Address: Xiao Tang Nanhai Nonferrous Metals Industrial Park, Shi Shan Town, Nanhai District, Foshan City, Guangdong Province, China

Zip: 528231 Tel: 86-757-8555 8828 Fax: 86-757-8555 0238

Website: www.jma.cn, www.jma-aluminum.com

E-mail: sales@jma.cn, jmmaster@jma.cn

MESSAGE FROM HKFA

Over the past decade, the architecture of facades has experienced a substantial transformation propelled by advancements in technology, heightened environmental consciousness, and the imperative for sustainable construction. Façades are the most important building element. They are the most difficult to design since the perception of iconic and technologically advanced façades is changing frequently.

The next decade promises to bring even more cutting-edge innovations in facade design, including new materials, designs, and technologies that will continue to transform the way buildings look and function. One of the biggest trends in facade design is the use of sustainable materials and energy-efficient solutions. Facades plays a critical role in the energy consumption of a built form. By using materials that reduce the carbon footprint, facade can create sustainable buildings that are better for the environment. Recent buildings are more responsive to the environment as well as the design. Materials such as timber, terracotta and recycled materials like steel and glass are being used in facade design to reduce environmental impact. Metals like copper, aluminium, corten steel, and brass alloys are now being explored as façade elements

They can be used in combination with other technological advancements like smart glass to create dynamic and energy-efficient facades. Advancements in technology are driving new possibilities in the architecture of facades. Digital fabrication and 3D printing are allowing architects to create complex and intricate facades that were once impossible to achieve. Smart facades are becoming increasingly popular, thanks to advancements in building automation. Smart facades are designed to adapt to changing weather conditions, regulate temperature and lighting, and improve energy efficiency. These facades can also be programmed to respond to occupant needs, such as adjusting lighting levels or opening and closing windows. Smart glass panels, for instance, enable us to actively control daylight and solar heat, enhancing occupants' comfort and significantly reducing energy consumption.

In conclusion, the future of facades is looking bright, with a focus on sustainability, biophilic design, technological advancements, and smart solutions.

About Hong Kong Façade Association

Hong Kong Façade Association (HKFA) was founded in 1998. It is a non-prof it organisation that aims to draw the industry together to serve the society, through activities organised by the association. HKFA aims to unite members on industry issues, guarantee bene f its for the industry, standardise industry norms, serve the entire membership, achieve co-operation in the competitive market and promote healthy development for the trade.

To enhance professional training in the façade industry, HKFA has successfully conducted professional courses in collaboration with universities, since 2011. Working closely with other professional institutions the Association promotes façade engineering excellence and provides support for their CPD programs by conducting periodic technical seminars covering different façade technology topics.

香港建築幕牆裝飾協會成立於1998年,是一個非牟利營運機構,旨在通過舉辦活 動,凝聚業界力量,共同服務社會。在業界問題上團結會員,保障行業權益,訂定規 範及服務全體會員,同時在競爭劇烈的市場上加強合作,一起推動行業健康發展。

為提升幕牆行業的專業培訓,自 2011 年以來,香港建築幕牆裝飾協會已成功與大 學合辦專業課程。協會並與其他專業機構密切合作,通過定期舉辦並涵蓋不同幕 牆技術的研討會,促進工程精益求精,並為他們的持續專業進修課程提供支援及 技術課題。

Hong Kong Faç ade Association Limited

Rm 04,12/F, Kenning Industrial Building

19 Wang Hoi Road, Kowloon Bay, Hong Kong www.hkfacade.org

Executive Secretary 行政秘書: Connie Man W.K.

E: info@hkfacade.org, T: +852 2704 7597

過去十載,由於技術進步、環保意識提升, 以及可持續建築的必要,幕牆建築經歷了 巨大轉變。幕牆作為建築物的重要元素,既 要突出其標誌性,再加上日新月異的技術, 令到幕牆成為最難的設計部分。幕牆未來 前景明朗,前途無可限量。未來十年,幕牆 設計將帶來更多尖端的嶄新概念,包括新 穎材料、設計及技術,將繼續改變建築物的 外觀及功能。

使用可持續物料及節能方案是幕牆設計最 大趨勢之一,幕牆在建築形式的能源消耗中 起著至關重要的角色。透過減碳物料,幕牆 能創造更環保的可持續建築。近期的建築 對環境及設計更緊貼市場所需,節能發展 對大廈從外來因素提供更佳的保護,保持 室內環境溫度、提升通風及自然採光,同時又確保內部能見度。 以減少對環境的影 響,現今幕牆設計採用木材、陶片及將低炭排放鋼鐵及玻璃、鋁合金等回收物料, 同時研究將銅、鋁、考頓 (Carten)及黃銅合金等金屬用於幕牆元素當中。這些物料 與其他如智能玻璃等先進科技混合使用,可創造既富動態,而且節能的幕牆。

科技進步為建築幕牆帶來新的可能性,透過數碼製造及立體打印,建築師可設計出 以前不可能的複雜和精細的幕牆。自動化大廈的普及,使智能幕牆變得越來越受歡 迎。智能幕牆不但應對不斷變化的天氣環境、調節溫度及採光、提升節能,還能透 過電腦程式設計將幕牆根據用戶所需,例如調整照明度、打開或關閉窗戶等而有所 調校。 智能玻璃板讓用戶能夠主動調節從太陽採光及採熱程度,提升用戶舒適度 之餘,又能顯著降低能源消耗。總而言之,尤其著眼於可持續性、親生物性設計、科 技進步及智能方案,幕牆的未來前景明朗。能採納並將此趨勢融入設計當中,將能 走在未來十年的房屋幕牆設計的前鋒。

Mr. Chan Ming Kei, Peter 陳銘基先生 Chairman of Industrial Affairs Sub-Committee 行業事務關注委員會主席 Senior Construction Manager (Facade), Entasis Limited 大師有限公司 高級工程經理(幕牆裝飾)

THE FAÇ ADE ISSUE #28 2023

The FAÇ ADE is the of f icial publication of Hong Kong Fa ç ade Association Limited

Publisher 出版商: Mike Staley

E: publisher@rofmedia.com, T: +852 3150 8988

Editorial Committee 編輯委員會:

Sammy Hui (Head of Editorial Committee) / Richard Shek / Elizabeth Dooley (Consulting Editor) / Mike Staley

Advertising 廣告: Bryan Chan

E: bryan@rofmedia.com, T: +852 3150 8912

Alfred Ng

E: alfred@rofmedia.com, T: +852 3150 8911

Designer 設計: Michelle Morkel

Translation 翻譯: Derek Leung / Kay Chan / Jasper Lau / Billy Leung

In-house photographer 攝影師: Walter Ding

Designed & Published by ROF Media

Printed by Elegance Printing

The FAÇADE is online at www.issuu.com/rofmedia

All rights reserved. No part of this publication may be reproduced in any manner, without the prior written consent of the publishers. All reasonable care is taken but accuracy of information rests with the clients and contributors; the publisher bares no responsibility for any factual errors that may occur.

Copyright 2023 Ring of Fire Limited

4

香港建築幕牆裝飾協會 香港九龍灣宏開道19號 健力工業大廈 12樓04室

FOREWORD

Zaha Hadid’s Kaloyan Erevinov speaks to the power of innovative façade design

ADVERTORIAL

PPG introduces a new breakthrough in powder coatings technology

COVER STOREY

UNStudio’s innovative City Campus for Booking.com opens in Amsterdam

FEATURES

Jinwan Huafa IBC an engine of growth for the coastal city of Zhuhai

Inspired by nature, Aedas integrates sustainability, culture & technology

ARCHITECTURAL DESIGN

ZHA’s Business Stadium Central - new gathering place for city of Vilnius

Gensler’s organic architecture integrates with Chongqing’s environment

EVENTS

18th International Construction Industry Elite Golf Tournament

HKFA supports field visit to Far East Curtain Wall Factory

TECH TALK

ConTech pOint leads in building information management

BIM technology development in the curtain wall industry

The FAÇADE #28 2023 | 5

Cover story 12 39

CONTENT

12 42 6 10 22 36 48 42 44 6 28 Table of Content

INNOVATIVE FAÇADE DESIGNS

Create Aesthetic & Functional Synergy

The Construction industry with its ever-evolving demands for innovative design, efficiency in logistics, reduced carbon emissions, and the incorporation of renewable technologies, is within the forefront of our global efforts in promoting advancements towards sustainable development.

The façade industry, as an integral part of the construction sector, plays a crucial role in shaping the inherent sustainability and energy efficiency of buildings. The current issues we face in the broader construction sector and the façade industry in terms of the design, manufacture, logistics, carbon footprint, and the integration of renewable technologies are extensive, so it is important for us all to be aware of these factors, trends and potential solutions which can pave the way for a greener and more sustainable future.

In recent years, there has been a growing emphasis on architectural designs whereby aesthetics and functional aspects work in synergy. This means architects, developers, and clients seek innovative façade designs that are visually appealing whilst maximizing energy efficiencies for occupant comfort.

Therefore, striking a perfect balance between artistic expression and sustainability measures by means of integrating advanced design software and technologies can aid us in optimizing and simulating façade performance to identify efficient and aesthetically balanced design solutions.

We know that buildings by and large, are responsible for a very significant portion of global energy consumption and greenhouse gas emissions. The development of advanced insulating materials has shown promise in significantly reducing energy consumption, but it is equally important to implement efficient design measures. The thermal performance of facade systems have a direct impact to the energy efficiency of buildings, and the industry is continually exploring ways to enhance thermal insulation, optimize glazing systems, and integrate smart technologies to regulate interior temperatures more efficiently.

It is also imperative that the façade industry looks to source sustainable materials and adopting environmentally friendly manufacturing processes. The use of energyintensive materials (like concrete and steel) continues to raise concerns about their carbon footprint, and there is a growing interest in exploring alternative materials, such as bio-based composites, recycled materials, and engineered wood products, which are sustainably sourced and will offer lower embodied carbon. Furthermore, the adoption of eco-friendly manufacturing practices, such as 3D printing and modular construction, can also further reduce waste and energy consumption.

The construction industry's global nature demands an intricate logistics and supply chain management. Local sourcing and the development of regional supply chains can reduce the environmental impact and enhance project resilience, and efficient transportation of materials and components can also look to reduce cost and carbon emissions. Digital technologies, such as Building Information Modeling (BIM) and Real-Time Location Systems (RTLS), can therefore be valuable tools for streamlining logistics and optimizing material use over projects.

As the construction sector comes under further scrutiny for its significant carbon emissions throughout the life cycle of buildings (from their operational phases to their eventual demolition), Life Cycle Assessment (LCA) can look to provide comprehensive views of the environmental impact from our built environment. This will enable designers and developers to make informed and positive decisions to minimize emissions, by adopting low-carbon construction methods and adopt renewable energy sources for carbon-neutral (or even carbon-negative) contributions to the environment.

The façade industry is also shifting further towards the integration of renewable energy technologies into building skins, with Solar photovoltaic (PV) panels, solar thermal collectors, and buildingintegrated wind turbines as examples of energy-generating façade elements. Furthermore, smart façades equipped with sensors and

