FUTURE PROTECTION The of

How NP Aerospace continues to evolve as demand increases for its composites expertise

Sustainability

Manufacturers can play a role in reducing emissions but collaboration is needed

Human resources

Mitigating the labor crisis through modern processes and solutions

Technology

Open technology standards and their link to advancing growth in manufacturing

Issue 208 - 2023

Group COO Joe Woolsgrove

Creative Consultant Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Annabelle Crook, Steven Dobinson

Editorial Administrator Amy Gilks, Afiya Lucombe Davis

Creative Lead Lee Protheroe

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe

Artwork Administrator

Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors

Philip Monument, Joy Francesconi

Head of Content Management

Adam Blanch

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Laura Thompson

Content Managers Johanna Bailey, Mark Cowles, James Fuller, Jeff Goldenberg, Melanie Joyce, James Page, Wendy Russell, Richard Saunders

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division

Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Hello and welcome to the January issue of Manufacturing Today. In this issue, our authors cover a variety of topics, including discussions around human resources, technology and sustainability. We also look at productivity, with US born thought leader David Rajakovich highlighting various management theories and the potential advantages they offer. “… strong leadership and a focused productivity strategy are central to the success of any company or organization..” he says. He also states that “the CEO should say as little as possible about what they believe until soliciting other opinions..” I would love to hear if that is your approach? This issue also gains insights from manufacturing leaders in a variety of sectors, including electronics and technology, sheet feeding and steel. Do they have any commonalities? Read on to find out!

© 2023 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

www.manufacturing-today.com

US Office 2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

LH@finelightmediagroup.com

Our cover story visits NP AerospaceJames Kempston, CEO, and David Petheram, COO, share why they expect a boom in diversification of sales and revenue. Turn

2 manufacturing-today 1 Technology Open technology standards and their link to advancing Sustainability Manufacturers can play role in reducing emissions Mitigating the labor crisis through modern processes How NP Aerospace continues to evolve as demand increases for its composites expertise FUTURE PROTECTION The of Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

to learn more.

to page 66

Follow manufacturing today at @mfgtodaymag manufacturingtodaymagazine

Libbie Hammond, Editor

Welcome manufacturing-today.com 1

Inside

Case study Productivity Sustainability Human resources Technology 12 16 8 20 22 Contents 2

this issue

54 Banner Engineering Exclusive Feature 28 Dalton Safety Exclusive Feature 34 Henry Repeating Arms Exclusive Feature 40 Schnitzer Steel TechPoint Exclusive Feature Exclusive Feature 48 manufacturing today manufacturing-today.com 3

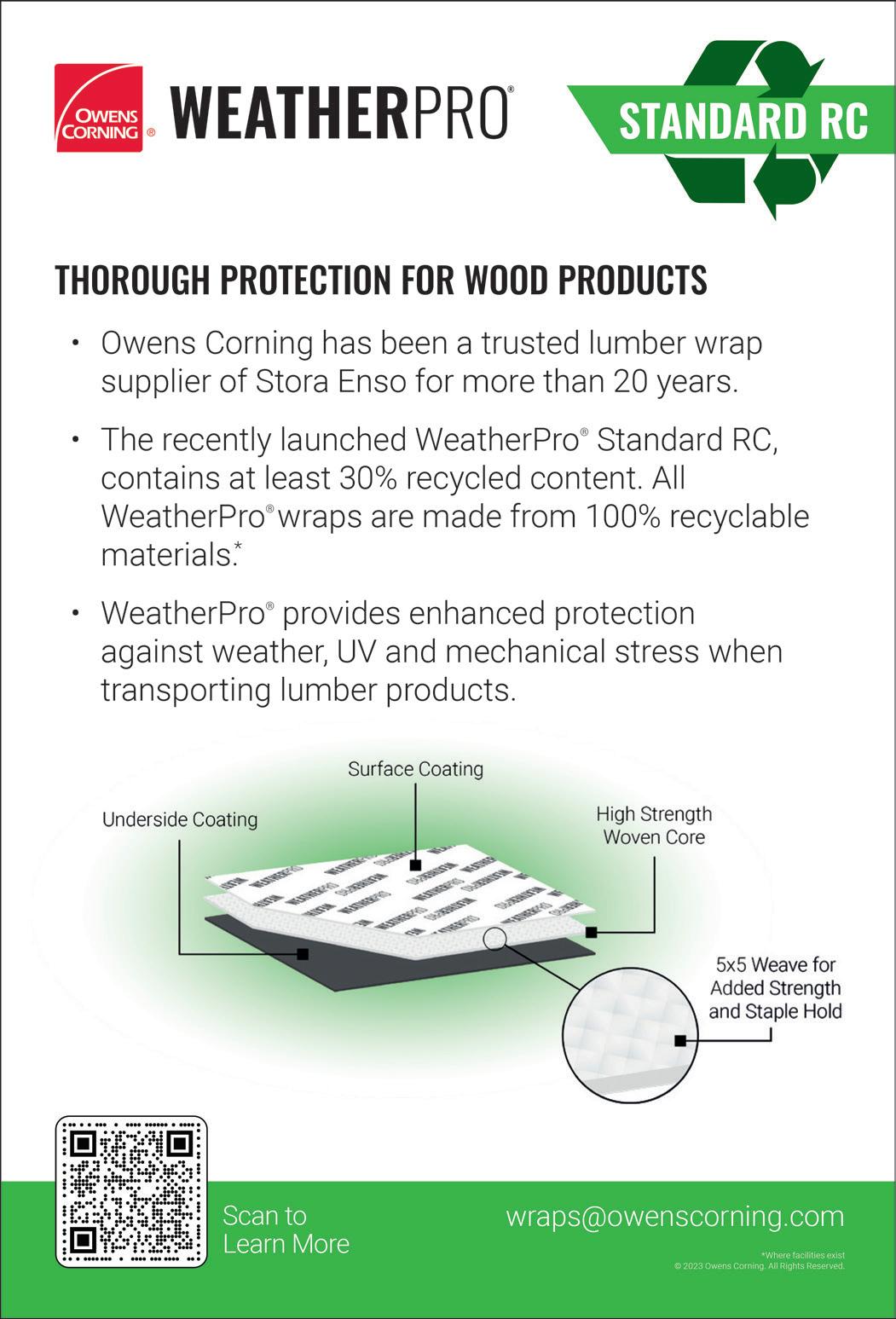

NP Aerospace Ontic EC Styberg Engineering Stora Enso Cover Story 72 Lessebo 60 94 80 66 Contents 4

Bazaar Group Cleveron Contura Steel AB Board24 100 122 108 114 manufacturing today manufacturing-today.com 5

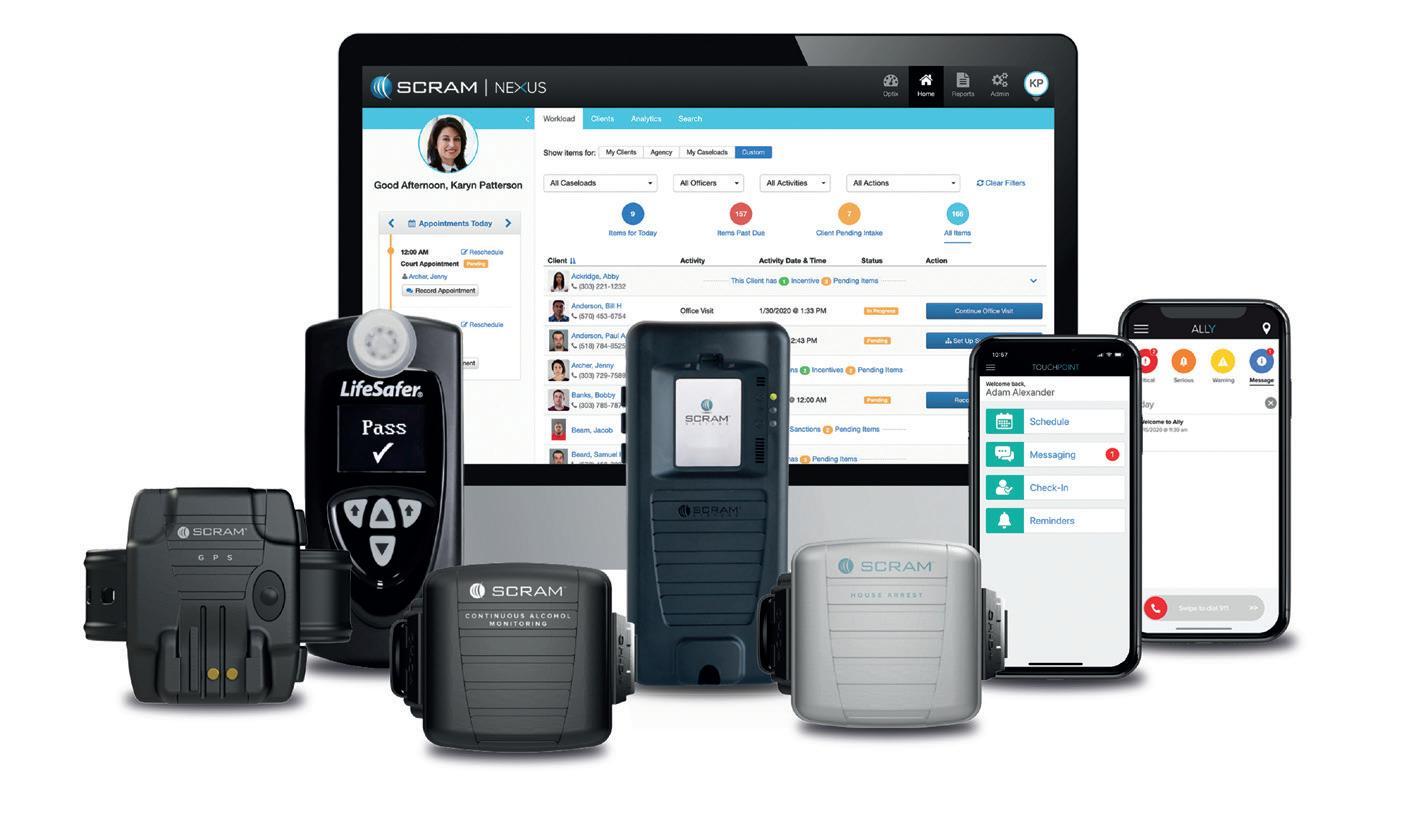

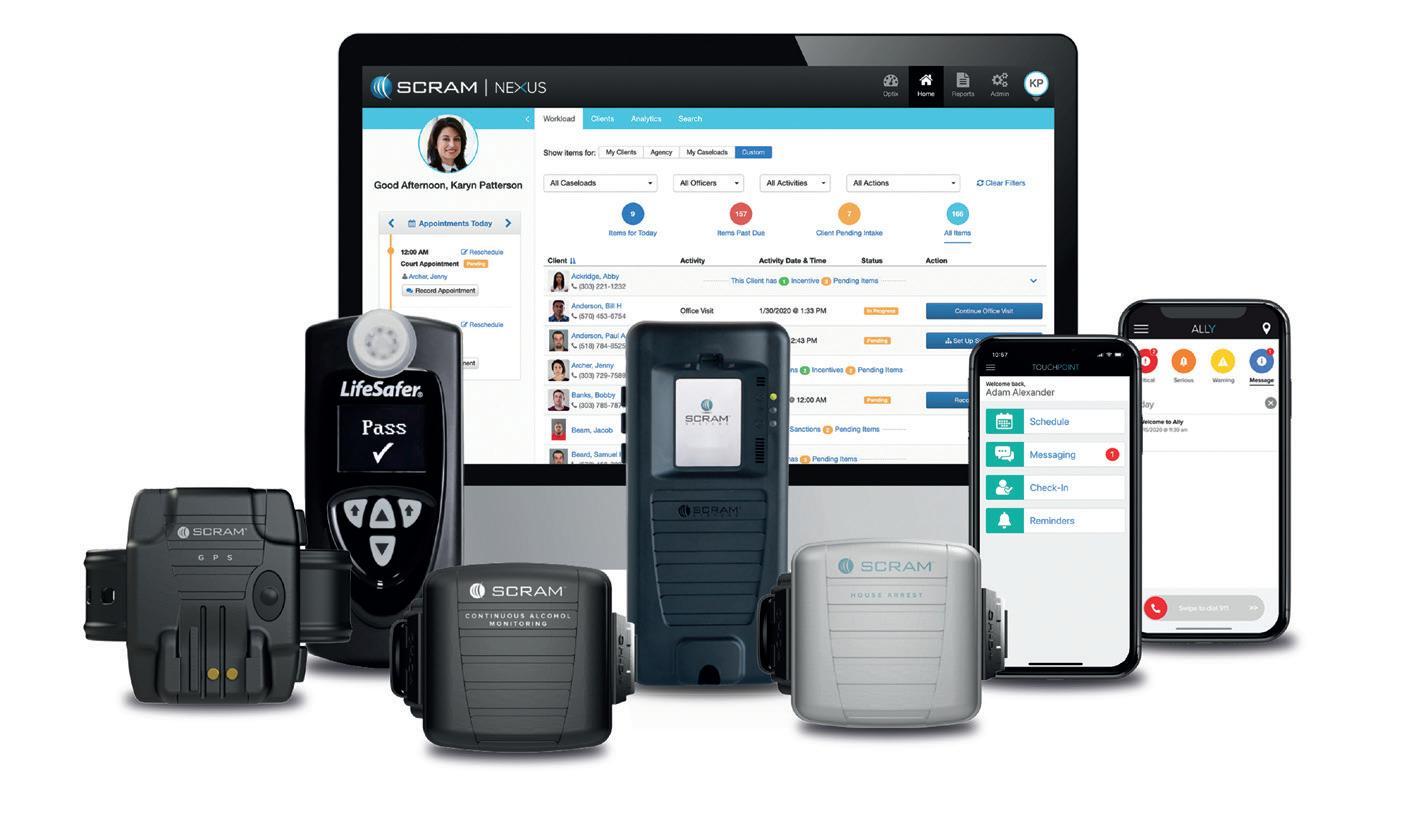

PPS Group SCRAM Systems 128

152 146 140

Jadex Wiegel

134

Contents 6

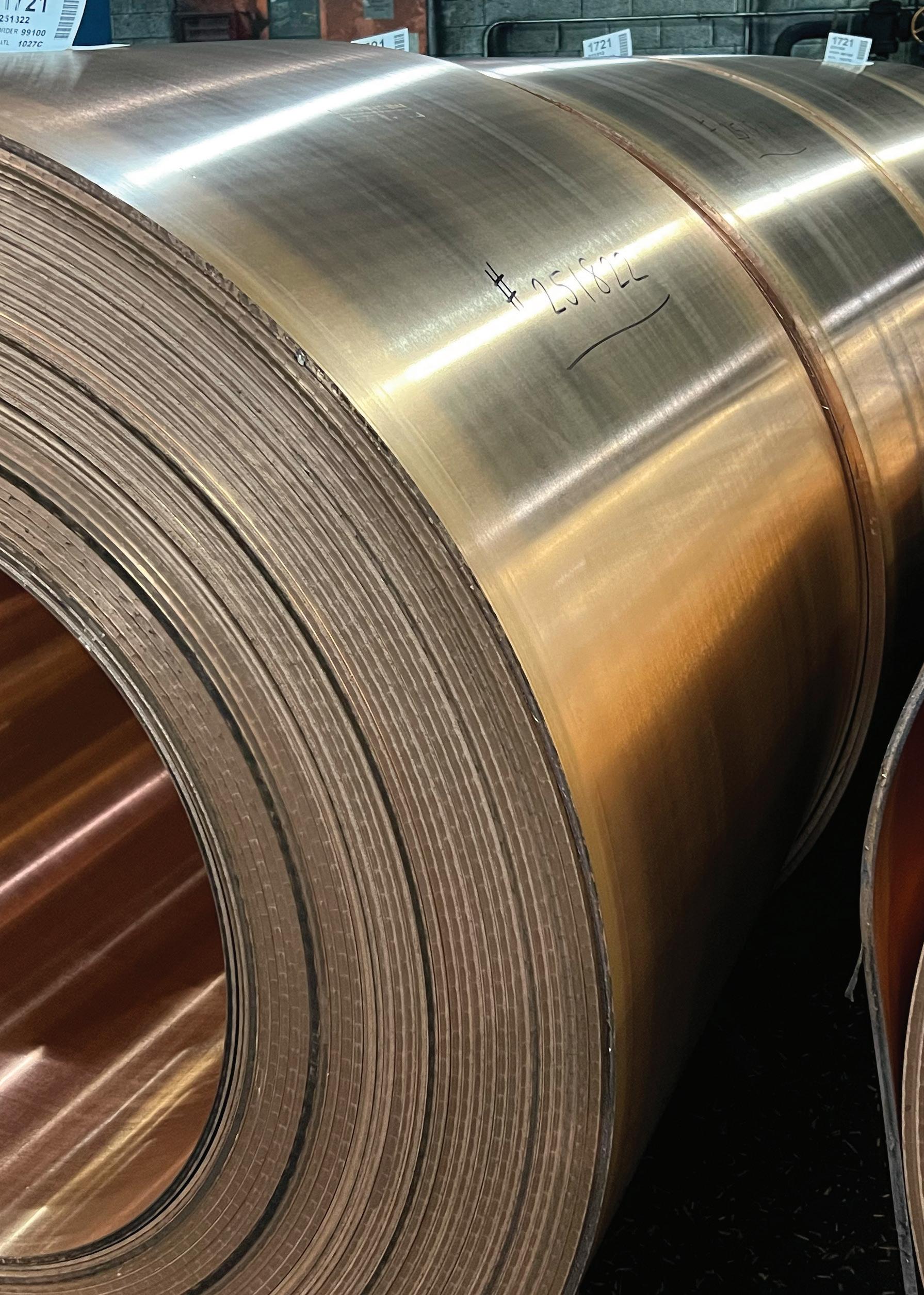

Revere Copper

Steel & Alloy Processing –Gonvarri Industries Romo Sanjo Bentley Laboratories 162 156 166 178 172 Gravotech Inc. manufacturing today manufacturing-today.com 7

FOOD FOR THOUGHT

Maximizing productivity through improved management theories

By David Rajakovich

By David Rajakovich

8

Businesses all across the globe share a common goal of increasing productivity, customer satisfaction and profitability, but in many cases, the go-to response is to blame the staff, rather than the management, when things go wrong. The reality, however, is that strong leadership and a focused productivity strategy are central to the success of any company or organization, and examining different strategies and scenarios is the first step on the road to success. If we look at the manufacturing and supply chain industries, at a high level, you need to be data-driven in making capacity decisions. In this regard, finding real probabilities – not just based on historical data but how the macro and competitive environment have changed – is key.

Productivity 9 manufacturing-today.com

Another key initiative is to examine different scenarios – such as what is the upside vs. the level of risk that you are taking on – and making sure the Board agrees with the approach. A very common mistake is encouraging groupthink by having the CEO give his or view of the environment first. Don’t ever be tempted to stray down this road. In fact, the CEO should say as little as possible about what they believe until soliciting other opinions. Undoubtedly, the Jury of Executive Opinion Method of decision is one way to avoid bias. As well, the Delphi method is similar in that it pools

David Rajakovich

anonymous expert opinions to reach an accurate forecast and prediction of the future.

Stay flexible

Another key to success is to be creative in the supply chain. For example, consider using ‘real options’. If the upside of capturing a market by moving quickly is large enough, paying suppliers to partially complete your product – even if it might go to waste – may be a good investment. Demand sensing is a relatively new idea, enabled by the Internet of Things, and using real time data to re-route shipments can maximize your profitability by ensuring products are getting to the places where they are selling the best.

“

“ When the collective shares a mindset, they don’t need to ask you about every decision – they know the answer before they even think of asking

“ “

Of course, demand shaping is related, in that you can use promotions, discounts and pricing decisions more generally to influence what the customer buys, keeping that finished goods inventory turning over as rapidly as possible.

There are so many easy mistakes made by companies, but it’s just as simple to avoid them too. Make sure that your metrics are financial in nature, and that it’s not just throughput for throughput’s sake. In my experience, managers tend to want to show good throughput, even if it ultimately results in stacking high value inventory in a warehouse. Remember, this does not contribute to the financial performance of the company, so don’t make this mistake. I would also not recommend looking purely at production per square meter. I’ve seen that result in a very cramped work space that only served to lower morale without any real financial gains.

Establishing a supply chain control tower is good advice and the better – and more timely – the information you have, the better your decisions can be on pricing, as well as on who gets how much of a scarce product, reacting to supply shortages, etc. Investing in tech, machinery, etc, in a way that maintains flexibility is key. Remember, you don’t know what products you’ll be producing in a few years’ time, so you need to stay flexible. Continuing to invest for the long term – using the Internet of Things to track global shipments – might seem like a daunting project, but if there is a clear plan to use it to optimize decisions, it could help gain you a competitive advantage.

Positive mindset

One of the most important factors in productivity is getting the product design right from the very beginning. If it is designed with shipping it in mind, supply chain costs will be lower. If it is designed with manufacturing in mind, it will share as many common components with other products (or future products) as possible. With this in mind,

it is vital that you involve production and supply chain teams early in product design. Use learning from the world of software – e.g. cohort analysis – to hone in on exactly the right products to build. This will mean you are building a great product that your clients love that is inexpensive to ship and efficient to build. Cohort analysis is about dividing your customers into groups – e.g. based on month of purchase, etc. When there are tweaks to the product, measure how it impacts satisfaction, sales, etc. That will point you in the right direction for future product updates.

