Scan the QR code with the mobile camera.

Scan the QR code with the mobile camera.

Scan the QR code with the mobile camera.

Scan the QR code with the mobile camera.

On the verge of an autumn that is expected to be complicated by the rising inflation, the industry faces new challenges at the European level, such as progress towards new housing systems without cages in farrowing pens. The ban on locking the sows in farrowing pens is becoming a reality in countries like Switzerland, Sweden, and Norway. Even in Spain, we already find breeders who are committed to working with free farrowing systems with excellent results. In this sense, proposals from the European Union are expected within the framework of a new animal welfare law for 2023, in which gradual elimination and finally the prohibition of the use of cage accommodation systems could be proposed.

For this reason, from Rotecna, we work to offer units that adapt to the new trends and needs of the industry, to improve animal welfare and facilitate the work of breeders.

New accommodation systems in a phase as complex as farrowing will also involve investing in staff training, a key factor in the success of farm production data. As is known, people are the most important asset of a farm, because they are the ones who carry out all the daily tasks and supervise the proper functioning of the facilities.

Already in the business field, we are a few weeks away from the EuroTier 2022 celebration in Hannover (Germany). Four years after the last face-to-face edition, we will be at the international benchmark fair for our industry again. You can find us in Hall 17—stand H06, where we will display our wide range of products for the industry, and we will meet again with our clients. See you in EuroTier!

Antonio Pinos, CEO, Rotecna.

Participation in international fairs.

The Witches of Viladrau.

Stainless steel drinkers.

Sows slat 600x600 mm.

Ramgerpig: “Thanks to Dositronic, we have noticed a significant increase in the piglet’s weight at weaning”.

How to face the change toward free farrowing successfully?

Uruguay doubles pork consumption in the last 10 years.

Director: Antonio Pinos.

Editor: Francisco García, Tamara Lombardo. Images edition: David Mercado.

Translation: Sam Smith.

Print: Imprenta Barnola. L-41-2007

Rotecna's World's editors accept no liability for contributor's opinion.

We arrived at the verge of autumn after a summer in which we travelled to the United States, Colombia and Vietnam, where we took part in the main events in the pork industry that are held in each of these countries, intending to bring Rotecna’s pig equipment solutions closer to its pork producers.

Aware of the importance and value of the World Pork Expo within the American pork industry and also worldwide, Rotecna ventured to be present at this year’s edition, which was held from June 8 to 10 in Iowa (United States). It did so side by side with American Resources, its distributor in the North American country, with whom we presented the latest news from our brand, such as electronic feeding systems or slurry management. Despite the current situation of inflation and growth in production costs, over 10,000 producers and professionals from the pork industry attended the event to learn first-hand about the latest news and technologies in our trade.

The Colombian city of Cartagena hosted from July 13 to 15 the twentieth edition of the Porkamericas International Congress, which Rotecna took part in, accompanying its distributor in the country. The event had renowned national and international speakers and a commercial exhibition with over 60 exhibitors. Rotecna’s products aroused great interest among those attending the event.

In its commitment to the Asian market, Rotecna travelled to Ho Chi Minh where, from August 3 to 5, the Ildex fair took place. Among all the novelties that our company presented to the public, the Dositronic, the electronic feeding system for pregnant or farrowing sows, was the focus of many looks and generated a lot of expectation. Over 10,000 participants from up to 45 countries attended the event, confirming the potential of the fair as a key to creating contacts and agreements for the livestock industry in Vietnam and Southeast Asia countries.

From November 15 to 18, Rotecna will take part in the main European event in the livestock industry, the EuroTier fair, to be held in Hannover (Germany), and in which we will present our products in a stand of 204 square meters. From Rotecna, we are already working to make our presence a success!

Rotecna has participated in the World Pork Expo, Porkamericas and Ildex Vietnam.

Catalonia is one territory where more women have been executed as witches and where the first known law in Europe on the crime of witchcraft has been documented in the book “Ordinacions de Les Valls de Àneu”, from 1424.