6

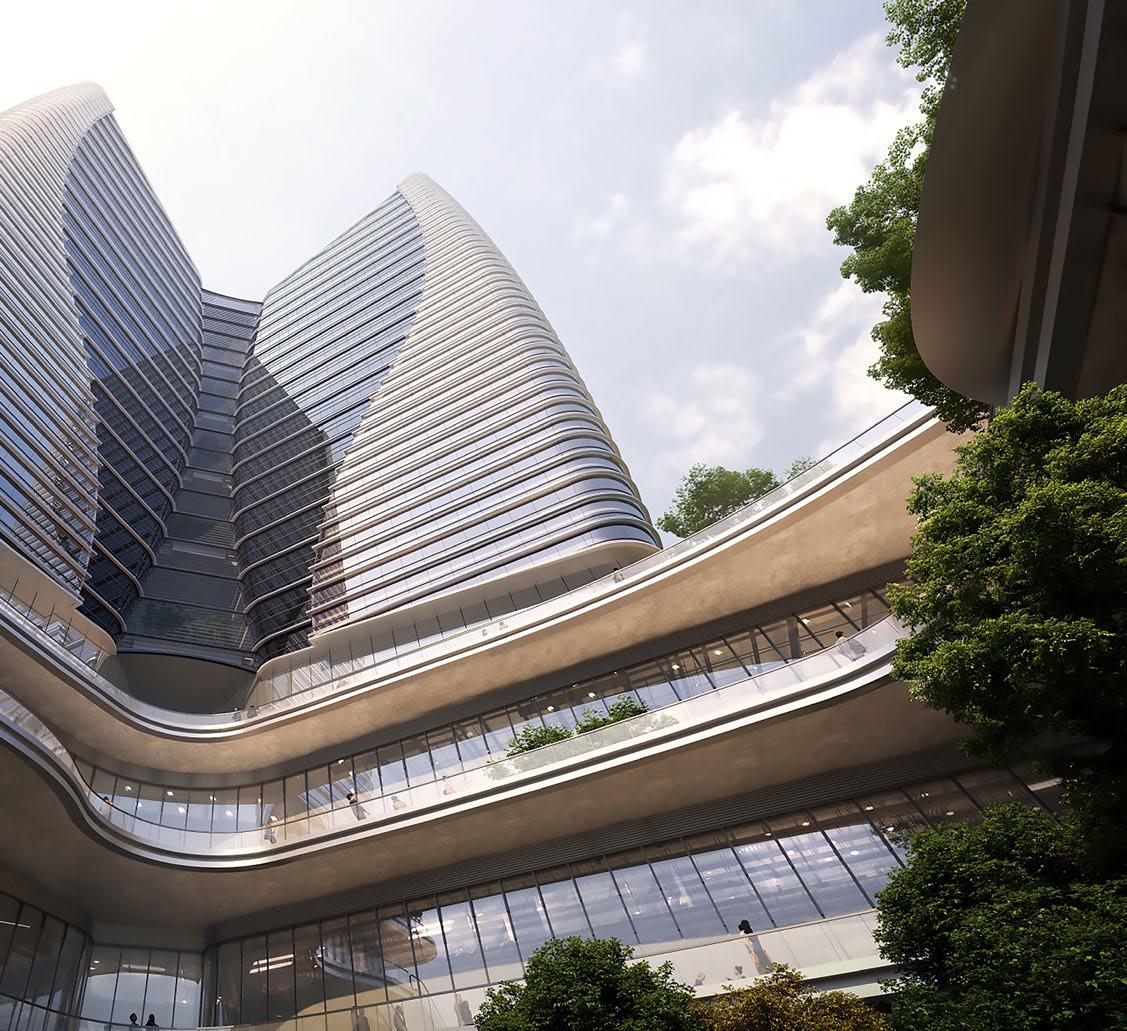

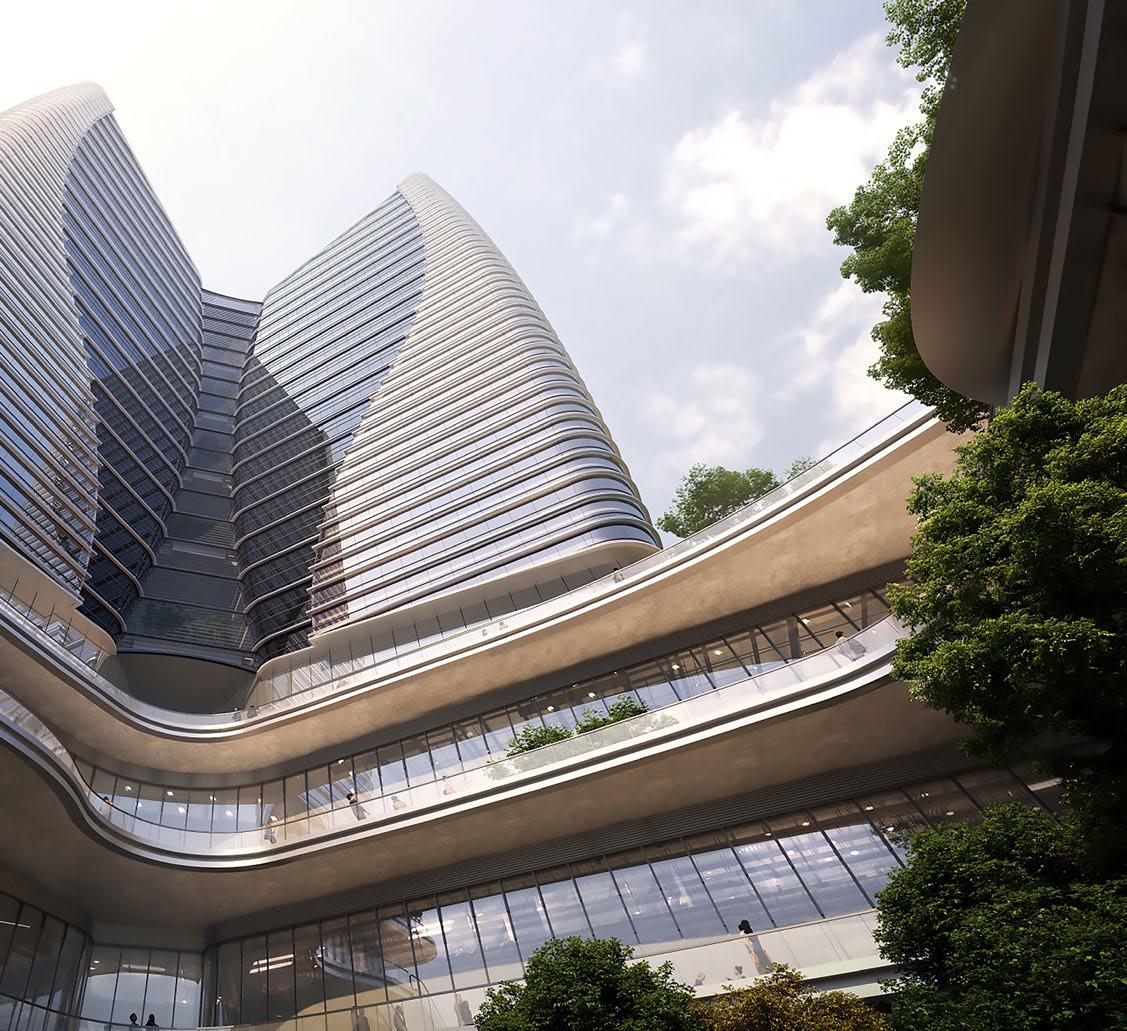

Sky SOHO

adaptive shading systems optimize energy use by responding to external conditions and occupant behaviours.

As we face more frequent extreme weather events due to climate change, the construction the design of façades needs to be responsive to these increasingly intense and adverse conditions over the long run. The façade industry and the construction sector in general, are undergoing transformative changes as they tackle the myriad of pressing issues in energy efficiency, sustainable materials, logistics, carbon reduction, and renewable energy integration.

Policymakers play a crucial role, in forging initiatives and policies to further stimulate and advocate the implementation of sustainable practices for architects, engineers, manufacturers to drive positive innovation. By prioritizing energy-efficient designs the industry on the whole, can look to make significant contributions towards a more sustainable and resilient built environment.

Collaboration amongst stakeholders and the relentless pursuit of innovative solutions will shape the future of the façade industry and construction, leading us towards a greener and more sustainable world.

Kaloyan Erevinov Senior Associate

Kaloyan Erevinov Senior Associate

The FAÇADE #28 2023 | 7 Foreword

Zaha Hadid Architects

Dongdaemun Design Plaza

Leeza SOHO

幕牆行業作為建築業不可或缺的一部分,在塑造建築物的可持續 性和能源效率方面發揮重要作用。目前我們在建築業及幕牆業面 臨多種設計、製造、物流、碳足跡及可再生技術整合等問題,因此我們必 須留意這些因素、趨勢及潛在解決方案,為更綠色和更可持續的未來 鋪路。

近年來,建築設計越來越重視美學和功能的協同作用。這意味著建築師, 發展商及客戶尋求創新幕牆設計,既要有視覺吸引力,同時最大限度地提 高能源效益,為使用者提供舒適環境。因此透過整合先進的設計軟件和 技術,在藝術表達和可持續性措施之間追求平衡,有助我們優化及模擬 幕牆性能,找到高效又美觀的設計方案。

我們知道建築物佔全球能源消耗和溫室氣體排放有一大佔比,先進絕緣 材料或能為大幅度降低能耗帶來曙光,與設計同樣重要。幕牆系統的熱 性能直接影響建築物的能源效率,業界正不斷探索提高熱絕緣、優化玻 璃系統和整合智能技術,以求有效地調節室內溫度。

幕牆業尋找可持續材料來源,並採用環境友善的製造方法亦至關重要。能 源密集型材料(如混凝土和鋼材)的使用持續引起大眾對碳足跡的關注, 促使發掘替代材料,如生物基複合材料、再生材料和工程木製品,這些材 料來源都是可持續,碳含量更低。此外採用生態友好的製造方法,如 3D 打印和模塊化建設,也可進一步減少浪費和能源消耗。

全球建築業要求精細的物流和供應鏈管理。當地採購及發展區域供應鏈 可減少環境影響,提高項目彈性,而材料和部件的高效運輸也可降低成本 和碳排放。科技如建築信息模型(BIM)和實時定位系統(RTLS),可成為 簡化物流和優化材料使用的有用工具。由於建築物的整個生命週期(從 營運階段到最終拆卸)均有大量碳排放,建築業因而受到關注。生命週期 評估(LCA)可提供建築環境對環境影響的全面分析,設計師和發展商可 以作出明智果斷決定,採用低碳建築方法和可再生能源對環境實現碳中和 (甚至負碳排),盡量減少排放。

Sky SOHO

幕牆業也進一步將可再生能源技術融入建築外觀,如太陽能光伏板、太 陽能熱集熱器和建築風力渦輪機等。此外,智能外牆配備傳感器和自動 調節遮陽系統可按照外部條件及使用者行為優化能源使用。

隨着氣候變化,大眾面臨更頻繁的極端天氣事件,長遠而言建築幕牆設 計需要應對這些日益加劇的危機。幕牆行業以至整個建築業界正在變 革,解決能源效率、可持續材料、物流、碳減排和可再生能源整合等眾多 緊迫問題。

決策者在推動及實踐可持續發展方面發揮重要作用,可制定倡議和政策, 鼓勵及倡導建築師、工程師和製造商積極創新。透過優先考慮整個行業 的節能設計,行業可對更可持續和更有彈性的建築環境作出重大貢獻。

持份者之間的合作以及對創新解決方案的不懈追求將主導幕牆業和建築 業的未來,引領我們走向一個更綠色、更可持續的世界。

札哈·哈蒂建築事務所高級合夥人

Kaloyan Erevinov

8

The FAÇADE #28 2023 | 9 Foreword

Dongdaemun Design Plaza

Leeza SOHO

PPG CORAFLON®

PLATINUM POWDER COATINGS

PPG has introduced PPG CORAFLON® Platinum coatings, a breakthrough in powder coatings technology that fundamentally alters what is possible with metal building coatings, not just in terms of how they look, but also their application and environmental performance.

This new innovation features high transfer efficiency, extended gloss ranges and improved corrosion performance on aluminium, plus a wider range of colors, glosses, micas and bonded metallics for metal building components.

This breakthrough is the result of PPG’s commitment to continuous innovation and providing our customers with marketleading coatings and systems.

Powder Coatings that Meet the Industry’s Highest Specifications

Fluoroethylene vinyl ether (FEVE) fluoropolymer powder coatings like Coraflon Platinum are specifically engineered for architectural extrusions and sheet aluminum and are compliant with American Architectural Manufacturers Association (AAMA) 2605 specifications for film integrity, chalk resistance and color change.

Coraflon Platinum represents an advancement in PPG’s FEVE powder systems, providing an extended gloss range from 5-85o, compared to 25-70o for standard FEVE powder coatings, plus a wide portfolio of aesthetics and textures that mimic cement and stone, terracotta and other natural finishes.

The robust protective layer provided by PPG Coraflon Platinum coatings can also create the look of anodized aluminium when specified in a matte (low-gloss) finish and provides corrosion resistance and longterm colorfastness not possible with the traditional anodized process.

Supporting Sustainability

While our coatings are covered by a 30-year warranty, architects can trust that their buildings are not only protected throughout their lifecycle, but also meet the strictest environmental standards.

The technology behind Coraflon Platinum powder coatings features 70 percent less e-cap (oven smoke and oven build up) and is specifically formulated without VOCs.

PPG Coraflon Platinum also has transfer efficiency rates that are 20 percent higher than standard FEVE powder coatings. This not only reduces waste with the ability to reduce overspray, it also improves corrosion performance on aluminum with a fast-film build that limits the need to reclaim excess powder.

CORAFLON Platinum Powder Coating Uses

Coraflon Platinum powder coating can be used on a variety of metal building components to provide a resilient protective layer with the industry’s highest levels of corrosion and weathering resistance, such as:

• Commercial and residential towers

• Universities and libraries

• Sporting venues

• Commercial centers

• Corporate offices

• Airports

Want to know more?

