SLING

TRAINERS - CAN THEY LAST?

Plett search & rescue: GA saves lives

Jim Davis: Instructors Having Fun!

Peter Garrison: Why have bent wings?

Hugh Pryor - Pilotless planes?

SLING

TRAINERS - CAN THEY LAST?

Plett search & rescue: GA saves lives

Jim Davis: Instructors Having Fun!

Peter Garrison: Why have bent wings?

Hugh Pryor - Pilotless planes?

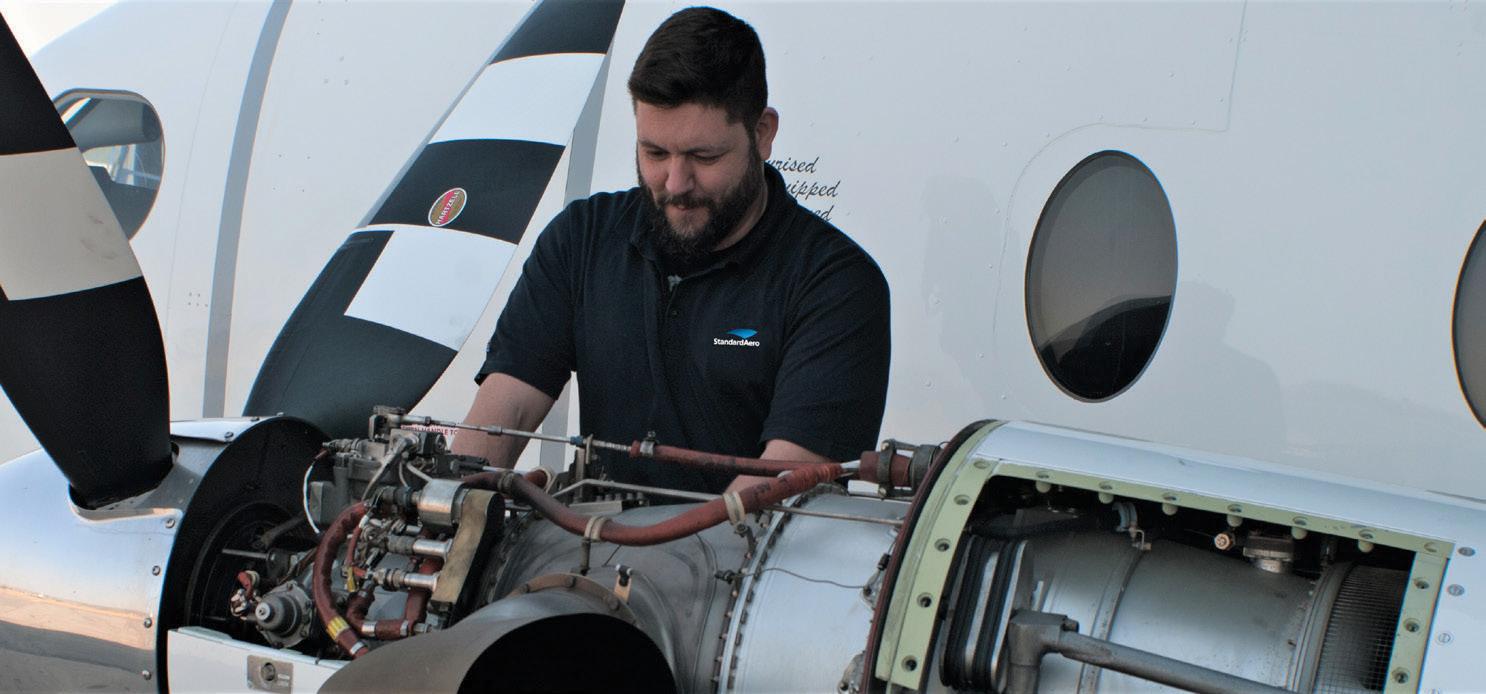

Passing the milestone of eight million flight hours has firmly established the Pilatus PC-12 as the world’s greatest single. Refunding on this experience, the new PC-12 NGX now offers 600-hour scheduled maintenance intervals, reducing operating costs and providing owners with more up-time. This proves the theory that time really is money.

pilatus-aircraft.com

Contact Pilatus PC-12 Centre Southern Africa, your nearest Authorised Pilatus PC-12 NGX Sales Centre for further information on Tel: +27 11 383 0800, Cell +27 82 511 7312 or Email: aircraftsales@pilatuscentre.co.za

THE QUESTION ARISES; who checks the DFE’s - who ‘guards the guards?’ Or as the regulators like to say, “You can’t expect what you don’t inspect.”

To check that the DFEs are not letting standards slide, the CAA employs Training Standards Officers (TSOs). These are career bureaucrats whose job it is to ‘oversee’ the DFEs.

Once again the DFEs are in open conflict with the TSOs. Nearly five years ago, in my ‘CAA Dossier’ series, I discussed the damaging toxic relationship in this, the highest levels of aviation. The issue went quiet for a while, but is flaring up again.

Some context may be needed. To evaluate DFEs the TSOs sit in on a DFE conducting a proficiency check on an instructor or flight crew. This can be a lengthy process, usually requiring an hour’s briefing, and then about three hours in the simulator, and another hour’s debriefing. You end up with at least four people in a crowded ‘sweatbox’ of a simulator cockpit: the two crew flying the plane, the DFE evaluating their performance and the TSO overseeing the DFE’s

contributing their lifetime’s worth of accumulated knowledge by taking these TSO posts. But in South Africa, many claim the inherent racial tension at the CAA has created a toxic working environment which just does not make it attractive enough.

So South Africa makes do with TSOs who were at best Grade 2 instructors – many years ago. This is far below the standard required by ICAO. Tensions between the underqualified TSOs and DFEs run high. Once again there has been an outbreak of cases reported to me of the TSOs grounding DFEs – by trapping them with arcane legal questions about the regulations.

The aggrieved DFE’s are reported to be resigning their DFE status in disgust. And thus the industry loses their vast repository of experience.

The odd thing is that the SACAA is fanatic about ICAO compliance and often adopts international standards – usually from either the FAA or EASA. This has produced a hashup of sometimes contradictory regulations and awkward outcomes. Thus, what the world considers to be Chapter 8 of the regulations has become Chapter 9 in South Africa.

important. ICAO requires the TSOs to be; ‘equivalent to, or more qualified’ than the DFEs they are evaluating. The challenge is where to find these very highly qualified instructors. In aviation around the world there are usually enough retired airline Training Captains who can be persuaded to continue

This then gives the TSOs the opportunity to create their own ‘tea-time rules’ of Technical Guidance Material, in one case even creating a personal ‘rubric’ of requirements.

The DFE’s naturally have an inherently low tolerance for the excesses of underqualified TSO’s and soon give up in disgust. And so, the loss of essential skills continues. Over the next few issues I will continue to investigate this worrying trend.

The CAA may like to think that it is the custodian of aviation standards in South Africa, but the reality is that the designated flight test examiners (DFEs) are the keepers of flying standards. Yet they are under threat.

Porsche Approved. Reignited by passion.

In order to provide you with an exceptional ownership experience, we guarantee:

• Vehicles are offered with a Pre-owned Plan Maintenance Agreement® at no cost, which is a service and maintenance pl an, subject to terms and conditions

• Each vehicle is checked using a comprehensive 111-point checklist

• Any repairs carried out are in line with the strict Porsche quality criteria

• Vehicles meet the Porsche safety and reliability standards

• Includes 24 hour Porsche Roadside Assist.

2015 – 911 GT3 PDK Including Maintenance Plan, 17,300 km, White, Black Leather, R2 175 000

2019 – 911 GT3 RS PDK Including Maintenance Plan, 3,700 km, Black, Black Leather, R3 750 000

2017 – 911 Carrera GTS PDK Including Maintenance Plan, 59,700 km, Miami Blue, Black Leather/Alcantara, R1 695 000

2017 – 911 Turbo S PDK Including Maintenance Plan, 7,700 km, Carrara White Metallic, Black/Bordeaux Red Leather, R2 895 000

2015 – 911 GT3 PDK Including Maintenance Plan, 17,300 km, White, Black Leather, R2 175 000

2019 – 911 GT3 RS PDK Including Maintenance Plan, 3,700 km, Black, Black Leather, R3 750 000

2017 – 911 Carrera GTS PDK Including Maintenance Plan, 59,700 km, Miami Blue, Black Leather/Alcantara, R1 695 000

2017 – 911 Turbo S PDK Including Maintenance Plan, 7,700 km, Carrara White Metallic, Black/Bordeaux Red Leather, R2 895 000

tailBeaconX combined with the AV-30 or supported third-party EFIS elevates your cockpit functionality while future-proofing your ADS-B transponder to meet US, Canadian, and future ADS-B requirements. tailBeaconX replaces your existing transponder while upgrading your rear position light.

tailBeaconX CONTROLLED WITH AV-30

Helping to keep the world a beautiful place, Airbus HCare portfolio offers the best combination of support and services for every customer. Starting the moment an Airbus helicopter is delivered, we’ll make sure your operations are carried out efficiently, safely and cost-effectively. Because when your focus is on the mission, our focus is on you.

We love ‘in your face’ pictures with dramatic impact, far more than static beautiful sunrise or sunset pictures. This photo has that impact in abundance.

Cape Town’s Morningstar airport based photographer, Francois ‘Cois’ Potgieter, writes; “I took this picture of an Ayres S2R-T34 Turbo Thrush crop sprayer piloted by Willie Marais while spraying wheat fields outside Durbanville. I had to move in close to the action to get this kind of dramatic image. When the easterly came up, Willie went lower and lower until the wheels touched the top of the crop. Notice the wet wheels.”

Cois used his Nikon D7100 with a Nikon 70-200mm lens at 1/160 sec and f10.

BRANSON MADE HIS NOW FAMOUS quote in 2014 after the fatal accident that killed one of his test pilots when SpaceShipTwo was prematurely feathered, (This is done by folding the empennage vertically and was discussed by Peter Garrison in October last year.)

With hindsight, Branson really had no idea just how dangerous space is. Nicholas Schmidle of The New York Times writes that; ‘riding in rockets is dangerous. Around 1.4% of Russian, Soviet and American crewed space flight missions have resulted in fatalities.”

Those are scary odds and were achieved by countries and space agencies with almost limitless budgets – far from the cash-strapped private companies that are trying to make space flight safe and affordable. The key is volume. Virgin Galactic said it aims to have, “about three launches per month sometime in 2023.”

This fatality rate makes Elon Musk's SpaceX achievements all the more incredible, and shows the massive hurdle that Branson and Jeff Bezos have to climb to have any hope of making space

flight a safe commercial tourist trip. A private space programme simply cannot afford a single fatality.

The FAA has come up with a 121 page rulebook — including an equation for calculating expected casualties — to assess the safety of proposed commercial spaceflight. For the FAA, an acceptable risk requires no more than one casualty per 10,000 missions. This is more than 100 times safer than the track record so far.

