FAIRE SON MARCHÉ (MAKIN’ GROCERIES)

FARM TO GLASS

RECIPE INSIDE

FROM FARM-FRESH PRODUCE TO MEAT, SEAFOOD, SAUSAGES AND CAJUN SPECIALTIES, WE HAVE EXACTLY WHATCHA WANT TO COOK — AND COMPLETE MEALS IF YOU DON’T FEEL LIKE IT.

FROM FARM-FRESH PRODUCE TO MEAT, SEAFOOD, SAUSAGES AND CAJUN SPECIALTIES, WE HAVE EXACTLY WHATCHA WANT TO COOK — AND COMPLETE MEALS IF YOU DON’T FEEL LIKE IT.

I cleaned and stocked the shelves. I unloaded the trucks. I washed and crisped (crisping is “produce speak” for misting) spinach, kale and other greens, which are on the wet wall. That’s what we call our fresh greens section.

Not many things were prepacked back then. I cut up ripe watermelons and cantaloupes. You can tell if a watermelon is ripe if it is symmetrical for the shape, heavy for the size, and has a yellowish spot where the melon was lying on the ground. Cantaloupes will have smooth, somewhat sunken, and rounded stems and a sweet, musky aroma. They will smell…like cantaloupe. The grapes came in bulk so we had to overwrap them, which means we picked out a perfect bunch, placed them on a tray, wrapped them, and weighed them. Nowadays they come in baggies

or clamshells. We also overwrapped the strawberries, which came in little green pint containers.

I loved working in the Produce department, learning all of the different varieties of fruits and vegetables — plus, it wasn’t as cold as the Meat department.

My boss was Kerry Adams, who is now one of our top produce buyers. Kerry started out as a Produce Clerk at Rouses #1, our very first supermarket, which was in Thibodaux. It was also the first store to carry the Rouses name. Kerry became a Produce Manager and then, in 2013, he came to work in our office with, among other people, Mr. Larry Daigle, who was our Local Produce Buyer at the time. Larry literally grew up in the produce business. He started growing and selling mustard and turnip

greens when he was just 13. He sold to my grandfather at our first store, Ciro’s.

Kerry loves to tell people that he was my first boss, and also that, when I came to work for him, my dad said, “Do not give him any special treatment, or you’ll hear about it. I want him to learn.” I was the one who cleaned all of the produce cases that summer, so I guess you could say he didn’t give me any special treatment….

We had the idea for the cover of this issue on a Tuesday at 4:57pm. It was Kerry who jumped into action and got our partner Capital City Produce to deliver all of the fresh fruits and vegetables on the truck to our office first thing the very next day for the photoshoot.

Donny Rouse, CEO, 3rd Generation

IT ALL STARTED WITH A PRODUCE TRUCK.

Donny Rouse, CEO, 3rd Generation

IT ALL STARTED WITH A PRODUCE TRUCK.

Creative Director & Editor

Marcy Nathan

Art Director, Layout & Design

Eliza Schulze

Illustrator

Kacie Galtier

Designer

Mary Ann Florey

Marketing Coordinator

Harley Breaux

Copy Editor

Patti Stallard

Advertising & Marketing

ron bonacci

Tim Acosta

Amanda Kennedy

Stephanie Hopkins

Nancy Besson

Taryn Clement

Marketing Interns

Peyton finch

Charlotte Ghrist

SARAH BAIRD

Sarah Baird is the author of multiple books, including New Orleans Cocktails and Flask, which was released in summer 2019. A 2019 Knight Visiting Nieman Fellow at Harvard University, her work has been featured in The New York Times, Washington Post, Saveur, Eater, Food & Wine and The Guardian, among others. Previously, she served as restaurant critic for the New Orleans alt-weekly, Gambit Weekly, where she won Critic of the Year in 2015 for her dining reviews.

DAVID W. BROWN

David W. Brown is a freelance writer whose work appears in The Atlantic, The New York Times, Scientific American and The New Yorker His most recent book, The Mission: A True Story, a rollicking adventure about a motley band of explorers on a quest to find oceans on Europa, is in bookstores now. Brown lives in New Orleans.

Susan Langenhennig Granger is editor of Preservation in Print magazine and director of communications and marketing for the Preservation Resource Center in New Orleans. Prior to that she was a news editor, reporter and feature columnist for The Times-Picayune and NOLA.com.

POPPY TOOKER

Poppy Tooker is a native New Orleanian who has spent her life immersed in the vibrant colors and flavors of her state. Poppy spreads her message statewide and beyond via her NPRaffiliated radio show and podcast, “Louisiana Eats!”

In addition to celebrating 100 years of City Produce, we are celebrating our Rouses Magazine; I’m personally celebrating 10 years as Editor in Chief of the publication. We’ve spent a lot of time, as we worked on this landmark issue, remembering where we’ve been.

We’d seen other grocery store publications, and wanted to start our own. The majority of these publications are recipe-focused, which is great. But the Gulf Coast gives us so much more material to work with — the culture here is like nowhere else. It was important to us that, along with recipes, we also feature the people, places, restaurants, bars, music and everything else that make our region so unique. Those are the things that I love about living here.

From our very first issue, which had Creole tomatoes on the cover — and quite a few typos — we quickly gained a loyal following.

In our early issues, we featured so much about red beans and rice, white beans and catfish, jambalaya, and an inordinate amount of spaghetti — spaghetti and meatballs, spaghetti mac and cheese, even weenie spaghetti with hot dogs or Vienna sausages — that at one point, I worried we might’ve run the same story twice. So, we expanded our menu. New Orleans was home for me, but like most New Orleanians, I was well-acquainted with and cherished all of the Gulf Coast, from the beaches of coastal Mississippi, Alabama and Florida, to the inland towns and rural areas where so much of the country’s produce is grown and harvested each year.

With so many great stories to tell, we also started theming our issues. We began dedicating entire editions to Bourbon, Barbecue, Pizza, Pasta, Hamburgers, Garlic, Seafood, Steaks and comforting Southern Food. (One of the stranger things I learned while researching that Garlic issue is that you can taste garlic with your feet. Really!)

We argued endlessly about gumbo and whether or not it should have tomatoes, as

well as what color jambalaya should be. We unwittingly left the rice out of Tommy Rouse’s jambalaya recipe and got hundreds of calls and letters and emails telling us just that — it was ricemaggedon. We did a word search in our 60th anniversary issue and accidentally cut off the last line.

We blackened absolutely everything for our Cajun issue…including the table that we were shooting on.

We’ve created multiple Italian issues because, let’s be real here, one helping of Italian food is never enough. And two Mardi Gras issues. To be perfectly honest, we might not be done covering these themes; we are truly spoiled with a wealth of subject matter.

We drank so much tequila for our Cocktail issue that I can barely remember writing any of the stories — or my letter. I freaked out a colleague in Thibodaux when I told him that I cracked a very expensive bottle as I was moving it to New Orleans for a photoshoot for our Bourbon issue — that is still one of my favorite pranks. I tried to prank our chef Marc, but he spotted someone filming and quickly stepped out of the way; I got pie in the face instead of him.

In every issue, we’ve shared tips from our experts on choosing steak and fish, and on baking, including sharing popular recipes like our Gentilly cake and Cajun tarte à la bouille pie.

Now, we intentionally repeat ourselves every once in a while, rerunning your favorite stories and recipes; we run our Holiday 101s every year. Thankfully, we have avoided repeating the same holiday recipes and stories every year — do you really need a recipe for a sandwich made with leftover turkey, stuffing and cranberry sauce?

One year we fried turkeys with Chef Nathan Richard, a 20-year veteran of the volunteer fire department in his hometown of Thibodaux. Last year we featured an

authentic Cuban flan recipe, porchetta (which almost none of us could pronounce), and the Chinese Zodiac for the Lunar New Year. We also baked so many pans of schnecken, to perfect a recipe that was sticky and gooey enough for Christmas morning, that schnecken became a curse word in our office.

When our first issue hit stores, we were already a few years into our “Where the Chefs Shop” campaign (later renamed “Best Chefs and Cooks Shop at Rouses”), a marketing effort I came up with that included chefs like world-renowned Paul Prudhomme, Cajun cooking authority John Folse and many more. It celebrates our region’s chefs, cooks and food makers. We’re about to relaunch it with some great new faces. I’m super-excited!

Thanks in part to that campaign, we’ve been able to run exclusive interviews with chefs and cooks from all over. I feel like they all talked about learning to cook at their mother or father or grandparent’s side. Like you, roots mean everything to them. To me, too.

