ROTECNAWORLD

NUMBER FIFTY-EIGHT 2024

TECHNOLOGY

FLEXIBLE SPIRAL FEED DISTRIBUTION SYSTEM

GLOBALPIG

D. PASCUAL: “WITH THE DOSITRONIC M, WE HAVE ACHIEVED ONE MORE PIGLET PER SOW”

PIGPRODUCTION

GERMANY CONTINUES THE DOWNWARD TREND OF ITS PORK SECTOR

PARTICIPATION IN INTERNATIONAL TRADE FAIRS

DOWNLOAD ANY APPS FOR READING

QR CODE & VIEW ROTECNA.COM

58

ROTECNA NEWS

the QR code with the mobile camera.

Scan

LETTER FROM THE EDITOR

The Spanish pork sector closed in 2023 with record prices. Despite being a period in which production was reduced due to various health reasons, pork reached record prices, and the year ended with an average of 1.87 euros per kilo of live pork.

In 2024, the industry will continue to face health challenges such as the reduction in the use of antibiotics, the fight against the high virulence of PRRS strains or the threat of the spread of African swine fever (ASF). To all this, new challenges are added this year, such as applying the new legislation on animal welfare in fattening. This will involve changes in the density of pens or the expansion of farms so as not to reduce the animal census.

Regarding Rotecna’s fair participation, we continue to be committed to being present at the sector’s leading national and international events and fairs. Thus, next May, we will participate in Ildex Vietnam, and in June, we will travel to the World Pork Expo in the United States. Then, in November, we will see each other at EuroTier 2024, the benchmark fair for our European sector, which is held in Hannover (Germany).

We are looking forward to a busy 2024!

Antonio Pinos, CEO, Rotecna.

CONTENTS

4. Rotecna News

Participation in international trade fairs.

6. Something About

Caramelles, a secular Catalan tradition.

8. Technology

Flexible spiral feed distribution system.

10. Global Pig

D. Pascual: “With the Dositronic M, we have achieved one more piglet per sow”.

14. Future News

LL. Vegas: “By reducing the stressors on the animals, we manage to reduce the productive losses of the farms”.

18. Pig Production in...

Germany continues the downward trend of its pork sector.

Rotecna World

Director: Antonio Pinos.

Editor: Francisco García, Tamara Lombardo.

Translation: Sam Smith.

Print: Imprenta Barnola.

L-41-2007

Rotecna's World's editors accept no liability for contributor's opinion.

DIGITAL VERSION

/issuu.com/rotecnapress

3

Nº 58 March 2024

PARTICIPATION IN INTERNATIONAL TRADE FAIRS

The U.S. pork sector has started the year with a busy schedule, with different fairs and congresses bringing together numerous North American professionals. Once again, at Rotecna, we have opted to be present at all these events through our distributor there and bring our most efficient and innovative solutions in pig equipment to North American farmers.

Thus, on January 24 and 25, we were present at a new edition of the Iowa Pork Congress, held in Des Moines, the capital of Iowa. This is the first pork-producing state in the United States, accounting for approximately 25% of the country’s pork production. Hence, participation in the congress was an excellent opportunity to share our experience and listen to the concerns of local professionals.

On the other hand, from January 28 to 30, we travelled to Atlanta, where IPPE Atlanta took place, another of the most attended events in the North American livestock sector. The event had 1,427 exhibitors and more than 31,000

Rotecna has participated in many events in United States and Mexico.

attendees. At the same time, on January 30, we also participated in the Illinois Pork Expo, an event held in Springfield, which brought together almost a thousand pork producers from the United States and included in its program the annual meeting of the Illinois Pork Producers Association, a meeting in which some of the difficulties that the U.S. pork sector is going through, due to low animal prices and the decline in production were addressed.

Finally, on February 13th and 14th, we participated in the Minnesota Pork Congress in Mankato. Once again, this event featured a wide variety of exhibitors, educational seminars, and other activities designed exclusively for hog farmers and other stakeholders in the pork industry in this state, the second with the largest hog count in the United States.

AMVECAJ Congress (Mexico)

The growth in domestic demand for pork in Mexico during 2023 has boosted its production, imports, and consumption. However, the low

4 ROTECNA NEWS

Rotecna booth at Iowa Pork Congress. Photo: Rotecna.

prices paid to pig farmers continue to be a significant problem for the sector, which must face major challenges regarding animal welfare and environmental impact.

The XXX AMVECAJ International Congress, held from February 7 to 9 in Tepatitlán de Morelos, addressed some of these issues by focusing on the concept of a “single health”. Once again, the event served as a meeting point for professionals in the pork sector, bringing together more than 2,000 people in the different seminars and training sessions. As always, Rotecna was present at the event through its distributor in the country, offering the latest solutions in pig equipment.

Upcoming Citations

In the coming months, we will travel to Vietnam to participate in a new edition of Ildex, the international trade fair for the livestock sector that has become a leader in the Southeast Asian region. In June, we will once again participate in the World Pork Expo in Iowa, the benchmark event for the pork sector in the United States. Finally, in November, we will be at Eurotier in Hanover to showcase our new pig equipment.

Rotecna was present at AMVECAJC.

Photo: Rotecna.

Rotecna was present at AMVECAJC.

Photo: Rotecna.

CARAMELLES , A SECULAR CATALAN TRADITION

With the arrival of spring and the celebration of Easter, it is a tradition that on Easter Sunday, groups of boys and girls, as well as adult choirs, go out into the streets to sing Caramelles. These popular songs stem from religious tradition but with time, have been updated, and introduced themes of humour and satire, related to the town where they are sung in some cases.

Origins and tradition

No documentation has been found to prove when or where this tradition began. Still, it is known that it was already celebrated in rural areas in the sixteenth century. The oldest are compositions with religious themes dedicated to the Virgin of the Rosary. During the nineteenth century, choral groups from different municipalities adapted this tradition, brought it to the cities, and revitalised it with new elements and musical pieces.

