16 Combat Obsolescence with a Second Source of Supply

By Ethan Plotkin and Siku Thompson GDCA, Inc., Livermore, CA

By Ethan Plotkin and Siku Thompson GDCA, Inc., Livermore, CA

21 Modern Space Innovations Open New Realms of Communication & Connectivity Across All Orbits

By Ralph Grundler, Director of SpaceBusiness Development, Aitech

COTS (kots), n. 1. Commercial off-the-shelf. Terminology popularized in 1994 within U.S. DoD by SECDEF Wm. Perry’s “Perry Memo” that changed military industry purchasing and design guidelines, making Mil-Specs acceptable only by waiver. COTS is generally defined for technology, goods and services as: a) using commercial business practices and specifications, b) not developed under government funding, c) offered for sale to the general market, d) still must meet the program ORD. 2. Commercial business practices include the accepted practice of customer-paid minor modification to standard COTS products to meet the customer’s unique requirements.

—Ant. When applied to the procurement of electronics for he U.S. Military, COTS is a procurement philosophy and does not imply commercial, office environment or any other durability grade. E.g., rad-hard components designed and offered for sale to the general market are COTS if they were developed by the company and not under government funding.

Soldiers assigned to the 2nd Armored Brigade Combat Team, 1st Cavalry Division supporting the 4th Infantry Division, maneuver an M2 Bradley fighting vehicle during Exercise Arrow 23 in Niinisalo, Finland, May 5, 2023. Exercise Arrow is an annual, multinational exercise involving armed forces from the U.S., U.K., Latvia, Lithuania and Estonia, who train with the Finnish defense forces in high-intensity, force-on-force engagements and live-fire exercises to increase militar

EDITORIAL

EDITORIAL SUBMISSION AND RELEASES

johnr@rtc-media.com

PUBLISHER/CEO

John Reardon Johnr@rtc-media.com

CONTRIBUTING EDITORS

Tom Williams

Glenn ImObersteg

Robert Hoffman

ART AND PRODUCTION

CREATIVE DIRECTOR

David Ramos drdesignservices@ymail.com

DIGITAL MARKETING MANAGER

Scott Blair Scott@blair-media.com

AD TRAFFIC

Vaughn Orchard Vaughno@rtc-media.com

FINANCE AND ACCOUNTING

Paige Reardon paiger@rtc-media.com

ADMINISTRATION/CIRCULATION

Dawn Dunaway dawnr@rtc-media.com

ACCOUNT MANAGER

SALES MANAGER

Vaughn Orchard Vaughno@rtc-media.com

CUSTOM AND CONTRACT SERVICES

John Reardon

Johnr@rtc-media.com

COTS Journal

CORPORATE OFFICE

RTC Media

3180 Sitio Sendero, Carlsbad, CA. 92009

Phone: (949) 226-2023

Fax: (949) 226-2050 www.rtc-media.com

PUBLISHED BY RTC MEDIA

Copyright 2023, RTC Media. Printed in the United States. All rights reserved. All related graphics are trademarks of The RTC Group. All other brand and product names are the property of their holders.

World’s Largest OpenRoaming Combined Network, Spanning All Nine Islands of The Azores and Freeing Users from the Need to Log In

The Wireless Broadband Alliance (WBA) announced that the Azores Islands Government and Tetrapi SA, local services company, are implementing OpenRoaming™ Wi-Fi hotspots throughout its nine-island autonomous region, representing the largest outdoor deployment of OpenRoaming to date.

Users can benefit from more than 250 planned OpenRoaming Wi-Fi hotspots. Tourists, citizens, first responders, and other users will stay securely connected across hundreds of indoor and outdoor venues such as hotels, airports, schools, public gardens, beaches, pools, libraries, sports pavilions, museums, government buildings, plazas, marinas, and tourist offices.

To begin using OpenRoaming, Azores citizens, tourists, and other users accept the terms

and conditions, and they are online. They select OpenRoaming in the network options or use a straightforward one-time provisioning portal to be automatically connected. Whenever their device is within range of an OpenRoaming hotspot, it will automatically and securely connect — no login required. All end-user devices that support Passpoint are supported, including Samsung, Apple, and Google phones.

The nine islands of The Azores, with a population of 250,000, occupy a strategic position in

The first implementation phase includes the Azores government’s broad network that spans the nine islands, public networks, and some public facilities. The city center’s largest education institution and enterprise offices are also part of the enablement. Phase two is being scoped and is planned to cover ferry terminals that receive large cruise ships, the local ferries doing hops between islands, large local hotel chains, and airports, realizing the final vision of holistic coverage.

the mid-Atlantic. As an archipelago of beautiful islands, they have a significant tourism industry, tea paddies, and vineyards. Over one million visitors a year visit island hop throughout their stay.

WBA OpenRoaming, currently available at over 3 million hotspots worldwide, frees users from the need to constantly re-register or re-enter login credentials — all while maintaining enterprise-grade security and privacy. The WBA OpenRoaming standard also enables enterprises, device OEMs, service providers, and others to provide performance guarantees and — with Wi-Fi 6 and 6E — a carrier-grade experience as users roam between different public/ private Wi-Fi realms.

The new contract will support NASA’s Artemis Missions VI-VIII.

Aerojet Rocketdyne recently received a $67 million contract from Lockheed Martin to provide propulsion systems for the Orion spacecraft planned to launch on Artemis missions VI-VIII. The Orion spacecraft recently completed a successful test flight during NASA’s Artemis I mission, proving it can safely carry humans to deep space on Artemis II. This new work extends the 2019 Orion Production and Operations Contract (OPOC).

“Aerojet Rocketdyne propulsion on NASA’s Orion spacecraft and Space Launch System rocket contributed to the success of the historic Artemis I mission, from liftoff to splashdown,” said Aerojet Rocketdyne CEO

and President Eileen P. Drake. “We’re proud to be part of a team that has demonstrated the ability to safely and efficiently carry astronauts on future Artemis missions, effectively ushering in an exciting new generation of human spaceflight.”

This contract option includes the delivery of three additional sets of Orion’s service module auxiliary engines and three other jettison motors. The eight auxiliary engines each produce 105 pounds of thrust to help maintain Orion’s in-space trajectory and position and supplement the Orion Main Engine. The jettison motor, located on Orion’s Launch Abort System (LAS), generates 40,000 pounds of thrust to separate the LAS from the crew module during both nominal operations and abort scenarios, allowing the spacecraft to continue on its journey. The jettison motor is the only motor on the LAS that fires during every mission.

Aerojet Rocketdyne was awarded a

separate contract in 2021 to provide new Orion Main Engines for future Artemis missions, and Lockheed Martin plans to use refurbished crew modules, which are propelled by reaction control thrusters, also built by Aerojet Rocketdyne, for later Artemis missions.

“Orion is NASA’s deep space exploration vehicle,” continued Drake. “Aerojet Rocketdyne is delivering the propulsion systems that will take the first woman and the first person of color to the Moon, create a sustainable presence on the lunar surface, and develop technologies that will one day enable us to send astronauts to Mars.”

The contract for three shipments of Orion propulsion elements will be managed and performed out of the company’s facility in Redmond, Washington. Work will also be conducted at Aerojet Rocketdyne facilities in Huntsville, Alabama, and Orange County, Virginia.

Leonardo DRS, Inc. announced that it had been recognized with the prestigious 2023 Herschel Award for developing advanced infrared detectors for ground combat vehicles using next-generation infrared sights. The Military Sensing Symposium (MSS) Materials and Detectors Specialty Group presented the award.

Leonardo DRS was joined by two other recipients that also made significant contributions to the development of the infrared technology known as 3rd Generation Focal Plane Arrays (FPAs), that have radically improved long-range imaging capabilities for defense applications.

The new FPAs are the core of the 3rd Generation Forward Looking Infrared (3GEN FLIR) program, which enables the detection, recognition, and identification of military targets from

civilian targets in operating environments and conditions. The deployment of this technology represents a long-term growth opportunity for DRS.

The Herschel Award is presented to an organization or individual who has contributed significantly to infrared device science and/or technology during the last five years. The stringent qualifications make the award a significant recognition in the defense industry’s competitive electro-optical and infrared sensor community. This is the company’s fifth Herschel Award.