The influence of strong leaders and the importance of understanding modern management theories should never be underestimated. Research by Digits found that over 50 percent of UK adults think strong leadership is key to organizational success. In fact, it was revealed to be more integral to company-wide happiness than teamwork skills, problem-solving and conflict resolution. There is no doubt that leaders who have mastered the positive business mindset will bring their team with them on the journey and empowering your team is a huge part of this. When the collective shares a mindset, they don’t need to ask you about every decision – they know the answer before they even think of asking. ■

David Rajakovich

www.linkedin.com/in/davidrajakovich

US born thought leader David Rajakovich grew up in Pittsburgh, Pennsylvania. Having graduated the prestigious La Salle University, and served in the US Army, David has gone on to work in top positions across several technology, e-learning and procurement companies. Familiar to the C-Suite, he has experience as Founder, VPO, Managing Director and CEO. At Skill Dynamics, David became a hugely positive disruptor in the world of e-learning, developing innovative new ways to transform higher education in business. Looking to the future, he plans to commit to a start-up or early-stage company and, through hard work and investment, take it to unicorn status.

Productivity 11 manufacturing-today.com

2 hours to achieve comprehensive visibility

Solution investment

Winkelmann minimizes the risk of business disruption and meets industry audit requirements with Forescout

170+ percent more assets discovered

Overview

Multiple days saved each month by SecOps

INDUSTRY Manufacturing ENVIRONMENT

• 6,800 wired and wireless assets across three continents

• 4,300 employees

CHALLENGE

• Lack of visibility into all connected assets on the network, including IT, IoT and OT

• Meet TISAX security regulations for automotive industry

• Minimize risk of business disruption from cyberattack

The Winkelmann Group is a multinational manufacturer specializing in technologically advanced metal forming processes, with core business in the automotive, heating and water industries. By implementing the Forescout Continuum Platform, the Ahlen, Germany-based company gained comprehensive visibility across its entire organization, including IT, IoT and OT assets in its production facilities in Europe, Asia and North America. The company also gained accurate, real-time asset inventory, continuous asset compliance, network access control (NAC) capabilities and more, all of which help minimize the risk of a breach or business disruption.

“ “ “

“

We needed network access control and segmentation, but first we needed to know exactly what was on our networks

— Niklas Kaiter, System and Network Administrator, Winkelmann Group

12

Business Challenge

To receive TISAX certification, a security standard required for German automotive manufacturers, Winkelmann Group had to implement NAC and network segmentation. In addition, the company had experienced a few virus incidents that disrupted operations of endpoints and servers. Thankfully, the company’s IT staff was able to fully restore the machines after these events. However, these cyberattacks, combined with audit feedback, led executives to rethink its cybersecurity approach and commit to investing in the right solutions to better secure its users and assets – starting with being able to see everything on their networks.

Why Forescout?

After its initial research into potential network access control and segmentation solutions, the Winkelmann Group downselected four vendors. “Forescout offered a much broader feature set and much more comprehensive visibility than any of the others, and Forescout was much easier to implement,” recalls Winkelmann Group System and Network Administrator Niklas Kaiter. “The competitors either did not have enough functionality or were too complicated and time-consuming to deploy. Forescout was much more flexible, with an intuitive dashboard, easy access to granular data, and seamless integration with many of the other tools and systems we use.”

SECURITY SOLUTION

• Forescout Continuum Platform

• Forescout eyeExtend USE CASES

• Asset inventory

• Asset compliance

• Network access control

RESULTS

• Rapid time to value

– comprehensive visibility within two hours, across IT, IoT and OT assets

• Initial real-time, accurate asset inventory after only half a day

• Security operations saves hours daily regarding network and asset management

• Minimized risk of breach with automatic, continuous posture assessment across all types of assets

• Accelerated time to detect and remediate vulnerabilities

• Facilitated policy creation and enforcement

• Has laid the foundation for ecosystem integrations and network segmentation

Case Study 13 manufacturing-today.com

Business Impact

Comprehensive visibility in hours, including IoT and OT “We initially guessed we had approximately 2,500 assets, but even the initial trial of Forescout showed 5,000, including IoT and OT assets, which we had never seen before,” says Kaiter. “We had wide-ranging visibility in just two hours, with most of the assets classified automatically. Expanding from trial to production deployment also took only two or three hours. Within half a day in full deployment, we could produce a real-time, accurate asset inventory with just a few clicks on the Forescout dashboard. Ultimately, we saw a total of 6,800 assets – over 170 percent more assets than we originally guessed we had.”

Upleveling security posture with easier device compliance

Winkelmann boosted its security by using the Continuum Platform to automatically and continuously assess the security posture of all connected assets. When an asset attempts to connect to Winkelmann’s network, the platform checks to make sure that antivirus software is installed

and running, Windows Firewall has been enabled, Windows updates are current, and that the asset is on the correct VLAN. If the antivirus software is not running, for example, the platform attempts to reactivate it. If the asset cannot be brought back into compliance automatically, an administrator is alerted for manual remediation, such as moving it to another VLAN.

“Besides asset hygiene issues, Forescout has uncovered serious vulnerabilities and threats, such as the use of blacklisted applications or a non-corporate laptop accessing our network via VPN,” notes Jan-Erik Strauss, also a system and network administrator. “We still see new things almost every week that we would never have seen otherwise.”

Reducing network administration burden

Deploying the Continuum Platform also saves Winkelmann’s small team of security and network administrators multiple days each month and makes their jobs easier. Just one example: in the past few years, after the company shifted from an onpremises antivirus solution to one in the cloud, as agents were uninstalled and

14

reinstalled, some endpoints ended up without any antivirus protection. “With Forescout, it was easy to see not only how many assets needed attention but exactly which ones and who they belonged to,” explains Jan-Erik Strauss. “The depth of asset information available is incredibly useful and saves us time in multiple ways.

“Forescout is exceedingly powerful yet quite easy to set up and use,” says Strauss. “We were able to configure the platform without much external help. The dashboard is intuitive, and it’s very easy to create new groups and policies and so on.”

“NAC but also so much more”

Although the Winkelmann Group saw value from Forescout on Day One, it has just begun to leverage the holistic capabilities that the Continuum Platform offers. In the future, Winkelmann plans to automate more security processes, add network segmentation and move from monitoring to policy enforcement for IT assets as well as machines on the factory floor. It has already integrated the platform with its VMWare infrastructure, firewalls and Active Directory and hopes to take advantage of seamless integrations with other systems in its environment as well.

When asked what he tells peers about the Continuum Platform, Kaiter replies: “You can invest one-quarter of what Forescout costs but then you’ll only have one-quarter of the security, or even less. You just won’t have the breadth of functionality you get with Forescout. We bought Forescout for NAC, but we use it daily for asset management and foresee many future use cases. Yes, it’s a NAC solution, but it is also so much more.” ■

www.winkelmann-group.de/en/

Forescout has uncovered serious vulnerabilities and threats … We still see new things almost every week that we would never have seen otherwise

“ “ “ “ Case Study 15 manufacturing-today.com

— Jan-Erik Strauss, System & Network Administrator, Winkelmann Group

STANDARDIZE TO DIVERSIFY

16

How manufacturing can regain innovation

By Aneil Ali

The British economy is now officially in a recession, which some predict will be the longest on record, and there is a real possibility that a global recession will soon follow. As is sometimes the case, the performance of the manufacturing sector was a leading indicator for this latest turn in economic health, with a decline in manufacturing productivity largely causing this recession’s first month of negative growth.

Of course, the mechanics of a recession are much bigger than any one sector, and while British manufacturing suffered an early loss, it is by no means an outlier in facing financial challenges. Nonetheless, it is worth recognizing that factors within businesses and industries have a role in decline just as much as the macroeconomic does. It could therefore be asked, what can manufacturing do now to regain growth and sustain it into the future?

Unleashing manufacturing innovation

One simple answer is innovation. In a difficult market, new customers and new lines of revenue do not arise from doing the same things as in previous decades: manufacturing businesses, like those in almost every other industry,

Technology 17 manufacturing-today.com

need to find new ways to bring new things to new markets.

Manufacturing also, however, faces particularly strong barriers in this regard. One obvious issue is that the capital investment and maintenance of machinery, plants, and skills – is expected to return value over the course of decades, making pivoting to new business models challenging.

A less noted issue, though, lies in the way that businesses can find themselves restricted even on the level of individual components. Manufacturing environments require efficient, secure, and reliable communications to control processes – and because vendors typically offer proprietary protocols to achieve that, manufacturers have limited scope for innovation in the ways that their key infrastructure is built. Locked into a single ecosystem,

innovation must happen at the pace the vendor sets, not the pace the manufacturer needs.

To put it another way, in an ideal healthy manufacturing sector, where businesses have the flexibility to innovate, we would expect to see real diversification in how manufacturers design, produce, and deliver goods. In order to enable that diversification, however, we first need to standardize an interoperable way to control, orchestrate, and integrate systems.

The benefits of open standards

This is the goal of The Open Group Open Process Automation™ Forum. Developing a common, standardsbased open architecture for process automation systems like humanmachine interfaces, programmable logic controllers, and manufacturing

18

execution systems, it aims to offer manufacturers an alternative to vendor lock-in in which they can elect to use the right component from the right supplier at every level of industrial control systems.

In a standards-based future operating context, manufacturers would be able to choose from a wider range of potential combinations of tooling, free of the limitations associated with the product development roadmap of any given supplier. With a diversity of best-in-class solutions available, they would be able to pursue alternative approaches as and when they hit the market.

At the same time, standardsbased protocols would unlock deeper insight into and integration of existing control systems, potentially offering a route to draw more efficient and flexible operations from a business’ existing machinery investments. By disassociating software configuration from hardware configuration, it would also make software innovations more portable, increasing the return on those investments.

The road to interoperability

The closed, proprietary ecosystems of the twentieth century served manufacturing businesses well across many verticals. Few sectors can boast the kind of reliability and specialization that a welldesigned manufacturing plant enjoys, and deeply integrated systems have been vital to that.

In the twenty-first century, however, it is becoming increasingly clear that this operating model is no longer fit for purpose. The rate of change that technology can

offer, and that markets demand, has accelerated, while more agile software-led approaches have become the norm. In a widely standardized environment, we can even see innovations being shared across manufacturing verticals, with developments in one area uplifting the entire sector. Getting there relies on taking a diverse view of manufacturing architecture and the roles that different actors have to play. End users, as well as outlining outputs in bid specifications, can define necessary interoperability needs like meeting the O-PAS™ Standard. Systems integrators can advance the transition to open standards by demonstrating the innovative potential of interoperable systems. Finally, suppliers can pursue standardization as a way of adding value to users who will, in the future, need to adapt and adopt technology ever more rapidly. ■

Aneil Ali

www.opengroup.org/forum/openprocess-automation-forum

Aneil Ali is Director at The Open Group Open Process Automation™ Forum. The Open Group Open Process Automation™ Forum is focused on developing a standards-based, open, secure, interoperable process control architecture. The Forum is a consensus-based group of end users, suppliers, system integrators, standards organizations, and academia. It addresses both technical and business issues for process automation.

Technology 19 manufacturing-today.com

For a list of the sources used in this article, please contact the editor.

RAISE the bar

Clean energy innovation is crucial for a low-carbon future says Professor Shannon Yee

As the world tackles the urgent crisis of a changing climate, manufacturers globally are under pressure to reduce their impact on the environment.

Limiting global warming to 1.5°C requires the world to cut 30 gigatons of greenhouse gas emissions annually by 2030. While electricity production, transportation and agriculture are all contributors, the manufacturing industry is one of the largest emitters of greenhouse gases. In the US,

manufacturing accounts for almost a quarter (23 percent) of direct carbon emissions. In Europe the situation is equally stark, with the industry emitting a total of 880 million tons of carbon dioxide every year.

So what role can the sector play to reduce emissions?

A recent article authored by Bill Gates on the state of the energy transition stated that the only way to avert a climate disaster is to invest aggressively in clean energy

20

innovation and deployment. To make progress we need tools and technologies that go beyond current capabilities, and those require innovation.

Until we do this, the economic toll of climate change will continue to escalate. In the US alone, the employment share of manufacturing has declined from 32 percent of workers in 1953 to nine percent in 2019, and manufacturing share of nominal GDP fell from 28 percent to 11 percent over the same period.

Responding to climate change through clean energy innovation holds the potential to reverse this trend. It provides an opportunity for manufacturers to strengthen the economy by creating jobs, increasing profits, and lowering costs – thus increasing competitiveness, while growing their green reputation.

Water and sanitation at the heart of climate solutions

Climate change has a major impact on water and sanitation. Approximately two billion people lack safely managed drinking water and 3.6 billion people do not have access to safe sanitation, representing around half of the global population.

2022’s UN climate change

negotiations and record droughts across the globe shone a spotlight on water, highlighting its crucial role in climate adaption and resilience. While new government led initiatives launched, including the Action for Water Adaptation and Resilience (AWARe), which sets out priorities for governments to provide transitional adaptation solutions across the world, the window for taking impactful action is closing rapidly.

Unsurprisingly, manufacturing is doing what it does best and bringing innovation to the table.

One example already in development is the single user reinvented toilet (SURT). In addition to being poised to be inexpensive and easy to deploy, SURT technology can reverse environmental strains. It has the potential to relieve contamination from 11 million miles of ageing (and leaking) sewer lines. It also promises to eliminate the main source of household water consumption – conventional flush toilets. Moreover, SURT technology can relieve the world of the main source of disease – unsafe sanitation in our communities and soil and water contamination in our lands.

Manufacturing can raise the bar on global climate goals and has the potential to make a positive impact on creating a net zero world. Clean innovations such as the SURT could be the answer. But we need collaborative action, and fast. ■

For a list of the sources used in this article, please contact the editor.

Professor Shannon Yee

www.g2rt.research.gatech.edu

Professor Shannon Yee works at the Georgia Institute of Technology. The Georgia Institute of Technology, or Georgia Tech, is a public research university developing leaders who advance technology and improve the human condition. The Institute offers business, computing, design, engineering, liberal arts, and sciences degrees. Its nearly 44,000 students representing 50 states and 149 countries, study at the main campus in Atlanta, at campuses in France and China, and through distance and online learning. As a leading technological university, Georgia Tech is an engine of economic development for Georgia, the Southeast, and the nation, conducting more than $1 billion in research annually for government, industry, and society.

Sustainability 21 manufacturing-today.com

THE FOUR PILLARS OF MODERN MANUFACTURING

Achieving success amid a labor crisis

By Richard Tester

22

Alabor shortage of 500,000 workers will cost the manufacturing industry $1 trillion by 2030. Though this has long been a concern amongst manufacturing leaders, today’s environment has created new challenges as the baby boomers who have dominated the manufacturing industry are now retiring in record numbers. This leaves manufacturing leaders questioning

if digital generations will embrace factory work as the generations before them did.

2.6 million baby boomers are nearing retirement age in the manufacturing industry alone, leaving a gap that millennials and Gen Zers don’t have the experience or numbers to fill. The factory is undergoing a transformation of its own with advances in technology, which further contributes to the challenge of finding skilled workers.

Human Resources 23 manufacturing-today.com

Why does this matter?

Each lost frontline worker costs manufacturers an average of $12,876, and manufacturing has seen the most significant growth in employee separations over the last year - quit rates are up 58 percent. Plants are facing increasing recruitment costs, salary expectations, and upfront costs like sign-on bonuses, but they aren’t seeing results from these efforts. Leaders need to turn their focus to other solutions.

Solution:

The four pillars of modern manufacturing success

Manufacturers need to invest in solutions that will ease the harmful side effects of an ongoing labor crisis. The following four pillars are actionable ways manufacturers can make the most of their existing workforces and nurture their talent pipelines.

#1 Empower and engage frontline workers

The benefits of investing in your frontline employees are clear, but challenges often arise when instilling these practices in the workplace. Manufacturers need to reframe the way they speak to employees - current and potential - about frontline jobs. By empowering employees to view factory jobs as long-term careers rather than just means to a paycheck, management will encourage employee engagement and expertise on the frontline.

Managers can help employees realize their value and find satisfaction in a workplace where their voices are heard and their opinions are respected. Giving employees responsibility and tools to succeed on the frontline will only increase their commitment and engagement.

Employees who are emotionally committed to their job have a 17 percent boost in productivity and reduced absenteeism by 41 percent. They are also more likely to stay on the job, reducing employee turnover by 59 percent.

#2 Emphasize immediate productivity

Managers often focus too much on future planning instead of immediate problemsolving, causing delays in productivity. If managers emphasize immediate action, workers can make course corrections in real-time and accelerate productivity despite external challenges. To accelerate and attack productivity head-on:

• Leverage real-time productivity stats and health status reports so workers can see how their productivity measures up, encouraging workers to take initiative.

• Acquire access to on-the-go troubleshooting where common issues arrive to trim expensive downtime costs.

24

• Provide self-serving training tools that help frontline workers complete tasks to build a culture of continuous improvement.

#3 Connect teams digitally

Historically, factory workers were hyperfocused on a small section of the production process, blind to the other parts of manufacturing and failing to maintain real insight into issues going on in other sectors of the factory. With this narrow-minded mindset, communication gets lost between teams, causing costly delays and inefficient problem-solving.

Sixty-eight percent of manufacturers have experienced higher production costs caused by communication delays. Fast, cross-team communication makes a real difference and ensures that workers can elevate problems and solutions to team members at all levels. This can also bring opportunities to build camaraderie and relationships that increase overall employee engagement.

#4 Simplify daily operations and toolkits

Employee engagement and productivity decrease with poor communication. Furthermore, 61 percent of manufacturing industry managers feel that using digital tools for communication can increase productivity.

When frontline workers have the ability to assess the context of a problem and its ramifications across multiple parts of the factory, they have more knowledge on who to consult and how to solve it. Digital devices that are intuitive, easy to learn, and frictionless can automate parts of the production process and help enable multiple parts of the business to communicate as one, while also helping workers take ownership of their roles and save skilled workers for tasks that challenge and excite them.

Digital communication tools can typically integrate third-party and custom applications for a fully connected business. Working together as a team helps the frontline worker feel empowered to take control of their lines, with more visibility to define and solve problems without upper management’s involvement.

Revolutionizing the manufacturing industry

Though many may feel the need to cut back on spending during economic uncertainty, manufacturers need to invest in modern solutions that can help revolutionize the industry to ease the effects of an ongoing labor crisis. These modern manufacturing best practices can help teams foster a mindset of continuous improvement and support success on the manufacturing floor. By reprioritizing the employee experience, manufacturers can increase productivity, reduce employee churn and maximize their profitability. ■

For a list of the sources used in this article, please contact the editor.

Richard Tester www.rzsoftware.com

Richard Tester is Founding Member & CEO at Redzone. Redzone deploys its social and coaching platform to manufacturing plants around the globe to enable frontline workers to communicate, collaborate and problem-solve right on the shop floor. On a mission to transform manufacturing performance by bringing dignity back to the frontline worker, Redzone’s software gives frontline teams the autonomy they need to take ownership over their jobs and creates a culture of collaboration and teamwork among the entire plant. The company’s 90-day hands-on coaching program sets the factory up for success, increasing plant productivity by nearly 22 percent and decreasing employee turnover by 32 percent.