Visit our Coraflon Platinum landing page on our website for more information.

https://www.ppgindustrialcoatings.com/enUS/coraflon-platinum

10

Innovative powder coatings that perform as well as they look

The FAÇADE #28 2023 | 11 Advertorial

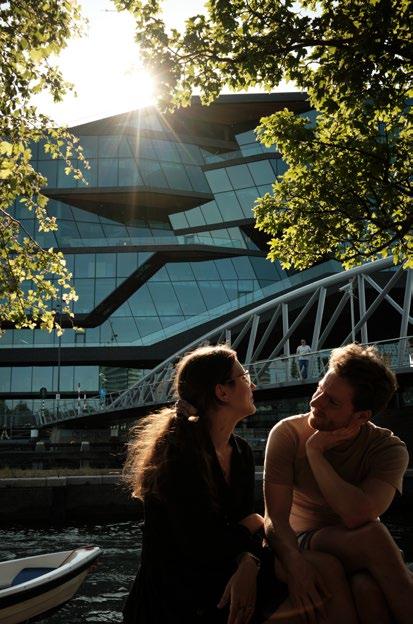

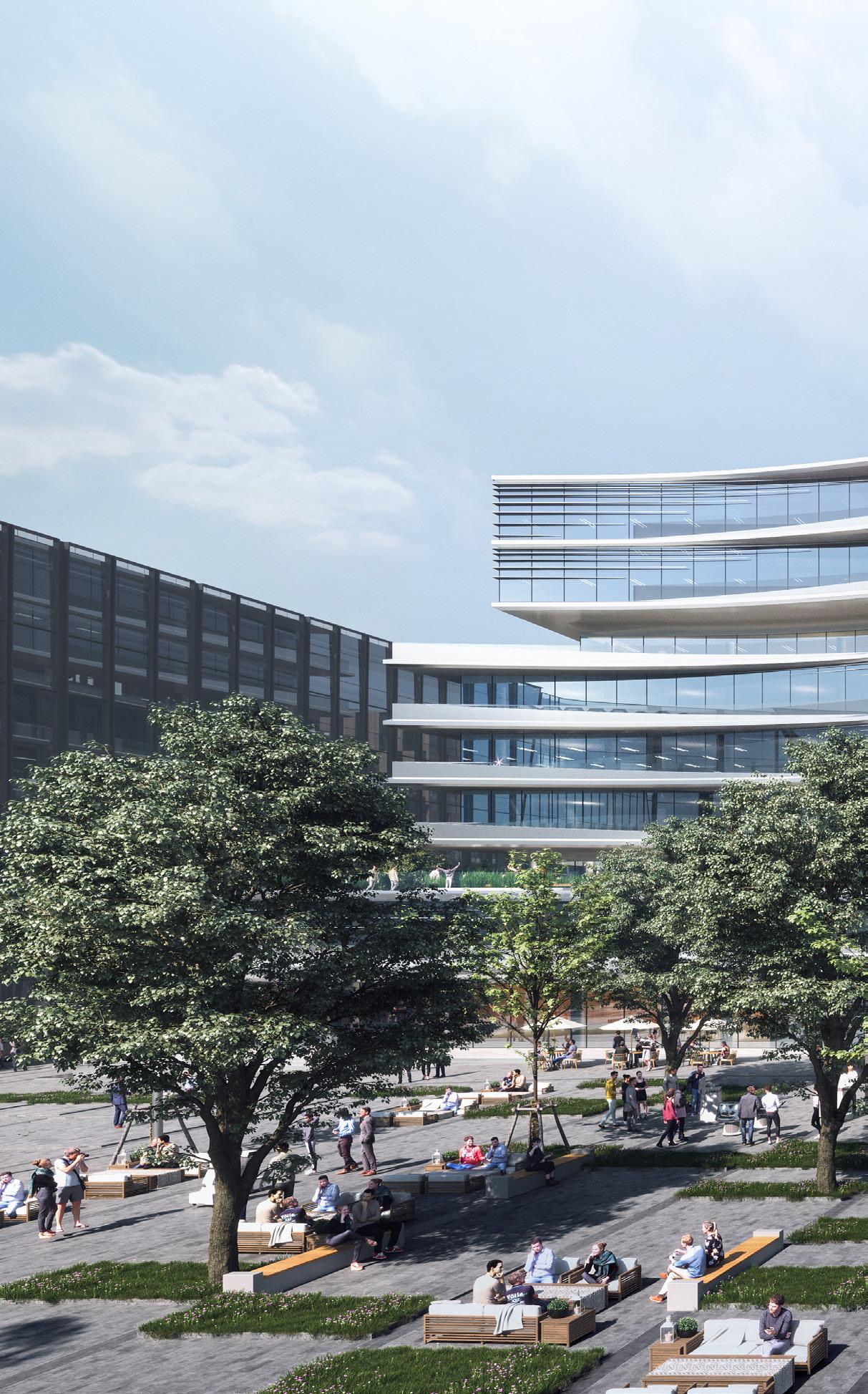

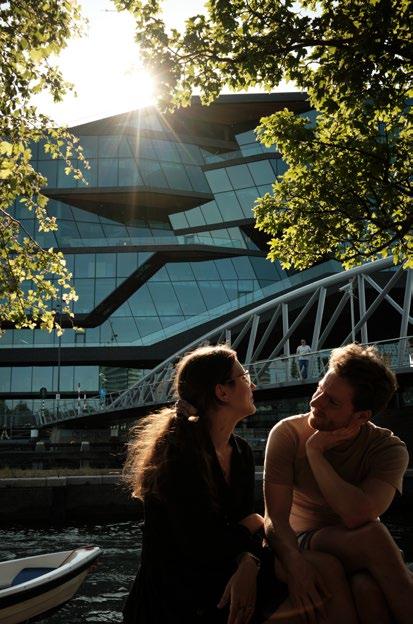

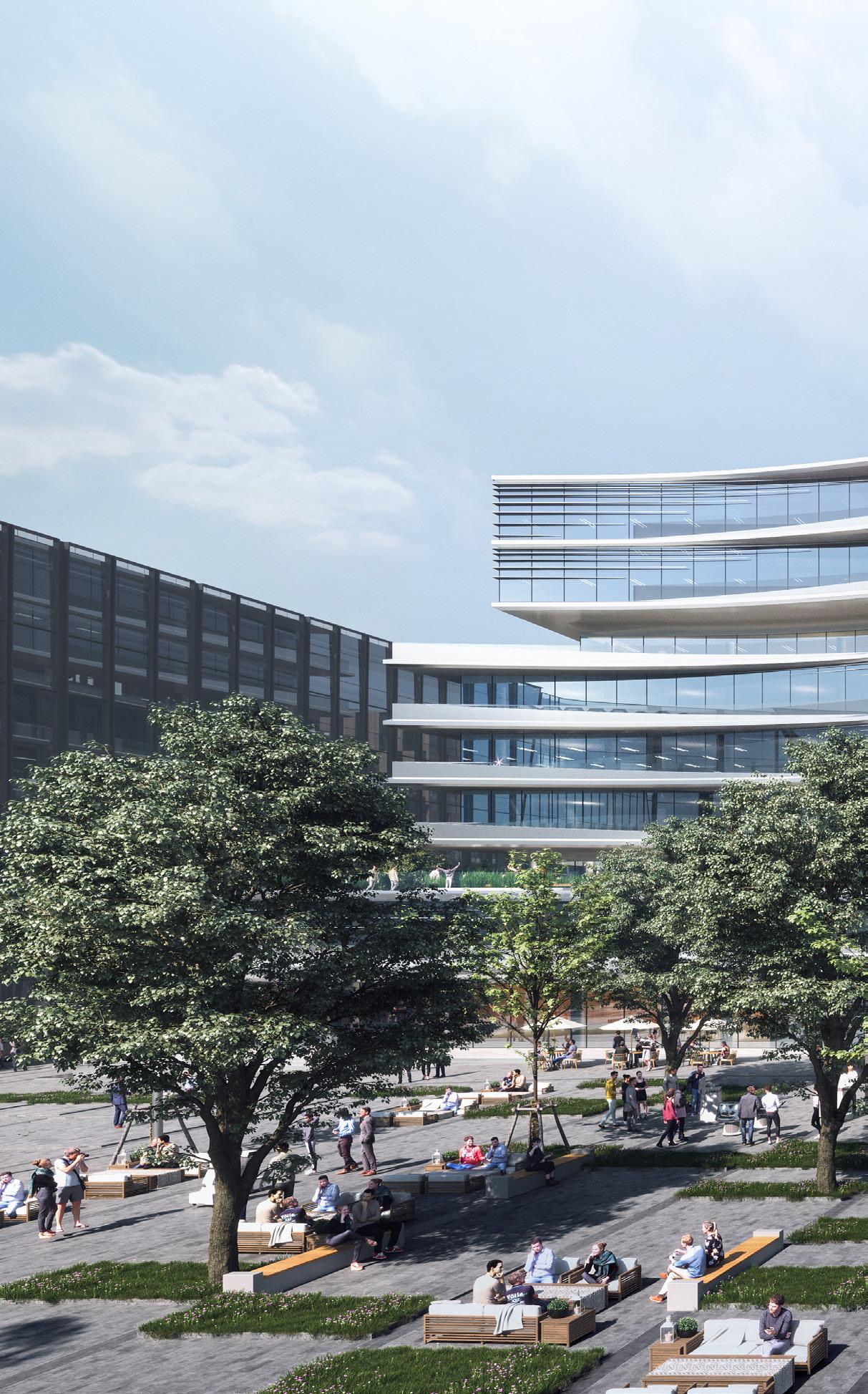

12 UNStudio’s new City Campus for travel leader Booking.com opens in Amsterdam

Text: Elizabeth Dooley Images: Hufton+Crow / Philippe Sarfati

In 2015, Booking.com, together with BPD (Bouwfonds Property Development), selected UNStudio to design their new campus in the centre of Amsterdam. From the outset, the goal for the buildings was to create a healthy community; to bring employees together and to attract new talent from across the globe.

Booking.com was keen for their headquarters to be a reflection of their leading position in the tech world and therefore considered the building to be an important tool in attracting and retaining top young talent from the industry. This goal served as the starting point for the design. During the research phase, visits were made to other successful tech company buildings. However, Booking.com wanted their building to provide a truly unparalleled experience for their employees, so a completely new, out-of-the-box and unique concept was required.

The FAÇADE #28 2023 | 13

Cover Story

Marnix Mali, Director of Real Estate and Workspace Services, Booking.com noted: “From the very beginning, our aim was to create an inclusive and sustainable space, where our colleagues from all over the world would feel inspired to do their best work, and all under one roof. UNStudio completely understood our vision and played an integral role in transforming our dream for the Campus into a reality.”

With the completion of the Booking.com City Campus in the heart of Amsterdam, all 6,500 employees of the Dutch travel platform, who were previously spread out among numerous locations across the city, can now work in the same building for the first time in more than a decade.

Alongside the adjoining residential component, the main campus building was designed to create the best possible contemporary work environment for Booking.com’s employees, as well as the most healthy and sustainable urban development possible. As the Lead Interior Architect, HofmanDujardin created and coordinated the interior fit out masterplan that combines the work of multiple international design firms.

Leading UNStudio’s design team architect Ben van Berkel said: “We wanted to create a building that could also operate as a ‘recruitment machine’. The focus was on serving the needs and behaviour of Booking. com employees, from the moment they walk in, to the end of their working day, and all the activities in between.”

Both the architecture and the interiors of the 65,000 m2 campus are primarily

designed to ‘connect’: to create a healthy and sustainable architecture of inclusion that supports diversity and stimulates serendipitous encounters among Booking. com employees, visitors, residents and the wide array of people who live, work or visit the Oosterdokseiland in the centre of Amsterdam.

“While the individual interior spaces enjoy a truly international flavour that reflects Booking.com’s core business, we wanted the overall concept for the building to serve as a reflection of Amsterdam – its location and the Dutch travel company’s homebase since its inception.

The architecture therefore combines the robust qualities and the industrial history of the harbour, with glazed detailing that reduces the overall immenseness of the building and gently reflects the glistening of the water and sky. The organisation of the interior meanwhile, is designed to charcterise the vibrancy of Amsterdam’s lively central neigbourhoods,” he adds.

UNStudio’s design for Booking.com’s City Campus also needed to strike a balance between the small size of the plot on Amsterdam’s Oosterdokseiland and the company’s growing employee base. The result is an ultra-compact building that accommodates 73,500m2 on a 6,000m2 ground floor plan.

To penetrate deep into the building, UNStudio decided to utilise a triple-glazed-window with a low glare value for the façade for maximum daylight gain. Here, UNStudio used 2.4m-by3.6m floor to ceiling glass façade elements, which service the floorplates that are over 20m wide. Additionally, the ceilings fold up at the façade to gain even more daylight within the building. While the clear height is actually 2.8m, it feels as though it is 3 metres due to semi-transparent ceilings and a stretched metal look.

The design is closely related to this very dense, central part of the city. The architecture combines the robust qualities and the industrial history of the harbour, while the

14

The FAÇADE #28 2023 | 15 Cover Story

glazed detailing of the facade reduces the overall immensness of the building and gently reflects the glistening of the water and sky. From the inside, the sweeping views over Amsterdam and 't IJ offer an almost cinematic experience,” says van Berkel.

The Booking.com campus is a state-of-theart sustainable and healthy place to work. All installations have been designed to support a fully flexible workspace. UNStudio used Under Floor Air Distribution, eliminating the need for ducts on the floorspace, while allowing a demandcontrolled supply of fresh air.

Radiant ceilings are used to allow for very comfortable heating and cooling. Split into three zones, the entire system is controlled through a grid network that ranges from 2.4m to 4.8m. Additional heating and cooling comes from an Aquifer thermal energy storage system within the building.

UNStudio continued to design for postoccupancy, including a Connected Building management system that features multisensors for occupancy, IR temperature, light levels including a very efficient lighting system with less than 4W/m2 of lighting, smoke detection, climate control, fire detection, access control, and exact 3d indoor positioning sensors for variety of future-proof use-cases to enable a

frictionless space for all employees and operations staff alike.

The design also includes 1,500 PV panels for power generation for the building. UNStudio also reused piling from the foundation of previous buildings, helping to reduce the amount of waste created during the construction phase. As such, Booking.com City Campus achieved a BREEAM Excellent design certificate.

