Equipment

The engineering challenges of reusing existing assets

Digital transformation

Where utilities need to focus to take core processes to the cloud

Business

energy How businesses can be part of the 2035 zero-carbon system

Issue 211 - 2022

A solution that can help mine maintenance managers achieve greater productivity in brutal settings

SHIELD

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Consultant Tom Vince Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Steven Dobinson

Editorial Administrator Amy Gilks

Creative Lead Lee Protheroe

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe

Artwork Administrator Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors Philip Monument, Joy Francesconi

Head of Content Management Adam Blanch

Client Sales Executives

Chloe Allman, Mark Cawston

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell

Content Managers Johanna Bailey, Mark Cowles, Jeff Goldenberg, Wendy Russell, Richard Saunders, Kieran Shukri

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

US Office

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426 T: (561) 778-2396

Hello and welcome to the December issue of EOG. The last issue of the year!

How have you fared in 2022? The sector has certainly experienced some further challenges, and energy prices continue to dominate the headlines. But, from the conversations we have with our contributors, it is clear that for many, despite the volatility and upheavals, the journey to Net Zero is on their agenda, the energy transition is underway and there is determination to decarbonize not only their own operations but also that of the supply chain.

There’s also evidence that they’re willing to think out of the box – for example, in our feature from npower Business Solutions, author Anthony Ainsworth reports on data that indicates companies could play a crucial role in decarbonizing the UK’s energy system. Do you think that is feasible?

Libbie Hammond, Editor

lh@finelightmediagroup.com

Our cover story looks at a product originally developed for the US military, which is now delivering benefits to the mining sector. Turn to page 4 to learn more.

Digital transformation processes to the cloud Equipment The engineering challenges of reusing existing assets Business energy be part of the 2035 zero-carbon system A solution that can help mine maintenance managers achieve greater productivity in brutal settings SHIELD Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Follow energy, oil & gas at

@EOG_magazine energy-oil-gas-magazine Welcome energy-oil-gas.com 1

Inside this issue Mining Equipment Business energy Digital transformation Cover Story 8 16 12 4 Contents 2

IMTT WUN H2 Capstone Infrastructure Corporation Calumet 24 30 46 36 energy, oil & gas magazine energy-oil-gas.com 3

SHIELD

Corrosion is a leading cause of tool and equipment degradation, downtime, repair, and early replacement in both surface and underground mining. Degradation can occur for reasons such as external atmospheric attack (on structural steel and concrete), erosion-corrosion (in the crushing/ grinding circuit and slurry lines), high temperatures, and aggressive solutions (within process streams).

At mine sites, conditions can quickly corrode tools like pickaxes, hammers, chisels, and shovels, as well as surface mining equipment such as trucks, dozers, excavators, and blasthole drills. Corrosion can also rapidly compromise underground mining equipment such as scoops, loaders, haulers, shuttle cars, crane lifts, and even ventilation systems critical for life support.

The harsh mining environment makes it difficult to sufficiently lubricate and protect tools, equipment, and electronics from

corrosion. Exposure to moisture, condensation, salt, and extreme wear and tear often accelerates corrosion, leading to failure and extended downtime. Internal components, electronics, and wiring are also susceptible to corrosion and electrolysis, which can compromise function and lifespan.

In response, industry professionals are turning to a unique anti-corrosion protectant, cleaner, and lubricant called StrikeHold®. The spray was originally developed to preserve and maintain US military weapons and heavy equipment for use in some of the harshest working conditions in the world. Today it is used to protect mining tools and equipment, including circuit boards, electrical circuits, and metal components in corrosive environments while improving electrical continuity and contacts. The spray not only protects the wide range of mining equipment comprised of such components, but also extends its usable life.

The harsh mining environment makes it difficult to sufficiently lubricate and protect tools, equipment, and electronics from corrosion

▶

A product developed for the US military is now protecting mining equipment from corrosion

4

Mining 5 energy-oil-gas.com

The use of StrikeHold has the potential to largely eliminate the effects of moisture, corrosion, and electrolysis in mining equipment. The micro barrier that it forms on components is so complete that an electrical charge cannot be passed from the metal into water. It also improves electrical performance by cleaning and protecting contacts and internal parts, including circuitry and connections. The anti-corrosive protectant sprays on clear or applies wet and dries in place.

The protectant is designed to waterproof components and can even be used on mining equipment that is already wet in the field. Because it has a specific gravity greater than water, when applied to a wet surface it penetrates to the hard exterior, pushes water from the surface, and coats the area.

Since the cleaner has anti-static properties, dust, dirt, and grime do not adhere to it in the natural environment. Dust blown onto a treated surface blows off cleanly with wind

or rain, leaving the coating intact. For this reason, the protectant and cleaner is used on hundreds of solar lighting fixtures along a coal mine roadway in Brisbane, Australia.

“The dust raised by the wind, passing vehicles, and coal trucks was very problematic for the solar panels,” says Daryl Bancroft, General Manager, StrikeHold Australia. “Once the panel is coated with the shield-like, completely dry film seal, it’s protected, and moisture, sand, dust, and dirt don’t stick to it. This eliminates a lot of preventative maintenance.”

He notes that for the mine site application the coating is also applied to printed circuit board assemblies for protection against moisture and corrosion.

“StrikeHold prevents moisture from getting into the electronics or componentry and provides continued dry lubrication. It stops the dust and other particles that attack the running gear, including circuit boards,” says Bancroft.

An anti-corrosion protectant, cleaner, and lubricant like StrikeHold is designed to waterproof components and can be used on mining equipment that is already wet in the field

An anti-corrosion protectant, cleaner, and lubricant like StrikeHold is designed to waterproof components and can be used on mining equipment that is already wet in the field

6

Bancroft says that his company is working with an underground mine in Western Australia to prevent corrosion of excavator alternators using the protectant. “The alternators in large excavators can erode and fail quickly due to accelerated corrosion. This caused excessive downtime since the excavators had to be towed away for repair and alternator replacement at high cost,” says Bancroft.

“As a form of preventative maintenance treatment, a dispenser could spray StrikeHold every hour or so to keep the alternator corrosion free. This could save thousands of dollars per mining machine in downtime and repair costs, and there are hundreds of machines running 24/7,” he adds.

When moving components require dry lubrication, the compound is also effective. The fast-acting, penetrating compound cuts through rust and dirt, quickly getting into metal parts to reduce excessive friction. The lubricant contains syntheticbased additives that act like microscopic

ball-bearings to minimize friction, facilitate maintenance, and improve operation.

As surface and underground mines seek greater productivity in brutal settings, getting the most out of their tools, equipment, and labor requires superior maintenance procedures that protect the investment and enhance long-term output. Mine maintenance managers that utilize easy to apply compounds that safeguard against corrosion and electrolysis will have an advantage in the field and marketplace. ■

A unique anti-corrosion protectant, cleaner, and lubricant, StrikeHold prevents rust and electrolysis in mining tools and equipment while improving electrical function. The spray was originally developed to preserve and maintain U.S. military weapons and heavy equipment in some of the world’s harshest working conditions.

StrikeHold www.strikehold.com.au

Since the StrikeHold compound has anti-static properties, dust, dirt, and grime do not adhere to it in the natural environment, but blow off cleanly with wind or rain