“The recognition by the Military Sensing Symposium for our extensive work in the complex area of advanced sensing humbles us. The development of the 3GEN FLIR FPA has been evolving for the past decade at DRS with close collaboration with the U.S. Army to bring this critical technology to our military personnel to provide an advantage on the battlefield,” said Jerry Hathaway, Senior Vice-President and General

Manager of the Leonardo DRS Electro-Optical and Infrared Systems business unit. “Our scientists, engineers, operations, and program teams have led many innovative developments, dating back to the advent of the first infrared sensors in the early 1960s, and the development of these next-generation infrared sensors continues to build on our heritage of innovation.”

The 3GEN FLIR technology combines MidWave Infrared (MWIR) and Long-Wave Infrared (LWIR) sensing capabilities into a single, high-definition sensor. It enables extended range and improved situational awareness over today’s widely fielded 2nd Generation LWIR-only systems. It is a key enabler for the next generation of FLIR sights, providing significant improvements in range and resolution under a full spectrum of degraded weather and battlefield conditions

Immersive Display Solutions, Inc. and Varjo announced they had signed an agreement to enhance their business relationship by leveraging Varjo’s industry-leading mixed reality head-mounted displays to expand IDSI’s simulation and training capabilities. By incorporating the Varjo XR-3 Focal Edition into IDSI’s solution offerings, they can provide a realistic training experience where trainees can engage in hands-on training while immersed in a virtual environment.

IDSI is a leading immersive training visual display solution supplier for military and industrial applications. Varjo is the global technology leader in advanced virtual and mixed reality hardware and cloud services for professional use, seamlessly merging the real and digital worlds in human-eye resolution. IDSI has deployed more than 600 training solutions over the past 17 years.

The partnership begins with IDSI integrat-

Broaden the focus beyond spyware to combat mobile surveillance threats and signaling infrastructure exploitation

Enea recently highlighted the types of spyware used over mobile networks at a public hearing of the European Parliament’s PEGA Committee of Inquiry into the use of Pegasus and surveillance.

Rowland Corr, Vice President of Government Relations at Enea, was one of several industry experts invited to share his expertise at the Committee of Inquiry, which consists of 38 Members of Parliament.

The PEGA Committee was formed in March 2022 by the European Parliament to investigate spyware, particularly with the alleged targeting of journalists, lawyers, law enforcement officials, diplomats, and other people of influence in the E.U. Corr appeared at the Committee’s most recent hearing on March 16, 2023, and prefaced his contribution by urging

ing Varjo’s latest XR-3 Focal Edition headset into IDSI’s turnkey Extended Reality (X.R.) solution, ChromaXR. ChromaXR is purpose-built to transport the user to a virtual training environment while still seeing the real world in the foreground (Augmented Virtuality). ChromaXR supports multi-mode occlusion, including video passthrough chroma, depth, or marker occlusion. The ‘chroma keying’ or ‘green screening’ technique is the preferred method to achieve clean, real-time separation of physical objects in the foreground from the virtual environment in the background, enabling tactile hands-on training.

ChromaXR also has the flexibility to operate in Virtual Reality (V.R.) mode for situations where gamified training is sufficient to meet the training objectives. The initial focus of ChromaXR is Joint Fires Training, whereby the XR-3 Focal Edition enables trainees to interact with physical equipment.

“We are pleased with the outstanding per-

the Committee to broaden its scope, highlighting the fact that other forms of spying beyond the use of spyware were steadily occurring over mobile networks that were relevant to the Committee’s concerns.

“Spyware is the tip of the iceberg in mobile telecom surveillance,” Corr commented. “Threat actors exploit vulnerabilities in mobile networks and governance gaps to execute unauthorized intrusions with impunity.”

Corr also pointed out that capability must be prioritized over mere compliance to combat the threat as the signaling security landscape evolves effectively. He continued, “This area of risk is not sufficiently understood, reported, or integrated at national levels. Critical infrastructure protection, cybersecurity, and national security all intersect when it comes to mobile network security. And the key to improving resilience may lie in emphasizing capability over compliance on the part of stakeholders - operators, regulators, or cyber agencies.”

Recently, the potential for access to EU-

formance of the Varjo XR-3 Focal Edition as an ideal complement to our traditional direct-view projected and LED immersive training systems.”

“Varjo XR-3 Focal Edition, with its high resolution and close focal range, is an ideal extension to our industry-leading immersive CAVE and spherical dome displays. Trainees can easily perform training activities such as reading maps, reading/writing, and exchanging tactical digital communications via simulated digitally aided close air support (DACAS) activities using the Android Team Awareness Kit (ATAK), which allows precision situational awareness, navigation, and data sharing,” said George Forbes, CEO of IDSI. “We are pleased with the outstanding performance of the Varjo XR-3 Focal Edition as an ideal complement to our traditional direct-view projected and LED immersive training systems.”

based infrastructure to be used by third-country actors as a tool for surveillance, separate from the use of spyware, has increased significantly. Corr continued to impress upon the Committee the importance of looking at surveillance threats beyond the primary use of spyware tools like Pegasus and, in parallel, focus on infrastructure as a whole:

“A key area of vulnerability is mobile telecoms signaling and the abuse of access to signaling infrastructure. To put this vulnerability into context as an area of surveillance risk - the use of mobile spyware weaponizes the personal device of the victim, and the use of mobile signaling weaponizes the network serving them. But in the hands of attackers, the mobile service becomes the cyber weapon.”

As 5G is adopted worldwide, there is a pressing need for secure interworking between protocols, network elements (across generations), and secure interconnections nationally and internationally. This represents an increasingly complex and critical area within electronic communications.

Boeing unveiled its Protected Wideband Satellite (PWS) design featuring Boeing’s Protected Tactical SATCOM Prototype (PTS-P) payload hosted aboard the U.S. Space Force’s Wideband Global SATCOM (WGS)-11 spacecraft.

“The joint force is relying on us to deploy capabilities that enable secure communications in a prolific jamming environment,” said Charlotte Gerhart, Space Systems Command’s Tactical SATCOM division chief at the U.S. Space Force. “We also need mission-relevant speed and affordability while being mindful of the evolving threat on the battlefield. The Boeing PTS-Prototype payload hosted on WGS-11 is an exciting leap forward for new warfighter capabilities.”

The combination of military satellite communications (MILSATCOM) and anti-jam

capabilities underpin the PWS design. Both programs are based on Boeing’s 702X software-driven technology enabling real-time and automated beam-forming for improved standoff performance and signal protection.

“The Protected Wideband Satellite combines significantly upgraded WGS capability with PTS-P’s automated anti-jam features,” said Michelle Parker, vice president of Boeing’s Space Mission Systems. “This capability sets the stage for future generations of protected wideband systems that can operate in both legacy transponder and new onboard processed modes.”

The program is scheduled for launch in 2024, with on-orbit testing slated for 2025. After an on-orbit demonstration, the PTS-P payload will be available to transition for operational use.

The PTS-P design features automated anti-jam capabilities, including jammer geolocation, real-time adaptive nulling, frequency hopping, and other techniques, harnessing the power of the U.S. military’s Protected Tactical

Waveform (PTW) to ensure the warfighter can stay connected in a contested environment.

By flying PTS-P on the WGS-11 spacecraft as part of the WGS constellation, PWS works seamlessly with all the existing WGS user terminals while allowing the gradual fielding of PTW modems in a theater of operation.

WGS provides the Department of Defense with a broad majority of tactical communications going through the constellation that currently includes ten satellites.

As a leading global aerospace company, Boeing develops, manufactures, and services commercial airplanes, defense products, and space systems for customers in more than 150 countries. As a top U.S. exporter, the company leverages the talents of a global supplier base to advance economic opportunity, sustainability, and community impact. Boeing’s diverse team is committed to innovating for the future, leading with sustainability, and cultivating a culture based on the company’s core values of safety, quality, and integrity.