Throughout the building, the architecture nudges employees to move by fostering engaging environments and by encouraging physical movement by use of stairs, bridges and galleries across all levels, including the rooftop. Even the emergency staircases become part of this concept, as untypically these are glazed along the atrium side, which not only encourages daily use, but also offers light views from the stairs and visibility from the other spaces in the building.

Special attention has also been given to the acoustics in both the office spaces and the atria, while alongside the generous daylight throughout the building, high-quality artificial light with very low glare enhances visual comfort.

The new campus is also state-of-the-art in terms of all sustainable solutions and achieved a BREEAM Excellent design

certificate. In addition, a connected building management system is incorporated to enable a frictionless space for all employees and operations staff alike.

The overall design of the campus reflects the functional, transparent and connected way of working at Booking.com and creates an integrated, flexible urban campus that reflects how we will work, live and connect in the future.

While UNStudio designed the urban approach and architecture for the campus, including the continuous spatial experience of the building. This includes a variety of amenities in the form of 28 micro holiday destination breakout spaces.

These communal areas are spread throughout the campus for use by the employees and are unique destinationthemed spaces, which include service points, restaurants, and breakout spaces with pantries.

The flexible and generous design of the work floors also made it possible to create numerous different working and meeting spaces. The variety of these meeting spaces and amenities gives the employees freedom of choice to ‘design their day’ for a healthy and productive work life.

16

The FAÇADE #28 2023 | 17 Cover Story

The FAÇADE #28 2023 | 19 Cover Story

20

The FAÇADE #28 2023 | 21 Cover Story

A Catalyst for Growth JINWAN HUAFA IBC

10 Design (part of Egis Group) has announced the completion of Jinwan Huafa International Business Center, an iconic landmark, as well as growth engine of the Jinwan District in the coastal city of Zhuhai, China.

Information and Images: 10 Design

22

The FAÇADE #28 2023 | 23 Feature

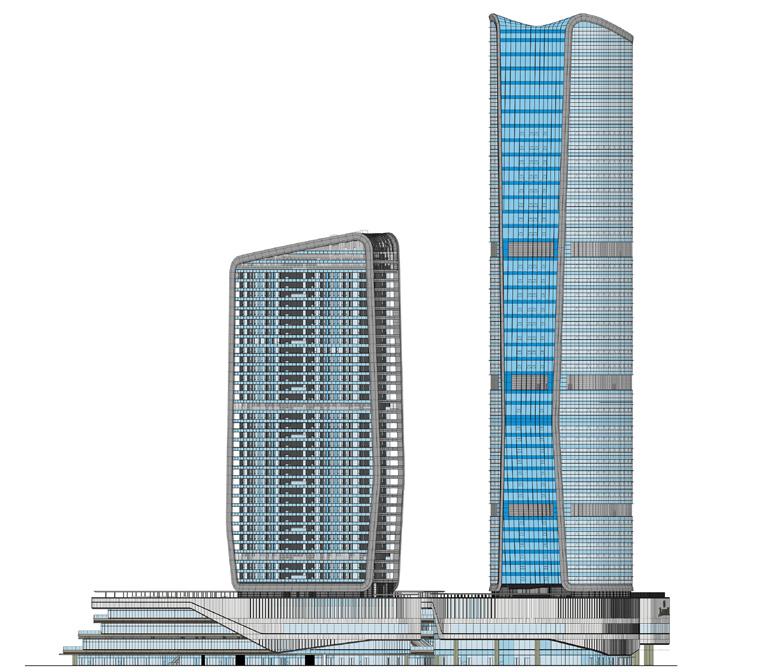

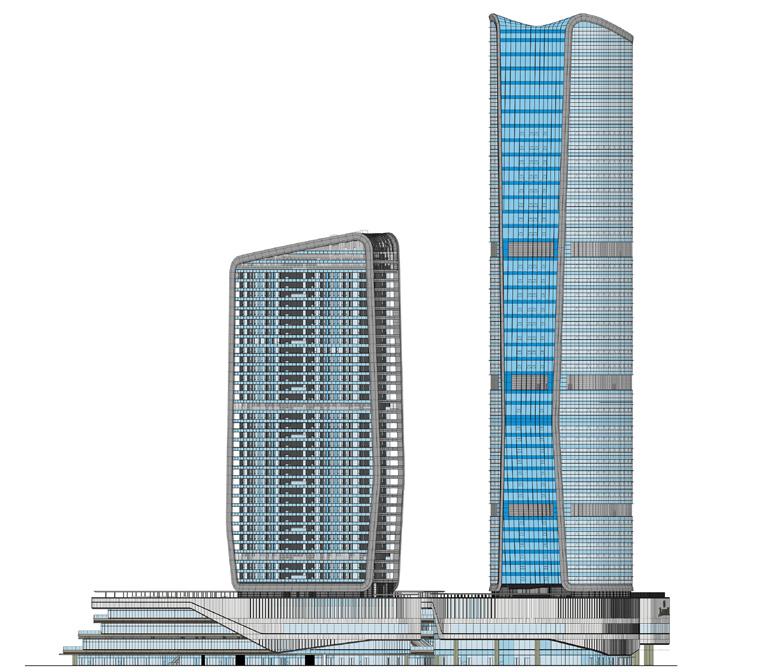

Located on a prime waterfront site in Zhuhai, China, the 172,033 square metre International Business Centre (IBC), is a mixed-use complex comprising hotel, office, serviced apartment and retail spaces. The project sits within a wider 3.8 square metre masterplan of the new Jinwan Aviation City which offers a mix of residential, cultural, civic, commercial, and retail facilities surrounding a new lake at the centre of the site.

The 210 m IBC is the third project that 10 Design has created for Huafa Group in the district, which will become a catalyst of growth and focal point for the entire district. The other two developments include the Industrial Services Centre and Jinwan Mall which sits across the Jinsha Lake.

The design of the IBC is inspired by the district’s history as an aviation site since the 1940s. Derived from aerodynamic shapes, the elegant twin towers resemble a pair of aircraft wings. The towers are both symmetrical about a vertical axis with the soft elliptical form at each end to create an elegant profile against the sky. IBC’s iconic design creates a new landmark for the district while allowing for an efficient planning envelope with regular floor plans conducive to office, hotel and apartment functions.

Located at the northern edge of the central lake, the two towers are oriented to maximise views toward the waterfront and the public park on either side. The towers, standing in strong dialogue with each other, complement to the district's notable north-south axis, framing views through the centre of the site.

Focused Facades

The glass curtain wall of the main tower captures the dynamic hues of the sunlight throughout the day and activates the entire area with integrated LED lighting after dark. Standing in juxtaposition to the main tower, the serviced apartment tower is expressed with

Consultants

Lead Design Architect - 10 Design

Local Architect - Guangdong Architectural Design & Research Institute

Co., Ltd.

Structural Engineer - RBS Architectural Engineering Design Associates

Façade Engineer - Sanxin Façade

www.10design.co

aluminium accent frames which outline the building silhouette while serving as passive shading devices for the apartment units.

The shared podium is a series of carved volumes, which defines the external pedestrian retail streets from the north arrival plaza through to the lakefront in the south. A flowing, open-edge balcony circulation provides multiple spectacular vantage points for visitors and offers opportunities for al fresco dining. These semi-open spaces encourage users to interact and connect with the public green space along the waterfront. The main entrance of the Marriott Hotel is also strategically located along the southern edge of the podium to allow for a glimpse of the waterfront experience on arrival.

The IBC is a unified statement of the ongoing transition of the Jinwan Aviation City, creating a dynamic gateway for the area as well as an animated public space welcoming visitors from adjacent communities and beyond.

24

The FAÇADE #28 2023 | 25 Feature

26

The FAÇADE #28 2023 | 27 Feature

INSPIRED BY NATURE AND PEOPLE

Integrating sustainability, culture and technology: Casting a spotlight on three new design projects by Aedas

Information and Images: Aedas

28

The FAÇADE #28 2023 | 29 Feature

SMART ARCHITECTURE MEETS ECOLOGICAL LANDMARK IN HANGZHOU

Aedas’ 63,032 sq m DESMAN (Hangzhou) Headquarters project is due for completion in 2025. Located in the Binjiang IoT (Internet of Things) Town, a cradle for high-tech industries in Zhejiang, Hangzhou, this efficient mixed-use building connects the major public green axis and overlooks the Smart Gate to the north and the landscape park to the south.

A humane design approach is inspired by the flapping wings of butterflies, representing the integration of sustainability, culture and technology.

The simple and elegant architectural form features softened corners using horizontally placed fins which wrap around the towers like a butterfly in flight, whilst the twin towers mimic butterfly wings tilting inwards towards the courtyard. Glass panels and metal components are adopted to create a bold façade resembling the wings through colour variance on the panels under different sunlight.

Glass louvers in the courtyard allow natural light to penetrate, while fluid multi-levelled podiums reduce mass while creating porosity between the outdoor platforms.

With multi-dimensional vertical open spaces, the project perfectly merges architecture with its surrounding urban texture, while the design optimises the natural topography to create a smart commercial space while integrating the multi-dimensional urban context and inheriting the corporate spirit.

30

Aedas 為德斯曼(杭州)設計的 63,032 平方米總部項目,預計將於 2025 年竣 工。這座高效的綜合體建築位於浙江省杭州市 高科技產業的搖籃—濱江物聯網小鎮,毗鄰連 接兩大重要公共中心的生態軸線“感知之軸”, 北側遠眺門戶節點智慧之門,南側是景觀中心 公園,區位條件與景觀資源俱佳。

人性化的設計理念源自蝴蝶扇動的翅膀,代表 著可持續發展、文化與科技的融合。建築輪廓簡 約優雅,剛柔並濟的線條,橫向勾勒的直線左右 延展,縱向弧線邊緣包裹,在頂部收縮變化形成 以中庭為中心向外舒展的蝶翼狀雙塔輪廓,表

現出雙翼扇動之張力。立面採用玻璃幕牆搭配 金屬構件,通過幕牆顏色的反差,構建出蝴蝶振 翅,將工業與美學完美融合。

中庭採用玻璃百葉達到綠意通透的效果,最大 程度降低其存在感,打造輕盈的建築體塊。配 合線條靈動流暢的多層次裙房,使建築群在整 個園區中脫穎而出。

設計將識別性、迅達性和功能性作為考慮的核 心,結合與城市可持續發展的關係,打造出有機 生態的可持續化產業基地,促進生態科技彼此 賦能,實現科技產業與城市綠脈共同生長。

The FAÇADE #28 2023 | 31

Feature

INDUSTRIAL

INTERNET HEADQUARTERS PROJECT

Located in Foshan Sanlongwan, this project marks the design of the industrial headquarters of global technology internet company, JOYY Inc. With a ground floor area of 443,956 sq m, it offers a vibrant commercial area alongside a quiet retreat encompassing sequestered offices and serviced apartments laden with green, open spaces.

“We seek to reconcile form, function and cost to create a new landmark for the Sanlongwan area that will become an emblem of technology and innovation,” said Aedas Global Design Principal Ken Wai.

With a total planned area of circa 77,716 sq m, the site is divided into two plots. Plot A comprises the headquarters and supporting functions. Based on the principles of TOD or transit-oriented development, the building is composed of five radial office building modules, extending to the riverside from a central open-air plaza, each containing supporting facilities including service business, an indoor basketball court and ring-shaped open-air courtyard. The towers are externally connected by a crescent-shaped volume, while the inner centre relates to a peripheral courtyard and corridor.

A 1000M FAÇADE

Complex mass edges counter the long, uninterrupted building façade of nearly a thousand metres, with the building blocks constructed in a jagged fashion to engender a rhythmic outline and layered development. The design dissolves the boundary between architecture and nature by introducing terraces and setback spaces that echo Lingnan’s landscape, and a public courtyard area elevating the first floor.

Wide and deep cornices are also a main feature of the façade, designed to reduce thermal radiation and minimise the need for indoor temperature calibration. It doubles as a sustainability feature that contributes to energy saving and emission reduction.

Meanwhile, Plot B, which overlooks a green riverside landscape to the north, includes an apartment tower, an office tower, and four single-family office buildings of differing heights, each attached to a retail block beneath. A sky corridor threads through the individual buildings along the river, with concentrated public spaces at the core and scattered courtyards. Coupled with the green roofs and the sky gardens introduced in the towers along the street, the design creates a multi-dimensional green urban landscape.

The FAÇADE #28 2023 | 33 Feature

TAIPEI’S GLIT TERING FAÇADE

Work is ongoing for the Taipai Zhongshan Changan Duan 345 Office Tower in Taipai, with Aedas Global Design Principal Dr. Andy Wen and Executive Director Yijun Qian leading the team in the design of this a waterfall-inspired office tower. Featuring rich Taiwanese office characteristics, the project boasts a gross floor area of 21,644 square metres and is said to focus on urban texture, architecture and people.

“Adopting the aesthetics of simplicity and authentic culture, we drew inspiration from the Shifen Waterfall in Taipai. The motion of the waterfall is perfectly captured into the bold architectural form, creating a partially undulating façade that glitters in the city,” notes Wen.

