LEADING THE SWITCH

A Q&A with SMMT Chief Executive Mike Hawes

Ecommerce

Sustainability

Issue 207 - 2022

Human resources Why the industry must put the needs of people above technology

Key success factors for manufacturer-driven marketplaces

How one company is using innovation to drive the green agenda

HERE TO SIMPLIFY COMPLEX BUSINESS SYSTEMS

Say goodbye to disconnected systems and boost operational e ciency. It’s time to experience SMARTER HR, PAYROLL & FINANCE.

MHRGLOBAL.COM

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Consultant Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Steven Dobinson

Editorial Administrator Amy Gilks

Creative Lead Lee Protheroe

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe Artwork Administrator Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors Philip Monument, Joy Francesconi

Head of Content Management Adam Blanch

Client Sales Executives Chloe Allman

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Laura Thompson

Content Managers Johanna Bailey, Mark Cowles, James Fuller, Jeff Goldenberg, Melanie Joyce, James Page, Wendy Russell, Richard Saunders

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Hello and welcome to the December issue of Manufacturing Today. Our features this month touch on a selection of topics – human resources, ecommerce, sustainability and cyber security. This latter point is increasingly important, as industry 4.0 and smart factories continue to advance – in fact author Dr. Aarthi Krishna states that in 2021, manufacturing became the most attacked sector by cybercriminals. “All advancements can be reset in a blink of an eye if security is not properly infused into the systems…” he warns. Turn to page 28 to find out more about the risks. This is our last issue of 2022 - what a year it’s been. I would love to hear from you on what the highs and lows were for your business, so please do get in touch.

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130 www.manufacturing-today.com

US Office 2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Why the industry must put the needs of people above technology Key success factors for marketplaces Sustainability How one company is using innovation to drive the green agenda LEADING THE SWITCH A Q&A with SMMT Chief Executive Mike Hawes Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Our cover story for December features a Q&A with Mike Hawes, Chief Executive of the SMMT. To read his insights into future automotive manufacturing challenges, turn to page 8.

LH@finelightmediagroup.com

Follow manufacturing today at @mfgtodaymag manufacturingtodaymagazine

Libbie Hammond, Editor

Welcome manufacturing-today.com 1

Inside this issue

Sustainability News Ecommerce Cyber security Human resources Cover story 16 30 20 28 24 8 Contents 2

Mike Hawes - Chief Executive, SMMT

Creation Technologies CHL Systems Econ Engineering Medstrom Exclusive Feature Exclusive Feature 44 52 34 40 manufacturing today manufacturing-today.com 3