Mining 7 energy-oil-gas.com

CLEAN delivery

By Tim Nicholas

Designing a high-performing filtration system – whatever the circumstances

8

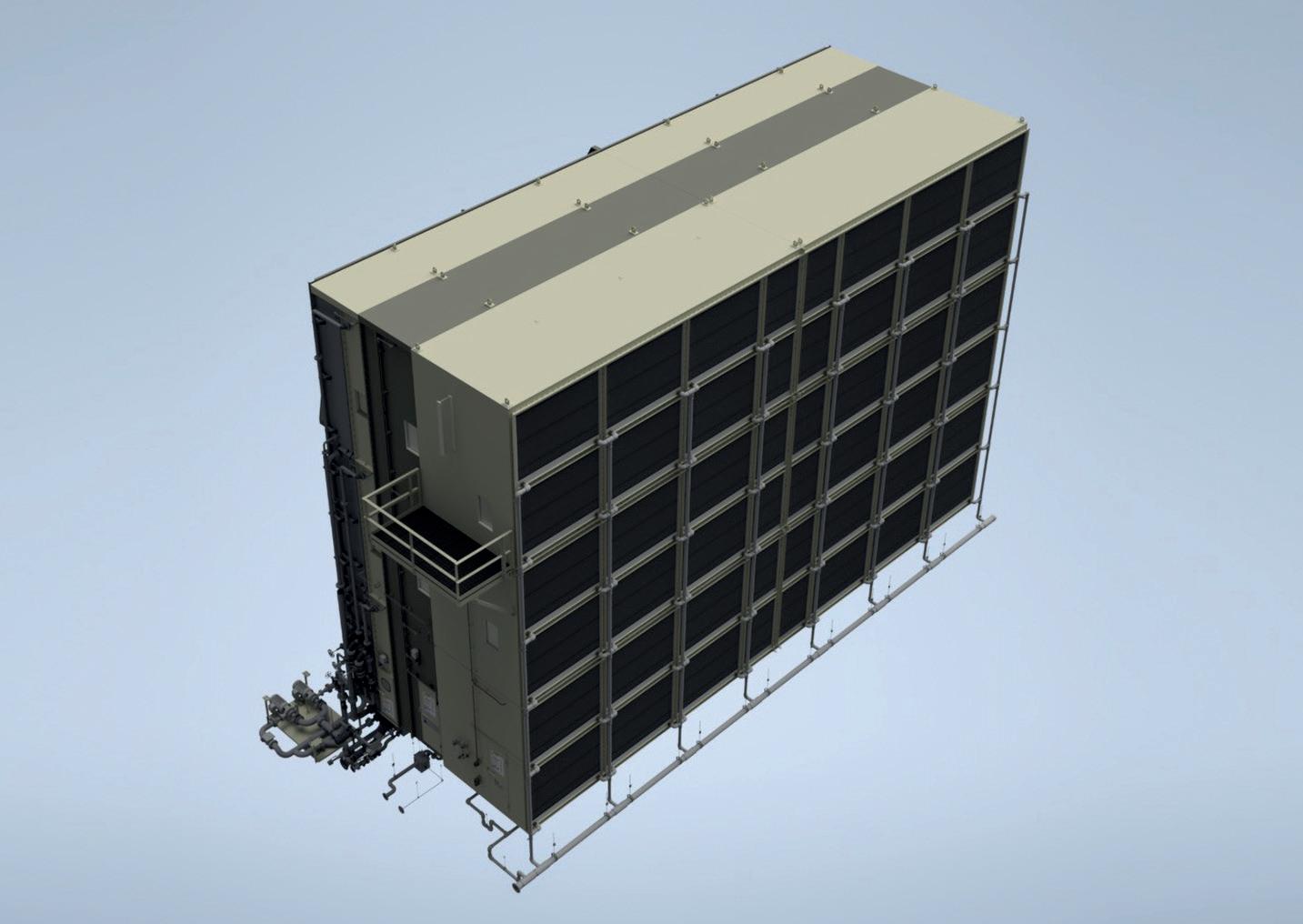

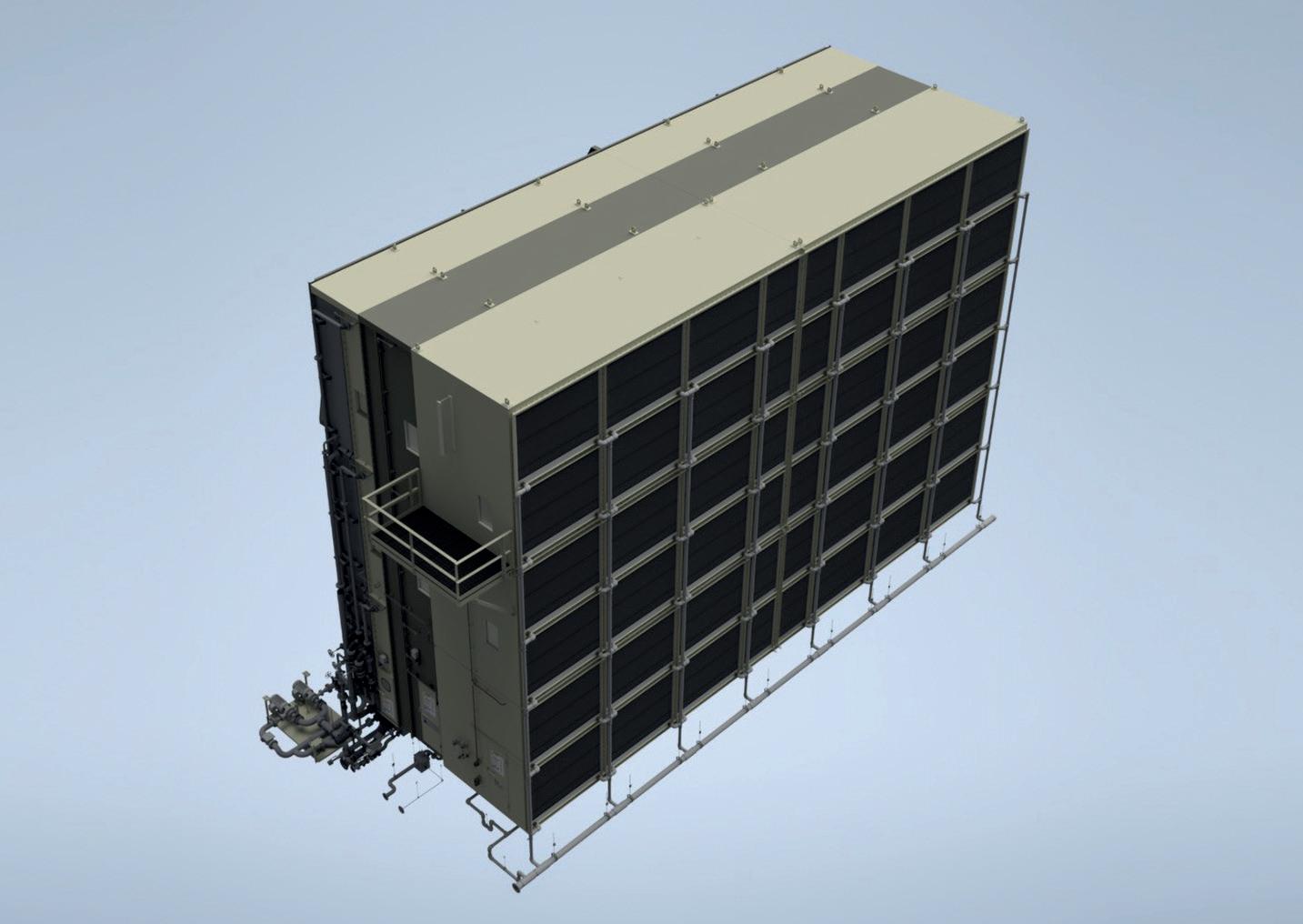

Sometimes it makes sense to reuse existing gas turbine equipment and associated filtration system at another site – but it is important that a filtration solution is designed for the specific, real-world environment in which it is installed. So, how can you be sure of an efficient, reliable, and effective solution when the system moves to a new site?

From time to time, the change in energy markets can demand projects to be delayed or cancelled. This can come from government policy change or even a lack of resources available, such as natural gas. When asked to adapt an existing system to be used at a different location – this requires experience and deep understanding of all elements of the filter house and the unique site conditions, along with the flexibility to re-engineer a successful solution.

While reusing existing equipment offers significant cost savings, it also presents some difficult engineering challenges. One of the first issues to address when reusing a system is its footprint. While parts of the filter house may remain the same,

a change to environmental conditions will likely require adjustments to be made to the filtration other equipment, such as water removal systems, may need to be installed.

There is much to be considered in the design of the inlet filter house and this all needs to be engineered to fit into the existing footprint. The move from a dry dusty area, to one with higher moisture and rainfall will require new systems to handle water and humidity to prevent sudden system blockages. Is the installation near the sea? If so, it needs to be designed to handle salt, which is hygroscopic in nature and will quickly move between solid, sticky, and liquid states in the presence of moisture. Are different filtration stages required to deal with volumes of dust and sand? Will a pulse system be required to periodically clear filters in high dust regions, and has this been configured to ensure continued, reliable operation? Does access for maintenance require a change to walkways, and has the aerodynamics of the overall air inlet flow been designed and modelled to optimize GT performance?