Human Resources 25 manufacturing-today.com

Making automation

Through innovative solutions, Banner Engineering makes implementing IIoT initiatives quick and easy

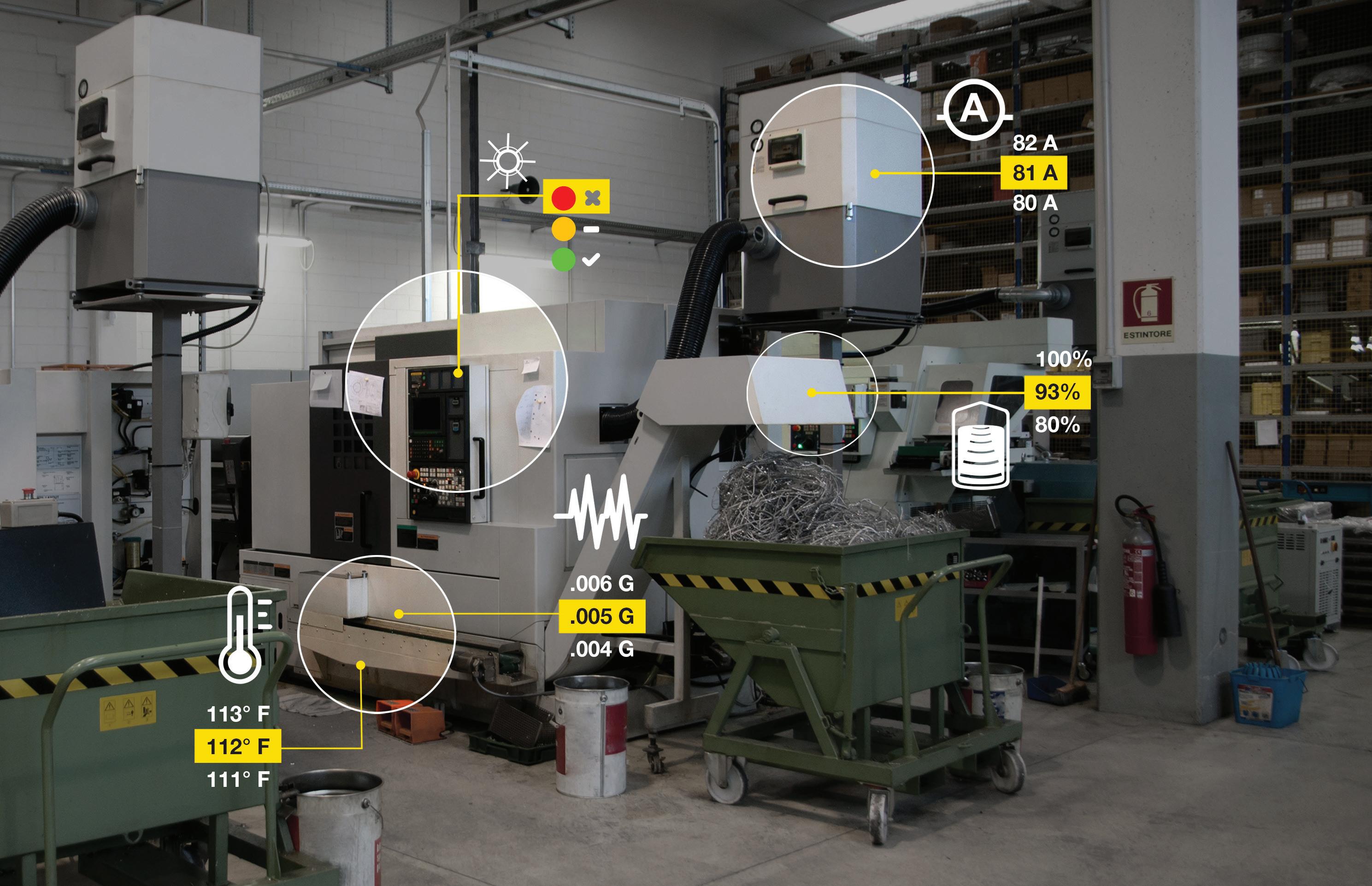

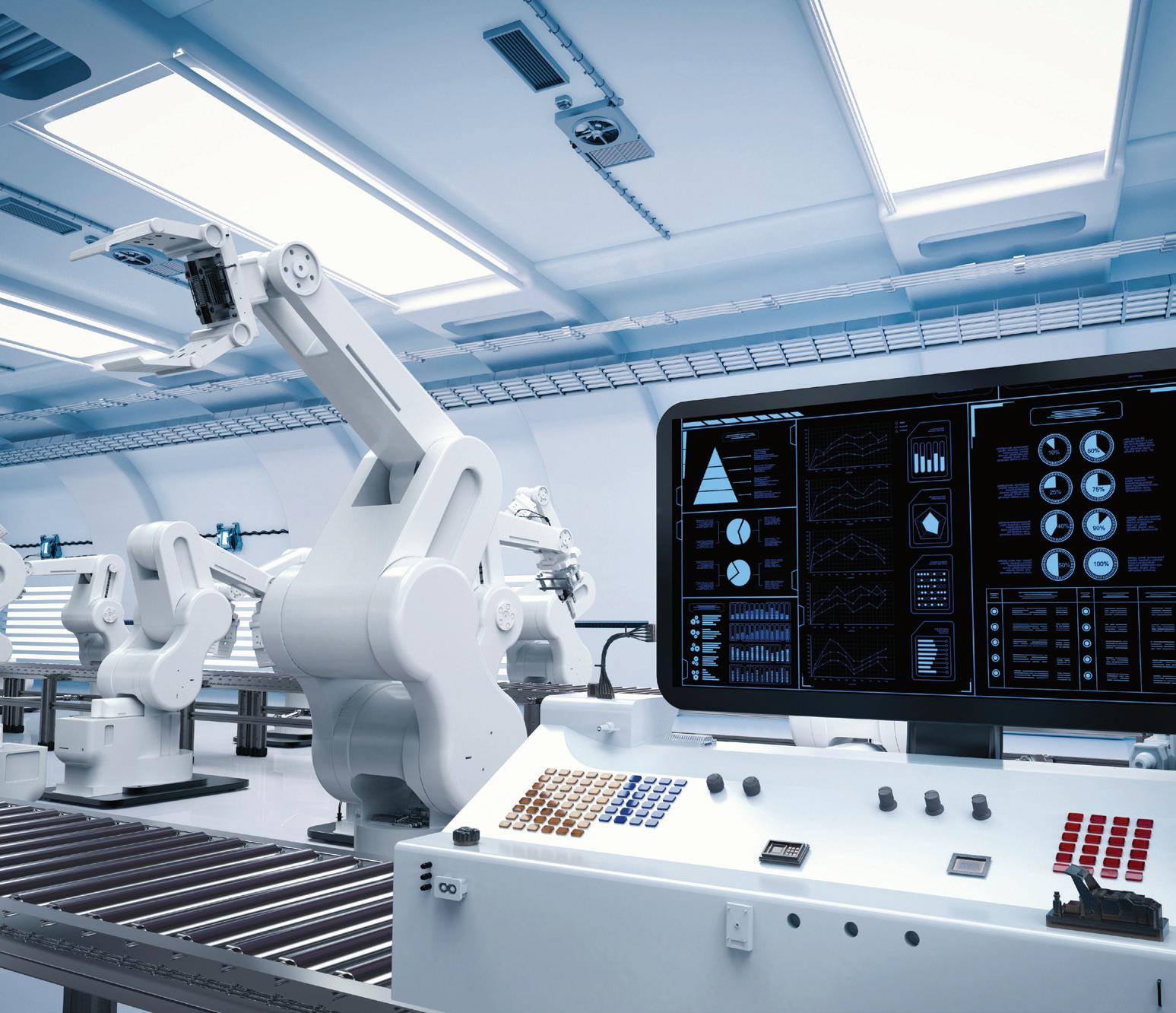

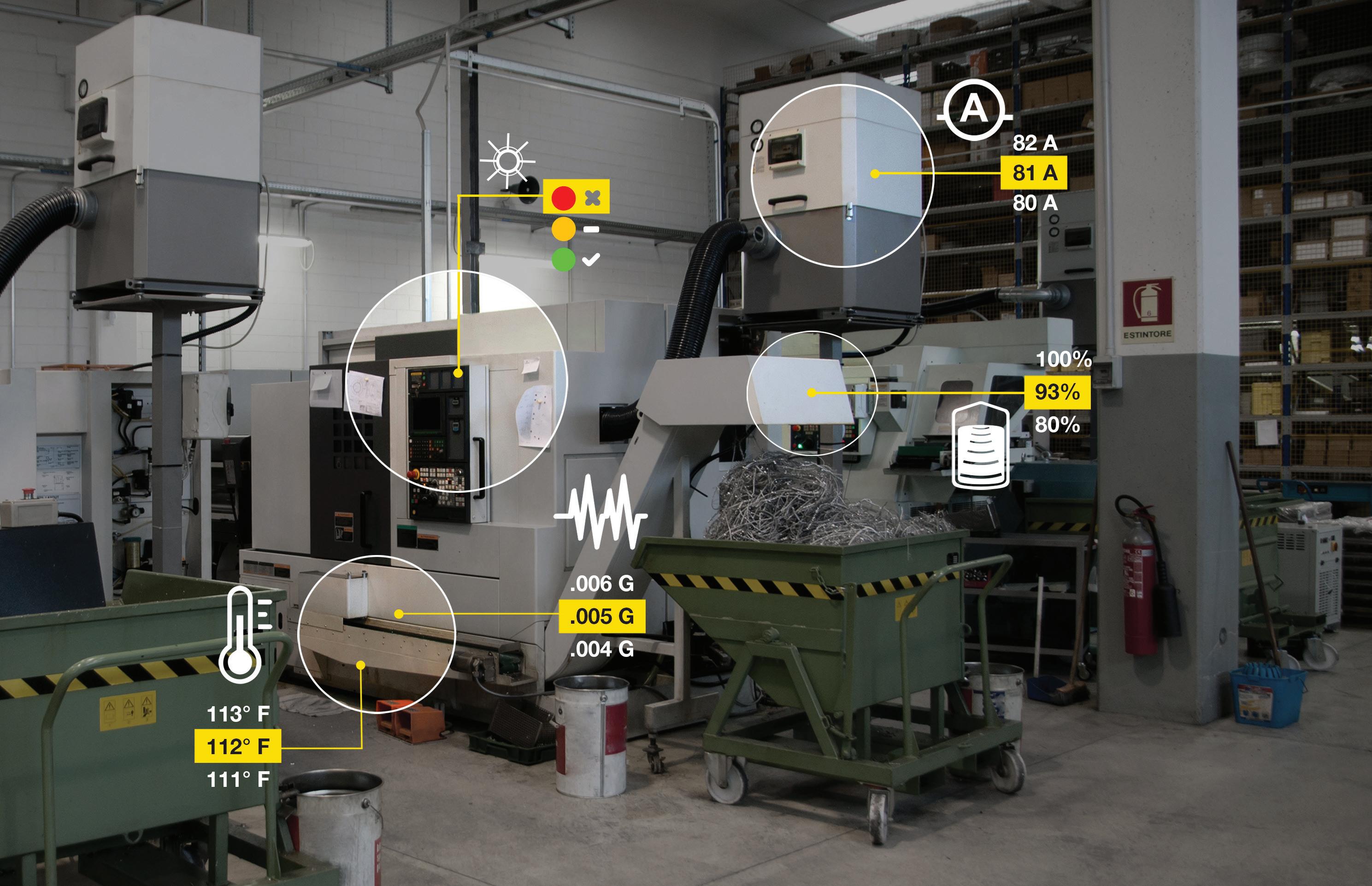

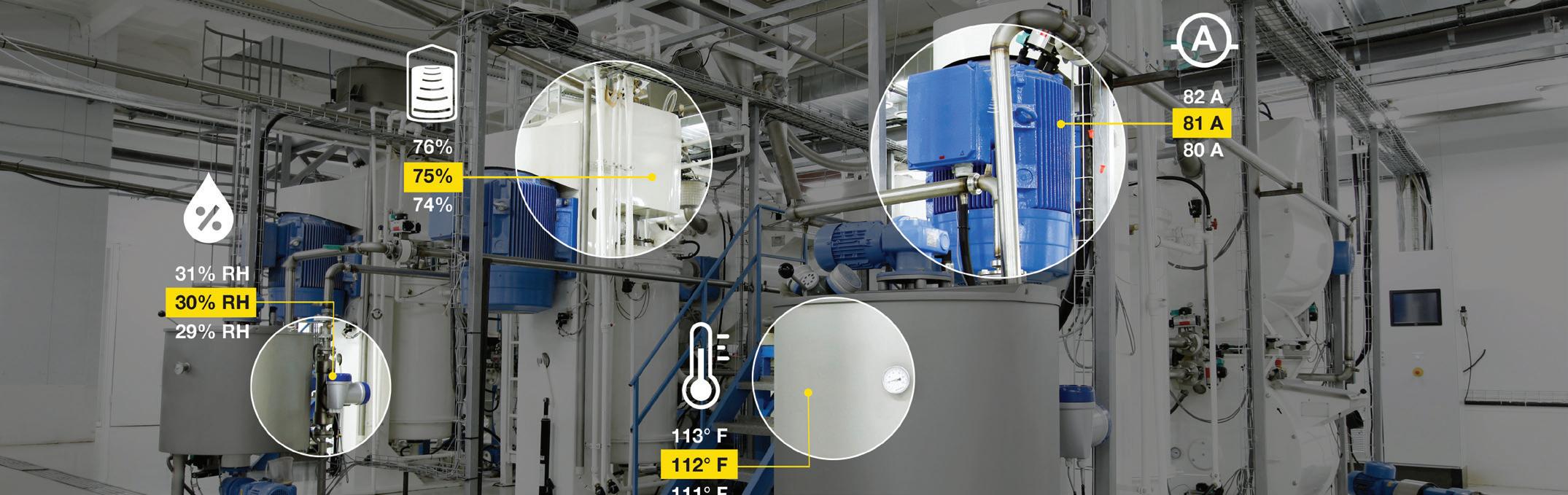

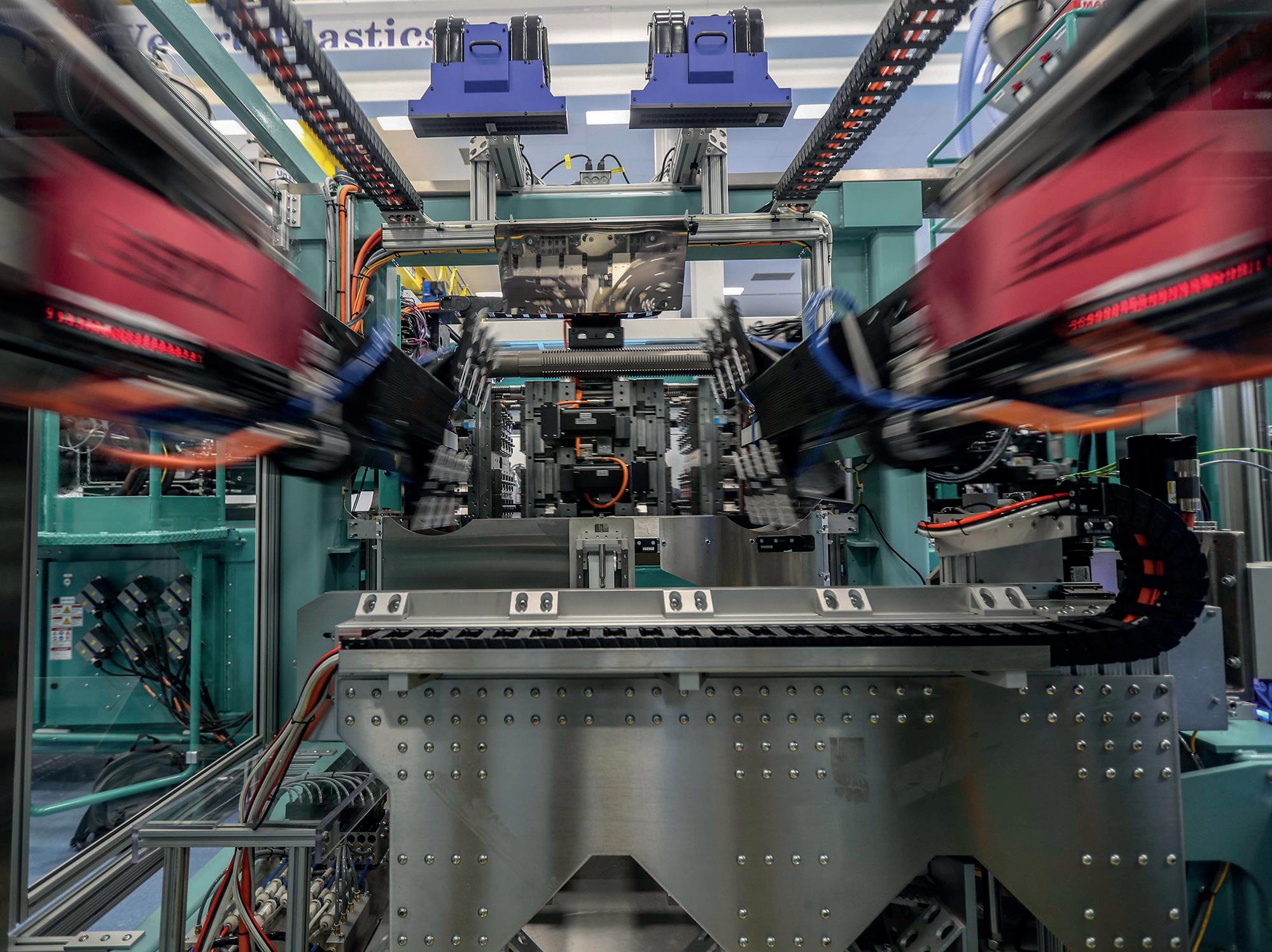

Until recently, machines have offered limited monitoring capabilities. However, the Industrial Internet of Things (IIoT) has opened up new ways to obtain and access machine data, understand its significance, and make equipment operate more efficiently. This combination of informational and operational technologies encompasses smart automation, which enables remote equipment monitoring and management, predictive maintenance, and process optimization, which can ultimately lead to increased profitability.

Though automation and smart automation are related, they are not the same. At its core, automation uses machines and technology to improve manufacturing efficiency, increasing productivity while lowering costs. Adding a smart component is a major technological leap from traditional automation, inserting a new communication layer between operator and machine that significantly enhances the ability to further improve return on investment.

Banner Engineering (Banner) is at the forefront of this smart automation evolution, taking a holistic approach to developing advanced technologies so machines are given a voice that provides a vast array of critical operating information to users in real time. More than 55 years of experience developing sensors, lighting, safety, and

Exclusive Feature 28

automation SMARTER

Engineering manufacturing-today.com 29

Banner

other products for customers worldwide provides the strong foundation on which Banner’s IIoT portfolio has been built.

Data-driven decision making

Smart automation goes far beyond sensors recognizing objects on a conveyor belt and turning on a light to tell an operator a part is not where it needs to be. Smart automation means taking data from the sensor and turning it into information that is useful far beyond the narrow scope of part presence. This information can be used to help users make critical decisions, such as when to order materials, employee, production, and maintenance scheduling,

determining if and when production lines need upgrades, and more.

For example, a metal-stamping operation with limited data intelligence capabilities can be transformed to collect and interpret previously inaccessible information to understand machine availability, performance, and quality, which are the essentials of OEE. Quality and performance can be monitored by photoelectric sensors counting good parts exiting the press, and pressure measurements from the press’ nitrogen cushions can be analyzed to correlate low pressures with a reduction in quality. Machine availability is easily monitored via current-monitoring sensors installed on the motor power cables.

Current-monitoring data also creates the ability to track energy usage on equipment. By combining the current measurement with the supply voltage and monitoring this result over time, plant managers can more accurately understand the costs of running their equipment. Not only can this data show which equipment is the most cost effective to operate, but also it can inform future equipment decisions via comparing the costs of maintaining and running existing equipment versus the costs of new equipment that uses less energy.

Data predicts maintenance needs

Traditionally, large manufacturers would have a vibration expert analyze motors and bearings on a monthly or quarterly basis, tracking readings and

Exclusive Feature 30

trying to proactively correct issues before failures occur. Other companies conduct maintenance at scheduled intervals or replace equipment when it fails. However, rich sensor data can be used for predictive maintenance: recognizing when maintenance is needed and proactively addressing issues before equipment breaks down.

Another example is using data to improve the efficiency and uptime of compressed air systems. By adding vibration, temperature, and current sensors to the compressor motor, along with pressure sensors downstream, data may be analyzed over time to track trends. If sensors recognize a motor temperature starting an abnormal rise, a technician can be dispatched to the compressor immediately to check on it. Or, if the motor begins to run more often and system pressure varies too much, it may be a sign of an air leak. Technicians can track down the problem immediately and avoid excess energy consumption and expense.

Access from anywhere

Using a cloud platform, such as Banner Cloud Data Services (CDS), sensor data can be stored and visualized remotely via intuitive on-screen dashboards. Individual alerts can also be sent via email or text that instantly notify operators of any changes detected. Remote system monitoring is one of the greatest benefits of smart automation. Depending on need, complete end-toend IIoT solutions deliver data via wired Ethernet connections, wirelessly via cellular connectivity, and through cloud services to reach necessary personnel wherever they are. Production and maintenance decisions can be made based on real-time information, even if users aren’t physically present with the equipment. This is especially useful for improving risk management in hard-toaccess or potentially hazardous areas, such as remotely monitoring long pipelines for leaks or tracking proper placement of items conveyed through dark and dirty locations.