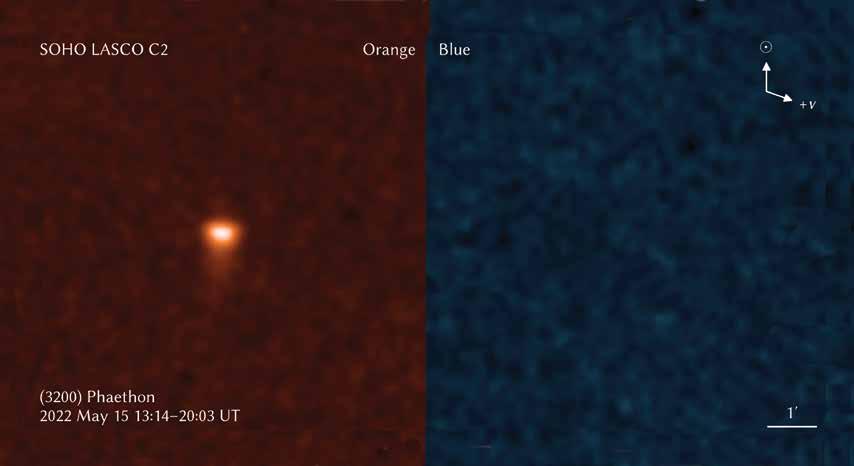

U.S. Naval Research Laboratory (NRL) scientists continue to break ground using the Large Angle and Spectrometric Coronagraph (LASCO) telescope. The telescope, which has been in operation for the past 27 years, is now collecting new information about the properties of asteroids and comets near the sun.

LASCO is one of 15 instruments on the joint NASA/ESA Solar and Heliospheric Observatory spacecraft launched in December 1995 to study the sun from its interior to its dynamic atmosphere and corona and its interaction with the entire solar system. It is a critical asset for heliophysics researchers that has revolutionized many areas of solar physics. Scientists and agencies worldwide rely on LASCO for operational space weather monitoring and forecasting. Its uninterrupted data stream provides near real-time warning of potentially hazardous Earth-directed coronal mass ejections.

Now, LASCO’s interchangeable imaging filters, which are sensitive to different wavelengths of light, are also being used to provide new insight into the chemical makeup of objects passing in front of its field of view and the processes they undergo as they experience extreme conditions in the near-sun environment.

“When a comet or asteroid gets close to the sun, the intense radiation environment can release a lot of sodium from the object’s surface,” said Karl Battams, Ph.D., a computational scientist in NRL’s Space Science Division and LASCO principal investigator. “We can use LASCOs filters to look for signatures of sodium or the presence of dust, helping us understand the processes occurring on the surface of the comet or asteroid.”

The environment near the sun is extraordinarily hostile to comets and asteroids. However, LASCO’s unique ability to image the near-sun region allows for studying the behavior of otherwise essentially inert asteroids

and comets as they undergo extreme physical and chemical processes.

In early 2022, Battams and CalTech Planetary Science Ph.D. Candidate Qicheng Zhang, a former NRL summer intern, devised a unique observing plan to leverage LASCO’s capabilities, leading to a pivotal new result regarding near-sun asteroid Phaethon. Their study, soon to be published in the Planetary Science Journal, overturns the widely-held belief that Phaethon produces a significant quantity of dust as it passes by the sun, instead finding it releases sodium. This is a substantial result regarding the asteroid that is set to be visited during a Japanese Aerospace Exploration Agency Destiny+ mission in 2028.

“Even after 27 years, we are still finding novel ways to get unique science out of LASCO,” said Battams. “It was never intended to study comets, yet with these recent observations, LASCO has upended years of belief about this asteroid and again demonstrated its unique worth.”

The Royal Air Force will create two new experimental aircraft with ground-breaking technologies in the latest step toward a sustainable aviation future.

The commencement of Project Monet, a joint initiative between the Rapid Capabilities Office (RCO) and Industry, will see the development of two experimental flying test aircraft to showcase the capabilities and potential of a range of sustainable technologies.

Using the aircraft as the testing focus, Project Monet will draw together expertise from across the RAF and Industry to evaluate how technologies can meet vital military requirements and the whole-life environmental impact of operating such a fleet of aircraft.

The range of sustainable aviation technologies includes the potential for all-electric bat-

tery power, synthetic-fuelled internal combustion engines, hydrogen cells, and hybrid.

The two-year partnership with Babcock and Swift Aircraft using light training aircraft will also deliver additional benefits by providing a means to evaluate a broader range of factors, including logistics, ground operations, human factors, and certification. In so doing, the work will provide important information which can be readily transferred to other environmentally conscious capability projects and developments.

Project Monet will add to the growing number of RAF successes in the sustainable aviation space, following the record-breaking fully synthetic aviation fuel flight in November 2021 and the world-first sustainable fuel military transport flight in November 2022.

The Royal Air Force’s drive towards greater use of alternative and sustainable fuel continues to gather pace. With the potential to maintain or enhance operational ability, this is a crucial endeavor for our Armed Forces and our collective mission to tackle climate change.

The Rapid Capabilities Office supports capability delivery to our Armed Forces personnel. Rapid Capabilities Office programs extend beyond equipment delivery into information analysis and people and process improvements. Through this, it aims to enhance capability delivered to the front line, explore opportunities presented by emerging technologies, and leverage diversity in thought with novel and innovative ways of working.

A German-modified M903 launcher successfully launched a Lockheed Martin PAC-3 Missile Segment Enhancement (MSE) interceptor in a flight test today. The German Air Force conducted the Germany Tactical Test / Operational Test 3 flight test against a virtual tactical ballistic missile target to prove compatibility between PAC-3 MSE and the German-modified Patriot M903 launching station.

MBDA Deutschland partnered with Lockheed Martin to perform the necessary launcher modifications to enable the PAC-3 MSE mis-

sile integration.

The test was a critical final step before Lockheed Martin delivered the first shipment of PAC-3 MSEs to Germany.

“Delivering PAC-3 MSE to Germany will enhance German air defense capabilities and increase lethality against evolving threats,” said Dennis Goege, Lockheed Martin Vice President of Central and East Europe. “The recent flight test proves that PAC-3 MSE is ready for deployment in Germany.”

The U.S. and German governments reached an agreement in 2019 to procure PAC3 MSE. Germany already employed the PAC-3 Cost Reduction Initiative (CRI) interceptor in their air defense arsenal.

Aitech’s Computing Technologies

Provide Critical Communication Infrastructure and Human-Machine Interface Processing Capabilities on Uncrewed Artemis I Test Flight To The Moon and Back

SAitech provided a media converter for NASA’s Orion spacecraft for data connectivity and a single board computer for Callisto, a vehicle-connected crew interface technology demonstration onboard Orion during NASA’s Artemis I mission. Callisto was developed by Lockheed Martin in partnership with Amazon with its Alexa digital voice assistant and Cisco with its Webex video conferencing technology.

Pratish Shah, General Manager of Aitech USA, noted, “As part of this first step for humankind’s return to, and the start of a permanent presence on, the Moon, Aitech is proud of our role in this historic Artemis I mission. The growing number of compute-intensive mission-critical applications pushing the envelope of data processing at the edge in space need reliable, radiation

General Dynamics Mission Systems and AMETEK Abaco Systems are partnering to deliver several new products featuring advanced encryption and anti-tamper-enabled capabilities to address the need for rugged, embedded, secure processing and storage solutions at the board level.

The partnership combines General Dynamics’ programmable, embeddable security for communications, networking, and related equipment requiring high-grade cryptographic processing up to Top Secret with Abaco’s innovative rugged embedded computing, networking, and processing technology. “Together, we are leveraging the complementary skills, knowledge, and experience of each company to enhance existing products,” said Scott Dunder-

dale, General Dynamics Mission Systems vice president, and general manager for Land and Air Systems. “The partnership will also help us develop new products and pursue business opportunities of mutual interest that will improve our rugged embedded systems capabilities.”

The partnership allows the companies to rapidly bring highly secure, open architecture and differentiated products to the market to address the defense industry’s most challenging embedded electronics requirements. Working together will allow the companies to build cybersecurity into the products from the start rather than a less effective bolt-on at the end.

Mike Underwood, division vice president, and business unit manager at Abaco, adds, “This unique partnership enables Abaco and General Dynamics to provide quickly advanced embedded cryptographic solutions for communications, networking, electronic warfare, and other mission operations worldwide. Working together, we will provide innovative answers to

tolerant, and proven technologies, like what we develop at Aitech.”