So far Branson has only launched a single crewed space flight in his SpaceShipTwo. With Branson on board, it came perilously close to disaster. Branson finds himself financially in a tight corner. It appears that he is having to take desperate measures to keep the Virgin Galactic dream alive, while at the same time keep his remaining stake in Virgin Atlantic airline going.

Branson has of necessity been unfailingly optimistic. Jon Ungoed-Thomass, writing in the Guardian, says if Branson’s claims to investors are unrealistic he could fall foul of US Investor protection laws. This has landed many others in

50,000 astronauts into space by 2019

Richard Branson famously said that “space is hard.” This is classic British understatement. It turns out that space is so hard Branson may end up in jail.

jail, most recently, Elizabeth Holmes of Theranos who has been jailed for 11 years for essentially selling fake promises. The sentencing of Holmes; “clearly sends a signal …….that puffery and fraud and misrepresentation will be prosecuted, there will be consequences and the end result is potentially decades in prison,” said The Washington Post.

Branson is particularly vulnerable because his method of getting to space cheaply is unique in that he uses a winged aeroplane to takeoff and land. SpaceX and Blue Origin (and NASA and the Russians) are sticking with the traditional vertical launch rockets that can blast-off without pilots. In contrast, Virgin Galactic requires pilots to handfly an accurate trajectory to get them into space. By requiring pilots, the risks for Virgin Galactic are far higher than its vertical launch competitors because each test flight is literally a matter of life-or-death. In comparison, SpaceX completed many test launches without crew before it risked live astronauts.

In this age of increasing pilot redundancy, it may be heart-warming to know that Branson is still relying on stick and rudder skills. But this approach to spaceflight was called into question on his only passenger flight to date. Schmidt reports that a Master red light illuninated, warning of a trajectory problem on the “entry glide cone.”

To glide back to Earth and land on the runway like the space shuttle, the spaceship must remain within a cone of airspace above the runway to be able to circle back down to land. SpaceShipTwo had not climbed steeply enough and the red light indicated that the rocket was outside the entry glide cone. The pilots took a fat chance. They could’ve/should’ve powered back, but were evidently under pressure to complete the mission successfully because Branson was aboard and competitor Jeff Bezos was expected to fly his New Shepard rocket a few days later. So, like good employees, the pilots raised the nose and pushed on.

The chances taken with this flight are just part of a plethora of problems Virgin Galactic has had. Perhaps his biggest problem has been scaling up the two-place SpaceShipOne into the commercial eight-place SpaceShipTwo.

In July 2011 SpaceShipTwo entered a flat spin. In the almost non-existent atmosphere, it took test pilots Dave Mackay and Mike Masucci incredible skills to recover it. In 2014 there was the fatal accident and in 2018 the spacecraft started rolling wildly. The post-flight inspection revealed manufacturing defects that required months to repair.

In 2019 one of the mothership Unity’s horizontal stabilisers, "popped like a bag of potato chips.” This close call led to the resignation of Todd Ericson, Virgin Galactic’s then Vice President of Safety and Testing. Schmidle says that Ericson shared his concerns with members of the board, which hired a retired Boeing executive to conduct a safety review. The irony of using a Boeing manager to monitor safety standards was presumably lost on the board. The Boeing manager prepared a substantial report covering all the organisational failures he believed were creating these serious incidents. However, Virgin Galactic refused to make this report available to investors and decided that it was safe to fly. Ericson resigned from his post.

Flight Test Director Mark Stucky was also deeply worried about the safety culture of Virgin Galactic. His key concern was that Branson and the rest of the Virgin Galactic team wanted to downplay (or even ignore) the systemic nature of the problems. This meant that the incidents could not be used as a learning experience.

It is instructive to note that in terms of the current key airline safety concept of a learning, no-blame ‘just culture’, Virgin Galactic has adopted the opposite approach and got rid of its critics. Ericson and Stucky found themselves

excluded from any further part in the company's safety discussions and then out of a job.

But something clearly needed to be done, so in October 2021 Virgin announced that it would ground its operation for eight months to review the systems and structures of its spaceships.

The pressures of the programme put Virgin Galactic’s already strained finances under yet more pressure – and something had to give. Branson has not only his own massive investment in the Galactic business, but the far larger investment of the many private investors who he sold the romance of private space flight to.

In this business model he now sells tickets for $450,000 each which, for just three minutes of weightlessness, seems a trifle expensive. He had initially said that he expected to send 50,000 astronauts into space by 2019. As reality hit, investors have become increasingly disillusioned and the share price has fallen from more than $55 to $3.50.

It’s therefore not surprising that bleeding investors are now lining up to sue Virgin Galactic, claiming that the defects in the programme were not properly disclosed in the prospectus.

The claimants say that they have internal corporate documents to support their assertions. In December 2021 Mark Kusnier and other investors claimed; “Unity and Eve were so rickety that every flight could be their last. Cracks appeared on Eve's wings after every flight and some were not fixed - so much so that a Virgin Galactic employee said the wings looked like spider webs….”

The core gripe is that the investors say that the many technical failures during flight testing of both the spaceships and mothership were not properly disclosed, enabling Branson to sell

statements were materially misleading

shares at "artificially inflated" prices. Naturally Virgin Galactic says that it always properly disclosed safety and design issues.

A United States judge found in November that some of Virgin Galactic’s statements were ‘indeed materially misleading’. This may have serious consequences for the Virgin Galactic team. From July 19, when the company listed, to October 2021, the company sold shares worth about U$892 million. Remarkably, Branson admitted that the proceeds from the sales of his shares were used to bailout Virgin Atlantic, which had been forced to the wall by the COVID lockdown.

by Virgin Galactic and Branson has said that he is committed to delivering commercial space rides to the 900 punters who have already bought tickets. How many will want to actually fly remains an open question.

In the meanwhile, Virgin Galactic says both the Eve and Unity aircraft have undergone an "enhancement program" to remedy the problems and create the required “high flight rate capability". In preparation for all the fare paying passengers, Virgin says that it will be conducting flight tests of the Unity spaceship in the first quarter of 2023.

guy@saflyermag.co.za

THE VOUGHT CORSAIR'S inverted gull wing suggested that there was something mysterious, but very special, about the aeroplane. Its purpose, however, was prosaic. The Corsair had a huge propeller, and the long stalky gear legs needed to provide clearance for it didn’t seem ideal for slamming down onto carrier decks. Bending the wing downward allowed the legs to be shorter.

Other aeroplanes had used this feature before the Corsair did, particularly during the era of fixed gears enveloped in voluminous fairings or "pants."

An early example was the Ha 137. Ha stands for Hamburger Flugzeugbau - Hamburg Aeroplane Factory - a subsidiary of the great German shipbuilding firm of Blohm und Voss. A dark horse in a Luftwaffe dive bomber competition, the sleek 137 lost out to the famous Junkers Stuka, which also had an inverted gull wing as well as its own built-in air raid siren. (The name Stuka, by the way, is just an abbreviation of the German term for a diving attack, Sturtzkampf, and would have stuck to whatever aeroplane won the contract.)

under license in Japan by the firm of Kawasaki, where Vogt worked before returning to Germany in 1933 to become head of aircraft design for Blohm und Voss. He remained in that position until the end of the war.

Unlike the names of Willy Messerschmitt (Me 109) and Kurt Tank (Fw 190, Ta 52), Vogt's is little known today, but he was a designer of great originality whose work spanned eras from the biplane to the cruise missile.

One design of his that still pops into view from time to time is the BV 141; in fact, it popped up in this column not so long ago ("World's Worst"). A proposed reconnaissance plane, the 141 was dramatically asymmetrical, with a single-engine fuselage offset to the left of centre and a glass-enclosed gondola to the right. The horizontal tail projected entirely to the left of the fin in order to give the gunner in the rear of the gondola an unobstructed field of fire. The oddity of the design caused much merriment at the time, but also made the aeroplane unforgettable. It had, in spite of being the butt of much mockery, excellent flying qualities.

The designer of the Ha 137 was a fellow named Richard Vogt. Vogt was a protégé of the German Claudius Dornier, whose eponymous company is still alive and well today. During the 1920s Dornier's designs were manufactured

Many of Vogt's designs were floatplanes or flying boats. One of these, the three-engine Ha (later BV) 138, started life with another gull wing, right side up this time, intended to get the

propellers as far as possible from the water. Twin booms emerged at the dihedral breaks to support the empennage, and the third 600-hp Jumo engine sat atop a pylon in the vee formed by the slanted inner panels of the wings. This arrangement turned out to have bad stalling qualities, and a second version of the design used a straight wing, a deeper hull, and a central nacelle towering above the rest. I find the result rather rakish looking, but the British magazine Aeroplane scoffed at it:

Richard Vogt, that original man, Turns out aeroplanes uglier than 'Most any other designer can.

This design was followed by a four-engine longrange mailplane, the Ha 139, which returned to the inverted gull wing, this time on floats. Three were built. Catapult-launched from ships and cruising at 130 knots, they crisscrossed the South Atlantic in the prewar years carrying mail and cargo for Lufthansa. They were followed by the BV 222 Viking, a six-engine flying boat of 150-foot span and 4,000-mile range intended as a transatlantic passenger-carrier, also for Lufthansa.

A structural peculiarity common to most Vogt designs was a tubular wing spar welded of

rolled steel sheet. He brought the idea with him from Japan and applied it to larger and larger aeroplanes; by the time it got to the Viking, the tube was almost six feet in diameter. A tube is not quite so efficient at handling bending stresses as the more usual I- or box-beam, but tubular spars carried twisting loads very well, they doubled as fuel tanks, and they lent themselves to simple, standardised fittings for attaching engines, fuselages and so on. In one Vogt design the fuselage pivoted about the tubular spar, allowing the plane to land with its low-slung fuselage in a horizontal attitude.

In the 1930s the flying boat was widely considered the logical type for transoceanic travel, not only for safety, but also because there existed few runways suitable for such heavy aeroplanes. A still larger model, the BV 238, succeeded the Viking. It was the heaviest aeroplane in the world, with a gross weight of over 200,000 pounds, a wingspan of nearly 200 feet and six liquid-cooled twelve-cylinder engines of 2,000 takeoff horsepower each. If necessary, four 1,500-pound thrust rockets of 80-second duration would help it get off the water. The 238, like the Viking, had a straight wing, and relied on a very tall, narrow fuselage to keep the propellers away from the water.

These aeroplanes were conceived in a Germany confident of victory. With postwar

civilian travel in mind, Vogt sketched a yet larger flying boat, similar in scale to the Hughes "Spruce Goose": the P 200 - P stood for Projektwith eight 4,000-hp engines, a 280-foot wingspan, a threestory fuselage resembling a miniature ocean liner, and a takeoff weight of 450,000 pounds. Hermann Pohlmann, the designer of the Stuka, who later wrote a history of the aeronautical activities of Blohm und Voss in the Vogt years, noted that the P 200, with its emphasis on spaciousness, comfort and elegance, reflected a mistaken conception of the postwar travel market. As the pragmatic American manufacturers of what would become the DC-6 and Constellation had already perceived, "speed makes comfort superfluous." We continue to suffer the consequences of that insight today.