For those among us who are cookbook enthusiasts, we’ve covered a range, from chef-driven to community-based, including cherished regional cookbooks that are passed down between generations. Even if you’re not a cook, they make for great reads. I have my own tattered copies of Talk About Good!, River Road Recipes, Pirate’s Pantry and Recipe Jubilee!

We’ve run endless lists, often with contributions from our customers: Best Dressed (po-boys), Pit Stops (barbecue), Pearls

(oysters bars), iconic dishes of the Gulf Coast, essential ingredients of the Gulf Coast, our favorite Asian restaurants for our fabulous Asian Food issue…. Right now, we’re working on the Best Saints Bars for our upcoming Saints issue.

We’ve covered festivals that celebrate food, wine, music, boudin and beer, and anything else recognized with a celebration. Let’s be honest: Down here, we will throw a party for just about anything. Music journalists have delved into the unique soundtracks of New Orleans, Mardi Gras, Jazz Fest, Festival International, and other events from around the region. Folklorists have provided insights into local traditions, including Cajun humor. We even drew our own comic strip with the Cajun duo Boudreaux and Thibodeaux.

We’ve shared local traditions of every hometown we serve.

In 2017, we recorded the definitive interview with the Cajun Cannon, Bobby Hebert himself, and then-LSU Head Coach Ed Orgeron, for our Tailgating issue. It took

me four hours to transcribe it, and I’m still not sure I got it completely right because of the accents. Together, the pair brought home the state title for the South Lafourche High School Tarpons in 1977.

Storytelling is so important to a magazine, especially this one, and I’ve heard every excuse for writers missing deadlines.

One writer who lived on the edge and, let’s just say, had a relationship of convenience with the truth, claimed cracked ribs, twice — different ribs, by the way — and two bouts of food poisoning, all within the same year.

There have been a lot of dead relatives and sick friends, excuses I chose to believe, even when the same person died twice. And while no one has ever claimed that their dog ate their story, one writer did miss a deadline because of a goat.

One writer began channeling the poet ee cummings and turned in a story without punctuation. Our copy editor threatened to quit if I hired that writer again.

But, overall, the quality of writing from our contributors has been exceptional.

Sarah Baird is a prolific writer and our most frequent contributor. Baird’s work has appeared in prestigious publications such as The Washington Post, Saveur, and Food & Wine, and she has authored three books on cocktails. She has never missed a deadline. She has also never owned a goat (to the best of our knowledge). Baird also pens our original horoscopes, which we feature once or twice a year.

David W. Brown is a longtime contributor to our magazine. His impressive command

Magazine. Brown has a new book that documents his two Antarctic expeditions, and he asked us to feature an excerpt in our magazine to ensure his mom doesn’t miss it.

I assign any stories on potted meat, pickled pig’s feet, pineapple on pizza or anything unappetizing to him.

Our team of contributors includes “Louisiana Eats!” host Poppy Tooker, cookbook author and Cajun food expert Marcelle Bienvenu, and Southern Food & Beverage Museum founder Liz Williams. Additional food contributors include Toni Tipton Martin, Michael Twitty, Justin Nystrom, Sara Roahen, food editor Judy Walker, and cookbook authors Lolis Eric Elie and Kit Wohl. Our cheese writer, Liz Thorpe, authored her definitive The Book of Cheese. Don Dubuc, aka the Outdoors Guy, covers outdoor topics for us.

Food writer and photographer Pableaux Johnson has been our authority on red beans.

when Pableaux and I were having coffee at a local donut shop, a woman delivered a baby in the bathroom. It was straight out of TLC’s I Didn’t Know I Was Pregnant.

We’ve also featured excerpts from renowned writers such as Rick Bragg and Ken Wells, who hails from Bayou Blue and began his career at The Houma Courier. Wells went on to become a longtime writer for The Wall Street Journal and has authored five novels centered around the Cajun bayous.

Upcoming issues include our Fall Saints edition, with stories by Mary Beth Romig. The Romig family has a strong connection to the New Orleans Saints, for whom we are the official supermarket. Mary Beth’s brother, Mark Romig, serves as the Saints’ PA announcer; their late father, Jerry, was the original PA announcer for the team.

Our holiday theme is Cocktails, and hopefully Wayne Curtis and Robert Simonson will once again be lending their libation expertise. Curtis has contributed to publications such as The New York Times, The Wall Street Journal, and Garden & Gun, and is the author of And a Bottle of Rum: A History of the New World in Ten Cocktails, while Simonson writes extensively on cocktails, spirits, bars and bartenders for The New York Times.

Writers, if I left your name out, you were probably late turning in your story….

I have been surrounded by very talented people from the very first issue. But if you’ve been a regular reader of this magazine, you’ve surely noticed changes over the years. When our art director, Eliza Schulze, joined our team four-plus years ago, her talents and creativity really took our design to a whole new level. She gives each magazine a distinct feel to match the distinct theme.

Kacie Galtier caught my eye as a chalk artist who created signs for our stores. I was so excited when we brought the Chalk department into our Marketing department! You’ve seen Kacie’s original illustrations throughout this magazine in the past five years, and on our reusable bags. Kacie also designed our 100 Years of City Produce

Mary Ann Florey was practically raised in Regina’s Kitchen, the legendary lunch spot in Mobile, Alabama. She uses her expertise — and friends and family — to help research, develop and cook recipes to go with our stories. Harley Breaux, our marketing coordinator, keeps us in line and on track. She and the rest of our amazing marketing team also contribute ideas for stories and recipes and photos.

Romney Caruso is our go-to food photographer. He has been a professional photographer for more than 25 years. You may not know that we prepare and photograph most of the food in this magazine at our Downtown New Orleans store. The photo studio is really our office. We don’t use any clever tricks to make the food look delicious, like subbing mashed potatoes for ice cream. And we eat almost everything we make on shoot days — everyone brings Tupperware; the rest we deliver to the Community Refrigerators around town.

Patti Stallard is our copy editor, proofreader and copywriter. She has decades of editorial experience in marketing and

publishing, and her copyediting comments are so insightful and witty that we could easily dedicate an entire magazine to them one day — and probably will. We take turns reading them out loud to each other.

I am honored every time you tell me you read an issue. I am tickled pink when you’ve recognized me in one of our stores. I know someone who plays in a second line band who describes himself as “city famous.” Me? I am Rouses famous, and proud of it.

I have shared a lot of myself on these pages. And you have shared a lot with me in return. I love hearing your family stories and reading your family recipes. I wish I had more of my own to share, but I’m better at appreciating food than preparing it.

It’s not just me, either. People tell our Marketing and Advertising Director, Tim Acosta, they feel like they know him from his magazine column, “Cooking on Hwy. 1.” It happened this week on an introductory Zoom call! I’ve been with Tim in

stores when customers have come up to ask him, “Whatcha cookin’?” He needs an hour to answer.

I spent most of my career on the advertising agency side helping a variety of local brands, as well as major national brands like Ruth’s Chris Steak Houses, define their personalities, before I crossed over to Rouses Markets full-time. None of it was as fun — or as fattening — as this.

In my Editor position, and in my role as Creative Director for Rouses Markets, I’m lucky enough to work with some pretty amazing people, and to share my ideas and much of my world with you.

This magazine really has been a passion project for our entire Marketing department for 10 years. The magazine is lagniappe — a little something extra — but we wouldn’t give up the extra work for anything. We do it because we love to do it. And we hope you love it, too.

“I don’t think there is any other supermarket that has a better magazine, and I don’t know if there are any food magazines that are better, anywhere.”

— Donny Rouse, CEO, 3rd Generation

ARROW-CIRCLE-RIGHT Back in college, I knew there was something different about my New Orleans upbringing the first time I suggested to someone that we cross the street to the “neutral ground.” He looked at me as if I were from Mars and asked, “The what? Do you mean the median?” Until that moment, I don’t believe I’d heard that word before. I only knew that grassy strip as the neutral ground.

The same style of New Orleans idiosyncrasy holds true when it comes to shallots vs. green onions. First as a student and later as a teacher, I would hold up the green shoots in question and ask the assembled: “What do you call this?” Inevitably, non-New Orleanians would answer “green onions” or “scallions,” while locals definitively pronounced them “shallots.” This anomaly passed all class and neighborhood distinctions. If you grew up anywhere in New Orleans, those green onions were shallots!