Witches’ hunt in Viladrau

Viladrau had the dubious honour of being the Catalan locality where more women where hanged. Legend has it that one night in November 1617, over 400 years ago, a group of women gathered in the forests of Sant Segimon. A few days later, a large hailstorm destroyed the crops, leading to a witch hunt, who were blamed for that disaster.

There will always be doubts whether the coven occurred, but interrogations under torture and killing women are well documented. The names of the fourteen women who were hanged are known, as well as the chain of severe weather that took place in those years. They accused all

these women of being guilty because they knew about natural remedies and had a pact with the devil, which is why they were executed in the centre of town.

In order that such a dreadful thing does not fall into oblivion, since 1997, and within the acts of the Fira de la Castanya de Viladrau, on October 31 at the fall of All Saints’ Night, Viladrau turns to the Witches’ Dance celebration, a staging of the events that happened with music, lights, and fire.

The Witches’ Dance is a dramatisation of the events, between the tragic incident and the legend: a group of witches is represented, with all the names and surnames of women accused of witchcraft and executed in the 17th century, dancing to the sound of drums around a bonfire they perform rituals to summon demons. Throughout the show, you can see how a judge tries to stop them, accusing them of having done

Viladrau was the town in Catalonia where the most witches were executed.

evil, but the devil casts him out. Only Saint Martin de Tours, patron saint of Viladrau, could dissolve the sabbat by showing himself and declaring having planted the Holy Cross at the summit of the Matagalls, driving the forces of evil to leave.

Before the Witches’ Dance, a performance which stars the children of the town, who, dressed as witches, talk about witchcraft and sing songs.

this has contributed to the Witches’ Dance being an important part of Montseny’s intangible cultural heritage.

Beyond the inhabitants of Viladrau, many shops and restaurants mobilise for this celebration. And it is then, in the middle of autumn, when Viladrau is a land of quality chestnuts and many restaurants adapt their menu to include this ingredient in their dishes. There are restaurants that on the night of October 31 offer haunted ‘tapas’, small versions of their well-known dishes that give them a peculiar name, such as, “the spider’s nest”, which is a chestnut cheese salad, or “the fingers of the judge, the prosecutor, and the executioner”, which is a bowl of sausages.

Every year, the dance performed by the women of Viladrau gains a more vindictive tone and of feminine empowerment than popular legend describes, since this celebration tries to make the events that occurred clear, those murders of women. In short, femicide.

The plot still includes topics from the religious tradition, but each year’s function tries to innovate and offer the viewer something new and differentiated from the previous year. All

The events that occurred in Vildrau have been the subject of research and a source of inspiration for many writers, who have included the subject in their literary works. An example is “Persecució de les bruixes de la comarca de Vic” (Persecution of witches in the region of Vic), written by the historian Antoni Pledevall, and which collects the information found in documents from the time in which the events occurred (the legal proceedings, torture to which they were subjected, etc.). Another book where the 14 women executed in Viladrau appear is “El Defensor de les Bruixes” (The Witches Defender). Written by David Grau, it tells the story of a Jesuit theologian who is sent to Viladrau to stop the execution of these women.

Every year, the dance performed by the women of Viladrau gains a more vindictive tone.The Witches’ Dance commemorates the execution of 14 women.

Water is an essential nutrient for living creatures (approximately 70% of muscle tissue is water) and its consumption encourages feed intake; therefore, aiding access to water for animals is key to their well-being and growth.

Bowl-type drinkers made of stainless steel allow water to be dispensed in the different phases of pork production: weaning, fattening and sows. Its oval design without edges or corners facilitates cleaning, makes them very resistant, minimises water waste, keeping it fresher and cleaner because of its reduced capacity.

Rotecna’s stainless steel drinkers have an adjustable flow pacifier system placed in the lower part of the bowl to minimise water waste and reduce slurry production.

• Made of stainless steel.

• Bowl-type design.

• Adjustable ½ male stainless steel pacifier.

½ female tube connection.

• They reduce water waste and slurry production.

• Water is renewed more often and is kept cleaner than in other types of larger-capacity drinkers.

• Easy to clean.

• Maximum durability and good finishes.

• No edges where animals could be harmed.

