Balanced

Technology

A data-driven, collaborative way of working is on the horizon for architects

Issue 122 - 2022

Human resources Is your business failing when it comes to diversity and inclusivity?

Affordable housing Shipping containers could hold the answer to the affordable housing problem

Davitt Design Build is taking creativity to a new level

elements

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Director Tom Vince Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Daniel Baksi, Alex Caesari, Danielle Champ

Editorial Administrator Amy Gilks

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork Administrator Rochelle Broderick-White Sales Director Alasdair Gamble

Project Directors

Philip Monument, Joy Francesconi

Head of Client Services Callum Arneil

Head of Content Management Adam Blanch

Head of Global Media Programs Mark Cawston

Project Managers Lewis Bush, Jo-Ann Jeffery, Ben Richell, Laura Thompson

Content Managers Mark Cowles, Jeff Goldenberg, Michelle Hernandez, Anthony Porretto, Markus Wellington

Media Sales Executives

Mike Berger, Reid Lingle General Manager Florida Division Ryan Finn Marketing Manager Matt Bone Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

US Office

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Hello and welcome to the October issue of Modern Home Builders. We have given the magazine a new look and I am keen to hear your feedback on the revamp. What do you think?

While the design may have changed, my focus on quality content remains and this month we cover a range of topics, from technology to homes created from shipping containers. This latter trend is something I have been increasingly seeing on Instagram and so I am glad to be including a feature on the subject, as it does seem to hold a possible solution to the affordable homes shortage. Our author says that they can be used to create ‘easy-to-build, modular masterpieces’ – a bold statement. Check out his argument on page 16.

Our cover story on Davitt Design Build shares insights from Vice President, David Whitney and Designer Mary Rae on how they use a team approach to deliver their extraordinary projects. Turn to page 20 to learn more.

Follow modern home builders at

Is your business failing diversity and inclusivity? A data-driven, collaborative way of working is on the horizon for architects Shipping containers could affordable housing problem Davitt Design Build is taking creativity to a new level elements Balanced Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

LH@finelightmediagroup.com

Libbie Hammond Editor

@MHB_mag modern-home-builders-magazine

Welcome modernhb.com 1

Inside this issue Software Affordable Housing Technology Human Resources4 12 8 16 Contents 2

home builders

Greater Austin Builders

Cole Construction

Kent Shaffer Homes

Cover Story Davitt Design Build

Celebrity Builders Wellborn Cabinet, Inc 54 44 28 48 36 20 modern

modernhb.com 3

POWERFUL COMBINATION

Data as a tool for the architecture of the future

By Håvard Haukeland

Technology is creating a fundamental shift across the architecture world; new digital tools have been completely transforming the way architects work. The 2D analogue plans of the past are evolving into networked 3D representations, data analysis and AI-supported software applications. These new tools bring a wealth of new opportunities – and challenges – that can empower them to design better, more resilient buildings.

The pencil has always been the first tool of choice for architects. However, with virtual reality (VR) and 3D printing coming into the picture, traditional tools are starting to gather dust. CAD was one of the early revolutions: digital drawings that communicated plans, sections, elevations and details, made architecture processes faster and more effective.

Architects are facing a rapidly changing and complex world to work in. However, change and innovation are constant. The construction industry is now undergoing

an upheaval, meaning that architects must familiarize themselves with the newest digital tools.

Tackling the future with data

From rapid urbanization, population growth to climate change – we are set to face some of the biggest societal challenges in the coming decades. Climate change is impacting the way people work and live in cities, and urban landscapes are becoming increasingly complex.

It’s not just cities and climate that are changing: the economic demands of architecture and construction are increasing too.

Architects are being challenged creatively and logistically; maximizing the limited space available while still maintaining quality of life and reducing environmental impact.

Building Information Modeling (BIM) – the core digital transformation for the industry – offers architects support in this increasingly complex construction landscape. It has created a hub of key

“ “

“ “ Climate change is impacting the way people work and live in cities

Technology 5modernhb.com

information for everyone involved – from stakeholders to team members of multiple disciplines – with quick and efficient access to dimensions, quantities, costs, deadline and materials, to name a few.

Other technologies help create entirely new perspectives on construction plans and building environments via 3D models, renderings and virtual reality (VR). These tools facilitate more efficient collaboration and greater stakeholder buy-in.

Using intelligent insights in design

While BIM has become essential in the construction phases of projects, however it’s often too complicated to be used effectively for early-phase design, to create and test different concepts. However, technology is absolutely vital in these stages to help conduct thorough analyses: after all, this is where up to 50 percent of the ultimate value is created. And, these analyses have – until now – been time-consuming and counterintuitive, as architects typically design first and then analyze, rather than the other way around.

However, workflow initiatives can now be turned on its head – thanks to cloud computing and the availability of digital data. Throughout the entire duration of a project, data can be a game changer for architects. From feasibility studies to elevating building performance, they can access detailed insights and make more informed decisions. Technology becomes an enabler to supercharge architects’ intuition and experience, starting from the early-design phase.

Artificial Intelligence (AI) is the next toolbox revolution that will help architects complete time-consuming, tedious tasks. Technology enables architects to digitally test a wide variety of scenarios and find optimal solutions within the chosen parameters. In particular, data and AI are driving a shift toward

6

“ “

“ “ Where mundane processes stunted the time of architects, new technological tools can free up their time and make them even more effective.

better results and a more outcome-based way of working. New creative approaches are inspired through risk-free testing environments, with design and analysis integrated on one platform. Factors that may impact design – such as daylight, noise, and microclimate – can also be incorporated and tested in real time from the start. Therefore, later down the line, a solid evidence-based foundation can be laid down for a more sustainable, cost-efficient construction phase.

Pencils, data and an architect’s expertise

The future is an exciting prospect for an architect’s toolbox. A data-driven, collaborative way of working is on the horizon. Where mundane processes stunted the time of architects, new technological tools can free up their time and make them even more effective. However, the one constant in this development is and remains the intuition and expertise of architects – this can never be replaced. While more archaic tools gather dust, the humble pen and pencil remains a tool for testing architects’ ideas; now paired with new sophisticated digital tools, they will only become more powerful. ■

Håvard Haukeland www.spacemakerai.com

Håvard Haukeland is Co-Founder of Spacemaker and Senior Director at Autodesk. Spacemaker is a technology company founded on the belief that there is a better way to design cities, and a vision that this needs to happen as the population of the world grows to new highs. An Autodesk product, Spacemaker, is a cloud-based AI software, empowering teams to collaborate, analyze and design real estate sites.

7modernhb.com Technology

8

SMART SOFTWARE

Today, 70 percent of construction projects are over time and budget. This results in a productivity gap worth approximately $1.6 trillion –equivalent to Canada’s entire GDP. This was far from ideal in the strong market we have experienced for the past decade but rising interest and mortgage rates make this level of overshoot entirely unsustainable.

The construction industry has not experienced similar efficiency gains to other industrial sectors over the past several decades. On large projects in particular, according to the Construction Owners Association of America (COAA), 63 percent of direct labor time goes to waste on inefficiencies such as waiting for materials to be delivered or travelling to the site.

Today’s challenges

As economic conditions worsen, businesses must maximize productivity and efficiency to protect their profit margins. Doing so demands a new approach to project management – and spreadsheets and digital systems not designed for the construction industry simply aren’t up to the task.

Modern solutions need to reconcile the complex logistical considerations, such as the ground conditions of individual sites, and building plans – no two are the same. At the same time, some tools are complex and require extensive training to use. This means that the wider team is unable to access or input information, limiting communication.

The key to project success in a challenging economy

Technology 9modernhb.com

Meanwhile, clients are increasingly used to having information at their fingertips. They expect regular updates, but these can be time-consuming to compile. Similarly, contractors and workers also expect high levels of communication to ensure they are at the right place at the right time and know what to do.

Managing all of these considerations using conventional tools and approaches is both time and labor-intensive, eating into thin profits. It also introduces the risk of fragmenting understanding, as there is no ‘single version of the truth’ accessible to all stakeholders.

How modern solutions can help The modern world is powered by software, and while it has been slower to reach the jobsite than other areas of life, there are

advanced, easy-to-use solutions available. Specialist project software – like Elecosoft’s Powerproject – is designed from the ground up for construction applications and can help at every stage of a project. Before breaking ground, the team can use the software to outline the critical path and determine where, when and how many skilled tradespeople will be required. This helps deliver accurate time estimates and costings, increasing the chance that a business will win a project. From there on, every member of the team can use the software to deliver profitably.

A further advantage of using software is the ability to create standard project templates. A four-bedroom home template, for example, can then be tailored for the end customer’s finish and budget and to take account of the unique conditions on the building plot.

“ “ ...software also needs to be able to react to changes

“ “

10

However, no plan survives contact with the real world for long, so software also needs to be able to react to changes. Current challenges, for instance, include worker availability due to sickness, fluctuating material prices, and a shortage of skilled workers. Any of these issues could snowball into a major problem if not addressed.

