Cocreator is to move away from a catalogue and Alain says “We want to take a designer’s creativity and bring it to the machine on the shop floor. Custom cabinetry is no longer a question of choosing inside a catalogue; it’s now taking a dream and making it reality.”

“What our team has accomplished over the last couple of years is just paramount. I’m so proud of the work they’ve done. We truly have an excellent team.”

FROM FINANCING TO IMPACT—THE POSITIVE RIPPLE EFFECT

In addition to financial investments, Cabico&co is also investing in innovative systems that will help drive the cabinet industry forward. Alain believes the biggest impact from these investments will be on his customers. “Ultimately, it will be much easier for our customers to work with us,” he points out. The process for a designer to design, order, and receive exactly what they envisioned will be more seamless. In addition, the impact on our employees will be positive. Their work will be more rewarding, and they will be able to use their talent and skillsets for customization and craftsmanship, which is what matters.”

“From day one, our purpose has been to contribute to our stakeholders, employees, and customers’ success,” he adds. “And for that, we’ve always had big ideas and visions regarding how we can get there to become their best partners. I strongly believe we need to invest in technology and be more efficient. We’re the early adopters of technology, and this is necessary to stay competitive in the North American cabinetry industry.”

30 WOOD INDUSTRY WINTER 2022

PROFILE

TOP: Cabico facility ribbon cutting ceremony BOTTOM: Cabico grand opening facility tour

“FROM DAY ONE, OUR PURPOSE HAS BEEN TO CONTRIBUTE TO OUR STAKEHOLDERS, EMPLOYEES, AND CUSTOMERS’ SUCCESSES.”

- ALAIN OUZILLEAU, PRESIDENT AND CEO, CABICO&CO

“We have amazing long-term financial partners that have helped us through this process. We are very grateful for the trust and support of the Business Development Bank of Canada (BDC), Desjardins, Export Development Canada (EDC), and Investissement Québec.”

LOOKING FORWARD IN CANADA

Alain is realistic about the challenges our industry faces. Despite those challenges, Alain believes there are excellent career paths in the cabinet industry and recognizes that, “We need to do a better job of educating Canadians on the career opportunities that exist within the trades. This is so important for the success of the industry as a whole.” When asked if Alain had considered taking production offshore, he responded by saying, “We are a proudly Canadian manufacturer. Here in Canada, our employees truly have an incredible work ethic and craftsmanship.”

ADVICE FOR THE INDUSTRY

Recognizing Cabico&co is a leader and a large manufacturer in Canada; Alain knows the industry is also comprised of a wide range of Small to Medium Enterprises (SME’s). To any company thinking of expanding and investing in more technology Alain reflects on his own experience at Cabico&co: “It’s taking significant time to plan and ensure we have the right equipment. We have had to assess the requirements based on the nature of our products and match the technology and equipment to those needs.”

Alain and his team have embraced a common vision—to go the extra mile. They want to attract the best talent, customers, and partners, and Alain believes that his facilities’ digital and technological transformation is a force for positive change. “It enables us to offer customers operational excellence to meet their expectations and ideas while providing a motivating work environment for our employees,” he adds. “I am very proud of my people, without whom the migration to updated industry processes would not have been possible.”

On behalf of the CKCA, we would like Alain and his team to know how proud we are of you too. Alain makes time from his very busy schedule to participate in one of CKCA’s committees and supports the work we continue to do to advocate for our industry. Alain doesn’t just talk the talk he walks the walk too.

CKCA President, Pete Fournier attended Cabico&co’s unveiling on

September 22 (and admits to taking pictures and being inspired by what he saw). As Fournier says, “Cabico is a proud member of CKCA and it’s these kinds of innovations that drives the industry forward and sets a path that inspires us all and shows us what is possible.”

CKCA would like to wish Alain and his entire team at Cabico&co the very best in this exciting next chapter.

www.woodindustry.ca 31

PROFILE

HARBOUR CITY KITCHENS

Can robots and employees work hand-in-hand?