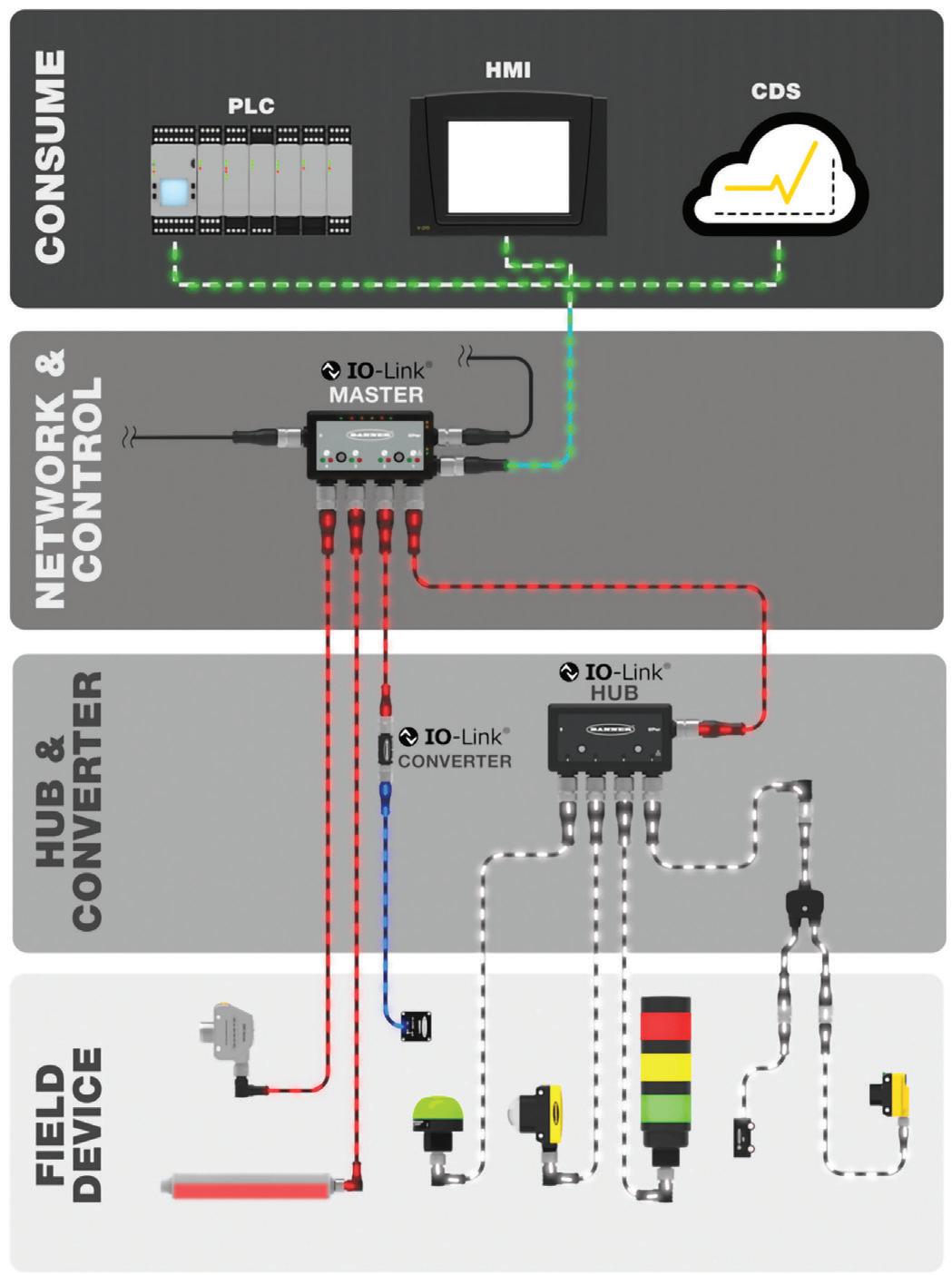

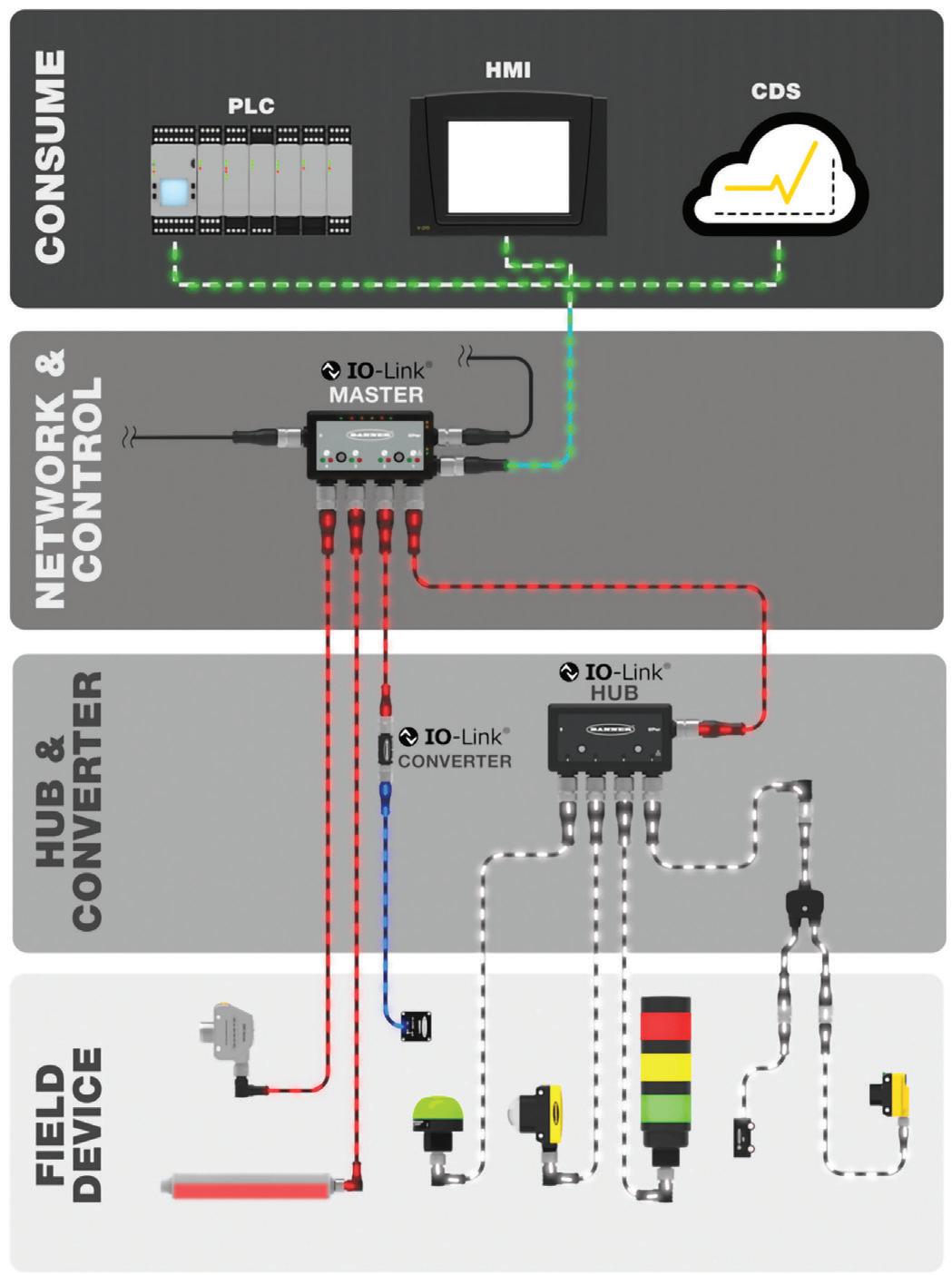

IO-Link standardizes device communication

To make smart automation a reality, Banner offers a large selection of devices that incorporate IO-Link, an industry-standard communications protocol. This protocol allows devices and software from different manufacturers to easily communicate and share data, enabling seamless interoperability across industrial networks. Because Banner’s IO-Link devices also send discrete signals, they can use standard unshielded 3-pin M12 cables. These readily available cordsets are cost-effective and install quickly, varying only by length. Standardized cabling also eliminates wiring and pinout errors and reduces installation time.

IO-Link devices are designed for simple device replacement without requiring extensive technical knowledge. With Data Storage mode, sensor device configuration can be saved on a port of the IO-Link master. If a sensor is damaged, even an untrained operator can quickly swap the

Banner Engineering manufacturing-today.com 31

damaged sensor with a new one. The correct device configuration is loaded automatically, and the new sensor is ready to go. No manuals, configuration documentation, or firmware updates are needed.

Another cost-reduction tactic made possible by IO-Link technology is to replace passive junction blocks with stackable space-saving IO-Link hubs. This method simplifies connections by sending IO-Link signals back to one industrial controller, which aggregates and outputs all signals via a single Ethernet connection to a control cabinet. It reduces wiring, cost, installation and troubleshooting time, complexity, and allows for a smaller control cabinet. Hundreds of individual cable runs to a control cabinet can be replaced with six Ethernet cables.

For those users with non-IO-Link devices, legacy hardware can be connected to IO-Link masters using Banner IO-Link converters. These converters change various types of signals to IO-Link, giving operators access to sensor-level data without having to completely retrofit expensive and complicated machinery.

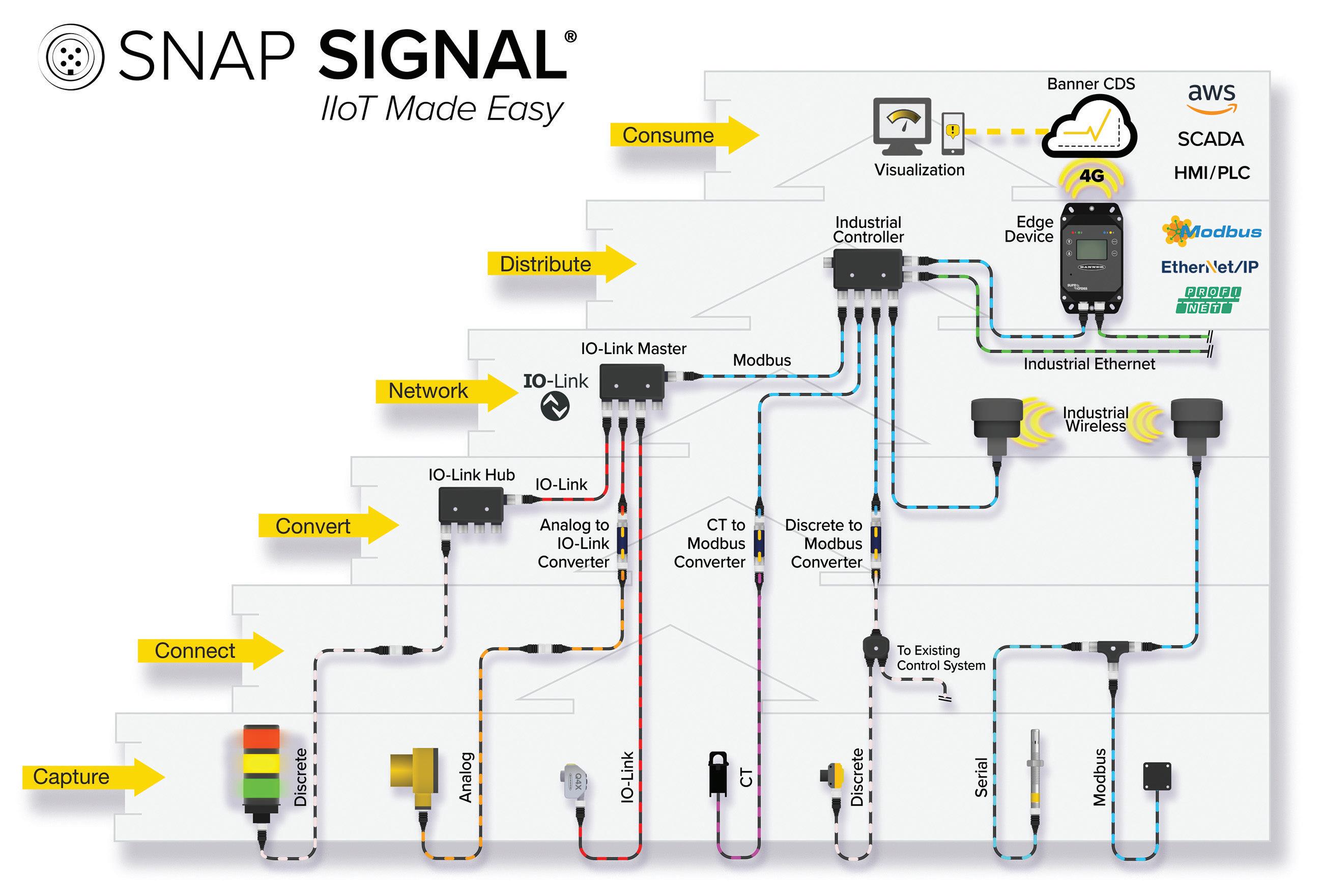

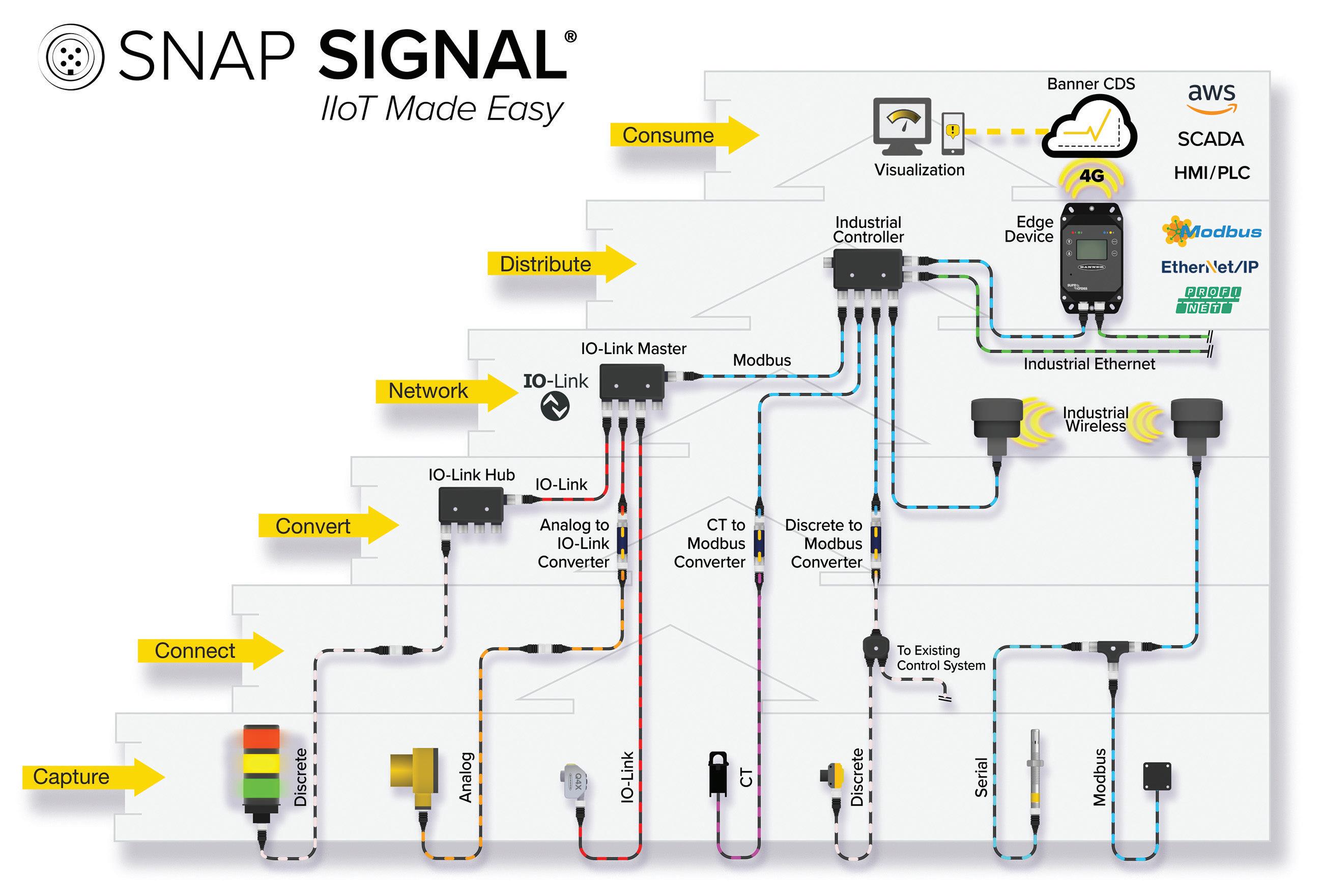

Unlocking potential with Snap Signal®

At the heart of Banner’s IIoT portfolio is Snap Signal, a suite of modular hardware and software that delivers actionable machine data. Data signals are captured from virtually any new or existing source, regardless of manufacturer, and converted to an industry-standard protocol. The data is then distributed locally, on

Exclusive Feature 32

a company network, or to the cloud for easy consumption. This enables and simplifies the complex task of data collection, analysis, and visualization. With Snap Signal’s ability to incorporate nearly any sensor signal found on a factory floor, Banner can build I/O systems that fully make use of rich data from both new and legacy equipment.

To accomplish this, Snap Signal taps into a device’s data stream, whether discrete, analog, or another type of signal. Even if device types are typically incompatible with each other, converters take their data streams and change them to matching industrial standards; think IO-Link or Modbus. By converting disparate signals to a unified standard, legacy sensors can be easily incorporated, and data can be seamlessly transmitted across multiple IIoT ecosystems.

Snap Signal combines performance data with predictive information. For example, a radar sensor that is monitoring the volume of liquid in a tank can display this level via an indicator light bar on the side of the vessel. When the tank level gets low, a connected controller can set the entire indicator to flash and notify an operator or send a text message to operators elsewhere that the tank needs to be filled to avoid disrupting production. A temperature and humidity sensor can be tied into the same system to monitor a nearby enclosure to ensure it does not overheat and cause the PLC or other electronics to fail. Indicators, sensors, connectivity, and logic can all be used together to enhance efficiency and reduce downtime.

Processing on the edge

The intelligence that drives smart automation systems is found in Banner’s DXMR90 series of controllers. These compact, programmable

devices consolidate signals from multiple connections, process data, and provide a gateway to the IIoT. Built-in logic controllers provide local processing of action rules and scripts for data analytics, condition monitoring, predictive maintenance, OEE analysis, diagnostics, and overall troubleshooting. With these forward-thinking solutions, Banner is empowering smarter automation and delivering the promise of IIoT to companies of all sizes around the world. ■

Banner Engineering is a US-based designer and manufacturer of innovative and industrial automation products, including sensors, smart IIoT and industrial wireless technologies, LED lights and indicators, measurement devices, machine safety equipment, as well as barcode scanners and machine vision. Since 1966, Banner has been an industry leader with more than 10,000 products, operations on five continents, and a worldwide team of more than 5500 employees and partners.

www.bannerengineering.com

Banner Engineering manufacturing-today.com 33

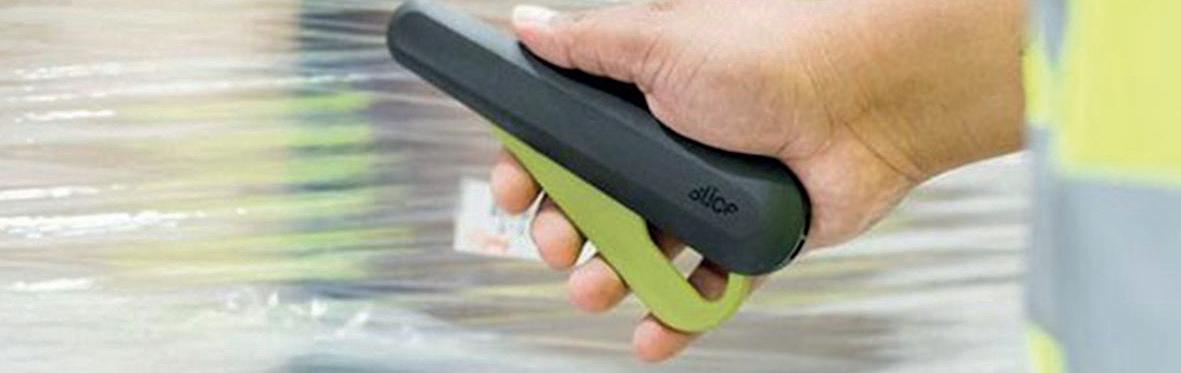

Match blade in heaven

How Dalton Safety has sharpened its operation to provide secure and dependable knives

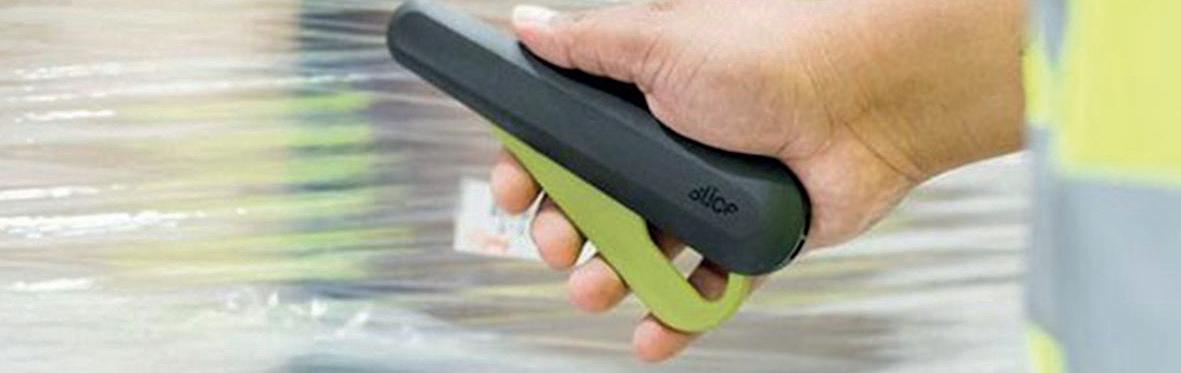

Dalton Safety is the result of a carefully crafted history, following the acquisition of Slice Inc, by Safety Products Holdings (SPH). After nearly ten years of representing Slice Inc as its master distributor in the UK and Ireland, the company was offered the opportunity to introduce the Pacific Handy Cutter (PHC) and Klever Innovations ranges to its portfolio. The two existing brands fall under the SPG banner.

Exclusive Feature 34

The business aimed to continue to represent Slice Inc as its master distributor, while marketing PCH and Klever under the Slice banner. However, this would have been confusing, which resulted in the creation of Dalton Safety. Today, Dalton Safety offers a selection of cutters, knives and accessories of the highest precision and quality.

New addition

Dalton Safety’s goal is to help Slice, PCH and Klever increase traction in the UK and Ireland, while adding complementary products to its range of knives. “I would like to think we are a very friendly group of individuals,” begins Mike Dalton, Managing Director, when discussing how the team over at Dalton Safety works together to achieve its goals. Mike explains that Dalton Safety is a family-owned company in the truest sense of the phrase, with a team that consists only of the Dalton family, Mike, Kate, Harry & Emily. Though, this changed recently when it brought on its first employee from outside the family. “We’re very excited about this chapter, and Demi is proving to be an excellent addition to the team.”

Safety manufacturing-today.com 35

Dalton

Our new gloves range will be available in January and we plan to introduce safety glasses at some point in 2023

“ “ “ “ Exclusive Feature 36

“We are a small team, however our network is quite extensive. We work closely with third-party providers, to create our website, marketing material and lead generation campaigns. We also work closely with our vendors to make sure we are fulfilling their needs of carrying the products they want us to sell. Our goal is to offer our customers next day delivery whenever possible,” says Mike.

Another significant milestone for the company was moving to a larger facility to accommodate the increased inventory. A larger facility has also allowed Dalton Safety to expand the offering of its own range, a development which, for Mike, has been particularly exciting. “In addition to the new products from PHC and Klever we are also introducing gloves, and will soon introduce additional products to complement our range. We continue to expand our customer base, which is fantastic,

and we are hoping to keep the momentum going with growing our team as well!”

Addressing customer needs

For Slice, the key technology can be seen in the way the blade is manufactured. The angle at which it’s ground means it is not quite as sharp as steel, but it is just as effective. “The Slice brand, especially, revolves around ergonomics. The box cutter was the first product the business introduced and has won several awards for its design. It’s comfortable to hold, and the blade doesn’t extend beyond the tip of the handle. This reduces the risk of puncture and injuries, and reduces the risk of damaging the contents of any box being opened. Most cuts happen when people change the blades, hence why a lot of companies use disposable products to avoid this. Slice have found the solution with a blade that is safer to handle,” Mike explained.