While a little historical research quickly yields several plausible explanations for our neutral ground vernacular, the same does not hold true for the shallot. As a child, I first learned about those little bulb onions, French shallots, from Julia Child on PBS. Even then I was puzzled, but no one could offer an explanation why — despite what Julia said — in New Orleans green onions are shallots.

Then one year I planted French shallots in my garden, and up from the ground came green shoots that looked and tasted much like green onions. That’s when it dawned on me that those original French settlers must have brought root vegetables and seeds with them to plant in New Orleans. It seems very plausible that, when old Creole recipes called for shallots, they were using the green, shallot tops, likely from their own gardens. Some Creole recipes even specified using only the green shallot tops while discarding the white bottoms with roots.

So…why do we call green onions shallots? Let’s just say it’s a neutral ground kind of thing!

– Poppy Tooker, Producer and Host of “Louisiana Eats!”

As we’ve been gearing up for our 100 Years of City Produce celebration, we’ve spent a lot of time talking about shallots. While some may argue that what much of Louisiana calls a shallot is actually a spring onion, I challenge anyone to convince the farmers in Terrebonne and Lafourche parishes, where sprawling fields of shallots were grown for generations. In photos, the shallots really are a sight to behold, with their giant green onion-like stalks and flowering bulbs.

We looked through the Packer Produce Red Book from 1927, which is like a phone book for farmers. It lists scallions and shallots, but no spring onions. We also looked at our old City Produce ad, which screams: “All shallot growers, we are now buying Shallots bunched or in the field, see us before you sell!” The City Produce phone number was only a few digits long.

My father-in-law and our founder, Anthony J. Rouse, Sr., worked at the T&P Shed washing and sorting shallots for his dad’s company, City Produce, and he was always telling old stories about loading shallots onto the railcars in Thibodaux to be shipped north.

I can remember passing fields of shallots in Chackbay and Schriever, and seeing the old trucks parked beneath the stately oak trees, loaded down with bushels of shallots

alongside crisp heads of cabbage and other vegetables.

Mr. Anthony really was a farmer at heart; he had his own backyard garden. I would sometimes help with harvesting the shallots. We would separate them into similar sizes, and secure them into a neat bunch with a blue rubber band. (They still bunch them that way today.) What the family didn’t need, Mr. Anthony sent to the Thibodaux store.

All of this talk about old-time shallots has our produce team working with today’s growers to regionally source spring bulb shallots throughout the year. Stay tuned.

ARROW-CIRCLE-RIGHT Elmer’s CheeWees are a snack made in New Orleans. Unlike most cheese curls, they are baked instead of fried. The Green Onion flavor is crafted using a blend of aged sharp cheese and Elmer’s own mild, sweet green onion spices.

Delight your palate with Italian quality, taste and style (and no artificial sweeteners!). Rouses Italian Sparkling Mixers are designed to make every cocktail and mocktail taste delicious.

Available in these varieties: Ginger Beer, Tonic Water, Club Soda, Light Tonic Water

EXCLUSIVELY AT

INDULGE IN THE SMOOTH PICK-ME-UP YOU CRAVE. AVAILABLE AT YOUR LOCAL ROUSES

Vidalia sweet onions are exclusive to a specific region in South Georgia, which encompasses 20 counties and is centered around Vidalia, Georgia and Toombs County. Most onions owe their pungency to sulfur in the soil, but the soil in the Vidalia region contains very little sulfur. As a result, the onions grown in this area are exceptionally mild and won’t make your eyes water when you cut them. The weather in the region is also ideal for growing Vidalia sweet onions, with average winter temperatures in the mid-50s, spring temperatures in the mid-70s, and an average monthly rainfall of 3.5 inches during the growing season.

By Ali Rouse Royster, 3rd Generation

By Ali Rouse Royster, 3rd Generation

Long after he opened our family’s grocery store, my grandfather’s heart was still in produce, which is where he got his start. I can practically still hear his voice lift up in excitement, about to tell a story of going out into the fields or down to the packing sheds with his dad — my greatgrandfather, J.P. Rouse, who I unfortunately never met. More than just telling stories about the past, Pa continued to work with produce farmers, both locally and worldwide, for as long as I can remember, and right up until the end. He loved visiting fields near and far, to purchase directly from farmers where he could, and to learn about innovations in farming — and with the modernity of global shipping, to see what was amazing and available to bring in for his neighbors, our customers at Rouses. When Pa started to slow down a little from actively managing most aspects of the business he founded, leaving the hustle and bustle to his sons, one of the first things I remember him doing was planting a few rows of crops on the batture, a little section of land that fronts the bayou across the street from his house, adding to his already large collection of backyard crops. I remember crossing the road to go see him when he was working in the garden with a few of my cousins, tending his cucumbers, tomatoes, eggplant and, at one point, watermelons. I know a lot of his fondness for produce fields is a testament to his early life with his dad, and a lot of my fondness for local produce certainly comes from him, which links me back to a greatgrandfather I wasn’t lucky enough to cross paths with, but whose roots still certainly ground our family.

Photo by Channing Candies

Photo by Channing Candies

That’s exactly what you’ ll get today when you buy Savoie’s. Trusted by real cajuns who grew up learning recipes from their parents and grandparents. nothing says flavor like savoie's.

& still family since 1955

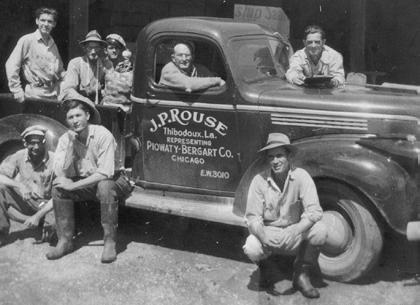

IT ALL STARTED WITH A PRODUCE TRUCK.

J.P. Rouse founded the City Produce Co. in 1923, bringing fruits and vegetables from local, independent farms to the rest of Louisiana and eventually to stores around the country.

Scan to experience our City Produce story.

“Around 1899, my greatgrandpa came over from Italy,” says Donald Rouse.

“He came in through New York with a sponsor, and he had to get work. He had to be settled in before he could send for his wife — my great-grandmother — and my grandpa.” The immigrant moved to Westwego, adjacent to New Orleans, where there was a thriving Italian community. There, he found a job on a little farm, and worked tirelessly until he could afford to set up a sharecropper deal with the landowners. “That is how he started in the farming business.”

Donald’s great-grandmother, and two children, came over in 1900.

Donald’s grandfather, Joseph “J.P.” Rouse, was barely a year old then.

In the early 1920s, J.P. moved to the Thibodaux, Louisiana area, because he felt the ground there was fertile and would be good for farming. Eventually, J.P. was able to buy 10 acres of land. At first, he planted watermelons, tomatoes and shallots — good, reliable local crops. To sell his produce, he opened a little stand on Jackson Street; he would load up whatever he had grown, then bring it all to the stand to sell. Over time, he managed to buy additional land and grow yet more.

“When he did that,” says Donald, “he started growing more shallots and bringing them to New Orleans to sell.” He founded his company in 1923, calling it City Produce.

As the company grew, every day he and his small group of employees would load his big green truck with the best produce he had grown, and drive it all over to sell. Because his crops were so prolific, he also brought shallots to what, at the time, were called “the sheds” in Thibodaux, where wholesalers would buy the crops, load them up on railcars, and ship them to other markets. (The sheds were a lot like the stands on docks today where you can buy fresh shrimp.) J.P. quickly figured out that he did not need to sell his products to other people to do the shipping — he could do that himself.

Eventually, when a shed opened and J.P. could set up shop there, he started selling his shallots to other markets. When demand exceeded his supply, he started buying shallots from other local farmers as well. For the Rouse family, supporting local farmers has always been a priority, and this is one of its earliest instances.

Unlike other shippers, J.P. or a member of his team would actually go into the fields where farmers grew shallots, and would talk to the farmers to get a feel for the crops, their likely yields and their quality. J.P. would buy entire fields rather than what was later harvested. Though he never knew exactly how much he was going to get from a harvest, he guaranteed farmers a certain amount of money for the crops — which was a win for everybody — and many local farmers soon worked out similar deals with him.

J.P. and his men began shipping produce out of Thibodaux to markets such as Dallas,

Philadelphia, Chicago, Pittsburgh — even as far away as the Caribbean. And they extended the reach of where they bought products, acquiring such crops as potatoes and sweet potatoes from Fairhope, Alabama and rural Mississippi, and red potatoes from areas in South Louisiana.