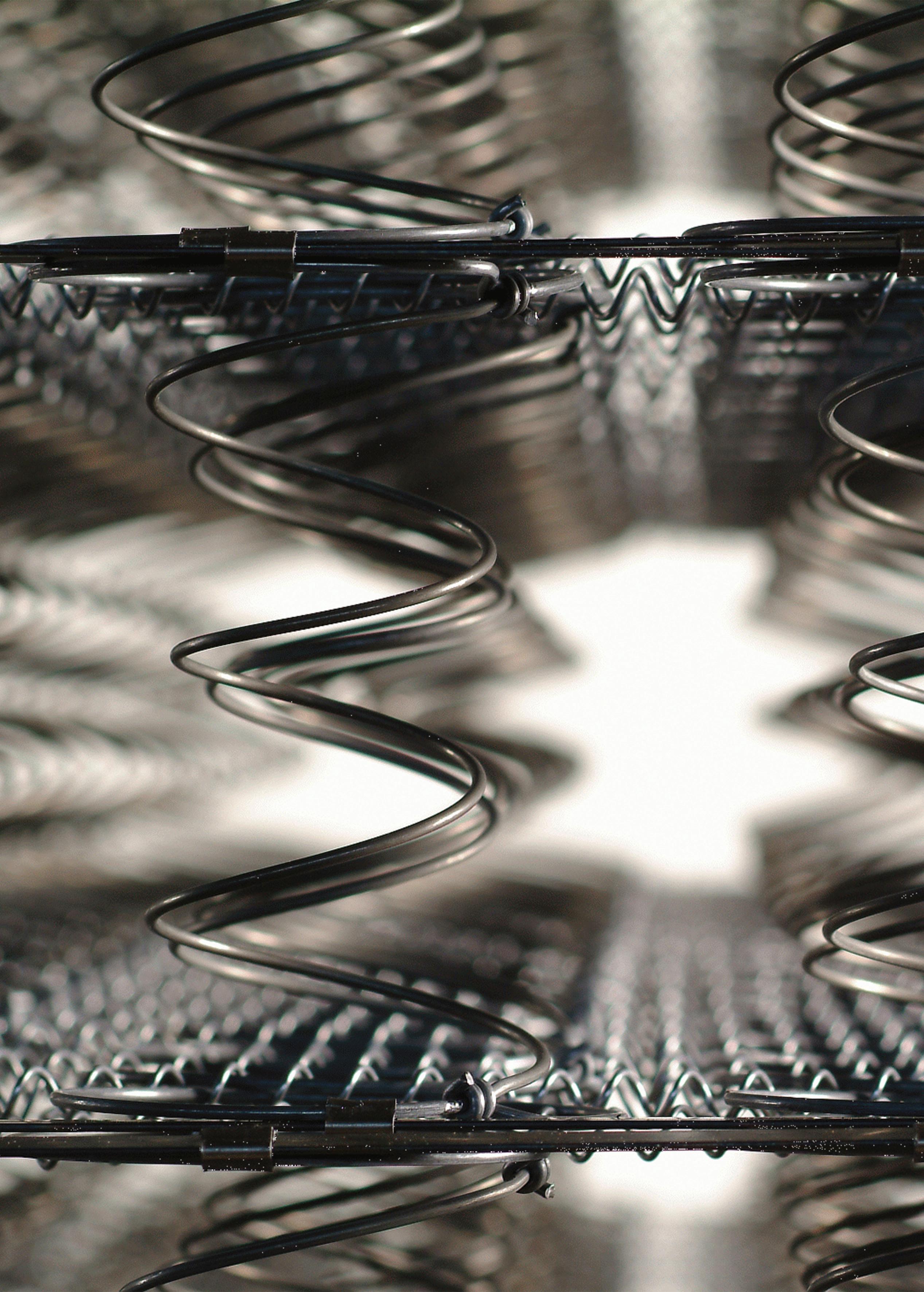

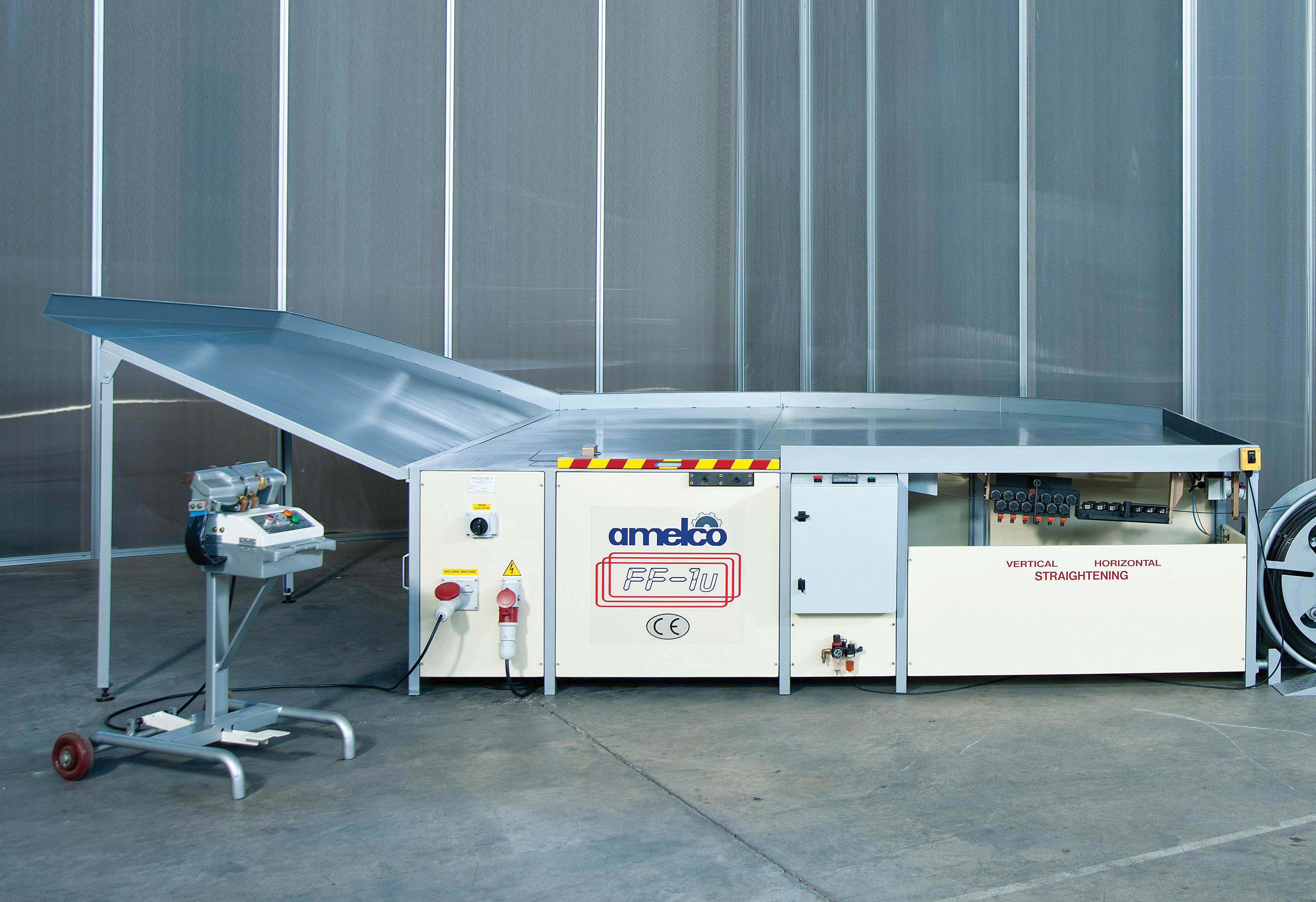

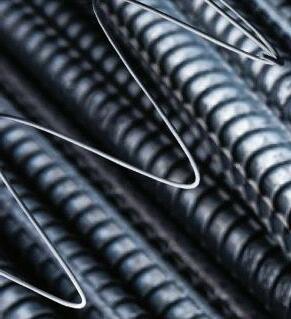