Dalton Safety manufacturing-today.com 37

He then dives into greater detail about the company’s catalog. “The PHC range offers a more traditional utility knife. We do get instances in manufacturing where the Slice blades are genuinely not sharp enough for the manufacturer’s task, which is where the PHC range benefits. PHC also offer self-retracting and auto-retracting knives, while Klever offer enclosed metal blade knives, either disposable or with replaceable heads. PHC and Klever also offer knives suitable for the food industry with metal detectable and antimicrobial versions. I would encourage people to browse through our websites to see what we have to offer.”

Continued expansion

Next year, Mike is hoping to build on the work the team at Dalton Safety has done in 2022, with the aim of growing the business further. “We will be expanding the company by increasing our customer base and the range of products we supply. Our new gloves range will be available in January and we plan to introduce safety glasses at some point in 2023. Based on feedback from customers we have some

interesting ideas for new products that will complement our range.”

Mike is determined to see the company’s catalog continue to grow over the next five years. He shares that once the business settles into its new warehouse space, the opportunities to expand its product range will increase tenfold. “We want to keep adding to our portfolio and continuing to see the kind of growth we have been getting in the last couple of years. I would like to see us with another three or four employees as well. I don’t believe we need to move warehouses, but if we did, it would be because our products are doing well, so I won’t be disappointed to see that happen,” he says. In conclusion, Mike is especially excited to see the company enter new markets that will likely take the business outside of the UK and Ireland, and at Manufacturing Today, we wish Dalton Safety all the best with this endeavor. ■ www.daltonsafety.com

Exclusive Feature 38

Dalton Safety manufacturing-today.com 39

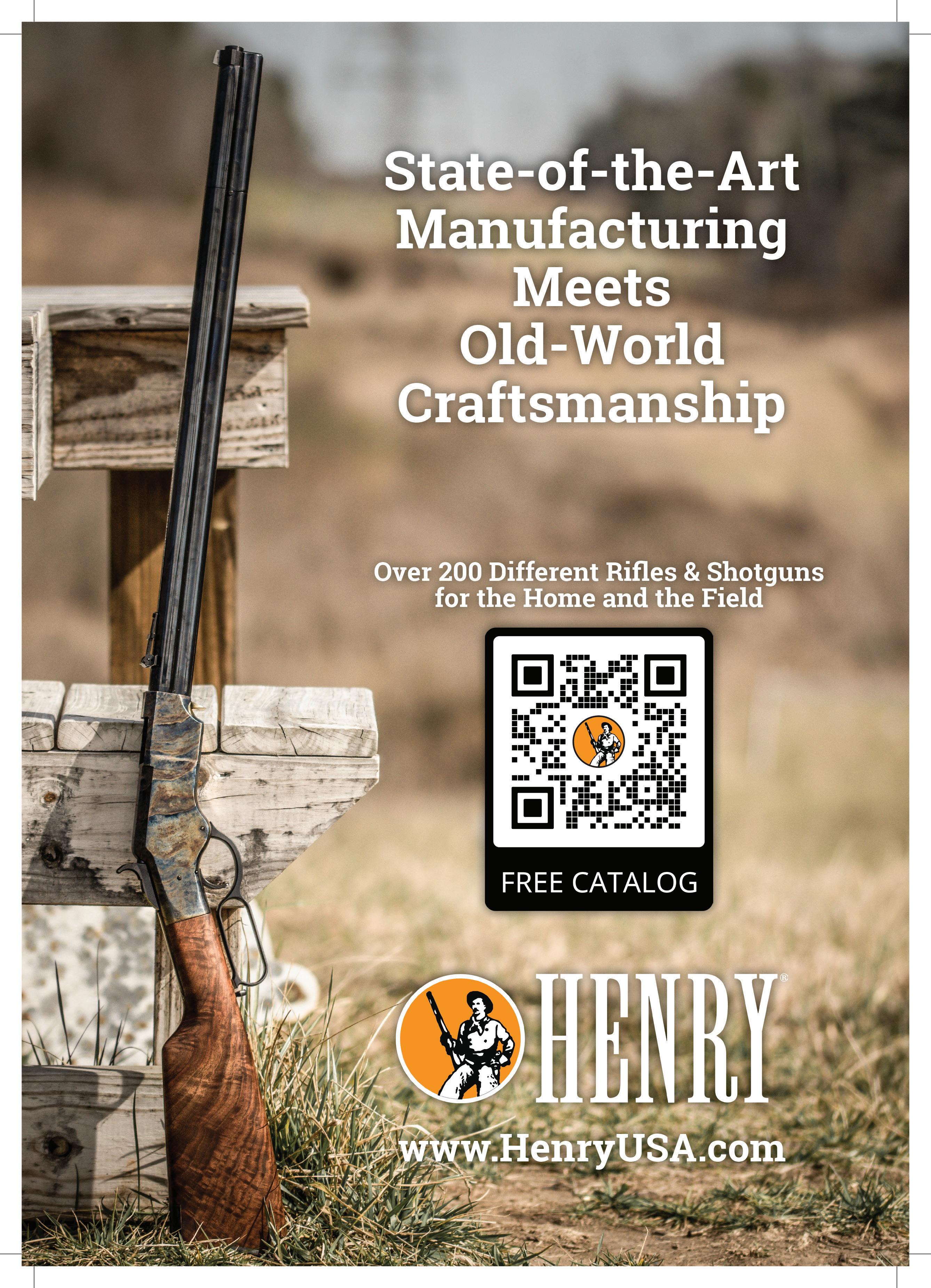

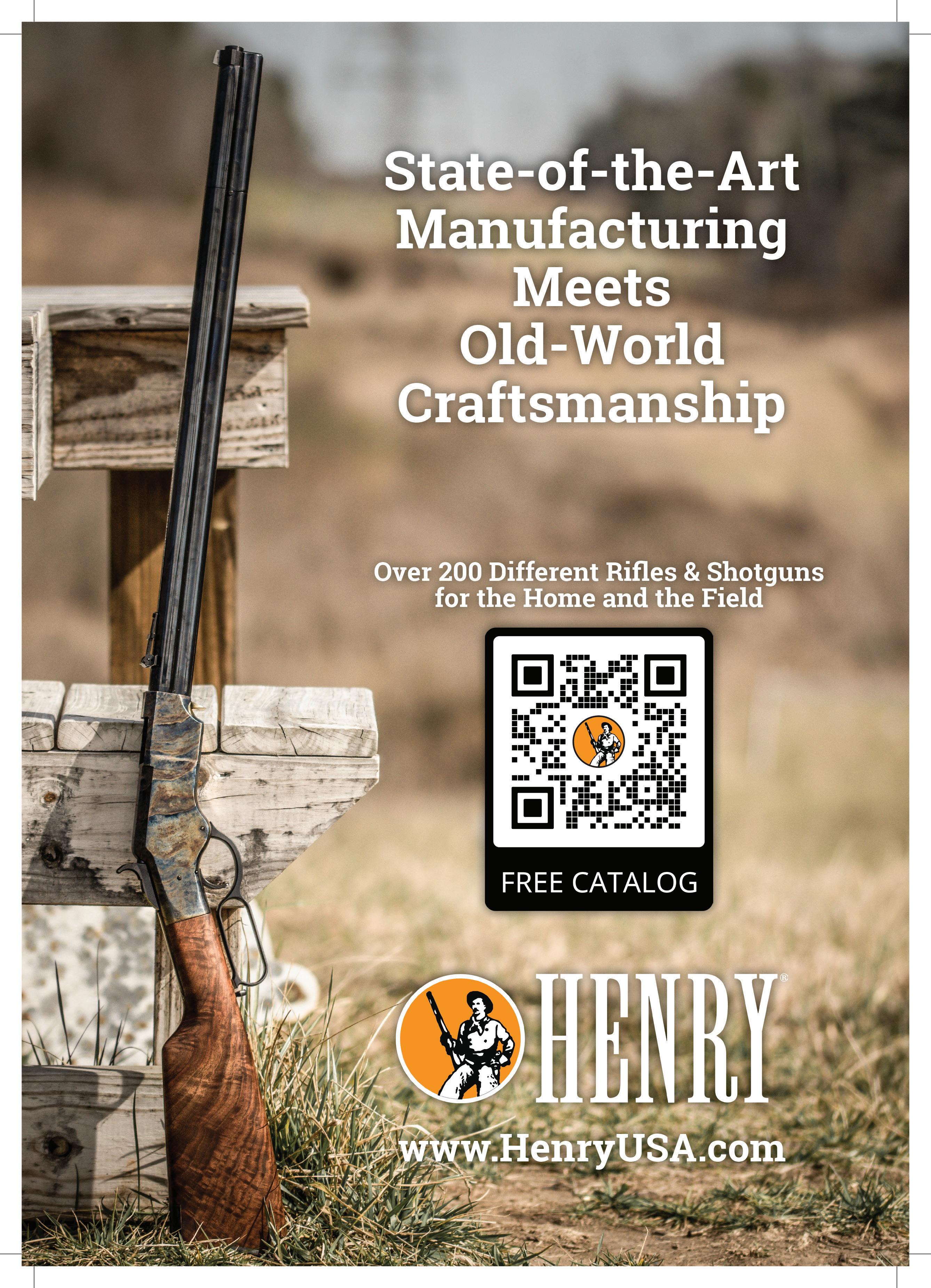

SON OF A GUN

Success is never certain, but for Henry Repeating Arms, an obsessive focus on the customer has kept it an industry leader for 25 years

Exclusive Feature 40

◀ Anthony Imperato, Henry Repeating Arms - CEO

Henry Repeating Arms (Henry) gets its name from Benjamin Tyler Henry, the famed gunsmith and inventor of the first successful lever action rifle patented in 1860. Carrying on the same spirit of manufacturing lever actions on American soil, this Wisconsinbased business shipped its first guns in March 1997, with only one model in the product catalog – the H001 Classic Lever Action .22. To date, it has sold over 1,000,000 of these rifles worldwide, and Henry’s product catalog now boasts well over 200 individual models in a wide range of calibers and finishes. Two years after the first shipment, the company introduced the award-winning Golden Boy rifle, which became its flagship model with a premium look and feel found nowhere else in the industry at the price point. At the time, all manufacturing and assembly took place in Brooklyn, New York.

As we stand in 2023, the business is one of America’s leading firearms manufacturers, founded in 1996 by Anthony Imperato, who now serves as the CEO. In 2008, the business moved operations from Brooklyn to a much larger facility on the waterfront of Bayonne, New Jersey, where the company still manufactures well over 200,000 guns annually at this location alone. Unfortunately, this facility was devastated by Hurricane Sandy in October 2012. However, with support from key vendors and other talented people, the facility resumed operations by the end of the year. In 2014, Henry announced the first models manufactured and assembled entirely at its current headquarters in Rice Lake, Wisconsin, which had previously been supplying parts for Bayonne assembly. In 2021, as a result of surging consumer demand, the company further expanded

manufacturing-today.com 41

Henry Repeating Arms

Exclusive Feature 42

its operations to an 84,000 square-foot facility in Ladysmith, Wisconsin, to provide additional space for parts manufacturing.

Just recently celebrating its 25th year in the long-gun manufacturing industry, we hear from Anthony, as well as Dan ClaytonLuce, Vice President of Communications, and Andy Wickstrom, President, about how Henry empowers its team to do whatever is necessary to ensure every customer is satisfied with their Henry purchase.

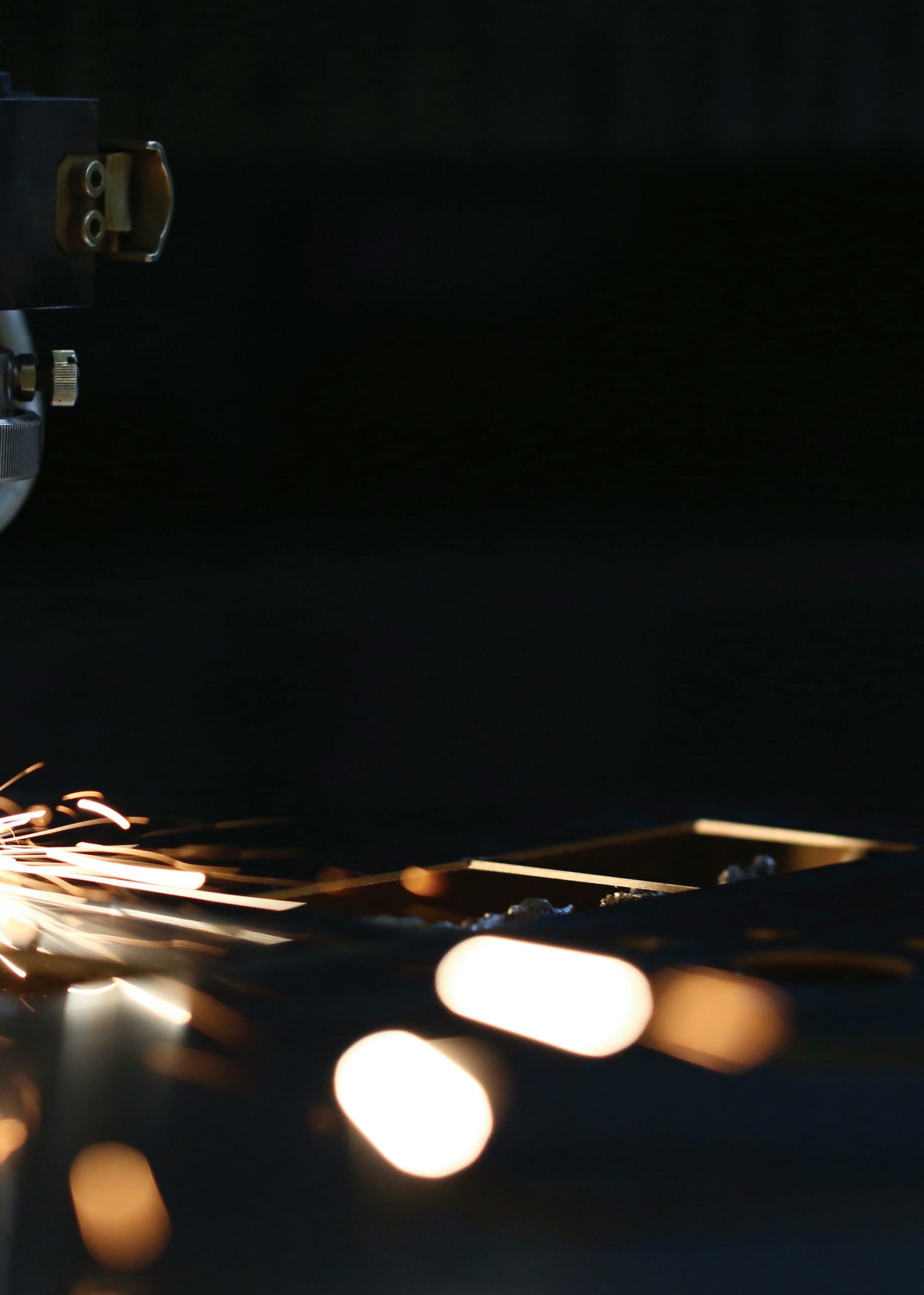

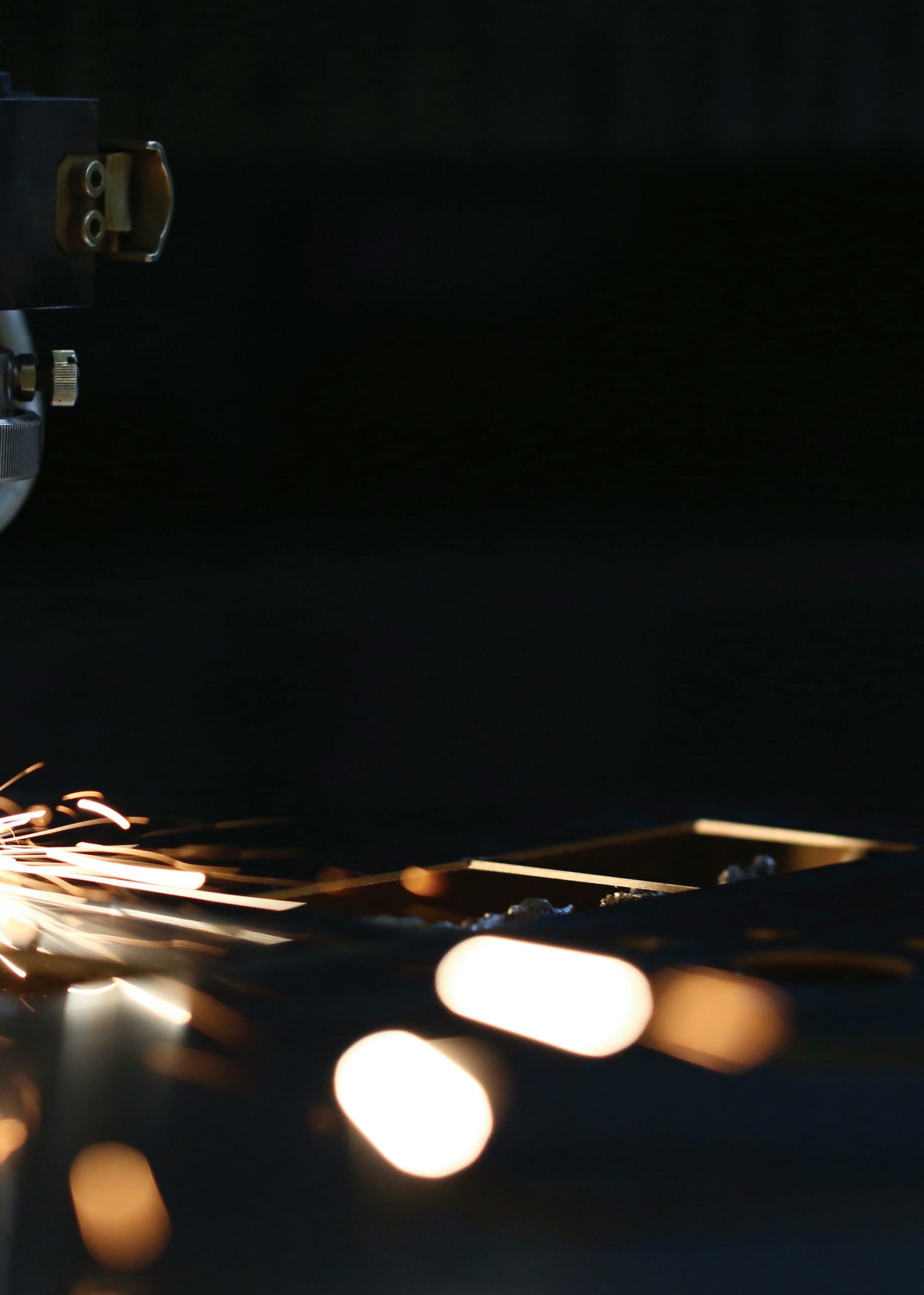

Innovation in action

What started as a small facility in Brooklyn, New York, has grown over the last 25 years to become a total of 350,000 square feet of high-tech manufacturing space shared between its locations in Wisconsin and New Jersey. “We currently operate three facilities,” shares Andy, “with the largest being the headquarters operations in Rice Lake. Across all three locations, we’re running more than 100 CNC machines because, at the end of the day, most of what we do to build guns is cut metal. We continue to invest heavily in automation for new products, while a portion of our resources is reserved for improving existing processes for current products. There’s a bit of a ‘new school meets old school’ dichotomy as well, because we have some old WWII-era Pratt & Whitney drills that we’ve rebuilt to newer specifications, including PLC controls and touchscreen interfaces. More recent technology also includes laser scanning to make incoming inspections more efficient and precise.”

Gun manufacturing is a loaded business, and contains a significant amount of innovation to keep up with safety standards and efficient usability, as we learn from Dan. “Despite the underlying technology of a lever action repeating rifle dating back all the way to 1860, we have found there’s still plenty of room for innovation to meet the needs of today’s outdoorsmen

and women. At any given time, we have design engineers actively working on products that might not see the inside of a store until five years later,” he shares.

Customer feedback

From exploring new metal finishes to developing automation, or even working with industry partners to develop entirely new calibers and cartridges, Henry places great importance on product innovation and invests heavily in the manufacturing capabilities needed to facilitate this process. Additionally, the business pays close attention to customer suggestions, and as their hunting needs evolve, so too does the company’s product line. “Quite often,” Dan continues, “new ideas come to us from our customers. We keep our ears to the ground on social media and other channels to see what people are asking for. We get emails and phone calls daily from our customers who

manufacturing-today.com 43

Henry Repeating Arms

want to let us know what they’d like to see in the next new Henry release. This feedback is priceless to us, and when we start seeing enough demand for a specific idea, we’ll start discussing it internally, do some market research, and start coming up with prototypes.”

Four promises

This attention to customer demand has enabled the company to produce industry-leading products, with one of the most popular recent releases being its X Models. “They’re a group of rifles and shotguns with a more modern look and feel. We’ve noticed that this range has attracted an entirely different audience than we’ve seen before in the lever action space. Most notably, the X Model rifles and shotguns feature durable synthetic furniture with integrated universal accessory mounting points, so customers can ‘dress up’ their firearm to meet their needs. For example, someone might purchase a Big Boy X Model in .357 Magnum and attach a silencer to make it incredibly quiet, or a flashlight for use in low-light situations and put a sling on it for convenience. With that, you have a versatile carbine that can be used for hunting in the morning and protecting the home at night,” Dan expresses.

What sets Henry apart from the other sellers is not only its dedication to excellent manufacturing processes, but also its commitment to quality. “We maintain four promises,” Dan highlights. “First, all the products are backed by a lifetime satisfaction guarantee, which is not found anywhere else in the industry. Second, our clients are guaranteed accurate and reliable firearms with craftsmanship and material quality that punches well above their price tag. Third, we offer the best customer service in the industry. Finally, every one of our rifles and shotguns embodies the company’s motto, ‘Made in America, or not made at all.’ While that may not be a primary driver for international customers, it’s a value that our customers take great pride in.”