When Anthony Rouse, who later founded Rouses Markets, reached age 14, he climbed into the truck driven by his father, J.P., and joined the family business, going dutifully to the sheds for the unloading, sales, loading and shipping of the produce. Much later, when Donald was a boy, he would join his father, Anthony, at those very sheds.

“I remember going to the shed as a kid and watching them load shallots,” Donald recalls. In those days, workers would load shallots into barrels, fill the barrels with ice, stack barrels in a railcar, and add more ice yet, to keep the produce fresh even as it traveled to places far from Louisiana.

The produce business had high times and low. City Produce weathered the Great Depression, though Anthony learned well the lessons of that hard time in American history. When J.P. died, Anthony Rouse and his cousin, Ciro, took over City Produce. But there was trouble on the horizon. The produce export business slowed as more products began shipping from Mexico. Concurrently, the oil industry in Louisiana was reaching its peak, and Anthony realized that farmhands would have other work options and would soon be in short supply, which would make

For the Rouse family, supporting local farmers has always been a priority.

City Produce is the first company that the Rouse family started after arriving in America from Sardinia.

the company harder yet to keep going. So Ciro started looking far and wide for what could be the family’s next move in the food business, and soon settled on the idea of opening a grocery store in Houma.

“They named it Ciro’s because, when you hung the letters on the outside of the store, Ciro’s had fewer letters than Rouse’s,” says Donald. “That’s a true story.”

The two put all their money (and a lot of the bank’s money) into this tiny, 7,000-squarefoot store, hiring two workers and doing everything else themselves: from stocking merchandise to working the register. Donald joined the company when he was old enough, bagging groceries and rounding up carts out front. When Ciro retired in 1975, Donald bought out Ciro’s interest in the company, and he and his father renamed the store “Rouse’s.” You might have noticed that Rouses stores today lack the apostrophe. The reason is because in those early days, the lightbulb in the punctuation mark kept burning out, and rather than continuing to spend the money fighting a losing battle, Anthony — ever a practical man — decided to take the apostrophe down from the store sign and solve the problem permanently.

“We still have relationships with local farmers,” says Donald Rouse. That is one of the best things about being a local company, he says, and generations after the founding of City Produce, Rouses Markets is more committed than ever to local farmers, and to bringing store guests the very best this region has to offer. “I feel like our responsibility as a company is to give back to the local community. Our responsibility is also to our team members and to our customers.”

To serve store guests today Rouses has also established a new partnership with Capitol City Produce in Baton Rouge.

For over 75 years, Capitol City Produce, a family-owned company, has provided the best produce of the highest quality for some of the most celebrated members of the culinary world — everyone from The Windsor Court hotel and Ruth’s Chris Steak House to the Ritz-Carlton. Now, shoppers at Rouses can enjoy that same quality, practically year-round.

“It’s a good partnership we have with them,” says Donny Rouse, the CEO of Rouses Markets. “We are two family-owned companies with strong roots in the produce business, and with our partnership, we’ll be able to expand our offerings and build more relationships with farmers throughout the Gulf Coast, so we can get that product to our customers.”

In addition, the Rouses team travels the country and goes around the world in search of the very best produce grown anywhere, anytime of year. Rouses Markets was one of the first grocery stores in America to offer organic produce and one of the first to bring in such once-exotic items as kiwis from New Zealand, guavas from Honduras and hatch chiles from New Mexico. Today, every Rouses location routinely offers hundreds of different fruits and vegetables for shoppers to enjoy.

When it comes to produce, Rouses prides itself on giving busy customers plenty of options. “One thing we continue to do in produce — that a majority of other retailers have gotten away from — is cut and package fresh fruit for our store guests,” says Donny. “We have that in every store — watermelon chunks, pineapple chunks, cantaloupe slices — we still do that every day. The national chains have stopped doing that just to cut their labor force, but that’s not important to me. We will continue offering cut fruit because it’s just what we do and how we will always do business. We offer our customers the best quality and convenience of fruits and vegetables there is.”

Innovation, quality and devotion to the community have always been essential parts of the Rouses ethos. They are intertwined with the entrepreneurial spirit that motivated J.P. Rouse and made City Produce a success. That dedication has carried across the generations, to every Rouses location. It is something the Rouse family has been doing for 100 years now. And it all started with a produce truck.

Innovation, quality and devotion to the community have always been essential parts of the Rouses ethos.... That dedication has carried across the generations, to every Rouses location. It is something the Rouse family has been doing for 100 years now. And it all started with a produce truck.

When someone mentions heading to the “truck farm” to buy produce, what picture springs to mind? Perhaps it’s the booming voice of the late, great Mr. Okra in New Orleans, driving his veggiepainted technicolor truck through the 9th Ward announcing, “I’ve got mirliton! I’ve got tomatoes! I’ve got cucumbers! It ain’t no use in cooking, if you don’t use fresh veg-e-tables!” Perhaps it’s swinging by a roadside, makeshift farm stand housed on a truck’s tailgate outside of Breaux Bridge, grabbing bundles of collards or turnip greens and slipping cash to the guy sleepily manning his sales post under an umbrella.

Between the end of the Civil War and the suburban sprawl of the mid 20th century, though, a very different type of “truck” farm was crucial to the agricultural ecosystem of South Louisiana. Truck farms were an enterprising, fresh-food-forward way of life for growers and families, feeding residents in urban centers like New Orleans using the yet-tobe-developed fertile lands in places like Gretna and Metairie (which even means “farm share” in French) to grow small and mid-sized farm plots of produce intended to be sold hyper-locally to the surrounding community. If heading to Rouses Markets is your idea of buying local in 2023, then checking in with your truck farmer was the 1923 equivalent.

Etymologically, the use of the term “truck” farm doesn’t refer to any four-wheeled, rattling Ford or Chevy, but instead comes

from the French word for bartering, troque

“The ‘truck’ in this sense comes from Middle English, trucken, from Old French troque, both meaning to trade, to barter, and springs from the fact that such commodities were often used as items of exchange — paying the local pastor with an occasional bushel of corn, for instance,” explained Merrell Knighten, an English professor at Louisiana State University , in a 1984 syndicated column. It wasn’t long after the rise of truck farms in Louisiana that the term “truck” even became synonymous with fruits and vegetables, the barteredand-sold items themselves.

The truck farms were also sometimes known as market gardens; the produce raised on truck farms (leafy greens, peas, artichokes, radishes, tomatoes, orchards of figs — the list is endless) was delicate, meaning that even if it could be shipped long distances to the likes of Memphis or Chicago, the risk of spoiling was too great a financial and product-wasting risk. This ensured that, for most of their popularity, truck farms sold almost exclusively at local public markets, becoming indispensable

community resources and a productive use of the rich farming land that hadn’t yet been targeted for any other type of development (like, ahem, suburban neighborhoods).

“The vacant lands in and about New Orleans are the most prolific in the United States, and equal in productiveness the richest soil in the world. The soil is especially well-adapted to the culture of vegetables, and the products are not only large and plentiful, but the flavor of certain kinds is superior to those raised in other and less favorited sections of the country,” The Times-Picayune proclaimed in an 1887 story. “There are thousands of acres of land, relegated to the alligators, snakes and other reptiles, swampy and subject to overflow, which with but little expense, compared to their ultimate value, could be drained and converted into truck farms which would more than doubly repay the cost of reclamation every year.”

The same 1887 Times-Picayune article also made note of how different truck farms around New Orleans had found a range of crops that grow splendidly in their specific locations — even if those garden

If heading to Rouses Markets is your idea of buying local in 2023, then checking in with your truck farmer was the 1923 equivalent.

plots were mere miles apart. “Various localities around the city are devoted to particular kinds of vegetables; thus large, fine onions, garlic, sweet and Irish potatoes come from St. Bernard and Plaquemines Parish...Grand Island and vicinity [is] noted for furnishing the finest and earliest cauliflowers...Metairie and the rear of the city for the earliest potatoes, peas, beans, cucumbers, eggplants. The best cantaloupes come from the farms along Metairie Ridge.”

Truck farms soon became viewed as economic engines for cities, serving as catalysts for growth and sustainability by keeping precious grocery consumer dollars local. “Fully self-sustaining, close enough to the city to be called ‘suburban’ and far enough out to enjoy country life... truck farms are city builders. Why should not Shreveport export green produce instead of import it?” The Shreveport Times lamented in 1924 as part of an impassioned plea for truck farms entitled — yes, all caps — TRUCK FARMS NEEDED HERE. “As much as those who started truck farms would benefit, the city would be as much

bettered. Prices of vegetables would lessen; the town would thrive because the merchants would have more customers to purchase their wares; the half million dollars that now goes to other cities would remain at home.”