Fortunately, modern software ensures that the project manager has constant visibility over these issues and can begin working to resolve them as soon as they arise, minimizing the chance of them causing major disruption. What is more the project manager has a complete history of all changes with supporting commentary should they require them at a later date.

When adopting digital solutions homebuilders should look to software vendors that regularly update their software with new features to meet real-world requirements. Powerproject, recently built upon its 4D planning capability and has exciting plans in 2023 that will further support the industry plan and execute complex projects successfully.

Learning from experience

Another common issue is discrepancies between the as-built scheme and the original design. A lack of as-built information results in loss of knowledge, leaving the loop open and limiting the potential for improvement over time.

Often, failure to update the as-built information is the result of limitations in the data recording process. Perhaps it is too challenging to use, only a few people have access, or the people who are responsible are too time constrained.

Modern project software accounts for this and ensures that everyone involved can easily update the information as they go. The software is designed to be as intuitive as possible, minimizing the need for additional training.

This software-based approach has been tried and tested in the construction industry, and it can deliver a range of additional benefits. For example, regular updates provide an audit trail which can be useful in the event of a dispute or litigation. Perhaps most importantly, a solid record of each build provides project managers with valuable lessons that they can apply going forward. For example, they can adjust the templates for the next build or modify timelines to optimize the process.

Maximizing efficiency in tough times

Margins for construction are small, so businesses need to take every available opportunity to work efficiently. Specialist project software is one way to maintain a competitive edge, address unforeseen issues, and deliver complex projects on time and on budget. Learn more at www.elecosoft.com homebuilders about how a dedicated project management solution for the construction industry can help homebuilders hit their targets. ■

For a list of the sources used in this article, please contact the editor.

Elecosoft www.elecosoft.com

Founded in 1895, Elecosoft provides software integrated solutions to support the lifecycle of buildings and facilities across a range of industries to drive efficient operations. From its centres of excellence in the UK, Sweden, Germany, the Netherlands, and the USA, its established portfolio of software is used during early planning stages through to construction and facilities management, driving the performance and day-to-day operations of customers’ businesses.

11modernhb.com Technology

12

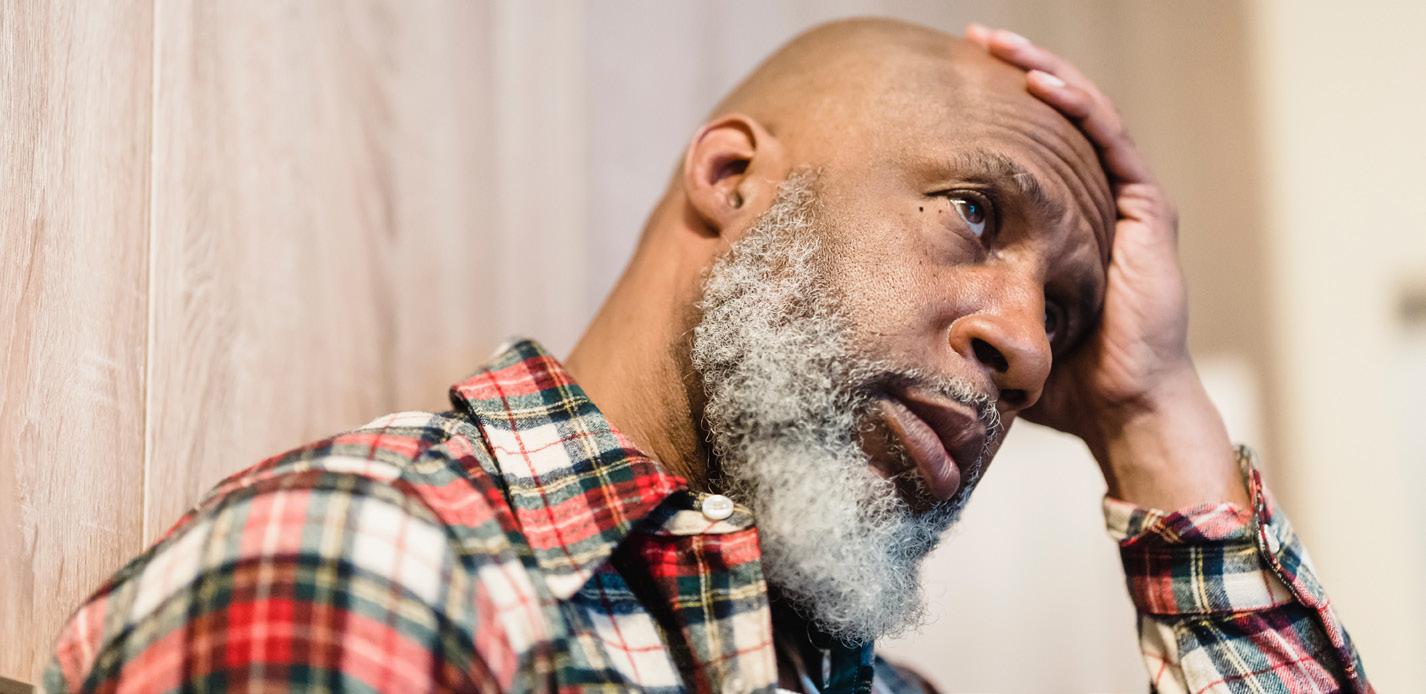

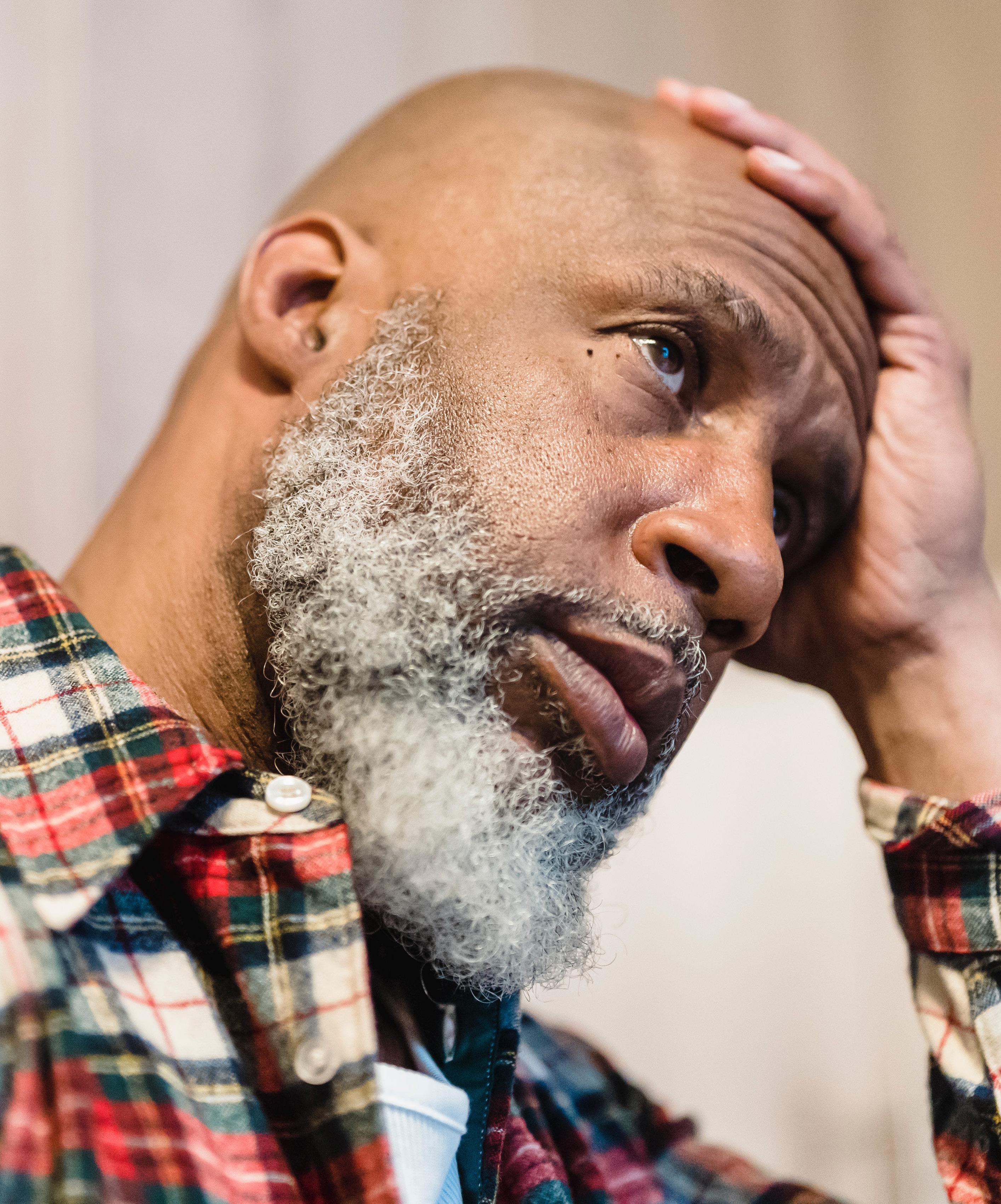

Human Resources

Working for everybody

How inclusive is your culture?