The Germans knew all about swept wings and jet engines back in the 1930s, and in 1943 Vogt proposed a four-jet bomber with a new sort of bent wing, the inboard panel swept back and the outboard one swept forward, like a letter W. The weirdlooking arrangement gained the transonic drag advantage of wing sweep without its attendant twisting stresses.

In March, 1944, with the factory a likely target for enemy bombers, the BV 238 prototype flew to a lake near Lübeck for testing. By then, flotillas of Allied night bombers were reducing cities to ashes, while by day fighters roamed the countryside strafing targets of opportunity.

Inevitably but rather sadly, the giant flying boat, moored in the Schaalsee under heavy camouflage, was spotted, strafed and sunk.

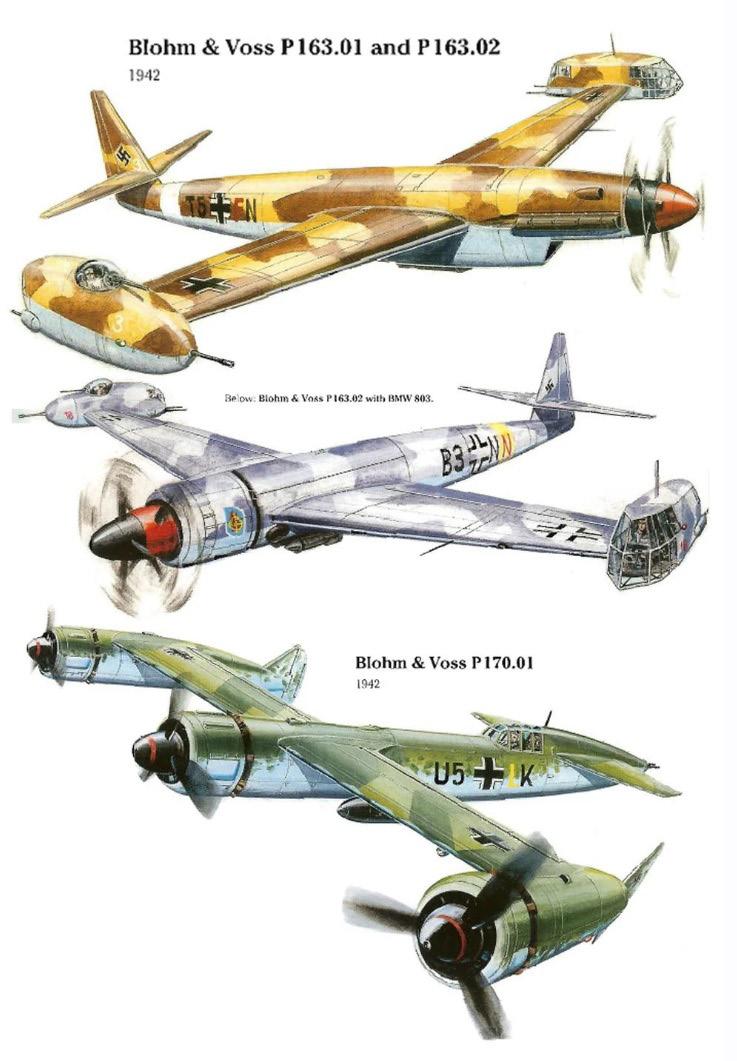

When Germany found itself on the defensive on both western and eastern fronts, increasingly bizarre and inventive designs flowed from Vogt's pen. Perhaps the knowledge that they would never be built freed him from the obligation of making them plausible. There were slender-winged glider bombs that resembled sailplanes packed with high explosive, and a weird machine, the P 163, whose crew of four

occupied two "gondolas" at opposite ends of the wing. The P 170 was a "fast bomber" with three big radial engines, two of them way out at the wingtips. The crew sat at the extreme tail of the central fuselage where, despite the asymmetricthrust issues raised by the wingtip engines, there was no vertical fin at all.

Vogt designed a small engineless interceptor whose prone pilots, towed into the stratosphere by Me 109 fighters, were supposed to dive into bomber formations, ramming their tails - a suicidal style of combat that to Stuka designer Pohlmann seemed more appropriate to Japanese culture than to German.

There was a series of tailless flying wings, mostly single and twin jets, with stabilizing surfaces offset aft from the wingtips on small pylons. Time was running out for the Third Reich, but Hitler's appetite for novel "reprisal weapons" was undiminished.

After the war Vogt, along with many other German scientists and technicians, was brought to the US, where he enjoyed a continued career with American aerospace firms, including Boeing. In the vast American aerospace establishment he worked in comparative anonymity. In Germany he had been more of a figure, and in old photographs we see him, short in stature but slim and good-looking, laughing with the intrepid test pilot Hannah Reitsch or showing der Führer and a raft of other Nazi bigwigs around the Blohm und Voss plant.

Richard Vogt died at 84 in Santa Barbara, California. Most of what he produced is forgotten today. It is the curse of engineering, unlike the other creative arts, that the constant evolution of technology leads us not only to discard obsolete productions but also to delete them from our memory. j

$ 250 000 USD

Negotiable

Airframe TTSN Hours: 8992.80

Most recent MPI: 25 April 2022

Aircraft Type: Cessna

Aircraft Model: 414A

Aircraft Registration: ZS-KRD

Aircraft S/N: 414A-0510

Propeller Type: McCauley

Propeller Model: 3AF32C505-C

Propeller Serial No.: 060002

Propeller Position: RH

YOU ARE AMONGST FRAGILE, yet lethal machines that are extremely unsuited to travelling on the ground.

Did you see Ryno’s cartoon last month? It was about the pupe starting a Cherokee facing up against the hangar doors? Here’s the story.

43 Air School was an operation I started and ran for many years. Sometime after I sold it I went back there to visit a friend. As I walked past one of the hangars, I saw an amazing sight. A student, in uniform, climbed into a Cherokee that was facing towards the closed hangar doors. At first I thought he would release the park brake and push the aircraft back, but no – this extraordinary person got himself comfortable in the left hand seat and strapped himself in. He then fiddled for a while and eventually started the engine.

I was intrigued. I stopped a few meters from his left wingtip to watch what happened. Well, there was more fiddling, and then he picked up the mike and made a call – presumably to the tower.

My jaw sagged. It was like watching one’s mother get on a bicycle facing towards the back wheel.

Eventually the engine stopped, our hero got out and stood on the wing with his hands on his hips, So, what are you staring at, huh?

I doubled over with laughter.

So much for planning – even if you are only going to taxi to the pumps you still need to do some basic planning.

• Make sure the chocks aren’t in front of the wheels

• The tie-downs are untied and there are no loose ropes to get in the prop.

• You are not going to blow dust into someone’s hangar

• You don’t have a flat tyre

• The towbar is not hooked in

• The wind is not going to whip the door off its moorings

• Control locks are not in position

• There is plenty of room to taxi where you want to go

So, instructors, it’s your job to teach pupes how to behave around aeroplanes. It’s like teaching your kid to look both ways before crossing the road. If they are around aeroplanes they need to be planning all the time.

It may say PREPARATION FOR FLIGHT on the form – but it really means is PLANNING. If you are anywhere near an aeroplane you need to be planning all the time.

Safe flying is about decision making

Jim’s lessons for instructors –

How many people have walked into props because of a lack of planning? What an absolutely horrifying experience if you are the pilot. Don’t imagine for a moment that if you see it’s about to happen you can stop the engine in time. You have no chance – it’s all over in a flash of blood.

Instructors, here’s a thought. When you taxi in with a pupil, get them to decide where they want to park. And do this right from their first or second flight.

It sounds like a small thing – but it’s not – it’s great for their confidence and their airmanship, and it gets them into the habit of planning everything when they are around aeroplanes. They need to think of the fuel state – do they need to refuel for the next pupil? – or perhaps themselves if they are flying early next morning. The time of day might dictate whether to park at the hangar. The wind is a consideration, as is forecast weather, and the availability of tiedowns.

If there are no overruling considerations, I always park with the tail towards the terminal

building, It’s just a hell of a good lifetime habit –there’s less chance of someone walking into a prop.

Safe flying is about decision making and planning ahead, so get your pupe into the habit of doing that right from their first lesson. Instructors are inclined to make all the decisions without considering whether the pupe has enough info to do it himself.

We are inclined to say, taxi to the threshold of runway 27, instead of saying, which runway would you want to use for takeoff this morning? They must then consider not only the wind, but other traffic, the slope, and perhaps the position of the sun.

So get them to take planning really seriously. No – I mean really, really seriously. I write a herd of accident reports and about half of the crashes start on the ground with poor preparation and planning. Skimpy preflights, overloading, insufficient weather info, being in a hurry, and – worst of all – trying to meet other people’s expectations.

If your pupe crashes one day through poor planning and preparation, it will forever haunt you. You have to set the example on every flight. Don’t let her skip one little thing. If she needs a ladder to check the fuel – then she must fetch one.

Enough said – on to the next heading.

The more you know about the machinery you command, the safer you will be.

Please read that again – it’s really important.

When I write accident reports I notice that a lot of crashes are caused by pilots simply not bothering to read the POH. As an instructor you have to set the example. You should know a lot more than the bare minimum. And one of your jobs is to get your pupes interested in what happens under the cowling.

If you fly a Piper you will find it easy to get the cowling open and have a good look under there. Not your thing? Well to be the best instructor around you need to develop an interest pretty smartly.

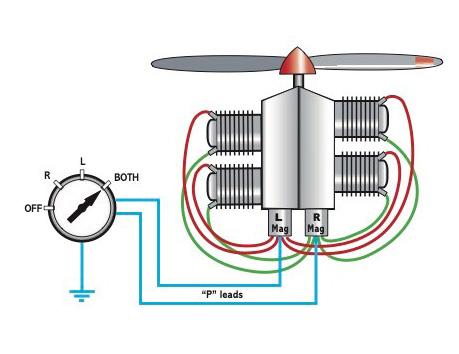

Let me grab your attention. You have heard of a magneto? Brilliant. Can you see one in there? Even better. If you are flying something with a Continental or Lycoming engine you will know that it has two magnetos on the back of the engine.

Each has four, or perhaps six, big thick wires sprouting from it. And each wire goes to a spark plug.

The important thing is that each magneto has a thin white wire that goes through the firewall into the cabin. This little wire’s job it to switch

the magneto OFF. That’s right – a magneto is always live unless you kill it by earthing this wire. So this wire goes to the mag switch, which either earths the wire to stop the mag from producing sparks, or unearths the mag which allows it to make sparks. So if the wire is broken the mag is LIVE, meaning:

• The prop may polony slice you when you move it just a fraction to fit the tow-bar, or to squeeze past the aircraft in the hangar. So if you ever see someone casually moving a prop, even slightly, your job is to do so much screaming and bitching that everyone within half a k will learn never to move a prop unless they are prepared to have the engine start.

• Also, if that little white wire is broken, your mag check will be invalid because you have no way of switching this mag off to see if the engine runs properly on the other one.

