PAM BUILDING

For 150 years, we have been designing, manufacturing and marketing high-quality complete systems for sanitary and rainwater drainage in buildings. We work exclusively with cast iron, a noble and durable material, of which we are specialists and market leaders.

Our mission: the safety and durability of buildings

Our cast iron solutions and systems contribute to ensure the comfort, safety and durability of the most demanding residential and commercial buildings. Their exceptional characteristics allow them to contribute to HQE, BREEAM, LEED and other international environmental certifications.

Our greatest strength : our teams

We rely on our technical know-how in order to remain the forerunners in our field.

This is why PAM Building capitalizes on the skills of its teams and integrates every year young graduates, in apprenticeship or in advanced training.

Thanks to our unique commercial approach, we have become a technical solutions provider able to anticipate our customers’ expectations.

Our technical team is available from the conception to the realization of a project.

Our business managers ensure a daily follow-up on the ground and guarantee the best conditions for implementation.

Our products, our people and all our teams are here to help you make the world a more beautiful and sustainable home together.

4 PAM Building

Our promise: to reduce our impact on the environment

Our 2025 vs. 2010 goals:

- 40 % of energy consumption

- 97 % of discharges of industrial water

Our commitment to reducing C02 emissions by 2030:

-

80% compared to 2017

At the heart of the circular economy, our DNA: recycling of metal waste

Our products are made of 99% recycled materials (mainly scrap metal), which can be recycled 100% indefinitely.

Cast iron is a simple and sustainable material that allows a smart reuse of materials. Resistant, reliable and durable, cast iron has a bright future ahead of it.

In 2021, we recycled the equivalent of of 21,000 cars.

- 84 % of nonrecovered waste

SAFE AND SUSTAINABLE BY NATURE

PAM Building 5

NEW AGILIUM®

PAM Building launches a new drainage solution that reduces its environmental impact and facilitates the daily work of installers. An innovation that is part of our eco-design approach.

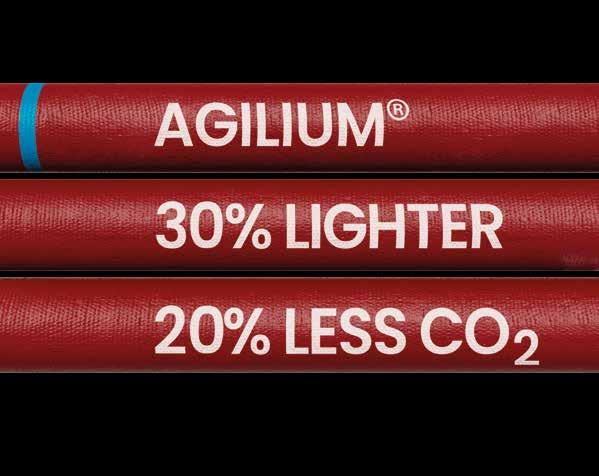

For plumbers

Easier to carry with a weight reduction of 30 %. Faster to install with less time spent on pipe handling.

SEE PAGE 18

For design offices

More agility with a space-saving in increasingly more constrained spaces.

SEE PAGE 19

For project owners

Better for the environment with a 20% reduction in carbon emissions.

SEE PAGE 15

AGILIUM®: INCREASED EASE OF INSTALLATION, 100% COMPATIBLE WITH EXISTING RANGES AND STILL AS EFFICIENT.

Fire resistance

Agilium® cast iron is a non-combustible metallic material with reaction to fire A1 and fire resistant up to 4 hours to protect people and property.

SEE PAGE 12

Durability

Due to their exceptional mechanical properties cast iron drainage systems prevent the worry of untimely and costly repairs.

SEE PAGE 14

Acoustic comfort

Noise is bad for your health. Agilium® cast iron systems easily meet the regulatory requirements, achieving exceptional performance for high acoustic comfort (luxury hotels, hospitals...)..

SEE PAGE 14

Environment

Agilium® cast iron is made from recycled materials and is fully recyclable. It reduces C02 emissions by 20%.

SEE PAGE 15

8 PAM

THE RESULT OF AN ECO-DESIGN

Evolution of the EN877 standard

The NF EN877 standard is evolving and allows to reduce the minimum thickness of the walls. The products carry the NF quality mark, which means that the conformity of the products has been verified by a third party.