The façade elements are a key feature of the project, with sinuous façades with soft edges expressed in coppery panels making up the main element of the tower. Dark tawny panels are displayed though an inwardly

concave arc to create a curved glass wall of contrasting colours. Meanwhile, a semi-exposed framing curtain wall uses reflective glass panels to minimise light pollution and enhance energy efficiency.

Inside, the lobby features white marble and bronze fins, with white and light grey floorings extending the fluid façade into the landscape and entrance area. A public recreational communal space with outdoor balcony and oftop garden create a biophilic and blurred exterior-interior public space, ensuring a people-centric working environment.

“The tower marks itself as an urban icon with a simple yet powerful architectural form. It makes a strong statement on the skyline,” Yijiun adds.

34

項目位於台北中心交通要道復興北路 與長安東路二段交匯口,總建築面積為 21,644平方米,由 Aedas 全球設計董事溫子先 博士、執行董事錢逸筠帶領團隊,打造這一座引 領台灣辦公風尚的“都市瀑布”,設計以現代的 建築語言抽象勾勒自然意境,構築“城市-建築人”三者間的全新對話。

「建築的設計靈感源自台北市著名的十分瀑布, 將瀑布的流動美妙轉化為建築形體,結合材料 與色彩,賦予建築強烈的雕塑感和美學價值。」 溫子先博士說道。

立面設計是項目的焦點所在,平滑柔順的建築 輪廓層層退進,模擬出瀑布飛流直下時極富層 次的跌落形態,在延續動感整體的同時,完美 貼合落物曲線要求,實現了美學與功能的兼顧 平衡。為了強調建築的挺拔感,設計採用豎明橫 隱的幕牆形式,並選用反射率不高於 0.25 的玻 璃,有效避免光污染,營造綠色環保建築。

室內大堂延續了外立面設計元素,通透挑高的玻 璃幕牆內,流線型的白色大理石牆面,搭配銅色 金屬構件,在簡約時尚的氛圍中營造出雅緻的 到達體驗。辦公空間靈活佈局,並設有室外露台 和屋頂花園,將自然引入建築,為員工提供戶外 交流與放鬆的彈性空間。

「台北捷運上快速掠過時,它能給人們留下深 刻的印象。建築的個性,為城市塑造出獨特的視 覺焦點,對於城市形象的營造和提升具有重要 的意義。」錢逸筠如是說。

The FAÇADE #28 2023 | 35

Feature

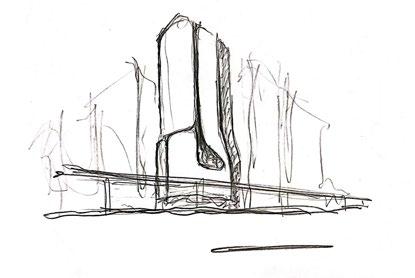

Lithuania at

VILNIUS BUSINESS STADIUM

Integrated within the Vilnius City Plan and the popular public square adjacent to the site, Business Stadium Central will be a new gathering place for the city

Information and Images: Zaha Hadid Architects

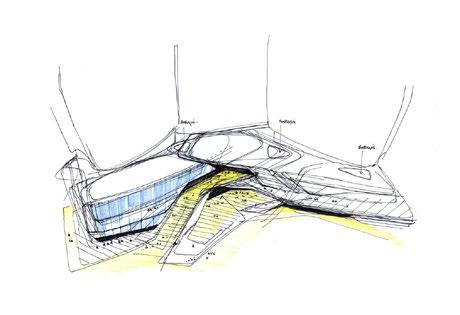

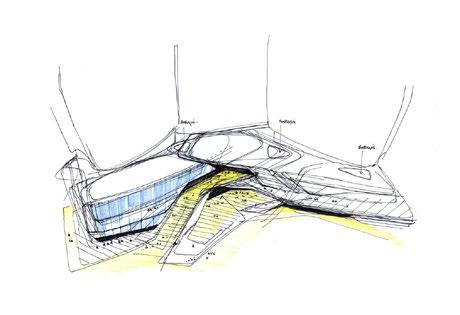

Integrated within the Vilnius City Plan and the popular public square adjacent to the site, the 24,000 square metre Business Stadium Central will be a new gathering place for the city.

With construction scheduled to start in the second quarter of this year, Business Stadium Central will create a variety of new public spaces and amenities for the city within a design that integrates flexible workplaces, encouraging interaction and collaboration together with extensive health and wellness facilities for use by everyone in Vilnius.

GEOMETRIC INTEGRATION

Consisting of two low-rise towers of 8 and 9 storeys, connected at street level by a courtyard atrium and two floors of public amenities, the centre’s design also connects its two towers via a skybridge at level five.

The curvature of the centre’s facades and its cantilevered balconies face towards the historic Gediminas Castle Tower in the heart of the city. Reinterpreting the dynamic geometries of the neighbourhood’s existing civic architecture, Business Stadium Central’s design incorporates 11,750 square metres of landscaped terraces, roof gardens and plazas that open directly onto the public square designed by Martha Schwartz.

Lined with cafes, restaurants and shops, its atrium courtyard will serve local residents, office workers and visitors. Elevators lead to top floors where the two public swimming pools, saunas, steam rooms and sun decks have panoramic views over Vilnius’ historic Old Town. Flexible office spaces located within the central floors of each of the towers are designed with maximum adaptability to extend the life-cycle of the development.

Differing in size and layout to suit a variety of companies from new start-ups to established international corporations, these workplaces connect with landscaped roof gardens and terraces offering views of the surrounding city.

SPOTLIGHT ON SUSTAINABILITY

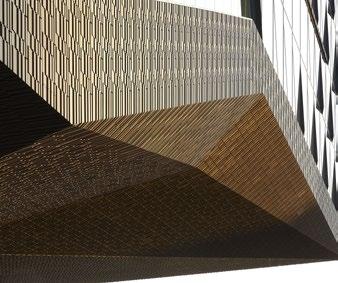

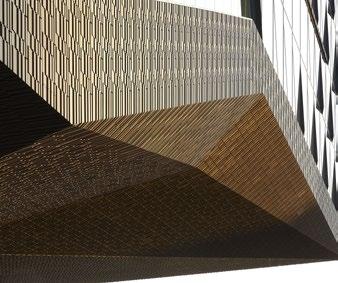

The centre’s glazed façades with precisely engineered external louvres transform into the warmer timber-based material palette of Business Stadium Central’s interiors.

Located within Vilnius’ humid continental climate, annual solar analysis has defined the composition of the façade’s louvres and balconies to reduce direct exposure from the summer sun while optimising solar heat gain in colder periods.

These external shading devices are aligned with the sun’s lower altitude between October and April of approximately 38 degrees and are perpendicular to the highest position of the sun in Vilnius’ summer sky of 151 degrees. Sustainable building systems will reduce the development’s embodied carbon in construction and its energy use in operation.

Digital optimisation design processes have minimised the amount of materials required for the structure and are integrated with procurement systems that increase the project’s recycled content.

36

A new place to gather in

The timber for the interiors will be from certified local sources and included within the project’s overall supply chains that have been established to reduce delivery distances. All specified materials are evaluated to enable disassembly and reuse at the end of the building’s operational life.

Using natural hybrid ventilation for most of the year, high-efficiency heat exchange and recovery systems will reduce energy consumption while double-insulated low-E glazing provides excellent levels of natural throughout all public spaces and workplaces.

The FAÇADE #28 2023 | 37

Architectural Design

38

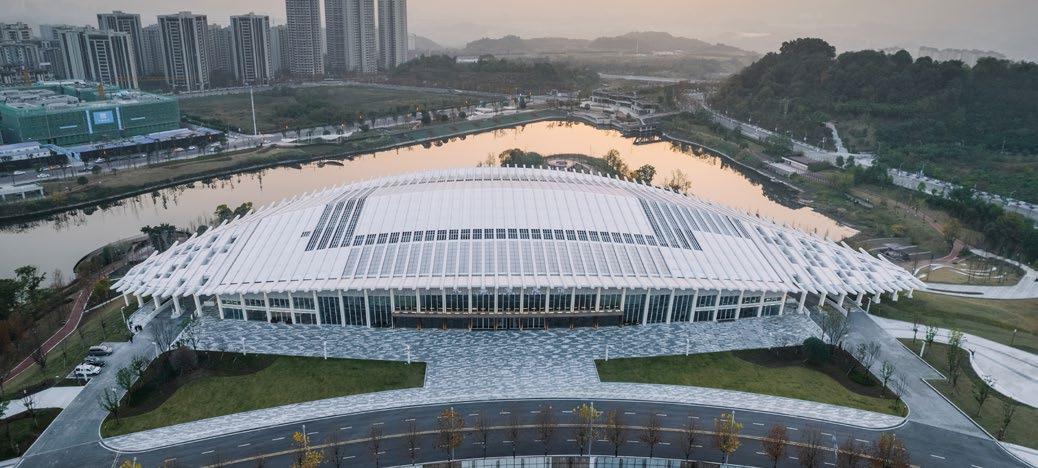

ARCHITECTURE

that integrates with NATURE

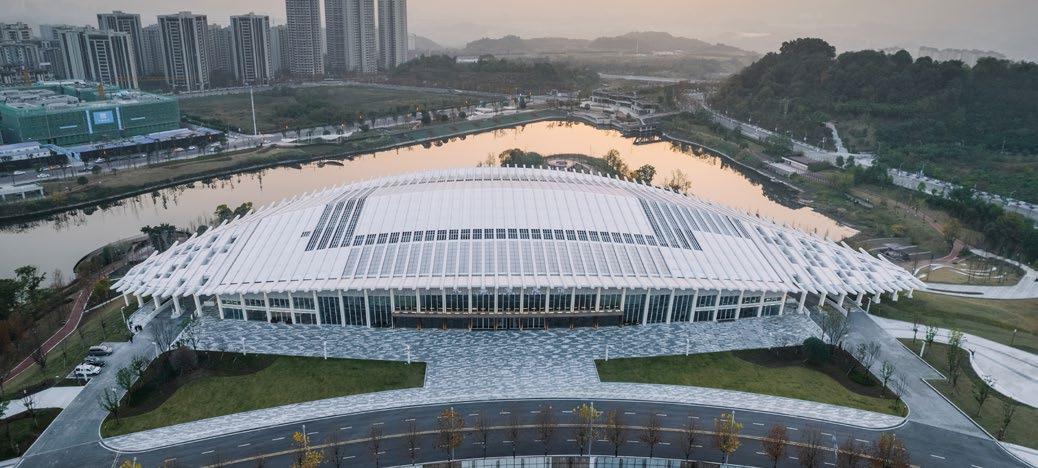

Built with a highly customised parametric design, Lijia Smart Hall, Chongqing, is recognised for its organic design that is integrated within a natural park setting.

Sitting at the Lijia Intelligent Park in the municipality of Chongqing, the 15,000 square metre Lijia Smart Hall is expected to become a central stage for the annual Smart China Expo, a professional event to encourage global exchanges of smart technologies and smart industry.

Looking from afar, Lijia Smart Hall rests like a cloud by the lakeside in the park. Coincidently, the name of the lake is Baiyun, which means white cloud in Chinese. Instead of a gigantic composition towering over its environment, Gensler’s design for Lijia Smart Hall achieved a real organic architecture that celebrates and is in conversation with nature.

HARMONY AND COEXISTENCE

Envisioning an iconic architecture piece that both lives up to its role and is fully integrated with surrounding lavish vegetation, the Gensler team developed the design focusing on eight principles— simplicity, relevance, timeless, distinction, scalability, technology, experience, and connectivity.

Inspired by the ambience of Chongqing—a city well-known for its mist-covered hilly landscape, and two major rivers that dissect the

The FAÇADE #28 2023 | 39

Architectural Design

Information and Images: Gensler

land, the architectural geometry features an organic and fluid style which coexists harmoniously with its environment.

One essential element contributing to the architecture style is Y-bar, a design system allowing flexibility to be adopted for various architecture elements including structure, roofing panels, ventilation systems, façade glazing, sky lights, light fixtures, and drainage system, offering a consistent aesthetic appeal throughout and lifting the large volume program in a graceful way.

Such a design language is retained in interior design, which is also done by Gensler. While following a more traditional Chinese style as requested by the client, the interior design team manages to create a holistic impression by weaving the Y-bar element into interior walls and the central core design. Unique landscape of Chongqing is encoded into details such as gate patterns and decorative glass.

PERFECTLY PARAMETRIC

To program the geometrically complex architectural form in a highly efficient and accurate way, Gensler introduced customised parametric design. Instead of updating each designer’s elements individually, parametric algorithms automatically updated all associated updates whenever a project-specific value was modified. This enabled a huge advantage in standardising building components during fabrication and construction.

The team furthered its efforts in innovation by applying Ultra High Performance Concrete (UHPC) for façade cladding. The sustainable and flexible material allowed the team to control the finish to a rustic white sculptural quality, which minimises building heat gain via solar radiation and reduces energy demand on HVAC system to keep the building cool during summer season.

Skylight and high glazing ratio bring plentiful natural light into the building throughout the day, creating a transparent space that is visually connected to the natural setting while reducing operation energy consumption. The well-lit pre-function zone serves as a pleasant relief for visitors between different sessions of events and forums.