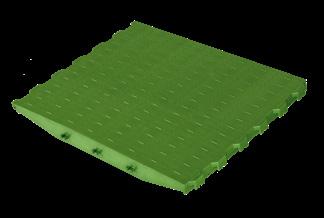

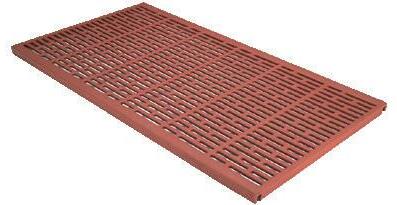

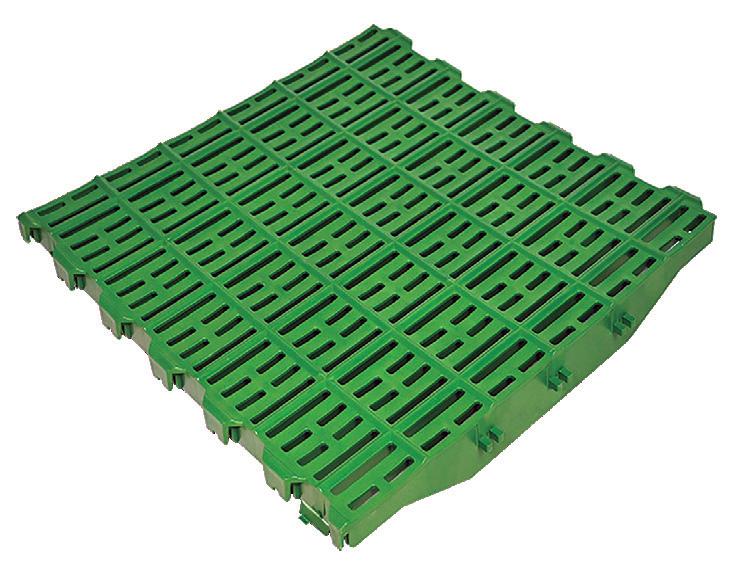

600x600 MM

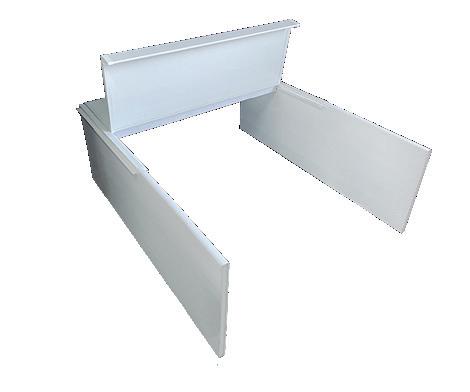

With extensive experience in the design and manufacture of floors for the different production phases, Rotecna expands its extensive range of slats with a new 600x600 mm slat model for sows.

The Rotecna Sow Slats are ideal for installing under the cage or free pen in the farrowing house, as they keep the animals clean and dry, providing the comfort without damaging the sows’ teats or the piglets’ hooves.

The direction of the interlocking ribs maximises strength, and with its concave chequered surface and convex ribs it ensures good drainage and excellent grip for the sows.

• Amplitude of 600 mm.

• Injected with heavy metal-free copolymer polypropylene.

• Surface with non-slip profiles.

• Ribs from joist to joist in the same direction as the bridges provide greater resistance and simplify hygiene.

• Ribs are interconnected in pairs, providing greater resistance.

• Good thermal insulation.

• Very resistant and durable.

• Very easy to clean and disinfect.

• Quick drying and excellent drainage.

•

Less heat loss from animals by contact.

• Soft non-aggressive surface with shoulders and nipples.

• Excellent grip for sows.

• Excellent traction for piglets to teat without damaging hooves or knees.