For the Lockheed Martin-built Orion spacecraft, the vehicle flown during the recent Artemis I mission to the Moon and back, Aitech developed a media converter that provided information connectivity as the main conduit data interface between Orion and the Electrical Ground Service Equipment (EGSE). Orion will enable humans to explore deeper regions of space and remain in space for extended periods.

Aitech also provided the C878 3U VPX Intel Xeon D-based Single Board Computer (SBC) for Callisto, a payload to test and demonstrate how commercial technology could support future crewed missions in space. Aitech’s C878 provided the computational core of Callisto’s Alexa and intercom capabilities.

The Artemis I mission launched on November 16 and splashed down back on Earth on December 11. Callisto was installed in the Orion cabin, and during the 25.5-day mission, virtual crewmembers extensively tested the payload from NASA’s Johnson Space Center. The testing demonstrated how the Alexa digital voice assistant and Webex video conferencing technology could be used to assist future astronauts on deep space missions.

Obsolescence is officially recognized by the US Department of Defense (DoD) as diminishing manufacturing sources and material shortages (DMSMS), or “the loss or impending loss of manufacturers of items or suppliers of items or raw materials.” Proactive management in all phases of a life cycle is crucial to avoid costly component replacements, ensure critical weapons system readiness, and reduce risks to warfighters.

It is imperative to go beyond conventional obsolescence management and reverse engineering techniques to create replacement circuit card assemblies (CCAs). Instead, target the supply chain at the root where the original product design was initially introduced by the original equipment manufacturer (OEM).

Legacy equipment manufacturers (LEMs) have established relationships with original equipment manufacturers (OEMs) as an alternative source that reestablishes the manufacturing capability for obsolete commercial off-the-shelf (COTS) and custom CCAs whose supply chains have been broken by electronics obsolescence.

Supported by legal agreements that protect OEMs, a second source of supply (SSOS) is a program that reestablishes the manufacturing capability to support production of parts with older product designs that have fragile supply chains. The SSOSs also include part sustainment plans that ensure a supply of qualified parts for as long as they are needed.

An SSOS for obsolete CCAs is a valid option if:

• the life cycle demand period of your program extends longer than the OEM is able to support it; and

• a life-of-type buy for an end-of-life (EOL) part will not be of sufficient supply to fulfill the lifetime requirements of the program.

The Waterfall Effect

The Unexpected Impact of Electronics Innovation Technology continually pushes the envelope of innovation to the detriment of long-life cycle systems whose designs must be frozen in time to avoid costly systems redesigns. Long life cycle systems are designed to have parts that are required to perform the same function reliably, year after year. Once parts for these systems are no longer in active

production, time and money must be spent to maintain and support the system’s longevity. At this stage they are commonly referred to as legacy or sustainment-dominated electronics systems.

New technology pushes old technology out of production, making long-life cycle legacy systems extremely vulnerable to part obsolescence. Maintaining a system whose parts are no longer being manufactured is incredibly challenging. The situation is further complicated by long design cycles that experience electronic component obsolescence in which parts drop out of the supply chain even before a system’s design is completed.

For weapon systems with electronicsintensive systems and even longer design

cycles, the sustainment operations and product support costs are higher than the original procurement cost. They also represent the major portion of the system’s total cost of ownership (TCO). When considering the entire system, related equipment, and replaceable assemblies, individual parts and components must be supported until the program is decommissioned or upgraded. Therefore, it’s easy to understand the potential cascading cost and side effects associated with sustaining a legacy system. In rarer and more troubling cases, some programs extend decades beyond the originally forecasted retirement and dismantle date.

When updated versions of electronics components are introduced and older versions become obsolete (e.g., microprocessors and computer memory), OEMs are forced to upgrade the CCAs (circuit card assemblies) whose designs use those old parts, even though customers are perfectly happy with the performance of their current version.

When manufacturers cease production of those older CCA designs, EOL notices that offer life-of-type buys (LTBs) often go out to customers, but defense program teams don’t have enough time to respond and adequately fund total life-cycle requirements. Later attempts to reverse engineer CCAs or upgrade current designs are hampered by the costs of rigid design control requirements (e.g., stringent qualifications and recertific ations) that are time consuming and can decimate both a program’s readiness level and budget.

In the face of budget shortfalls, long funding lead times, inventory shortages, and

the rapid evolution of technology, programs often find themselves out of sync with rapidly accelerating commercial markets and scrambling to find the parts they need to achieve operational readiness. LEMs (legacy equipment manufacturers), with the capability to offer a second source of supply (SSOS) can help programs stay synchronized with commercial markets and avoid the costs of upgrading until absolutely necessary.

Sourcing: Second Source of Supply As a Qualified Option

Why Old Parts Are So Special Launching and supporting a new program is completely different than managing the ongoing effectiveness of a defense system as it ages. Military, avionics, and naval markets are unlike the commercial markets that can perform technology upgrades and refreshes more readily than defense programs. The lower frequency of design updates in the defense sector leads to increased problems associated with obsolescence, and those problems impact missioncritical systems.

Program managers (PMs) need long-term sustainment planning and ongoing access to critical parts to fend off obsolescence and control total life-cycle systems management (TLCSM) costs. The TLCSM accounts for implementation, management, and oversight by the PM (life-cycle manager) of all activities associated with a systems life cycle. Those activities include all sustainment protocols that aim to ensure life-cycle sustainment and readiness outcomes to improve system operational effectiveness (SOE) for the war fighter techniques outlined in the DoD’s SD22 guidebook (“Diminishing Manufacturing Sources and Materials Shortages: A Guidebook of Best Practices for Implementing a Robust

DMSMS Management Program”), representing traditional best practices to proactively manage CCA obsolescence.

Unfortunately, these practices often fall short when supporting aging programs that require long-term, ongoing access to COTS parts that have proprietary technical data—the kind of intellectual property (IP) data that resides in complex electronic units that are essential to larger systems. COTS parts inherently present unknowable and unpredictable sustainment cost factors that jeopardize a program’s ability to stay aligned with TLCSM road maps, aking it nearly impossible to integrate a robust DMSMS management plan.

Nearly every military weapons system contains COTS CCAs.

In order to compete successfully, OEMs of COTS and custom CCAs must introduce new technology in product road maps, inadvertently leaving behind a small number of customers, including defense programs, that rely on a steady supply of older model parts. When COTS parts reach their EOL, the remaining inventory within the open market or supply chain is quickly consumed by the more agile commercial industry customers.

As technology ages, it’s difficult to control the supply chain and retain reliable sourcing of all parts. COTS and custom board manufacturers are generally resistant to prioritizing older, low-volume products over new product introductions and higher revenue. That strategy results in defense programs’ loss of control of the COTS supply chain, control that is required for a strategic

sustainment approach.

In order to compete successfully, OEMs of COTS and custom CCAs must introduce new technology in product road maps, inadvertently leaving behind a small number of customers, including defense programs, that rely on a steady supply of older model parts. When COTS parts reach their EOL, the remaining inventory within the open market or supply chain is quickly consumed by the more agile commercial industry customers.

Market competition will continue to be a critical forecast element in fluctuating sustainment cost for programs.

Delaying the inevitability of obsolescence can sometimes be accomplished with a lifeof-type buy, but programs are often unable to purchase enough parts because the use and growth of weapons systems are unpredictable. When a program can achieve timely funding for an LTB, it’s not unusual for inventory to sit on shelves for decades, only to be scrapped years later.

This cycle of reactive scrambling to forecast and fund LTBs is a chronic occurrence for PMs because COTS components an reach EOL at disturbingly fast and volatile rates.

Automotive, industrial, and other aggressive sectors compete vigorously for leftover COTS parts after they reach EOL. The result is that, even if you plan well and reserve funding for a proactive LTB, if you need more, those items may not be available due to the deterioration of the supply chain.

IWhen looking to the aftermarket, it’s difficult to reverse engineer highly technical military or avionics electronics, let alone

Figure 2: Unlike the consumer electronics sector, sustainment-dominated equipment sectors must prepare for a total cost of ownership for decades (20–50 years). However, extending the availability of existing technology over several decades is only possible if you have complete control over the entire supply chain.