Exclusive Feature 44

Henry Repeating Arms

The emphasis on customer satisfaction is rooted within the values of the company, which was instigated by Anthony’s passion for strong and lasting relationships. “When people ask me what business I’m in,” he says, “I often respond that I am in the ‘keep everyone happy’ business. Work is all about relationships, and that’s something that was instilled in me early on.

“Growing up, I worked behind the counter of my family’s law enforcement supply and gun store in Brooklyn, and that’s where I understood the importance of relationships in business. Despite now being a global company, I want to treat every interaction that someone has with our company as if it was a customer walking through the door of that little gun shop. Of course, I can’t respond to every single email or phone call myself, so then it becomes a matter of transferring that mentality to every one of our employees. It doesn’t matter if they’re a customer service representative answering the phone or a CNC operator; every employee knows the importance of people in what we do.”

Charitable work

For Henry’s leaders, part of what makes their niche work in manufacturing so rewarding, are the organizations that form its network. Anthony takes a moment to acknowledge the dedication that the company’s supply chain has invested in the company’s success. He also recognizes that a large number of nonprofits around the country depend on Henry’s support, and this impact is nothing short of priceless. “I’ve had the pleasure of traveling the country to meet those whose lifework is leading some of the largest and most impactful non-profits that help support their deserving constituencies. From the law enforcement officers that put their lives on the line daily to serve their community, or the men and women that have answered the call of duty to serve their country, or the EMS personnel that work tirelessly to save lives every single day, Henry Repeating Arms is proud to help the cause.”

manufacturing-today.com 45

This then triggers the topic of social responsibility. Another way the business celebrated its 25th anniversary, is through a surge of support to local and national communities. Last year, Anthony pledged one million dollars to a wide variety charitable groups, including children’s hospitals, military veterans, law enforcement and first responder organizations, and many others. “To achieve this hefty amount, we did something special. We created and donated a limited-edition series of 1000 Golden Boy Silver Anniversary Edition rifles, which raised the money for us to distribute across the categories we are proud to support.”

Positive impacts

Henry Repeating Arms is known throughout the industry for these endeavors, which are run through the charitable branch of Henry called ‘Guns for Great Causes.’ “I started this to help financially support individual families of sick children that face immense medical bills for lifesaving treatment, and it has grown in scale year over year,” Anthony says. “Now, beneficiaries of our fundraising efforts still include those individual families, but we’re also helping support wildlife and habitat conservation agencies, shooting sports and hunter education organizations, and national and grassroots groups that advocate for Americans’ right to keep and bear arms. These groups mean a lot to me personally and professionally, and I am forever grateful to our customers and employees who enable us to make these positive impacts.”

As America’s debate on the Second Amendment continues to gain traction, it is businesses like Henry Repeating Arms that are ensuring rifles are safe and reliable, and from what we have learned, securing this guarantee depends on industry-leading manufacturing. “Every day, we try to take one more step toward being the best company, not just in the lever action space but in the overall firearms industry. We have a great team

of incredibly talented people who help me sail the ship to get it done,” says Anthony.

“Five years from now, we’ll be offering our customers even more choices, our investments in increased capacity through automation and workflow optimizations will be firing on all cylinders, and our company will be right on the tip of everyone’s tongue when thinking about a quality, American-made firearm.”

In closing, Anthony shares that when he reflects on the last 25 years, he believes gratitude is at the heart of the company’s success. “I am so thankful for our hardworking employees, our loyal customers, and great industry partners in our Henry retailers, distributors, vendors, and others. Without them, this achievement would not have been possible.” ■ www.henryusa.com

Exclusive Feature 46

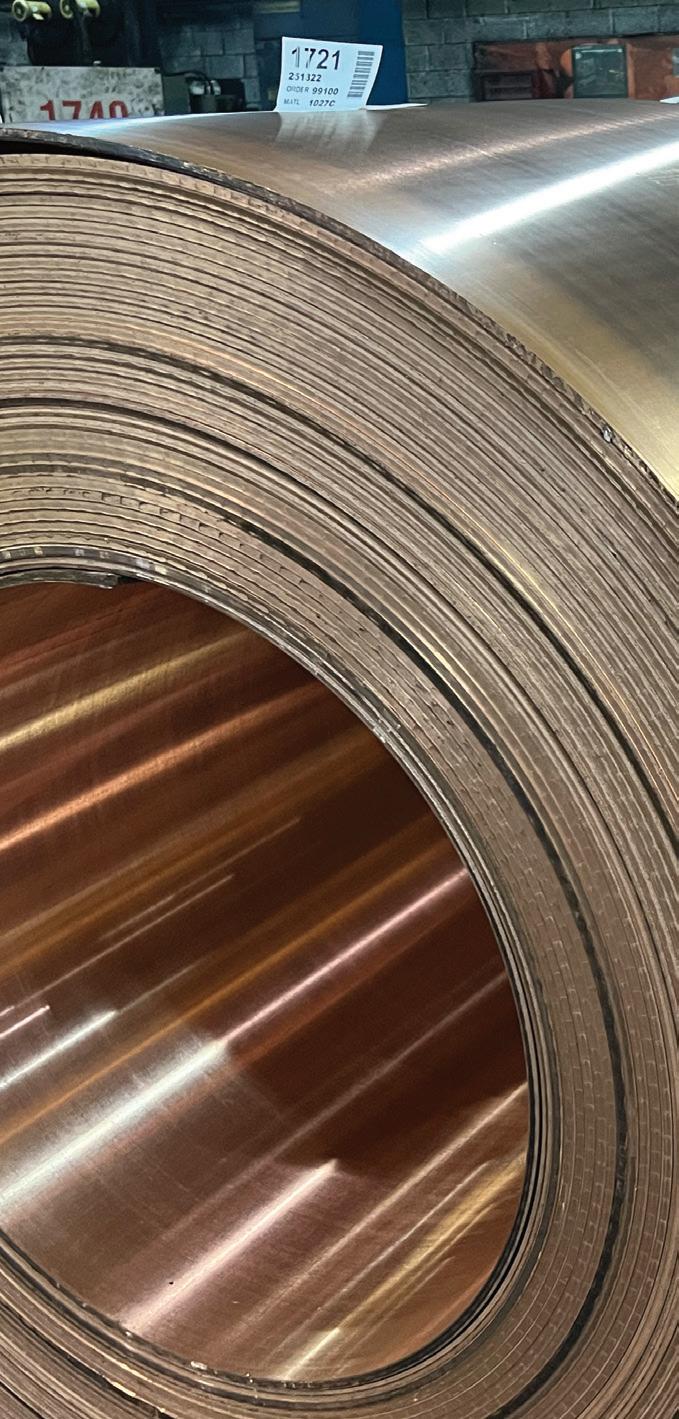

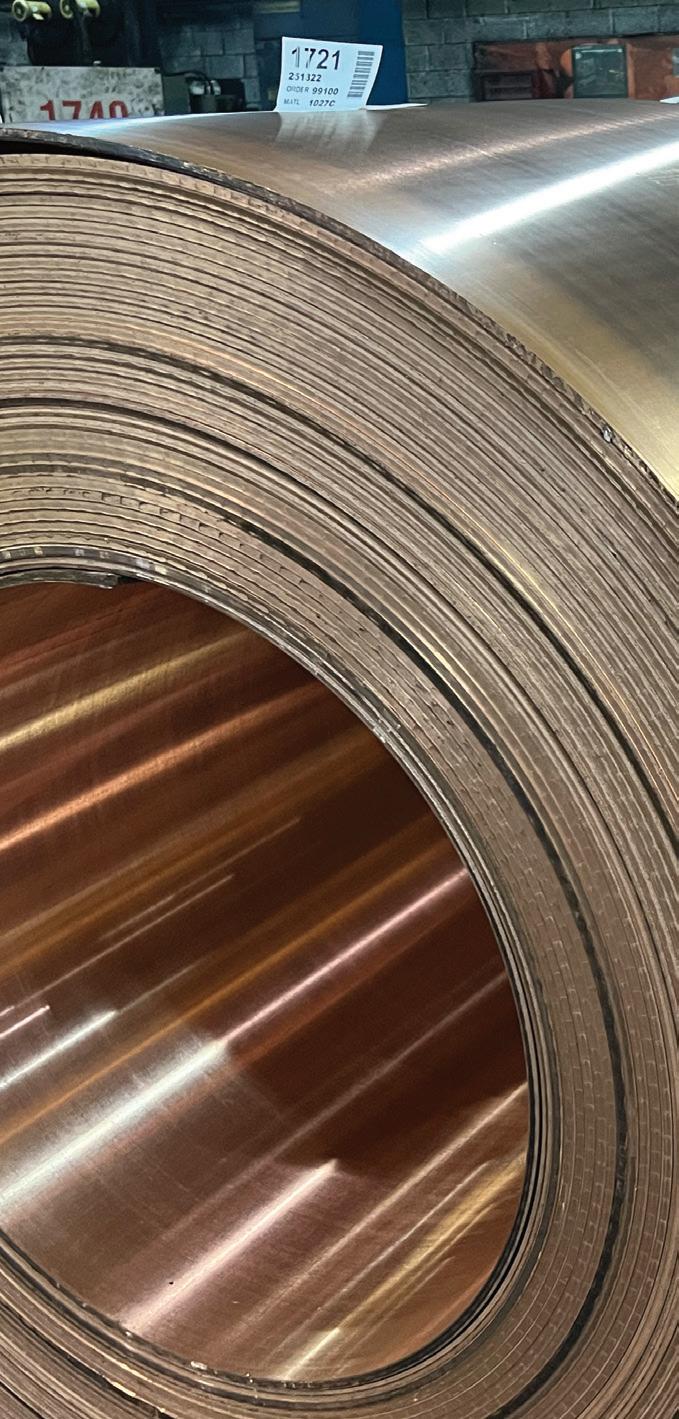

Schnitzer Steel is Recycling Metals for a Low Carbon Future

For more than a century, Schnitzer has developed robust networks to collect, process and deliver recycled metals to meet the needs of virtually all economic sectors

Schnitzer Steel is one of North America’s largest manufacturers and exporters of recycled metals with operating facilities located in 25 states, Puerto Rico, and Western Canada.

The Company began operations in 1906 in Portland, Oregon, and although the size, scale, and global reach of Schnitzer’s business is very different than it was more than a century ago, the Company’s core mission remains the same: recycling and resource conservation.

Schnitzer operates regionally based hub and spoke models throughout its North American footprint which enable efficient logistics and materials management of ferrous and nonferrous metals via totes, containers, trucks, railcars, barges and ships. The Company’s operations advance regional circular economies by ensuring valuable materials are kept out of the landfill and are redesigned into new products.

“We’ve been in the recycling business a long time; way before it was fashionable,” explains

Jim Devine, Schnitzer’s Vice President of Nonferrous Purchases and Sales. Devine

Jim Devine, Schnitzer’s Vice President of Nonferrous Purchases and Sales. Devine

Exclusive Feature 48

Schnitzer Steel manufacturing-today.com 49

In January 2023, Schnitzer was named the most sustainable company in the world by Corporate Knights

“ “ “ “ Exclusive Feature 50

leads the Company’s team responsible for engaging directly with customers and suppliers to purchase, process, and recycle nonferrous metals. “Early on we recognized the enormous potential to add value to the economy by retrieving materials set for landfill and innovating ways to ensure they are used again,” he added. “Our regional operations support the supply chain and reduce the carbon footprint of manufacturing activity.”

Schnitzer’s integrated operating model encompasses 54 metals recycling facilities, including seven metal shredders, 51 Pick-nPull auto parts recycling and retail stores, and a state-of-the-art electric arc furnace steel manufacturing operation in McMinnville, OR which sources much of its recycled ferrous metal feedstock from the Company’s own operations to produce finished steel products like rebar, wire rod and other specialty items. Through Schnitzer’s growing recycling services portfolio, the Company also provides important sustainability and materials management to national manufacturing and retail customers in nearly every state in the US

“The beauty of having a broad but regionally focused footprint is that it allows us the unique ability to provide door-to-door service for our customers wherever they are,” explains Devine. “Our fleet includes everything from 4x4 containers to barges and rail cars, and we can offer a variety of pricing options to our suppliers. We aim to be the recycler of choice by handling all of our customers’ material and ensuring it’s recycled in accordance with environmental and regulatory requirements.”

A Responsible Partner

Schnitzer’s history of success in the industry is evidenced by numerous awards and accolades collected over the course of decades for leading performance in sustainability, ethics, transparency, responsible operations, and employee engagement. In fiscal 2022, Ethisphere® Institute recognized Schnitzer as one of 2022 World’s Most Ethical Companies®

for the eighth consecutive year, Newsweek recognized Schnitzer as one of America’s Most Responsible Companies of 2022 for the third consecutive year, Schnitzer was re-certified as a Great Place to Work® for the second consecutive year. The Company received the Sustainable Markets Initiative’s Terra Carta Seal, was recognized by the CDP for performance on climate and water and rated by EcoVadis for performance in sustainable procurement.

“We pride ourselves on our reputation for ethical business practices as we partner with customers in 25 countries on five continents,” said Devine. “It’s an integral part of our culture and our customers as well as suppliers appreciate these awards and recognitions as representative of our Company values.”

Most recently in January 2023, Schnitzer was named the most sustainable company in the world by Corporate Knights, a leading media and research organization focused on corporate sustainability performance, as part of their Global 100 List. This important recognition reveals a growing spotlight on Schnitzer’s products and services as strategic solutions for companies, industries, and governments focused on carbon reduction. It also highlights the Company’s role in advancing metal-intensive technologies such as electric vehicles, wind and solar technology, and battery storage systems.

Schnitzer Steel manufacturing-today.com 51

Meeting the Demand for Recycled Metals

Schnitzer’s longstanding relationships with customers and suppliers across the world reflect the Company’s strong service culture. Its product offerings, logistics solutions, and pricing strategies meet the needs of the Company’s diverse customer base, which ranges from the general public to contractors and national account holders. In the commercial sense, Schnitzer takes a partnership approach by assessing a company’s supply chain.

“Customers are increasingly focused on the environmental impact of their supply chains and are looking to companies like Schnitzer to both shorten the supply chain

and help lower the carbon intensity of finished products and technologies,” explained Devine.

Using one ton of recycled metals as compared to corresponding virgin material in the manufacturing process can result in up to 58 percent less CO2 emissions for steel, 65 percent less CO2 emissions for copper, and 92 percent less CO2 emissions for aluminum, highlighting the inherent value in Schnitzer’s recycled products and offerings. In fiscal year 2022, Schnitzer sold 4.6 million tons of recycled ferrous metals, 687 million pounds of recycled nonferrous metals, and 465,000 short tons of finished steel products made from recycled ferrous metals.

Increased demand for the products Schnitzer offers is connected to the growth in manufacturing in the US and globally, among

Exclusive Feature 52

other drivers, to produce technologies associated with decarbonization like electric vehicles and renewable energy infrastructure. In the spring of 2022, the Company acquired Encore Recycling and Columbus Recycling in the US southeast, bringing its regional footprint to 24 recycling facilities, including its first metal shredder in the region.

“These acquisitions support a growth strategy to increase our ferrous and nonferrous volumes and provide recycled metals to manufacturers,” said Devine.

In support of the Company’s growing recycling services offerings, in November 2022 Schnitzer acquired ScrapSource LLC, a materials management company based in Dallas, Texas which focused on providing

metals recycling management services and solutions to manufacturers, fabrication facilities, and service centers across North America. The addition of ScrapSource offers opportunities to scale Schnitzer’s national sourcing platform, enhance and expand the Company’s services to national manufacturing and retail customers and increase supply flows within the Company’s operating regions.

Looking to the Future

When looking to the future for Schnitzer, Devine sees the Company building on recent growth to attract new customers. He points to continued investments in Schnitzer’s advanced metals recovery technologies, which enable the Company to diversify its product offerings and enhance the ability to competitively meet the needs of domestic and international customers.

“I’d like to see Schnitzer continue to expand our footprint into new regions and become the one-stop solution for manufacturers,” explains Devine. “From a technology perspective, our advanced metals recovery systems allow us to extract more nonferrous metals like copper and aluminum from metal shredding activities, meet global metal content and quality requirements, and create product optionality for our customers. On the services side of our offerings, we bring transparency to the process of collection and management. We also offer enhanced data and reporting options for our customers on the environmental benefit of introducing these recycled materials back into the marketplace as raw materials to produce new products. Together this is a powerful combination with direct connection to the circular economy and a more sustainable future.” ■

Jim Devine is Schnitzer’s Vice President of Nonferrous Purchases and Sales. Contact Jim directly by emailing jdevine@schn.com www.schnitzersteel.com