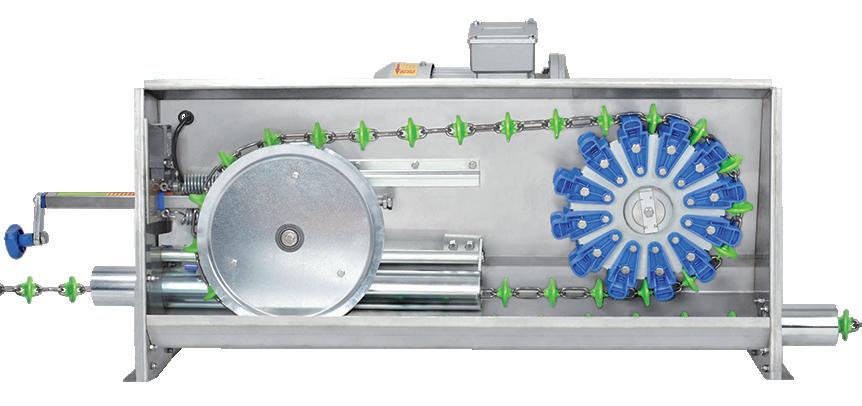

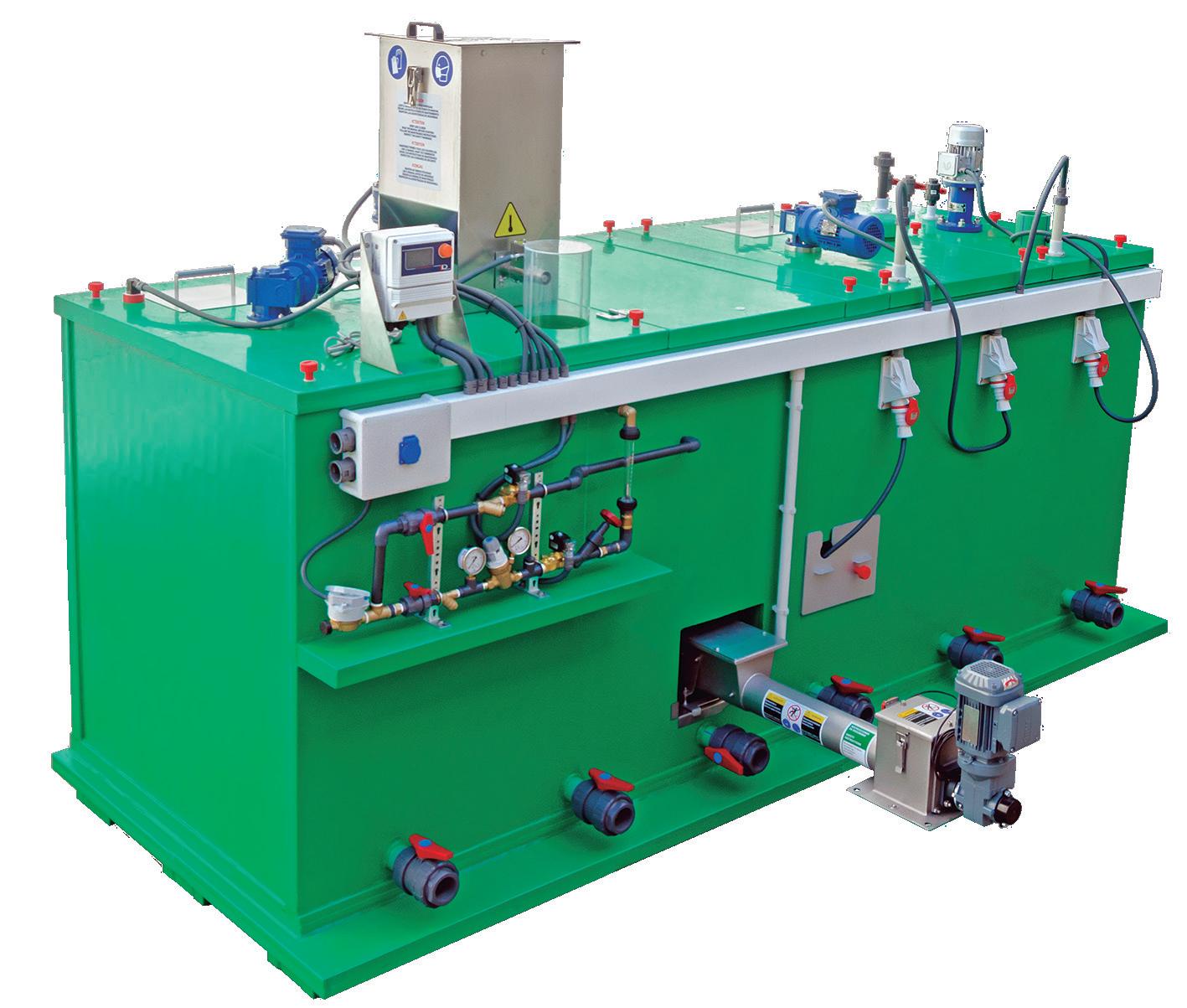

Ramgerpig is a family livestock company in Solsona (Lleida) that has different sow farms with 2,800 stalls, besides 11,000 fattening stalls and another 16,900 integrated stalls. For a few months they have opted, with excellent results, to work with the Dositronic electronic feeding system in farrowing wards. That is why we spoke with Albert Pijuan who, together with his cousins, is the fourth generation of the family that continues with the pig farming trade.

This farm has grown depending on family financial availability. In 1988, they built a first phase comprising 300 sows, which in a few years was expanded to 500 sows. Later, in 2004, we reached 1,000 sows and, finally, in 2021, we made the last expansion until we reached the 1,600 sows that we currently have. We should note that this has always been a farm

in Phase 1 and Phase 2. We have 11,000 own fattening stalls, and we have another 16,900 integrated fattening stalls. In addition, we are a company that is characterised by having its own multiplier. We produce conventional pork and also ‘Ral d’Avinyó’ quality pork.

We have a quarantine area, about 500 meters from the farm and with a capacity to accommodate 200 gilt. This area is filled every two months with an all-in-all-out system. Then there is the mating-control area with 480 cages, the gestation park area, where we have several warehouses with semi-box pens and, since the last expansion, we have a warehouse with 360 self-capture cages. We have the farrowing unit with 364 places, of which 112 are free farrowing units adapted to animal welfare and have the

Dositronic electronic feeding system installed. Finally, we have a transition of 4,500 places.

Why did you decide on the Dositronic electronic power system?

We decided on this system in order to optimise the sows’ consumption throughout lactation, besides individualising the number of feeds, as well as their schedule.

What benefits would you highlight from using Dositronic?

It is a system that allows us to reduce feed waste; it is a very practical, simple and intuitive system for the breeder. We also value that we can change the individual ration of each sow from the device itself and that for us it represents a very significant reduction in the workload on the farm. Finally, we consider it to be a very good value for money option.