Source: Optimum technology insertion into systems based on the assessment of viability, P. Sandborn.

reconstruct the manufacturing process. OEM mergers and acquisitions (resulting in product discontinuation), employee attrition, and the passing of time cause a situation in which availability of required schematics, test equipment, pick-and-place machine programs, and numerous other critical elements to rebuild production capability are not assured.

Technical data have many facets and layers, many of which are proprietary. Understandably, OEMs closely guard their IP to avoid losing hard-fought advantages in a competitive marketplace.

But LEMs (legacy equipment manufacturers) are not driven by new product introduction; instead, they focus only on sustainment. They present an innovative alternative solution that is a natural evolutionary step in the electronics industry’s quest to bridge sustainment problems driven by OEM product discontinuation and the impact electronic obsolescence has on defense programs with sustainmentdominated systems. This bridge, supported by LEMs, allows PMs to integrate a cost-effective and proactive sustainment solution that meets program mandates to improve system operational effectiveness (SOE). A second source of supply (SSOS) is a hybrid DMSMS solution that uses collaboration with OEMs to obtain access to technical data and collaboration with PMs to integrate sustainment parts plans that will restart the production line and deliver qualified parts, effectively fixing/freezing the supply chain of ny given CCA.

The concept of obsolescence management has spurred the creation of DMSMS and obsolescence management programs rooted in the belief that obsolescence is an issue that can be solved. But obsolescence is not an issue that can be solved. Obsolescence is an inevitable eventuality, and many of the “solutions” employed by PMs today deliver urgent stop-gap measures that address only

the high priority problem parts reports (PPRs) for CCAs. This approach temporarily provides relief for critical readiness issues but does nothing to address future demand requirements. This style of management ensures a future in which the exact same CCA will again need another DMSMS solution until a forced system redesign is the only viable sustainment option. This reactive scenario carries a high price tag and is a driving factor in increased total cost of ownership (TCO).

One of the main reasons programs continue to focus on mitigation strategies instead of implementing lasting parts sustainment solutions that actually meet their lifetime requirements is the complexity of demand forecasting. Without knowing at the beginning of a program exactly how many parts will be needed to support a system to the end of its program, a lasting solution seems out of reach. When those complexities are compounded with funding uncertainties, effective sustainment solutions remain obscure, and trying to resolve parts obsolescence issues entirely can seem like an exercise in futility.

The LEM’s unique position and focus allows them to understand that demand forecasting and funding, as well as production capability, are all only aspects of a successful SSOS effort. With the appropriate strategic engagement* an SSOS program can serve both the TLCSMand performance-based life cycle.

An SSOS provides a reliable method of extending the life of electronic assemblies that are used in complex defense and avionics systems.

THE BENEFITS OF SSOS:

• Significantly extends the life of electronics beyond the manufacturer’s end-of-life notice

• Reestablishes or continues the manufacturing production of CCAs

• More effective than other aftermarket

DMSMS solution options: reverse engineering, technology refresh

• Eliminates the scrambling, risk, and lead time usually needed to source genuine (i.e., not counterfeit) parts

• Assures system readiness via a predictable, secure production cycle and supply chain

• Eliminates the need to fund unplanned, obsolescence-forced technology refreshes

Based on an accurate understanding of DMSMS and obsolescence risk, the SSOS establishes programs that deliver parts/ product availability and life cycle sustainment plans as opposed to continuously reacting to obsolescence-driven DMSMS issues with short-term fixes..

Re-Production: Second Source of Supply (SSOS)

An SSOS reestablishes manufacturing capability for obsolete CCAs. It is a cost-

finally, reengineer the CCA’s manufacturing capability. The SSOS process delivers all the information necessary to maintain the production supply chain for obsolete CCAs. Moreover, the production capability is designed and maintained to meet the program’s life-cycle requirements as described in an integrated parts sustainment plan.

costs are easily identified and anticipated. Finally, there is no requirement to commit to future production volumes.

An LEM uses questionnaires and meetings to capture the information needed to fully understand the program requirements, forecasts, and scope of required sustainment effort.

Armed with that information, the LEM develops an SSOS proposal that maps out the reengineering efforts and sustainment of manufacturing capability to provide transparent sustainment cost and lead times for qualified parts. By working with the OEM to verify functional compliance and with prime contractors to requalify the supplier, an SSOS allows the program to essentially “fix” the supply chain.

The SSOS proposal not only should include fixed pricing for establishing manufacturing capability and options to ensure the ongoing availability of the CCAs and electronics assemblies to meet program demands, it also should be fundable and flexible enough to account for shifts in demand.

effective approach that fulfills ongoing program requirements and ensures that older designs remain available for as long as they are needed.

IBy developing ongoing relationships with suppliers, the LEM ensures long-term availability of the CCA for the customer while supporting the OEM supplier’s strategic objectives and desire to support the customer.

The LEM collaborates with the OEMs, the program, and the prime contractor to protect and transfer the technical data or IP, establish a parts sustainment plan and,

Typically, an SSOS proactive solution is less expensive and faster to implement than traditional reverse engineering alternatives. An SSOS strategic solution offers programs a predictable fixed cost for a replacement CCA for the life of the program, without interruption.

The nonrecurring engineering (NRE) ssociated with an SSOS is also less complicated and poses a lower risk to quality. Thus, an SSOS not only reduces future costs but makes those costs more transparent.

The CCA does not deviate from OEM specifications, and future CCA sustainment

Loaning reference CCAs to those who support the larger assembly (often the prime) enables verification/certification that the new LEM-manufactured cards are fit for their purpose.

Determining whether your program can benefit from an SSOS solution typically takes six to eight weeks and includes the gathering of qualifying information and stakeholder collaboration. If it is determined that a form, fit, functionally equivalent, remanufactured CCA is a feasible sustainment solution, the program may decide to have an LEM proceed to develop a comprehensive SSOS proposal.

program options that might improve SOE, is recommended.

The COTS and custom CCA sustainment solutions require a comprehensive approach driven by a reliable team of DMSMSexperienced electronic industry professionals who can bring together the available supply chain and OEM resources to deliver sustainment options to PMs that provide life-cycle sustainment assurance with costs that are knowable.

SSOS can be compared to an extended assurance policy purchased to supplement the factory warranty once it has expired and the OEM ceases parts production. In many situations, SSOS is cheaper, faster, and less risky than traditional alternatives.

Lead times for an SSOS proposal vary between six to twelve weeks, depending on the state of the technical data and the health of the supply chain that supports the CCA.

Implementing SSOS for COTS and custom CCAs typically requires some level of NRE (nonrecurring-engineering) to reestablish manufacturing capability and is offset by cost savings of the alternatives, such as avoiding or reducing expensive recertifications.

Therefore, programs are strongly advised to assess SSOS in the context of a side-byside business case analysis of all available DMSMS solution options. Working with an LEM that offers BCA support services, including an economic evaluation of potential

By Ralph Grundler, Director of Space

By Ralph Grundler, Director of Space

Space is no longer the sole domain of government agencies and aerospace & defense companies. With new players and technological goals entering the space sector, the capabilities of new space electronics are encouraging the deconstruction of past methods and pushing for a new and improved world order of space technologies.

With this growing renewal of interest to explore space, from expanding low earth orbit (LEO) and near earth orbit (NEO) applications to innovating technologies for the potential of GEO and lunar missions as well as long-term habitation in space, comes a hotbed for new applications. (Figure 1)

Space exploration drives a continuous effort

to design capable, reliable, and efficient systems. The idea that space electronics should be one large, all-or-nothing, expensive system is becoming a concept of the past. The space industry is constantly pushing for designs with tighter system integration and increased computing performance; meaning engineers are then asked to fit these goals within the particularly small size, weight, and power (SWaP) profiles.

Growing sectors in space technologies have led to the expansion of what is possible in space. Optimized payload and launch technologies are as critical to today’s space exploration as satellites, spacecraft, and stations being put into orbit. New innovations are constantly being woven into space electronics to ensure system survival through the severe shocks, temperature, EMI, and radiation of the space environment.