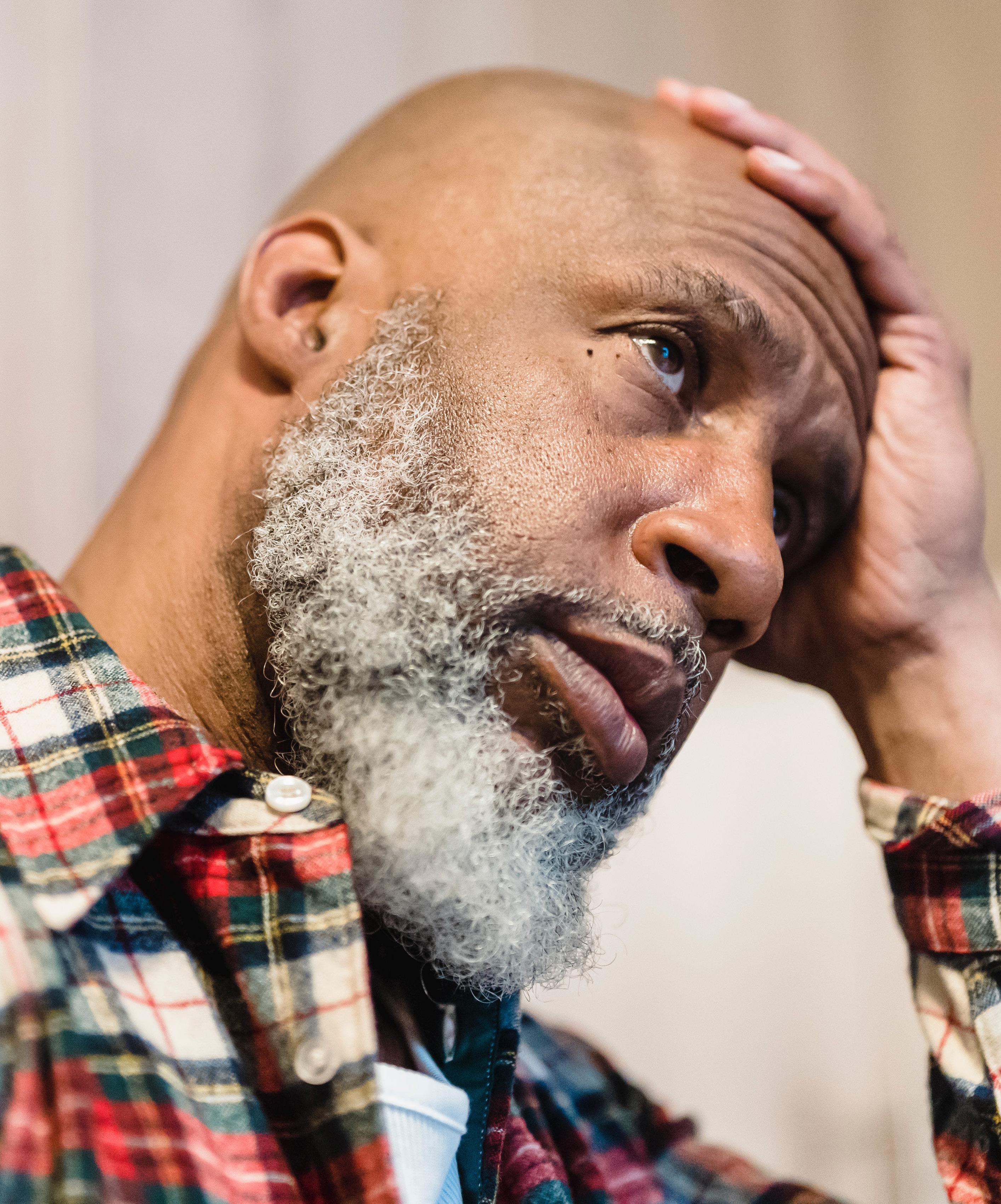

By Robert Ordever

Does the construction industry care about diversity and inclusion (D&I)? The statistics indicate that too few organizations are taking D&I seriously, however the tide appears to be turning with some construction businesses breaking with tradition and actively trying to diversify their workforces. But is hiring more females, ethnic minorities, LGBTQ+ employees and those with disabilities enough? The simple answer is ‘no’! Diversifying the workforce must go hand-in-hand with ensuring an inclusive culture, otherwise employees who identity as ‘different’ may feel marginalized and ignored.

The construction industry is failing with inclusivity

The construction industry continues to be dominated by white males with just one in ten construction workers a woman and all racial minorities, apart from Hispanics, poorly represented.

In the UK the outlook is no better, with women making up just 15 per cent of the UK construction industry (of which approximately two per cent work

onsite); employees from ethnic minorities comprising just six percent of the workforce; and disabled employees also making up just six percent of the workforce.

It’s hardly surprising then, that only 61 percent of construction workers believe that everyone is on a level playing field when it comes to growing and developing their careers, and just under half (48 percent) feel that their opinions are fairly represented within their organization’s leadership team (O.C. Tanner’s Global Culture Report).

And it appears that discrimination is commonplace with almost half of construction workers having witnessed instances of obvious discrimination at work with a further 43 percent witnessing unintentional discrimination.

Inclusivity and equality are failing, and when society is so poorly represented within an organization, discrimination is far more likely. However, representation is just one aspect of inclusivity. Nurturing a fair, open and appreciative culture is also key for delivering equality. And with the construction industry still perpetuating a ‘macho’ culture in which people don’t feel able to speak up, this makes driving D&I initiatives especially challenging.

13modernhb.com

It’s time to rethink inclusion

The first step towards change is to stop approaching D&I with the aim of ‘reducing exclusivity’. By focusing on not making employees feel ‘left out’, this leads to segmenting people into categories and approaching inclusivity in a onedimensional manner, seldom looking at complex minority combinations. Such an approach often means that D&I is broached at key employee touchpoints such as the recruitment process, onboarding, career milestones and during learning and development programs.

Inclusive practices are simply not built into daily employee experiences.

The impacts of a one-dimensional approach to D&I are significant with employees who identify as ‘different’ in some way suffering greater burnout, feeling a lesser sense of belonging, and experiencing more instances of microaggressions.

True inclusion must be reflected in the everyday employee experience such as

through interactions with co-workers, one-to-ones with leaders and in the giving and receiving of appreciation.

How to build inclusion into the everyday experience

For inclusion to become part of the daily working experience, there are a number of key steps construction businesses can take.

Firstly, leaders must be taught to lead through inclusion so they foster more inclusive environments. This is a skill in itself because it’s all too easy for leaders to create environments and situations that are more favorable to certain employees. As part of being inclusive, leaders must become skilled in effectively communicating to employees that their unique identities are appreciated and valued, and learn how to support each individual equally and fairly (not just the ‘favorites’). Plus, the most successful leaders have a modern rather than a traditional mindset - focused on mentorship and

14

advocating for their people rather than gatekeeping and control. Modern leaders are compassionate and understanding, getting to know their employees on a personal level, and by taking time out to ask simple questions like “how are you doing?” and “how can I help you right now?”, they can encourage employees to open-up about any challenges and prejudices they might be facing.

Secondly, giving all employees a voice and supporting them, will create a more equal culture. When employees are given permission to express their personal opinions and feedback on ideas, this opensup new viewpoints. And when people feel comfortable to talk openly about their unique identity, such as being gay or having a disability, this helps to challenge taboos and create a more accepting culture. Ultimately, what employees see, hear, and experience from the organization is crucial, and should always reinforce acceptance and inclusivity.

Introducing a staff recognition program is another simple and yet powerful means to support inclusivity. A recognition-led workplace culture in which purposeful, personalized and authentic appreciation takes place daily, and both managers and peers can recognize and reward employees’ efforts and results, helps to avoid a culture of ‘favorites’. Recognition also enhances employees’ sense of belonging - making the recipient feel an important and valued part of the organization’s success - and strengthens workplace connections through the very act of giving and receiving appreciation.

Furthermore, investing in technology can support D&I efforts. In fact, more organizations are using advanced technologies like artificial intelligence, machine learning and recognition platforms, to assist with D&I. And organizations that implement at

Human Resources

least one element of D&I technology experience extremely positive cultural and business outcomes. Fifty-two percent of organizations are currently using advanced technology to support D&I efforts, and 45 percent are considering it to support recognition initiatives and better their company cultures.

It’s now or never!

It’s time for construction businesses to hire diverse workforces, and then nurture inclusive cultures to allow these workforces to thrive. This means building inclusion into the very fabric of the organization so that everyone’s unique characteristics are recognized and celebrated. Yes, being inclusive is the morally right approach, but it also makes smart business sense with organizations that possess truly inclusive cultures enjoying greater success. In fact, they’re twice as likely to meet or exceed financial targets, six times’ more likely to be innovative and agile, and eight times’ more likely to achieve better business outcomes. With such compelling reasons to improve D&I, what are you waiting for? ■

For a list of the sources used in this article, please contact the editor.