On this farm, we are currently working with two feeding curves, one of them adapted for nulliparous sows and another curve for the following deliveries. The frequency of administration in both curves is five daily doses with two schedules: winter and summer.

Our daily work with the Dositronic consists, first, of looking at all the sows that have not had optimal consumption on the computer, and then going inside the rooms and changing the individual ration of the sows based on the colour that the Dositronic control panel says.

What does it mean to have all consumption data computerised?

In our case, it allows us to know each sow’s real consumption throughout lactation, see its loss

of body condition and be able to implement individualised feeding curves for each sow.

At the productivity level of the sows and the litter, have you noticed improvements?

Because of a higher feed consumption of sows thanks to Dositronic, we have noticed a significant increase in the piglet’s weight at weaning. Regarding the productivity of the sows, we have noticed an improvement in their body condition at weaning and a decrease in the weaning-covering interval, which is a highly important factor in prolificity at the next farrowing.

Besides Dositronic, what other Rotecna products do you have installed on the farm?

We have several Rotecna products: hoppers, dispensers, drinkers, drag systems, slats and many others.

and attention of their technical and commercial departments towards their clients.

What are your primary concerns at the health level?

As in the entire industry, the primary concern at the health level is the African swine fever (PPP), and in the particular area, currently, what concerns us most is the PRRS. Fortunately, so far we have stayed away from the new strains of this virus.

have an external quarantine with exhaustive biosecurity measures, a carcass container far from the farm with a separation between clean and dirty areas, our own transport without contact with any slaughterhouse and external loading docks. It should also be noted that our farms are in an area of low pig density such as Solsonès.