Levels of radiation in space can cause various problems for electronic components. While there are rad-hard electronic parts that resist the effects of radiation, these can become very expensive, and not all space missions require this as intense radiation resistance. Rad-hard boards and systems certainly have a home in space electronics but are best suited for specific application environments. And in comparison to applications requiring less radiation tolerance, overall demand for rad-hard electronic parts is relatively low, which can drive up their costs even more.

Traditional space suppliers needed space-graded electronics that meet cost restraints while maintaining the necessary radiation resistance. With commercial off-the-shelf (COTS) components, these abilities can be met.

COTS is a concept that has been introduced previously; its popularity has increased due to the commercial market expansion. COTS systems can capitalize on proven computing technologies in highly rugged space environments, creating a cost-effective method to rapidly conceptualize innovations in areas such as launch vehicles, payloads, satellites, and future habitats.

While there are several instances where space electronics are fueling innovations, here we look at four distinct areas that provide a deeper look into market shifts to come.

Habitat: As space exploration expands, the concept of habitats to safely host humans in harsh space conditions is becoming more relevant. As seen with the Lockheed Martin-built Orion spacecraft flown during the recent Artemis, I mission to the Moon and back, mankind’s progress towards inhabiting space is in the sites of space program developers. The ultimate goal of habitat development in space is to provide long-term, sustainable living spaces for humans.

Artificial Intelligence (AI) has been tasked with ensuring that space habitats are viable by analyzing equipment data and enabling situational awareness to provide data and recommended decisions to occupants. The growing number of compute-intensive mission-critical applications pushing the envelope of data processing at the edge of space need reliable, radiation-tolerant, and proven technologies.

In addition to a media converter that provided information connectivity as the main conduit data interface between Orion and the Electrical Ground Service Equipment (EGSE), Aitech’s C878 3U VPX Intel Xeon D-based SBC provided the computational core of Callisto (including Amazon’s Alexa voice-activated virtual assistant and Cisco’s WebEx) and intercom capabilities. Onboard Orion, Callisto was a payload to test and demonstrate how commercial technology could support future crewed missions in space. (Figure 2)

Satellite: A new wave of satellite technology innovation has emerged in recent years. Low-cost space access and the smaller size and weight of satellites have revolutionized the space industry and space exploration for all players. By reducing satellite costs, there are many new opportunities for exploration and research. With COTS, small satellites (smallsats) rapidly replace their larger and more costly predecessors. This allows agencies to send hundreds of networked smallsats into low-earth orbit, creating unified con-

stellations to provide global coverage.

Smallsats are creating new opportunities in communication, navigation, earth observation (EO), and research and development for the space industry. LizzieSat, the flagship multi-mission microsatellite from Sidus Space, a leading Space-as-a-Service satellite company, seamlessly links with the Sidus constellation to leverage the complete in-space services of the Sidus fleet. Aitech has provided custom Command and Data Handling (C&DH) flight computers and peripherals for this program.

Payloads: Constantly growing more sophisticated, payload systems have enabled the testing of new technologies in space by contributing to the understanding of and response to the increase in available data. The variety of payload types has increased, encompassing communication, navigation, observation, scientific, human support, cargo, etc., all of which help determine the capabilities and limitations of developmental space technologies. To survive severe shocks, vibration, temperature, EMI, pressure, and radiation, payloads require ruggedization yet must still be lightweight and as compact as possible to reduce launch costs and maximize the space on the spacecraft or rocket.

Payloads are the part of a spacecraft or rocket tasked with achieving a mission’s objectives. Scientific payload systems, for example, are used to study various aspects of space and the impacts that may affect people on Earth. Particularly, OSIRIS-Rex provides NASA with insight into the Bennu asteroid by collecting samples. Bennu’s close orbit can be potentially hazardous to Earth, but with the advanced technology this payload systems provide, scientists can

take preventive measures long before impact. In addition, this spacecraft includes a suite of scientific instruments to study Bennu’s geology, mineralogy, and composition, as well as its orbit and rotation. (Figure 3)

Figure 2: Not only did Orion serve as an exploration vehicle to enable deeper human space exploration, but it also included Callisto, a technology demonstration launched onboard Orion during the Artemis I mission in November 2022.

Figure 2: Not only did Orion serve as an exploration vehicle to enable deeper human space exploration, but it also included Callisto, a technology demonstration launched onboard Orion during the Artemis I mission in November 2022.

Launchers: For payloads, satellites, or any spacecraft to be released into space, launchers must generate massive amounts of momentum to overcome Earth’s gravity and successfully put space systems into orbit. High costs have been a bottleneck since previous launch technologies had a one-and-done lifespan.

With recent developments and multiple launch techniques in evaluation, reusable launchers are encouraging more innovative, cost-effective solutions for the future of space. For example, Aitech’s NVIDIA-based, space-characterized S-A1760 Venus AI supercomputer became the first use of GPGPU technology in space during the successful launch and re-entry of NASA’s Low-Earth Orbit Flight Test of an Inflatable Decelerator (LOFTID) in November 2022.

The common thread of today’s space exploration is the digitalization of electronics using COTS systems that rely on open standards and highly adaptive scalability. COTS systems are heavily applied to the Space Digital Backbone (DBB). This “information highway” approach provides a unified, flexible, and scalable communication infrastructure for the increasing number of IoT technologies implemented into space technologies. (Figure 4)

The Space DBB enhances space electronics across all orbits by removing connectivity and computing limitations and the associated performance bottlenecks that have forced spacegrade, radiation-tolerant electronics to lag generations behind Earth-bound technologies.

The Space DBB architecture includes four main elements:

• Open Standard Networking

• Edge Computing with AI/ML

• Network Attach Storage (NAS)

• Cybersecurity

This concept has paved the way for unprecedented space innovations, including the launch of the commercial space market, such as Virgin Galactic’s successful 90-minute suborbital flight of the Unity V22 that utilized a rocket motor controller from Aitech as well as the development of the NASA HALO lunar gateway for longterm deep space exploration and redundant smallsat constellation networks, like LizzieSat from Sidus Space. The Space DBB streamlines high-performance onboard computing and expedites valuable data assets for transmissions, eliminating significant technical challenges, like extremely slow communications.

The opportunities can be endless by implement-

ing the Space DBB techniques into the current space industry focus. COTS hardware in a Digital Backbone architecture enables space solutions providers to meet aggressive schedules using proven, reliable embedded designs to mitigate program and mission risks throughout the lifecycle of a space program. With AI and edge computing, space applications can take gathered data and efficiently discover patterns and anomalies to ensure successful innovations for the future.

There is a growing need for reliable, space-rated systems that meet the ever-evolving technology requirements around communication, imaging, and processing capabilities. Proven and reliable COTS electronics enable aggressive development-to-deployment schedules and provide embedded designs with enhanced capabilities and performance.

The space industry and the opportunities it presents will only continue to grow. A paradigm shift in the approach to building space electronics has paved the way for a whole new economy of commercial spaceflight and the development of future versatile space missions. Using cost-effective COTS-based electronics across the Space DBB infrastructure reduces latency risk and cost while increasing connectivity throughout LEO to the deepest space missions, ultimately helping to build a far more efficient and intelligent space industry.

GbE Applications Include PoE Cameras, LAN Access Points, VoIP Phones, Touch Screens, Card Readers

Transtector, an Infinite Electronics brand leading to end-to-end power and signal integrity solutions, has released two new outdoor, IP67-rated Power over Ethernet injectors and a PoE-compatible splitter.

The new injectors add power to a PoE-capable device through its Ethernet data cable, eliminating the need to run a separate electrical cord and install a power outlet near it. The splitter removes power from a powered Ethernet cable and separates it into its own power cable, which is helpful for non-PoE devices requiring separate power and data inputs. This prevents having to install an outlet near the device and allows the use of existing Ethernet and PoE infrastructure.

The outdoor 1 Gigabit Ethernet PoE injectors and PoE splitter are helpful for any RJ-45 network device that supports PoE, including

The POEOD1GAT-TT is a 30-watt, 54-volt, one-port, end-span PoE injector that supports 802.3at+ and 802.3af IEEE standards. The POEOD1GBT-TT PoE injector features a 60-watt, 55-volt, one-port operation and complies with 802.3at+ and 802.3bt. The new POESOD1GBT-TT PoE splitter supports a 60-watt, 12-volt, one-port operation and complies with 802.3at+ and 802.3bt.