However, if the little white wire shorts against something metallic, that will kill the mag, and the engine will only run on the other one. And things can get even worse because when you do a mag check at 1800 rpm you will get a loud explosion in the silencer which may dislodge a baffle. This can later cover the outlet of the exhaust and cause the engine to stop whenever it feels like it.

Understanding magneto wiring is important.

He did all the right things

If you haven’t a clue what I am talking about, then you have four options:

• Give up flying.

• Buy an old and unreliable, single-cylinder, four-stroke motorbike. It will teach you all you need to know about basic engines.

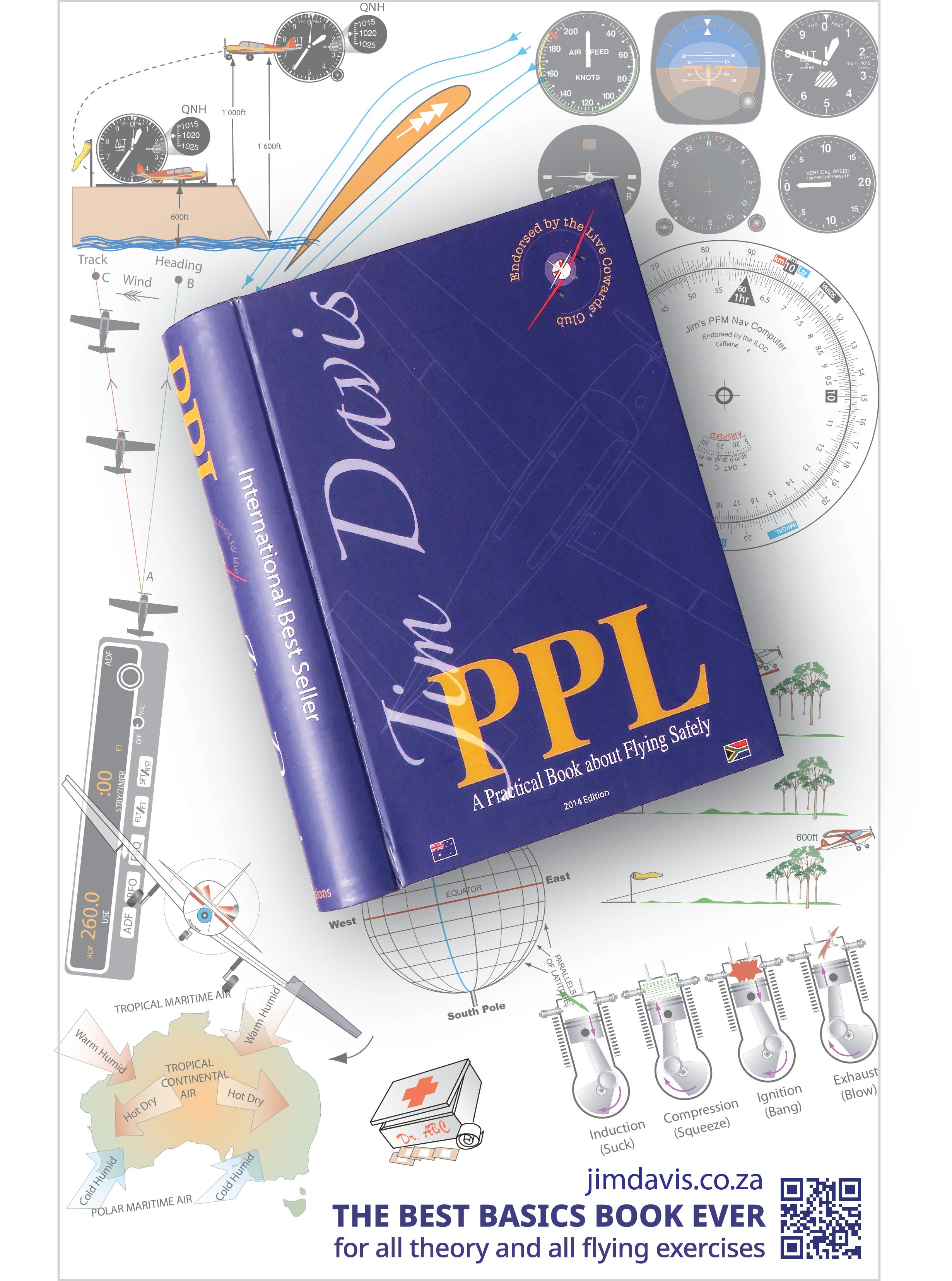

• Buy a copy of the Jim Davis PPL manual and go to page 154 to learn about magnetos, and other lovely mechanical things.

• Decide you really do want to be the best instructor, so ask your maintenance guy to show you around his AMO – then take your pupils there. You can all learn a hell of a lot by just watching – you don’t need to get oil on your nice white shirt

Here’s a story about a guy in a Bonanza with his wife and two young daughters. They were going to land at Stellenbosch, near Cape Town.

When he selected the gear down, he got no greens. He decided to fly to the main airport where they had “the equipment”. A good move. On the way there he asked his wife to dig out the handbook and read the emergency gear extension procedure. An even better move.

He did all the right things and then started cranking the little handle that winds the gear out. Unfortunately he cranked it the wrong way. The gear had actually extended most of the way by gravity, and his cranking pulled it back in. He landed like that, ruining the prop and the engine in the process.

With systems savvy he could have figured it out and landed with the wheels down.

Short story – a good instructor understands the systems.

This has to be one of the worst, or least, taught exercises in the book.

The other day I asked a Grade 1 instructor to lend me the fire-extinguisher from his Cardinal so I could photograph it. It took him a full two minutes to unclip it from its mounting under the seat. And he was standing next to it – not flying the aircraft and groping for it one-handedly below his butt.

A hundred and twenty seconds is a hell of a

long time when you are on fire. The truth is that we are simply not prepared for fires. We don’t practice them and we don’t give them serious thought.

If your pupe asks you to demo an emergency procedure you should be able to swing straight into it.

Hell, we are talking about emergencies – lifethreatening things that happen suddenly and unexpectedly. This is no time for trying to remember stuff from five years ago, and fiddling with things you have never touched before.

If something suddenly goes wrong your immediate reaction must come from recent memory. There’s no time to pull out a checklist if your engine fails soon after takeoff.

Your immediate, or memory actions, are Speed, Field, Fuel, Flaps. (This is a SAAF list that has been given a hell of a lot of thought – don’t try to mod it - you won’t improve it.)

• SPEED lower the nose smartly to maintain flying speed.

• FIELD aim for the best available. (The 30º rule is stupid.)

• FUEL check selection and pump.

• FLAPS as required

• If you are flying a twin, maintain direction and airspeed. Then your memory actions will be:

• GEAR UP

• FLAPS UP

• IDENTIFY – dead foot dead engine

• CONFIRM – throttle back the suspect engine

• FEATHER

Now trim, calm down and think what to do next.

This is where you need a written checklist – and there isn’t one in the POH or anywhere else –you don’t even need to look. You need to do almost random things, some of which may not even apply. Cool the good engine and close the cowl flaps on the failed engine, tidy up the power levers, switch off alternators and fuel pumps on the dead engine crossfeedng fuel, replan your flight, notify ATC and so on.

It's hopeless trying to remember everything –particularly if you have a high workload with traffic and ATC.

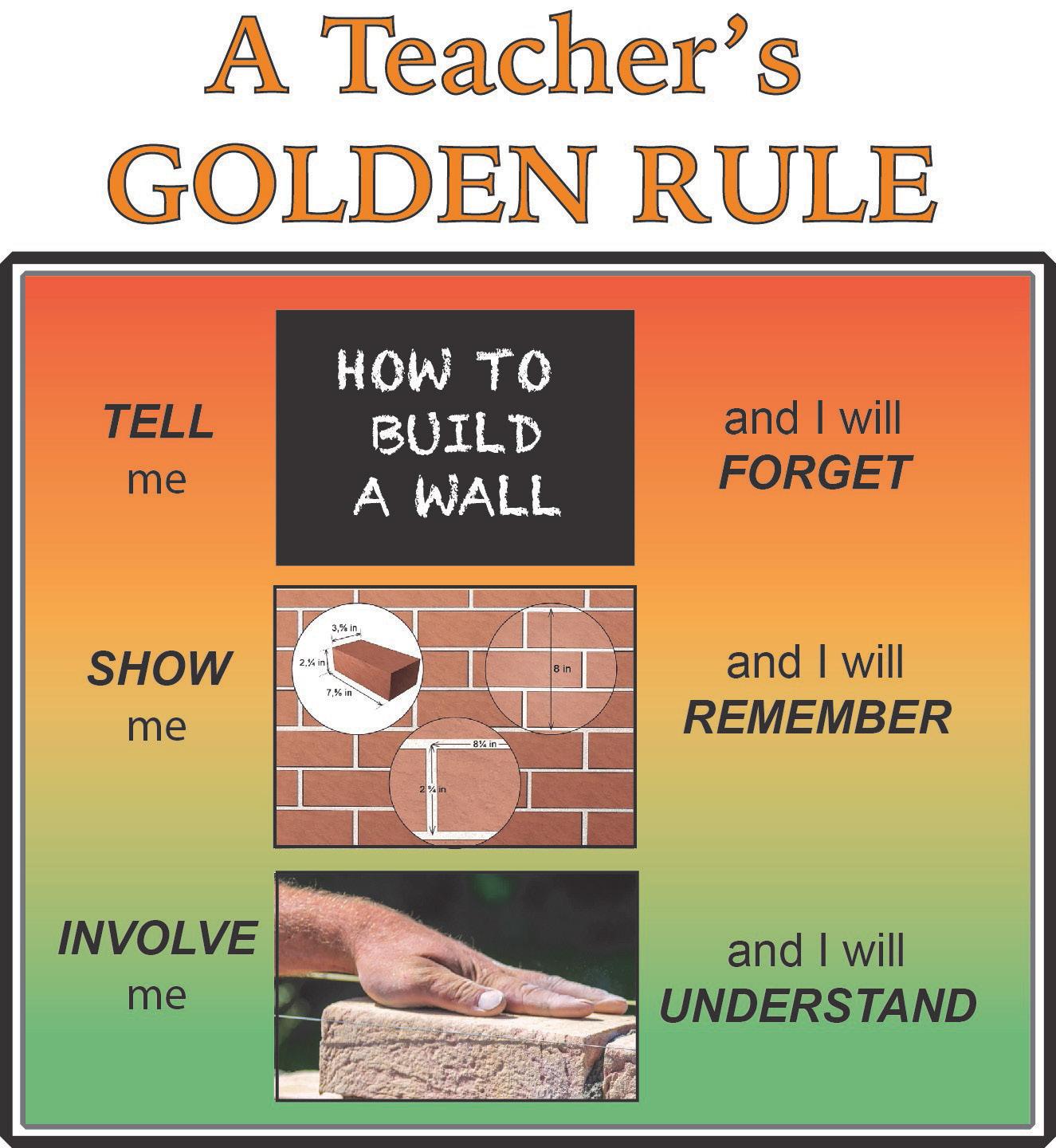

So this brings us to a wonderful golden rule for all teachers, lecturers, instructors, mentors, tutors, trainers and professors: Building a wall.