A uniform airflow through the filter bank is essential to minimize the pressure loss, and to ensure the filter efficiency and filter life are optimized Equipment 9 energy-oil-gas.com

“

“ “ “

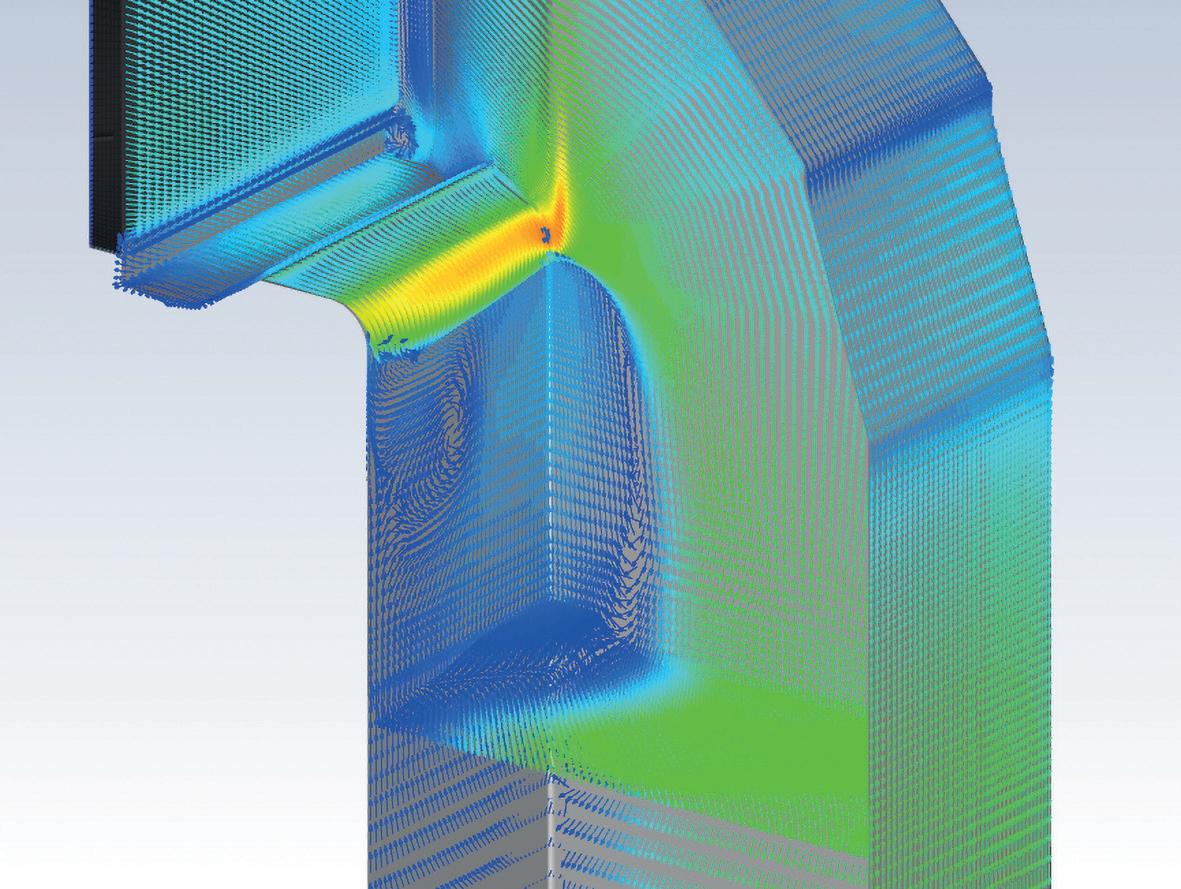

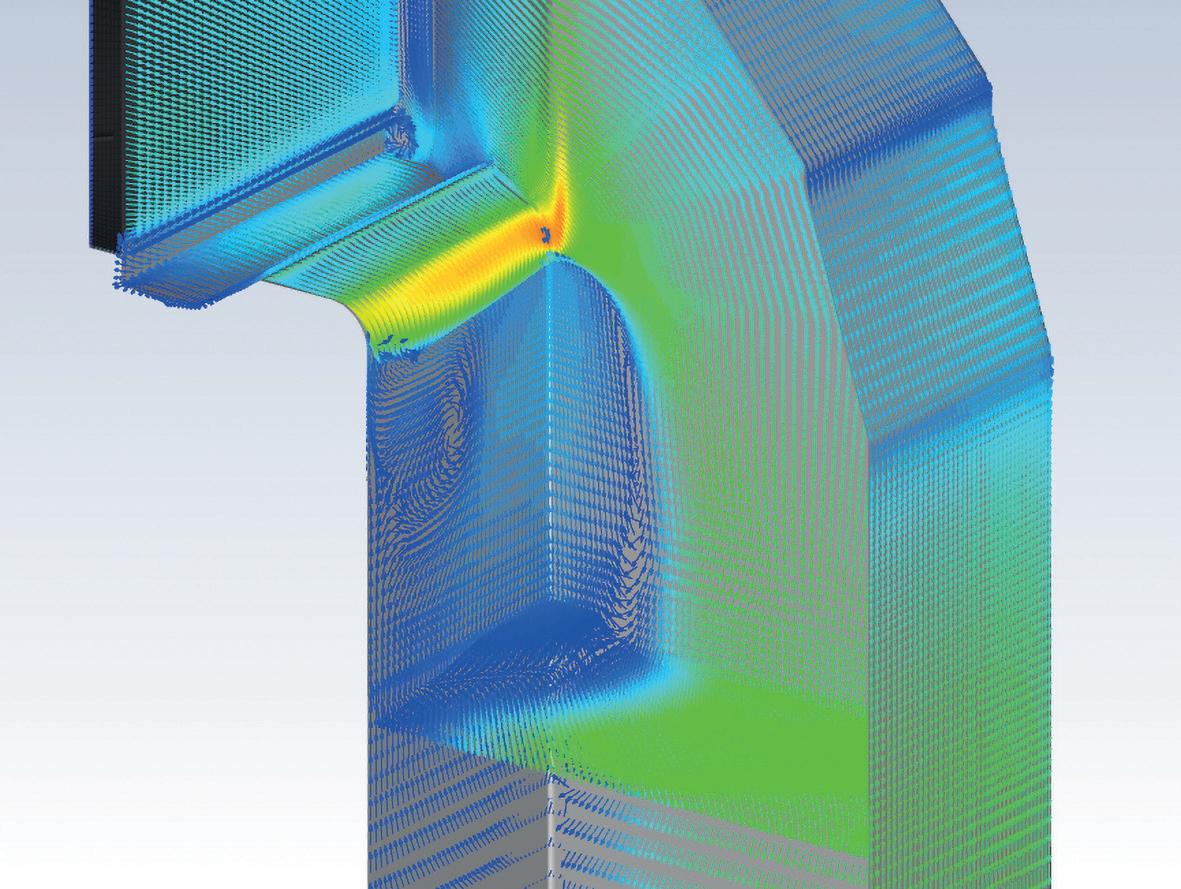

CFD simulation of the ducting aerodynamics downstream a filter house Why are aerodynamics so important?

GTs consume huge volumes of air and, especially for smaller or highly compact GT packages, suboptimal aerodynamics can affect efficiency, power output, and overall reliability. A uniform airflow through the filter bank is essential to minimize the pressure loss, and to ensure the filter efficiency and filter life are optimized. The overall design of the filter house should encourage an even distribution of flow across the whole filter array. If the flow is not optimized, the operation of the filters and the GT itself will be compromised. Why is this? If a system has been designed to operate with 500 filters, for example, but an uneven air flow means only 400 are being fully utilized, these 400 filters are doing the work designed for 500. This can result in pressure loss, shorter filter life and, potentially, lower filter efficiency.

To ensure good aerodynamics throughout the GT inlet, requires consideration for layout and elevation. Sharp angles and

transitions that are not smooth will affect air flow. Even prevailing winds and the location of external structures need to be considered: if the air inlet is positioned next to a wall, it is inevitably going to reduce air flow efficiency. If the filter house is installed low down, the filtration system may suck up dust from the ground. If it is situated near sources of emissions, this will attract additional particulates that will need to be handled by the system.

Whether a new filtration system or for the repurposing an existing one, while experienced filtration engineers may be able to assess risk areas, good Computational Fluid Dynamics (CFD) simulation is an essential tool for highlighting problem areas. It will help ensure all components of the filter house are interacting correctly and enable different solutions to be considered to optimize the system for both performance and cost. This can be especially vital in

10

Reconfigured filter house design for higher moisture and rainfall conditions

studying the options available in an existing footprint and give insight into how GTs and their inlet house will perform in their realworld conditions. The aim is to have no nasty surprises once the system is running!

Summary

The design of an inlet house for a GT installation requires in-depth understanding of the complex issues presented by different real-world environments and the interaction of different components required to ensure a maintainable, longlasting, high performing solution.

There are occasions when it makes sense to repurpose an existing system and significant cost savings can be made. However, the engineering challenges to optimize the performance of such a solution should not be underestimated. It requires significant experience, a company that can work closely with site engineers, and deliver the flexibility

and ingenuity to ensure reliable, predictable protection of the GTs. If the inlet filter house is designed correctly, operators can achieve optimum GT efficiency and extend system life and availability, while reducing overheads. ■

Tim Nicholas www.parker.com/gtf www.parker.com parkerhannifin.com

Tim Nicholas is PowerGen Market Manager, Gas Turbine Filtration Division, Parker Hannifin. With more than 50 years of experience delivering innovative solutions for gas turbine inlet filtration and monitoring fleet-wide performance data, Parker’s Gas Turbine Filtration Division provides a full range of inlet systems and filters engineered to help customers meet their operating goals. Parker Hannifin is a Fortune 250 global leader in motion and control technologies.