By James Risdon, Wood Industry Contributing Writer

Harbour City Kitchens

Harbour City Kitchens

An Automatech Robotik arm — massive, red and powerful — reaches out across a computer numerical control (CNC) machine and with the grace and precision of a surgeon takes care of the doweling and insertion on a piece of material.

Then, firmly but gently, the arm picks up the material and hands it over to be sent to an edgebander. Alone. No human beings needed.

“Prior to this, you used to have a person at the machine who would take the material, put a label on it, dowel it, and sort it away on a cart for the edgebander,” says Craig Bryden, Harbour City Kitchens’ managing director of business operations.

“The Automatech Robotik arm is now, in a sense, that person,” notes Bryden. “It picks up the piece off the router, drills it if it needs doweling, and puts it onto a conveyor belt which delivers it to the edgebander.”

In Harbour City Kitchens’ roughly 50,000-square-foot shop on the outskirts of Victoria on British Columbia’s Vancouver Island, in Saanichton, automation is everywhere.

“This is the future — and the way to go,” says Bryden.

By buying another CNC machine and turning over its operation to Automatech Robotik equipment, Harbour City Kitchens is hoping to boost its output and become far more productive than it had been in the past.

“It’s only one person (being replaced) but it’s one person that never gets sick and it can work from 5 a.m. to midnight — and this function is typically the bottleneck in a shop,” explains Bryden.

The massive, robotic arm, as impressive as it looks, though, is only the visible part of the automation solution at this workstation. After the four-by-eight feet sheets of material are cut, they pass under a canopy-like visioning system that takes pictures of the cut pieces and lets the robotic arm know what to pick up next.

www.woodindustry.ca 33 COLUMN

THE ULTIMATE WOOD SCREW Specifically engineered for manufacturing cabinetry and solid wood furniture. (519) 279-4044 www.wood-maxx.ca sales@wood-maxx ca Untitled-31 1 2022-05-10 12:34 PM

Craig Bryden, Harbour City Kitchens

–CRAIG BRYDEN

“If there are quality issues with the pieces, (the visioning system) will be able to spot them,” says Bryden. “It wasn’t an immediately obvious, slam-dunk solution, but we felt it was worth it and, as we continue to evaluate it, it will educate us.”

But this level of automation isn’t cheap. The Automatech component of the work station set Harbour City Kitchens back about $500,000 and the new CNC machine was another $500,000, figures Bryden.

The return on investment (ROI) for those purchases is still difficult to determine as it will depend on how much use the shop can actually make of the new equipment in a real-life setting.

However, while ROI is obviously important, so is long-term growth. Tommy Gagnon is CEO of Automatech Robotik in Saint-Apollinaire, Quebec. He says, “In Canada, we are beginning to see the ‘early majority’ market segment that is now integrating robotic

automation within their factories. They all share a common goal: growth. Where you start is not the most important part, but rather where you want to go and how fast you want to get there, are key goals for business. This is what robotic automation gives you — a very strong tool to achieve your growth objective, quickly.”

Bryden is confident this investment will pay off. “If we grow to where we want to be, then the ROI on this will be fairly quick — a couple of years,” he says. “But if it’s not doing that and operating 12 to 16 hours a day, then it would have been better to just leave an employee standing there.”

The arrival of this equipment at Harbour City Kitchens did not — as some might fear — cost any employee his or her job. The existing employee who was overseeing the use of the older CNC machine is still doing that work nearby — and keeping an eye on his robotic coworker.

“At the start, there were a few joking comments about it taking over their jobs,” says Bryden. “But the guy that it ‘replaced’ is still there. He’s just doing something else. Our plan is to have more employees.”

Harbour City Kitchens is no stranger to automation. It embraced technology early on, buying a Homag Storeteq system roughly a decade ago to take sheets of material pre-loaded into it, store them in a compact, fenced-in area in the shop, and then place them where they are needed to maximize the efficiency of the workflow.