So you can:

• TELL the pupe what to do – and she will forget, or,

• SHOW her what to do – and she will remember, or

• INVOLVE her by building a checklist together. Yes?

Instructors tread VERY carefully when training for engine failures in a twin. You are approaching an incredibly thin line. Although you may know how to handle the situation, you have no idea what the pupe is going to make it unrecoverable.

I strongly advise you not to shut down and feather near the ground, and I mean circuit height or below. I can think of half a dozen training disasters which were caused by seemingly competent instructors allowing pupils to put them in deadly situations.

This often happens during an asymmetric go-around – this seemingly simple operation can quickly become fatal. I will discuss it again when we get to the section on multi-engine training. Basically, a fatal situation can gently creep up on you, and by the time you realize what’s happening your backdoor has slammed shut.

The danger doesn’t have to happen suddenly through someone pulling the wrong lever at the wrong time, although that’s often the case.

Let me tell you about how the dreaded, 20,000 hour Swannie – a senior testing officer with the CAA – crashed a 150 HP Apache at George in this way. He’s the guy who used dirty tricks when testing you.

He was testing a Commercial Pilot for his instrument rating renewal. While on a left-hand downwind for runway 11 Swannie failed the left

engine and told the pilot to intercept the ILS localiser and follow the glideslope down for a landing.

Reasonable? Actually no. Although Swannie had a thousand hours on PA23s he hadn’t thought this one through, because the failed left engine is the one that has the hydraulic pump to work the gear and flaps. This means that when you select the gear down, it free falls, causing massive drag, but it doesn’t lock into position.

To lock it you have to pump like hell on the donkey’s-dong emergency handle until it has filled up the hydraulic lines. Then the last couple of pumps lock it in position. After that, some more pumping will deploy the flaps.

If Swannie had understood the system and done a little planning, he would have realized that he had put the pilot in an impossible situation. If he lowered the gear as he intercepted the glideslope, which is common practice, it would have caused so much drag that the poor little 150 asymmetric horses would not be able to keep them on the glideslope, and they would crash short of the runway.

On the other hand, if they left the gear to the last moment, they wouldn’t have time to pump it down, and would do a belly landing, on the runway, in a perfectly serviceable aeroplane. This is exactly what happened.

Which brings me back to my point. Instructors, no matter how experienced you are, be extremely cautious of shutting down and feathering even at circuit height.

This story again emphasises the importance of understanding the systems.

Next time I’ll tell you how I came this close to losing an Aztec while turning final on one engine at PE.

pump like hell on the donkey’sdong j

“It’s not going to last. You know that, right?”

“Yes, well I guess we’ll see.”

That was how conversations went when I arrived in Port Elizabeth with our first Sling in December of 2012.

WELL, IT’S 10 YEARS ON and our fleet of six Slings have accumulated in excess of 35,000 flight hours. ZU-IAE has 7,300 hours on it, making it the highest hour Sling in the world.

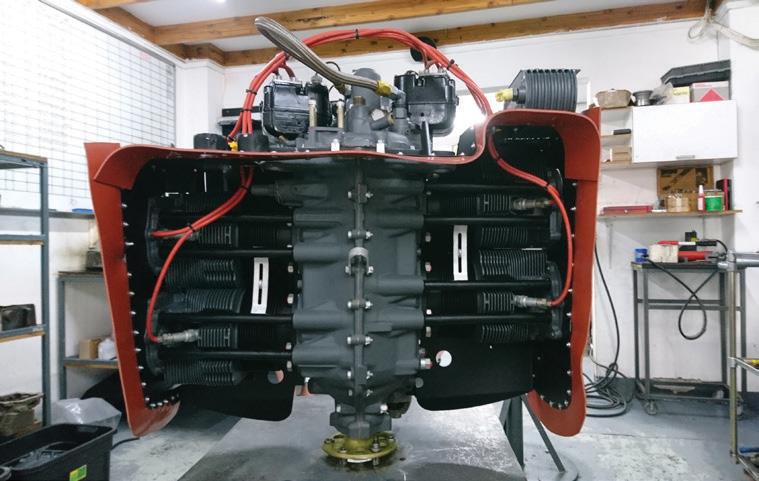

This article tells the story of our experience of keeping our Slings airworthy. And that really is a convoluted tale, because we pioneered the Rotax 912iS engine at the same time, so let’s start with that.

On paper the iS has triple electrical redundancy and it should never fail. Will I fly it across the Atlantic though? Ha! Don’t be silly! No. Yet I would do it behind its more humble older brother, the 912ULS carburettor fed version of the same engine.

Why is that? Well Rotax has still not managed to completely sort out the stator (alternator), which is prone to heat damage and is a single point of failure. When it gets damaged and short circuits, the engine runs off the battery, until that goes flat….and then it’s a case of no electricity, no engine.

Stator failure does not catch you by surprise though. It has heaps of telltale signs that become increasingly evident over time. Though we dutifully train for engine failure, it isn’t something that I ever seriously worry about with the iS, but as for the Atlantic.…she’s a big place.

So why put up with the complex iS engine when the simple ULS is more reliable? Well on a good month at Madiba School of Flying our injected iS engines save me R50 000 in fuel compared to ULS engines. I will forgive it many things for

they crash really well

that. You just can’t argue with 14 litres per hour in the cruise. In practice, we taxi a lot at FAPE and we spend a lot of time in the circuit, so real life fuel burn at the school is 10 litres of car fuel per hour.

Another reason for loving the iS, is that the computer records every spurt, fart and hiccup the engine makes. Every MPI begins by plugging a laptop into the engine and downloading the logs for examination, and there’s a program that displays the information in graph form. It’s easy to overlay graphs for comparison, and anomalies stick out.

This is all good and well for a flight school with dedicated maintenance personnel standing by. If I were going to own a Sling for personal use out in the sticks, I would most definitely choose the ULS engine.

Gearboxes on the iS engine have proven to wear. The issue was substantially remedied when, around 2017, Rotax introduced a specific oil feed directly onto the gears. Even so, the gearbox makes for rough starting of the engine, especially on the first start of the day. So rough that the airplane reminds one of nothing so much as a dog shaking off water.

Some of our aircraft are worse than others, and we can’t figure out why. It’s so bad that you can’t run traditional gyro instruments. We once removed a non-working A/H and broken bits of gimbals came tumbling out. Instrument panels crack and our MGL screens break at their mounting points. Recently one of our instructors came in saying he had smelled a burning smell in flight – and it wasn’t and oil smell. Our very experienced engineer noticed that the exhaust was up against the cowling. He then noticed

that the engine wasn’t sitting straight in the airframe, so he removed the cowlings. Closer inspection revealed that one of the high tensile engine mount bolts had snapped. I am not exaggerating when I say the iS shakes on startup. Hung starts produce prolonged shaking, but I don’t want Rotax to hate me, so I will stop there. They have been very good to me.

Rotax has now offered me two free gearboxes to test. They have never stopped developing the gearbox and I won’t be at all surprised if the shaking thing is now behind us. I didn’t tell them I was writing this. Through all the years, this is how Rotax have done things. They just don’t stop until it's right.

We have also now begun rewiring the starting circuits of our aircraft to bring them into line with the latest directives from Rotax, as endorsed by Sling Aircraft. It gives the engine’s computer more time to come on line prior to engine start and though it is early days on a brand-new engine that we have just flown, I am choosing to be optimistic. So far, so good.

There’s one more thing; Call me old fashioned, but my mind works better in pictures. I get more information from a single glance at the faces of my six little analogue friends than I do from thinking about the numbers on those precise digital displays who each demand my brain’s focused attention.

Our MGL Voyager screens have done 35 000 hours with us. When they break down, we send them to Cape Town and the guys at MGL fix them. The displays cost only R5000 to replace, so it’s easy to keep the units in great shape.

Our Garmin radios and transponders are so good that it’s easy to forget to mention them. In all this time I have only had one transponder breakdown on me. That really helps when you are trying to keep aircraft in the air.

Okay, so back to our instrument rattling gearboxes. Gearbox inspections are required every 600 hours on the iS. They mostly make it to their 2000-hour service life now.

The solution to the hammering the gyros were taking was to replace the DI and AH with Garmin G5’s which have no moving parts. Cost for the two units fitted was R100 000. Eish! We were under pressure to have a suitably equipped aircraft for night/instrument training though, so we went ahead and spent the money.

When we upgraded the second aircraft, we fitted MGL’s Blaze singles. We tried the AH, DI and Altimeter as a trial, and we have been very impressed. Though the Garmin display is similar to what I had in the Beech 1900D that I used to fly, the MGL units are perfectly good, and they cost only 5% as much as the Garmins. Sometimes local is lekker.

Rotax have replaced gearboxes and stators free of charge under warranty. Honour is a value they adhere to. It’s been 10 years though, and one would have hoped that the issues would have been sorted out by now. The engine costs half a million Rand. For that money I would like an engine that does not rattle my bones in the morning.

Rotax engines run to 2000 hours without wear. The only thing that they absolutely will not forgive you, is exceeding maximum RPM. Do that to a Rotax 912, and it will coldly and dispassionately kill you. It doesn’t take long for damage to set in.

It’s hard to over rev an engine fitted with a trusty old fixed pitch Warp Drive prop, but there are horrible electrically controlled, flight-adjustable

it will coldly and dispassionately kill you.

props on the market that have killed many a Rotax engine and sometimes the people who flew behind them as well. There are propellers specifically for Rotax engines which use the traditional, tried and tested, hydraulically controlled constant speed method to control the prop, so you won’t have unscheduled over speeds. It doesn’t even cost any extra compared to the electrically controlled units. Sling Aircraft will fit the prop of your choice.

Covid and the war in Ukraine have been tough on the whole world, and perhaps it contributed to Rotax struggling to produce engines for a while. This resulted in three of our aircraft being grounded for an extended period of time with time-expired engines, but engines are now slowly starting to trickle through again. For a while now, there has been no engine oil available from Shell, which is the Rotax recommended oil.

We treat our 2000-hour engine replacement cycles as an opportunity to overhaul the airframe as well.

Madiba is structured around an expected 450 hours per month, and that model requires that we employ maintenance staff on salary rather than to pay an AMO a per-hour rate. That translates into a R55,000 fixed overhead per month, but the upside is that we can maintain our aircraft to our heart’s content. It’s hard to imagine how we might otherwise have adequately maintained the airframes.

Our Slings work hard. They are banged into the runway day after day and year after year by those whose eyes and minds and hands have not yet reached consensus on how to give expression to their desires to re-unite their craft to terrafirma.

So how did our airframes do? Well, they proved to be surprisingly resilient. I have to add that we operate out of FAPE with its long tar runways.

The skin of the aircraft is thin. Empty weight is 400 kg and all-up is 700kg. That means two guys each weighing 100 kg can take off with full tanks and fly from PE to Harare non-stop and have 3 hours in reserve. The downside of the thin skin is that flaps are vulnerable to people stepping on them, and flight controls are prone to hangar rash. Replacing dented skins is relatively inexpensive though and it’s quick and easy to do, thanks to the use of pop rivets.