manufacturing-today.com 53

Schnitzer Steel

Exclusive Feature 54

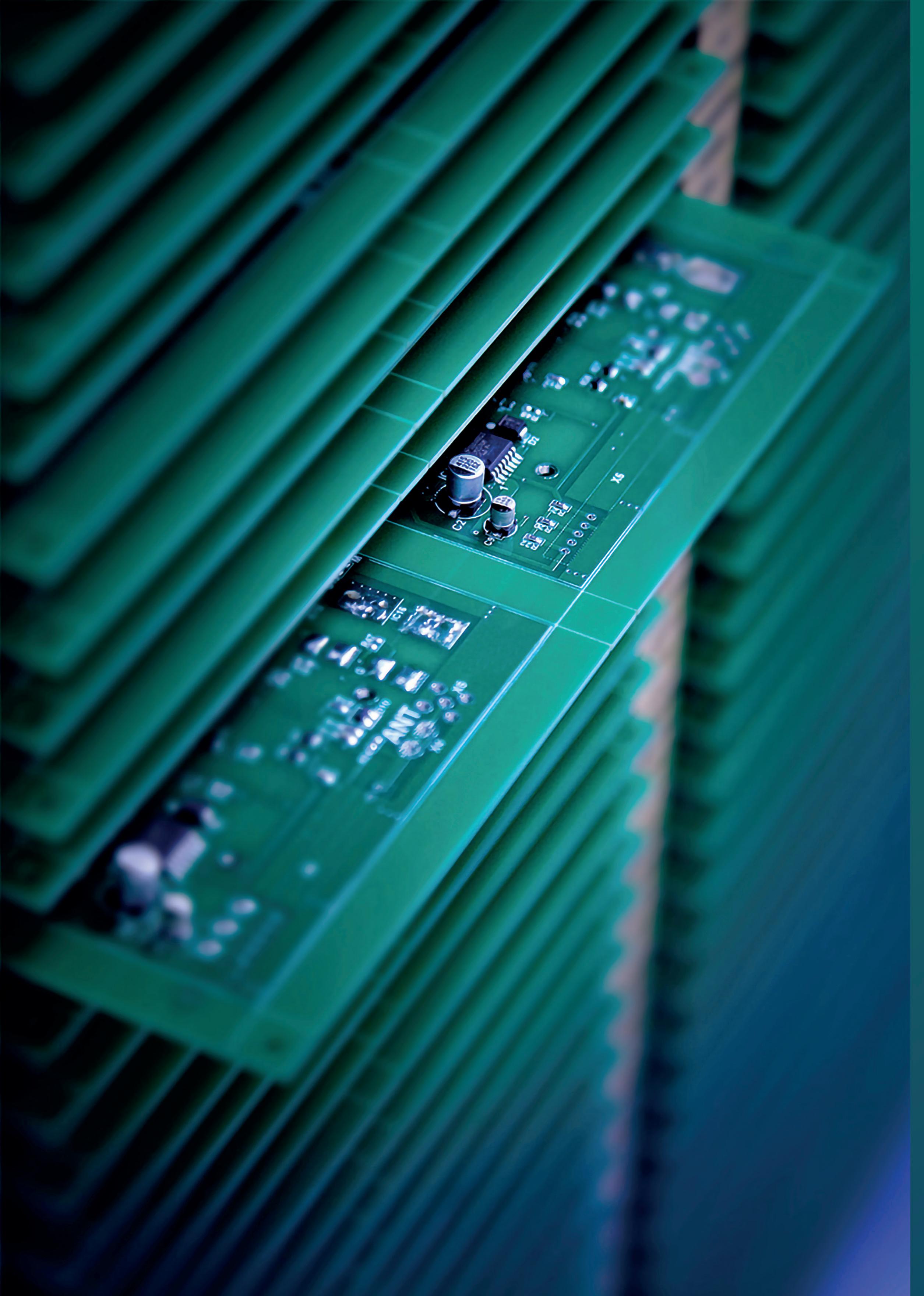

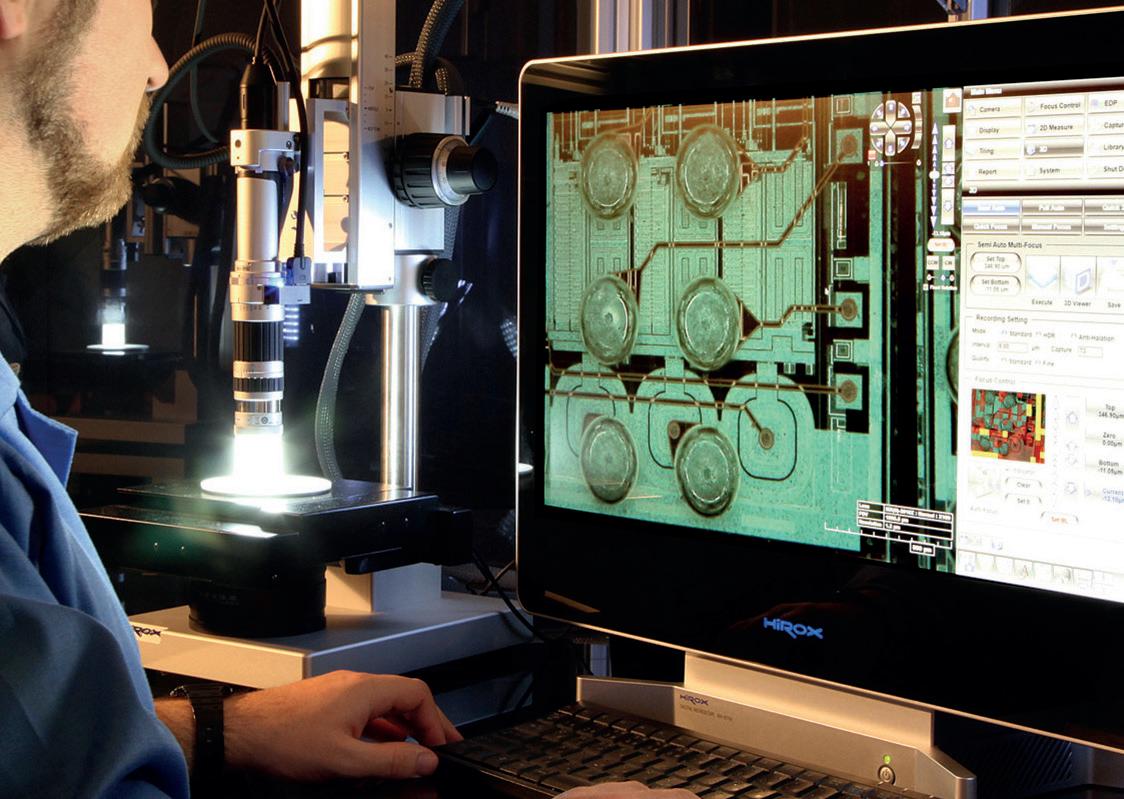

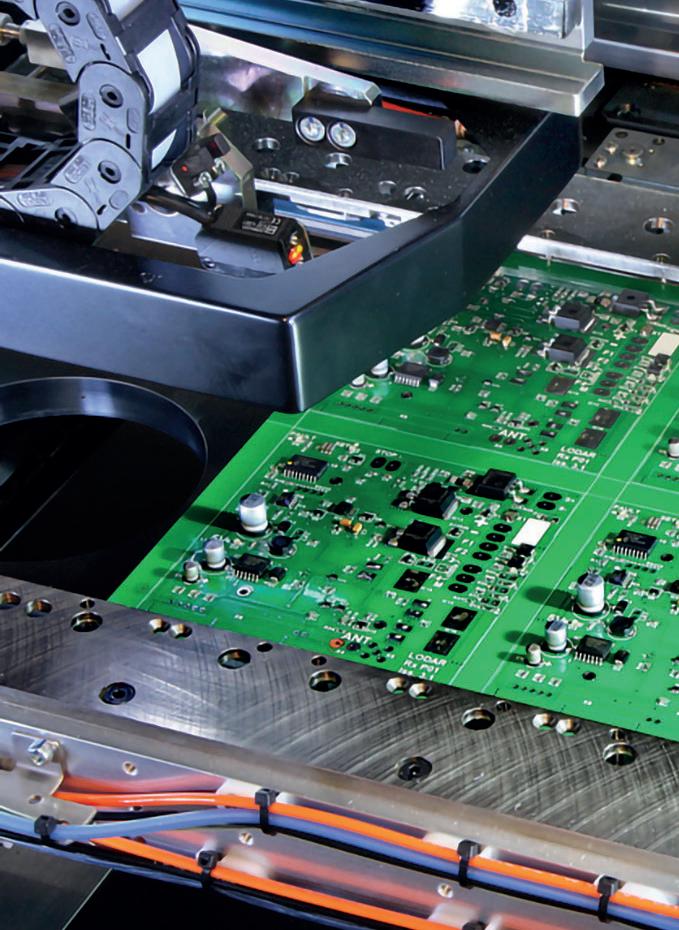

ELECTRIFYING FUTURE An

Braving the new digital world with TechPoint

There is no mistaking that the world is becoming an increasingly digital space. Two-letter acronyms abound: AI, VR, EV, and so on. The digital economy feels like a tangible prospect now. We have already surpassed the dates that Marty McFly went back to the future (2015) and Rick Deckard stalked the gloomy, dystopian streets of Ridley Scott’s Blade Runner (2019). We are living in a brave new world.

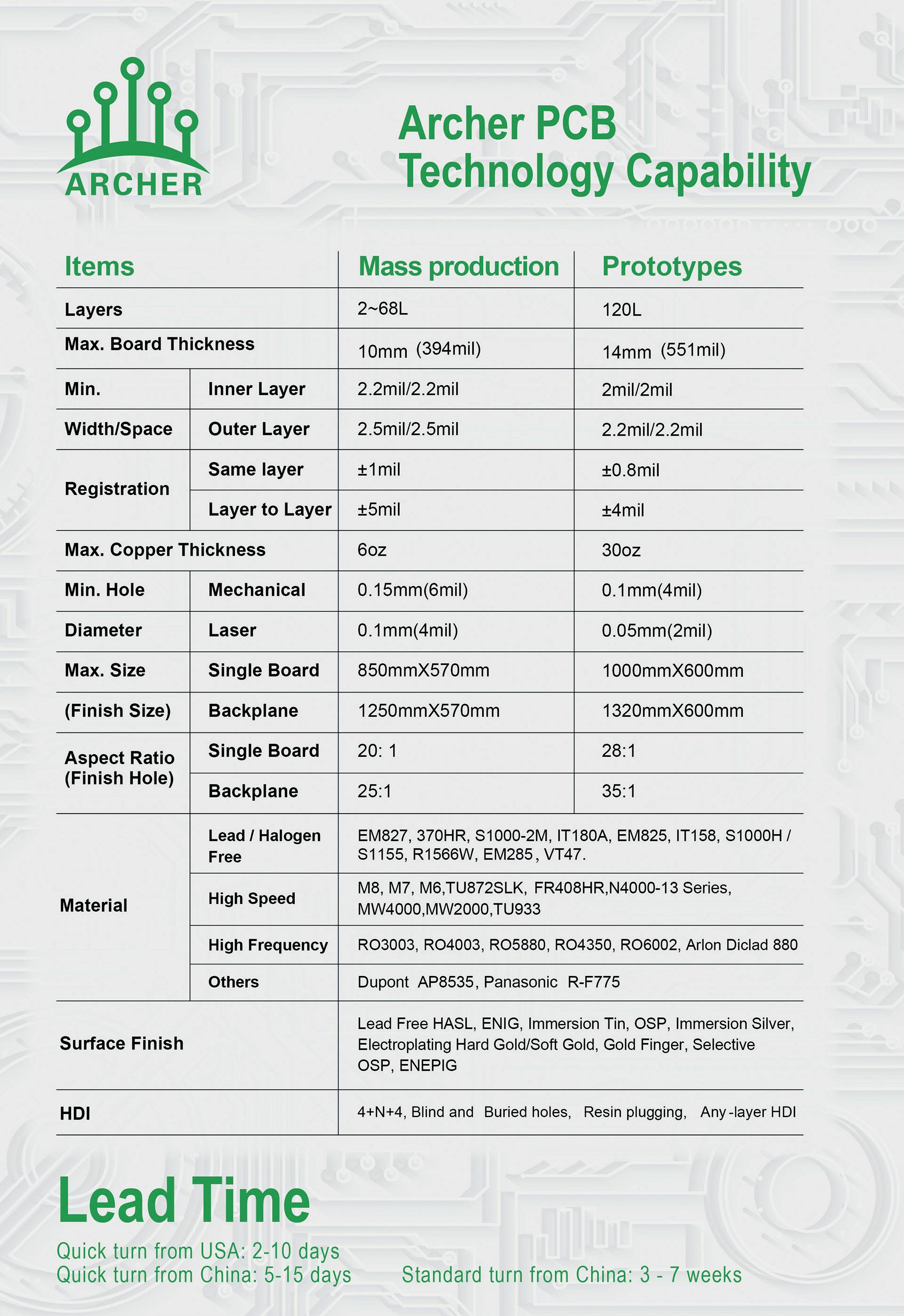

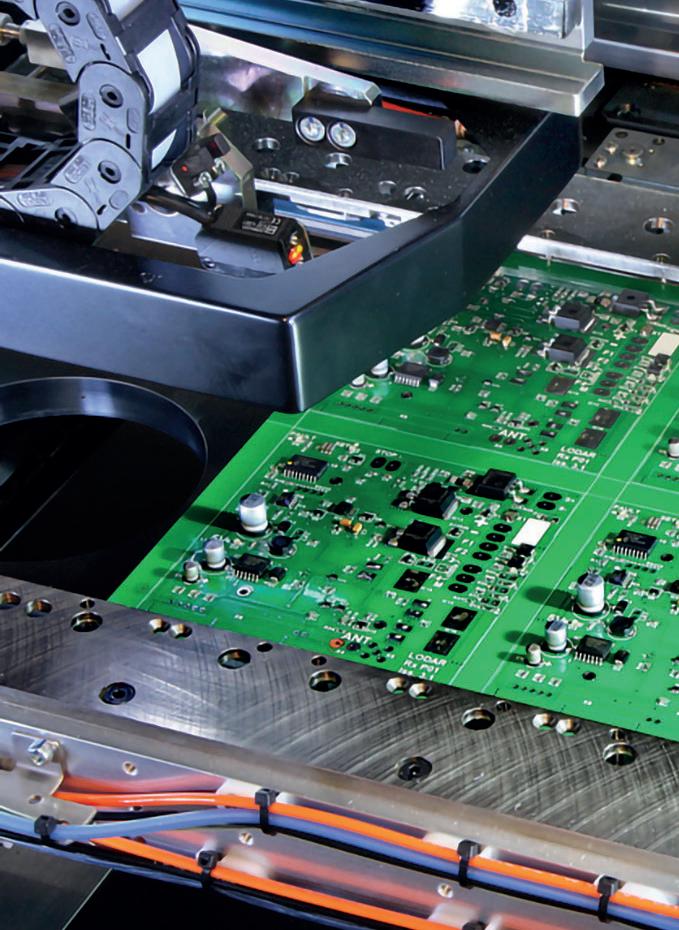

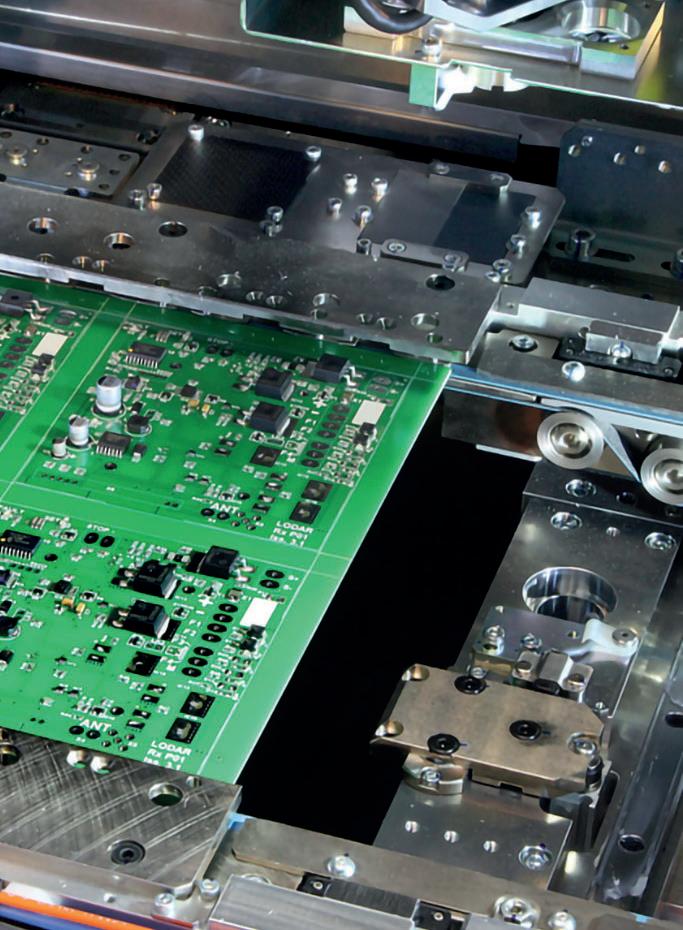

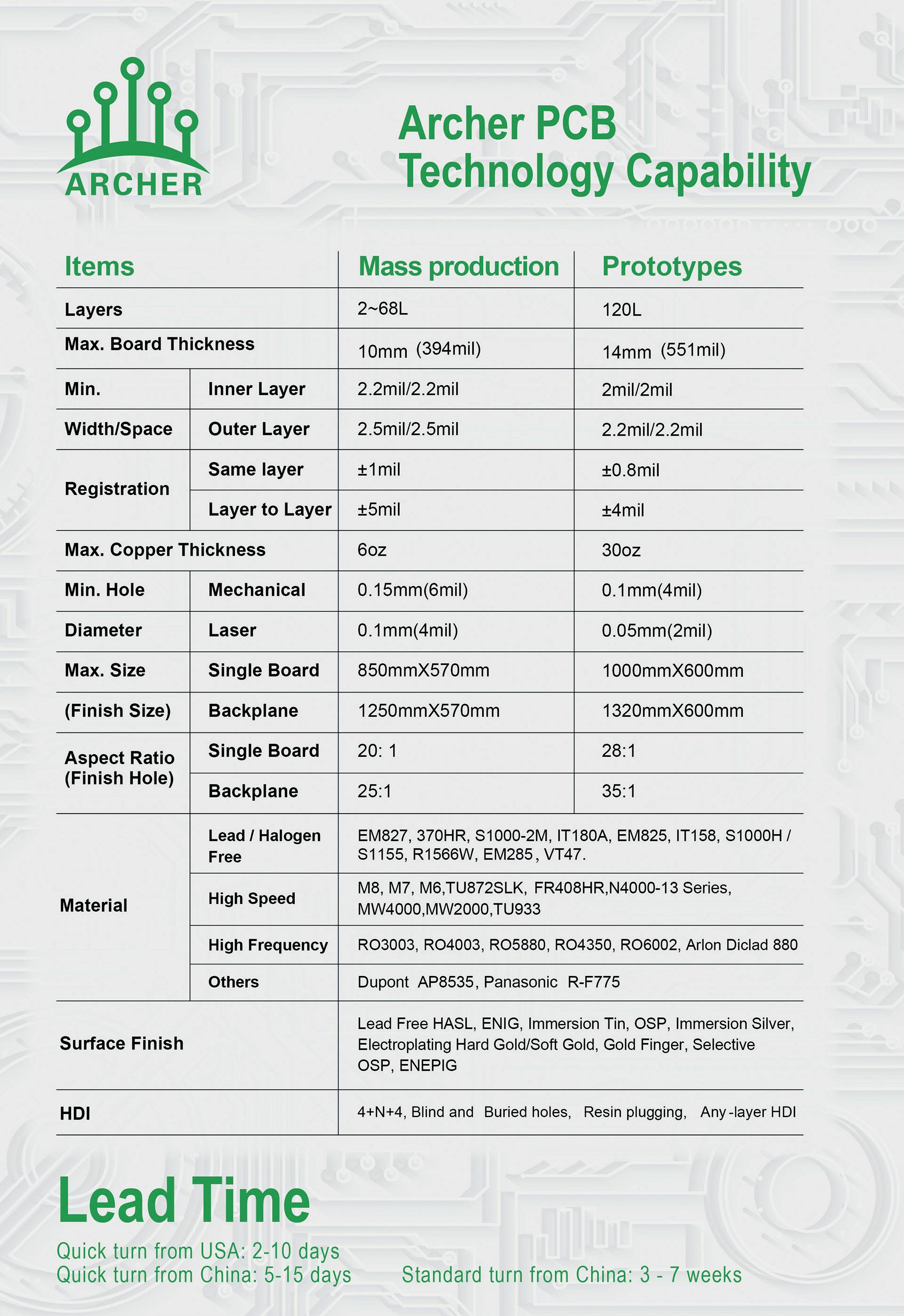

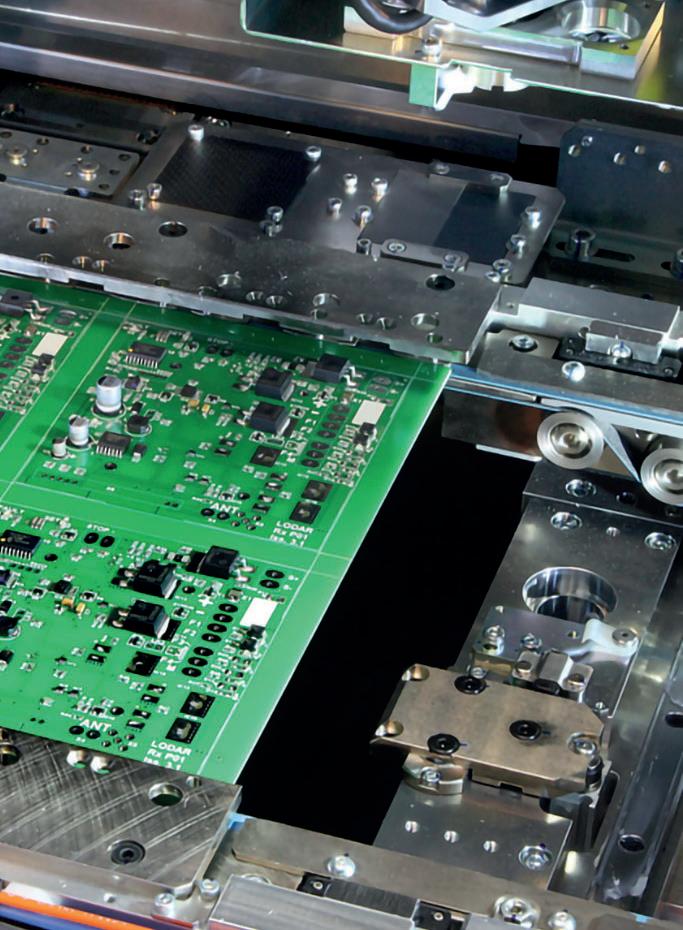

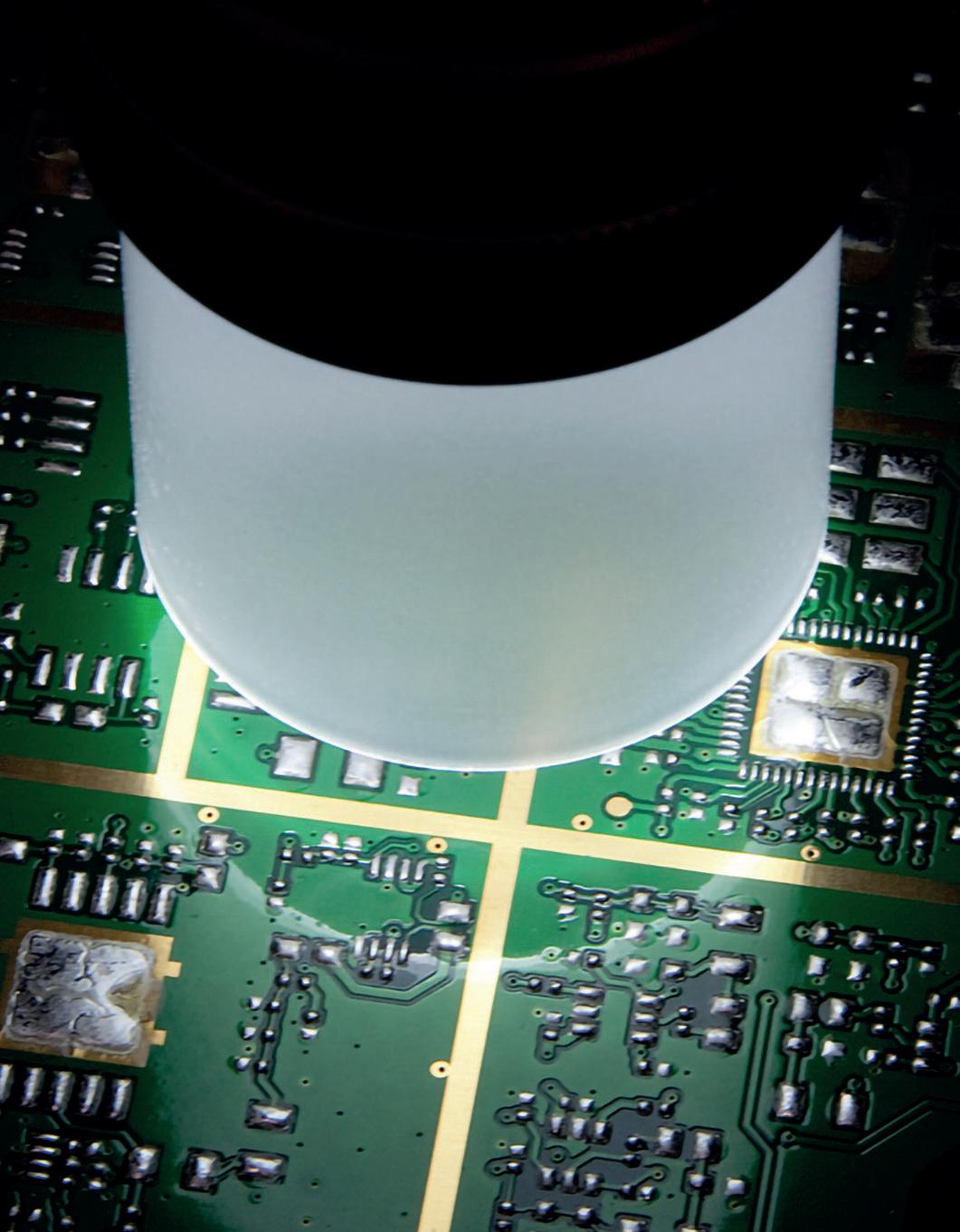

And the proof is in the data. For instance, in the last two years alone, the acceleration of our increasingly digital landscape has stimulated unprecedented growth in the demand for electronics and electronic components across the world. An explosion of new products – cameras in doorbells supported by phone apps, next-generation gaming consoles right the way through to electric cars – have elicited predictions of the global electronics market growing from $484 billion in 2021 to a staggering $541 billion by the end of 2022. New

applications supported by Edge Computing are facilitating faster decisions by the user, and developments in manufacturing techniques means smaller, more complex printed circuit boards (PCBs) can be built, further creating new opportunities.

