9 minute read

Innovation

SSN-COE Team Gets Rs 12 Cr Grant from DST for Solar Ingot Manufacturing Tech

Dr. Ramasamy, Dean (Research)

Advertisement

Researchers at SSN-COE have been awarded a Rs 12 crore grant from the DST, for tech they believe can catalyse India’s solar ingot and wafer manufacturing abilities

SSN College of Engineering (SSN-COE), Chennai has announced that a team of its researchers led by Professor P. Ramasamy, Dean (Research) have been awarded a grant of Rs 12 crore by the Department of Science & Technology (DST), Government of India, towards Directional Solidification (DS) technology that has the potential to catalyse India’s solar wafer and ingot manufacturing abilities. Wafers and ingots are the building blocks for manufacturing solar cells and modules and are essential to India’s clean energy plans. Globally, solar wafer and ingot manufacturing is dominated by China followed by countries such as Japan, Taiwan, and S. Korea.

The research features an indigenously designed Directional Solidification (DS) technology system for growing highperformance multi-crystalline silicon ingots. This, the team believes, will aid the production of cost-effective, nextgeneration solar wafers and ingots and paves way for domestic manufacturing of large and better-quality silicon (mc-Si) ingot with enhanced efficiency of solar cells.

Dr. Ramasamy, Dean (Research), SSN College of Engineering, Chennai said, “multi-crystalline silicon is an important material used in production of low-cost, high-efficiency solar cells. Our indigenously designed Directional Solidification (DS) technology system will allow us to grow high-quality mc-Si ingots suitable for the fabrication of solar cells. We also aim to transfer this technology to industries to indigenously manufacture highperformance mc-Si solar cells, taking a crucial step towards an Aatmanirbhar Bharat.”

The team designed and developed mathematical simulations to use on industrial Directional Solidification (DS) system to produce high-quality silicon (mcSi) ingots. They studied – melt- crystal interface shape, impurities, and von mises stress under different temperature profiles to achieve better quality silicon (mc-Si) ingot. Further, transient global heat transfer model was used to optimise the temperature profile of the Directional Solidification (DS) process. It is the most efficient simulation to receive a slightly convex interface shape with lower thermal stress, and lower impurities in the silicon (mc-Si) ingot.

The research has been published in the journal Material Letters. SSN-COE Solar Ingot Manufacturing Grant

Dr. Kala Vijayakumar, President, SSN Institutions said, “This research by our faculty has the potential to help our country realize its renewable energy goals and at the same time encourage local manufacturing to become more self-reliant.”

Currently, India has a domestic manufacturing capacity of only 3 GW for solar cells and is heavily dependent on imports to meet its requirements. In 201819 alone, India imported USD 2.16 billion worth of solar photovoltaic (PV) cells, panels, and modules. Chinese companies dominate the Indian solar components market, supplying about 80 percent of solar cells and modules used in the country. This breakthrough research, the team claims, has the potential to enable the country to reduce its dependence on imports and become more self-reliant.

However, with the technology-focused on multi-crystalline cells, there is the issue of efficiency improvements to consider too. Keep in mind that global manufacturers have gone off multicrystalline manufacturing, and even in India, mono PERC modules overtook multi-crystalline in 2020, according to some reports. Thus, any further investment into mc will be at a huge risk of investing in old technology.

'Chillermill' World's First Hybrid Renewable Energy Powered Freezer for Covid-19 Vaccine

Hyderabad-based commercial cold chain appliances manufacturer Rockwell Industries Lmt. launched the world's first-ever storage chiller and freezer that runs completely on the hybrid renewable energy source (wind and solar energy) on Thursday.

The all-new Off-grid vaccine chiller/ freezer 'Chillermill' is useful to store COVID-19 vaccine at the required temperatures, ranging from Rs. 40,000 to 1 Lakh. The entire system is certified by the National Institute of Pharmaceutical Education & Research (NIPER) Hyderabad. Also, the company has rolled out its new Covid-19 vaccine freezer series.

Consolidated with a unique patent of wind & solar energy the ‘CHILLERMILL’ range powers up of itself. The freezer comes with two high capacity variants (FR170 & FR240) and brings down the operational and energy cost to zero. A new world chilling technology with up to 72 hours of enhanced autonomy. It runs on 100 percent hybrid renewable energy with unique patented wind & solar energy Brand “SOLARMILL”.

Speaking to ANI at the launch of the product, Prateek Gupta, Director of Rockwell Industries Ltd said, "The vaccine storage chiller and freezer called 'Chillermill' is the first of its kind as it runs on hybrid renewable energy, which takes its source from solar as well as wind. This chiller/freezer gets its required power from the renewable energy source." "The Chillermill fits the Covid-19 vaccine temperature requirements. This chiller/ freezer can provide a temperature setting up to -20°C. This has been approved by the World Health Organisation. Some vaccines need temperatures to be between 2°C to 8°C while some other need temperatures to be at -20°C," Prateek added.

Ashok Gupta, the Managing Director of Rockwell Industries Ltd said, "Now we have decided to enter the medicine segment. We have developed a Cold chain supply system for the vaccines to be delivered and stored at the right temperatures called 'Chillermill', which is both a freezer and a chiller." "The cost varies from Rs 40,000 to Rs 1 Lakh plus the energy source," Gupta added.

Explaining their plans to circulate the freezer at a large level, Gupta said, "We are also planning to partner with the government to provide these freezers to the hospitals and health care units of rural areas, where there is a need for such machines. Under the Corporate Social Responsibility (CSR) funds expenditure, these machines can be purchased and donated to the hospitals when needed," he added.