The main landing gear is composite and I have had to replace at least six of them through the years, which means they are good for around 6000 hours. If you consider that at the flight school we do five landings per hour, and that

replacement cost for the gear is around R35 000, then that translates roughly to R1 per landing. That’s not bad.

Flight controls are operated by push rods that run through bushes. When you replace these bushes, the aircraft just feels like it’s factory new again. The difference in feel really is fantastic.

The original push-button flap switches didn’t last, and Sling replaced them with sturdy rotary switches. You have to change the instrument panel though, or put up with an ugly patch. Sling Aircraft kindly provided us with the CAD drawing of the panel and so we are able to make the required changes.

Fuel tanks have been leaky; not so much dripping fuel, but leaving ugly brown stains around some of the rivets. We generally disassemble ours completely and clean the skins to original aluminium before re-applying

PRC (very expensive, terribly gooey stuff, that seals holey aluminium sheets) at major inspections. This also provides an opportunity to inspect wing spars. I always marvel that a spar that has done thousands of hours can look like it came out the factory that same morning

At Madiba we operate in the salt air of our coastline, yet we have had no real corrosion problems, due to the fact that all skins are alodined. One of our dashing young hour builders managed to fly so low over a salt pan that he inadvertently splashed down into the 40% salt solution. We washed that little plane down with plenty of fresh water, but for the longest time you could run your finger in places and it would come out white with salt. At the last major inspection we tore it down to kit form and really looked for corrosion, and found that it was limited to just a few mild steel brackets. I test flew it after the rebuild and honestly, it’s the best Sling I’ve ever flown.

Climb-out after takeoff was at 110 kts and 700 ft/ min with a brand-new engine! I had the engineer on board as well to monitor engine parameters and to help with swinging the MGL compass. The pictures in the article are of this aircraft, ZU-IBZ. You would never say it has 5000 hours on it.

Last year the factory considered a possible maximum hour service life for the airframe. When the first aircraft left the production line, no one imagined that there would be Slings with more than 7000 hours. I thought about that number. In the course of maintaining our aircraft, none of them still have all their original parts, and some of them have been substantially rebuilt. If for example it was thought that maybe the wing spars were getting on in years, we could buy a new set of factory-built wings, which costs a mere fraction of the purchase price of a new aircraft. The same goes for any component on the airframe.

It is a very easy and inexpensive aircraft to

replace parts on, and there are no limits in terms of what can be done. With a suitable maintenance plan there is no reason to write off airframes.

Crashworthiness

Over the years our students have crashed the Slings, and they crash really well. I once test flew a Sling after it’s MPI. A careless apprentice at our previous AMO had left the nut off an aileron hinge bolt. It’s a long story, deserving of its own article. Neither myself nor the two engineers who each have a lifetime of maintenance experience noticed the missing nut during the triple pre-flight inspection. I don’t know how we did that! You can see me there on the security camera footage energetically moving the aileron up and down, for heaven knows what reason. If only I had looked for the nut! But there was no record that anyone had worked on it. Well of course the bolt fell out in flight, causing the stick to become jammed in the full left deflection position. It could move freely in the fore and aft plane only. I found that rudder authority exceeded that of the ailerons, but only at almost full power and high speed. So how do you land a plane in that condition? Well the short answer is, you don’t. You crash.

A subsequent internet search revealed that just about nobody else had managed to survive that particular set of circumstances, including the test pilot for Cirrus Aircraft. All I can say is that the Good Lord saved my life that day.

The Sling took it. I walked away, which means it was a good landing. And then we went ahead and fixed it. We just kept stripping until we found that the parts were no longer damaged. That point was behind the cockpit, and I believe that is the secret of its crash-worthiness. It is the crumpling that absorbs the impact.

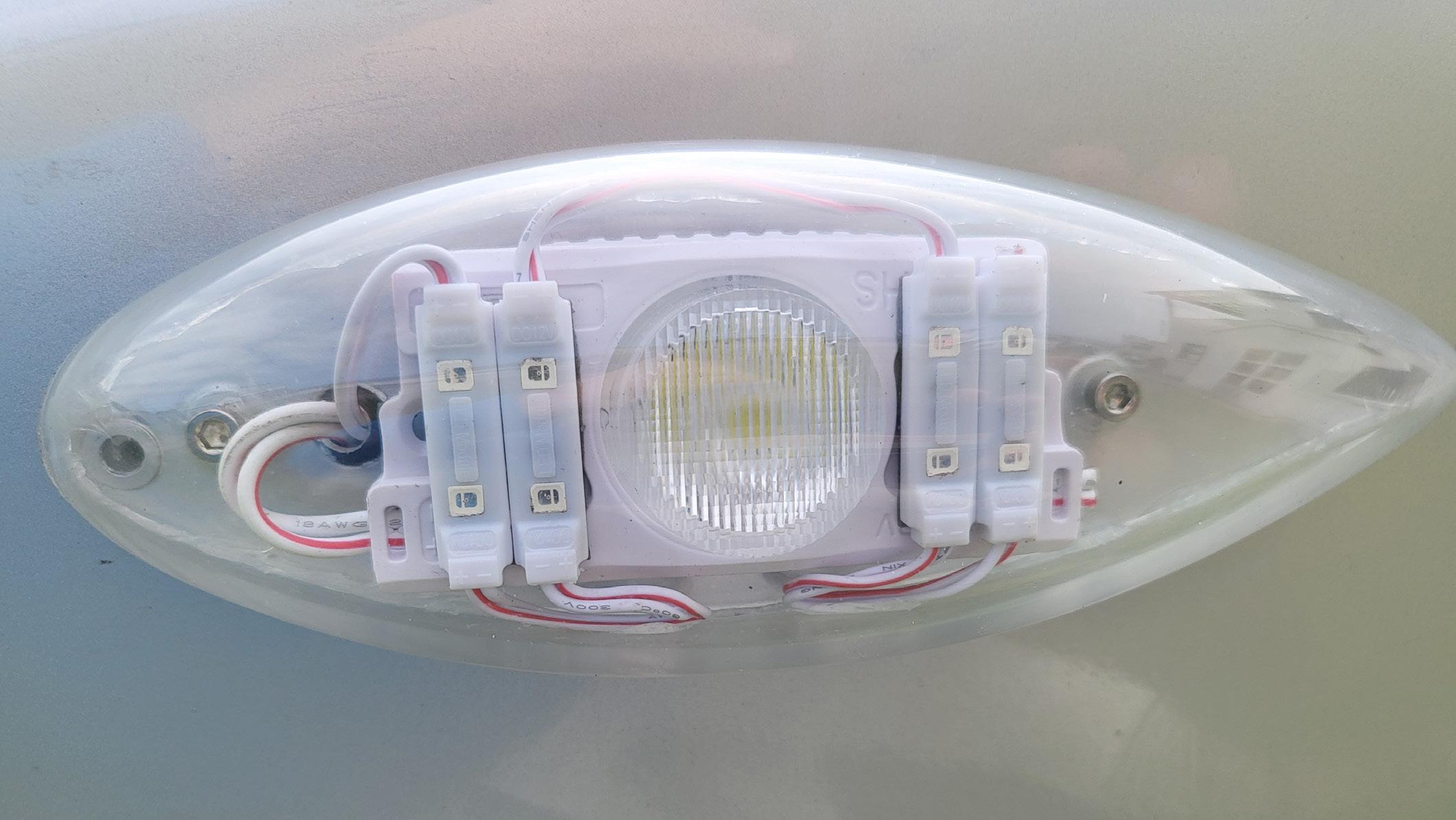

There are anomalies. It takes far fewer man hours to repair damage resulting from a collapsed nose gear, than it does to repair damage from a tail strike. The tie down point in the tail acts like a guillotine and shears a bunch of structural rivets which then requires the entire tail of the aircraft to be removed to enable repairs. I designed a 200 gram spring-steel tail skid in place of the tie down and we said goodbye to damaged tails. Of-course we ran it by the factory’s design department. Same goes for the nav lights. The original sets cost R20,000 and never lasted. We replaced them with lenses we designed, and LED strobes/navlights which cost R700 for the entire set, didn’t need high voltage, and were brighter.

At the end of the day, for us who use Slings commercially, there is absolutely no difference in the way we have to maintain the aircraft compared to certified aircraft. And AME’s have a singular disability to understand the difference. Maybe that’s a good thing.

So what does it cost to maintain a Sling?

Well that rather depends on its flight hours. For the first 2000 hours it will require 10 hours of labour at MPI plus oil and filters, which will come in at less than R10,000, or R100 per hour of operation.

After the first 2,000 hours, wear and tear becomes a factor that should be anticipated and planned for. By 4,000 hours you should be prepared to do some work on your aircraft to keep it in good shape. You will be replacing the instrument panel and all the toggle switches. Front windscreens become crazed in time. They easily last 4000 hours but since they only cost R4500, replacing them then is a good idea.

banged into the runway year after year

Canopy rails get tired and since canopies that stick are a safety hazard, they should be replaced. There are at least two items on the airframe that crack and have to be replaced, but Sling has become highly professional at remedying those kinds of defects, and at bringing out accompanying Service Bulletins. Rudder cables need to be checked. Throttle cables got sticky and were redesigned. Brakes got metal lines near the wheels because the plastic lines couldn’t stand the heat. As Sling hours around the world accumulated, problems emerged and they were overcome.

You can’t beat the fact that Sling is local. Their AMO section has every imaginable part in stock, and couriers deliver overnight. That simply translates into less downtime. Aircraft sitting on the ground cost money.

Ten years ago, I bought my Slings for around 1.1 million Rand. Now I would have to pay more than double that for a new one. That’s fantastic news for resale. The days where you could pick up a second-hand Sling for less than a million bucks are over. These days there’s seldom a week goes by that I don’t have someone calling me to see if maybe they could convince me to part with one of mine. In fact, as I write this, it is

only the middle of this week and I have already had a phone call and an email. To put it into perspective, a Sling kit costs R900,000 and then it is not a factory-built aircraft, so it can’t be used in a flight school. Add an engine, a propeller, radio, transponder, instruments, multi-function display and the cost of building and paint… it wouldn’t make sense to sell.

As I conclude this rather lengthy article, I do believe that the jury may finally, and confidently deliver its verdict. After 35,000 hours on our fleet, and hundreds of thousands of Sling-hours around the world, the only competent verdict must be that Sling Aircraft, as an organisation, has grown up, and that their little aeroplane has become the world’s ultimate training machine.

It is possible to keep the aircraft in a perpetually new condition. Mine certainly are in great condition. So now I can answer those who had told me they wouldn’t last. My Slings are tough, and they did last. But more importantly, they are inexpensive and easy to maintain.

Landline: 011 614 2471

Mr. Gomes: 082 412 6669

Carla: 083 602 5658

A Dynamic team to meet all your requirements.