The singers usually stand under the balconies to sing these songs accompanied by different

On Easter Sunday, groups of boys and girls, as well as adult choirs, go out into the streets to sing Caramelles.

musical instruments. Traditionally, they collected eggs and money that people gave them to make a collective meal that same day, in the afternoon, or a few days later. That is why the typical costume for singing these songs has a single basket or a long stick adorned with ribbons and a basket at the end. The basket is raised to the balconies so the neighbours can leave their donations there.

The oldest in Catalonia

Sant Julià de Vilatorta (Barcelona) performs the oldest documented caramelles in Catalonia. These songs originated at the end of the sixteenth century with the song of The Joys, sung by the brotherhood officially established in 1592. Indeed, the initial intention was to pay homage to the Virgen del Roser, but it became an Easter town custom over the years. In Sant Julià de Vilatorta, the original has endured, which, thanks to the clothing, the instrumental accompaniment and popular music very much its own style, added to the fact that it has been

6 SOMETHING ABOUT

Sant Julià de Vilatorta performs the oldest documented caramelles in Catalonia.

transmitted uninterruptedly from generation to generation, makes it an exceptional festival.

On Easter Sunday morning, the procession of Caramellaires del Roser, led by the flag of that virgin, goes through the streets of the town singing The Joys. They are followed by two rows of caramellaires dressed in capes and high-top hats with red bows.

Each caramellaire has a staff or turned rod, with a plaque with a picture of Our Lady of the Rosary on the front and the text of The Joys on the back. The procession sings The Joys with an ancient polyphony, followed by a group of musicians accompanied by wind instruments. The musicians are dressed in a long purple cape, a high-top hat of the same colour and a navy blue bow.

The procession is completed by children in festive costumes carrying turned walking sticks, with a bouquet at the top and ribbons of all colours. Three basket makers, dressed in velvet, sash and a traditional Catalan barret cap, go knocking on doors and collecting contributions from the villagers. A basket maker carries the typical candy basket, which is well decorated, on top of a pole with rope and pulley to make it reach balconies and windows.

In addition to The Joys of the Virgin Roser, a new custom was established in 1902. Every year, a new three-part piece is premiered and composed for the occasion by local authors. These works are usually Sardanas, waltzes, or habaneras of two or three voices.

Also, since 1977, the “Aplec Caramellaire” has been celebrated on Sundays after Easter. Groups from other towns are invited, and all the groups in the Plaza Mayor sing collectively. Afterwards, they have a fellowship meal.

Celebrated in many places

Choral groups in many Catalan municipalities adopted this tradition during the nineteenth century. In this way, and over the years, in many places, both Catalonia and the Balearic Islands, the singing of Caramelles is celebrated, although with different variants of the same tradition.

One of the most important events in Caramellaires is the annual meeting in Súria (Barcelona), where more than 500 singers of all ages and from different groups honour this tradition.

During the confinement, due to the COVID-19 pandemic, they did not want to lose the tradition in many places, so they managed to sing and interpret the caramellas from their balconies or by videoconference.

In Agramunt, the Caramellaire Aires del Sió Group walks the municipality’s streets every Easter Sunday, keeping the tradition alive.

7

A group of people singing Caramelles.

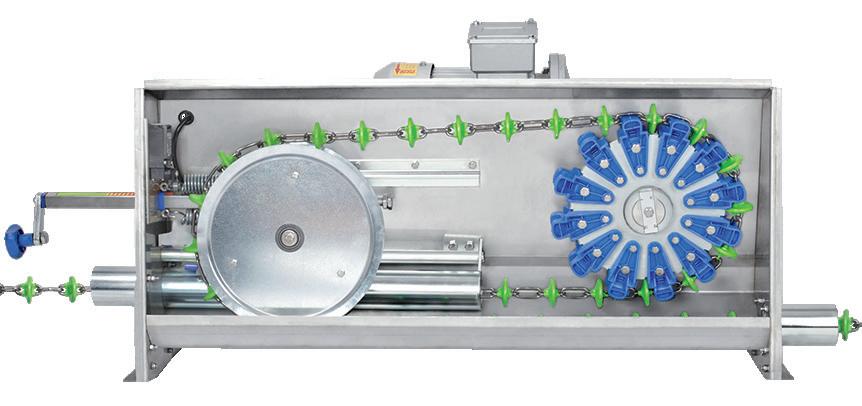

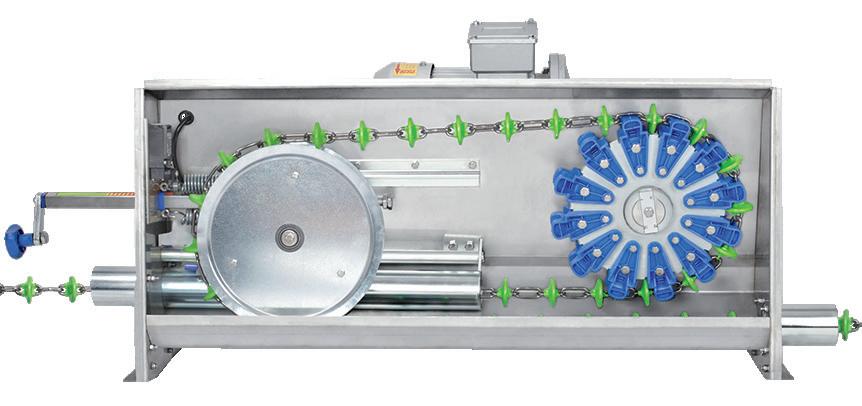

FLEXIBLE SPIRAL FEED DISTRIBUTION SYSTEM

Rotecna has two types of automatic dry feed distribution systems for pig farms: chain drags with cleats and flexible spiral fluidisation.

In this article, we are going to focus on flexible spiral systems, in which the line starts at the silo and ends at the motorised unit that rotates the spiral on its axis inside the tube. This fluidises the feed as it moves inside and moves from the silo to the engine. These systems are ideal for extended areas and where a high load flow rate is required.