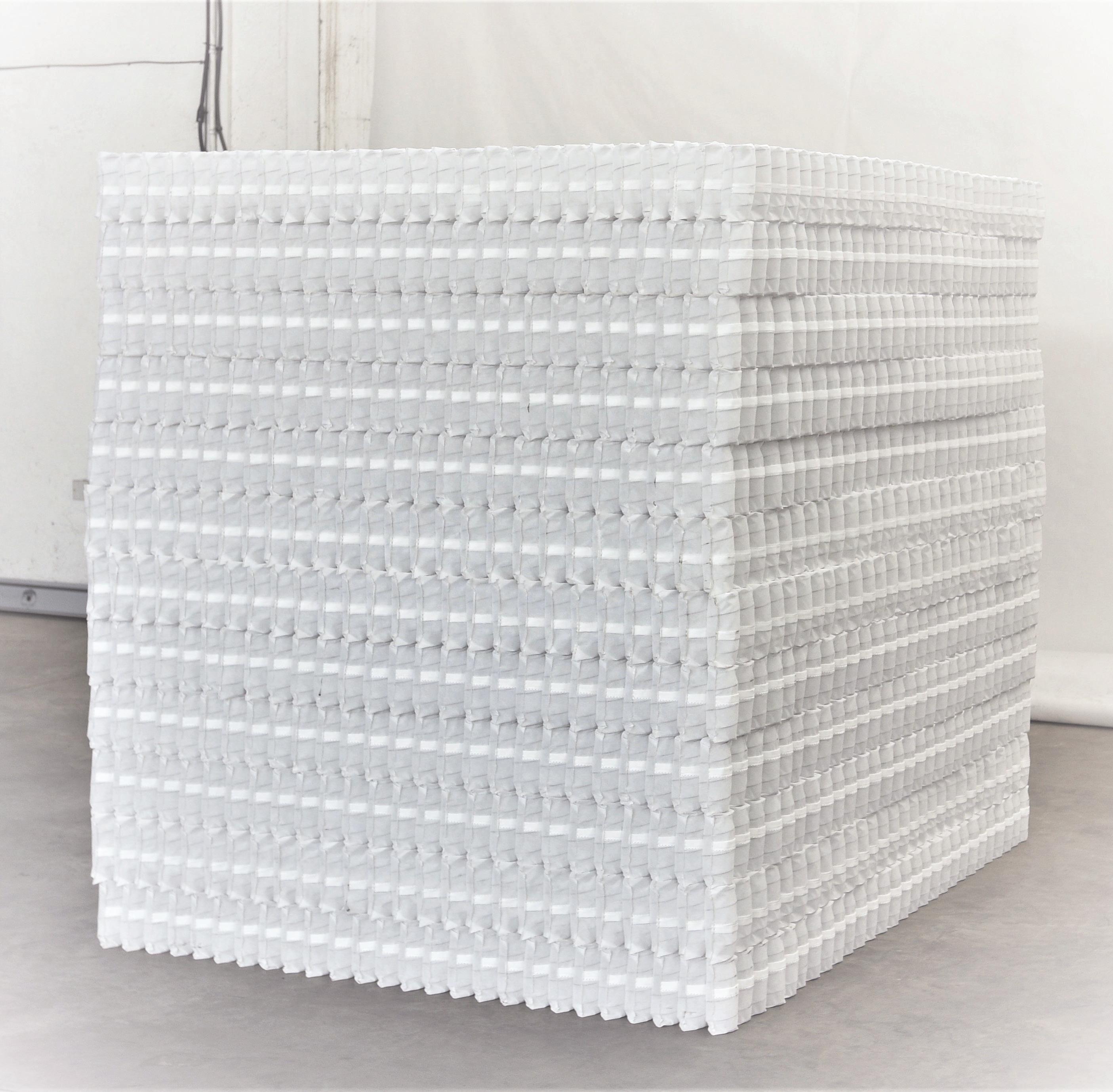

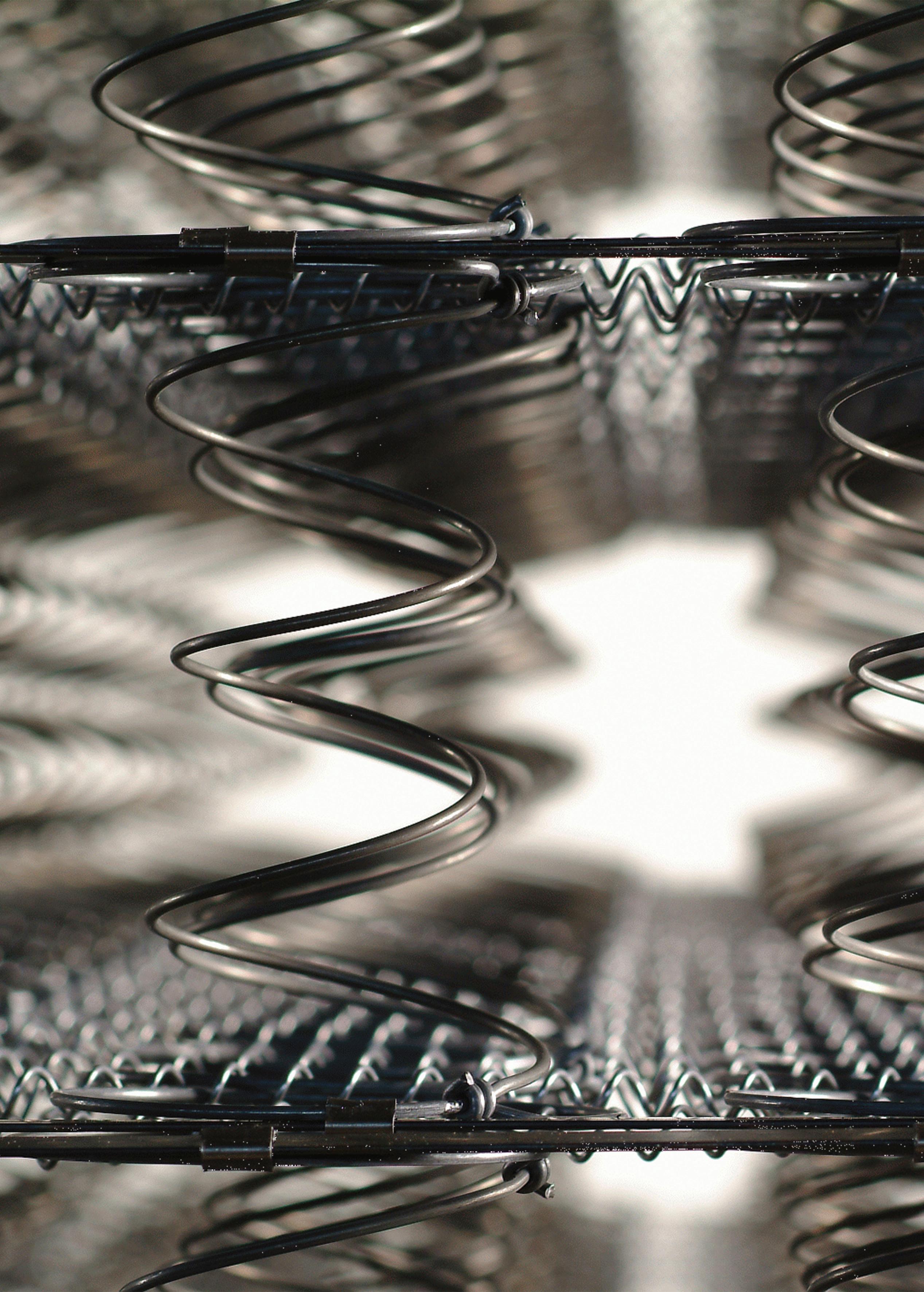