40

The FAÇADE #28 2023 | 41

Warm spring weather greets the

18TH INTERNATIONAL CONSTRUCTION INDUSTRY ELITE GOLF INVITATIONAL TOURNAMENT

Co-organised by Hong Kong Façade Association (HKFA), 18th Kinlong Cup International Architecture Industry Elite Golf Invitational Competition, was successfully held on 10 April, 2023.

HKFA VP, Sammy Hui, lead a delegation from Hong Kong and gave remarks at the Opening Ceremony, as well as presenting awards to the day's winners.

"The event was warm and welcoming with this healthy and happy industry event creating synergy for industry elites to connect together for better collaboration," said Hui.

Held at the beautiful Mission Hills Gold Club, more than 300 business elites from industries such as real estate, architectural design, consulting, decoration, steel structure, and the door, window and curtain wall industries, participated in this year's competition, the first since the end of the three year pandemic.

由香港建築幕牆裝飾協會(HKFA)協辦,第十八屆堅朗杯國 際建築行業精英賽高爾夫邀請賽,於4月10日成功舉辦。

香港建築幕牆裝飾協會副主席許志鵬先生率香港代表團到訪,並於 開幕式上致辭及為當日的獲獎者頒發獎項。

「這次活動氣氛熱烈,喜見健康愉快的行業盛會,匯聚業內精英為了 更好的合作而再聯繫在一起。」許先生說。

今年的比賽在美麗的觀瀾湖黃金會所舉行,來自房地產、建築設計、 顧問、裝飾、鋼結構、門窗和幕牆等業內的三百多名商界精英也參加 了今年的比賽,這也是三年疫情結束之後的首場比賽。

42

Events

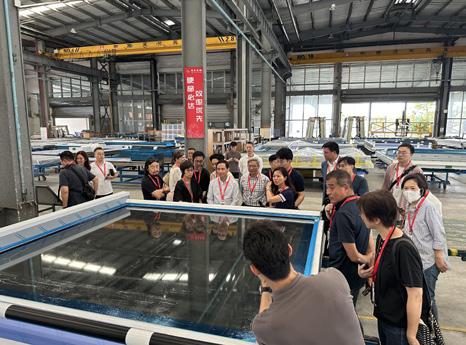

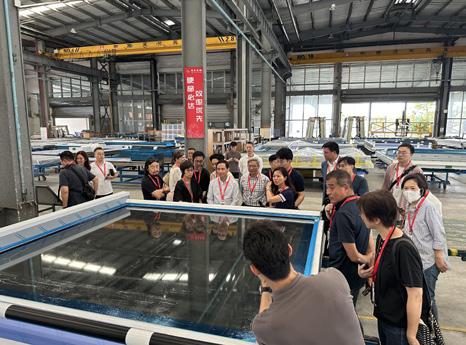

Far East Curtain Wall (Zhuhai) Factory Visit to GBA

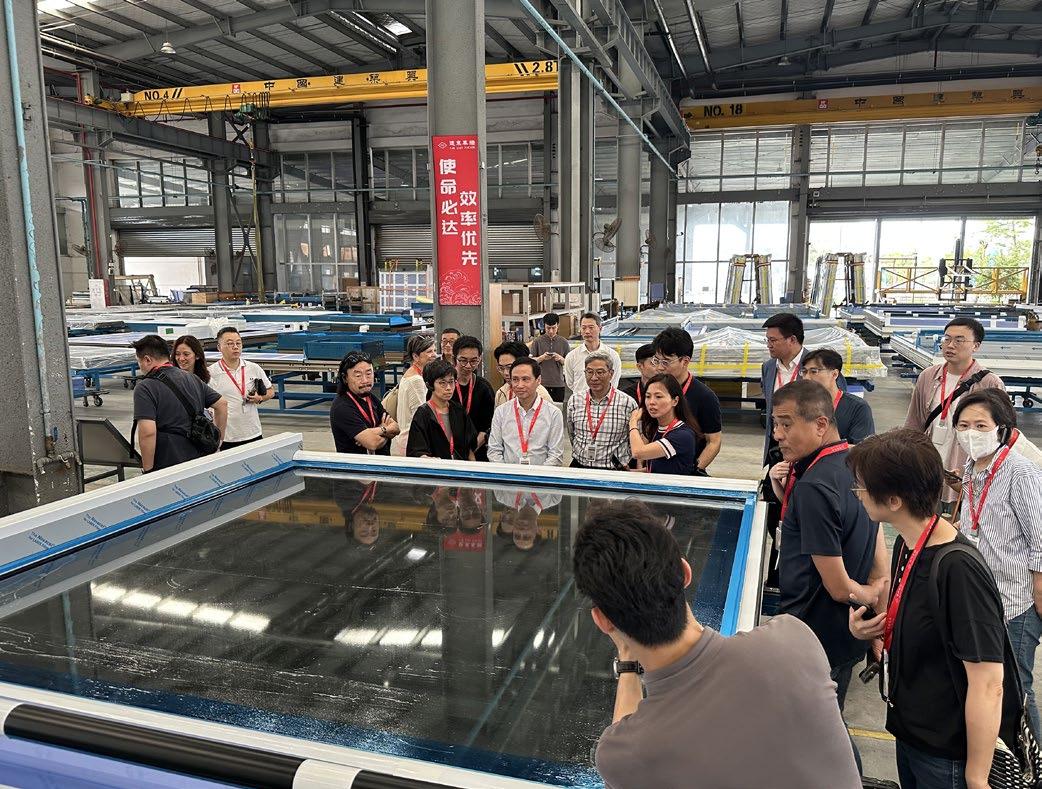

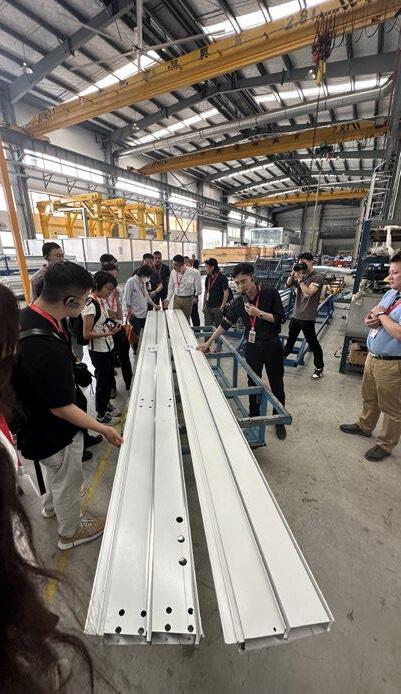

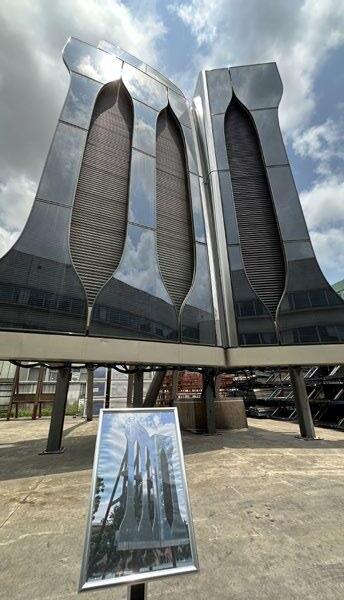

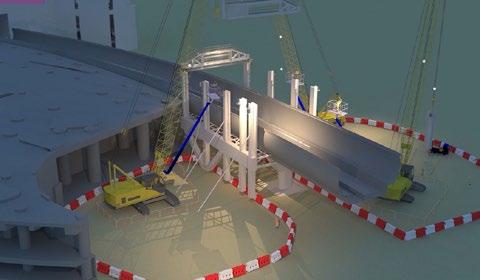

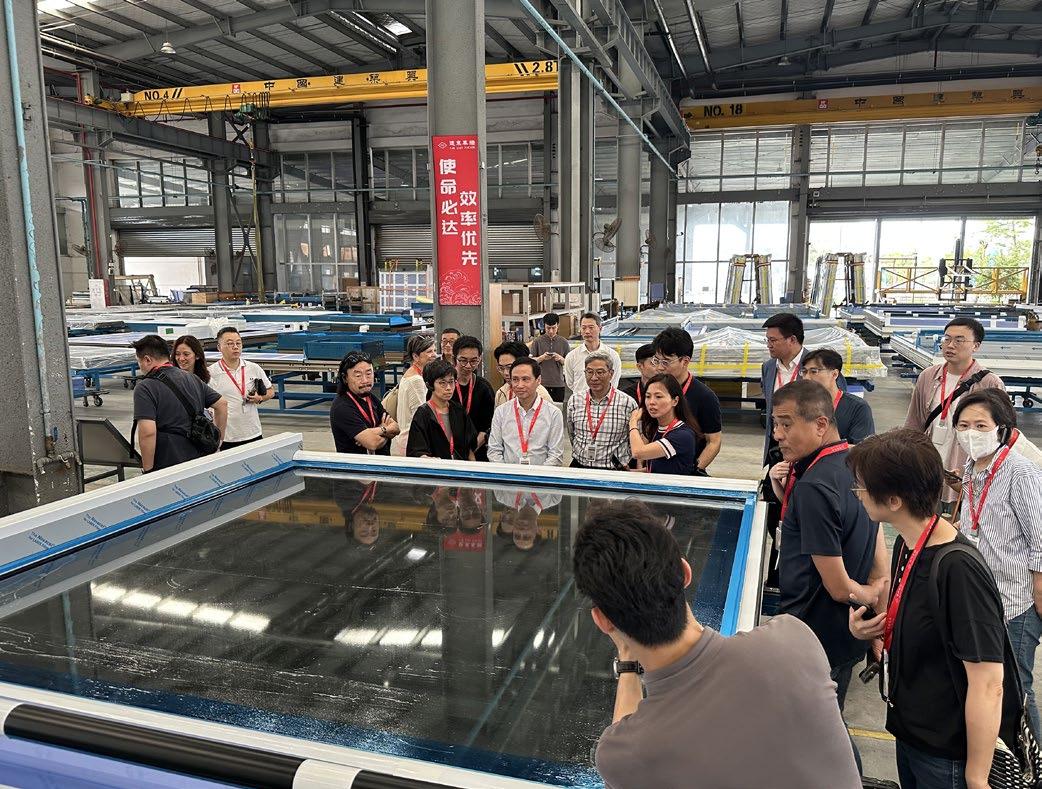

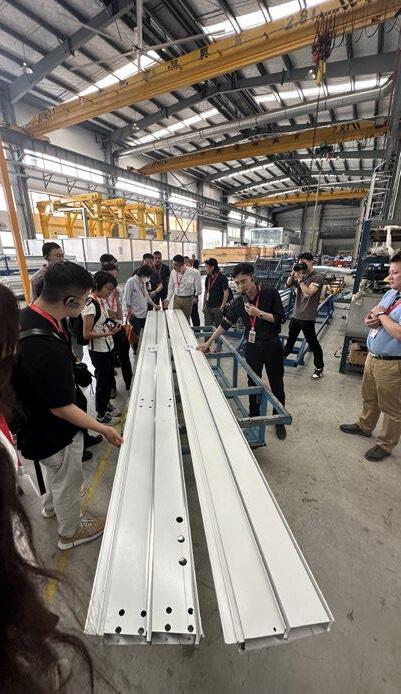

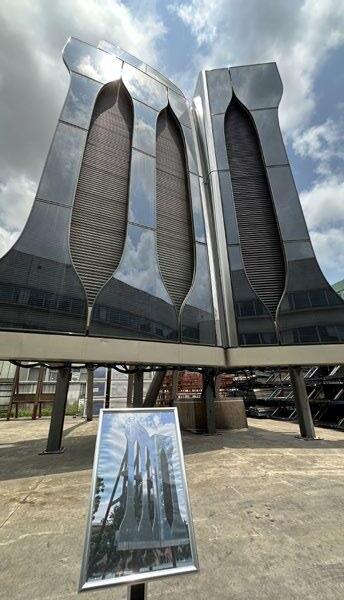

Supported by the Hong Kong Façade Association (HKFA), a group of HKFA members, led by Ms. Yinmei Chan, chairman of the Hong Kong Branch of the American Institute of Architects (AIA), visited the factory of Far East Curtain Wall in Zhuhai on 6 May.

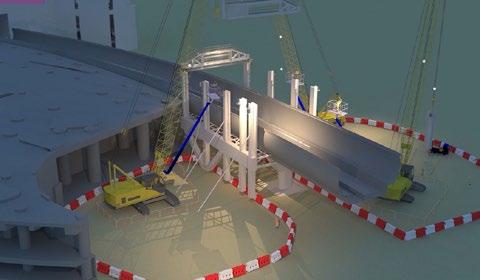

During the visit attendees experienced the production of complex curved curtain walls for use in high-rise buildings currently under construction in Central Hong Kong. The visit helped everyone to understand how to use robotic arm technology for aluminium extrusion fabrication worked, while they were also able to observe, the prototype mock-up of double curved curtain wall panels.

The factory visit helped those present to understand the electronic processing of drawings transferred from BIM to the factory’s automated production process, while sharing the details that must be considered in the design of such complex exterior wall systems.

The Far East technical team also introduced BIPV facade technology. Through the comprehensive addition of the BIPV system in the Zhuhai factory perfectly showing the building’s curtain wall photovoltaic integration from the roof using light-transmitting BIPV laminated glass, BIPV curtain wall, BIPV skylight and even BIPV balustrade, as well as incorporating various sustainable items into the design, in order to create a more environmentally friendly building, whilst also maintaining user comfort.