The silo cone

Its function is to connect the silo with the transfer unit and allow it to be closed. They can be single, for one transfer unit (made of injected plastic and available with a wall of 45º for granules and 60º for flour), or double (made of plastic or fibreglass) for two transfer units. The cone and the closing squeegee allow the exit of the transfer units to be at 30º or horizontal, depending on which direction they are connected.

The C&D trasnfer unit

It is the beginning of the circuit, and one end of the flexible spiral is connected to its axis. The transfer unit is made of stainless steel, and its

shaft incorporates a feed outflow control system and an inspection door with a rubber gasket to ensure no water enters. In addition, for farms where flour is supplied, a cast ball can be inserted into the transfer units to create vibration, which improves the lowering of the flour and makes it harder for the feed to clump together. transfer units can be single (single-line), double (two-line) or triple (three-line), depending on the diameters of the lines.

Rotecna uses a unique bearing system for the axle of the transfer unit, as both the bearing and the grease nipple are encased in a plastic housing for more excellent safety, as it prevents severe breakdowns in the spiral and lines. Suppose the bearing collapses due to lack of lubrication. In that case, the heat generated by the friction melts the plastic bushing, preventing the bearing from becoming entrenched and the spiral from locking at one tip, which would cause a severe breakdown. This can happen if bearings

8

Technology

with metal bushing are used. On the other hand, when the plastic bushing melts, the system begins to make a noise when the spiral rotates, which warns that it needs to be replaced without deforming or breaking the flexible spiral or causing severe problems in the line or the transfer units. The bearing oiler is easily accessible for maintenance and greases the bearing at least once a year.

Line Tubes

The spiral lines work in traction (the spiral tends to open when rolling and pushes the transfer unit and the motor), so PVC pipes are ideal for their strength and lightness. At the beginning of the line, curves with a perfect radius can be used to minimise spiral rubbing and tube wear. The line tube diameters we work with are Ø55, Ø75 and Ø90 mm, and are made of an exceptionally abrasion-resistant material with UV protection.

Flexible Spirals

The diameter of the spiral has to be adjusted to the tube in which it is to be used, and this, in combination with the step of the spiral turn, marks the volumetric flow rate of the system. The size of the steel sheet that composes it, together with the rotation speed of the spiral, marks this flow rate. Ascending and curved sections can affect this flow rate, especially when working with flours, as they can be compressed.

Rotecna uses reinforced steel spirals with a blade size, bend radius, and return pitch specially designed to maximise flow. This flexibility minimises friction with the tubes in bends

and their wear and maximises the system’s maximum length. Along the lines’ route, inside the buildings, according to the distribution of the pens, drop inlets with their respective downpipes are installed for filling ad libitum feeders or dispensers for animals with restricted feeding.

As a linear distribution system, the feeders or dispensers are filled consecutively: first, second, third, and so on until the end of the line. A sensor is installed inside the last hopper or dispenser so that the motor stops when it is complete.

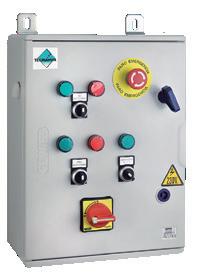

Control unit

The control unit of Rotecna’s spiral distribution system is made with a stainless-steel body and translucent cone to make it easier for the farmer to inspect and check that the system is working correctly. This unit has a safety sensor that stops the motor in case the sensor placed in the last feeder or dispenser does not. The geared motor is attached to the unit’s body and rotates the spiral at about 350 rpm (revolutions per minute). The spiral is connected to it with a clamp that incorporates the reducer’s axis.

Power supply systems must be designed and sized according to the needs of each facility. In each case, Rotecna analyses and offers the best solution for the optimal feed distribution inside farms, offering reliable, efficient and safe systems.

9

D. PASCUAL: “WITH THE DOSITRONIC M , WE HAVE ACHIEVED ONE MORE PIGLET PER SOW”

Linked to the livestock environment since his childhood, Daniel Pascual took the reins of the family business approximately 20 years ago. What was originally a farm of 300 sows has gradually grown thanks to the dedication of Daniel and his brother Francesc. After successive expansions, in 2021, they reached a capacity of 1,700 sows, and they did so with a clear commitment to technology with the installation of Rotecna’s electronic feeding system, the Dositronic M, with which they have already achieved excellent production results.

When and why did you decide to get into farming?

I entered this world through family tradition and vocation. My father was a rancher, and for a long time, he worked as a cattle farmer, although in the end, he transformed the farm into a sow’s farm. Therefore, livestock farming has always been present in my home; for me, it has been a vocation, something that I have always liked.

What is the origin of the farm? How has it evolved?

The farm was created in 1997 and initially had 300 sows. When I joined the business, in

The Pascual Gardeñes Agricultural Farm in Térmens (Lleida) works with Rotecna’s electronic feeding system in its 392 farrowing pens.

around 2004, we expanded to 750 sows. Over time, we have grown in phases, little by little, and when my brother joined the company, we finished giving the business a boost with a new expansion plan, with which we reached 1,700 sows. We currently work with Inga Food, one of the largest integrators nationwide.

How is it distributed?

In gestation, we have two mating areas and three group gestation houses. On the other hand, in maternity, we have two sheds with 392 farrowing pens (20 farrowing pens per room) and a small one with a capacity for about 140 sows to prepare them for farrowing. Finally, there are two transition sheds with seven rooms each and a total capacity of 5,400 piglets.

10

GLOBAL PIG

Daniel Pascual in a farrowing pen. Photo: Rotecna.

How many people work there, and how do they divide the tasks?

Our team consists of eight people. One of them is in charge of maintenance tasks, another person is in the transition area, and four work in the farrowing pens. I am in charge of the management and organisation tasks, as well as the gestation, along with one other person.

Why did you choose the Dositronic M electronic power supply system?