Robert Ordever www.octanner.com

Robert Ordever is European MD of workplace culture expert, O.C. Tanner. O.C. Tanner is the global leader in software and services that improve workplace culture through meaningful employee experiences. Its Culture Cloud is a suite of apps and solutions, including recognition, service awards, wellbeing, leadership, and celebrations that help people thrive at work. O.C. Tanner provides these and other services for thousands of the most respected companies in the world.

15modernhb.com

Thinking out of the box

The search for affordable housing continues to be an uphill battle for homeowners nationwide. Around half of Americans now say affordable housing is a problem where they live - a ten percent increase since 2018, according to the Pew Research Center. It’s a trend that has only been accelerated by the Covid-19 pandemic, which severely delayed new-build construction rates and brought the world’s supply chains to a halt. Today, there’s simply not enough homes available to meet demand, resulting in record-high prices and a press for change.

Even if prospective buyers can find homes that fall within their budget (and don’t fall victim to bidding wars), it’s likely to eat up a major chunk of their income. The United States Census Bureau reported that 23 percent of Americans spent over half of their monthly income on housing in 2020. And while salaries have gone up, so have home prices - at about 24 times the rate. In short: people need more reliable, affordable housing - and quickly.

So, it’s no wonder that both personal and commercial home builders are looking beyond traditional building options to satisfy demand. Enter the shipping container home: an economical - and more sustainable - alternative to traditional home construction. Shipping containers have proven such a viable option for quick and affordable housing, they’ve even been transformed into accommodation for people experiencing homelessness as part of humanitarian projects across the country.

A growing movement

Shipping containers have been transformed into tiny homes, office spaces, and retail popups for years. Long considered a niche market, shipping containers are picking up momentum mainstream as the push for more imaginative solutions to current housing challenges continues. More recently, the movement has sparked a flurry of popular interest, spurring blogs, television shows, and influencers who have built their reputations on constructing, decorating, or living in container spaces.

Many Americans are turning to shipping container homes says Maximilian Birner

16

It’s no surprise why they’ve become so popular. Shipping containers are completely customizable, more sustainable, and quicker to construct than traditional homes. They can also be much more affordable, depending on the homebuyer’s preferred size, location, and how they choose to modify the home.

Affordable housing, shipped wherever you like

One way in which shipping containers are disrupting traditional homebuilding is their ability to drastically cut development times and costs. This is in part fueled by their immediate availability, with more entering the market every day. There are about six to eight million containers set to be retired from commercial use in 2023-2024. Once retired, these containers will be available for purchase by commercial home builders and ready to be delivered to the location of their choice. Boxhub is democratizing access to both new (or ‘one-trip’) and retired shipping containers, taking care of sourcing, inspection, and delivery on behalf of homebuilders nationwide.

Easy-to-build, modular masterpieces

Another element that makes shipping containers easier to work with for home construction is that they come in standardized sizes, specs, and load-bearing capacity. Home builders can choose from a simple range of options, with the most popular sizes being 20and 40-foot containers. Each is built the same way out of the same materials. This uniformity makes shipping containers easy to combine, stack, and configure as needed throughout the home design and development process.

The predictability of container home construction also cuts development times down substantially for both single-family and multifamily dwellings. Because of their modularity,

shipping containers can be configured to create homes as large and complex as clients like - or as simple and compact as a single container.

Adaptable to any location, preferences, or budget

Another aspect that makes shipping container homes a desirable alternative to traditional homes is that they can be customized to fit any buyer’s needs or budget. You can keep costs at a minimum with standardized prefab units, or you can explore a world of customizations and embellishments depending on your clients’ locations or personal preferences.

From a financial standpoint, shipping container homes can be far more affordable than building a traditional home. They require less new construction materials in order to be made livable, reducing expenses even further. In fact, with the right knowledge and resources, a basic, single-family shipping container home can be built for as little as $25,000. For a more luxurious, fully kitted space, a 320-square-foot container apartment averages around $80,000, including all appliances and fixtures. What’s more, these prices are predicted to decrease sharply over the next couple of years, as more modular housing companies enter the market and materials become more readily available. ■

For a list of the sources used in this article, please contact the editor.

Maximilian Birner www.boxhub.com

Maximilian Birner is Co-Founder & CEO of Boxhub, a leading e-commerce and logistics platform enabling the seamless purchase, delivery, and repurposing of shipping containers. Founded in 2017, the marketplace has become a trusted partner for thousands of buyers across the United States.

“ “...container homes can be far more affordable than building a traditional home. “ “

Affordable Housing 17modernhb.com

20

Davitt

The INNOVATION element

Classic and contemporary: Davitt Design Build’s chic approach to luxury home construction

modernhb.com 21

Design Build

In 1982, Matt Davitt brought to life Davitt Design Build to be a specialist in coastal and luxury home building. Matt, a certified master builder and leader in the design-build industry both regionally and nationally, is often called upon to discuss design-build concepts, building trends and economic conditions facing the construction industry. Since the company’s inception, Matt has worked hard to build a team of talented architects, designers, expert builders, and project managers. “Our work can be seen throughout Rhode Island, Massachusetts, and Connecticut, and we work predominantly with highend clientele,” shares Vice President David Whitney.

David, along with Designer Mary Rae dives deeper into the inner workings of Davitt Design Build, with a focus on the successful completion of the Modern Coastal Castle. “Customers come to us with a piece of land, or a

teardown rebuild, and we take them all the way from permits, through coastal resource management, to the design and construction of the home. There are three operating divisions that we support within the company. The first is the design build, which is our largest operating entity. We also have an insurance division, which started about 30 years ago, and specializes in high-end residential insurance restoration. If there is fire or water damage, we come in, negotiate with the insurance companies to remediate the loss, and ultimately do the rebuild,” David highlights. He adds that the third division focuses on land development and speculative new construction, again specializing in luxury and coastal homes.

Before we dive into recent projects, David gives us an overview of how the company works closely with its clients to make their visions a reality.