HKFA and AIA would like to thank Mr. Gao Fei, General Manager of Far East Curtain Wall (Hong Kong) Co., Ltd. for his support, and Mr. Zhu Minfeng, Chairman of Far East Curtain Wall (Zhuhai) Co Ltd and his technical team, allowing participants to fully understand the latest façade automation technology.

44

The FAÇADE #28 2023 | 45 Events

46

由 AIA 美國建築師學會香港分部會長 Yinmei Chan 女士率領之下,幕牆協

會作為活動支持機構,一眾會員於5月6日參 觀了遠東幕牆位於珠海的加工廠房。

感謝遠東幕牆(香港)有限公司總經理高飛先 生的鼎力支持,以及遠東幕牆(珠海)有限公司 董事長朱敏峰先生及其技術團隊帶領,讓參 加者全方位了解最新幕牆自動化加工技術。 過程展示出在香港中環正在興建中的高層建 築複雜雙曲弧形幕牆生產線,讓眾人了解如 何利用機械臂加工幕牆鋁型材,此外亦參觀 了雙曲單元的觀察樣板,了解從 BIM 轉化的 電子加工圖傳送到工廠自動化生產過程,加

深認識箇中必須考量的各項細節,於設計此等 複雜外牆系統時需要考慮的事項。

遠東技術團隊同時介紹了幕牆整合太陽能光伏 技術,通過全面在珠海廠房加建 BIPV 系統,完 美地實踐建築幕牆光伏一體化,從屋頂採用了 透光 BIPV 夾膠玻璃、BIPV 玻璃幕牆、BIPV天 窗、以至BIPV 欄杆等,在設計中盡量納入任何 可持續的措施,用以打造更環保的建築物,同時 保持用戶的舒適度。

活動相片請瀏覽

https://hkfacade.org/photo-gallery/photogallery-2023/

The FAÇADE #28 2023 | 47

Events

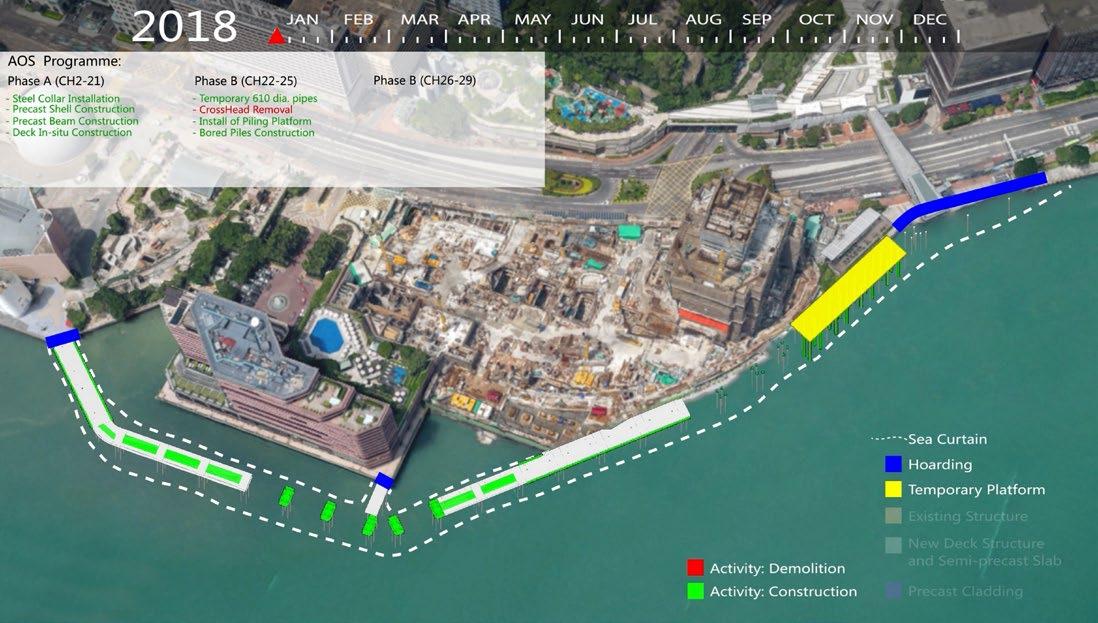

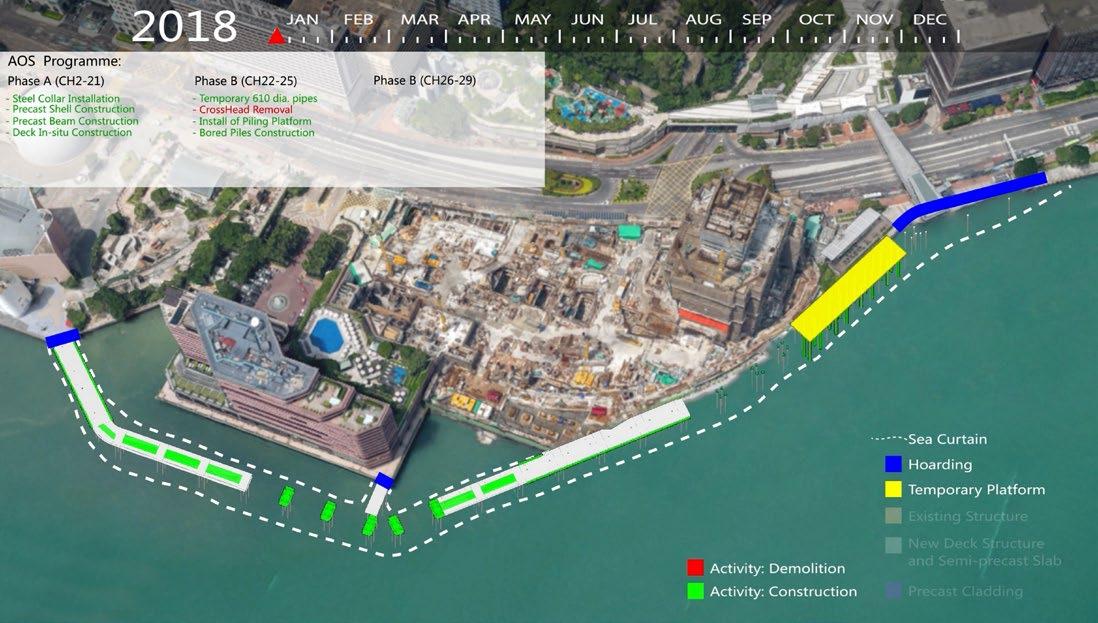

LEADING THE FIELD IN BUILDING INFORMATION MANAGEMENT

The Façade talks to ConTech pOint about the latest technologies available for the AEC industry

Text: Elizabeth Dooley

Text: Elizabeth Dooley

Founded in 2018, Hong Kong technology company ConTech pOint (CTO) is a specialist in bespoke digital solutions for clients in the design and construction industries, helping professional practices in their migration towards digital delivery. The company works to promote the use of Building Information Management (BIM) and other technologies, such as Common Data Environment (CDE) , Digital Works Supervision System (DWSS), Smart Site Safety System (SSSS) and project management cloud SaaS.

Today, the CTO’s footprint covers commercial and residential developments, institutional projects including sports facilities, theatres, education and medical facilities, and civil infrastructure projects, such as roadworks, tunnels and bridges.

As Welie Ng, General Manager, explains, with a headcount now standing at around 50 people the company’s skillsets include

BIM and building engineers with CIC chartered project management qualifications; an IT development team with web and app developers supported by project managers and specialists in product and service customisation; IT support and customer success; dfMA digital designers and MEP design coordinators.

“We recruit staff with these four core skillsets and with the relevant experience for construction projects during the inception, design, construction and handover stages of work. It is a basic requirement that our staff are not mere digital technicians but are seasoned leaders, coordinators and engineers who understand the process of local practices.”

Ng, acknowledges that today and in the coming decade, Hong Kong is facing a critical shortage of skilled engineering professionals, including BIMers. Indeed, CIC Hong Kong estimates a shortfall of between 1000-2000 BIM managers and coordinators in the next

48

ten years. “Basic training is commonly available from local education and vocational institutes. However, competent BIMers need to be supported in real practice after basic training. IT and support professionals, as well as design professionals within the construction industry are also in scarce supply currently in Hong Kong, and dedicated professionals must be trained in-house,” he observes.

While there are other technology companies in the market, CTO prides itself on being a first-choice partner due to its extensive experience of local private and public works currently in the tender, design, construction and fabrication phase of projects. Further Ng points out that around 25% of CTO employees are chartered CIC professionals. CTO also provides realtime BIM without software to support remote, collaborative and coordination works, as well as producing grade AA simulation in-days for clients through engaging video and visual materials.

“Our realtime BIM, hoisted in CTO’s proprietary CDE SaaS platform, can facilitate BIM quantity take off (QTO) to help surveyors improve productivity from BIM practices. QTO is a fully automatic material calculation engine and application platform based on building information modelling. It uses digital technology to shorten the calculation and update time of major engineering material consumption. The SaaS cloud system, known as Construction Information Anywhere (CIA), acquired ISO 27001 and 27017 certificates for its IT and Cloud security. This is one of the very few platforms in Hong Kong that can handle document, drawing change management workflow and site safety. CIA is specifically designed for local design and construction practices and includes features that enable us to tackle construction pain points, such as working on no-network-coverage areas, as well as supporting teamwork in small groups, and front-line works with back office engineers. Documents are fully searchable, and the online document and drawing registries allowing engineers and surveyors to crunch data within the system using common spreadsheet formats such as Excel,” he explains. “Our CIA System is on the Pre-approved List of the Construction Industry Innovation and Technology Fund (CITF) with the Pre-approved Code PA20-127.” Ng added.

SCOPE OF SERVICE

CTO as an independent BIM advisory, consultancy and auditor with ISO 19650 BIM professional recognition, work includes designing digital workflows, covering but not limited to BIM project

management, modelling, design, coordination, simulation, quantity take off (QTO), augmented reality capturing through 360 degree photos and 3D scanning, as well as auditing the quality and progress of a BIM-enabled project.

CTO works with all sectors within the Architecture, Engineering and Construction (AEC) industries, including owners and project managers, architects and consultants, main contractors, package contractors and facility managers. The company briefs clients through workshops with their staff, augmented with BIM technologies and has also delivered basic BIM software training for a large local contractor to over 1000 staff of mangers, engineers and surveyors.

“Our customised CIA solution is targeted primarily at developers and main contractors, while this propriety CDE platforms are designed to elevate the performance of all players within the AEC industry. As such, we are able to position ourselves as a key member of the client’s consultant team or technical partner, through formulating BIM strategies and contractual arrangements, technical specifications and execution plans for specific projects. For example, for architects this might mean helping to visualise and evaluate their designs through BIM, or for main contractors enriching their competitive profile to meet BIM expectations and to deliver BIM-enabled constructions, plans and to audit control measures,” he explains.

The output is impressive: CTO’s propriety CDE has been commissioned for more than 80 projects, served more than 5000 users and 400 companies, with 11 types of workflows digitally deployed for document approval and more than 1.2 million documents handled digitally via the Cloud.

Examples of CTO’s BIM projects include a commercial project at Chap Lap Kok, where CTO used BIM to produce all CSD and CBWD drawings, eliminating manual drafting work and eliminating all drawing inconsistency issues; a residential development in Wong Chuk Hang where the company helped orchestrate all designers to deliver and collaborate within a BIM environment to allow the project owner to evaluate the design flat mix to maximize return value and to eliminate major multidisciplinary buildability

The FAÇADE #28 2023 | 49

Tech Talk

issues at the tender stage of work; working with the architect at a hospital project to automate over 500 layout drawings with design iterations in just four months; use of reality capture technology augmented with BIM at a conservation project in North Point to retrofit the architectural, structural and E&M fabric of an irregular-shaped building to millimetre grade accuracy.

BENEFITS OF BIM

CTO as a technical solution, BIM is designed to enhance productivity, transparency and scalability, by digitally automating manual and repetitive processes, identifying and tracing times, people and tasks, and making digital processes and data through cloud-based solutions made accessible anytime and anywhere. The effect, according to Ng is, better quality projects delivered by collaborative teams with less risk.

“BIM allows owners to take back control of production information and hence make more intelligent and confident decisions leading to better visual and performance outcomes, better cost control, social response, and end-user benefits,” he says.

But it’s not just about adding value through reducing construction costs and increasing ROI. Technology is also about modernisation of an industry keen to absorb talents to cope with the volume of Hong Kong’s upcoming development challenges.

From a management perspective, Ng advocates that project teams can take a more active role in the design, planning and construction processes, with drawings and documents such as work permit approvals, site conditional constraints, site progress, incidence and compliance issues and related figures made transparent and timely to all participants

“At CTO, we believe that BIM helps us to raise the ESG quotient of corporations, enhance supply chain sustainability, and to work collaboratively and remotely to tackle any complex situation, thus enhancing business continuity,” he says.

“It allows us to add value to our clients’ operations and projects by drastically increasing efficiency relating to information handling at all stages of work, whilst reducing redundancy in harnessing 3D visualisation, reducing time lost in correcting erratic design and site work, while improving responsiveness to sensitive and ad-hoc issues and creating reusable sustainable data for ongoing and coming projects,” he adds.