It is a system that allows us to control the feeding of the sows well, and for me, who controls it from outside the farrowing rooms, it helps me check if the sows have eaten well or not eaten. In addition, the different feeding curves offer a wide range of possibilities when feeding them. Since you can give from one to eight feedings a day, you can control the kilos of feed you give, apply winter or summer schedules, specific curves for gilts or non-gilts, etc. We also decided on this system because of the manual labour savings it entails and because it impacts the tranquillity of the room, as there is no schedule to feed the sows. In addition, we have noticed significant productive benefits from the use of Dositronic.

What are these productive benefits?

Above all, we have seen improvements in the growth of the piglets and the amount of milk the sows produce. In addition, with the Dositronic M, we have achieved one more piglet per sow. On the other hand, we have also managed to make it more even when the sow goes out to mate.

How

many feed curves do you work with?

We work with three feeding curves: one for gilts, one for multiparous with a little more feed since gilts don’t eat as much, and now I’m trying another with six feedings a day, which I think the sows eat a little more feed with.

How is the feed management with the Dositronic M?

Once the curves have been assigned to each sow, what is done every day is to check on the computer the sows that have not eaten, which the truth is that there are usually very few. In a farrowing shed with 392 places, only seven or eight might not eat. So, you go straight to those sows to see why they haven’t eaten. This is a great advantage since you don’t have to worry about the others, with the time savings this represents.

11

Interior view of one of the farrowing rooms. Photo: Rotecna.

Daniel working with the Dositronic M program. Photo: Rotecna.

What does it mean to be able to have all consumption data digitalised?

It is an advantage because it makes it easier to check the data. You have sow histories with information on the sows’ consumption during each farrowing, which is essential information for us. In addition, in the same lactation phase, we can see what the sow ate ten days ago, which is impossible with other systems.

In addition to the Dositronic M, what other Rotecna products have you installed on the farm?

Almost all the products we installed are from Rotecna. We have dispensers, feeders, slats, heating plates, etc., all of which have yielded excellent results. We also installed the TR5 hopper at weaning, which is very functional and allows us to regulate the feed quantities very well.

Overall, what do you value about Rotecna?

Above all, their after-sales service is excellent. As far as Dositronic M is concerned, they always answer any questions we may have very efficiently.

“Having all consumption data digitalized is an advantage because it makes it easier to check the data”.

On the other hand, what are your main health concerns?

The main concern is the PRRS we have suffered over the last year, which has been very hard. The other primary concern for the industry is African swine fever (ASF). We don’t have it here yet, and I hope it never does, but the truth is that it’s getting closer and closer. The entry risk is high with the large influx of piglets from abroad.

What biosecurity measures do you take to reduce the risk of disease transmission?

We have all the measures that the administration forces us to take. We have a perimeter fence, a clean area differentiated from the dirty area, foot baths at the entrances, etc.

What future challenges do you face for the farm?

The area we are in is already challenging to grow in, so our goal is to reduce costs. To do this, we want to adapt as much as possible to all the technological advances available for pig farming, as we have already done with Dositronic M or cleaning robots.

12 GLOBAL PIG

Farrowing pen with Dositronic M. Photo: Rotecna.

LL. VEGAS: “BY REDUCING THE STRESSORS ON THE ANIMALS , WE MANAGE TO REDUCE THE PRODUCTIVE LOSSES OF THE FARMS”

Animal welfare is based on four principles: good feeding, suitable housing, good health and species-appropriate behaviour.

Since 2018, pig farms have obtained the Welfair® Animal Welfare certification. This seal verifies that the animals on these farms have a level of animal welfare above the European legal minimum (one of the most demanding in the world). More and more farms are obtaining this certification. It is essential for your customers and, in the future, undoubtedly for the end consumer. To learn more about wellness trends and Welfair® certification, we spoke to Lluís Vegas, Welfair®’s lead auditor.

In recent years, animal welfare has become one of the fundamental pillars of pork production. What caused this change?

The large distributors saw that the consumer wanted to know more about how animals are raised and under what conditions to choose between animals raised with a higher or lower animal welfare status and to have a certification that verifies it. These were the beginnings, but over the years, it has evolved, and the requirements are becoming increasingly demanding.

What defines animal welfare?

Currently, the level of animal welfare is based on four principles: good feeding, suitable housing, good health and species-appropriate behaviour.

What change in animal welfare has been a turning point for the pork sector?

If we talk about facilities, the change that has had the most impact in recent years on pig farms has been the need to install more water outlets to improve the animals’ intake, prevent them from being thirsty for a long time and thus reduce stress. Through the Welfair® certification, to obtain a good score in the principle of good feeding, facilities are required to have a ratio of ten pigs per drinker at most to avoid competition for the resource and at least two drinkers per pen because when there are only one drinker, and a breakdown occurs, or faeces contaminate a drinker, the animals run out of water for some time. On the other hand, if there is an alternative water outlet, animal welfare will improve. We have also moved towards using more enrichment material, which allows animals to express their natural behaviour of rummaging and foraging. In this way, by evaluating when they are used, we can see that organic materials, straw, straw pellets, softwoods, etc., are some of the most

14 FUTURE NEWS

Lluís Vegas during an audit at a pig farm. Photo: Ll. Vegas.

suitable enrichment materials since they are edible, deform and change smell... so they stimulate the pig more to express its natural behaviour. Ideally, straw bedding would have to be used, although this is more difficult to do. As for straw, its use has been dramatically increased on pig farms. For example, we have managed to ensure that sows temporarily kept in cages during gestation and farrowing also have enrichment material, reducing typical issues appearing during these phases.

What are the advantages of applying all these animal welfare measures at the production level?

The main benefit of all these measures is that, by reducing the stressors on the animals, we manage to increase their welfare and reduce the productive losses of the farms. However, animals have a genetic limit, i.e. there will come a time when the costs we invest in improving animal welfare will no longer have a productive return. Therefore, in the future, consumers will have to be aware of the extra costs if they choose products labelled with higher animal welfare requirements. Precisely, the European Welfair Quality® project

in its origin, in addition to evaluating the welfare of production animals, was created to define the concept of “from the farm to the fork”, which allows, with the use of certifications, to detail and justify the price of meat if it increases and, thus, protect farmers who are applying higher standards in animal welfare.