The de Lavaud process

A unique manufacturing process, optimized for Agilium®, with investments partly supported by the Grand Est region.

In the de Lavaud process, historically developed by Saint-Gobain, the liquid metal is poured into a bare steel shell and undergoes very rapid cooling.

A graphitization annealing process, followed by ferritization, results in pipes with exceptional mechanical properties.

* Minimum value of wall thickness up to -1 mm, by comparison with Table 6 of the NF EN877 standard.

The quality of products is guaranteed

We have obtained the most recognized international quality marks, all delivered by third party certification: Marque NF, Q+, Gost (Kitemark and Sintef are under process).

PAM Building 9

DN Minimum wall thickness (mm)* 100 2,0 125 2,5 150 2,5 200 3,0 250 3,5 300 4,0

LONGEVITY

ACOUSTIC COMFORT

ENVIRONMENTAL IMPACT

PERFORMANCE FIRE SAFETY

02 10 PAM

PAM Building 02 PERFORMANCE

AGILIUM®

We have conducted numerous tests in accredited European laboratories and in our R&D center, which confirm the excellent performance of Agilium® cast iron.

FIRE SAFETY

Pipes are the arteries of a building.

In the event of a fire, the risk is that these pipes will sustain and spread the fire throughout the building. Choosing PAM Building cast iron systems means ensuring the safety of people and property.

Reaction to fire

• Reaction to fire is the ability to ignite and to feed the fire,

• Agilium® drainage systems are A1 fire rated and completely non-combustible. They do not generate smoke or droplets in case of fire.

The Euroclasses establish a classification of reaction to fire that are harmonized throughout Europe that can be used to compare materials and product performance.

EUROCLASSES

A1 -A2 s1 d0

A2 s1 d1

A2 s2 s3

Agilium® complies with the new standard EN877 and maintains equivalent performance to our current cast iron drainage solutions. 12 PAM

Fire resistance

• The fire resistance of a product is its ability to resist fire for a given time and not transmit the fire to an adjacent room,

• Agilium® cast iron is a non-combustible metallic material with a melting point higher than than 1000°C.

Criteria PRODUCTION of SMOKE

s1: Low production of smoke

s2: Medium production of smoke

s3: High production of smoke

s2 d1

B s1 d0

s3

Criteria MOLTEN DROPLETS

d0: No molten droplets

s2 d1

C s1 d0

s3

d1: Molten droplets that persist for less than than 10 s

d2: Molten droplets

s2 d1

D s1 d0

s3

Classes other than E-d2 & F

Fire resistance test results

Following fire resistance tests carried out by Efectis on slab and wall penetrations, multiple firewall solutions are envisaged:

• In the vast majority of cases, no protection is necessary,

• Optimization of the thickness of the slab by adding concrete blocks at the level of the crossing,

• In some cases, because the fire resistance classification implies a limitation of the heating on the side opposite the fire, insulation in the area of the penetration is necessary, carried out by the use of mineral wool shells.

ISOVER Ultimate® Solution

ISOVER U Protect Pipe Section Alu2 u171

"ISOVER ULTIMATE® concentric mineral wool shells aluminum coated, allowing a fireproof passage for cast iron networks".

Fire resistance tests carried out by Efectis.

Fire resistance tests carried out by Efectis.

PAM Building

Concrete blocks at the level of the slab crossing.

DURABILITY AND MECHANICAL STRENGTH

Reduced maintenance costs due to the mechanical properties of cast iron.

Aging behaviour: cast iron is characterized by a long life span of 70 years, in particular thanks to the stability of its mechanical properties, in comparison with the aging of polymers and their deterioration.

Resistance of Agilium® cast iron to impacts occurring in parking lots and basements in technical rooms (cellars, garbage rooms...).

ACOUSTIC COMFORT FOR THE OCCUPANTS

Agilium® retains the acoustic performance with an airborne sound insulation of La,A 46dB(A) according to the EN 14366 standard, for a discharge flow of 2.0 l/s.

(Test report P-BA6/2021E, tests performed at the Fraunhofer Institute).