Truck farms were also a way for lowerincome Louisianans to not only corner the market on a potentially well-paid agriculture career, but find a place to call home: Truck farms were quite often residential spaces for their growers, meaning that buying into the pastoral life of a market gardener was a 24-hour-a-day, 365-day-a-year lifestyle commitment. Many truck farms across the region were operated by African Americans, while Italian American truck farms operated all over Harahan, Kenner and St. Bernard Parish, growing herbs, beans, peas, zucchini and beyond. (A teenage J.P. Rouse got a job at a truck farm in Marrero raising potatoes and cabbages!)

Immigrant families — including Chinese laborers who farmed in a collective model near Gretna, both for their local community and, eventually, nationwide shipping

— were particularly drawn to the truck farm ideal, and local newspapers were consistently rich with advertisements promising a better existence, and plenty of opportunity, through classifieds about the draw of the market garden lifestyle:

ARROW-CIRCLE-RIGHT BE INDEPENDENT 1926 RAISE WHAT YOU NEED ON A TRUCK FARM

(The Shreveport Times , 1926)

ARROW-CIRCLE-RIGHT WAVELAND, Miss.— 35 acres, with improvements, $750; good for truck farm; adjoining Brown’s vineyard.

(The Times-Picayune, 1899)

ARROW-CIRCLE-RIGHT IN THE “MAGIC CITY” OF BOGALUSA. For sale, 26 truck farms. If you are interested call to-day or to-morrow.

(The Times-Democrat, 1907)

ARROW-CIRCLE-RIGHT PARADIS TRUCK FARM. $500 buys an improved truck farm; any vegetable you grow will make every payment except the first; all farms front the railroad and a good wagon road. (The Times-Democrat, 1906)

With the rise of refrigerated railroad cars and technological advancements that

helped move prone-to-rotting fruits and vegetables longer distances, truck farm produce was also eventually carted out of Louisiana to wholesalers nationwide — though the emphasis on local-first sales never waivered when compared to the gambit of out-of-state shipping.

“At present, satsuma oranges are moving to markets in large express shipping from Oakdale. Saturday one dozen crates left for northern markets carrying fine samples of the Oakdale fruit. This fruit was shipped from the John J. Seily truck farm of Oakdale and according to report are of the best on the market,” detailed a 1929 Clarion-News article about the bounty being hauled out of the small Allen Parish community. “The truck farm...contains around 105 bearing trees...[with] an average of 500 orange or more. They are now good and ripe and will be harvested within the next two weeks. Already many crates have been sold to local markets.”

By the 1950s and 1960s, though, the small-is-good, market-selling ethos of truck farms found itself beginning to look like a relic of the recent past as highway

systems with refrigerated trucks spread tentacles across America, making moving produce long-distance simpler, and airlines took flight, eager to take shipments of produce in their bellies. In the span of a decade, large-scale, big business farming — complete with mechanization and lab-engineered chemical sprays, like herbicides — squashed the homespun truck farms in a David vs. Goliath battle that was over before it even began.

“The thoroughbred truck farmer is, like the whooping crane, a vanishing breed...[and] truck farming as the sole source of income is becoming a scarce situation,” Kathy Tilley wrote for The Town Talk in 1971. “The shrinking truck farm industry is directly related to labor problems. The small farmer can’t afford mechanical harvesters and at the same time manual labor is not available in abundance. Competition is another problem, not rivalry between local farmers but crops imported from other areas.”

Even still, the crop-based culture built by truck farmers — where local residents celebrate produce that’s special to their area — hasn’t faded with time. Take

Tangipahoa Parish, for example: Amite City was described as a strawberry-centered growing spot for truck farmers as far back as 1892.

“Amite City is surrounded by a country which is an ideal one for perfect truck farming. It is considered to be the best in this whole section of the country. Strawberries…are produced in abundance and form the main shipments from this place to the markets North, West and South,” The Weekly Times-Democrat of New Orleans proclaimed in 1892. “The industry, truck farming, peculiar to this part of the country, is in its highest element of success in and around this town.”

The strawberries grown in and around Amite City today might not be on truck farms, but the spirit of the market gardeners’ ingenuity lives on through sheer quantity — Tangipahoa Parish presently grows 79% of Louisiana’s strawberry crop. The ways in which seeds planted by truck farmers have sprouted into deeply rooted cultural phenomena will continue to grow, even as market gardens themselves are tilled over into the fertile soil of memory.

ARROW-CIRCLE-RIGHT Spring onions are known as shallots in many parts of Louisiana. Young onions that are harvested before they have fully matured, spring onions have a bulbous white base that looks a bit like a mini onion. The have a mild, slightly sweet onion flavor.

ARROW-CIRCLE-RIGHT Green onions, also known as scallions, are also sometimes referred to as shallots, especially in New Orleans. These onions are harvested when they are very young and have not yet formed a bulb. The white bottom part is usually firmer than the green top and has a more intense flavor, while the green part is milder tasting with a more delicate texture. The green part can also be used raw as a garnish — and is often used as a topping for a whole host of Cajun and Creole dishes, like crawfish etouffée and jambalaya.

ARROW-CIRCLE-RIGHT A leek and a green onion are related, but they are not the same thing. Leeks have a mellower, less tangy flavor compared to most varieties of onions, with a subtle hint of garlic.

ARROW-CIRCLE-RIGHT Shallots are another form of onion altogether. They have a more complex and nuanced flavor than green onions do, with a subtle sweetness and a hint of garlic-like flavor. Their flesh is whitish-purple. Shallots do form a bulb, which is made up of multiple cloves similar to garlic. Shallots are grown in many parts of the world, but they are particularly associated with France, where they are an important ingredient in classic French cuisine — and are always found in the culinary arsenal of gourmet chefs in any country. Dried shallots are typically sold as a spice, while fresh shallots are sold as whole bulbs, with the brown papery skin intact. You can find them in the produce department alongside onions and garlic.

Joseph P. Rouse immigrated to America from Sardinia, Italy’s second-largest island, in 1900. He arrived at Ellis Island, New York, accompanied by his mother, Marie, and an older brother. His father had come over more than a decade before. Joseph was barely a year old.

The Rouses were part of the New Immigration of Italians. That period between the 1880s through the 1920s saw the arrival in America of more than four million mostly southern Italian immigrants who’d left their homeland in search of work and a better life. Many arrived wide-eyed and anxious, having left family back in their Italian homeland. Nearly three-quarters of those immigrants who arrived during the New Immigration were farmers and laborers.

J.P. Rouse’s first job in America was at a family truck farm in Marrero raising garden vegetables.

There were truck farms all over the West Bank of New Orleans, in Harahan, Little Farms (now part of River Ridge) and down in St. Bernard Parish. Farmers who worked at places like the Picone truck farm and Lauricella family truck farm raised artichokes, tomatoes and fava beans; the literal fruits of their labors were then trucked to New Orleans’ public markets.

Italian immigrants also settled in the part of Kenner that runs from Williams Boulevard and Kenner Avenue to the St. Charles Parish line. Produce grown in Kenner’s “Green Gold” fields was ferried to the French Market via the O-K Rail Line, which ran between New Orleans and Kenner from 1915 to 1930. Kenner’s large Italian population still celebrates St. Rosalie, the patron saint of Palermo, with a procession every September.

ARROW-CIRCLE-RIGHT In 1923, having saved enough money working at the family truck farm in Marrero, J.P. Rouse and his wife, the former Leola Pitre, moved to Thibodaux, where he opened City Produce Company He bought fruits and vegetables from big farms in Chackbay and Choctaw, then trucked them to the public markets including the French Market.

ARROW-CIRCLE-RIGHT Many budding Italian entrepreneurs had stalls at the French Market, where business was almost all wholesale. Chisesi Brothers, now famous for their hams, started in the French Market selling live chickens from a basket. Other immigrants peddled food from horse-drawn carriages and later trucks. Each salesman traveled the same route every day, so people knew when and where to look for him.

ARROW-CIRCLE-RIGHT The Dole Fruit Company traces its roots back to the early French Quarter fruit carts. The Vaccaro brothers, who peddled fruit, joined another immigrant family, the D’Antonis of Baton Rouge, to form Standard Fruit & Steamship Company. They dominated the banana business and helped make New Orleans the world’s largest fruit importer in the early 19th century. Dole acquired 55% interest in the Standard Fruit & Steamship Company in 1964. It later acquired 100%.