Is the cost of resources and personnel in animal welfare a handicap?

In animal welfare, the farmer continuously invests economically, not only in the material required but also in time and labour. For example, you need staff to check daily that the animals have their enrichment material. However, I believe that farmers know that the future is going in this direction, and although it requires time and effort, we all know where we have to go, and that is what the industry is doing.

What animal welfare aspects need improvement in the different production phases?

Starting with maternity, we have the widespread legislative initiative about the end of the cage era. Although we thought the European Union would legislate in this regard this year, it seems that it has stopped due to inflation. However, we will work on mating and releasing the sows and reducing cages to the minimum possible time for insemination management. In lactation, farrowing pens will be established with no confinement or minimum confinement, where the sow can move around and is locked up only for the bare amount of time necessary. The European Union knows that if it implements this legislation now, costs will increase, and many farmers will not be able to afford it so that it will be a gradual evolution. In terms of transitions and fattening, welfare measures will also be increased. Now, newly-built farms must adapt to the new regulations regarding densities, feeder spaces, number of drinkers, etc.; next year, these

15

FEEDING

HOUSING GOOD HEALTH APPROPRIATE BEHAVIOUR WELFARE CRITERIA 1. Absence of prolonged hunger 2. Absence of prolonged thirst 3. Comfort around resting 4. Thermal comfort 5. Ease of movement 6. Absence of injuries 7. Absence of disease 8. Absence of pain 9. Expression of social behaviour 10. Expression other behaviours 11. Good human-animal relationship 12. Positive emotional state General table of the principles and criteria of the Welfair® protocols.

WELFARE PRINCIPLE

GOOD

GOOD

regulations will be applied to existing farms. The regulation says that there must be one feeding point for every fifteen animals in transition. Still, it should be defined that it is a feeding point since there are five-mouth hoppers, which are supposed to be five feeding points, but there are other systems in which it is not so clear, such as in single-mouth feeders where up to three piglets can eat. Finally, we will continue to progressively eliminate cages during gestation, increasing animal resting surface area and using enrichment material.

As I mentioned, some seals and certifications certify the application of animal welfare measures on farms. What does it mean to have these badges?

The certifying bodies verify that a farm has a level of animal welfare above the legal minimum, which in Europe is already the most demanding in the world, and we are still in the process of improving. The Welfair® certifications in animal welfare for pigs began in 2018, and what has been done is firstly, to be increasingly demanding every three years, then to maintain scientific criteria and to increase the score that is required of the farms to, in our case, receive the Welfair®

certificate. At first, a minimum score was needed, making it possible for companies to adapt gradually; later, 55 points were required, so many farms had to improve to keep this certificate. In the future, the next step in terms of assessment will be to double the required score again, and we are working on improving specific criteria for this. For example, a minimum exploratory behaviour might be required, and the percentage of mortality could be penalised, among other things.

How do these certifications work?

It is usually the owner of the farm or the integrating company who requests that the farm have an animal welfare certification. Therefore, the farm contacts one of the more than 20 certification bodies that can issue Welfair® certificates, to carry out an audit. From there, the certification can be done individually, on a single farm, which must be renewed annually, or grouped, where an audit of a representative group of the total number of farms in the company is done annually. In this case, the company must have a global management system, according to which they must also carry out internal audits based on a checklist of prerequisites and a series of mandatory protocol measures and send the results to the certification body. In addition, they are also audited annually by this global management system. Suppose there is a nonconformance in the audit regarding prerequisites or non-obtaining the score. In that case, they have 30 days to correct it, and additional review and follow-up measures are applied, such as the unannounced audits introduced this year.

What aspects are considered in an audit to grant an animal welfare certification?

The audit has two different parts. On the one hand, the assessment of the animal welfare of

16 FUTURE NEWS

Image of an audit in an Iberian pig production. Photo: Ll. Vegas.

the farm, based on the Welfair Quality® protocol, where we analyse a series of measures based on the observation of the animal that will give a numerical value to 12 criteria, and these 12 criteria will provide a numerical value to the four principles aforementioned: good food, suitable housing, good health and species-appropriate behaviour. For example, in the principle of good nutrition, we value the absence of hunger and thirst. In the absence of hunger, we look at the body condition of the animals, which tells us if they are eating everything they need to. In the absence of thirst, we look at the number of drinkers, the ratio of animals to drinkers, and the cleanliness of these drinkers. In reasonable accommodation, we value comfort in rest, ease of movement and thermal comfort. This is all a part of the audit. On the other hand, we make a checklist of prerequisites of about 40-50 points where aspects of legislation and other aspects of biosecurity and hygiene are assessed. An audit on a fattening farm can take between 4 and 5 hours, and on a sow farm, from 5 to 6 hours.

“We will continue to progressively eliminate cages during gestation, increasing animal resting surface area and using enrichment material”.

What

is the future of certifications? Will it be essential to have them?

There are species for which these certifications are practically essential, such as laying hens or dairy cattle, because the consumer demands it. I believe that the consumer will also want to be able to decide what meat they buy based on the information on the labelling about the conditions under which that meat was produced.

GERMANY CONTINUES THE DOWNWARD TREND OF ITS PORK SECTOR

With a highly advanced and high-tech structure, the German pork sector is one of the most powerful in the world. According to 2022 data, the country ranks fifth in the ranking of the largest producers and exporters of pork. However, the German pork sector is reducing its activity due to factors such as the entry of African swine fever (ASF), the impact of the COVID-19 pandemic and the difficult economic situation of many farms. Despite all this, the degree of self-sufficiency of German pigs remains high, and in 2022 it stood at 145.3%.