Equipment 11 energy-oil-gas.com

On the agenda

12

Two places utility companies should focus when taking the core to the cloud

By Markus Bechmann

Customer service portals have been the focus of utilities’ cloud transition, and for good reason. The polished usability of Amazon and its ilk have raised the userexperience bar. Just as pressing is that, for climate-related, economic, and geopolitical reasons, customers are increasingly producing their own renewable energy, so they’re buying less power from utilities.

Utilities are making up for lost revenue by positioning themselves as one-stop shops for all things powerrelated. They’re doing that by offering bundles of products and services to help customers comparison shop, purchase, finance, install, and service various combinations of solar panels, heat pumps, battery boxes, electricvehicle (EV) charging ports, energy efficiency measures, and more.

This is a sea change, and it’s obvious that the cloud-based customer experience solutions capable of managing such

complexity far eclipse the sophistication of those from the ‘good old days’ (from the utility’s perspective) when a customer’s data profile included a meter number, billing address, and not much else. What’s less obvious is that, for these and other new business models that will be critical utilities’ long-term success, core processes must also make the cloud transition. There are lots of reasons for this, but let’s focus on just two of them: billing systems and distribution-related solutions.

If you can’t bill…

Whatever their limitations, legacy utility billing systems can deal with more than a meter number and a billing address. But even ones

As with core billing systems, taking distributionrelated solutions to the cloud can be a stress-inducing process

Digital transformation 13 energy-oil-gas.com

“ “ “ “

capable of managing a few pricing tiers based on seasonality or usage are rarely up to the task of mixing and matching various hardware and service solutions into products designed for different customers. And if you can’t bill, you can’t bundle.

At the same time, utility leaders rightly worry about the risks of moving to the cloud their proven, robust on-premise transaction processing and billing systems. These are mission-critical systems at utilities selling electricity, gas, and water to thousands or even millions of customers.

A digital transformation that enables dynamic product and service bundling inevitably introduces risk. That risk must be minimized at the core, and one way to do that is to recognize that, while core systems may enable competitive differentiation, they don’t drive it. Billing and similar core processes should operate in the cloud as they have for years: based on industry standards perhaps

adjusted at the margins at a particular utility. The caveat here is that a core cloud billing solution must support new products that customer-solution apps plugging into an open cloud platform can offer.

Tackling intermittency

On the distribution side, while transmission operators are known for their second-bysecond knowledge of the state of their systems, the same doesn’t hold true closer to end customers. Distributed generation is pushing more and more intermittent renewable power into the distribution grid even as electric vehicle (EV) sales – which introduce potential demand spikes not seen since air conditioning gained popularity a half century ago – skyrocket. Utilities must manage loads in a much more complex environment, and doing so will require the collection and management of enormous amounts of data. As EV penetration climbs

14

from about one percent of the US fleet today to the majority of it in the coming decades, utilities must dynamically manage demand to avoid grid-crushing demand spikes as commuters arrive home and plug in at roughly the same time. Vehicle-togrid technology that lets EVs act as battery packs to flatten daytime demand spikes will similarly depend on real-time intelligence that’s only feasible in a cloud environment.

In addition to load balancing and dynamically managing an increasingly complex delivery system, cloud-based systems operating on unified datasets lend themselves to machine learning and analytics for optimizing customer offerings. One imagines future scenarios in which artificial intelligence-powered solutions predict usage patterns; dynamically assemble portfolios of hardware, service, and software solutions based on individual customers’ energy-related expenditures; present bundles of varying ambition and cost to those customers, and then price and bill based on subscription- or even outcomebased models. Such a vision involves endto-end cloud integration from supply-chain partners on through to customers.

As with core billing systems, taking distribution-related solutions to the cloud can be a stress-inducing process. And similarly, the vastly advanced capabilities of these solutions –combined with the scalability, ease of innovation, and other advantages of the cloud – makes this move a wise one.

For the advantages of end-to-end cloud integration to materialize, utilities’ core processes must follow customerservice trailblazers to the cloud. There will be risks, but one can minimize them by understanding that most of a utility’s competitive differentiation happens at the edge. Proven, secure core processes can move to cloud and then be strategically enhanced on an innovation platform to

support the creativity and innovation utilities will need to thrive in the future –while keeping the lights on today. ■

For a list of the sources used in this article, please contact the editor.

Markus Bechmann is the Global Vice President for Digital Strategy of SAP’s utilities business unit. SAP is the world’s largest provider of enterprise application software. It helps companies of all sizes and in all industries run better by redefining ERP and creating networks of intelligent enterprises that provide transparency, resiliency, and sustainability across supply chains. SAP’s end-to-end suite of applications and services enable its customers to operate profitably, adapt continuously, and make a difference worldwide.

Markus Bechmann www.sap.com

Digital transformation 15 energy-oil-gas.com

POWER POTENTIAL

Could businesses hold the key to a zero-carbon energy system asks Anthony Ainsworth

16

For more than a year, the UK energy market has experienced a period of unprecedented volatility, with the resulting high wholesale prices impacting all businesses. Policymakers have now put short term plans in place to offer some relief from rising energy costs, including the Energy Bill Relief Scheme (EBRS), announced in September 2022, which provides support for businesses for the next six months.

However, this begs the question of ‘what’s next’? Clearly, a longer-term and more sustainable approach is needed to help businesses reduce energy demand and limit their exposure to the global markets.

The good news is that many businesses are already taking control of their own energy future. Many of these are doing so by investing in sustainable on-site generation. In fact, in our Business Energy Tracker report, which launched earlier in 2022, more than a quarter (27 percent) of respondents said they are planning to invest in this measure to combat energy risk.

It’s easy to see why; it not only provides businesses with a route to lower energy costs, increased self-sufficiency and reduced dependency on the grid, it also helps reduce emissions.

But, looking beyond this, it could also enable them to play a crucial role in decarbonizing the UK’s energy system by reducing our dependency on imported natural gas, resulting in lower costs and greater energy security.

This could be a future where businesses become central to a changing, decarbonized and decentralized energy system that is powered by renewables.

How? This is something our latest report - The Future of Energy: The critical role of business in a zero-carbon world - investigated.

Business energy 17 energy-oil-gas.com

Towards a businesspowered future?

Via Imperial Consultants, we commissioned Dr Gabriel D. Oreggioni from Imperial College London to provide his own independent opinion and conduct scientific modelling on the future potential of sustainable on-site generation technologies, including wind, solar photovoltaic (PV), battery storage, biogas and biomethane.

The report assesses whether they could feasibly replace the electricity generated from imported natural gas by 2035. It was based on the projection from the Climate Change Committee’s Sixth Carbon Budget that, by that date, the UK would require 16 TWh of power from imported natural gas.

The scenarios explored in the report show that by 2035:

l On-site wind capacity within commercial and industrial facilities could reach between six and 29 GW

l Installed roof-top solar PV could account for 6.5 GW

l Biogas power generation could be up to 16 TWh

l Hydrogen and biomethane injection could be close to 33 and 7.5 TWh, respectively

In addition, the report predicted that having more business-generated power will lower energy costs, with the overall levelized cost of electricity for the proposed options ranging between £49 and £261/MWh, lower than the wholesale prices we’ve seen recently. Crucially, it will also support the net zero ambition, with emissions savings of up to 6.7 MtCO2/year.

It also shows that businesses who are investing in sustainable on-site generation technology now will reap significant benefits, by futureproofing their operations, cutting energy costs and reducing exposure to volatility in the marketplace. Over time, the report shows that energy invoices for all businesses have the potential to be reduced, by doing their bit to help balance the grid and increase energy security.

In short, the power generated by businesses has the potential to revolutionize the status quo and set the UK on the path to decarbonization and energy independence.

Unlocking the power potential of business

What this report shows is that businesses really do have the power to shape our energy future.

“ “

...we believe that this modelling provides a compelling case for policymakers to encourage more businesses to be part of the 2035 zero-carbon system 18

“ “

However, achieving this requires policy and incentives to support it, such as incentives for hydrogen injection and tax deduction for equipment purchases, which could further encourage businesses’ involvement in energy production. Businesses will also need to adapt - and have support to do so - for example, modifying production schedules to make use of renewable intermittent electricity generation surplus and to ensure they can better integrate with their surrounding communities. However, what we wanted to demonstrate was the potential. And, we believe that this modelling provides a compelling case for policymakers to encourage more businesses to be part of the 2035 zero-carbon system and contribute to the national agenda of energy independence and Net Zeroboth now and in the future. ■

For a list of the sources used in this article, please contact the editor.

Anthony Ainsworth is Chief Operating Officer at npower Business Solutions. As one of the UK’s largest energy suppliers, it can draw on an in-depth understanding of the energy marketplace and of business energy needs to create solutions that are both innovative and practical. npower Business Solutions already works with more than 20,000 businesses across a range of industries.