ARROW-CIRCLE-RIGHT Giuseppe Uddo, the founder of Progresso Foods, also started as a peddler, selling olives, cheeses and tomato paste in New Orleans, first from a horse-drawn carriage — his horse was named Sal — and later from a truck. Eventually Uddo purchased a small warehouse on Decatur Street. After World War I, Uddo bought a tomato paste factory owned by the Vaccaro brothers in Riverdale, California. Business expanded from there.

Like farming, produce vending was a common livelihood for Italian immigrants who settled around the Gulf Coast.

...when J.P. Rouse and his wife, Leola (née Pitre), moved to Thibodaux, where he opened City Produce Company. Rouse bought fruits and vegetables from big farms in Chackbay and Choctaw, then trucked them to the public markets.

...when J.P. Rouse and his wife, Leola (née Pitre), moved to Thibodaux, where he opened City Produce Company. Rouse bought fruits and vegetables from big farms in Chackbay and Chocktaw, then trucked them to the public markets.

...when L.H. Hayward, founder of produce and dry goods company Camellia, began selling red beans at the Old French Market in New Orleans.

…when Elmer’s Chocolate, having discovered a delectable candy made and sold at a Canal Street department store, bought the recipe and began producing it themselves. Thus was born Heavenly Hash.

…when L.H. Hayward, founder of produce and dry goods company Camellia , began selling red beans at the Old French Market in New Orleans.

...when Frank Mosher and Mose Lischkoff started a company called Magic City Food Products in the basement of a Hill’s Grocery Store in North Birmingham, Alabama. Magic City Products would officially become Golden Flake, Inc., in the 1940s.

…when Frank Mosher and Mose Lischkoff started a company called Magic City Food Products in the basement of a Hill’s Grocery Store in North Birmingham, Alabama. Magic City Products would officially become Golden Flake, Inc., in the 1940s.

...when Elmer’s Chocolate, having discovered a delectable candy made and sold at a Canal Street department store, bought the recipe and began producing it themselves. Thus was born Heavenly Hash.

…when entrepreneur Alvin Baumer borrowed some cash from his future father-in-law to purchase Mill’s Fruit Products, a small syrup company in New Orleans whose product was used to make the shaved-ice summer treat called sno-balls. Part of the sale included a recipe for a hot sauce made with cayenne peppers called Crystal Pure Louisiana Hot Sauce. Today you can find Crystal Hot Sauce everywhere.

It has been tremendous to see the growth of Rouses over the years.

...when entrepreneur Alvin Baumer borrowed some cash from his future father-in-law to purchase Mill’s Fruit Products, a small syrup company in New Orleans whose product was used to make the shaved-ice summer treat called sno-balls. Part of the sale included a recipe for a hot sauce made with cayenne peppers called Crystal Pure Louisiana Hot Sauce. Today, you can find Crystal Hot Sauce everywhere.

To see a strong Louisiana business continue to grow, as we both have, from generation to generation, is a testament to the values that our families have instilled in us. The way Donny has expanded the Rouses footprint across the Gulf Coast has been amazing. It is pushing me to strive to leave my own legacy at our company.

…when the Curtiss Candy Company of Chicago, Illinois, came out with a sensational chocolate-covered, crispy peanut butter candy bar and held a public contest to choose its name. The winning entry: “ Butterfinger.”

...when the Curtiss Candy Company of Chicago, Illinois, came out with a sensational chocolate-covered, crispy peanut butter candy bar and held a public contest to choose its name. The winning entry: “Butterfinger.”

…when the first filled candy bar became the coveted delight of children and discriminating adults everywhere. They called it Milky Way

...when the first filled candy bar became the coveted delight of children and discriminating adults everywhere. They called it Milky Way.

— Alvin “Pepper” Baumer III, President, Baumer Foods, Crystal Hot Sauce

...when — as if all that weren’t enough — severy brown bag school lunch in America soon packed a new chocolate drink called Yoo-hoo and sandwiches filled with newfangled Welch’s Grape Jelly.

… when — as if all that weren’t enough — every brown bag school lunch in America soon packed a new chocolate drink called Yoo-hoo and sandwiches filled with newfangled Welch’s Grape jelly.

It can sometimes feel impossible to separate iconic buildings and public spaces from the role they play in the identity of a city and the greater public consciousness. When a typical person looks at the Eiffel Tower, they don’t think about how it once housed both a post office on the first floor and a newspaper, Le Figaro, for six months in 1889.

The Sydney Opera House, with its one-enveloping-the-other shell structure, is among the most photographed buildings in the world, but few people remember that the forecourt of the space became a venue for sheep shearing and ski-jumping into the harbor when Australia celebrated its bicentennial in 1988. Easily recognizable spaces live many diverse lives, most of which are forgotten in the shadow of their enduring grandeur.

The same depths of storied — often forgotten — history is true of New Orleans’ French Market, a public space that has bustled and thrived for centuries while reflecting the wants, needs and desires of an ever-changing city. It can be impossible for casual visitors snacking on beignets at Café Du Monde to visualize all the intricate parts that have whirred as part of the French Market’s role as the city’s culinary and agricultural lodestar, not to mention how its position as a living, breathing organism has shifted over time. Long before there were grocery stores, the French Market was the hub for ingredients and wares, and wandering through the market’s (messy, assuredly boisterous) buildings was a liveaction stroll through the bounty of Louisiana’s rich meat, seafood, vegetables and fruits.

Today, it’s easy to see the French Market as the iconic sum of its parts, but by puzzling out the cogs that have made the French Market hum throughout history, we can get a more holistic and enduring picture of what this public space means not just for today, but for yesterday and tomorrow.

The history of trading, bartering and selling wares next to the Mississippi River outdates both the French Market and the City of New Orleans itself. As far back as 1675, nearly 100 years before the first “official” iteration of the French Market opened, indigenous groups like the Choctaw, Chitimacha, Ishak, Tunica and Natchez nations traded provisions on the riverbanks, not only among themselves but with exploratory parties from other countries. The native name for the trading post was Bulbancha — meaning “land of many tongues” — in reflection of how many different cultures gathered there to swap necessities.

The French Market’s architectural design has been a revolving door of construction styles and bottom-up rebuilds over its lifetime, but one feature has always remained: It is a series of buildings — largely open-air — and not a single structure.

“The pile of buildings that composes the French Market consists of several different edifices — the Meat Market, the Bazaar Market, the Fruit Market and the Vegetable and Fish Market. All of these are under different roofs. The medley throng of life that goes on [there] is as picturesque, as unique…as if overhead were the gay tents of Constantinople stalls,” writes journalist Catherine Cole in her 1916 work, The Story of the Old French Market. “What a mingling of people it is!”

While the oldest extant French Market building dates back to 1813 and housed the anchor industry of the operation, the Meat Market, the market’s first “official” build-out dates back even earlier. According to the French Market Corporation’s historical archives, the Spanish erected the city’s first open-air food market building around the year 1782 (through some records indicate an earlier date of 1770 for the first market) on the corner of Chartres and Dumaine streets, which was relocated to a site on what is now Decatur Street between St. Ann and Dumaine in 1790. “A series of hurricanes destroyed several early structures at this location,” the record notes, “but the building erected in 1813 as the Meat Market has survived to the present.”

Until the restoration and cleanup efforts funded (in part) by the Works Progress Administration (WPA) in the 1930s, the French Market was characterized largely by its grit and chaos, both structurally (the first iteration of the market was built out of cypress wood) and on an active, day-to-day basis. The Meat Market, seafood stalls, fruit stands, flower sellers, vegetable hall and — eventually — coffee purveyors all clamored loudly with their sales pitches, spilling over into one another’s action as groceries were made, and the richness of South Louisiana put on full display.

Before the French Market was given its current moniker, it was known throughout town as Le Halle des Boucheries — or the “Meat Market” — due to the fact that it was the

only place in the French Quarter allowed to sell meat because of the decidedly hands-on and (let’s face it) gory nature of butchering.

“Plunging incontinently into the meat market, a great clatter of coffee-cups, a cheery chumping as of chopping meat, various cries and polyglot invitations to buy, an omnipresent hum and hustle, with other sights, scents and sounds of traffic — all these await us,” proclaims an 1875 edition of The New Orleans Bulletin. “The butchers are naturally lords paramount of the scene. Here are butchers rotund, sturdy and civil, the Anglicism of their features Americanized by three generations’ descent; butchers of the old French type, so elderly, clean shaven and obsequious that you would not be surprised at a pig-tail being whisked into your face during their brisk gesticulations; butchers akin to the modern Parisian, with the closest cropped heads; butchers more or less remarkable, but all busy, and all more or less animated.”