Decline in activity

According to data from the German Federal Statistical Office (Destatis), in November 2023, the country had around 17,200 farms, down from the 60,100 farms in 2010. This decline has also led to a 24.6% reduction in the country’s pig herd, which currently stands at 22.3 million head. The data reflects the trend towards larger

Despite its potential as a market, the number of farms is decreasing year after year, which impacts the pork sector’s activity.

pig farms. Thus, if in 2013 the average was 1,000 head per farm, in 2023 the average was 1,300.

The decline in the herd has also had a clear impact on pork production, from 5.56 million tonnes in 2015 to 4.49 million tonnes in 2022, 19.2% less. On the other hand, the number of pigs slaughtered has also decreased over the last few years. In this regard, 47 million pigs were slaughtered in 2022, 20.6% less compared to 2015. However, pork still accounts for the majority of meat production in Germany.

In addition, with the decline in production, the lack of piglets to meet German domestic demand has become more acute. For this reason, the country depends on importing piglets and pigs destined for slaughter, consequently impacting biosecurity and the balance of the sectoral food chain. Last year, Germany increased its imports of live piglets and pigs for slaughter for the first

18 PIG PRODUCTION IN

Image of a weaning pen in Germany. Photo: Rotecna.

time since 2020. Specifically, it imported almost 9.5 million piglets, 8% more than in 2022, mainly from Denmark and the Netherlands. On the other hand, imports of pigs for slaughter reached 1.5 million, 20% more than in 2022. Despite this increase, the current figures are far from those recorded in the years before the COVID-19 pandemic.

Despite the difficult situation, Germany has a privileged position in the international pork market and remains one of the world’s leading pork exporters. 2022 it exported 2.4 million tonnes of pork, while imports stood at 1 million tonnes. The balance of these figures assumes a positive sectoral external balance of around 1.4 million tonnes. Although the statistics are good, exports and imports have fallen by 20.8% and 18%, respectively, compared to 2015. In 2022, Germany imported 66,020 tonnes of pork and processed pork from Spain, worth €275.1 million.

Pork consumption

The German market has always been one of the largest pork consumers, as pork is one of the main ingredients of its varied gastronomy. However, between 2015 and 2022, pork consumption fell by 19% to

around 36.6kg per inhabitant yearly.

The growing popularity of vegan trends and animal rights movements have been some of the main factors impacting pork consumption in Europe. Despite its decline, consumption of this food in Germany remains one of the highest in the world.

Challenges and future

Possibly the biggest challenge for the German pig industry today is the fight against African swine fever (ASF). The disease was first detected in the country in September 2020 in the Brandenburg region. Although the virus has decreased recently, in 2023, 880 cases were identified in wild boars and one in a herd of domestic pigs. The situation remains delicate in some

federal states near the border with Poland, the European country with the most significant impact of this virus.

In addition, animal welfare remains a priority for the German government, which plans to allocate one billion euros in aid this year to improve pig farms and implement management practices that improve animal welfare standards.

Finally, issues such as healthy eating and environmental sustainability are becoming increasingly important among German consumers when determining their food demand; countries supplying pork to Germany will have to pay particular attention to these issues and adapt their production, export, and promotion policies.

19

Animal welfare remains a priority for the German government.Photo: Rotecna.

OWN DESIGN AND MANUFACTURE

30 YEARS DEVELOPING HIGH RESISTANCE PLASTIC (POLYPROPYLENE) FEEDERS

FEEDERS

GROW FEEDER MAXI Fattening, WTF

GROW FEEDER MINI Weaning

SOW FEEDER Farrowing

SWING R3 DUO Weaning, Fattening, WTF

SWING R3 WET Weaning, Fattening, WTF

SWING R3 TUBE Weaning, Fattening, WTF

TR7D FEEDER Weaning

PANS

TR4 FEEDER Weaning

TR5 FEEDER Weaning

TR2 FEEDER Fattening

TR3D FEEDER Fattening

SF3D FEEDER Fattening, WTF

SOW BOWL Farrowing, Fattening, Gestation

FEEDING BALL Farrowing, Gestation

MAXI PAN Adaptation pan - Weaning

MAXI HOPPER PAN Adaptation pan - Weaning

MAXITAINER para MAXI PAN Tank for liquids

TECNA PAN Plato 1ª edad Adaptation pan - Farrowing

EASY PAN Plato 1ª edad Adaptation pan - Farrowing

WALL PAN Adaptation pan - Farrowing

MINI PAN Adaptation pan - Farrowing

MINI HOPPER PAN Adaptation pan - Farrowing

MINITAINER Tank for liquids

ANTI-STRESS FEEDER ANTI-STRESS CHAIN

Rotecna, s.a. Polígono Industrial, s/n, nave-3 · 25310 Agramunt (Lleida) SPAIN · Tel: +34 973391267 · Fax: +34 973391232

ELECTRONIC FEEDING MANAGEMENT SYSTEMS

DOSITRONIC M Farrowing

DOSITRONIC G Gestation

EVOFEED Transition

SILOTRONIC

DRINKING BOWLS & VRH-3 VALVE

VRH Gestation and farrowing

VRH-3D

Gestation and farrowing

SWING DRINKER Weaning and fattening

EASY DRIKER MINI Farrowing (piglets)

EASY DRIKER MIDI Weaning

STAINLESS STEEL DRINKERS Sows, weaning and fattening

COVERS AND NI-2

NI-2 CORNER Farrowing

NI-2 MOBILE Farrowing

NI-2 WEANING

5W LED

LAMP

DISPENSERS

CLUTCH DISPENSER

DOSIMATIC

SIMPLEX D-2

FOUR FIVE SIX-D

SIX-S

SEVEN

Gestation and farrowing

THE MOST EXTENSIVE RANGE OF PRODUCTS FOR PIG EQUIPMENT

60Ø / 63 - 70Ø mm

ULTRA-RESISTANT CHAIN 38Ø / 44Ø mm

AUGER SYSTEM

CHAIN AND DISK SYSTEM

• Shock absorbing teeth system.

Easy adjustable chain tensioning system with graduation scale.