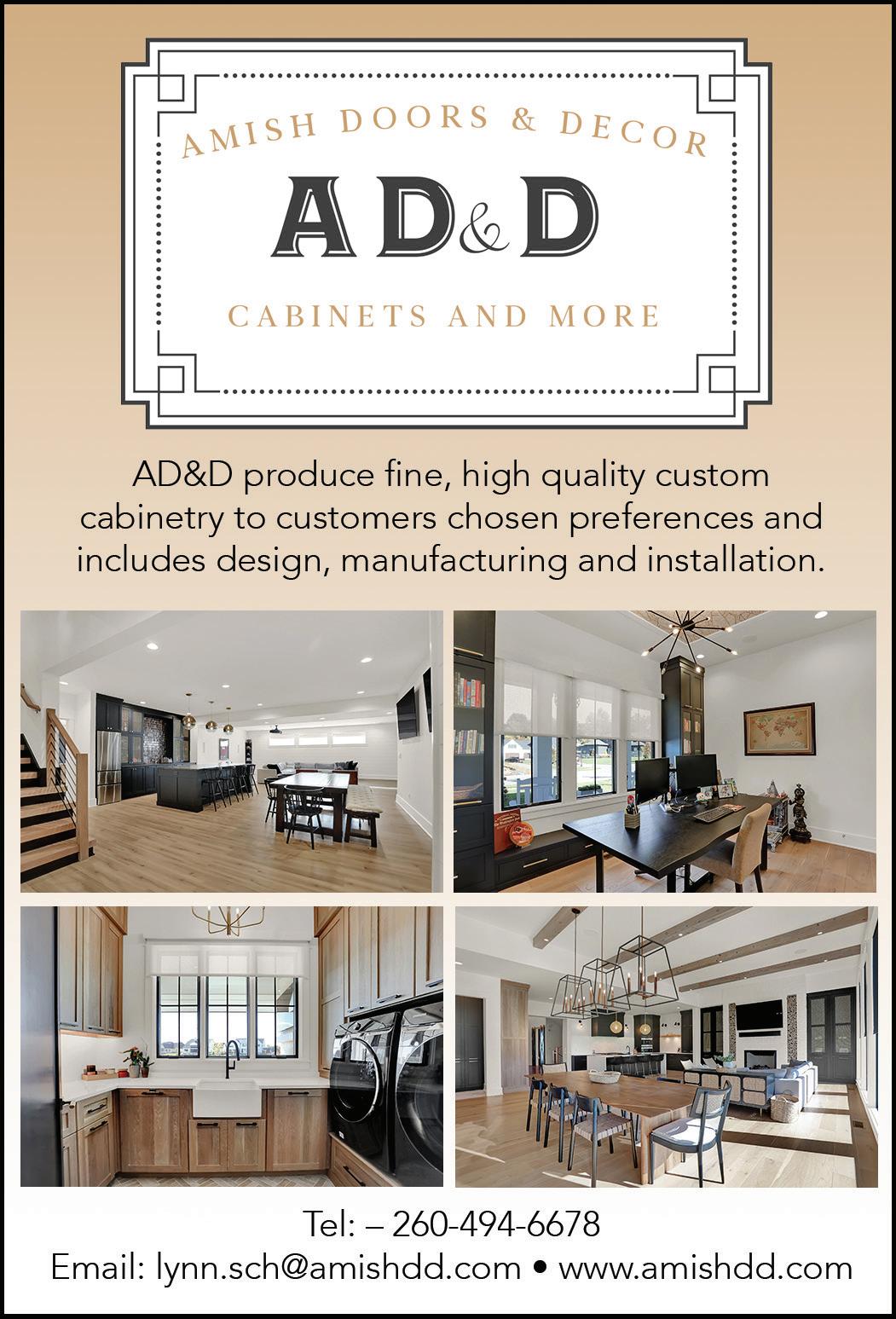

Arnold Lumber Company

Arnold Lumber Company is a familyowned and operated business, specializing in lumber and building materials, including kitchen and bath cabinetry, and masonry supplies. We have been building trusted relationships with builders, remodelers, homeowners, and the community since 1911. Customer service, top brands, quality products and reliability are the foundation we built our company on. We aim to provide our customers with superior products and delivery, while supplying the highest possible level of service. Visit www.arnoldlumber. com to learn more about the services and products we offer.

Our friendly and experienced staff are always happy to answer any questions you may have.

22 Davitt Design Build

TRUST SINCE

ARNOLD LUMBER COMPANY BUILDING

1911 BUILDING MATERIALS | DOOR & MILL SHOP | KITCHEN + DESIGN | MASONRY PRODUCTS We feature high-quality Andersen® products. “Andersen” and all other marks where denoted are trademarks of Andersen Corporation. ©2022 Andersen Corporation. All rights reserved.

24

“We focus on a team-oriented approach. When you first call Davitt Design Build, we assess the project and conduct an initial introduction and scope review. Mary joins as well to gain design insights.

“Our sales team works from the clients’ feedback, which involves a great deal of communication, listening, and collaboration, so we can create something that is based truly on our client’s vision, while providing design and budgetary guidance from our team. I think that is what draws clients to us too; we are not in it to create a home for ourselves. It is about taking client ideas, conveying them to the team, and then bringing those ideas to life,” David highlights.

Attention to detail

To share a prime example, we ask David and Mary to share the process that brought together the Modern Coastal Castle, which was inspired by an Italian fortress used on the set of a James Bond movie. “This was such an interesting way to start a home. Clients usually come with interior pictures, but in this instance, the customer had a vision and took creativity to a new level from the outset. We finetuned their vision to merge two worlds with an old Italian fortress exterior and a modern sleek interior.”

Davitt

Each level of the home features a walkout deck, with expansive windows that showcase the surrounding ocean views. The rooftop platform overlooks Narragansett Bay and the Beavertail Lighthouse. The property also boasts a manmade rock garden and lavender-lined pool. “It is one of the premier spots in Rhode Island, 1.4 acres along the water, overlooking Narragansett Bay. Mary helped the clients design the fortress to feature a modern interior, while blending the unique positioning of the lot and its environment. There was a multitude of elements the team had to balance, while designing the home, and the final product speaks to the experience, adaptability, and creativity of our team,” David shares.

“We did every single detail,” says Mary. “We went through each room; we talked about trim molding, and we wrapped the plaster around the windows to make a sleek finish. The

We fine-tuned their vision to merge two worlds with an old Italian fortress exterior and a modern sleek interior

“ “ “ “

modernhb.com 25

Design Build

kitchen for example is darker, because it works well with some of the whiter countertops. Those are the kinds of details that we care about.”

On projects of this scale, both leaders are aware that challenges will always arise. For example, as we learn from David: “We had to cut into the studs in the kitchen to bring

in an oversized marble shelf. Above it, we had a window needed to be engineered to correctly match the fitting, while ensuring the structural support of the wall.

Any passersby will notice the home’s clean lines, incorporated to mitigate the old fortress shape, which has given the design more character,

26

according to David. “The texture to it, the monotone color, the shadows that fall on it shows its age; each of these add wonderful elements that make the building beautiful. The front door, for example, is a giant flat front door, but when you get close to it, you can see the studded-beam detail. This feature makes it look like an old wooden door that has been around for centuries,” Mary explains.

Davitt

Regarding the exterior, the design elements surrounding the home are just as stunning. “When we were digging the foundation, we uncovered many boulders on the lot, and we decided to use them to create a rock garden to surround the house, which gave the impression that the rocks had always been there. I feel that this brought nature back with a modern element,” David details. The pool patio was cut into existing ledge to create an irregular pattern, and, against the backdrop of the bay, the sharpness of the outside features was an excellent complement to the softness of the property’s surroundings.

Customer experience

The project took a total of 12 months to complete, and Mary expresses that this new build showcased the expansiveness of Davitt’s capabilities. “I think it’s fun for us to push the boundaries, which is why we absolutely love working on projects like this,” she says.

The Modern Coastal Castle is not the only one of its kind, and it certainly will not be the last. Both David and Mary are excited for what lies in store in the years to come, and the variety of projects the company will take on. “Our pipeline is full for the remainder of 2022 and 2023. The company has grown from 20 employees to 35 in the past five years. My background is in the financial sector and private equity, and I have seen all too often that when companies grow quickly, they may lose the essence of what they were built on. For us, the core values of our success are quality and teamwork, and as we grow our team, I know that our reputation will remain as an industry leader in design build. For me, it is about being strategic and purposeful with our growth to continue to deliver on our highstandards of quality and customer experience,” David concludes. ■

www.davittdesignbuild.com

Design Build modernhb.com 27

ROOTS Putting down

28

Kent Shaffer Homes

MEMORIES and making

Find out about Kent Shaffer Homes: a woman-led custom home builder on a client-focused mission

We were very fortunate and continued to grow our business during the pandemic,” begins Kristen Shaffer, President at Kent Shaffer Homes (KSH), an Indiana-based custom home builder that we last featured in Modern Home Builders back in 2018. So, it has been good to catch up.

“Naturally, like everyone else, we did struggle, especially with procuring materials and dealing with labor shortages,” she goes on. “Nevertheless, we made sure that we were able to meet deadlines – every time. One of the major changes we made during the pandemic that we are still implementing now is making all design selections upfront (instead of later on in the process).”

modernhb.com 29

30

Once a client signs a contract to begin a build, KSH will start working on selections immediately, with the aim of getting these finalized within the first and second month of the project. “The process has become less stressful for our clients; they can now get their selections out of the way, and then just enjoy seeing their house being built before them,” Kristen explains. “As far as costs are concerned, being a smaller company that does not spend money on extra staff and office space, we are able to absorb as many material price increases as possible in order to make our clients’ dream homes attainable.”

Kristen is a third-generation builder and recently took the helm of the company, leading as President at KSH, the family-run business that takes its name from her father, with whom we spoke in 2018. Yet Kristen is no novice; prior to her new appointment,

she was already taking on individual custom home projects, including the 2018 winner of the Home-A-Rama in Central Indiana.

Bringing design to life

As President, Kristen has continued to grow the business and has more than doubled the number of homes that it builds each year. Meanwhile, she has managed to stay rooted in the family traditions and client-forward approach that her father and grandfather both applied over the course of their long and successful careers as builders.

Through the generations, the family name has become synonymous with craftmanship and high-end construction. KSH works with a knowledgeable and experienced team of designers, craftsmen, and some of the best architects in the state. “We are a smaller company and remain very hands-on,” says Kristen. “As a result, we are able to create

modernhb.com 31 Kent Shaffer Homes

Lee Supply

At Lee Supply, we are proud to partner with Kent Shaffer Homes. We love the attention to detail that Kent and Kristen put into every home and the exceptional experience and quality they provide when personally working with customers. It’s that family-run, personal touch, and emphasis on quality that we admire and respect most in them. The team over at Kent Shaffer Homes are some of the best designers, architects and carpenters in the business, delivering beautiful dream homes to loyal and repeat customers in some of the most exclusive neighborhoods. We are very proud to assist Kent and Kristen in bringing their customers’ dreams to reality by providing high-end beautiful lighting, appliances, and plumbing options to choose from. Thank you Kent and Kristen for the great partnership!

personal relationships with our clients; we are their main point of contact across construction and at all construction meetings.

“By utilizing buildertrend.com as a form of communication throughout the build process, the client’s role has never been easier,” she goes on. “The homeowner can approve all selections through there, view the project schedule, and send us any questions they might have. We also involve our designer upfront before we even meet with the architect. This enables us to put together a design plan, which then helps to guide the architect through our vision when they do step in. Further down the line, this prevents changes – both interior and exterior – being made later on.”