Today, the Meat Market building is home to the constantly photographed, ever-recognizable Café Du Monde.

The Fish Market inside the French Market rotated locations several times over the course of its lifespan — and was often bundled together with the Bazaar Market — but never lost its undulating spirit of watery aliveness.

“The glistening slabs of gray marble reflect the overhanging pent roofs, and Spanish mosses are twisted about the slender bars of iron on the stands. In baskets of latanier lie blue and scarlet crabs; in others are dark red crawfish looking like miniature lobsters. On beds of moss, like smaller lobsters still, the delicate river shrimps are fighting for life. They may be still powdered with the grits that tempted them into the fisherman’s net,” writes Cole in 1916. “Croakers hang in silver bunches; flat pompanos, their sleek skins shining, lie side by side with bluefish, Spanish mackerel, and trout for tenderloining. If you buy crabs, by the way, the dealer throws over them a handful of Spanish moss in which they tangle their claws and cannot get away.”

In Charles L. Thompson’s 1950 work, Chronological History of The Old French Market: The most historic spot in America’s

most interesting city from 1770 to 1937, Thompson discusses in great detail the French Market’s ever-shifting seafood hall. “The first fish market was erected in 1840 and was for sea food only. However, it became overcrowded and when the new market was erected…originally intended for a vegetable market, [it] was given over to the fish dealers, to relieve the congestion…. From that period on the little fish market was transformed into a Bazaar; in fact, it became known as the Bazaar Market, and from that time on it was occupied by numerous dealers in dry goods, notions, etc., as well as a number of novelty dealers…it resembled a mid-way plaisance of a fair or Carnival.”

This swapping and sharing of space between divergent products at the French Market wasn’t unique to seafood, though. In the late 1800s, the Fruit Market often found that poultry purveyors would set up shop in its midst — squawking, feathers flying and all — until the rebuild by the WPA largely sanitized and separated the spaces once and for all.

Thanks, in part, to the French Market’s unique position near shipments coming off of the Mississippi River and, more important, an entrepreneurial free woman of color named

Long before there were grocery stores, the French Market was the hub for ingredients and wares, and wandering through the market’s (messy, assuredly boisterous) buildings was a live-action stroll through the bounty of Louisiana’s rich meat, seafood, vegetables and fruits.

Rose Nicaud, the French Market has been synonymous with the development of New Orleans’ coffee culture for over 200 years. After purchasing her freedom, Nicaud sold café au lait from a pushcart around the French Market beginning in the early 1800s, eventually saving up enough money for an uber-popular permanent coffee stand inside the French Market and inspiring countless other African American women along the way.

If the Meat Market was the lionizing head of the French Market, then the stalls of the Vegetable Market (known, at times, as the “hall of vegetables”) were its ever-bustling, whipping tail. This became particularly true by the turn of the 20th century, when Italian immigrants, many of whom operated truck farms, largely ran the show at the Vegetable Market and provided ample, locally grown produce to a public that had become increasingly interested in adding greenery to a collective diet that was, until then, almost exclusively meat- and grain-based.

“On the vegetable stalls…the faded red column that helps to support the roof wears at its capital a gray drapery of cobwebs

looped loosely over the graceful iron brackets that spring toward the roof. All the rich wonders of an almost tropic garden are piled about this column,” Cole observes. “Shallots savory enough to tempt one…hang in bouquets; crisp salads, chicory, lentil, leek, lettuce, are placed in dewy bunches next radishes, beets, carrots, butter-beans, alligator pears (a sort of mallow or squash), Brussels sprouts (idealized cabbage); posies of thyme and bay and sage and parsley; a bunch of pumpkins; and overhead, like big silver bells strung on cords, those everlasting garlics braided on their own beards.”

J.P. Rouse even brought local produce — shallots, cabbage, potatoes — from nearby farms to sell at the Vegetable Market in the 1920s, establishing a precedent for a commitment-to-local through public market sales that set the stage for future generations to build a produce shipping company and, eventually, grocery stores.

If you thought that vendors selling items outside of the agricultural framework — hand-poured candles, artisanal soaps, local artists collectives like today’s Dutch Alley Artist’s Co-op — were only modern-day

additions to the fabric of the French Market, think again. Almost from the market’s beginning, indigenous craftspeople offered their wares alongside the agricultural mainstays. “In the early American days there were several tribes to be found here including Indians from Bayou Lacombe as well as...from several tribes the remnants of which still existed in Mississippi, some of them came right to the French Market with their herbs and roots as well as basketry and beadwork and disposed of their merchandise,” writes Thompson, who also notes that vaudeville shows and traveling dentists were commonly seen throughout the mid- to late-1800s. “They were to be found in the Bazaar Market and also in the Vegetable Market and are remembered by many of the older merchants and inhabitants, as they were still to be seen up until 1910. The also sold…handmade pottery that did very well.”

Beginning in the mid-1800s, a middle section of the French Market known as the Bazaar Market brought dry goods, fortune tellers, trinkets, flowers and knickknacks of all types from a diversity of sellers, contributing to the multicultural, ever-cacophonous sounds of space.

New Orleans’ first public market, the French Market, was once the centerpiece of 34 public food markets, which formed one of the most extensive municipal market systems in the United States.

Café Du Monde is the oldest tenant of the French Market dating back to 1862.

Like Café Du Monde, most coffee and chicory brands originated in New Orleans, including Luzianne, CDM, French Market and Union, all of which are owned by Reily Foods. William B. Reily started a wholesale grocery business in Monroe, Louisiana, then moved to New Orleans in 1902, where he founded the Luzianne brand.

ARROW-CIRCLE-RIGHT There are 24 sugar parishes in Louisiana. The warm climate is perfect for growing sugarcane

Most years, Louisiana produces more than 15 million tons of sugarcane, which yields about 16 million tons of raw sugar. At Rouses Markets, we have our own brand of sugar. It is 100% Louisiana sugar, grown by Louisiana farmers.

ARROW-CIRCLE-RIGHT Matt Ranatza is a third-generation farmer who calls Belle Chasse, Louisiana home. Back in 1937, his grandfather sowed the seeds for what would become a farming legacy by growing the first-ever Creole tomatoes. Since then, Matt has been carrying the torch and expanding his farm to include cauliflower, cabbage, peppers, squash, eggplants, satsumas and navel oranges.

ARROW-CIRCLE-RIGHT The Steen family is one of the country’s last remaining producers of unrefined cane syrup. Their syrup, which has a rich caramel flavor, has been a local favorite for over 100 years. They also make a thick, syrupy molasses.

ARROW-CIRCLE-RIGHT

The Garber family, consisting of Michael, Matt and Wayne, continue a farming legacy that dates back to 1881 in Iota, Louisiana. Their farm, spanning 5,000 acres, is situated on a sandy ridge between Bayou Nezpique and Bayou Des Cannes in the heart of Cajun Country in South Louisiana. The region benefits from the gentle, moist breezes blowing in from the Gulf of Mexico and the nutrient-rich sandy loam soil, which provides an ideal natural environment for cultivating their signature Louisiana yams, known for their sweetness and golden hue.

ARROW-CIRCLE-RIGHT Louisiana’s citrus groves span nearly 600 acres of fertile land, yielding a bounty of oranges, grapefruits and lemons every year. The crown jewel of the harvest, however, is the seedless and delectably sweet satsuma.

Louisiana’s citrus harvest takes place between October and February and includes a variety of fruits such as Washington navel oranges, satsumas, mandarins, lemons, grapefruits and kumquats. The most abundant time for Louisiana citrus is during the period from Thanksgiving through New Year’s Day. These fruits are primarily grown in the southern region of the state, with Plaquemines Parish being the top producer.

ARROW-CIRCLE-RIGHT At the H.J. Bergeron Pecan Shelling Plant, located near False River in New Roads, Louisiana over five million pounds of pecans are shelled every year. The Bergeron family not only manages their own orchards but also procures pecans from over 90 growers across Louisiana.

Courtesy Steen’s Cane Syrup Courtesy Bergeron Pecans ARROW-CIRCLE-RIGHT Liuzza Produce Farm, a fifth-generation, family-owned business, is the largest strawberry and vegetable farm in Louisiana.ARROW-CIRCLE-RIGHT The warm climate and fertile soil of the Gulf Coast are ideal not only for growing tomatoes, strawberries and sweet potatoes, but also for cultivating cabbage.