The Future of Energy: The critical role of business in a zero-carbon world, can be downloaded: https://npowerbusinesssolutions. com/future-of-energy

Anthony Ainsworth

Anthony Ainsworth

19 energy-oil-gas.com Business energy

Customer confidence

ExxonMobil and Mitsubishi Heavy Industries (MHI) have joined forces to deploy MHI’s leading CO2 capture technology as part of ExxonMobil’s end-to-end Carbon Capture and Storage (CCS) solution for industrial customers.

The joint effort combines ExxonMobil’s and MHI’s years of expertise in the industry and strengthens the companies’ ability to provide customers with solutions that will help advance a lower carbon future. By working together, the companies will provide industrial customers with the confidence that their CCS projects will be designed, built and executed effectively.

Climate collaboration

Neste and Airbus have come together to advance the use of 100 percent Sustainable Aviation Fuel (SAF) as a key solution to helping reduce greenhouse gas emissions in aviation. Neste and Airbus recognize that one of the biggest challenges in accelerating SAF use is the ramp-up of SAF production. This collaboration is laying the foundation for Airbus and Neste to explore business opportunities together and jointly promote the production and use of sustainable aviation fuel. The focus will be on the technical development of SAF, fuel approval and testing of current and future production technologies.

“This collaboration with Airbus connects a pioneer in the aerospace industry with a

Return on investment

ABB has introduced its energy management system ABB Ability™ OPTIMAX® to the green hydrogen market.

“Scaling up green hydrogen production requires significant capital investment as well as high operating costs,” says Sleman Saliba, Global Product Manager Energy Management for ABB Process Automation. “Nearly 70 percent of the total operating costs to run a hydrogen plant comes from the required electricity. With OPTIMAX®, for between oneto-three percent technology investment, operators can run their industrial processes in the most energy efficient way and gain up to 20 percent reduction in electricity-based costs.”

leader in renewable fuels. The combined knowledge and expertise of the companies will help advance the use and availability of SAF as a means of transitioning aviation towards more sustainable energy sources and reducing the climate impact of aviation,” says Thorsten Lange, Executive Vice President, Renewable Aviation at Neste.

20

Mining milestone

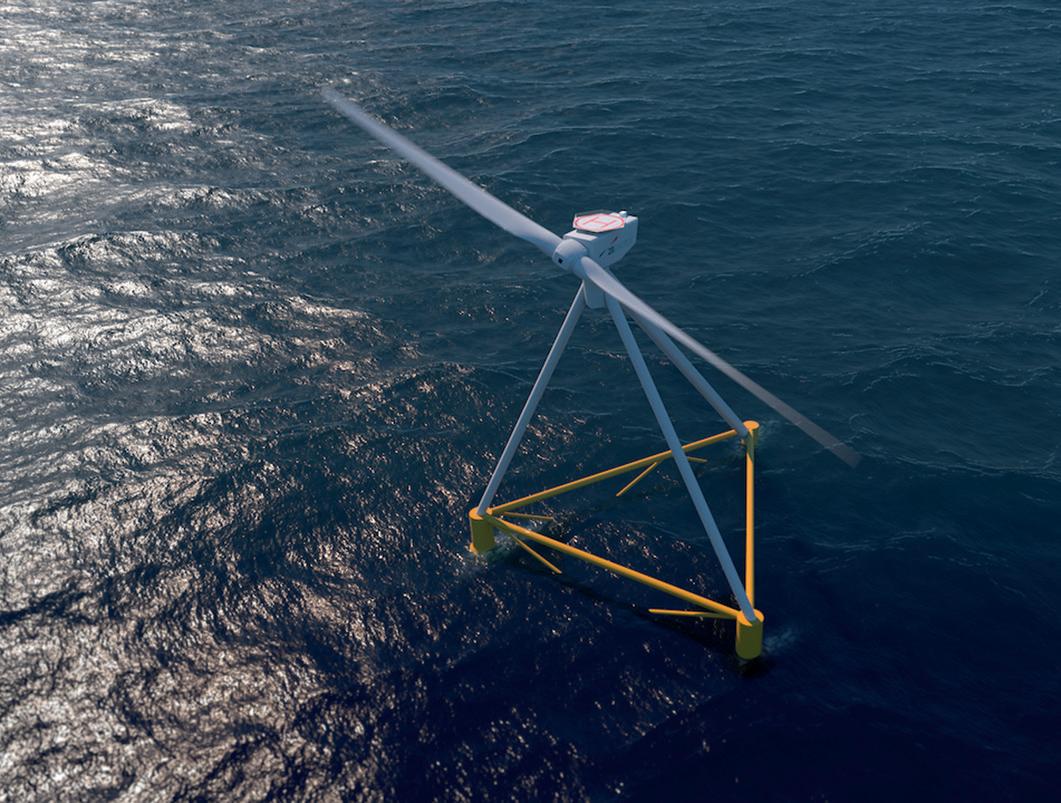

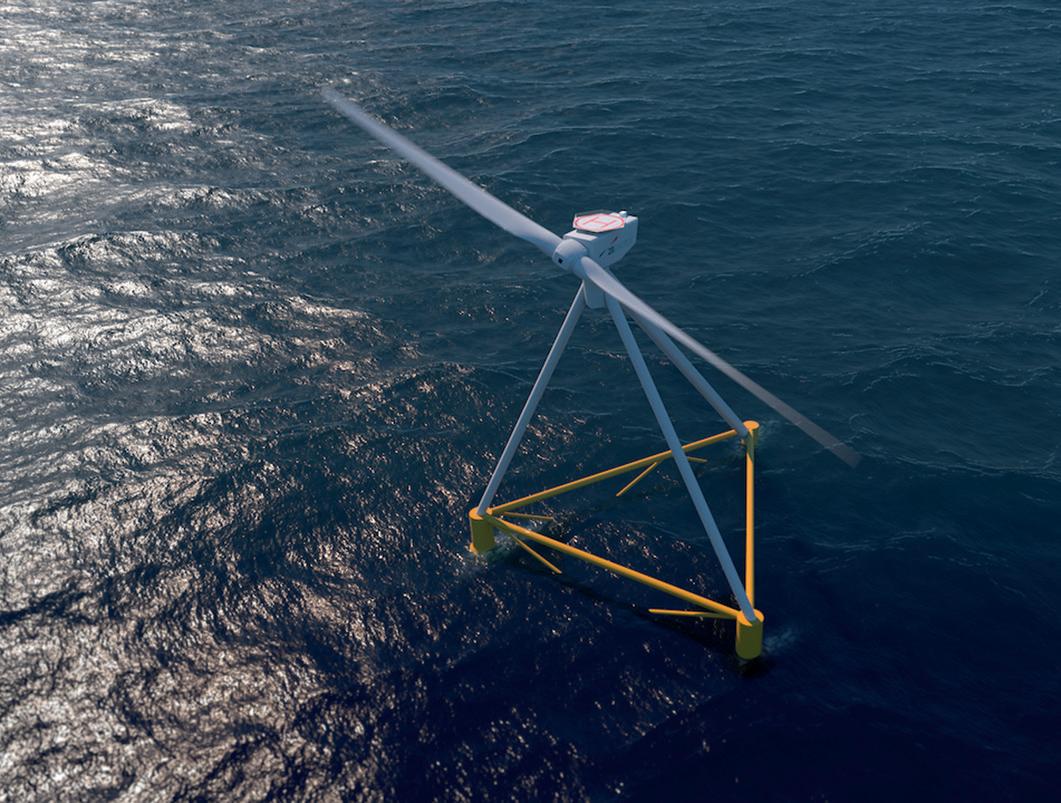

A pan-European project has launched in Paris to accelerate the roll out of the next generation of floating wind technology for a competitive, more scalable and industrial deployment.

The ambitious initiative is being led by a consortium of 13 partners from eight countries including Technip Energies as project coordinator, X1Wind, Naturgy, 2B Energy, Hellenic Cables, Technical University of Denmark, Hydro, Ecole Centrale de Nantes, Schwartz Hautmont, Ocas, Tersan Shipyard, Ocean Ecostructures and Cybernetix.

Backed by the European Commission under the Horizon Europe program with public funding of €16 million, plus private funding from partners and shareholders, the project is anticipated to run until 2027.

Laure Mandrou, SVP Carbon-Free Energy Solutions of Technip Energies, says: “Floating

wind is one of the lowest carbon electricity generation systems to meet the energy demand in a sustainable way. The NextFloat Project represents a unique opportunity to test a novel and disruptive version of this technology at full scale, driving cost curve reductions in order to deliver industrial-scale projects at the earliest possible stage.”

energy-oil-gas.com 21 Industry News

Greener andcleaner

A renewable energy revolution is underway at IMTT

A renewable energy revolution is underway at IMTT

24

International-Matex Tank Terminals –better known as IMTT – is a name that’s been synonymous with petroleum in North America for more than 80 years. These days, the company is leading the way with a ‘greener and cleaner’ revolution in the oil and gas industry.