The conversation then turns to a broader overview of modern home building as experienced by an individual client. “First, we sit down one of our customers to discuss their budget,” explains Kristen. “We will help

32

determine guidelines that the homeowner needs to follow to stay under that budget. For example, the square footage of each floor, the exterior elevation, and what kinds of finishes are wanted. All need to be discussed openly and honestly early on to avoid unrealistic expectations or any unwanted surprises down the road. We then set up a design consultation with the decorator to put a design plan together.

“Once we have the design plan in order, we will meet with the architect and start the design of the home,” she details. “Both myself and the designer will be present in those meetings to help, and we will therefore ensure the homeowner stays on budget and make sure their design ideas are realized in an effective and practical way.

“After we have the final set of prints, we can price the home,” adds Kristen. “Since we have a design plan from the decorator, this helps to guide us with pricing and makes sure that we are pricing what the homeowner wants. We are then ready for the most exciting part: building the home! Even then, we will continue to meet the homeowner at key phases of the build, making sure everything is as it should be.”

By putting that process into action – time and time again – KSH has built more than just a portfolio of custom homes across Indiana. It has built a reputation for them. A strong one. With that kind of recognition comes plenty of exciting projects.

“We are currently working on a build where the client wanted 3D renderings created for the entire interior of the home,” Kristen notes. “The

We are then ready for the most exciting part: building the home!

“ “ “ “

modernhb.com 33 Kent Shaffer Homes

decorator worked with the company to get pictures of all the finishes – light fixtures, flooring, furniture, and so on. We were able to provide the homeowner with a 3D view of exactly what their home would look like on the inside.

“Projects are just becoming cooler and cooler,” she admits. “We have been doing indoor basketball courts and display garages with car elevators; however, I think my favorite touch is a secret door in a study or basement which leads to, say, a little speakeasy or a secret reading room for children. Right now, the most challenging aspect of being a custom home builder is rising prices and

the shortage of materials and labor we are currently seeing.”

KSH has remained creative when it comes to materials, adapting to what is and is not available at any one time; it is all part of the standout experience the company offers. Fortunately, Kristen goes on to highlight that she believes the availability of building materials is destined to get better.

Forming relationships

Although, she admits a shortage of skilled labor and rising costs will continue to be a challenge. “In the current market, where material pricing is constantly rising, it is really

34

important to have a good relationship with everyone that you work with,” Kristen asserts. “All our suppliers give us plenty of notice about price increases, and that means we can order materials in sooner if we need to. Many of the vendors we rely on have had a relationship with us for nearly four decades; they are just as invested in our success as we are in theirs!

“It is also important to have good relationships with our subcontractors because of labor shortages that are plaguing the industry,” she observes. “Truth be told, subcontractors could go and work for just about anyone right now because of the high demand for skilled workers. However,

our subcontractors will put us before other projects because of the relationships we have formed with them. Ours stay with us – and, in turn, we continue to trust them because of mutual respect and appreciation built slowly and steadily over time.”

KSH is keeping busy. For instance, it has a Home-A-Rama-featured house coming up that it will be breaking ground on in 2022. “The show is located in Promontory in Zionsville and will be hosted in the spring of 2024,” Kristen concludes. “The scenic lots in this new development have to be seen to be believed; it will be stunning. Further down the road, we aim to be doing what we have done for the past 40 years: completing builds that allow our clients to put down roots and make memories to last a lifetime.” ■

www.kentshafferbuilders.com

www.kentshafferbuilders.com

modernhb.com 35 Kent Shaffer Homes

Crafted with passion

Paul and Doug Wellborn are two brothers who launched Wellborn Cabinet, Inc (Wellborn) in 1961. That name is also an apt description of the products that the company, which recently celebrated its 60th anniversary, manufactures. They are born to hardworking hands of honest Americans and built with

a special kind of care and attention to detail that is only made possible by people that love their craft.

Though the company began in a 3200-square-foot building and chiefly produced low-cost kitchen and bath cabinets for government-financed housing, the business has dramatically evolved over the years. After purchasing his brother’s half of the company in

People who care: this is more than just a slogan for Wellborn Cabinet, Inc

36

1986, Paul Wellborn, who still serves as President & CEO, became the sole owner. What followed was consistent growth and expansion year-overyear. The company’s customer base shifted to residential kitchen and bath dealers, and that move has since paid dividends.

Today, Wellborn offers six core product lines and manufactures its kitchen and bath cabinets from start to finish in its own 2,000,000-squarefoot facility in Ashland, Alabama. Recently, Paul

sat down with us to talk about American manufacturing, quality cabinetry, and a $4.5 billion trade case against China that took him all the way to Washington, D.C. and into an audience with the President.

“Over the years, many family-owned cabinet companies in the US have merged together,” he begins. “We never did. In fact, we are the largest privately-owned cabinet manufacturer in the country, and it is a true family business. All of the family works here. I have five children, and all of them are part of the company and some of my grandchildren are, too!”

Made in the USA

A tight-knit community of workers under one giant roof ensures that Wellborn Cabinet, Inc manufactures some of the best cabinetry in the country, promoting a quality of craftmanship with which the company – and the family name itself –has become synonymous.

The Wellborn family, and many of the families working within the company, take immense pride in producing highquality cabinets in the US, hand-crafting every product in Alabama. “If you do research, as we do, on products by our competitors, then you will generally find that the quality of some imports is not as

▲

Paul Wellborn, President & CEO

Wellborn Cabinet, Inc

▲

Paul Wellborn, President & CEO

Wellborn Cabinet, Inc

modernhb.com 37

good,” Paul reveals. “They might look convincing, but they will not last! It might be that the glue has not been properly applied to the face frames, or something else entirely.

“By manufacturing our cabinets here in Alabama, we can make sure they are very high quality,” he adds. “In fact, I have had customers tell me that a kitchen they bought from me 30 years ago still looks as good as it did on the day they bought it!”

The dedication to being ‘made in the USA’ does not stop with the product, either. “We just installed a new planer mill, which is about 105,000 square feet and is all American-made,” says Paul. “The steel we used was made in America; all the conveyors and the

machines were manufactured here. We even made our own concrete, so we definitely know that was made in the US! It all means that everything is of the best quality, and that shows in each and every product that leaves our facility.”

Family environment

Out of the growing workforce of around 1300, more than 140 employees make up the Quality Control team. Their job is to ensure – across 30 different quality checkpoints – that only top-quality products are manufactured under the Wellborn name. Consequently, the company meets requirements set by the Kitchen Cabinet Manufacturers Association (KCMA) and prides itself on the fact that face frames are built with mortise and tenon joints to create strong, long lasting, quality cabinets.

Darlington Veneer Company

For over a century Darlington Veneer Company (DVC) has been committed to producing decorative hardwood plywood for building material distribution, kitchen cabinet, hospitality, and institutional furniture manufacturing, displays and exhibits, as well as the architectural millwork trades.

We are dedicated to producing top quality panel products with impeccable customer service and attention to detail that only a company that has been around for over 100 years could. DVC blends rich knowledge based on a century of production, and engineering expertise with modern manufacturing techniques and a commitment to sustainability, which results in a superior product.

We have so many good people here, and sometimes that includes whole families –brothers, sisters, moms, and dads, some of whom started right out of school

“ “ “ “

▼

The Wellborn family

Wellborn

Cabinet, Inc 38

modernhb.com 39

These face frames are then sanded by hand on the inside edges and fronts to provide a smooth surface to the wood.

When asked about the enduring success of the business, Paul is quick to reply. “It is people,” he asserts. “I believe in people, and I thank God for the people we have here. We have so many good people here, and sometimes that includes whole families –brothers, sisters, moms, and dads, some of whom started right out of school. It definitely makes a difference in a company to treat

people as we would want to be treated. We have a slogan on our trucks: ‘People who care.’

“But, for us, that is not just a slogan. Our people care; they are dedicated to everything they do. In turn, we are dedicated to them. We have an on-site day care center, a gym for exercise and to keep fit, and a medical clinic with nurses on standby. For those that want to relax, we also have a 35-acre lake behind the plant with up to 15lb bass – making it a perfect place for a bit of fishing after work. I enjoy coming to work every day because it is an

40

Wellborn

absolute pleasure; it is like a large family working together. It makes me proud of the environment the entire team has created over the years.”

As Paul goes on to point out, however, when he talks about the people side of the business, it is not limited to the ones working within the facility. “Within our wider family are our suppliers,” he details. “As we set up good suppliers that perform well, we dedicate ourselves to them like we do our own people. It is much better to build a relationship that can stand the test of time. Suppliers are critical for our business. At the end of the day, they make sure we do not run out of product! Even if it is as simple as some screws; without a screw to hold your hinge in place, your cabinet will always remain unfinished.”

Century Components

Century Components’ line of world-class kitchen cabinet accessories is purpose-built to make your kitchen highly efficient without compromising on beauty. Our product line includes lazy Susans, pull-out waste systems, pull-out organizers, drawer organizers, the revolutionary X-Series Bracket System™ for roll-out shelves, and more. Each product is designed, tested, crafted, and finished in Ohio’s Amish Country, where each craftsman continues a long tradition of fine woodcraft.