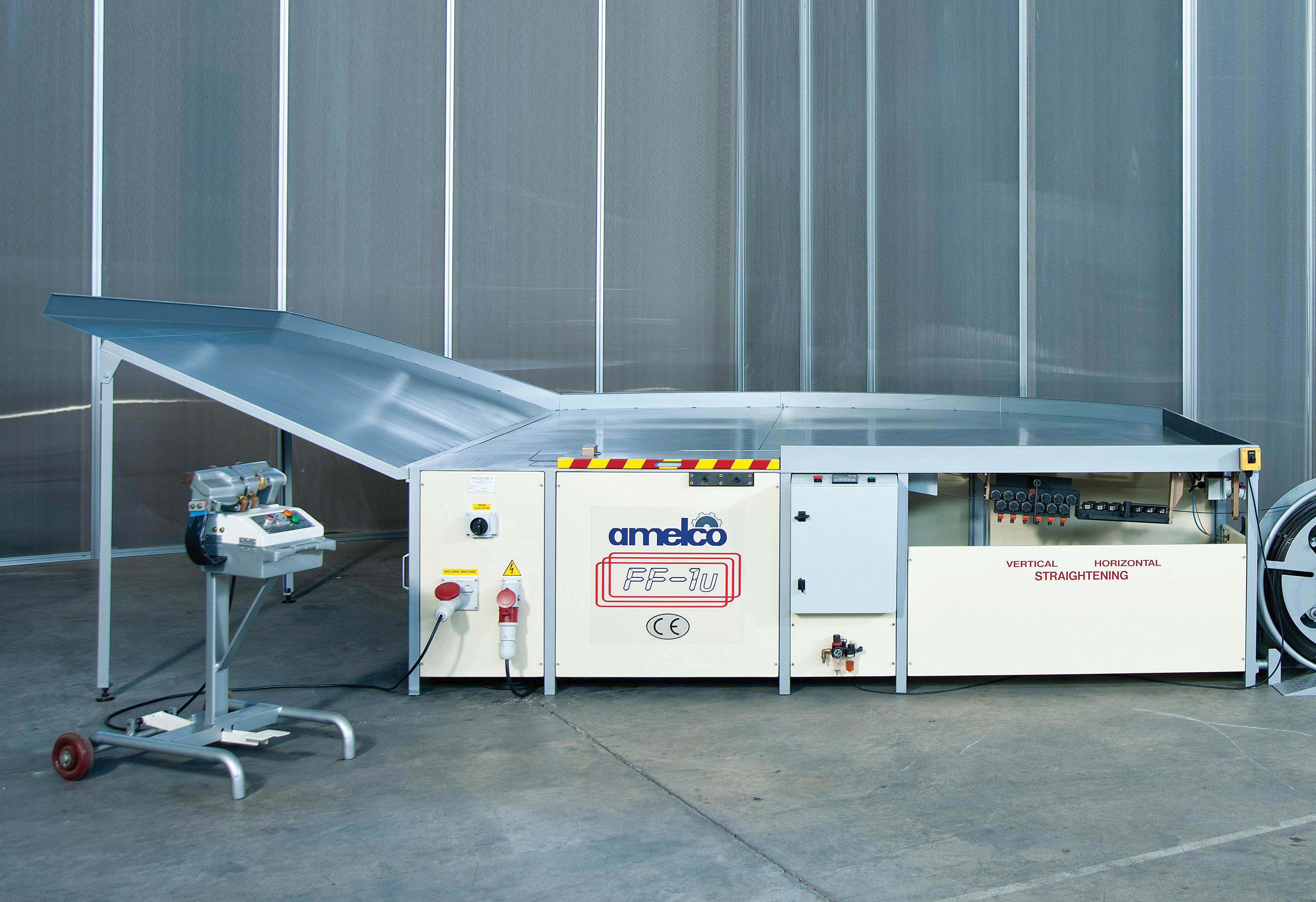

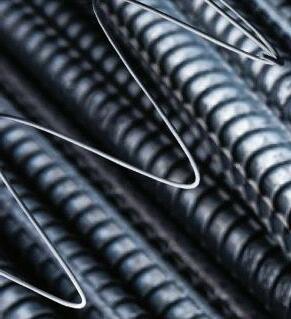

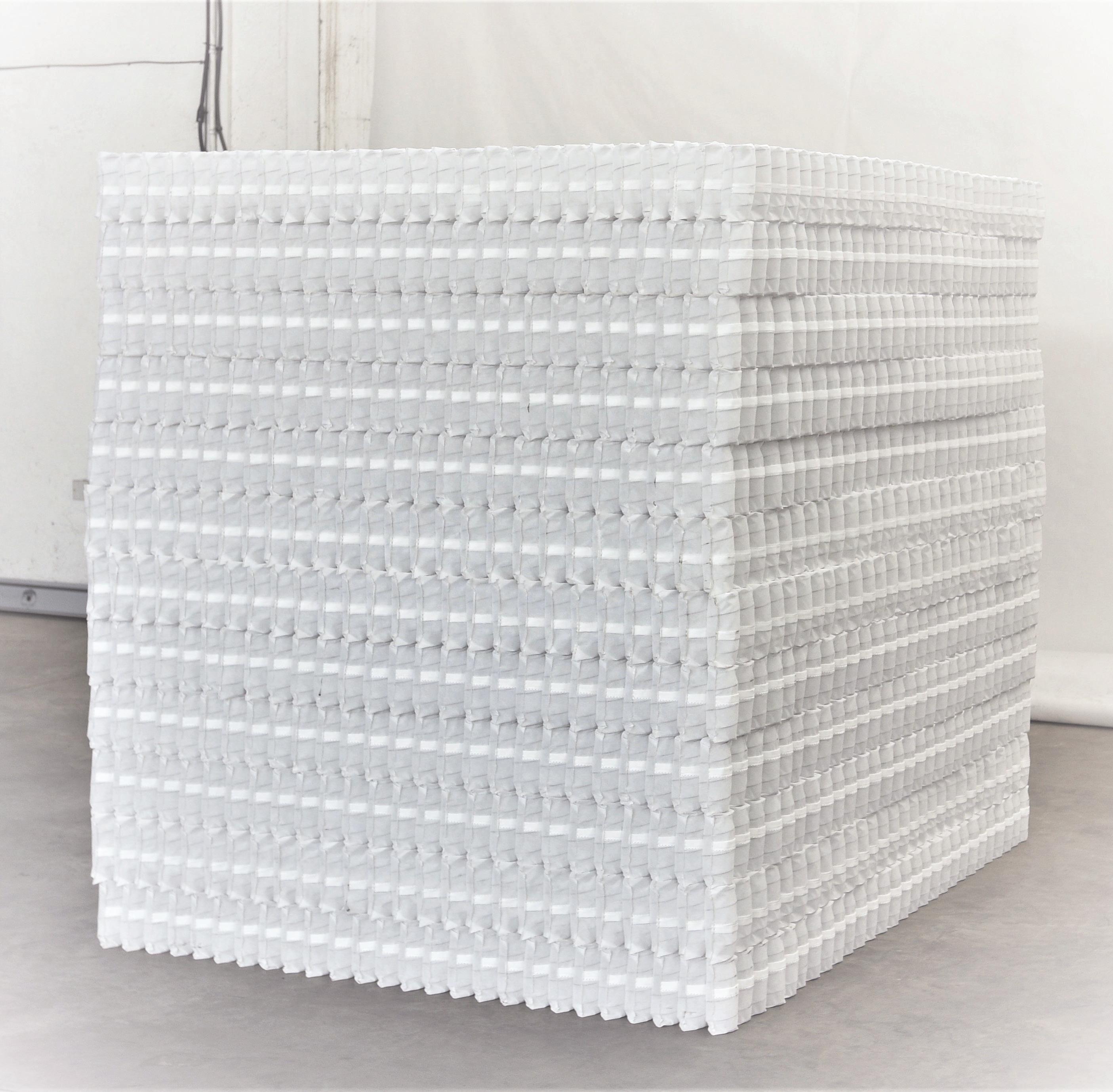

Boss Design Roche Amelco Industries Ltd Gartner Refrigeration Switlik 58 64 70 86 78 Contents 4