While petroleum is still very much part of the picture, IMTT is focusing heavily on energy transition and improving support and logistics for greener fuels – with a focus on renewable diesel and feedstocks, sustainable aviation fuels and cleaner marine fuels.

It’s a slick transition for the bulk liquid storage company, and also a smart response to the ever-increasing demand for low-carbon energy solutions and sustainable fuels.

“In the next three to five years we will have upwards of 60 to 65 percent of what our business would consider ‘greener and cleaner’,” says Carlin Conner, Chief Executive Officer of IMTT. “When we bought the business two years ago it was probably 30 to 35 percent.

“But it’s important to appreciate that we are dealing with percentages and it doesn’t mean we are shrinking the legacy petroleum business. We are managing that side of the business still – and there is still lots of demand for legacy petroleum. The increase in percentages is really a function of new investment in the green space.”

IMTT energy-oil-gas.com 25

Headquartered in New Orleans, Louisiana, IMTT is an industry leader in the handling and storage of bulk liquid products from its 17 terminals across North America. Those bases handle everything from petroleum and biofuels to commodity and specialty chemicals, alongside vegetable and tropical oil products for its many customers which include refineries, chemical manufacturers, and distributors.

IMTT has developed a strong reputation for supporting the renewable road fuel market with mass storage of products including renewable diesel, biodiesel and ethanol. The company’s huge success in collaborating with customers has recently

Carlin Conner, Chief Executive Officer of IMTT

Carlin Conner, Chief Executive Officer of IMTT

We will continue to work hard, to continue to grow our greener and cleaner share of the business and continue to transform IMTT...

26

“ “ “ “

led to two major expansion projects –each worth over $100m – that will handle renewable diesel feedstocks in addition to supplying renewable diesel to the market.

The first project, which is now live, involves tankage, rail facilities, and two pipelines. IMTT receives renewable diesel feedstocks that it delivers to the renewable diesel plant. The plant then returns renewable diesel, which is distributed to the market.

Carlin continues: “In the meantime we have also announced a very similar project at our Geismar facility, which is upriver from New Orleans, where we have contracted with Chevron/REG to receive and handle renewable diesel feedstocks produced at their plant.

We will then deliver the feedstock via pipeline to their renewable diesel plant and we will receive finished renewable diesel back for distribution to the market.

IMTT energy-oil-gas.com 27

“Both of these projects are backed by long term contracts, and both are completely in the renewable space, basically taking rendered fats and vegetable oils as feedstocks and creating a cleaner diesel that can be used on the road.”

But the growth and development at the Geismar terminal doesn’t stop there. IMTT is also building out its methanol tankage and pipelines to expand its existing relationship supporting Methanex, the world’s largest producer and supplier of methanol. In addition to being a chemical used for everyday products, including plastics, paints, and construction materials, methanol is also a clean energy source used to fuel everything from cars and trucks to ships and boilers.

Adding tanks, increasing storage, installing new pipelines, and making new connections. It’s all happening at IMTT and so it’s no surprise that the company is serving an increasing number of customers operating in the ‘cleaner and greener’ space.

With an array of large capacity terminals in major US and Canadian markets, IMTT fully intends on leveraging its footprint to continue growing on the energy transition front. At the moment, the company is involved in preliminary discussions that may result in exciting new logistics infrastructure being built on the Mississippi River which could potentially be used in the production of another low carbon energy source – blue ammonia.

It is expected that there will be opportunities on the river for Asian and European renewable energy firms to support the development of blue ammonia production, and IMTT has the logistics, infrastructure, and facilities available to help make these clean fuel ambitions a reality.

“We believe it’s a win-win,” says Carlin. “Obviously the environment benefits from that, and we also believe industry benefits as well. Like with everything we do, we have to do it right – and we have to do

28

it in conjunction with our communities. That to me is about education, as well as standing up for what we believe.”

It’s all about forward progress with IMTT, and the company has come a long way in various other areas of its operations. Historically the organization’s safety record was “unacceptable”, according to Carlin. Before the company was bought and he became Chief Executive Officer two years ago, huge strides had already been made to create a culture that puts safety first and foremost.

Nowadays, Carlin and his management team are extremely proud that IMTT’s safety record is ten times below the industry standard in terms of incidents. The aim is now ‘destination zero’ where processes are so effective that future years can go by with no health and safety incidents taking place at all.

More exciting projects are in the pipeline for 2023 around energy transition and playing a significant part in tackling

climate change. But what is the vision for IMTT for the next five years?

“More of the same,” insists Carlin. “We will continue to pursue energy transition projects. Our brand name around this is ‘greener and cleaner’. We will continue to work hard, to continue to grow our greener and cleaner share of the business and continue to transform IMTT from a legacy petroleum business to a company that is servicing all sorts of new, clean and exciting fuels in energy.

“As always, we want to thank our employees. None of this is possible without the fantastic roster of employees – and it’s everyone from the operating floor all the way through to headquarters. We have a great group that is focused and loyal, creative, smart, and committed.” ■

www.imtt.com

IMTT energy-oil-gas.com 29

30

Carbon-zero

collaboration

WUN H2 is the operating company of a venture between Siemens Financial Services, the gas trading company Rießner-Gase and the utility company, Stadtwerke Wunsiedel (SWW). The project, to build one of the largest green hydrogen production plants in Germany, started approximately three years ago, and was officially inaugurated and ready to produce green hydrogen in September 2022. Today, up to 1350 tonnes of green hydrogen can be generated annually from renewable solar and wind power in the Wunsiedel Energy Park. Hydrogen is generated by an electrolyzer with a total capacity of 8.75 megawatts.

How WUN H2 is uniting heavyweight industry players in the production of green hydrogen

WUN H2 energy-oil-gas.com 31

As Dr. Philipp Matthes, Joint Managing Director, explains: “The Wunsiedel plant includes a two-step compression system up to 500 bars. There is 500-bar storage and a filling station on-site. The intention is to have the hydrogen collected by trucks and delivered to local and regional, commercial and industrial customers. Additionally, the hydrogen can be distributed via a pipeline to a neighboring Combined Heat and Power (CHP) facility that provides process heat for wood pellet production. These currently run exclusively on natural gas, but we have the option to substitute significant amounts of the natural gas with our hydrogen to enable the decarbonization of these processes. Thirdly, there will be a hydrogen refilling station for trucks and commercial vehicles This option will be implemented by spring 2023 and enable the decarbonization of the mobility sector.”

In roughly ten seconds, we can fully power the plant up or down, and react really quickly to changes in energy production 32

“ “ “ “

Hydrogen is a key technology to energy transition. The innovative approach in Wunsiedel will enable greater independence from the grid. Dr. Thilo Rießner, Joint Managing Director, explains: “The electrolyzer produces a current that splits water into hydrogen and oxygen. If the electricity is produced by renewable sources, such as solar or wind, the resulting hydrogen is also considered to be renewable.

“We have always needed hydrogen, and have had to source it from elsewhere, usually from big chemical plants, and not always without difficulty. As a family-owned, medium-sized industrial gas company, we wanted a new source of hydrogen: one that is renewable. We encountered the project in Wunsiedel between SWW and Siemens, and the concept developed from there.”

Philipp continues: “This shareholder concept brings together Siemens, the

big technology provider incl. its Financial Services arm, the sales partner with the gas knowhow, and the municipality to anchor all the local factors.” As such, the Wunsiedel green hydrogen project serves as a model for production. However, it is not without its challenges.

Philipp explains: “The biggest challenge is the lack of a regulatory framework for green hydrogen in Europe. There is the Renewable Energy Directive II which is currently under discussion with the European Union, but is yet to be implemented into law. This is primarily because there is currently no global trade in this product, and no industry or regulatory body has taken the step of providing an express standard or definition. Without one however, it is difficult to approach potential customers. In the absence of regulatory standards, what constitutes green hydrogen will

WUN H2 energy-oil-gas.com 33

need to be contractually agreed between the buyer and seller. At the moment, customers cannot be reassured of the real value of green hydrogen. That is one of the biggest problems. It prevents securing long-term contracts, without which it’s practically impossible to plan strategically. It makes everything challenging for the bankability of the project. That said, we have nevertheless been able to secure a non-recourse project finance scheme, which to our knowledge is a first, at least in Germany, maybe even Europe and worldwide. Siemens Financial Services played a key role here with its capabilities to combine the technical world with financial expertise.”