What future challenges arise for the farm?

Our challenges are always directed towards better biosecurity and implementing process automation, which allows us to reduce the workload, improve competitiveness and reduce costs. In this sense, of the 364 farrowing stalls that we have on this farm, 150 already have the Dositronic electronic feeding system and, in the coming months, one of our challenges is that we implement this system in all farrowing pens.

What do you value about Rotecna?

What we value most is that it provides us with products that are exceptional value for money and offers practical, simple and very easy-to-clean products. Finally, we want to highlight the care, proximity,

What biosecurity measures do you take to reduce the risk of disease transmission?

We believe that the greatest biosafety measure is to have our own multiplier that allows us to ensure that the origin of our replacement is always the same and with a known health status. In addition, we

Dositronic allows us to reduce feed waste and it is a very practical, simple and intuitive system.

behavior of the sow.

Several European countries, such as Switzerland, Sweden and Norway, currently forbid the use of cages in farrowing pens. Austria will ban their use from 2033, although it will allow them during the critical survival period of piglets (minimum space of 5.5 m²). In Germany the permanent use of cages will be phased out and is planned to be banned by 2035 (minimum space 6.5 m²). In Denmark from October 18, 2022, Danish producers will be able to apply for the fund for the changeover of farrowing rooms with free sows or temporary restriction cages.

Transformation to free lactation is due to be completed by the end of 2024. In the UK, 40%

of lactating sows are housed in systems with outside access and the industry has declared a willingness to increase alternative indoor farrowing systems. In New Zealand, the high court declared that as of November 2020, cages in farrowing pens are illegal.

In October 2020, a committee of citizens from various countries of the European Union presented to the European Commission, a European Citizen Initiative (ICE), after collecting 1,397,113 citizen signatures in the 28 countries of the European Union. The initiative, which gets the name End the cages age (“Let’s end the age of cages”), urges the Commission to ban the use of

individual cages for sows, both lactation and gestation. New EU proposals for a new animal welfare law are expected by 2023.

The Commission intends to propose the gradual withdrawal, and finally, the prohibition, of the use of such cage systems, that in the case of pork production will affect its use in the period between weaning and mating, the first four weeks of gestation and in farrowing. The new legislation is expected to take effect in 2027 and provides for an immediate ban for new farms, with a phase-out period for existing ones, as has been done before when implementing similar restrictions.

Different studies have shown that farrowing cages have a negative influence on the physiology and farrowingJosep Rius. Rotecna R+D Department. Image of a free farrowing unit equipped with Rotecna products and the Dositronic electronic feeding system installed. Photo: Rotecna.

Worldwide, however, most lactating sows are still confined in cages during the week before delivery and all lactation. From an economic point of view, this housing system has advantages such as saving space and handling time, ease of maintaining high levels of hygiene in the pen and a lower risk of crushing piglets. However, different studies have shown that farrowing cages negatively influence the sows’ physiology and delivery behaviour, causing a stress response that can affect the duration of deliveries and the piglets’ survival.

Worldwide most lactating sows are still confined in cages during the week before delivery and all lactation.

Pens with free farrowings and enrichment material.Photo: Rotecna.

Sow stress reduction Management measures related to the reduction of stress in the lactating sow can contribute to better farrowing and suckling dynamics. Oxytocin release is greater when the sows are relaxed. This hormone stimulates uterine contractions, promotes the expression of maternal behaviour and maximises milk excretion during the lactation period. Longer breastfeeding cycles have been associated with increased oxytocin levels and their relationship to lower levels of stress hormones, such as cortisol. In this sense, the control of the environmental temperature, the interventions, the noise, the adequate supply of water and food and the provision of nesting material are essential. Likewise, the measures that contribute to increasing the vitality of the piglet are of special importance, mainly with the decrease in the birth weight of piglets in hyper-prolific sows.

Ensuring a correct encolostrum of the piglets, the equalisation of the litters considering the weight of the piglet in relation to the average weight of the litter and the appropriate temperature to avoid situations of hypothermia are crucial factors to highlight to improve the piglets’ vitality.