“Close to home, close to you” is put into practice by only using domestic hardwoods and basing our production and distribution operations in the middle of America’s heartland; avoiding frustrating import instability and resulting in the industry’s best lead times. Standard products ship in two to four working days, and custom orders in only three weeks, making Century the easy choice for discerning cabinet shops, distributors, and dealers across the nation.

If you want to add Century to your product line, visit centurymade.com or call us at 330-852-3610.

Cabinet, Inc modernhb.com 41

Wellborn offers cabinetry for every room in the home, and across six product lines: Home Concepts, Select, Premier, Estate, BathScapes, and Aspire. All of which provide a wealth of options to choose from. From a material standpoint, Wellborn uses wood, medium density fiberboard, decorative laminates, and embossed and heavy textured melamines.

The beauty of wood

Examples of wood include cherry and character cherry, which is synonymous with luxury and offers a rich, distinctively red appearance, but is also available in a multitude of colors like caramel, ginger, espresso, and nightfall. Maple and character maple is finely textured, lures the eye with a natural luster, and can be chosen in colors like ash, castle, drift, and river rock (among plenty of others). Authentic American red oak features

▼ The Aspire

line

42

an open-pored grain pattern and is available in dark, light, medium, and natural. Finally, Hickory, which Paul reveals his company began working with before many other competitors, classically offers contrasting colors from dark to light, while also being incredibly durable and featuring dramatic wood characteristics.

At the top of the portfolio is the Aspire line, which was designed for higher end homes. The Aspire Full-Access Frameless line gives any space a sleek and modern look. With over 30,000 door styles, species, and finish combinations, the customization is truly in the hands of the customer. There are literally thousands of cabinets, accessories, and semi-custom options which offer even more design flexibility. As standard, premium all-plywood cabinet construction is used.

Strong future

Paul is also no stranger to politics, particularly when it comes to protecting the industry to which he has dedicated his entire working life. “As members of the American Kitchen Cabinet Alliance (AKCA), we were part of filing the largest trade case (ADCVD) against China in history. We won the case in a five-to-zero vote with the International Trade Commission, or ITC. The Chinese were using an illegal trade method known as “dumping” to undersell American Manufacturers.

“If a kitchen cabinet cost them $150 to build, they would sell and ship it to America for $50. Losing as much money as they had to for as long as they had to until they closed every manufacturer’s door in America. Thanks to the diligent work of the Trump administration and our team at AKCA, our industry - and over 250,000 jobs - were saved.

“We stayed in Washington, D.C. for about two years, walking the halls of the Capitol,” he reflects. “We met with many

senators, congressmen, and President Trump on multiple occasions. Realizing that we could lose an entire American industry, most of our elected officials as well as President Trump supported our efforts.”

ADCVD cases come up for renewal every five years, but after winning this first round, Paul is looking forward to a strong future buoyed by a healthy backlog of orders. “The cabinet business has done pretty well,” he concludes. “Therefore, we believe in the years to come, we will continue to do well thanks to our dynamic approach to business. In the next three-to-five years, if business stays the way it is, the company could show growth anywhere from 50 percent up to double what we are doing today. We are constantly on the lookout for new things to make that possible.” ■

www.wellborn.com

Wellborn Cabinet, Inc modernhb.com 43

The

FULL PICTURE

Cole Construction: The story of two brothers, and their journey from flipping homes to Chattanooga’s premier custom home builder

44

Based in Chattanooga, Tennessee, Cole Construction is the brainchild of brothers Matthew and Warren Cole. It was Warren who first started buying and flipping homes in 2008, renovating properties prior to sale. When Matt joined him in 2012, they teamed up to launch the company, taking on a mix of remodeling and custom homes.

Fast-forward to the present, and the company has established itself among Chattanooga’s leading homebuilders. After exiting the remodeling business a few years ago, the company is now focused purely on new-build work, carrying out between 15-to-20 homes a year, including two or three spec homes.

Speaking to Modern Home Builders, Warren is enthusiastic about the pair’s nearly 15 years in business, despite a steep learning curve at the outset. “We’ve learned a lot since starting the company,” he admits. “During a build, there are always ups and downs; the biggest lesson we’ve taken on board has been the need to ensure a solid marriage between our clients and our team. We interview clients as much as they interview us, because we want to guarantee that we can work well together. Our homes can take anywhere from nine-to-14 months depending on the size, so a positive relationship is essential.”

Detail-oriented approach

Homebuilding is a competitive field.

According to Matt, what distinguishes the company is a penchant for detail. “We put a lot of effort into the process, both before the build, in terms of our estimating, spec sheets, and more, and during the build,” he comments. “When you’re building

Cole Construction modernhb.com 45

a home, there are a million decisions to be made – and it can be quite overwhelming. We’re fortunate enough to have an in-house architect who can help us provide accurate pricing from the outset, and set the right expectations for our clients.

“Similarly, our interior designer takes our clients to view different products at various showrooms, guiding them through the process of making selections,” Warren continues.” Particularly as lead times have become increasingly crazy, providing that level of organization and support has been crucial. We also maintain strong lines of communication at all times, giving clients the opportunity to call, ask questions, and

maintain a full picture of what’s going on with their build.”

The success of Cole Construction’s detailoriented approach is evidenced in the host of completed projects to which the company can lay claim. “We’ve built beautiful homes for a number of awesome clients,” Matt reflects. “One that pops into my head is Jasper Highlands, a mountain community located on the outskirts of Chattanooga. The first build we took on was an acre, right on the brow of the cliff. We hit rock quite soon after drilling down, and after consulting our structural engineer, we ended up drilling down a further seven feet

Often, it’s just a really cool house, and clients who are a pleasure to work with “ “ “ “

46

to ensure it was secure. It was a project that involved a lot of alterations to make it work, but the result was a home with spectacular views, delivered on-schedule, with which the client was really satisfied.

“All our projects stand out for their own reasons,” Warren adds. “Often, it’s just a really cool house, and clients who are a pleasure to work with. One piece of land that we own and can’t wait to build on is 31 N Crest Rd on Missionary Ridge. The land used to be the Tiki Palace – owned by Billy Hull, it was once the talk of Chattanooga. We can’t wait to sell it, and we hope whoever the new owners are, that they’re keen to incorporate some of the nostalgia that comes with the location.”

Developing relationships

More projects are set to follow. Cole Construction is eagerly anticipating demand from the opening of the River Gorge Ranch subdivision, also located within the Tennessee mountains. “The developer completed the lots about three-to-four months ago, and they’ve recently opened up for sales, with almost 150 sold already,” Matt reveals. “Over the next six months, that’s a big opportunity for spec homebuilding, along with the potential to build up a strong base of new clients. We hope to establish ourselves as a preferred builder, and if we’re successful, it will allow us to keep growing and expanding.”

Looking to the long term, Warren hopes to further extend its capacity, with a view to building between 30 and 40 homes each year. “We like to make a point of growing,” he comments. “A lot of pieces have to come together to get that to work, including a number of new hires over the next few years. We are licensed in Georgia as well so we have builds there as well. In fact, we build approximately 40 miles from our office so that includes Ooltewah, Dunlap, Signal Mountain, Lookout Mountain, Soddy Daisy and other areas.”

The company also draws strength from a series of successful creative partnerships. “Chattanooga is relatively small, so there are only a handful of suppliers in town,” Matt points out. “As I tell our clients, most of them aren’t even in the phone book. What we have done, however, is select those who can best meet our timelines, with workable quotes. We’ve been developing those relationships for the last half a decade, and the result is a set of subcontractors who really know our processes and have the ability to work with us smoothly. That doesn’t happen overnight, and at the same time, there are always those with whom you work successfully on one project, but it doesn’t quite work when you move to another. It’s our top priority to treat them fairly and keep those we want to work with on board.” ■

www.colebuild.com

modernhb.com 47 Cole Construction

BUILDING A NAME FOR ITSELF

How Michigan-based Celebrity Builders is becoming a household name

F ormed in 2003, by Michigan-based childhood friends, Troy DeHoop and Rob Vis, Celebrity Builders, LLC (Celebrity Builders) has transformed from a specialty partnership providing construction framing services to an in-demand custom home builder that places high priority on detail, craftsmanship and customer care.

As President, Troy DeHoop, explains: “The house that I’m in right now is my home. I have an office here and I primarily work from this space. In fact, my home was our first parade home. A parade home is selected for prospective clients to come and tour. We meet people in the property and it’s

48

Celebrity Builders modernhb.com 49

an ideal way to showcase what we can do. Since our inaugural parade home, we have hosted a Spring Parade every single year, with the sole exception of the pandemic.”

Building trust

While the company’s framing crews still provide a service for both Celebrity Builders and local contractors, the custom home building branch of the business is achieving stellar status. Troy points out that while business is booming, he and Rob have no intention of compromising on customer care.