34

Thilo continues: “New technology brings considerable uncertainty; banks prefer established market technologies. It was a challenge to secure this non-recourse finance from UmweltBank, which while exclusively financing ecological loan projects, did still rely solely on projected cashflows.

“Another challenge is in achieving an affordable price for green energy. The markets are very volatile at the moment. A Power Purchase Agreement (PPA) is a long-term agreement between a renewable developer and a consumer for the purchase of energy. While they may have guaranteed good prices in the past, it’s very difficult to secure them at today’s prices.”

Building flexibility

In terms of the project’s future-proofing strategies, the Wunsiedel plant was designed to enable growth and an increase in production to up to 17.5 megawatts. This would be no mean feat, however, and will require sufficient off-take and compression system capacity. Philipp continues: “Part of our plan is to extract the waste heat produced by the electrolysis process and deliver it to neighboring facilities for their use. Furthermore, we aim to use the oxygen that is being produced. Due to its current low value however, the concept is still in development. It will be much easier to implement once we’ve doubled the size of the facility, as we’ll have a greater quantity to sell. The plan at the moment is to include oxygen in a nearby waste water facility’s processes to enable more energy efficiency. This will tie in with the overarching aim of WUN H2 which is to utilize all value streams: hydrogen, oxygen and heat.”

One of the main drivers for WUN H2 is to build up flexible energy loads by converting the available renewable energy into storable hydrogen, making it available for applications in mobility and industry. This is especially useful when, on sunny and

windy days, more energy from renewable sources is produced than needed. As Thilo explains: “In roughly ten seconds, we can fully power the plant up or down, and react really quickly to changes in energy production.”

While the Wunsiedel plant is one of the biggest today, when contemplating future energy needs and hydrogen production, it’s unlikely to remain so, as the region is not a big metropolitan area, and in terms of what more can be achieved, there are limitations. That said, from a broader shareholder perspective, its impact is likely to be vast if the approach is replicated and implemented by other municipalities.

Looking forward, Thilo concludes that “the main thing is to ensure stable and reliable production. Then, of course, when everything is running smoothly, we can proceed to the next step and increase our output. The market is relatively new, so there are very few experts, and those experts are still learning. It will take some time to embed the knowledge that’s needed to ensure seamless operations for the future.” ■

www.wun-h2.de

WUN H2 energy-oil-gas.com 35

A transformed company

36

Have you met Calumet? Find out about one of the world’s leading specialty products manufacturers as it shifts its focus towards sustainable solutions

Calumet

.com 37

energy-oil-gas

In June, we featured renewable diesel producer Montana Renewables, the sustainably focused segment of the Calumet family. In this issue of Energy, Oil & Gas, we turn our attention to Calumet’s broader business, exploring its history, increasing emphasis on sustainability, and rapidly growing host of capabilities.

While many of its businesses are more than 100 years old, Calumet in its current form was founded in 1990 with the purchase of a Princeton, Louisiana-based naphthenic lubes facility. Since then, the company has transformed into a well-refined and profitable powerhouse within the specialty products business niche. Growth inevitably means progress, and with Calumet it is no different. The company has ventured out into new terrain over the last three decades, blazing trails in areas that naturally supplement its existing footprint.

This business has been built one customer, one product, and one asset at a time

“ “

38

“ “

Now one of the most highly integrated specialty products players in the industry, that growth mindset has undoubtedly paid dividends. Headquartered in Indianapolis, Indiana, Calumet operates in over 90 countries from ten integrated production and formulation facilities across the US and a host of distribution points. The company is split into three distinct segments: specialty products and solutions; performance brands; and, as mentioned previously, Montana Renewables, where Calumet is currently focused on converting a large part of its Great Falls facility into an innovative, renewable feedstock processing plant.

Across its businesses, Calumet finds solutions to sustain and enhance life’s essential products – from the tires on your car to the balm on your lips – and delivers them to medical and pharmaceutical, industrial, personal care, transportation, energy and

Innospec

Innospec is at the forefront of Renewable Diesel (RD) fuel additive technology supporting partners, like Calumet, working side-by-side on their Montana Renewables project. Innospec is the leading RD additive provider with over half of all RD currently being produced domestically treated with Innospec additives. Our product line is designed to meet our customers’ lubricity, conductivity, and cold temperature operability requirements for RD and RD / Biodiesel blends. We help ensure fuels leave the refinery on specification, and continue to benefit downstream customers that choose low-emission sustainable fuels. Contact our team today to find out how we can help you.

energy-oil-gas.com 39 Calumet

40

chemical, food and agriculture, and home and electronics markets.

Products include base oils, food grade white oils, solvents, esters, waxes, petrolatum, fuels, asphalts, finished lubricants, greases, horticultural spray oils, renewables, and gels. Base ingredients such as these find their way into familiar household items like ointments, baby oil, lubricants, paints, and candles. Calumet also owns high-end retail and industrial brands such as Royal Purple, TruFuel, Bel-Ray, and Orchex.

Offering us an insight into the behind-thescenes operations and progressive ethos of Calumet is company CEO, Todd Borgmann. “This business has been built one customer, one product, and one asset at a time,” says Todd. “We are building partnerships that can evolve to meet current business needs. This mindset allows us to serve our customers differently and, as a result, we have cultivated

Baker Hughes is the downstream market share leader in North America for hydrocarbon treatment. Its extensive experience and technical knowledge of the refining industry has been key to ensuring success for Calumet. Baker Hughes’ personnel acts as an extension of its customers’ engineering teams to maximize asset reliability and profitability.

Recently, Calumet and Baker Hughes expanded their relationship to include the chemical treatment and services at the new Montana Renewables Diesel Unit to ensure a successful startup and operation.

Baker Hughes’ BIOQUEST™ product line includes new technology and services specifically designed for the unique challenges of renewable diesel processing. Baker Hughes’ leading position in the renewables market enables it to provide this growing industry segment with forefront solutions.

Baker Hughes

Baker Hughes

energy-oil-gas.com 41 Calumet

a deeply integrated business and a rich culture of innovation – both of which are core competitive advantages for Calumet.

“To give you an overview of the asset base, our four facilities in northwest Louisiana operate as one cohesive specialty unit,” he continues. “Here, we have tight distillation capabilities, and a broad array of hydro-treating, dewaxing, and blending competencies. Next, we have six upgrading and distribution

facilities where we can upgrade base stocks into complex food grade and pharmaceutical products or create finished branded products that serve retail channels through our highperformance lines. With our diverse, integrated asset base, we simply can do things others cannot.”

For those who value innovation and operational optimization, Calumet offers a seemingly endless number of opportunities. The Indianabased company is committed to deploying unique solutions to clients’ problems, and that has not gone unnoticed. As Todd goes on to explain, the company has built a strong reputation and separates itself from competitors by identifying and addressing these needs.

We provide more than 1800 products to more than 2500 customers around the world

“

“

42

“ “

“We provide more than 1800 products to more than 2500 customers around the world,” Todd details. “With each client, we apply our innovative spirit. We also look at our ability to serve evolving demands. The pivot at Montana Renewables you wrote about previously is a great example of Calumet’s ability to move quickly to fill a need. In two short years, our team has transformed our Great Falls asset and positioned us as a leader in producing Renewable Diesel (RD) and Sustainable Aviation Fuel (SAF), two of the highest growth markets in energy.

“We can innovate at scale, and in times like we’re seeing today where customers’ needs are evolving quickly, Calumet can shine.” reveals Todd. “We’re also seeing interest in sustainable specialty options, and we are very excited to further deploy our growing expertise in sustainable markets across Calumet’s specialty offering.

TANCO

Since TANCO’s beginning in 1979, we have exceeded customer expectations through our commitment to safety, reliability, and excellence. In our 40-plus years of business, we’ve continuously excelled in health and safety performance, work quality, environmental stewardship, and customer service.

We specialize in above-ground storage tank construction and repairs, and want to come alongside you to help you accomplish more with less stress and keep your tanks in service. We have worked closely with Calumet for many years, and have consistently performed at the highest level at multiple Calumet locations across the country. The services we provide Calumet range from tank design and engineering services to tank maintenance and repair, and turnkey new tank construction projects.

The team at TANCO values the trusted relationship it has built with Calumet, and looks forward to many more years of working together as a trusted partner in Calumet’s family of contractors.

energy-oil-gas.com 43 Calumet

“ “

“In fact, we have already begun to do so, and I am proud to share two recent examples,” he comments. “First, our highest growth product this year is BioMax. This biofriendly lubricant developed for the global shipping market performs at an incredibly high level. Also, in the near future we’ll roll out a wax product designed to meet the needs of environmentally conscious candle customers. Both of these examples demonstrate our commitment to doing things differently – for both our clients and the planet – without sacrificing the quality and performance that

rely on.”