manufacturing-today.com 2 1

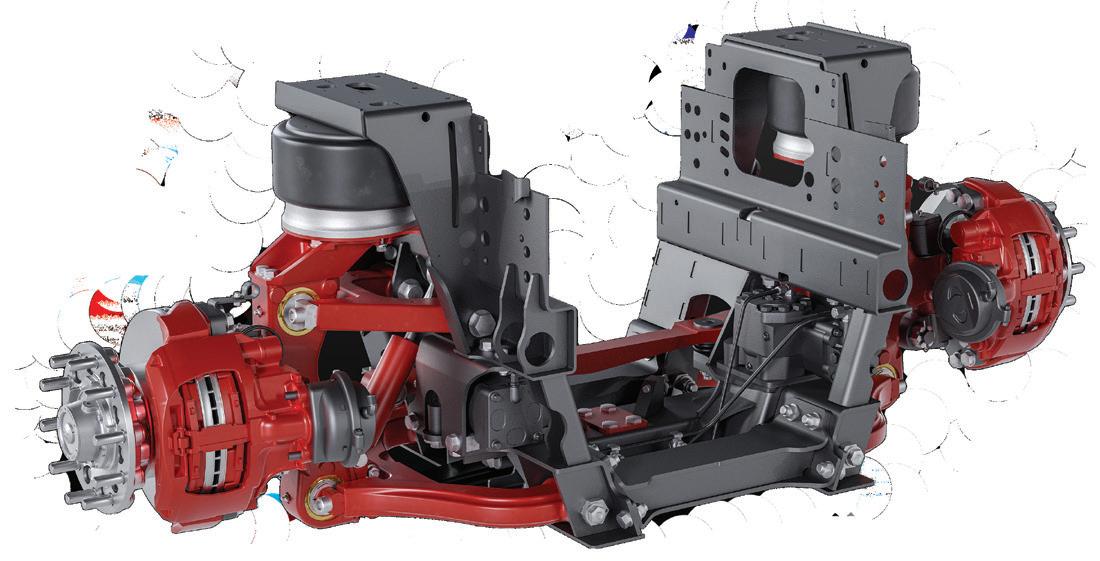

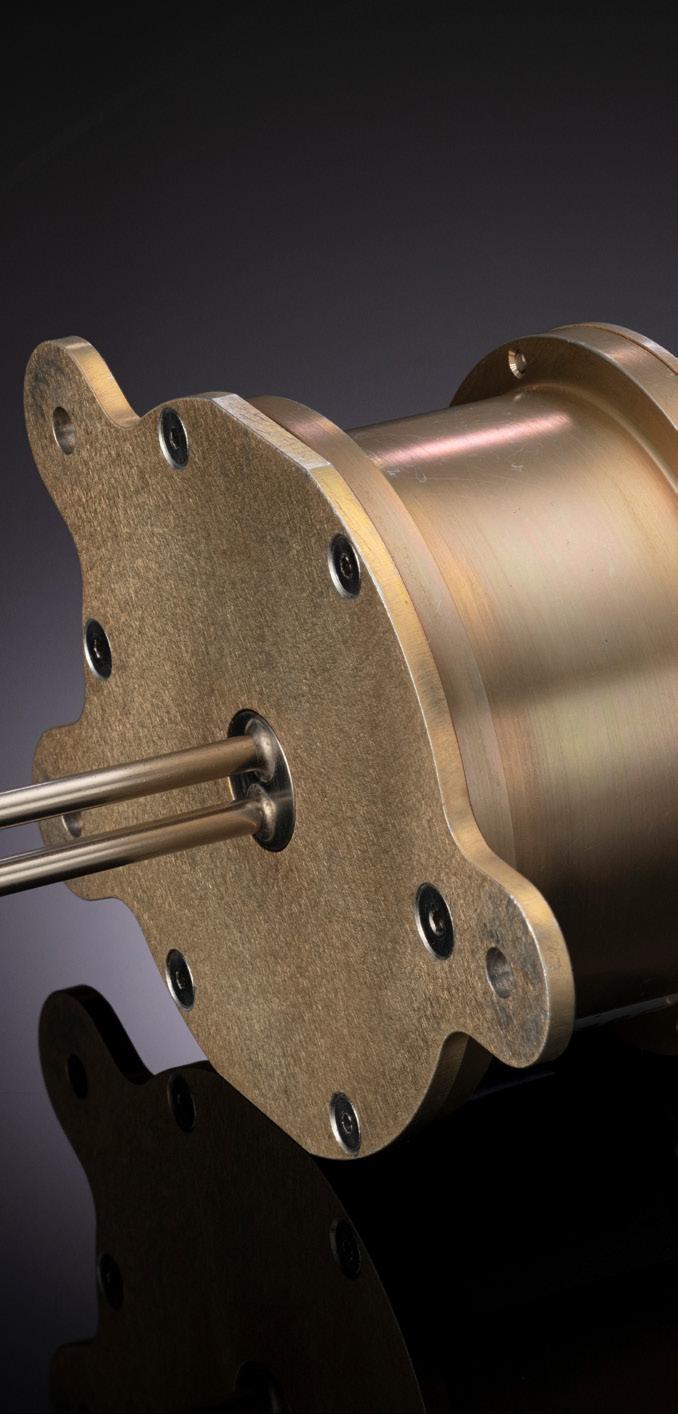