“We have worked together to develop solutions to decrease dependence on direct labor and create consistency in an otherwise inconsistent process,” says Homag managing director, Marco Fernandes. “Our most recent collaboration has resulted in realizing a highly automated and consistent production environment which achieves just that.”

34 WOOD INDUSTRY WINTER 2022

“EVERYONE THINKS IT’S COOL. YOU BRING CLIENTS IN AND EVERYONE IS IMPRESSED WITH HOW ADVANCED IT IS.”

COLUMN

Harbour City Kitchens

And that’s just the beginning. “When we put that in, it was one of the first in Canada,” says Bryden. “Now, it’s pretty common for any decent-sized shop.” With its latest investments in innovation, Harbour City Kitchens is hoping to significantly increase its capacity and up its annual sales volume by roughly 50 per cent, from roughly $20 million to $30 million, says Bryden.

Already, there are two early pay-offs for the business. The first is a boost to employee morale. The company’s roughly 55 workers on the shop floor — and the other about 25 who work in the offices — get a charge out of being part of a company that embraces the latest tech. And then, there’s the “Wow!” factor when bringing in prospective clients to tour the facility. “Everyone thinks it’s cool,” says Bryden. “You bring clients in and everyone is impressed with how advanced it is.”

But it wasn’t always that way. When Bob Philipchalk first opened the business that was to become Harbour City Kitchens decades ago, it was no more than a small cabinetry shop in Greater Victoria. Over the years, it grew

www.woodindustry.ca 35

“WE HAVE WORKED TOGETHER TO DEVELOP SOLUTIONS TO DECREASE DEPENDENCE ON DIRECT LABOR AND CREATE CONSISTENCY IN AN OTHERWISE INCONSISTENT PROCESS.”

Quiet, Turn-Key Quiet, Turn-Key Indoor Dust Collection Indoor Dust Collection Modular Baghouse Modular Baghouse Central Dust Central Dust CCollection ollection Combustible Dust Combustible Dust EExpertise xpertise

– MARCO FERNANDES, HOMAG MANAGING DIRECTOR

Trust the Clean Air Experts.

Scan to find the right solution for you!

COLUMN

Harbour City Kitchens

and eventually moved into its current digs in 1985.

Today, Harbour City Kitchens is owned and operated by the latest adult generation of Philipchalks, Scott and Tim Philipchalk, and long-time school classmate and later co-worker — and now co-owner — Craig Bryden.

“We bought into the business in 2005 and then bought the building in 2010,” says Bryden. “We all worked here right out of high school. I was doing the delivery of the cabinets and then shipping and receiving.”

By the mid-1990s, the company was heavily into the multi-family market

but there was a lot of competition in that space and margins were tight. The then young owners made a bold business decision. They shifted into the single-family, custom cabinetry market.

“We sold off a lot of the equipment we had — half of it — and shifted from

36 WOOD INDUSTRY WINTER 2022

COLUMN

LEFT: Shane Coppinger Harbour City Kitchens RIGHT: Harbour City Kitchens

stocking things on the shop floor to a leaner operation,” says Bryden. A newly created inventory room freed up a lot of floor space and Harbour City Kitchens used it to start making wooden cabinet doors after acquiring another manufacturer.

Always looking for new opportunities, the entrepreneurs even tried — and succeeded for a while — at making caskets early in the millennium. But after doing that for only a few years, the company divested itself of that side of the operation, selling off casket-making business to a funeral company.

These days, the booming Vancouver and Victoria housing markets provide Harbour City Kitchens with more than enough customers. “Right now, we can’t even keep up with the demand locally,” says Bryden.

Finding enough workers, though, is a lot more challenging and another one of the reasons the company is moving towards more automation to ramp up capacity. Company-wide, we’re looking to add 10 to 15 employees over the next two years,” says Bryden.