Corners with easy aperture system.

Silo extraction system with an agitator.

The silo outlet system consist of a silo boot, a transfer unit and a slide gate assembly that allows horizontal and inclined installation.

TRANSFER UNIT

SPIRALS 55Ø / 75Ø / 90Ø mm

CORNER 50Ø / 60Ø

GEAR MOTORS

DOWNPIPES 50 - 60 - 90 63Ø mm

EXTRACTION SINGLE / DOUBLE

www.rotecna.com

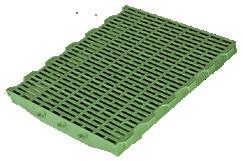

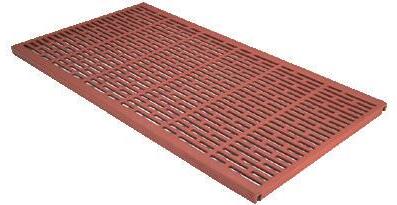

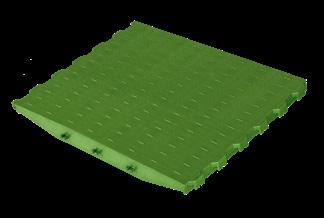

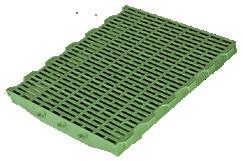

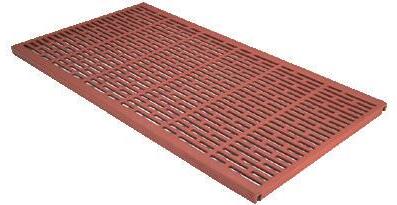

SLATS measurements in cm

WEANER 10

BLIND

PVC PROFILES (50,25,10 cm)

CLOSE PVC PEN DIVIDERS

OPEN PVC PEN DIVIDERS

DOORS

FAST LOCK BRACKETS

U BRACKETS

SOLID GRIP

PANELS

BLIND PANEL 1200X1000

VENTILATED PANEL 1200X1000

PANELS MADE TO SIZE

PROFILES FOR PANELS

DOORS

POLIAMID UNION BRAKETS FOR PANELS

FLOOR

DELTA BEAM

PROFILE 135 / 120

T PROFILE Perfil 120 / 90

DELTA NET SYSTEM Raisable flooring system

ERGOFIX Bracket for plastic and concrete grills

BASIC POST BEAM Stand for pig grill support beams

CLICK-IN Insert to blind concrete grills

PVC

10X40

20X40

10x50 WEANER

60X40 60X50 60X60 60X80

60X40

60X60 PARTIAL BLIND

60X50 60X60 10% OPEN

60X50 A

20X60

60X50 B SOW 60X20 60X30 60X40 60X60

60X80

TO FINISH 60X40

ELECTRIC PLATE 60X40 120X40 120X50 120X60 WATER PLATE 60X40 120X40 120X50 120X60 CAST IRON 60X40 60X60 FERROCAST LEVEL BED 60X60 120X60 FERROCAST RAISED 120X60 100X60