TG Hylift Develops A Robotic Cleaner For Floating Solar Modules

AGerman engineering manufacturer has developed a cleaning robot optimized for installed floating solar modules. It can also be used for solar modules installed on land. The robotic cleaner uses only water without any detergent and works with batteries, maikig it an optimum option for floating solar plants by avoiding any water pollution.

With floating solar just coming into its own, with projects over the crucial 50 MW size making an appearance, the need for solutions like this was long felt, and the latest innovation will probably spur more such announcements soon for the growing segment.

The robot is now being tested in a floating photovoltaic installation by Isigenere, a Spanish engineering company, and supplier of floating photovoltaic structures. The company has tested its new cleaning robot in a 500 kW floating installation built on an irrigation pond in the province of Mérida, in southern Spain.

The cleaning robot named, hyCleaner black Solar facelift, has a modular design and uses only water without any detergent or chemical additive to clean the panels. The robot uses water from an existing irrigation reservoir in the facility in Spain. However, its manufacturers claim that you can also use rainwater, tap water, and recycled water, as well as all kinds of water preparation systems.

The water supply is connected via a connecting link, and power is supplied by incorporated lithium-ion batteries. The robot is simply placed manually in the first row of modules and can be driven by an operator, via remote control with a range of more than 100 meters. Its design ensures minimal disturbance when moving around the installation, and its large track wheels increase movement between the different photovoltaic modules.

Interestingly, the cleaning robot also has an edge detection system, which automatically stops it when it reaches the edges of the module.

Depending on the type and intensity of the dirt, the robot can be operated at different speeds. The rotating wash brush has a width of 1100 mm and modifies perfectly according to the width of the module. It cleans the surfaces of the modules and frames in a single operation.

The robot can also be used in inclined installations, claims the manufacturer.

Moreover, Isigenere perceives that since their Isifloating design does not have maintenance aisles between rows, cleaning robots like this one is an ideal solution. "In this way, large continuous photovoltaic surfaces are created," says the company.

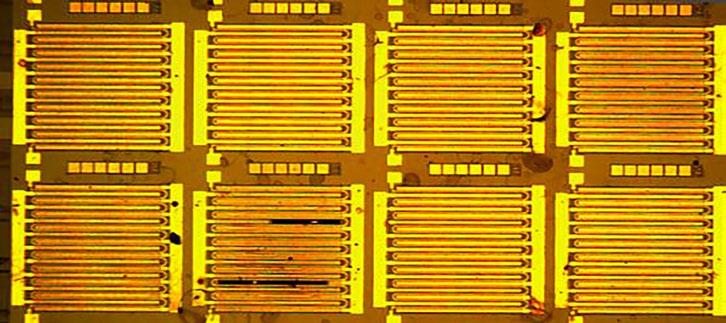

1st Ever Indigenous HEMT That Could

Revolutionise EVs, Transmission

Anew High Electron Mobility Transistor (HEMT) has been developed that is a normally OFF device and can find use in EVs, power transmission, etc.

A team of scientists from Bangalore has developed a highly reliable, High Electron Mobility Transistor (HEMT) that is a normally OFF device and can switch currents up to 4A and operates at 600V. This first-ever indigenous HEMT device made from gallium nitride (GaN) is useful in electric vehicles (EVs), locomotives, power transmission and other areas requiring high voltage and high-frequency switching would reduce the cost of importing such stable and efficient transistors required in power electronics.

Power electronic systems demand high blocking voltage in OFF-state and high current in ON-state for efficient switching performance. Specific transistors called HEMTs made of aluminium gallium nitride/ gallium nitride (AlGaN/GaN) provides an edge over silicon-based transistors as they allow the systems to operate at very high voltages, switch ON and OFF faster, and occupy less space. Commercially available AlGaN/GaN HEMTs use techniques to keep the transistor in normally OFF state, which affects the stability, performance and reliability of the device.

Therefore, to meet this need, Prof. Mayank Shrivastava, Department of Electronic Systems Engineering, his co-investigators Prof. G. Narayanan, Prof. Digbijoy Nath, Prof. Srinivasan Raghavan and Prof. Navakanta Bhat, from Department of Electrical Engineering, and Centre for Nanoscience & Engineering, and their students, all from Indian Institute of Science Bangalore (IISc), have developed the new kind of HEMT, which is in the OFF state by default and works like any other commonly used power transistor.

Such transistors are called e-mode or enhancement mode transistors. Supported by the Department of Science & Technology (DST), Government of India, under the ‘Make in India’ initiative, they developed the new technology and device architecture using an Aluminium titanium oxide gate.

The developed technology is a first of its kind, which uses a type of chemical called ternary oxide (composed of two different metal ions combined in an oxide matrix or Al, Ti and O), which behaves like material having larger positive charge concentration (p-type material). It does away with intrinsic reliability and performance issues of the in-use industrial techniques for e-mode HEMTs, allowing the development of efficient power switching systems.

This device will now be taken up for the prototype development and field-testing level (TRL 5). The scientists used aluminium titanium oxide as the gate oxide, where the percentage of aluminium could be controlled during the fabrication process. Since aluminium titanium oxide is stable, it resulted in high reliability of the transistor.

The projected overall power device market is set to cross the 18 Billion $ mark by 2020, out of which the market for HEMTs is projected to cross the 5 Billion US$ market. So, GaN HEMTs will acquire a major share of the power device market. With a growing market for electric vehicles in India, such an indigenous development can make India self-reliant for transistor technology.

The paper “Positive Threshold Voltage Shift in AlGaN/GaN HEMTs & E-mode Operation by AlxTi1-xO based Gate Stack Engineering” was published in the IEEE Transactions on Electronic Devices. The team of students that worked on the project, research include Sayak Dutta Gupta, Ankit Soni, Rudrarup Sengupta, Heena Khand, Bhawani Shankar, and Nagboopathy Mohan.