When we consider the geopolitical backdrop of the past year, booming figures such as these are made even more impressive. Indeed, since the brusque arrival of Covid-19, global supply chains have been placed under extreme pressure; the entire end-to-end network, at certain moments, appeared to be close to breaking. Material shortages and the scarcity of materials led to many manufacturers struggling to meet frantic, rising demands. But companies – and, more specifically, those behind them – pushed through.

In reality, this was a long time coming. While the pandemic brought its own tensions, it also exacerbated many preexisting issues, including an excessive dependence on outsourcing an array of manufacturing

TechPoint manufacturing-today.com 55

◀ Group CEO Gary Mitchell

operations to cheaper overseas alternatives and over-reliance on justin-time production means. With the ongoing war in Ukraine and mounting tensions between China and Taiwan, further disruptions to global supply chains seem evident – uncertainty has become the new normal; that much is certain.

Competitive edge

Helping many on this Homerian journey of hardships is TechPoint, a unique end-to-end supply chain consultancy and electronics manufacturer. As our recent conversation with Group CEO Gary Mitchell made clear, within the context of fragile supply chains and demand outpacing supply, Original Equipment Manufacturers (OEMs) are currently placing a special emphasis on recalibrating their supply chains: sustainability, efficiency, and resiliency are three cornerstones that must be recognised as we approach Industry 4.0 and a future that will no doubt be burdened by similar geopolitical difficulties.

“The electronics and technology sector is currently experiencing a period of mass innovation and change,” begins Gary. “Buzzwords like Industry 4.0 and

Internet of Things (IoT) show evidence of the revolution that is currently going on.”

What does that mean for the industry?

“Most sectors are showing an increased rate of New Product Introduction (NPI),” explains Gary. “We are seeing shorter product life cycles in all sectors and as a result we are seeing a faster rate of NPI released to the market.”

Technology, internet, global communication. All these evolving factors drive market change. As Gary makes clear, the times are a-changin’ with unprecedented speed: “Many of our customers’ Research and Development (R&D) teams are dedicated to this technological evolution of sorts; it keeps them in a competitive space as they launch innovative products and utilize new technologies within a challenging environment.

“R&D teams are all striving for that competitive edge,” he goes on. “If you look at our capabilities at TechPoint, we are ultimately a service provider – and that means we help companies focus on their core business. They can outsource or employ us as a partner for some of their key services (the design process, testing components, sourcing alternative components, finding applications, and so on).”

Exclusive Feature 56

Ensuring partner organizations thrive in a complex global marketplace, TechPoint leads from the front with four Centers of Excellence, all providing clients best-inclass services in supply chain management, rapid prototype development, and specialist electronic contract manufacturing.

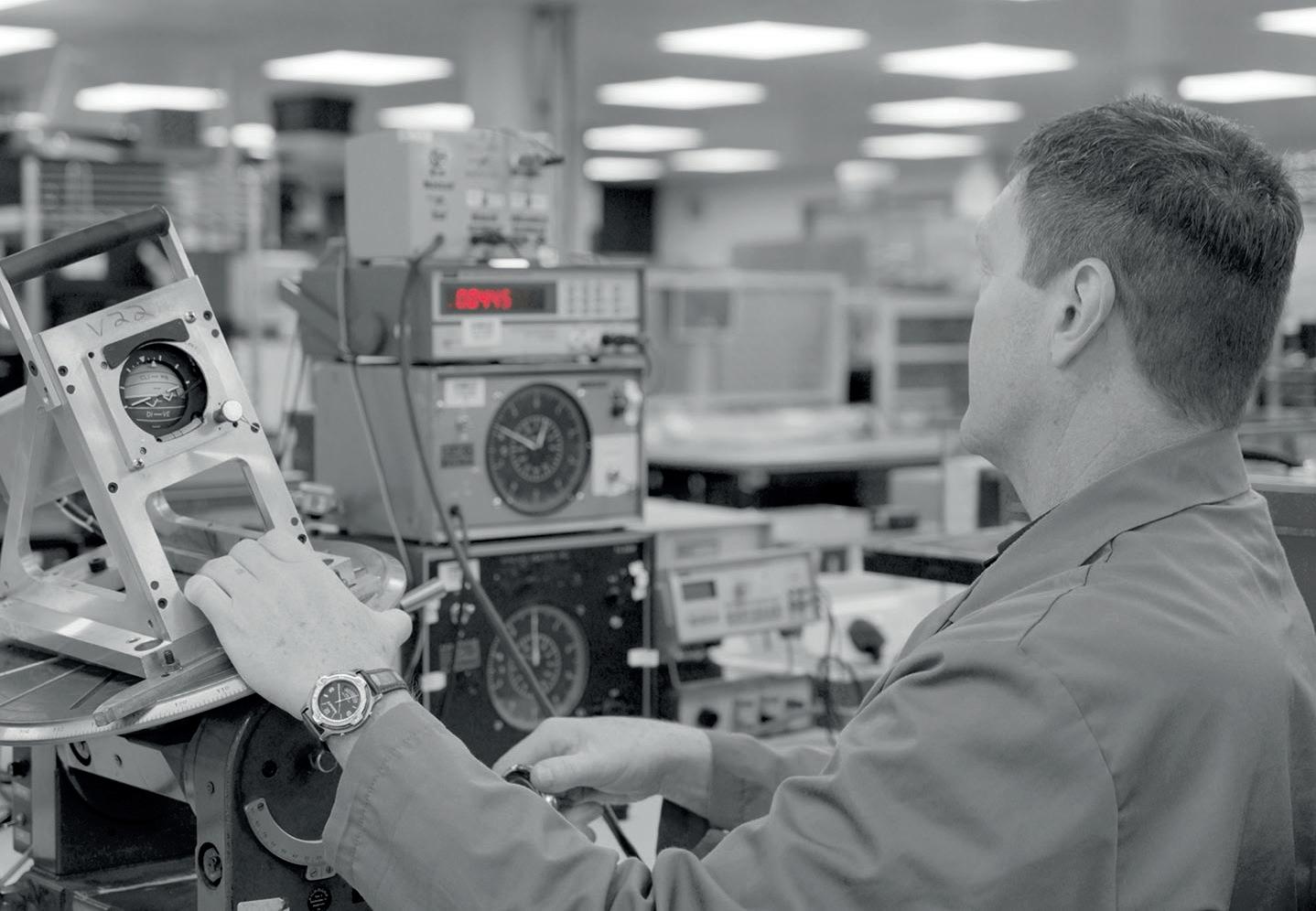

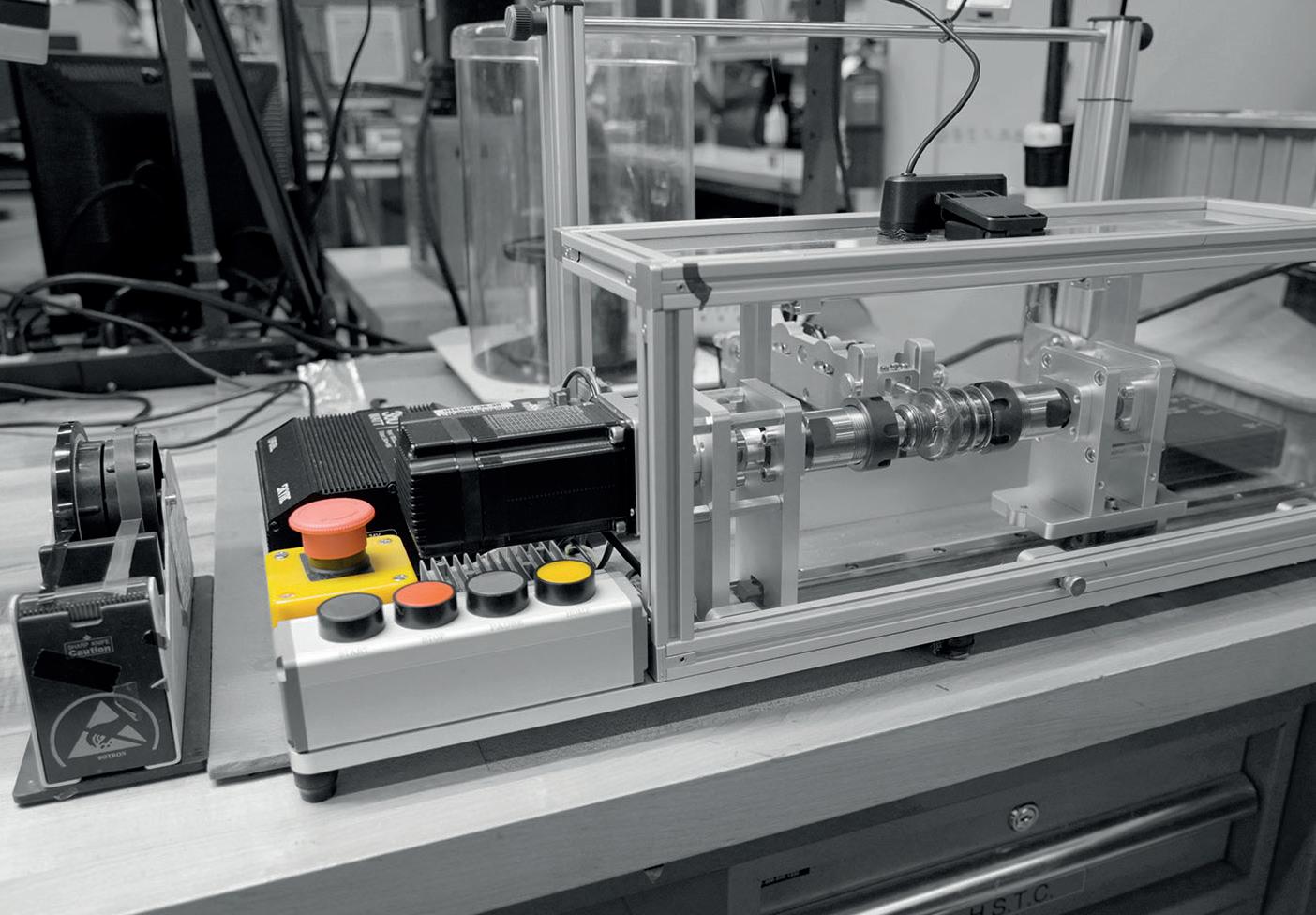

Increased synergies

Three TechPoint tenets – scale, flexibility, and unrivalled customer service – are lived by a team of experts delivering bespoke technical solutions, utilizing tomorrow’s technology today. As a group, TechPoint and its subsidiaries (Vanilla Electronics, Bela Electronics, Golledge Electronics, and Interconics) work to supply value to some of the leading multi-national electronics businesses in the audio, aerospace, medical, automotive, defense, and industrial sectors.

“As a proactive consultancy with extensive market knowledge and industry connections, we can help customers when they launch new products in their respective markets,” says Gary. “Though

innovation is often driven by customers, we are on hand to carry that sense of progress forward, doing as much as we can by coming up with plenty of creative ideas. But we are also innovating our own processes, breaking new ground with solutions for engineering, assembly, and supply chain grievances.”

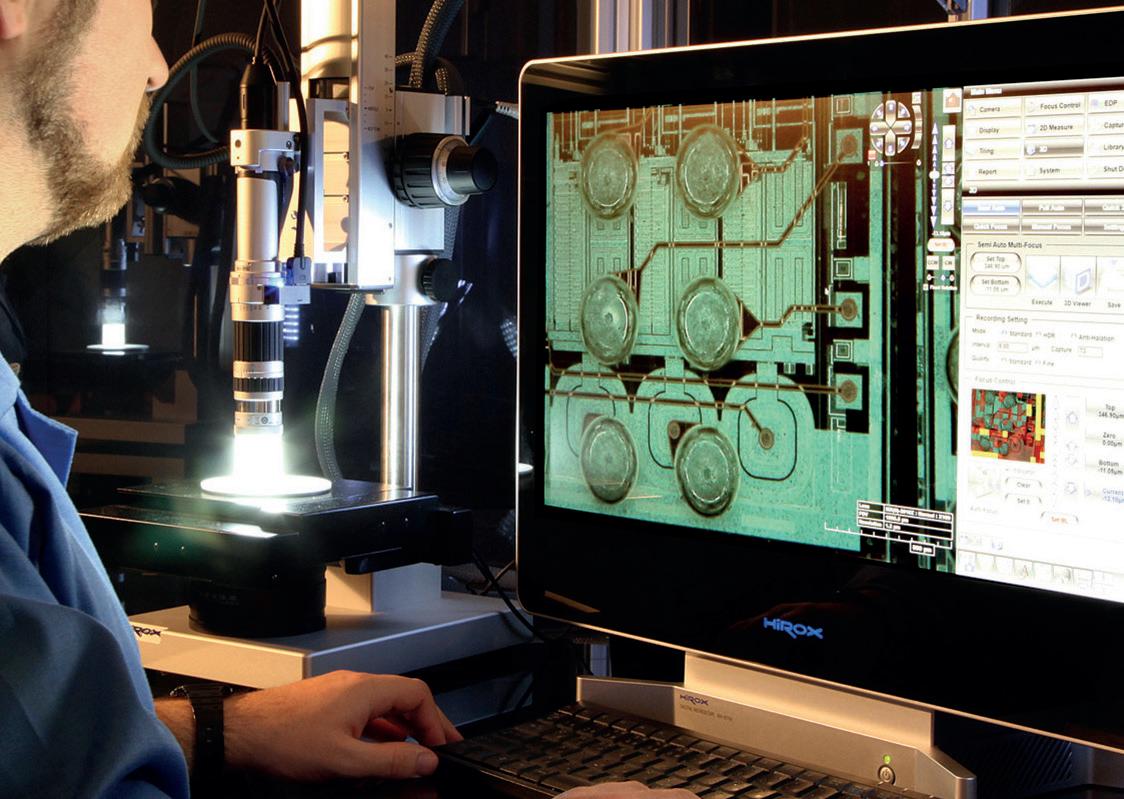

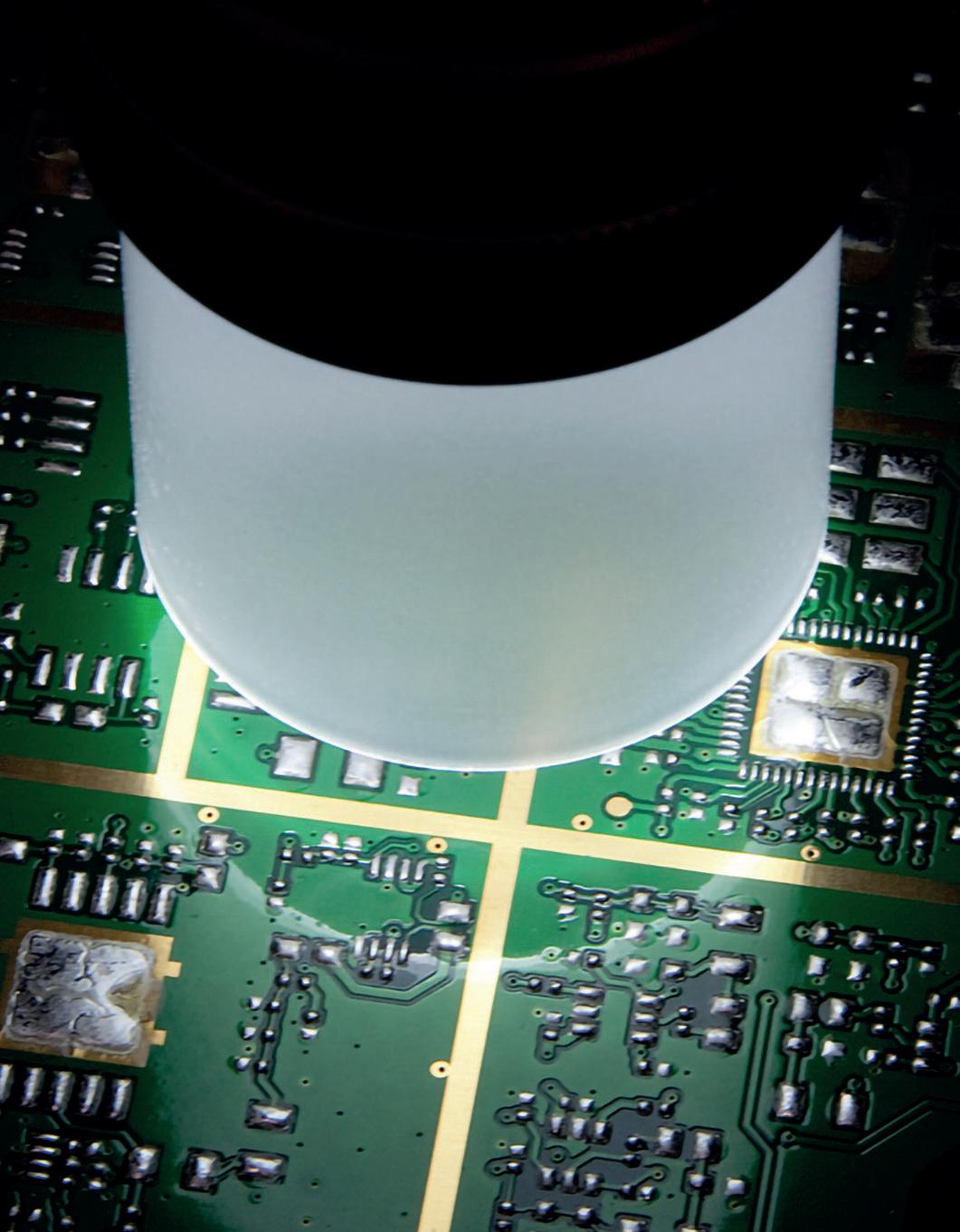

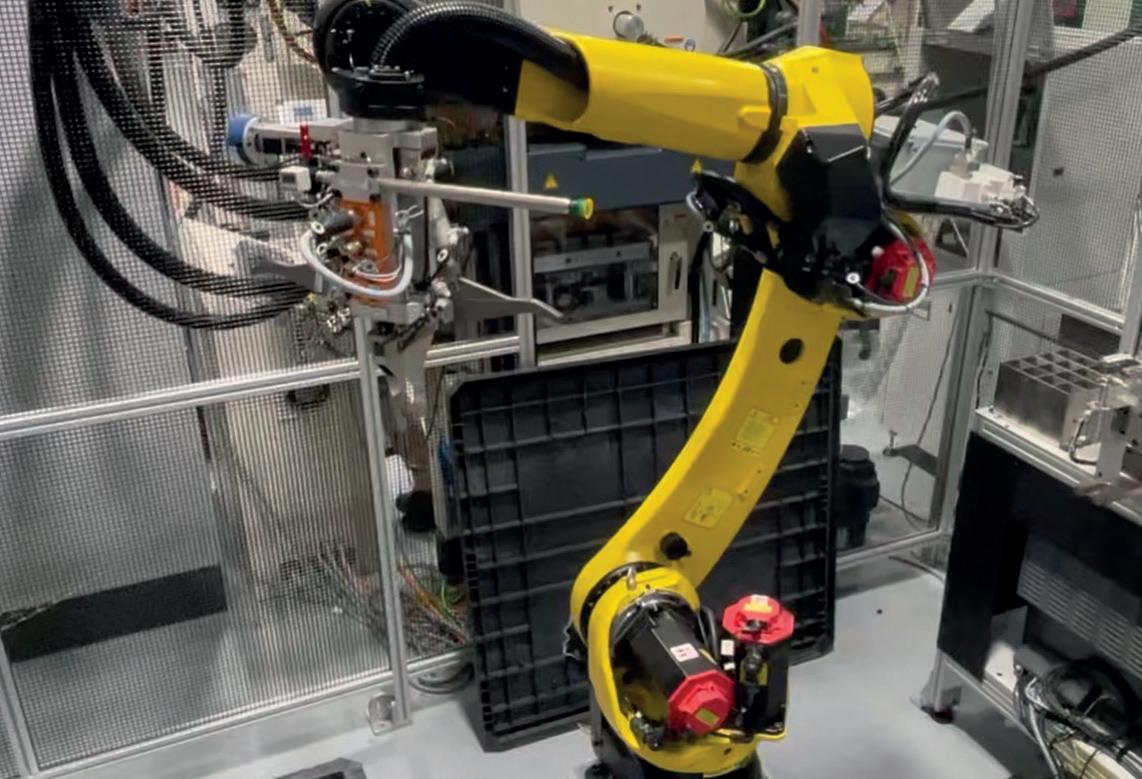

TechPoint has grown a lot in the last year. Each month, it is morphing and evolving into a holistic consultancy with a deep knowledge of technology roadmaps to better pinpoint the shrewdest investments companies can make. In fact, TechPoint continues to invest and often makes specific investments in technology needed by customers. “For example, we have invested in 3D X-ray and optical fiber splicing as well as several soldering robots which improve quality and efficiency for our customers. Though this is not necessarily new technology, it is a new service and we are innovating in terms of how we are applying it for our customers.”

This follows the group’s recent rebrand, where it consolidated the various entities under its roof as one prism of TechPoint companies. “We wanted to

We wanted to reinforce the group as a technical powerhouse with strong capabilities, experience, and skills within the electronics field TechPoint 57

“ “ “ “