The new injectors and splitter are housed in rugged metal enclosures and have an IP67 rating for outdoor and industrial use. They have removable grommets for sealing, which allow them to be used with existing pre-terminated cables. They can be mounted to a wall or flat surface. Other features include LED indicators, terminal power blocks, and a grounding lug.

“Our new, IP67-rated PoE injectors and splitter are proving to be especially useful for transportation and telco applications, with cameras and access points being the main areas of use. They are also very functional for smart office and residential use, focusing on lighting and security,” said Dan Rebeck, Product Line Manager.

Spectrum Control introduces a dual-line common mode panel mount EMI filter that reduces space and weight by 50% compared to two single-line filters. The industry’s only dual-line EMI filter that integrates a common mode choke in a 0.690” diameter package occupies less real estate on a power supply panel or chassis than alternative approaches and addresses emerging compact designs in military/ aerospace, commercial, and industrial applications.

The dual-line common mode panel mount EMI filter combines a compact package with high performance to meet Size, Weight, Power, and Cost (SWaP-C) requirements. It delivers reliable EMI filtering of common mode noise from 30 kHz to 1 GHz and differential mode noise from 30 kHz to 10 MHz. Its innovative design employs a common mode choke and Line-Line capacitor to allow noise attenuation from both lines on inputs and outputs of A.C. or D.C. systems.

Designed to meet MIL-PRF-15733, the EMI filters have standard voltage ratings from 50 V to 200 VDC/130 VAC, 400 Hz. The experienced engineering team at Spectrum Control can also develop custom configurations.

Because of its high-performance and compact package, the dual line common mode panel mount EMI filter provides benefits in a wide range of power supply applications. It suits commercial and military aerospace designs, including antenna arrays, radar, control, and navigation systems. The EMI filter can also be used in railway systems, analyzers, flow meters, test instruments, and other industrial applications.

Spectrum Control spectrumcontrol.com

New Push-Button Attenuators Address Wide Range of Applications

Pasternack has just introduced a new series of push-button attenuators to address multiple applications, including test instrumentation and cellular, wireless, and satellite communications.

Pasternack’s new line of continuously variable attenuators features even greater maximum power ratings of 5 and 10 watts, an operating frequency range of up to 18 GHz, and attenuation levels of up to 50 dB.

The new variable phase shifters provide frequency ranges at 2 GHz, 4 GHz, and 8 GHz, along with a 100-watt power rating. These variable phase shifters also have adjustable phases at 60 degrees/ GHz, 90 degrees/GHz, and 180 degrees/GHz.

The step attenuators are engineered for supe-

rior R.F. performance with frequency ranges of 6 GHz, 8 GHz, and 18 GHz. They feature attenuation levels including 10, 60, 70, and 99 dB, and attenuation steps at 1 dB and 10 dB depending on the model.

Pasternack pasternack.com

Rapid Silicon, a provider of A.I. and intelligent edge-focused FPGAs based on open-source technology, announced its Vega eFPGA I.P today. The Vega eFPGA I.P. is an embeddable standalone FPGA IP core, which is flexible, powerful, and efficient to enable a programmable solution to your SoC. Its customizable and scalable architecture allows the design of custom eFPGA I.P. from 1.5K to 100K+ Logic Cells, configurable BRAM, and DSP MAC tiles. The eFPGA I.P. also comes with I.O. tiles covering all sides of the I.P. for easy SoC integration. The Vega IP also includes an FPGA configuration block for easy eFPGA configuration and can be configured with different combinations of CLB, BRAM, and DSP tiles.

“We are thrilled to launch our Vega eFPGA I.P.,”; said Naveed Sherwani, CEO of Rapid Silicon. Customers can tailor the Vega IP to meet their needs with its highly configurable architecture. The Raptor Design Suite makes it easy for customers to integrate the I.P. into their SoCs, reducing time-to-market and development costs. We are excited to see the innovative solutions our customers will create with the Vega eFPGA I.P.

The Vega eFPGA I.P. is built based on foundry-specific standard cells, which makes it easier to port to different foundry and technology nodes. It is easy to embed into an SoC and comes with configurable input/output, clocking, and test/ DFT pins. Vega IP has soft FPGA configuration logic and can be integrated with SoC using JTAG or APB interface. Vega IP has an internal power grid that can be connected to the customer’s digital SoC power grid. It is highly configurable and can be ported easily to other technology nodes.

The Vega eFPGA I.P. license comes with Raptor Design Suite - the industry's first and only commercially available open-source toolchain for FPGA. It has a complete FPGA design tool chain, including Simulation, Synthesis, Placement, Routing, Bitstream Generation & Configuration. Raptor has integrated LiteX and Migen IP management integration for easier I.P.

Integration - Our design suite includes Rapid Power Estimator for I.P. power estimation

Rapid Silicon rapidsilicon.com

MicroSys Electronics announces a new evaluation kit for its myriad System-on-Modules based on the NXP Semiconductors S32G processor family. Deployed in-vehicle networks as headless controllers, these highly integrated and performance-scalable processors support ADAS and other functions for increasingly autonomous vehicles. Developers can use the new miriac evaluation platform, which is designed as a modular single board computer (SBC), to test the performance balancing of their applications and to connect their CAN-, LIN-, FlexRayand 100BASE-T1-based peripherals via automotive connectors. The evaluation kit includes NXP S32G274A and/or new NXP S32G399A based myriad System-on-Modules, a carrier board in the shape of a dedicated modular SBC, as well as the appropriate power supply, cable sets, and

Anritsu Company introduces the Pulse Radar Measurement Function MX284059B software for its Signal Analyzer MS2840A that, creates a single-instrument solution for auto-

a pre-installed Linux image.

Developers of mixed-critical safety applications benefit from up to eight Arm Cortex-A53 cores and four Arm Cortex-M7 dual-core lockstep pairs. This is sufficient to process LiDAR and video data alongside functionally safe vehicle control. When extended with one or two Hailo-8 AI processor modules, the evaluation kit provides numerous pretrained computer vision models for situational awareness. OEMs using such application ready System-on-Module based platforms – for which MicroSys also develops certification-ready system designs – gain access to rapid prototyping, advanced connectivity for their specific use cas-

mated pulse radar measurements to dramatically reduce cost-of-test and test time on the production line and in the field. The MS2840A, when equipped with the new software and the USB Peak Power Sensor MA24406A/18A/40A, supports tests of Tx characteristics that typically require a spectrum analyzer, oscilloscope, power meter, and frequency counter.

es, comprehensive software support, and documentation required for safety certification up to ASIL D. Target markets are real-time connected and increasingly autonomous vehicles, all types of mobile machines, as well as automotive test and measurement equipment.

MicroSys Electronics www.microsys.de

The MX284059B software has a more comprehensive pulse-width measurement range than previously available with the MS2840A and supports new interlocked control of the USB Peak Power Sensor MA24406A/18A/40A for automatic high-accuracy Tx power and pulse-width measurements. Using short pulses, the single-instrument solution can accurately test high-performance radar, including aerospace and maritime applications. It also supports long-range radar using long-repetition cycles.

S-, C-, X-, and Ku-band (3 to 15 GHz band) pulse-radar Tx tests can be conducted with the Signal Analyzer MS2840A-based solution. Automatic tests of Tx power and frequency, pulse width, pulse rise/fall times, repetition frequency, and spurious emissions can be made. Spurious emissions test results are evaluated based on Recommendation ITU-R SM.329, SM.1541, and M.1177 using masks superimposed on the MS2840A test trace display.

All test stages, from data acquisition to spectrum emission mask creation for Tx spurious emissions, are fully automated. The Signal Analyzer MS2840A saves measured data, measurement screens, and pass/fail results in an integrated manner for enhanced evaluation.

Curtiss-Wright’s Defense Solutions division has announced the latest enhancements to its PacStar IQ-Core Software suite of unified communications network management solutions. IQ-Core Software v5.1.15 updates include enhanced network configuration and management capabilities, new device support, better visibility of endpoints in secure environments, and contemporary security auditing and management features.