Labour shortages are not only making it more difficult to find good workers but also driving up wages. Although it can be a lengthy process to bring in workers from other countries through Canada’s immigration programs, Harbour City Kitchens is looking into that option as well.

“Labour costs for us in manufacturing have jumped up about 25 per cent in the last few years since COVID-19,” says Bryden. “An entrylevel job is now $20 per hour and it’s hard to find people.”

www.woodindustry.ca 37

IS WHAT ROBOTIC AUTOMATION GIVES YOU – A VERY STRONG TOOL TO ACHIEVE YOUR GROWTH OBJECTIVE, QUICKLY.” – TOMMY GAGNON, CEO, AUTOMATECH ROBOTIK COLUMN SUBSCRIBE for Free KEEP YOUR FINGER ON THE PULSE OF THE CANADIAN MARKET WITH Canadian industry news, feature articles, product profiles, design and technology updates delivered to your inbox every week. WEEKLY E-DIGEST www.woodindustry.ca www.lemondedubois.com

“THIS

FOLDING WOOD & BENDING MINDS

A deeper dive into kerf cutting for the laser

By Lev Uzlaner, General Manager Trotec Laser Canada & Don Connell, Marketing Director Trotec Laser Canada

As woodworking has evolved over time, many woodworkers have incorporated the use of laser machines, especially for cutting and engraving. When using the machines for engraving, woodworkers can personalize projects, add logos, and create intricate patterns, while a more experienced user might engrave wood for inlay work. However, using a laser machine for cutting is not as straight forward.

Lasers don’t commonly cut wood sheets thicker than 1”, and that would depend on the type of wood being used. For example, while a 400W laser can cut a 1” solid wood sheet in one pass it may not be able to go through cork material because of “vulcanization;” the process where the

char of the burnt cork prevents the laser from further penetrating the material – usually due to the compression of the material itself. Halfinch cork is tough to get through with even three passes without massive charring effects.

However there are methods to get around some of these challenges. An alternative technique, called “kerf cutting,” is a process of cutting detailed line patterns in a specific sequence in order to manipulate a flat sheet of wood, which may not bend or be pliable, into a piece

38 WOOD INDUSTRY WINTER 2022 COLUMN

LEFT AND RIGHT: Trotec Laser Kerf cutting

of wood that can bend and fold depending on the direction, amount and length of cut lines. For example, using a 12” x 24” sheet of solid maple wood, we might begin by cutting six vertical “major” lines in the centre of the sheet going from top to bottom. These “major” lines are composed of smaller “minor” lines, 0.5” - 1” in length, with a 0.25” space between them. It is essential that these minor lines be staggered during cutting, with the resulting pattern not unlike a brick wall. Here too, stability has been added through purposeful offsetting of each piece, thus preventing weak spots while allowing for much greater flexibility. Although simple, this very basic kerf-cut hinge will permit a wood sheet to fold completely in half. The way a flat sheet of wood can fold and bend doesn’t only depend on the type of line pattern cut into it, but on other factors such as: the thickness of the wood, the length and amount of each break between the minor dotted lines, as well as the distance between each of the major lines. The wood thickness will greatly affect the results, for example if the wood is quite thin like a 1/8”, fewer major lines are needed to get a bend. If the wood is ½” thick, for example, one would need a greater number of major lines to help the fold, otherwise the bend will get stuck only half way. The amount of minor lines is also important; too many will result in a very brittle fold that will likely break after the first try.

Too few minor lines will not give a full fold or bend. Distance between major lines is also very important. If they are too close together the wood will break from brittleness, but too far apart will not produce a fold.

It is best to do a lot of trial-and-error with kerf cutting to get the right result. There is no one-size fits-all approach

with kerf cutting because each project, material, and design will be different from the next. Whether a woodworker is creating a book cover with a simple bend, or a complex 3-D pattern for an interior design project, knowing the endgoal result will make the process run smoothly and allow the woodworker to produce the best product every time.