Refurbish your aircraft and / or helicopter. Best prices guaranteed

Aircraft registration: ZS-JYV

Date and time of accident: 22 May 2014 1432Z

Aircraft type: Cessna 172N

Type of operation: Private (Part 91) Shanike

Investments No.5 (Pty) Ltd

PIC license type: PPL

License valid: Yes

PIC age: 21

PIC total hours: 59.1

PIC hours on type: 31.2

• This discussion is to promote safety and not to establish liability.

• CAA’s report contains padding and repetition. I have paraphrased extensively for clarity.

Synopsis:

On Thursday, 22 May 2014 the pilot and two passengers (student pilots) took off from Heidelberg on a private flight to accumulate hours towards his commercial pilot’s license.

Last point of departure: Heidelberg Aerodrome (FAHG)

Next point of intended landing: Heidelberg Aerodrome (FAHG)

Accident site: farm Gelida Bellegings. 5375’AMSL Met: Temp:15°C; Dew Point: 5°C; Wind 340°/10 kt; QNH: 1029 hPa

POB: 1 + 2

People injured: 3

People killed: 0

approximately 48 metres from the wires.

The propeller separated from the engine and was found 33 metres from the wires. The engine and empennage separated from the fuselage. The wreckage pattern was confined to the impact point with the ground.

The aircraft was seen by a farmer flying low in the area. One passenger stated that there were no abnormalities with the aircraft whilst flying low in the general flying area. The passenger said the pilot intended to simulate a forced landing while flying into the sun.

The aircraft impacted high tension wires with the nosewheel at 5,6 metres above the ground. It then hit the ground in a nose-down attitude

Emergency services took the seriously injured passengers and the pilot to the nearest hospital.

The pilot suffered severe head injuries. He was later flown to a hospital in Egypt to be closer to family, so he was not available to provide information. The investigation relied on information from the passengers, both of whom sustained serious injuries.

The company that owned the flying school had a chequered history. It started with an excellent reputation but was subsequently sold twice, the second time to a government agency specifically to train non-white students. R63 million disappeared overnight and all the aircraft fell into disrepair, and were cannibalised.

Would you sit in the back of one of these aircraft flown by a newly qualified, 21 year old pilot who was planning to do some low flying, into the sun and taking a pretty girl along as his first passenger? Neither would I.

And yet the same story keeps repeating itself – you can generally see accidents coming long before takeoff. You just need to list the facts, and then ask yourself if you would sit in the back. So, if we can all do this, and we can, then why can’t the pilot?

Well he probably can, but he mostly reasons that he is smarter than average and he can manage to do XYZ safely, despite the apparent dangers. But my guess is that my old friend PPP – Passive People Pressures – prevails. He has committed himself to meeting the expectations of his pax, his boss, his family or his friends.

Of course the antidote to PPP is to ask yourself if you would undertake this flight without any pax and without anyone else’s expectations nagging at you.

Okay let’s get back to the practicalities of this accident.

The regs say that over open country you may fly as low as you like provided you are not a “… hazard or nuisance to persons or property on the ground or water…”

So, was he legal? – yes. Was he sensible? Of course not. But is any 21 year old sensible when in charge of fancy machinery with a female admirer looking on?

But there’s a solution to this – actually, two. The first is discipline. If the school has a culture of professionalism and training that continually makes pilots aware of the risks involved in each exercise – then those risks are much reduced.

The second answer is more complicated –it hinges around the written and unwritten contracts that the school has with the pupil’s sponsor and the pupil himself. If there’s no written contract then we get into muddy waters.

Pupils who are on a commercial pilot course may think that once they get their PPL they can do what they want – and legally there is no regulation to stop them doing exactly what this guy did. He took his friends as passengers while doing some hour-building – those words give me the horrors.

Every hour between PPL and Com should be constructive – not just jolling.

I believe the school has a moral, if not a legal, responsibility to use every one of those hours constructively. In other words, every flight must be properly planned, briefed and authorised. And therein lies a potential problem.

A little while ago I wrote about two com students who were killed while the PIC was building the required night hours. They flew into a mountain. There was no flight planning. They simply used a cellphone for navigation on a moonless night in bad weather. They were both killed. Was the school responsible, or the pilots themselves?

The accident report was vague about whether the flight had been properly authorised. If it had – then the authorising instructor had a responsibility to see their flight plan and flight log, and give them a thorough briefing. I suspect this didn’t happen because a totally blank, but bloodstained, flight log was found in the wreckage.

Where do legal liabilities lie? I have no idea, but I feel strongly that when parents hand over money to have their offspring trained to be commercial pilots, the school has a moral responsibility to see that the youngsters’ flying is properly planned, supervised and safe.

I chatted to the guy who had just taken over as CFI when the accident happened. He told me what I guessed was the case, the talk of practicing forced landings, was just that – talk. There were no practice forced landings, one survivor invented that story to justify the low flying.

The new CFI also said that, ironically, this was one of their best students. Sadly being best doesn’t make one immune to showing off.

When I had my own flying school, I adopted a novel approach to low flying training. I deliberately made the exercise as unpleasant

as possible. The idea was to make this such a miserable flight that it stuck in the pilot’s mind for the rest of his life – he would never want to do it again.

Although it was unconventional it worked extremely well.

I would make sure there was a strong wind, to guarantee plenty of low level turbulence. I would then take the aircraft down low, using the extra speed energy, if necessary, to pull up smartly in the event of suddenly spotting power lines. I would also point out that I was trimming up so there was a tendency for the aircraft to climb if my attention wandered.

In this configuration I would fly the standard racecourse pattern to demonstrate the airspeed/groundspeed relationship, into wind and downwind; as well as the apparent skid or slip in the turns. This to emphasise the importance of looking outside while trusting the power setting to look after your airspeed, regardless of huge changes in groundspeed. And learning not to fight with the rudder to sort out apparent skid or slip – the ball will mainly look after itself.

I would then get the student to take over –making sure that they needed considerable forward stick pressure.

The pupe would always gain height as soon as they took over – partly because of being groundshy, but largely because of the uncomfortable stick pressure. I would then badger them to get lower and lower until they were really unhappy and sweating.

This worked. I never had a pupil wanting to do low flying after that.

the same story keeps repeating

• Unplanned low flying is suicidal.

• Planned low flying calls for a crystal clear windscreen.

• Brief pax not to disturb you.

• Know the area, and any obstacles.

• Never do it in a valley – wires cross valleys.

• In bad weather or poor viz use climb speed and one notch of flap.

• In good viz carry a bit of extra airspeed

• Beware groundspeed and skid/slip illusions caused by wind.

• Have the best tank selected and the fuel pump on (most engines).

• Beware carb icing.

• Set mixture before going low.

• Keep one hand on the stick and the other on the throttle.

• Climb before fiddling with radios, carb heat or other stuff.

• Get pax to help with lookout.

• Look straight ahead – don’t be distracted.

• If you are following a powerline beware

others joining from the side.

• Don’t look for wires – look for poles and pylons.

• Beware bracing wires for radio masts

• Don’t fly through gaps in the trees – wires may lurk there.

• Power lines often have a tough thin wire above them.

• Ask yourself if you are trying to impress someone else.

• For photography – you fly, someone else photographs.

• Beware high density altitude and rising ground.

• Cross rising ground diagonally.

• Note poor VHF range.

• Beware birds over lakes, rubbish dumps etc.

• Height illusions over open water and sand dunes will kill you.

Only do it if you have been properly trained and you comply with ALL of the above.

ON THE TCA SIDE there are seven new registrations – four fixed wing, two helicopters and a glider.

Very interesting is the Airbus A340-600 ZS-MFC. This one is twenty years old and was originally ordered by Swiss Air. However, she wasn’t delivered to them but went to Iberia in Spain instead. She was with them until June 2021 when she was sold to a company in Malta and converted to a freighter. She was sold again in March 2022 to Air Atlanta Iceland and flew to Johannesburg in August 2022. The last time I saw her, a couple of months ago, she was parked at SAA Technical. As per usual the CAA will not divulge her owners name, so I have no idea who has bought her. This is frustrating.

African Air Charter have registered their second Boeing 737-36E that they’ve acquired from Cayman Airways.

There is a Robinson R44 that comes from the UAE and a BK117 from Australia. The Beech 1900 ZS-SEM is a returnee, having been in Australia for a while.

Airlink have registered another Embraer 190. This one also comes from Virgin Australia.

The glider I mentioned is a M&D Flugzeugbau JS-MD 3 Rapture. The JS-MD 3 is a fully EASA certified aircraft in the 15 and 18m class and combines highest performance with a M&D jet sustainer system.

On the NTCA side there are four more Sling 4 TSIs registered. This aircraft is getting more and more popular as time goes by. In November Sling Aircraft celebrated their 1,000 th sale – and this happened back in April!

We continue to lose large numbers of aircraft to the export market with another fourteen departing our shores in November. Of the fourteen there are five ex Mango Boeing 737800s which have been returned to their owner in France where they have been stored at Tarbes. This leaves Mango Airlines with no aircraft. The government is insistent that they’re still looking for a buyer for this company but with no aircraft left I doubt they’ll ever find one.

This month’s amendments show a whole variety of aircraft movements.

ABOVE: The end of Mango's fleet - ZS-SJA B737-800 exported to France. Photo Ray Watts.

BELOW: Another Mango departure - ZS-SJD a B737-800 exported to France. Photo Ray Watts.

BELOW BOTTOM: ZS-BLV is a BN2A Islander exported to Mozambique. Photo Ray Watts.

ABOVE: The end of an era - Safair's last L100 ZS-OPS L382G has been exported to the USA. Photo Ray Watts.

BELOW: An unlikely import - TF-MFC is now ZS-MFC.

BELOW BOTTOM: ZS-TBB in a Cessna Caravan C208B with an executive interior - now exported to Australia. Photo Ray Watts.

There’s also a very old DC9 ZS-TRJ (ex 1Time aircraft) that has been operating overseas for some time that has now been officially exported to Guernsey.

Safair’s L382G Hercules has been sold to Lynden Air Cargo in the USA as N411LC but is still standing outside Safair’s hangars at OR Tambo at the time of writing.

A Britten Norman Islander that has been operating in Mozambique for some time has finally been registered there and an old Grand

Central friend, Cherokee PA28-180, ZS-EBY has gone to Namibia.

A Jonker Brothers JS1C glider has been sold in the Czech Republic.

It’s the end of the year again and I must thank all the people who have helped me out over the past year with information and photographs. To all of you HAPPY CHRISTMAS and a very prosperous New Year. j

ONLY THREE TYPE CERTIFIED AIRCRAFT appear this time around. The Cirrus ZS-JBC takes up the registration once used by a Mooney which crashed at Rus de Winter on 20 September 1979. The registration was also allocated to another Cirrus serial number 0108 back in 2011 but this registration was cancelled soon after this as she remained in the USA as N797KA.

Another JS-MD 3 Rapture Glider has been imported from Germany this month. This makes three of these gliders that have been imported this year. It is notable that they bare being imported from Germany – yet they are made in Potchefstroom.