IQ-Core Software has numerous ways to provision and configure communications systems. These now include configuration plan support for selected devices. The operator can send plans to a system, compare them against actual device configurations, and then activate a plan so that the system is using the new configuration. Enhancements have also been made to IQ-Core profile templates to enable scriptable configuration of an entire management environment.

This version of IQ-Core Software includes updates to expose more critical operating information about industry-standard satellite modems and radios, enabling operators to stay within a single interface for complete network management. Additional features have also been added to the ‘generic’ device type, which can be used to manage any network device that IQ-Core Software does not support natively. These new features include viewing, exporting, and alerting for interface and throughput data and integrated access to a device console.

Curtiss-Wright is a leading supplier of Commercial Solutions for Classified (CSfC) solutions, and IQ-Core Software has extensive support for the certificate and VPN management needs of CSfC environments. Complex tasks can be accomplished in minutes, from infrastructure gateway configuration to secure endpoint management. IQ-Core Software v5.1.15 updates these capabilities to include enhanced support for Continuous Monitoring (a CSfC requirement), bulk provisioning, and secure endpoint rekeying.

A new audit logging system has been added to IQ-Core Software in this release to ensure operator actions are audited and stored securely,

DoD-approvedly. User session control has also been improved to provide inactive sessions are terminated, and reauthentication is required when roles change.

IQ-Core Software is now fully supported and tested under Microsoft Windows Server 2022 and Microsoft Windows 11, in addition to previous versions of Microsoft Windows.

IQ-Core Software is a comprehensive management software application designed for secure, tactical, and distributed network management –ideal for edge networks in disconnected, intermittent, and limited (DIL) environments. It comprises four major editions: IQ-Core Network Communications Manager (NCM) for nodal management, IQ-Core Crypto Manager (CM) for CSfC management, IQ-Core Remote Operations and Management (ROAM) for distributed management, and IQ-Core Endpoint User Manager (EUDM) for secure endpoint management.

IQ-Core Software v5.1.15 contributes to tactical mission success by reducing network misconfiguration, improving uptime, simplifying troubleshooting, and providing cyber situational awareness to tactical networks. It advances the PacStar product family’s mission to enable tactical,

expeditionary, and mobile organizations to modernize networks. This powerful software allows operators to field the most advanced technologies and achieve cyber overmatch while driving down complexity and training costs. It accomplishes this through an intuitive and integrated user interface that makes system setup and operation quick and easy to learn.

Curtiss-Wright created and manufactures COTS-based rugged, small-form-factor expeditionary and mobile communications systems. It developed integrated network communications management software, IQ-Core Software, for the military, federal, state/local government, and emergency responder markets. The company’s patented IQ-Core Software, hardware technology, and integrated solutions provide secure command, control, and communications systems, particularly in remote or infrastructure-starved areas. The industry-leading PacStar family of advanced communications solutions addresses various military, intelligence, and commercial applications. In addition, PacStar communications systems are ideally suited for commercial/industrial organizations with mission-critical field communications requirements.

Curtiss-Wright’s curtisswright.com

SElma Electronic offers a VPX Chassis Manager that aligns with The Open Group Sensor Open Systems Architecture™ (SOSA) Technical Standard 1.0 and supports the Modular Open Systems Approach (MOSA) standardization initiative from the U.S. Department of Defense (DoD).

The new VITA 46.11 Tier 3 chassis manager is a standalone unit or can be mounted on a carrier card. 3U and 6U conduction-cooled plug-in and aircooled 3U versions are also available. The card offers firewall support, SOSA out-of-band command support, and 16 digital inputs and 16 configurable digital outputs that provide a high degree of system management function.

Ideal for use in a wide range of embedded computing applications through the military and defense industries, the new chassis manager helps ensure overall system health and proper operation. This includes maintaining a components and sensor inventory and receiving reports and notices

DIGISTOR announced that the National Security Administration (NSA) added its FIPS 140-2 L2 SSDs to the Commercial Solutions for Classified (CSfC) list. These DIGISTOR drives are the only commercial SSDs to achieve this listing, and the company’s Citadel™ K Series is now the simplest and most affordable way to produce CSfC-level secure data at rest (DAR) solutions for top-secret programs.

“The leak of highly classified Pentagon documents in recent weeks underscores the the vital importance of securing sensitive data. For the first time, companies working on secret government programs that require CSfC to have a reliable and affordable solution to secure data at rest for programs requiring the highest levels of security,” said Randal Barber, CEO of parent company CDSG. “As the foundation of our Citadel pre-boot authentication solutions, these drives provide critical infrastructure organizations, industry, and military and government agencies access to

from installed intelligent field replaceable units (FRU). The SOSA-aligned chassis manager can also adjust the fan speed for over/under temperature conditions and report or shut down the system due to over or under voltage and current conditions.

Mark Littlefield, director of systems products for Elma Electronic Inc., commented, “With a chassis manager aligned to SOSA, we’re able to give system engineers a tool that monitors overall health and also identifies anomalies and takes corrective action in systems developed to meet today’s interoperability initiatives as put forth by the DoD.”

Additional features include power management and cooling control, event sensor logging, electronic keying, and card hot-swap monitoring. A

redundant IPMB ensures maximum system uptime. The chassis manager operates over an extended temperature range of -40°C to +85°C.

A web-based graphical user interface (GUI) monitors up to 12 fans, eight analog inputs, and six external thermistors. All data is presented in a clear, concise graphical representation with complete sensor information available with the click of a mouse. Parameters that can be monitored include health, voltage, fan RPM, power, temperature, device I.D., serial and port numbers, and software versions.

the most advanced, highly secure SSDs available with both the critical CSfC and NIAP listings.”

With the CSfC listing, customers can trust that the solutions they develop to secur e DAR in laptops, desktops, and other devices, meet the highest security requirements for sensitive and classified data. By using DIGISTOR Citadel solutions, organizations can complete and deliver CSfC secure DAR projects more quickly and to more customers.

CSfC is an NSA strategy to provide cybersecurity solutions using commercially available industry solutions. DIGISTOR is listed in the Hardware Full Disk Encryption section on the CSfC Component List with the Common Criteria/NIAP validation report number CCEVS-VRVID11297-2023.

This news follows the company’s announcement that its COTS-level priced FIPS 140-2 L2 certified self-encrypting drives achieved Common Criteria certification on the National Information Assurance Partnership (NIAP) Product Compliant List (PCL).

Multicore PowerPC and ARM platforms feature DO178C RTOS, integrated DDS/TSS

DDC-I, a leading supplier of software and professional services for mission and safety-critical applications; North Atlantic Industries (NAI), a leading supplier of embedded computing solutions and power supplies; and Real-Time Innovations (RTI), the largest software framework company for autonomous systems, today announced that they have collaborated to offer a MOSA-aligned SWaP-optimized, a platform for avionics targeting FACE applications. The multicore platforms combine NAI’s PowerPC and ARM-based Configurable Open Systems Architecture (COSA) single-board computers and multifunction I/O with DDC-I’s Deos' FACE™ Technical Standard, Edition 3.1 conformant Operating System Segment (OSS) software and RTI’s Connext software connectivity framework.

“DDC-I, NAI, and RTI have joined forces to offer avionics developers a modular, certifiable, pre-integrated FACE-targeted platform,” said Greg Rose, Vice President of Marketing and Product Management at DDC-I. “The systems combine world-class multicore performance, versatile I/O and safety certification capabilities with a proven DDS framework that streamlines communications accelerate integration and enhance reuse and application portability.”

“Deos running on NAI’s COSA architectures provide an excellent safety-critical RTOS platform for our connectivity software,” said Chip Downing, Senior Market Development Director of Aerospace and Defense at RTI. “Together, COSAÒ, Deos, and Connext TSS offer a modular, reusable open architecture solution that combines FACE, ARINC 653, POSIX, and DDS into a COTS solution stack that reduces integration and certification risk while speeding time to market.”

“We are excited to be working with DDC-I and RTI to offer our customers integrated platforms that combine our high-performance ARM Cortex-A53 multicore capability and configurable I/O with a bestin-class safety-critical RTOS and communications framework,” added Lino Massafra, Vice President of Sales and Marketing at NAI. “Developers requiring the highest level of design assurance now has a rugged, flexible, off-the-shelf solution that accelerates certification and deployment of safety-critical systems.”