Unlike other materials, the acoustic performance of Agilium® cast iron is guaranteed:

• Without technical advice,

• Without addition of specific parts,

• Without specific assembly (gluing, welding, etc...).

14 PAM Building

Agilium® Process Other processes (not PAM Building) Provision of the European standard EN877 Tensile strength on specimen in MPa (average values) 310 270 200 minimum Crushing strength on ring in MPa (average values, DN 100 pipe) 515 360 350 minimum Brinell surface hardness in degrees HB (average values) 165 245 260 maximum

ENVIRONMENTAL IMPACT

Agilium® is our first eco-design, in line with our new environmental roadmap.

The plumbing package at building level

The plumbing package represents less than 5% of a building’s C02 emissions (data from life cycle analysis), according to a sensitivity study conducted in France by the Bastide Bondoux, Pouget and Tribu design offices, on a 4-story office building (4,000 m2). With Agilium®, it is possible to go even further.

20% less CO2 emissions with Agilium®, compared to our current ranges

This performance is validated by comparing our new Agilium® Environmental Product Declaration (EPD) with the one previously available on the environdec database (www.environdec.com).

11,2kg

*UFC = Functional Unit = 1 ml of drainage system

<5% OF CONTRIBUTION TO CO2 EMISSIONS FROM OF SANITARY EQUIPMENT AT THE BUILDING LEVEL

And still unbeatable in terms of circular economy!

99% RECYCLED

Fully RECYCLABLE

Tower Saint-Gobain certified BREEAM, LEED, HQE and effinergie using PAM Building drainage solutions. PAM Building. PAM Building 15

STANDARD

C02 eq/UF* AGILIUM®

C02 eq/UF*

8,9kg

RANGE

PRODUCT RANGE OFFER

03 16 PAM

AND COMPATIBILITY BIM DIMENSIONS COATING PRODUCT MARKING AGILIUM®

PAM Building 03 PRODUCT RANGE

PRODUCT RANGE

A complete new offer with 30 new references (pipes and fittings) to replace the current range. PIPE -30% lighter*

6 diameters, from DN100 to DN300 (see page 21)**

• Average reduction of 30% compared to the standard range,

• A 3 m Agilium® DN100 pipe weighs just 17 kg, compared to 24 kg for the standard range,

• The outer diameter is maintained,

• Slight increase in inner diameter.

** Exists with external standard coating or with zinc coating for a higher resistance to external stresses due to climate exposures.

WIDE RANGE OF PRODUCTS AND COMPATIBILITY

• You can mix Agilium® pipes with fittings,

• You can mix pipes of the standard range with Agilium® fittings,

• You can use most standard joints,

• You can keep most of the reservations for standard range with Agilium®

18 references (see pages 21 - 22)

* Average weight reduction compared to the range.

NEW LIBRARY OF BIM OBJECTS

• Revit format,

• Coexistence with the old library.

DES I G N FEASIBILITY R E NOVATION ENDOF LIFE CONSTRUCTION OPERATION BIM READY

Standard range

Standard range Pipe Agilium®

18 PAM

FITTINGS -15% lighter* Agilium® Pipe

Fittings

Fittings

SHORTER FITTINGS REQUIRING LESS SPACE IN THE VOID

• Reduced sealing zone at the ends,

• External diameter maintained,

• Weight reduction* 15% on average.

In the example above the footprint is reduced by 2.3 cm. Contact us for other configurations.

COATING Pipes

1 Exterior coating red brown acrylic primer with an average dry film thickness of 40 microns

2 Cast iron manufactured according to the de Lavaud process

3 Interior lining: Two-component epoxy coating, ochre color, average dry film thickness 130 microns

Fittings

Exterior and interior coating in red brown epoxy with an average thickness of 70 microns.