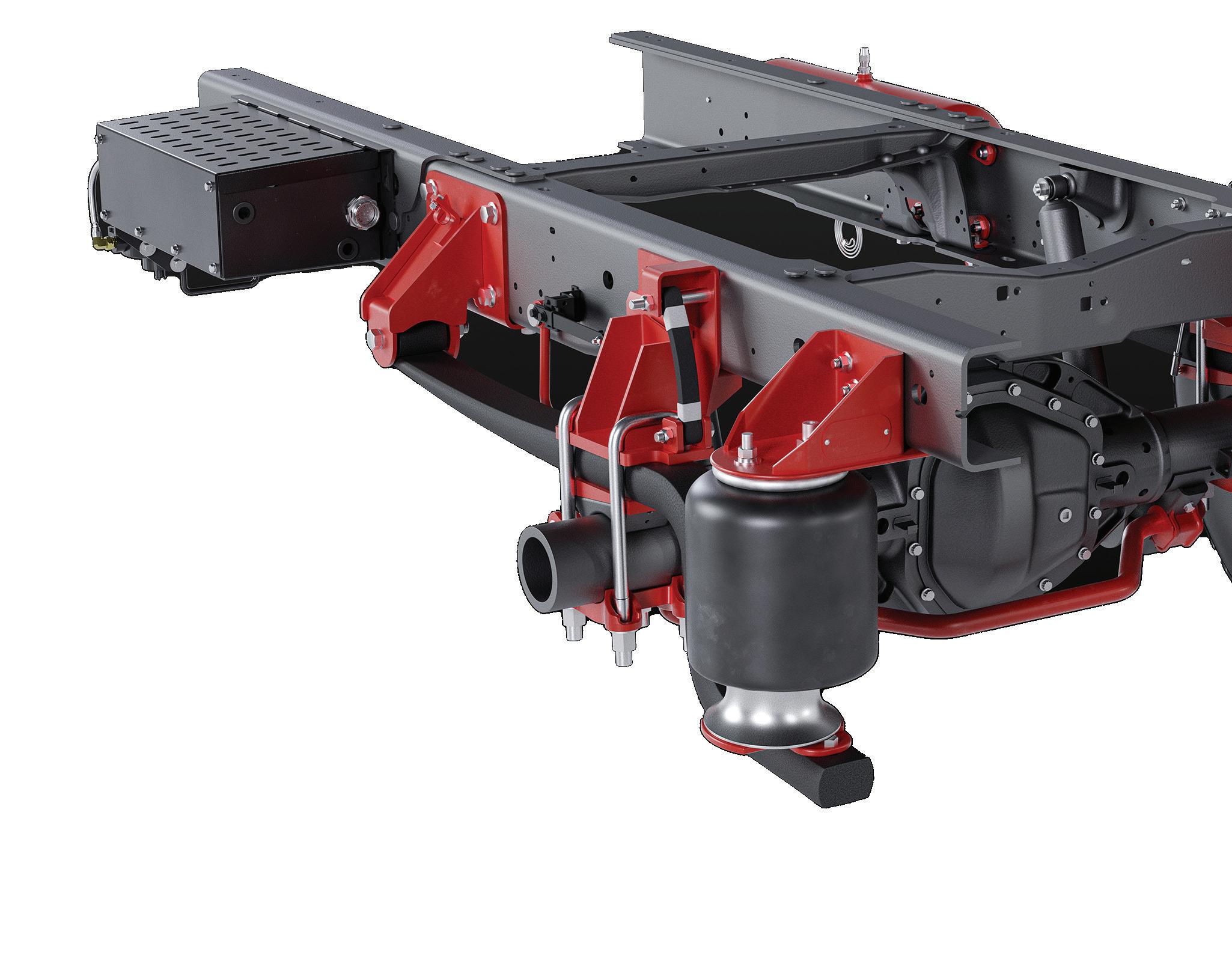

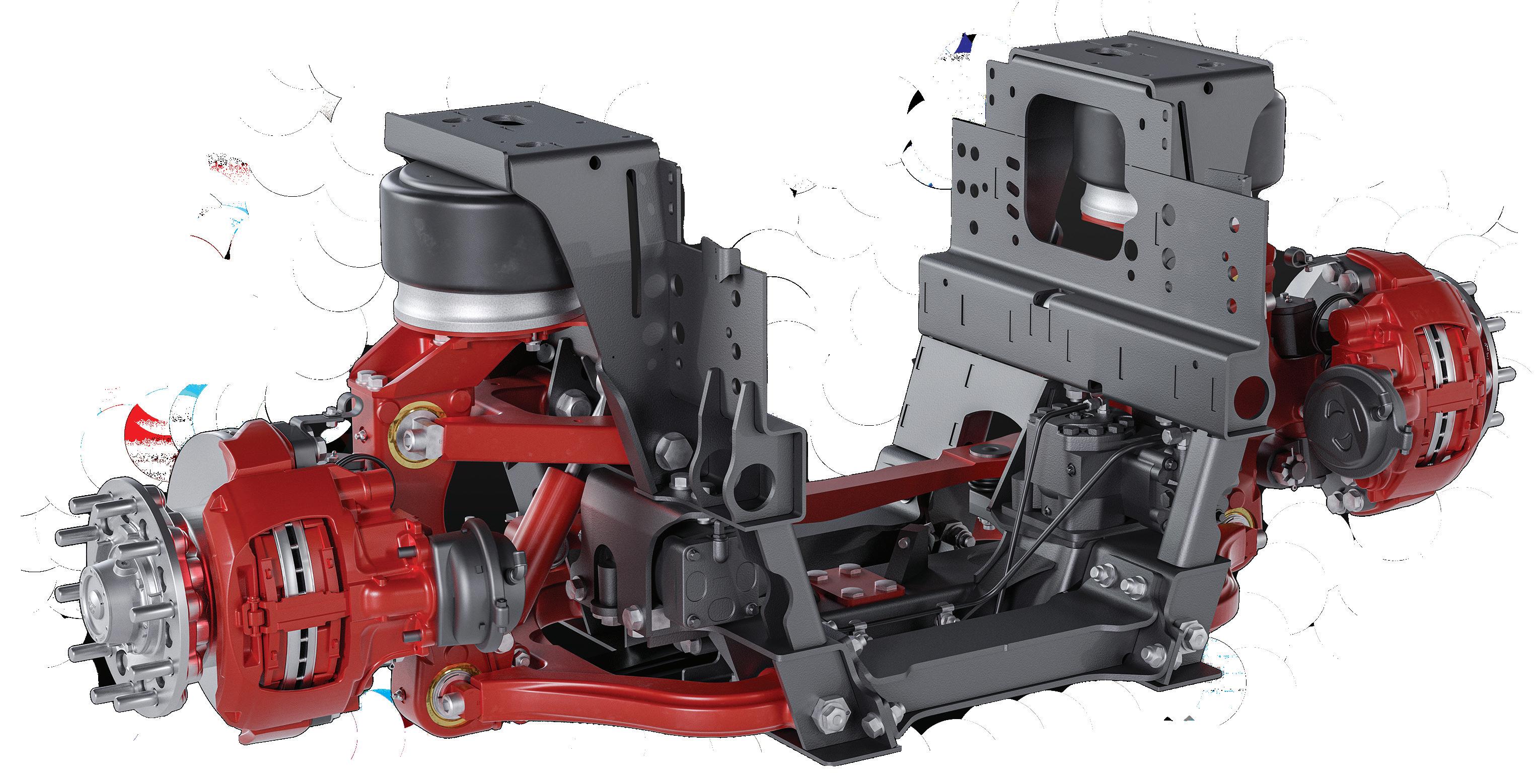