For Calumet, the next six months are set to be an exciting period; the company expects to see the culmination of several years of work from both Montana Renewables and its specialty business. “Currently, at Montana Renewables, we are in a commissioning phase, and we’ll be running within weeks,” says Todd. “And our specialty business is performing as well as I can remember.

our customers

We can innovate at scale, and in times like we’re seeing today where customers’ needs are evolving quickly, Calumet can shine

44

“ “

“Looking beyond that is yet more exciting,” he concludes. “In Montana we have a big opportunity to continue to expand, develop even more local feedstocks, and grow into the largest SAF producer in North America! In our specialty business we have a number of high-return projects that will further integrate our business, increase the optionality we offer our customers, and ultimately deepen the competitive advantage that Calumet has today.”

energy-oil-gas.com 45 Calumet

Uncapped potential

Why the fast-growing Capstone Infrastructure Corporation is looking west to expand its renewable energy portfolio

46

It has been a momentous year for Capstone Infrastructure Corporation (Capstone) since we last spoke with CEO David Eva in 2021. Founded in 2004, the Canadian developer, owner, and operator of clean and renewable energy facilities has made short work of investing in and operating clean power businesses, such as wind, solar, hydro, biomass, and natural gas co-generation power plants. Subsequently, Capstone has become a reputable name in

the Canadian energy industry, pioneering the drive for greener energy usage.

During our last discussion, we covered the development of the 132 MWac Claresholm Solar Project – as of 2021, Canada’s largest solar facility – which achieved commercial operation and is successfully producing clean power. “Just over half of Claresholm’s generation capacity is contracted by TC Energy, but certainly, the plant has been running well in a period of robust merchant

construction-today.com 47

Infrastructure Corporation

Capstone

pricing in Alberta,” David reveals. He highlights how the company has also secured purchase agreements with Keyera Corporation, Pembina Pipeline Corporation, and the City of Edmonton, which is the largest direct procurement of renewables by a Canadian municipality to date. The purchase agreements allowed Capstone to accelerate the development of over 300 MW of new wind and solar projects in Alberta,

with the Michichi, Kneehill, and Buffalo Atlee projects already in construction, and the 192 MW Wild Rose 2 wind farm following closely behind.

“Alberta is known as the birthplace of wind energy in Canada,” David says. “The province supports the only open electricity market in the country, providing opportunity for corporations to reduce their carbon footprints by purchasing emissions-

Above: Claresholm Solar Project, Alberta

Above: Claresholm Solar Project, Alberta

48

free electricity and carbon offsets directly from renewable power producers. Further, by taking advantage of Alberta’s world-class wind and solar resources and capturing those resources with modern wind turbines and solar PV modules, we are able to provide our customers with exceptionally competitive and reliable solutions to achieve their decarbonization goals,” he notes, adding that the area continues to be a significant market for the company.

Building from its success in Canada, Capstone is now entering the US market, exploring more opportunities in California, which is looking to be just as promising. “When we began this journey, we saw great potential in Alberta, but we have seen similarities regarding market demand and growth in California, where there is an exceptional amount of support for renewable energy. Another advantage is the stability of

Astroenergy

The Astronergy panels supplied for this Claresholm Solar Project is ASTRO Series; a reinforced bifacial module with double glass. Enhanced with excellent encapsulation structure and strengthened frame, this type is specially designed for severe hail (45mm, 30.7m/s), and unfriendly environments with high reliability requirements. The module has passed severe damp and heat 2000 hours, thermal cycle 600 and PID 300 tests, which were verified and approved by CSA certificate-C450 and PVEL certificate-PQP.

Astronergy is proud of the delivery of ASTRO series PV panels for Claresholm Solar Project, and has a very good cooperation experience with Capstone Infrastructure. The quality policy of Astronergy is to create a world-famous brand and to provide lasting, quality products and solutions for customers.

To find out more visit www.astro-energy.com/en

construction-today.com 49

Infrastructure Corporation

Capstone

“ “

The Skyway 8 Wind Farm is a 9.48 megawatt (MW) wind energy project near Southgate, Ontario

The Skyway 8 Wind Farm is a 9.48 megawatt (MW) wind energy project near Southgate, Ontario

50

I am pleased to share that despite the obstacles of the last two years, the demand for renewable energy continues to grow and Capstone continues to deliver in a challenging environment

“ “

the regulatory regime in the state, which will help further encourage a dynamic market.”

To this end, Capstone recently announced a new joint venture with Eurowind Energy, a Danish renewable energy company, to advance several of the projects in its California development pipeline.

“Several years ago, we also added energy storage projects to our development efforts, which is where we see the next major opportunity in our business. With the extensive growth of wind and solar, and the long-term need to further decarbonize our power grid, as an industry, we must address the need to have power available when customers need it – and do so with non-emitting sources. For example, energy storage allows us to capture excess energy when wind is blowing and the sun is shining, and then re-inject that electricity into the grid when it’s required. That is a big part of

BIrd Construction Your partner for a sustainable future

As one of Canada’s leading construction companies, with operations coast-to-coast, Bird Construction (Bird) provides a comprehensive range of construction services to all of Canada’s major markets.

Bird’s collaborative culture and innovative, solutions-focused approach, helps our clients meet their sustainability goals. Drawing from our 100-year history and multi-disciplinary expertise, Bird delivers deep carbon retrofits and sustainable building construction, as well as self-perform services for renewable power, low-carbon energy, carbon innovation, energy efficiency and small modular reactors.

There’s a roll for all of us to play in decarbonization, let Bird be your partner of choice

construction-today.com 51

Infrastructure Corporation

Capstone

our strategy in California, and we are starting to take some of the successes we are seeing there and apply them in places like Alberta and Ontario.”

With more than 110 MW of construction projects underway, and 192 MW Wild Rose 2 project planned for 2023, Capstone stands in good stead to achieve its goal of a total installed capacity of 1 GW. “We are very pleased with the level of progress we’re making, and I am particularly proud of our team for making this possible,” David adds.

“Alongside Alberta and California, we are also very active in Ontario with multiple energy storage development projects in the province currently underway,” David notes. “What we are seeing is a big push towards capacity projects that are either dispatchable, have generation, or have storage potential. In addition, over the next five years, we expect to expand into several additional markets in North America.”

Being able to make impressive ground so quickly has not been

Above and left: First panels installed at the Michichi Solar Project, Alberta

52

an easy journey. However, considering the challenges inflicted by the pandemic, David is proud of the efforts the business has implemented to remain a leader in the energy industry. “We have been in this sector for a long time, and our projects can take years to complete. Fortunately, in some instances, they can move quicker than anticipated, and I am pleased to share that despite the obstacles of the last two years, the demand for renewable energy continues to grow and Capstone continues to deliver in a challenging environment.”

Taking this strategy forward, David highlights that the near future will be focused on the completion of current projects, as well as continuing to drive forward development efforts, with a focus on looking after supplier relationships. “There is an urgency for businesses to establish themselves as leaders in their sectors, and demonstrate they can overcome the challenges within the industry as best as possible. This is why it is crucial for

Capstone to maintain strong supplier relationships, and invest time in developing our networks to ensure that our quality is not neglected. This will ultimately be our strategy over the next five years as we strive to become a multi-gigawatt North American player in renewable energy, and energy storage.”

Beyond these plans, David is excited about the development of renewable energy and storage in markets that the business deems to be attractive, and is determined to maintain the business’ high level of innovation to meet the demands of its customers. “Whether this is through speed of execution, specific products on renewables, or continuing to conduct ourselves to the highest standards, we know that the years ahead will be even more prosperous than the ones before,” he concludes. “I am so proud to be part of this journey.” ■ www.capstoneinfrastructure.com

Above: CEO David Eva addresses stakeholders at the Michichi Solar Project, Alberta

Above: CEO David Eva addresses stakeholders at the Michichi Solar Project, Alberta

Infrastructure Corporation construction-today.com 53

Capstone

Delivering Sustainable Innovation in Investment Casting

Discover how Hitchiner is innovating with sustainable practices.

hitchiner.com/green-goals

Anthony Ainsworth

Anthony Ainsworth

A renewable energy revolution is underway at IMTT

A renewable energy revolution is underway at IMTT

Carlin Conner, Chief Executive Officer of IMTT

Carlin Conner, Chief Executive Officer of IMTT

Baker Hughes

Baker Hughes

Above: Claresholm Solar Project, Alberta

Above: Claresholm Solar Project, Alberta

The Skyway 8 Wind Farm is a 9.48 megawatt (MW) wind energy project near Southgate, Ontario

The Skyway 8 Wind Farm is a 9.48 megawatt (MW) wind energy project near Southgate, Ontario

Above: CEO David Eva addresses stakeholders at the Michichi Solar Project, Alberta

Above: CEO David Eva addresses stakeholders at the Michichi Solar Project, Alberta