1 2 3 STANDARD RANGE PAM Building 19

PRODUCT MARKING - PIPES

For easy visual differentiation in the warehouse and on the construction site:

• Blue marking

• Single blue ring at the end of each pipe

PRODUCT MARKING - FITTINGS

EAN code label for simplified inventory management

20 PAM Building

code for simplified inventory management

EAN

Product name Compliance with the standard Classification of reaction to fire Compliance with the NF mark Dimension of the pipe Country of origin

Compliance with the Q+ mark

AGILIUM® - PIPE

AGILIUM® - FITTINGS

L H W

a W a L H q a a L H q W

45° and 88° PAM Building 21 DN L H W Weight Product Code 100 3000 110 110 16,8 283723 125 3000 135 135 24,8 283724 150 3000 160 160 30,5 283725 200 3000 210 210 46,3 283726 250 3000 274 274 66,4 283727 300 3000 326 326 86,7 283728

Angle DN L H W a q Weight Product Code 45° 100 139 149 110 65 72 1,3 283867 125 167 175 135 75 80 2,0 285291 150 194 197 160 83 85 3,0 285292 200 253 254 210 106 106 5,4 285293 88° 100 160 162 110 103 52 1,8 283868 125 190 192 135 120 57 2,8 285294 150 223 225 160 140 65 4,4 285295

Check availability with your distributor or PAM Building contact.

Check availability with your distributor or PAM Building contact.

AGILIUM® - FITTINGS

Single branches to 45° and 88°

22 PAM Building H b d c r q p L W L b o H c r q p W H b o c r q p L W

branches at 45°

Double

Angle DN dn L H W b c o p q r Weight Product Code 45° 100 100 223 245 110 185 185 60 230 152 35 3,3 283869 125 100 248 255 135 202 202 53 234 157 40 4,3 285296 125 270 291 135 220 220 71 283 178 40 5,3 285297 150 100 278 277 160 222 227 55 253 176 50 5,7 285358 125 295 308 160 238 238 70 285 190 50 6,7 285298 150 323 342 160 260 265 82 324 212 45 8,0 285299 200 100 327 291 210 256 260 35 257 180 60 8,2 285300 150 369 362 210 294 295 68 332 220 55 11,3 285301 200 410 429 210 327 329 103 408 260 55 14,9 285302 88° 100 100 165 206 110 98 108 108 167 57 34 2,5 283870

availability with your distributor or PAM Building contact. Angle DN dn L H W b c d p q r Weight Product Code 45° 100 100 337 245 110 185 185 60 230 152 35 4,14 283871

Check

AGILIUM® Zn

Agilium® Zn is recommended for applications in coastal areas, directly or indirectly exposed to climatic stresses, polluted atmospheres or confined areas such as cellars, crawl spaces. This range may be exposed also to external aggressions during manufacturing processes and condensation.

COATING Pipes

1 External coating: red-brown, acrylic primer paint, average dry film thickness of 40 μm

Anti-corrosive layer: flame-applied zinc metal coating of 260 g/m2 on average

Cast-iron made with the De Lavaud process

Internal coating: two-component ochrecoloured epoxy coating, average dry film thickness of 130 μm

FOCUS ZINC COATING

External coating corrosion resistance test to neutral salt spray of 3500 hours according to standard NF-EN ISO 9227_2017

The zinc metal coating is an active protection provided by the galvanic action of a zinc-iron cell. This action is two-fold:

• Formation of a stable protective layer of insoluble zinc salts,

• Self-repairing of any damage.

Zinc metalisation is an excellent corrosion inhibitor and is extremely effective at extending the lifespan of products subject to backfills or climatic stresses.

Zinc spray coating

Self-repairing action: a white line of zinc salt shows that the damage is completely plugged.

PAM Building 23

PRODUCT MARKING - PIPES

For easy visual differentiation in the warehouse and on the construction site:

• Yellow marking

• Double blue ring at the end of each pipe, including "Agilium® Zn"

24 PAM Building

EAN code for simplified inventory management

Product name Compliance with the standard Classification of reaction to fire Compliance with the NF mark Country of origin Dimension of the pipe Compliance with the Q+ mark

Check availability with your distributor or PAM Building contact.

PAM Building 25 L H W AGILIUM® Zn - PIPE DN L H W Weight Product Code 100 3000 110 110 16,8 288629 125 3000 135 135 24,8 288630 150 3000 160 160 30,5 288631 200 3000 210 210 46,3 288632 250 3000 274 274 66,4 288633 300 3000 326 326 86,7 288634

Fire resistance tests carried out by Efectis.

Fire resistance tests carried out by Efectis.