There are three different types of free farrowing indoors:

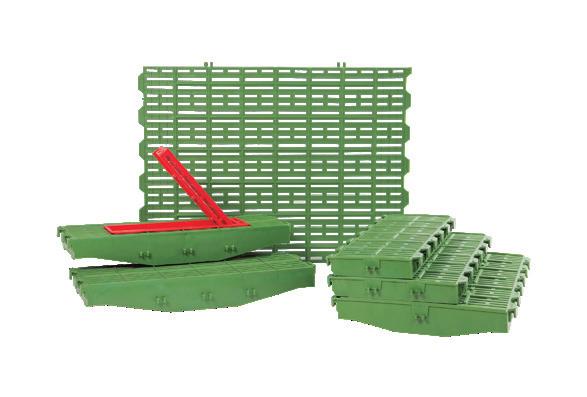

• Temporary confinement: The sow can turn around, but her movements may be temporarily restricted around farrowing. The cage is usually used before and during delivery until a few days after delivery. The cage is then opened until weaning.

• Individual pens with zero confinement: The sow is housed individually in the pen and is not restricted at any time

• Group systems: The sows and their litters are mixed before weaning. Most are based on a co-lactation system.

Undoubtedly, if sows are offered the opportunity to express their behavioural needs, their welfare levels increase substantially. However, their freedom to have space to move around in without being locked in a cage brings new challenges that will need to be successfully achieved so that their yield is not affected. Some of them are:

• Protection for piglets against the increased risk of crushing.

• Type of floor of the farrowing spaces.

• Farrowing pen design to optimise space.

• Provide manipulable material so that the sow can satisfy its need to build a nest (even partially).

• Management of the feeding system.

• Staff security.

• Management of conflicting sows (aggressive, passive or not very maternal, etc.).

• Hygiene of the pens and the sows.

All of them have their importance, but the main one is to protect the piglets. Various comparative studies of non-confinement or semi-confinement accommodation compared to cage systems show stillbirths increase with the former. The risk

increases because the piglets are more exposed to being crushed by their mother. However, the system change implies some variations, especially in handling, that if applied with the rigour and with the help of the appropriate equipment, can contribute to reducing their negative impact.

Rotecna, with the innovative spirit at the service of the farmer who has always characterised it, in 2018 already collaborated with FAWEC (Production animal welfare education centre) of the Faculty of Veterinary Medicine of the Autonomous University of Barcelona in their project to test different models of free farrowing stalls by supplying their equipment. Afterwards, these models have been adapted to the different needs of farmers in many projects with free farrowing wards.

The nest and the care that can done with it are the key allies the farmer has to reduce the risk of increased piglet mortality. Piglets must learn to recognise their comfort space and shelter as soon as possible. Once they have colostrum, locking them for 20-30 minutes two or three times during the first day is enough for them to recognise the nest as a place of refuge and comfortable rest. They learn quickly if the temperature of the room and that of the nest are adequate. However, it should be noted that, in the opposite case, especially in places with hot climates or hot summers, their learning is negatively affected because the temperature differential between the room and the nest decreases, and the piglets do not go to the nest to rest, they do it anywhere else in the farrowing pen, thus increasing the risk of being stepped on or crushed. The solution in these cases would be to reduce the temperature of the pen as much as possible and adapt the temperature

of the nest to the needs of the piglets, depending on their age and weight. In these circumstances, some farmers choose NI-2 Mobile for its versatility of use depending on the temperature needs of the animals.

As already shown in the comparative study between polypropylene and concrete panels, polypropylene panels facilitate cleaning and disinfection tasks thanks to their smooth and non-porous surface, provide significant savings in labour, water and electricity consumption, reduce the production and transport of manure and, more importantly, a scenario where the reduction of antibiotics and food safety are essential requirements for the sustainable production of pork, polypropylene and PVC panels are a fundamental tool to prevent animal diseases.

Rotecna offers a wide variety of models and sizes of plastic and cast iron slats that provide for the needs of sows and piglets in farrowing, such as keeping animals clean and dry and providing them with the comfort without damaging the teats of the sows or the hooves of the piglets, ensuring a good grip.