PROFILE

www.woodindustry.ca 39

WEINIG HOLZ-HER CANADA 800.361.9367 | www.holzher.ca

TIME TO SHARPEN YOUR

TECHNOLOGY THAT BRINGS YOUR SHOP TO THE NEXT LEVEL

Trotec Laser Kerf cutting

THERMWOOD –

Multipurpose 43

High-performance threeaxis made from fully stress-relieved structured steel for nested-based custom cabinets, custom furniture and support products. A direct driven spindle with a speed range up to 24,000 RPM is cooled with an electric fan for quieter running and contains ceramic bearings for longer life, and for less maintenance. The bar Style Automatic Tool Changer mounts behind the rear of the table and holds the tapered tool holders. The Automatic Tool Length Sensor provides an automatic method of measuring tool length and entering tool length offset numbers into the control, compensating for the new tool length and eliminating the need to precisely locate the cutter bit.

PILLAR MACHINE – HP5D, Horizontal Bore, Dowel and Panel Grooves

The HP5D is designed to machine parts used in TFL, TFM, paper wrapped, vinyl wrapped or thermofoil doors. The model HP5D is a horizontal point-topoint bore and dowel insertion and panel groove machining center. It is designed to CNC position a drill spindle, bore a hole, then CNC position the dowel inserter, inject glue or water (for pre-glued dowels), and insert the dowel into the hole. It also can cut a panel groove in the centre section of the inside edge of the door stile and the entire inside edge of the door rail material. There are two fixed zones and two pop-up zones, which are standard in the base model HP5D allowing for pendulum processing.

SUGATSUNE – Leveling Glides

From restaurant tables to warehouse storage racks, these gliders improve safety, streamline workloads, and protect property by making it easy to: Level out working surfaces and stabilize loads on uneven flooring, mobilize heavy objects without lifting using highperformance gliders, and protect furniture and equipment from the wear and tear of being moved. The glides minimize the logistical challenges and safety risks associated with heavy equipment while providing a high degree of precision and a convenient ease of use.

ASI ARCHITECTURAL –Coffer

Coffer is available in modern or traditional options. Select hardwood moldings are preengineered and precision cut to represent craftsmanship that reflects the nostalgic past most often identified with traditional millwork. Coffer has a geometric three-dimensional beam and panel appearance. Materials are a combination of Hardwood and Class A Fire Rated Particle Board or Class A Fire Rated MDF. ASI Coffers use 15/16″ HD T-grid, which gives 100% accessibility; the system is composed of a lid (panel) and a decorative grid cover in a modern or traditional style. Coffer Modern has clean, straight lines with a contemporary profile.

HOMAG – The Raumwunder, DRILLTEQ V-310

The DRILLTEQ V-310 vertical CNC processing center includes comprehensive solutions for milling, drilling and grooving on a footprint of 11 m² to offer high-quality and individualized CNC processing in limited spaces. It features up to 45 drilling spindles, 2 swiveling grooving saws, a dowel insertion unit and a C-axis with unit interface. The units can be easily combined with an 8-position tool changer and adapted to the application situation. The machine also relies on a new system without safety mats –with safeScan. If the lasers detect movement or entry into the operating area, the machine stops without interrupting the program.

BLUM – TANDEMBOX antaro

All TANDEMBOX antaro applications are based on the TANDEMBOX cabinet profile. Low-friction cylindrical nylon rollers are designed to withstand load bearing classes of 30 and 65 kg and deliver quality motion for the lifetime of the furniture. TANDEMBOX antaro is characterised by its clear-cut design and rectangular gallery. This means one can carry minimalist design through to pull-outs and drawer sides.