ARROW-CIRCLE-RIGHT Ben Becnel, Sr. and Ben Becnel, Jr. are a father-and-son duo who have been cultivating their family-owned farm for over 40 years, representing the fifth and sixth generations to do so. According to the Becnels, the key to their success lies in their fertile delta soil, which is located in Plaquemines Parish, Louisiana, along the Mississippi River. With 250 acres of fields and trees, their land is situated roughly 15 miles downriver from the Belle Chasse Tunnel, around Jesuit Bend, resulting in their satsumas, oranges, grapefruits and Meyer lemons having a distinctively rich and sweet flavor. The Becnels also supply Rouses with Creole tomatoes during the tomato season. Before hitting the shelves, their sweet potatoes must undergo a weeklong curing process to deepen their flavors and set their skins.

ARROW-CIRCLE-RIGHT Sessions Farm, a family-owned farm situated in Grand Bay, Alabama, has been passed down through second and third generations. Initially, the farm grew corn, soybeans and watermelons. Now, the farm has diversified, harvesting a wide range of crops all year round.

ARROW-CIRCLE-RIGHT

strawberry industry in the Florida

of Louisiana traces its roots back to the 1800s, when enterprising immigrants from Hungary and Italy began cultivating the fertile land, now recognized as Louisiana’s Berry Belt. Ponchatoula, Louisiana is known as the Strawberry Capital of the World, a title it holds with pride.

ARROW-CIRCLE-RIGHT The fertile fields of St. Bernard and Plaquemines parishes, located in the southeastern part of Louisiana, are where Creole tomatoes thrive. Thanks to the unique river soils and warm climate, these parishes produce tomatoes that are incredibly sweet and bursting with an intense, “tomatoey” flavor. While Creole tomatoes are the star of the show and even have their own festival, a range of tomato varieties are cultivated along the Gulf Coast. Tomatoes typically reach their peak during the hottest days of summer.

ARROW-CIRCLE-RIGHT Florida produces more watermelon than any other Southern state. With its long and hot summers, the Sunshine State offers the perfect climate for growing. While watermelon is available year-round, the sweetest and most succulent fruit can be found between the months of May and September. During this time, production peaks in top watermelon-growing states such as Louisiana, Mississippi, Alabama, California, Georgia, Florida and Texas. So, if you’re craving the juiciest and most flavorful watermelons, be sure to keep an eye out during these peak months.

ARROW-CIRCLE-RIGHT Trey Harris of Harris Farms (located in Springfield, Louisiana, approximately seven miles west of Ponchatoula) dedicates acres of land to growing strawberries exclusively for Rouses Markets.

ARROW-CIRCLE-RIGHT Trey Harris of Harris Farms (located in Springfield, Louisiana, approximately seven miles west of Ponchatoula) dedicates acres of land to growing strawberries exclusively for Rouses Markets.

This year, New Orleans celebrates the 100th anniversary of Camellia Brand Red Beans. This means that for over 5,200 Mondays, Camellia has been on our stoves during the day and on our plates at dinnertime. Just as important, however: They’ve been at the center of our community and our culture too.

“We feel more like a citizen of New Orleans than just a company here,” says Vince Hayward, the CEO of L.H. Hayward & Co., which owns Camellia. “Red beans are one of the great traditions of the city, and we are so fortunate to be part of what makes New Orleans what it is.”

Though a hundred years is a long time for any company, the story of Camellia goes back even further than that. Like so many Louisiana culinary success stories, the tale of Camellia Brand beans began at the French Market. In 1850, a ship carrying an immigrant from the West Indies named Sawyer Hayward docked in the port of New Orleans. Industrious and looking to make a living for his family, he got into the into the business of dry goods and beans, which he sold to French Market vendors. Even then, the French Market was old — it had been the city’s produce hub for more than half a century — and Sawyer’s crops were a success.

In part, it is because Sawyer was from the Caribbean, where beans are a dietary staple. He knew what the people wanted, and how best to cook and eat them. In the 1800s, just as today, New Orleans was a food city, attracting immigrants and empires from all over the world, and the tradition of red beans and rice on Mondays was going strong.

Sawyer’s son, Lucius, and grandson, Lucius Jr., eventually joined the nowburgeoning business of beans, and in 1923, the latter founded the L.H. Hayward & Co., naming their brand Camellia after the favorite flower of Lucius Jr.’s wife, Elizabeth. That same year, the company moved into an old cotton warehouse on Poydras and South Front streets in New Orleans — present-day Convention Center Boulevard.

An early indicator that the company would be around for a hundred years was its willingness to adapt. At the time of its founding, you bought beans in brown paper bags that were filled with a scoop from big burlap sacks. With supermarkets growing in popularity in the 1940s, Gordon Hayward, son of Lucius Jr., had a stroke of genius: Why not prepackage beans in store-ready, individual, one- and two-pound bags? Gordon’s revolutionary cellophane packages, each adorned with a camellia flower, soon became synonymous with premium-quality beans.

That high level of quality is exactly why the city embraced Camellia Brand, and why it is still going as strong as ever. “The fact that we’ve been doing this for 100 years means we’ve learned a lot about what it takes to source the beans, we know which characteristics our consumers have come to expect, and learned a lot about what it takes to clean them up properly,” says Vince Hayward, who is the greatgreat-great-grandson of the company’s founder, and the fourth generation of his family to lead the company.

Beans are an agricultural item, he explains, describing how they vary from region to region and year to year. They are like fine wine, in that soil, sun, weather and water affect flavors in subtle ways.

“Many of our efforts are centered around making sure that we have consistency in the package, and that when our consumers cook our product, that it comes out like they expect it to,” says Vince. “And we are really, really selective.”

Being around for so long means that the company’s relationships with their growers have deep roots. “We have generational relationships with our growers,” Vince says.

“We’ve been working with our growers for many, many years — in some instances, my

grandfather did business with their grandfathers! So there is a real continuity there, where they’ve come to know what we expect, and they grow what we need.”

And they need a lot. Every day, L.H. Hayward Co. packs a stunning 100,000 pounds of Camellia peas, lentils and beans for grocery stores everywhere, including your local Rouses Market. In fact, Camellia Brand beans are the best-selling red beans in the United States, by far — which makes Camellia not only a business success, but a sort of international ambassador for the city that made it all possible.

“If you mention the dish of red beans and rice anywhere in the world, the city of New Orleans instantly comes up in that conversation,” says Vince. “The dish is tied to the city, and vice versa. It’s one of the emblems of New Orleans, which is one of the great food cities in the world.” Though there are many theories for why this dish specifically so conjures the spirit of New Orleans, given that the city is celebrated for so many culinary creations, Vince thinks that it is because red beans and rice is the rare, almost universally affordable dish that — when cooked in that New Orleans style — is utterly filling and lands perfectly on the palate.

“A dish of red beans and rice is a tradition that crosses economic and geographic boundaries,” he says. “It’s something that we all enjoy, no matter who we are. So for that reason, among so many others, I feel very fortunate and blessed to be able to operate this company.”

To celebrate its 100th anniversary, Vince says that the company is engaging artists, the city, schools — everyone. The goal is less to throw a party for themselves than it is to throw a yearlong party for the community that has for so long embraced Camellia Brand. First, they’re making a documentary. “We commissioned a filmmaker to create a film on the relationship that the city has with the dish of red beans and rice, and the culinary implications of that,” Vince explains. “In essence, how the dish has impacted families for generations.”

Another way they are celebrating is by literally giving back to the community, making significant contributions to the Second Harvest Food Bank of Greater

New Orleans and Acadiana, the largest food bank in Louisiana, feeding about 32 million meals to over 200,000 people a year across 23 parishes.

Lastly, he says, the company and Camellia Brand are taking their show on the road, touring public schools in the state. “We’re talking about beans and where they come from and how they make it from a farmer’s field to their table, and of course, the dish itself,” he explains. On these stops, they will also be exhibiting the documentary they filmed, which helps contextualize red beans and rice in our culture, and how the local cuisine is as much about spiritual and cultural nourishment as it is physical. So far, Vince says, the tour of schools has been a great experience. And it might also be contributing to the next generations of entrepreneurs in the state. “It has been wonderful having conversations with the schoolkids. And interestingly enough, many of their questions have been about business: what it’s like to run a company and how can they get in business.”