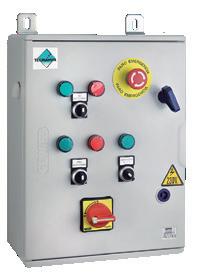

Besides all the advantages offered by electronic feeding in farrowing wards, Dositronic M offers the possibility to change or adjust any parameter without the need to enter the farrowing rooms using a PDA. Relevant aspect because the sows in freedom can show a higher level of aggressiveness than if locked in a cage. Thus avoiding any type of accident with caregivers and the assurance that the sow will continue to eat properly as planned, even if she is aggressive in protecting her litter.

Swine production in Uruguay is characterised by having experienced significant growth in the last ten years in terms of consumption. Despite this, this increase has not been found in production, which has been decreasing in the last decade. The country only has a small production of around 13,000 tons of pork per year.

As mentioned, the most relevant change that has occurred in recent years in the Uruguayan pork industry has been the strong increase in domestic demand for fresh meat. In this period, pork meat consumption per capita in the country has doubled thanks to the increase in imports, since local production has been suffering a decrease since 2015. The consumption of pork meat in Uruguay has reached 18 kg per inhabitant per year, a number much higher than the 9.7 kg consumed in 2010. This consumption has been based on imports from countries such as Brazil (which is the principal supplier), Spain, Germany, and Chile.

Despite this, the increase in consumption represents a growth opportunity for national production, something that could partially displace pork imports. This trend is expected to continue to rise thanks to greater competitiveness in the price compared to other meats.

Another of the peculiarities of the Uruguayan pork industry is the heterogeneity of actors and business models. Most of the Uruguayan pork production is in the hands of integrated companies that range from pig farming to marketing their meat. These companies, thanks to the technology and investments made, have reached productivity levels similar to those of Brazil (the world’s leading exporter). Small and medium producers, some of them grouped into cooperatives, could not access the improvements that technology offers and still require a lot of investment to improve their productivity and competitiveness to cope with the increasing competition for imported

However, this increase is not reflected in local production, since consumption continues to be based on imports.Weaning shed in Uruguay equipped with Rotecna products. Photo: Rotecna.

meat. Many of these small producers have been abandoning pork production in recent years, thus causing livestock activity concentration in the integrating companies.

But both large and small producers must face the main problem of the Uruguayan pork industry, of which we have already spoken, the relentless fall in national production and the advance of imported meat in the domestic market. Also, although many Uruguayan farms have achieved good levels of productivity, companies are not taking part in the growing international market for pork, which is a significant loss.

Despite these issues, Uruguay has strengths to develop its pork industry, such as adequate climate, water availability, grain production, good health status, and an excellent reputation as a food producer. However, the pork industry needs to take a few more steps and adopt the latest

available technologies, improve biosecurity, invest in training for staff working on farms, adapt the health system for meat export, etc.

The increase in pork consumption could bring different opportunities and investment possibilities for the Uruguayan pork industry.

In this sense, they expect foreign capital and the importation of genetics to contribute to the development of pork production. Imports will be an important factor in competition given their increase in recent years, which can lead to an improvement in local production.

Finally, it should be noted that Uruguayan pork has great value, since it is very healthy meat produced without growth hormones or antibiotics, unlike imported meats, usually frozen.

Fattening shed in Uruguay equipped with Rotecna products. Photo: Rotecna.

Source: Uruguay Agricultural Policy and Programming Office.

Fattening shed in Uruguay equipped with Rotecna products. Photo: Rotecna.

Source: Uruguay Agricultural Policy and Programming Office.

GROW FEEDER

GROW FEEDER

Fattening,

SOW FEEDER Farrowing

SWING

SWING

SWING

TR7D FEEDER

TR4 FEEDER Weaning

TR5 FEEDER Weaning

FEEDER Fattening

TR3D FEEDER Fattening

SF3D FEEDER

Fattening, WTF

SOW BOWL Farrowing, Fattening, Gestation

FEEDING

Farrowing, Gestation