40 WOOD INDUSTRY WINTER 2022

PRODUCT SHOWCASE

BERENSON – Brookridge collection

Brookridge, Berenson’s new collection blends understated shapes and organic contours. The collection features a range of pull lengths, including 12” appliance pulls, making it easy to use the products across the home, on small appliances, pantries, barn doors, etc. Both a round and square knob options are offered; they can also be mixed and matched. The Brookridge square knobs offer a mixed geometric look, combining a square head with a cylindrical post. They can be used to complement shaker or raised panel doors. The round knobs offer a more understated look with slight edges and soft turns.

ALVIC USA –Vivid Reality collection

The Vivid Reality collection presents 15 outdoor-inspired colours divided into two stories–New Warmth and In Living Colour. Applicable to Alvic USA’s stock collection of panels, cabinet components, and edgebanding, Colour story New Warmth showcases solid colours in yellow, terracotta, and red tones. These hues create a foundation for modern counterpoints when paired with white, black, neutral, and woodgrain elements. The In Living Colour story combines freshness in three colours: balanced green Verde Salvia, navy blue Azul Marino, and blue-green Agua Marina, as well as depth with several woodgrains and stone abstracts.

CEFLA –UniDry-G

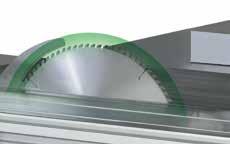

BIESSE GROUP – Selco 7 Series

Biesse’s Selco 7 Series is a beam saw with one cutting line, offering high performance in reduced times. The 7 Series is ideal to meet the needs of medium and large furniture manufacturers. Available in an array of configurations, the 7 Series is also available with a variety of features to meet the most demanding production and flexibility requirements in panel sizing. With the Patented Twin Pusher, the most enhancing of available features, two machines function in one and can improve throughput by up to 60%. Additionally, the “Quick change” system is a fast, safe and ergonomic device for replacing blades without using tools. Selco panel saws deliver the most innovative and feature rich machines on the market.

EGGER – PerfectSense® Feelwood Lacquered Boards

With PerfectSense®

Feelwood lacquered boards, EGGER combines an ultramatte lacquered surface with embossed-in-register (EIR) woodgrain textures for a natural look and feel.

PerfectSense Feelwood lacquered boards’ matte coating and low gloss level give the wood reproductions more depth of colour and contrast, delivering a more authentic appearance. Additionally, the lack of reflection on the surface better reveals the woodgrain texture at any angle. The new lacquered boards are durable, hygienic, fingerprint resistant and stain resistant.

The all-new UNIDRY-G automated drying system turns a twohour dry time into a two-minute dry time with a technology launched at the CeflaLive open house event last summer.

Powered by either natural gas or propane, this drying oven is a compact and efficient system for drying a variety of parts. Drastically reducing dry times when compared to traditional drying technologies, this unique system generates an intense and controlled amount of infrared energy, which when combined with air movement allows for efficient and clean drying. It can be used as a stand-alone unit or in-line with other technologies that further enhance the automated nature of a paint line.

VITAP – Point K2 2.0

The Point K2 2.0 is the technological evolution of numerical control machines for wood processing.

The power of 4 machines is concentrated in one machining center: cutting unit, profile unit, drilling unit, routering-nesting.

The patented Vitap Bar Nesting System® technology allows the 5 faces of the panel to be machined in 4 minutes.

Among the features that make the Point K2 2.0, there is the patented DDT System Double Dynamic Transport® technology, a double clamp technology for seamless panel movement, and the 4 sides milling device 0-3 mm. Point K2 2.0 has a new automatic tool changer warehouse and has a working area (Y axis) of 1250 mm.

www.woodindustry.ca 41

PRODUCT SHOWCASE

24%

24% of small businesses surveyed in 2022 say they are impacted by rising interest rates.

Source: The Scotiabank Path to Impact 2022 survey

2 to 1

Canada’s aging population means that the worker-to-retiree ratio is expected to shift from 7 to 1, 50 years ago, to 2 to 1 by 2035.

Source: Immigration, Refugees and Citizenship Canada, 2022

$28.3 billion