THE FUTURE IS NOW

He also has a comment for the industry that if BIM is not adopted as widely this could lead to Hong Kong suffering from a lack of competitiveness, and with larger and more complex construction projects leading to the city being left behind by the increasingly digitised and modern production supply chain of mainland China.

“There are wide misconceptions that projects can still be realised without modern BIM or digital tools, or that it’s solely the client’s or the designer’s responsibility to come up with feasible and effective building design. Other misconceptions are that nothing can be done to help Hong Kong’s ageing workforce or that they’re too old to take on the additional burden of replacing traditional tools with digital ones. This is simply not true – BIM is something to be added to the skillset rather than hinder it and Hong Kong cannot afford to fall behind, and CTO exists as a partner to help bridge this gap,” he concludes.

50

There are wide misconceptions that projects can still be realised without modern BIM or digital tools, or that it’s solely the client’s or the designer’s responsibility to come up with feasible and effective building design.

- WELIE NG, GENERAL MANAGER

- WELIE NG, GENERAL MANAGER

The FAÇADE #28 2023 | 51

Tech Talk

52

The FAÇADE #28 2023 | 53 Tech Talk

54

The FAÇADE #28 2023 | 55 Tech Talk

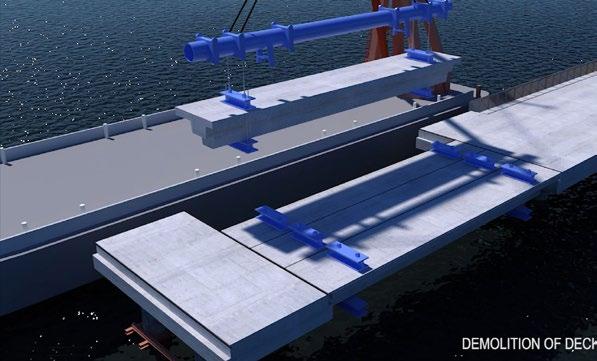

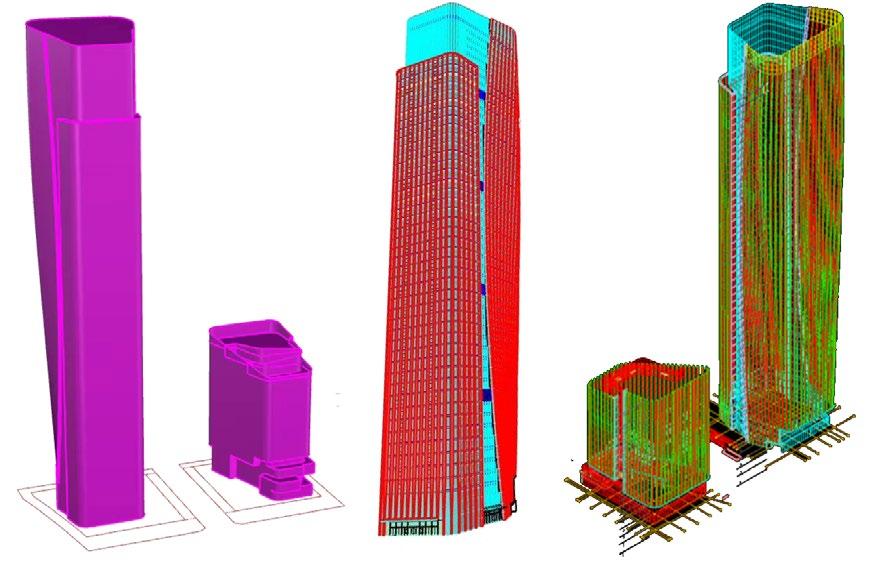

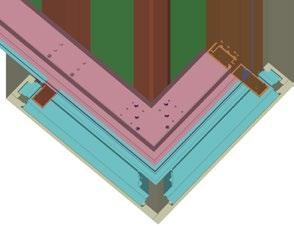

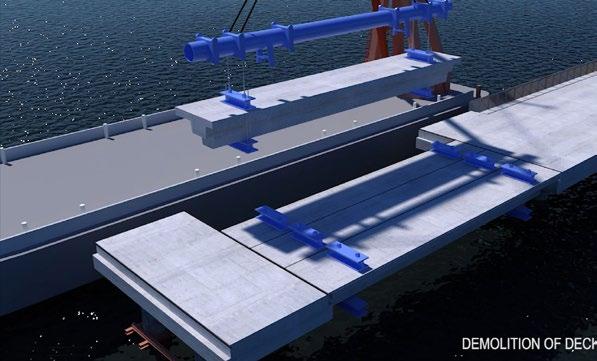

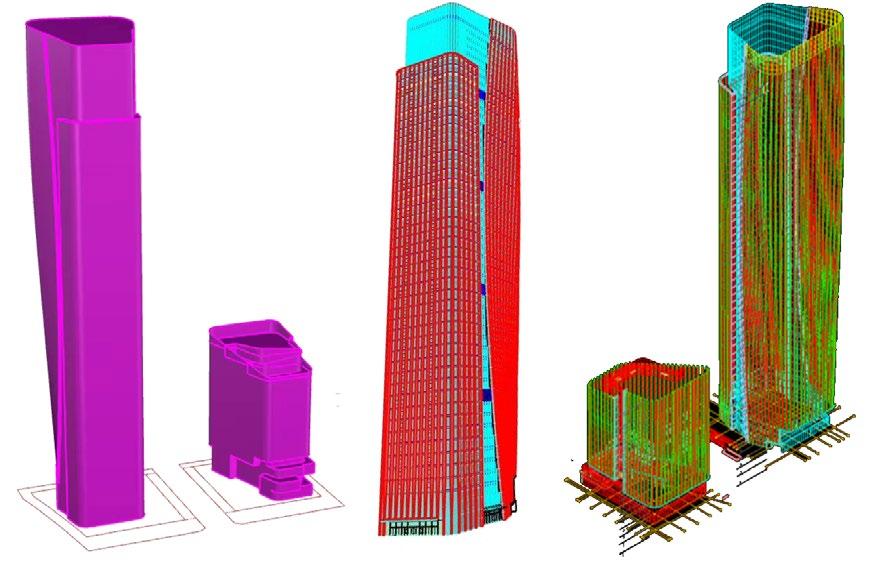

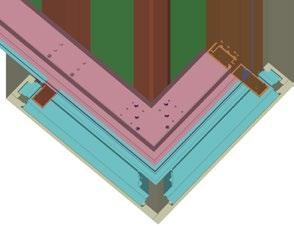

Discussion on BIM Technology Development of Building Curtain Wall Industry in Hong Kong

What is Design Visualization?

This is a very cost-effective application. If I were to convince a client to implement BIM as a BIM consultant in Hong Kong, design visualisation would be my selling point. That is to say, BIM implementation is completed once the model achieves LOD300 or at most LOD350. Unfortunately, almost every tender requires BIM model to be LOD 400 and LOD 500, a must for projects from Swire, Nan Fung, and Henderson.

Here is some common software that BIM uses for design visualisation:

“bimobject” for BIM Family inventory; Revit and Tekla for BIM modelling; BIM TRACK and NAVISWORKS for design problem solving and tracking; BIM 360 for cloud storage and multi-platform model viewing; Numerous other applications, such as HoloLens for AR, Ecodomus for point cloud scanning and model comparison are available.

In fact, the application of BIM in design visualisation makes a lot of sense. For instance, a baseline model built according to a tender drawing to visualise the drawing of 2D CAD to 3D model. A 3D model developed according to the shop drawing to see if the layout, section, elevation, details, schedules and callouts of the shop drawing are consistent.

To check whether there is sufficient detail drawing at corner location, whether the embedded part of the drawing has integrated various structural conditions and changed into various styles, whether the whole working point, working line and grid are consistent with CAD drawing.

Most importantly, when the model is submitted to the main contractor, it becomes the centre point of all data.

The mechanical and electrical outlet locations, aluminum plates, fences, ceilings, structure and curtain wall converge into one giant data-much model, making it easier for the main contractor to manage and coordinate the progress of all parties and to know where the consultant needs to provide guidance.

What is Design for Manufacture and Assembly (DfMA)?

DFMA is a concept during design stage when manufacturing and assembly are taken into consideration so that the products designed by engineers have good manufacturability and assemblability.

Fundamentally avoiding the manufacturing and assembly quality problems in the later stage of product development. DfMA existed even before BIM. The pagers, motor cars and other products we used were moulded during their design phase too. The design process and modelling are inseparable.

When the model is finalised, so is the design and this model can be directly used in moulding for product prototype. The construction industry began to promote the use of building information modelling technology 20 years ago, which gradually developed into today’s BIM.

DfMA then has been given new meaning and technical requirements under BIM. DfMA has applied in-depth with BIM in the concrete prefabrication of Housing Authority, MIC composite house advocated by CIC, special-shaped curtain wall unit plates, steel structural components, steel framework of piers, etc.

After the Hung Hom station ‘incident’, the government has also been promoting the prefabrication of steel bars which also requires the BIM model to achieve DfMA.

56

Singapore’s BCA is leading Asia in applying BIM with DfMA. Back in 2017, Singapore required online submission of BIM models for all projects for review to adopt the method of “submit first and review later”, with a retrospective period of seven years. BIM has since become inevitable, like doing taxes!

In the same year, DfMA guidelines were launched. Thanks to the abundant modelling resources in Malaysia, India, and the Philippines, they afforded the human resource needs for projects in Singapore, so they can adopt DfMA. On the contrary, Hong Kong stayed in its comfort zone and, for a short period of time, tendering was not even allowed without the membership certificate issued by HKIBIM (Hong Kong BIM Society). Fortunately, “or equivalent” has been added to the requirement now.

So, should the curtain wall industry in Hong Kong encourage DfMA?

What benefits will DfMA bring to the project?

I am not sure how to explain this from a technical point of view, but maybe the failure of BOARD (遠大) and Jangho(江河) in the Middle East provides us an answer. A DfMA level BIM model provides more control over supply chain management strategies and more space to negotiate on procurement, hence, more profit.

Since the completion of Zaha's Opus project in 2016, my team has been present in Dubai over recent years providing DFMA and FIM services. We have grown over 40% of the market share because our services do not stop at model development.

We also provide procurement service for our Dubai's customers directly from Foshan, Dongguan, Huizhou and other places. DfMA

is the most cost effective in comparison with BIM for BIM and Design Visualisation while the benefit ultimately goes to the real estate developer.

When can we out-source a job to multiple contractors to balance the cost? Which material or systems are more suitable for remeasurement according to area, while others remain within units? Which measurement system should we use to set price with manufacturers? How do we determine when to sign contracts with contractors? Is it possible to compare DfMA model with baseline model and see which VO items are certain?

Clients’ interest in BIM would increase dramatically if we can relate the cost management with the model instead of just design coordination. Unfortunately, developing a curtain wall DfMA model requires Rhino or Catia while 90% of our local BIM modellers use REVIT. There are no more than four companies that can provide curtain wall DfMA in Hong Kong. (For the specific recommendation list, please refer to the HKFA Secretariat.)

Therefore, curtain wall contractors should reserve enough budget when surveying the price to avoid taking risks because of the high cost of DfMA. Though contracts require LOD400 or LOD500 BIM model, an unfinished LOD350 could be a more cost-effective option.

Co-Founder of VDC Engineering Limited

Wayne has 15 years’ experience in BIM, VDC & DfMA Design and Engineering. Wayne has been in a principal manager role for the HKAA’s Mega size Project: Third Runway Concourse and Air f ield, New Traff ic Control Tower. He is also ant icipated couple of remarkable façade BIM projects in Hong Kong and Dubai. He has prof icient in combining the virtual design and construc t ion work f low with dynamic risk assessment methods in large-scale construc t ion projects.

The FAÇADE #28 2023 | 57

WAYNE LIN

Tech Talk

58 Tech Talk

Since 2002 ROF Media has grown in partnership with Hong Kong’s Building Industry. Renowned in the local development community for unrivalled client servicing and innovative content creation, we are 100% focused on providing high-quality media services for the Architecture, Engineering and Contracting (AEC) sectors.

In a crowded marketplace, relevant, professionally designed and eye-catching content is important to represent your company’s prestige, expertise and scope of services, contributing to an industry-wide dialogue of ideas and knowledge sharing. ROF Media is part of the dialogue where industry is most active.

We specialise in creating tailor-made content for our client’s advertising, media, marketing and communication, in print and online. For more information visit www.rofmedia.com

Subscribe to our e-Newsletter Follow us on LinkedIn Read our books @ISSUU We Publish

Dow Building Science website: dow.com/buildingscience Visit us on Twitter @DowHPBuilding Contact Dow Building Science: dow.com/customersupport Visit us on LinkedIn Dow High Performance Building © 2022 The Dow Chemical Company.All rights reserved.

Building tomorrow with Carbon Neutral Silicones

Kaloyan Erevinov Senior Associate

Kaloyan Erevinov Senior Associate

Text: Elizabeth Dooley

Text: Elizabeth Dooley

- WELIE NG, GENERAL MANAGER

- WELIE NG, GENERAL MANAGER