“We spend a lot of time with a client before we even begin construction. I, personally, sit in every design meeting with the client and architect to discuss desires and requirements, and balance that with the budget. While we want every client’s home to be that of their dreams, it also needs to meet practical needs and be affordable. From architect drawings and interior design consultation to initial cost estimate, the first stage of our home-building process can take up to six months. Home-building is a process for us, not an instant transaction. The actual build can take anywhere from eight months to two years. Effective planning makes for a stress-free and fun experience, and this is why we don’t intend to take on too many projects at any one time.”

Indeed, Celebrity Builders doesn’t just take pride in constructing homes; customer and supplier relationships are equally important. Troy continues: “We like to meet or speak with our clients at least every two weeks. Communication is key, being available and talking to our

50

homeowners is essential. We have a current project that is actually a client’s second build with us. That is pretty much the biggest pat on the back you can get. In fact, we will lose money before we lose a relationship. Grand Rapids, Michigan, is a little-big town, word spreads fast and negative experiences will be shared. We want to avoid that. We have genuine relationships with our clients and that is reflected in repeat business, invitations to our clients’ social and family events and positive word of mouth.

“Clients are trusting us to build their dream home,” continues Troy. “Most of our customers are looking to build their forever home. We always ask whether they envisage living in their home for years to come. Nine times out

Celebrity

of ten, the answer is yes, and they choose Celebrity Builders to realize their dream because they have seen what we can do.”

In terms of supplier and subcontractor relationships, it would seem that sometimes being an amenable and easygoing partner can be a drawback. As Troy expounds: “I think we have a nice relationship with our subs and suppliers. We are fun and easy to get along with. While we are proud to nurture respectful and loyal relationships, being easygoing can put us on the backfoot. It’s crucial that we’re not bumped down the schedule, and as such, this is a conversation in which we currently need to engage.

“The construction industry has changed over the last two years. Lead times are all over the place. To mitigate, we sometimes take

“ “

It’s refreshing when a client truly trusts you to work your magic

“ “

Builders modernhb.com 51

52

delivery of products, ahead of usual schedule, to secure stock. Add the labor shortage into the mix and it can further complicate matters. Consequently, our subcontractors are struggling to stay on schedule and this has a knock-on effect on us. Ultimately though, it’s crucial that our project schedules are not derailed, as it can be difficult to get back on track.”

One notable project of which Celebrity Builders is incredibly proud is Georgetown Estate. The west Michigan little-big town mentality can be beneficial. The company’s reputation preceded it and while other contractors were in the running, following a productive meeting, Celebrity Builders won the business. As Troy enthuses: “It’s refreshing when a client truly trusts you to work your magic. That was a really fun project. Communication was easy and the client had total faith in us throughout. The project was not without its challenges however. Covid hit three months prior to completion, work was shut down and we were unable to feature the home in our Spring Parade. Luckily, the build was not delayed extensively. We abided by the rules and the client understood. Even now, we regularly return to carry out additional, little builds for them, which speaks volumes about the success of the project. It was a positive experience and we are proud to be their go-to guys.”

Growing numbers

Looking forward, Celebrity Builders is delighted to have six new custom builds in the pipeline. While business will inevitably ebb and flow, often in line with raw material price fluctuations, the order book is looking buoyant. From a large, ranch-style home to a gated-community development project, the duo certainly has its hands full. “Although we’re currently pricing projects, we are in the happy

Celebrity

position of having to inform prospective clients that they’ll need to wait until the beginning of next year to begin their build,” explains Troy.

“We have a couple of really exciting projects on the horizon: one on Spring Lake with an infinity pool and 7000-square-foot residence and the other, in Holland, and the largest for the business to-date, will be 8000 square feet and boast a six-door garage. Both are in the preconstruction phase, waiting in-line, and ready to go.”

Celebrity Builders

boasts 11 employed framers and a burgeoning number of support staff who focus on surveying, estimating and scheduling. To accommodate its growing numbers, Troy explains that the plan for the business is “to secure its own premises with office space and a conference room. That is two years down the road and we currently have a realtor looking for suitable properties.

“As far as volume of work is concerned, I mentioned earlier that between eight and ten homes a year is where we’re most content. I tend to work on the pre-construction and construction phases and Rob handles the fittings, fixtures and services. We complement each other in that regard. I am a schedule producer and he tends to finesse the project. I would say in five years from now, we will hold steady at around eight to ten houses. That is what we are good at and what allows us to build the customer relationships of which we’re so proud. While we anticipate the number of projects remaining relatively stable, the size and customization of those homes will inevitably grow. While inflation is obviously a factor, we are evidently attracting more lucrative projects, involving bigger budgets and more customized homes.” ■

www.celebritybuildersllc.com

“ “

I would say in five years from now, we will hold steady at around eight to ten houses

“ “

Builders modernhb.com 53

&FOR urban lifestylesACTIVE

Getting to know the team behind Greater Austin Builders – a standout and award-winning custom home builder

54

Greater Austin Builders

There is nothing quite like a new home. The light bounces off the freshly painted walls with life-affirming luster and the new houseplant beside the mantlepiece gladly soaks it up; windows, doors, and skylights open with ease; no clunking, grinding, or clanging can be heard. Cool in summer and warm in winter. It is a win-win – for the homeowner and the planet. More efficient fixtures and fittings, in addition to the more environmentally friendly building materials themselves, ensures that dwellings are less carbon intensive (and also more economical to run). Toilets flush, cabinets close silently, lights do not flicker, and floorboards refuse to squeak. It is everything you could ever want.

modernhb.com 55

But what about a new home that is completely customized to your own specifications? Now wouldn’t that be the icing on the cake? That is where Greater Austin Builders (GAB) comes in.

End-to-end process

As a premier custom home developer in the Greater Austin area, GAB is committed to providing purpose-driven, high-performance, and top-quality properties that utilize bespoke designs. By working in this way, the company has found itself in the business of turning dreams into concrete (or wooden) reality for buyers in the heart of Austin, Texas. If you are looking for a convenient lifestyle at a sleek new address, then contacting GAB might just be the best thing you can do.

The firm provides bespoke homes that perfectly match the Austin lifestyle mix of urban and active – and it has not gone

unnoticed. Voted one of the Best Builders for 2021 by Austin Home, buyers can rest assured during what can sometimes be a daunting time. So, let us get to know the faces behind the GAB name. There are three principal owners of the business, and we will begin with Keith Howard.

Keith has experienced a long and successful career in real estate and has been part of the local home building industry for over 16 years. He worked for numerous home builders prior to becoming a custom home builder in 2006 and prides himself on the fact that he is prominently involved throughout the entire home construction process –all the way from project conception and initial meetings to final completion and the handing over of keys.

Along with long-time childhood friend, Chester Wilson, Keith created GAB in 2012 to bring high quality custom homes, at a fair

56

price point, to its growing list of customers. On a more personal note, Keith married his high school sweetheart in 1999 and has three boys, which they are raising in Austin. In his spare time, Keith is a keen sportsman, coaching numerous youth teams, and is also highly involved in his church.

Recognized name

Next, we turn our attention to Keith’s childhood friend, Chester Wilson. Being a lifelong Austinite, Chester has witnessed the city evolve and grow in style and substance since the early 1980s. Having been raised in Austin, Chester is very familiar with all parts of the Central Texas region. Therefore, he can bring a local history and context to every home he helps to create.

Moreover, being a realtor, builder, and developer, Chester can really stretch his wings and promote a strong level of service and experience across the GAB corporate family. After the formation of GAB, the company got to work on setting a firm foundation to keep the family business and Austin building innovation and its noteworthy style alive. Setting them up for success well into the future. Indeed, to do so, Chester and the team proudly collaborate with some of the brightest architects in the city, and strive to lead the consumer in style, efficiency, and quality.

The third owner of GAB is Macon Foster, who likes to say that he has been in the home building business since he was just 16 years old. Back then, he would spend his weekends installing interior trim for his father’s Dallas-based company. Macon has always placed a special emphasis on building top-quality homes that exceed market expectations. His new product lines have been implemented in multiple markets across the country, and they have consistently received regional customer satisfaction awards.

Greater Austin Builders

With GAB since January 2013, Macon is eager to contribute his acumen for creating spaces that combine aesthetic quality with overall value. In short, he makes a fine addition to the company’s innovative redevelopment services in Austin’s city core. In his spare time, Macon enjoys bicycling, traveling, and barefoot water-skiing on Lake Austin.

The close-knit team that we have spent some time getting to know is the driving force behind GAB; together with subcontractors and suppliers, the company has carved out a strong market share – and even stronger name for itself – in the Greater Austin region. As we look towards a future unhampered by pandemicinduced restraints, it is fair to assume we will be hearing a lot more about Keith, Chester, Macon, and those three big letters: GAB. ■

www.greateraustinbuilders.com

modernhb.com 57

www.kentshafferbuilders.com

www.kentshafferbuilders.com

▲

Paul Wellborn, President & CEO

Wellborn Cabinet, Inc

▲

Paul Wellborn, President & CEO

Wellborn Cabinet, Inc