TRAP SLAT 60X40* 20X60 WEAN

60X50

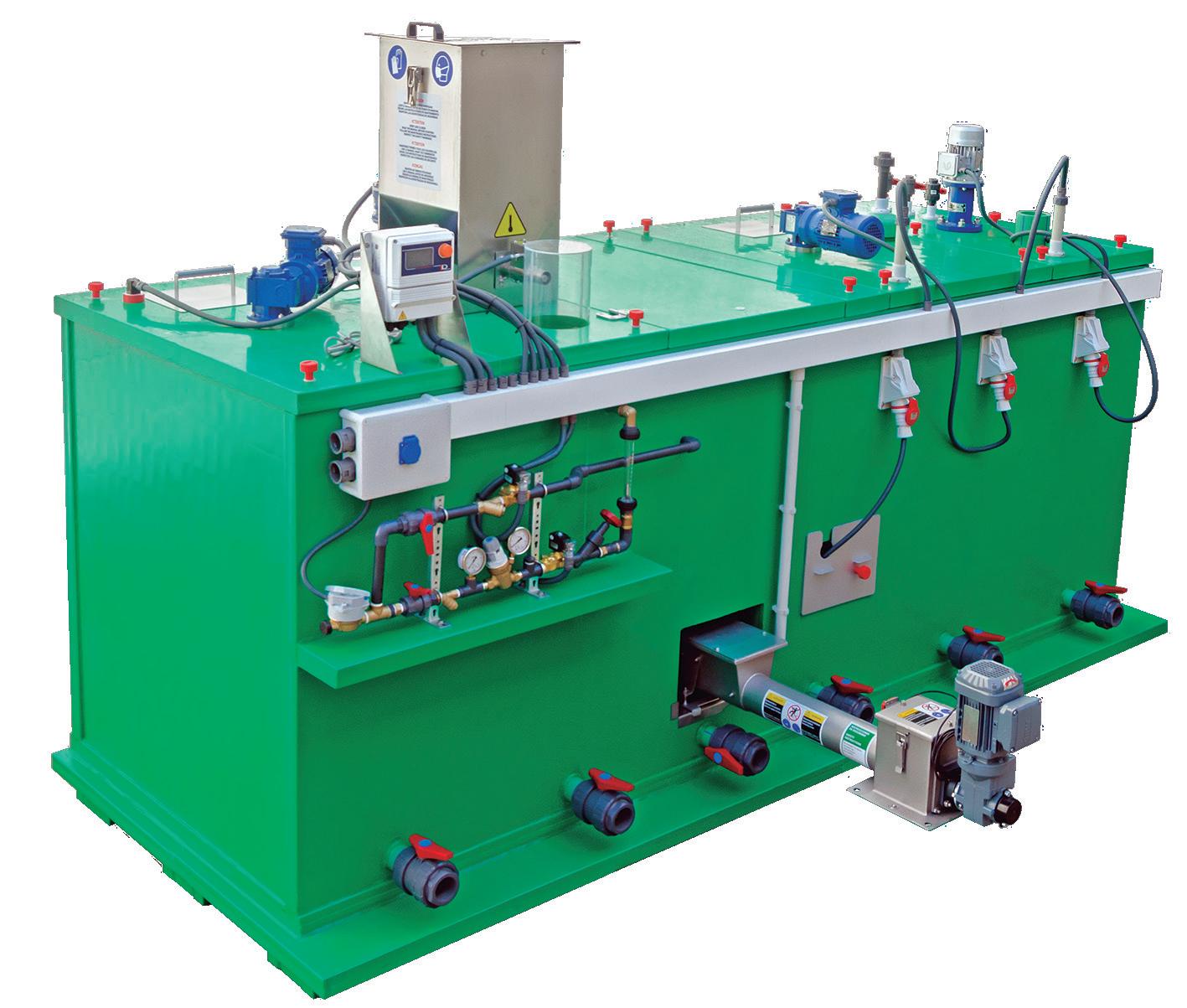

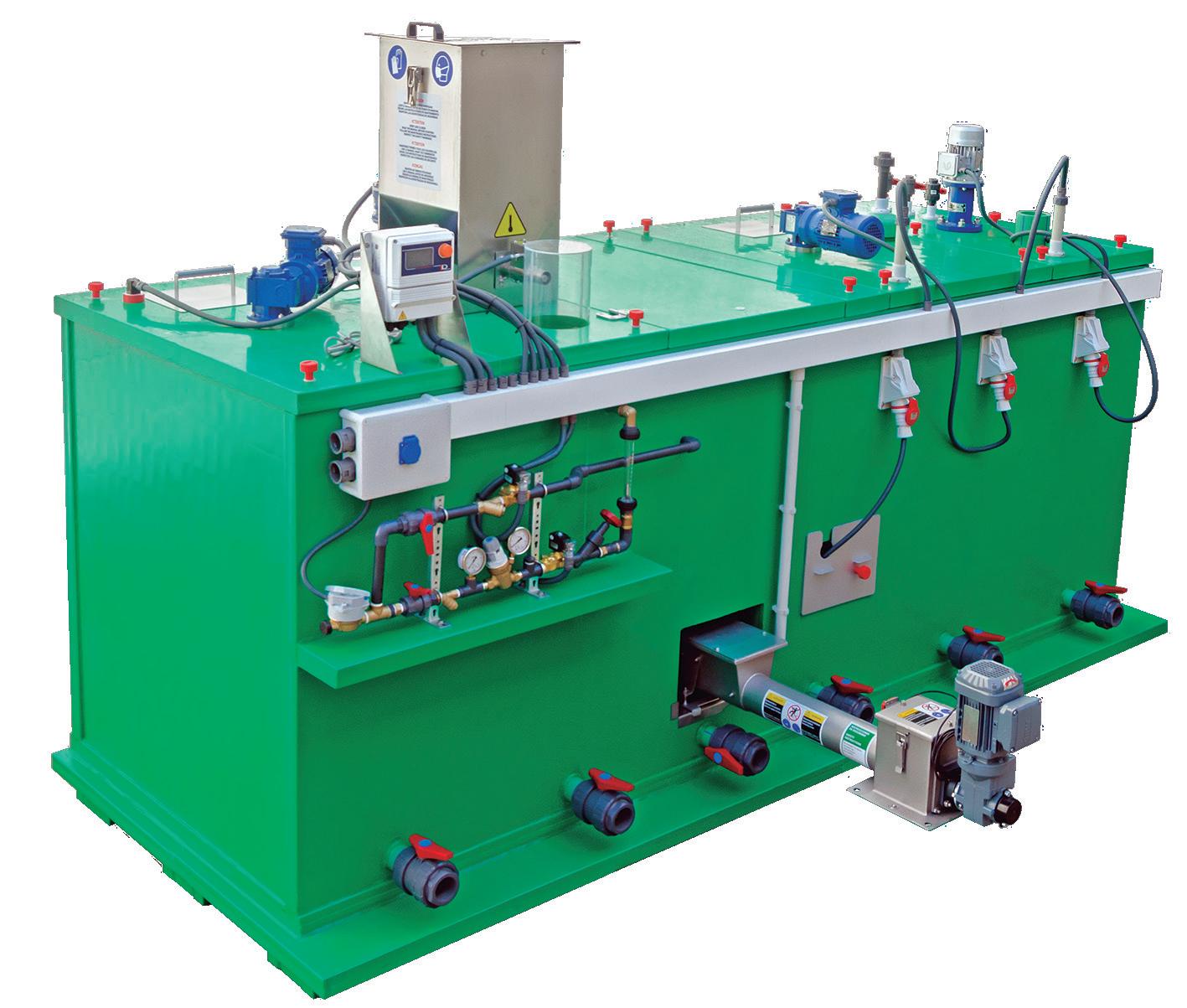

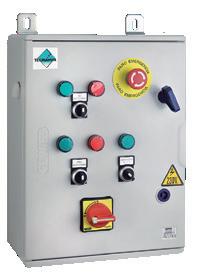

SOLIDS SEPARATOR TP-01 AGITATOR ELECTRONIC FLOW METER SUBMERGIBLE VORTEX PUMP THE MOST EXTENSIVE RANGE OF PRODUCTS FOR PIG EQUIPMENT www.tecnapur.com COMPONENTS OF THE TECNAPUR SYSTEM CONTROL PANELS TECNAPUR is a product by Rotecna, S.A. Pol. Ind. N-3 · 25310 Agramunt (Lleida) Spain • Tel. (+34) 973 39 12 67 • www.rotecna.com • rotecna@rotecna.com PHYSICAL-CHEMICAL REACTOR Scan the QR code with the mobile camera.

Rotecna was present at AMVECAJC.

Photo: Rotecna.

Rotecna was present at AMVECAJC.

Photo: Rotecna.