There are seven Non Type Certified aircraft registered which include the fourth ARLAC MK1 Mwari. There is also a mystery helicopter, ZU-RRA which is registered as a Blue Bir BB1 which I suspect may be a rebuilt Robinson. The balance of the registrations are a mix of

Cheetah, Jabiru, Sling, Savannah and Vans RV aircraft.

We continue to lose aircraft to the export market and December was no exception with nine TCA and three NTCA aircraft being deleted from the register.

One of the old Comair/British Airways Boeing 737-800s has gone to Bermuda.

The last Meyers 200D aircraft in South Africa has been exported to the USA. Although we didn’t see her around very often it’s a pity to lose this aircraft. Notably – it was the last flight test air to air shoot former SA Flyer editor John Miller did before he passed away.

Two North American aircraft, a T6 Harvard and a T28B Trojan have been exported to Kyrgyzstan – a most unusual destination for South African registered aircraft.

These are the last amendments for 2022 and as is usual the month of December has been very quiet when it comes to aircraft added to the register.

ABOVE: Harvard, ZS-WFD is one of a number of planes exported to Kyrgyzstan. Photo Rob Krummeck.

BELOW: ZS-ZWU B737-800 has been exported to Bermuda. Photo Ray Watts.

BELOW BOTTOM: An early CASA 235, ZU-SOO, CN235-010 has been exported to Mozambique. Photo Omer Mees.

ABOVE: ZS-PCM, is a Cessna 208B Caravan exported to the USA. Photo Ray Watts.

BELOW: ZS-TKZ, an Airbus Helicopters EC130T2 has been exported to Madagascar. Photo Ray Watts.

The balance of the exports has gone worldwide, with places like Czech Republic (a Jonker JS1/C), Algeria, Germany, Austria, Madagascar, New Zealand and Mozambique.

The CN 235-010 ZU-SOO is an interesting aircraft as it is a very early model Airbus CASA 235, being serial number 008 and is a 1987 model. She was part of the Botswana Air Force (OG-1) before being sold to Togo as 5V-MBM and then sold in the USA as N124CL and then N820CA. She was also operated for a short

while by the Madagascar Air Force and is now in Mozambique as FA801.

Tail piece: -

May I wish a prosperous New Year to all of you.

CAN I INTEREST YOU in some new independent research in physics proposing a new theory for how a wing generates lift? It is getting lots of attention. It offers significant economic/financial advantages to companies, as well as benefits for pilots.

I provide some details below:

Background: Albert Einstein tried and failed to explain lift and how airplanes fly in 1917. No one has solved the conundrum since. See the article: "No One Can Explain Why Planes Stay in the Air." 1 Feb 2020, Scientific American Magazine. www.scientificamerican.com/article/ no-one-can-explain-why-planes-stay-in-the-air/

Yet there is no attempt to solve or explain the unproven physics of lift. No conferences, no research papers, …. nothing. Engineers and physicists simply ignore it or claim that it is solved. Aeronautical engineers are taught that fluid mechanics (Navier-Stokes equations) explain lift, despite the lack of experimental proof and the problems with the NS equations.

Since 2014 I’ve worked on independent research in applied physics, which has been self-funded. The focus has been applying Newtonian mechanics to provide novel explanations for the physics of lift and other activities, such as swimming, sailing, and skydiving. The main paper is titled: “Newton explains lift. Buoyancy explains flight.” It is fairly radical by the standards of physics.

More precisely, I’ve written some pre-print research papers, which can be found online at www.researchgate.net . See also direct link: https://www.researchgate.net/profile/ Nicholas-Landell-Mills .

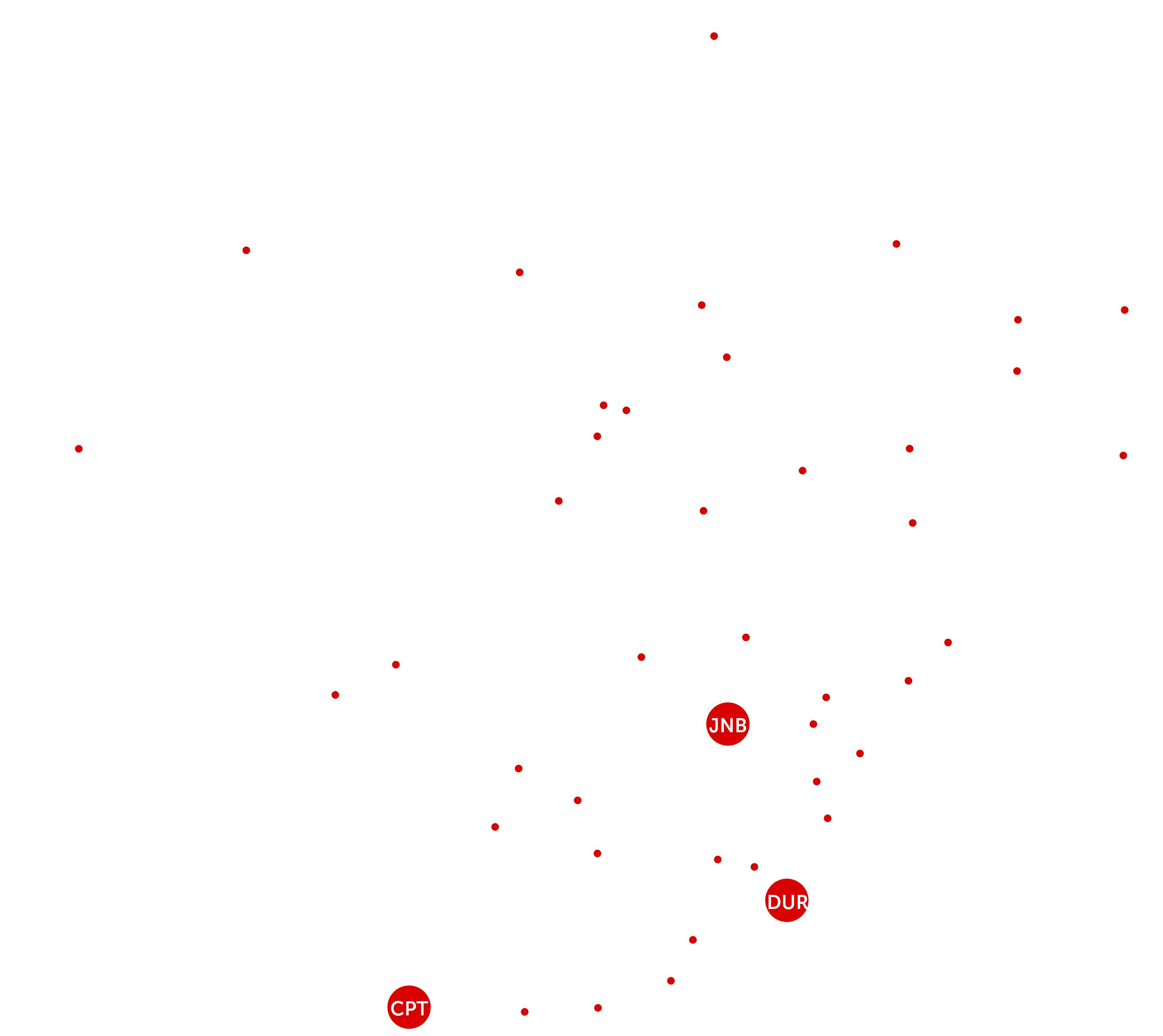

Since August 2019, online views and downloads of my papers have grown almost exponentially, doubling about every 9 months. Now at >100,000 views and >25,000 downloads. This is a lot for academic research papers from an unknown author. Apparently most PhD papers only get 20 views. See attached graph of the weekly online views. So there is interest in this research that I do.

The physics of lift is worth solving. It could save billions of $$$ in fuel from more efficient wing designs; and safety improvements by allowing pilots to become better aviators. These potential economic benefits far exceed anything that work in quantum and relativity physics has delivered in the last 80 years combined. For example CERN in Geneva cost billions to build in the 1950’s, but has delivered nothing of economic benefit. No new products have resulted from CERN’s work. Quantum computing remains a distant promise, as always.

Personal background: I’m 56 years old, British, living in France, and a graduate of Edinburgh University, UK (M.A. class 2:1 in economics). I had a private pilots (PPL) license for 20 years. I flew and maintained a homebuilt airplane. Before 2014, I worked in finance for 25 years.

Nick Landell-Mills j

Knysna based helicopter pilot Duran de Villiers used his Airbus H120 helicopter and local area knowledge to pull off a remarkable rescue in the Plettenberg Bay mountains.

CYCLIST ALAN BRODERIC had been reported missing by his family after going for a cycle ride in the Knysna forests on Saturday 3 December.

The Broderick family was on holiday from Johannesburg and Alan’s wife Gail says, “We got in touch with SANParks on Saturday afternoon. An appeal for the public to join the search was issued by the family on Sunday.”

This was all the invitation local EC-120 helicopter and all-round bush and budding aerobatics pilot Duran de Villiers needed.

Duran explains, “I grew up in Knysna and ride a bike there often and so know the forests quite well.”

Duran used Alan Broderick’s last GPS location from the Sunday. He says, “Even though Alan had been missing since Saturday, I only heard about it on the Sunday morning. His daughter Laura got hold of me on WhatsApp and I asked her to send me all the information she has. She sent me his last GPS location just south of Deepwater. I did a bit of Google Earth map research and since I knew the forest fairly well, I realised that he had probably turned off on the ridge line that was one ridge further north than the one he had intended to.”

Using his knowledge of cycling in the area, Duran said that he thought about what Alan would have done if he had been on the southern ridge trail. It would have let him into the river and his only option would have been to carry on going down the river.

Duran continues, “The main search and rescue operation and had set up in the Diepvallei area, which made sense as you have to start searching somewhere.”

“On Sunday afternoon I was at my hangar at Reenendal which is only about 5-minute flight from Diepvallei. After having being contacted by Alan Broderick’s daughter Laura, I said to myself; let me just get airborne and see what I can. I fuelled up the helicopter and with the GPS pin of Alan's last known location, along with some math and what I thought a cyclist would do thinking they are on the Petrus se Brand route but are in fact riding a different ridgeline more north, which would seem to be nearly identical in direction, look and feel.

what I thought a cyclist would do

This is a big factor to why and how Alan got lost.

“The forest, and especially the canopy, is super thick, so I followed the route that I assumed he would have taken. When I came to the dead end that is the river, based on the knowledge that he was a cyclist trying to get to Plett, I followed the river south-east towards the coast. I flew about an hour and a half trying to find him, but unfortunately couldn't. It was getting dark by then and I just had not been able to see him. I had the sun setting in my eyes, was flying solo and with a dark and incredibly thick forest canopy making it near impossible to spot anyone. But I had a strong gut feeling that he was where I thought he was. It turns out that Alan actually had heard me on the Sunday afternoon as I flew overhead.”

“The plan was to get airborne again early Monday morning, with my good friend and fellow pilot John Grant Bozman who I would pick up at Plett Airport along with Marc Rodgers, both part of NSRI and search and rescue in and around Plett.