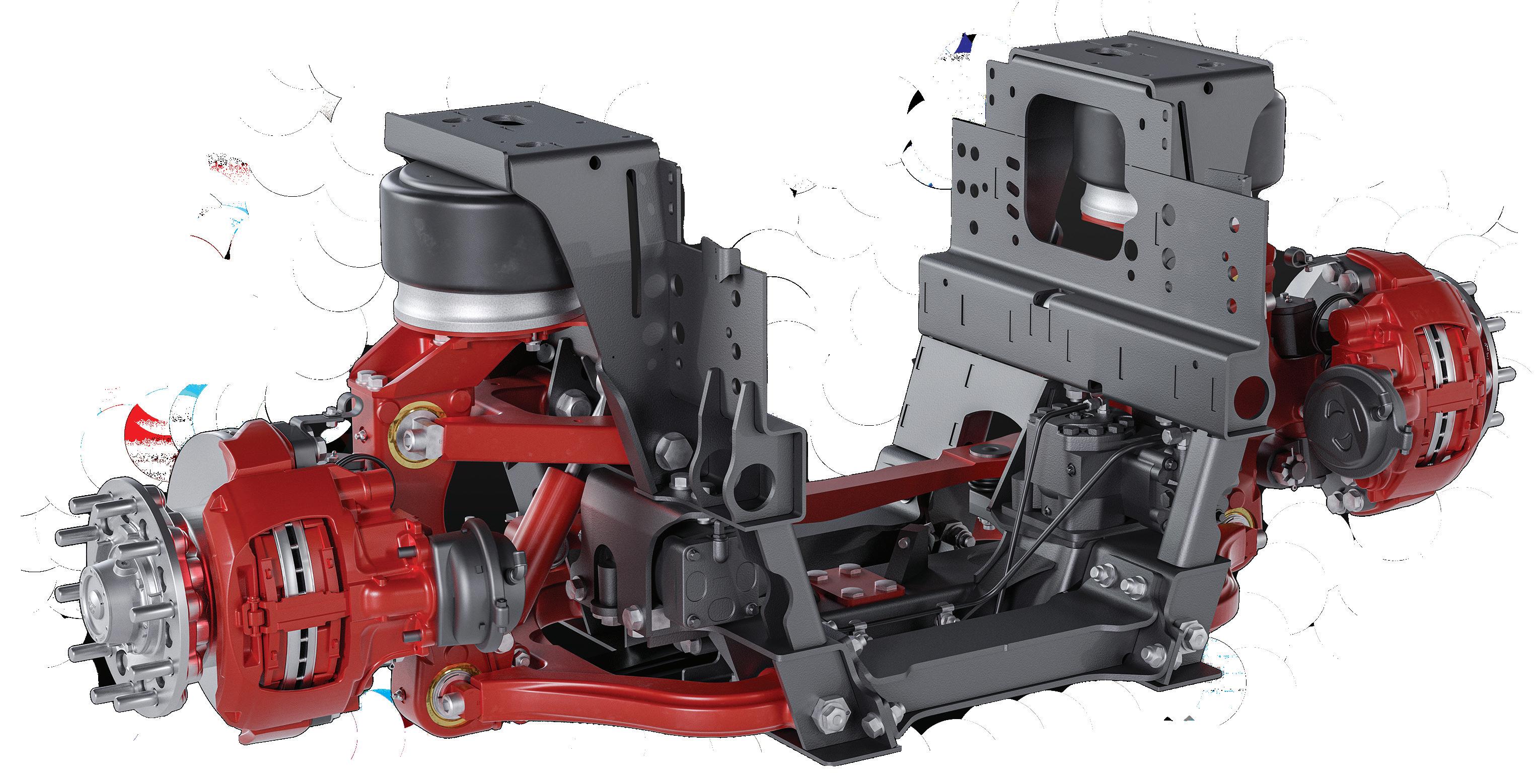

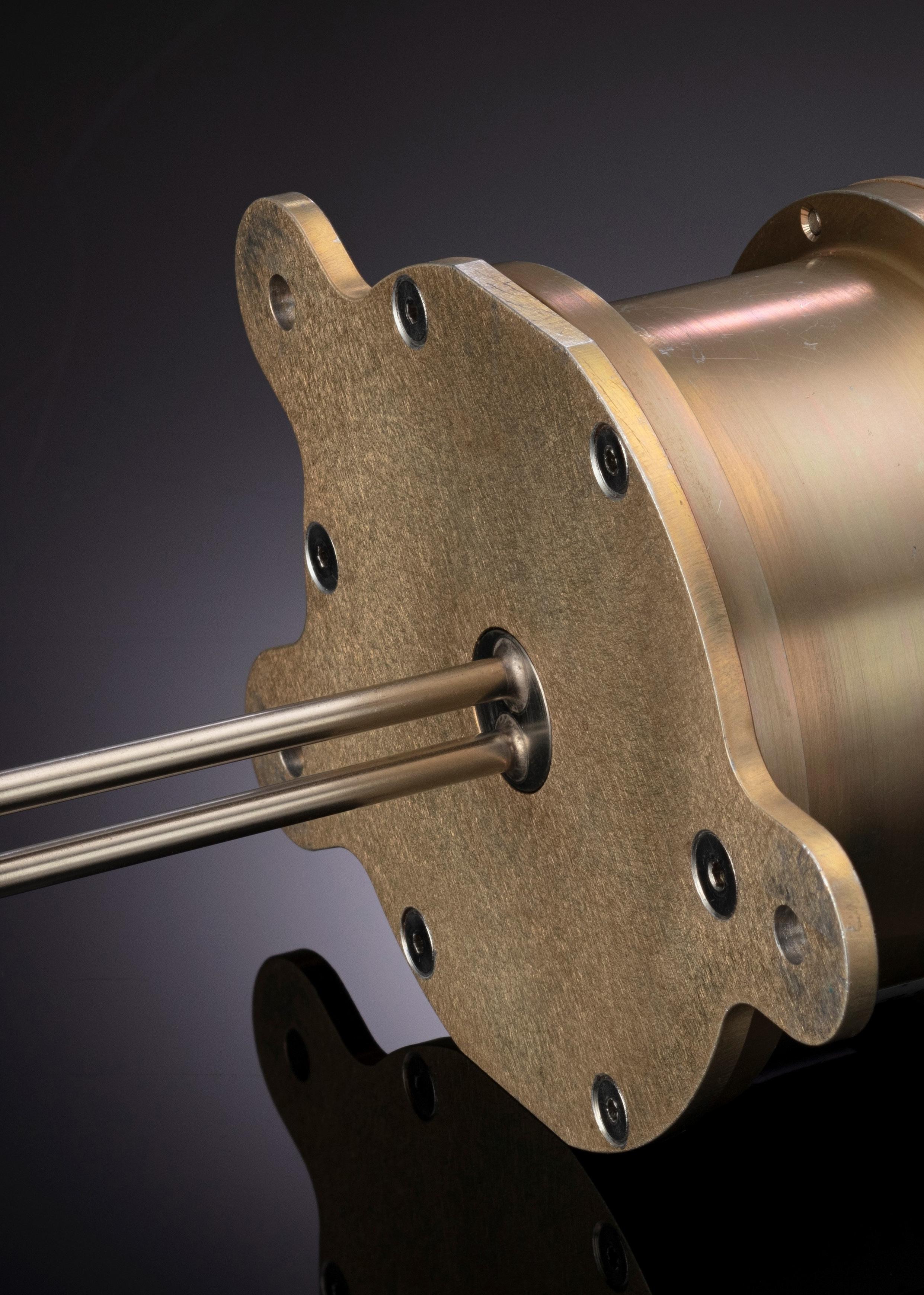

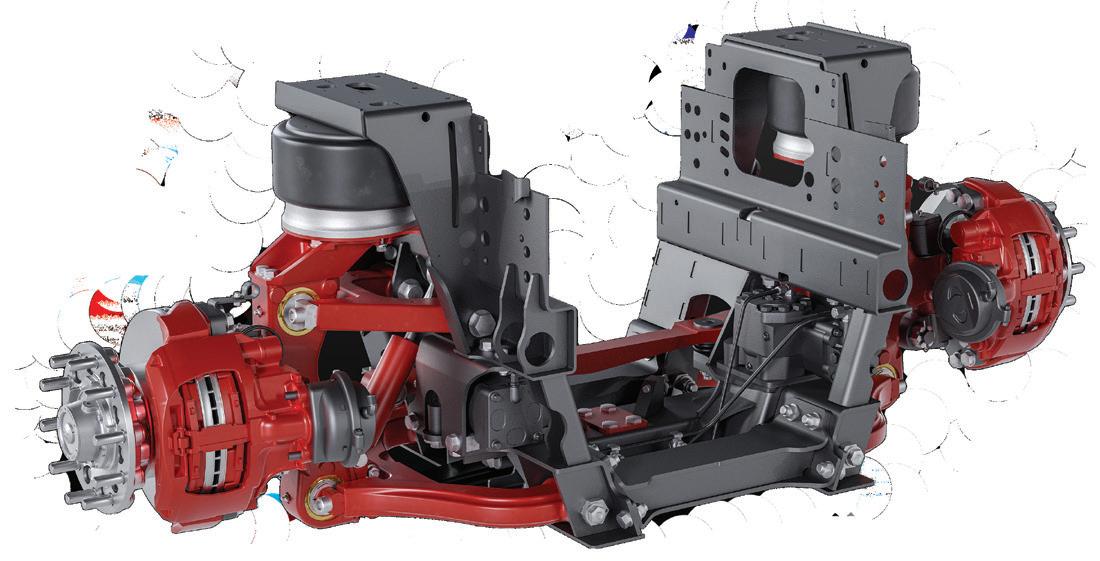

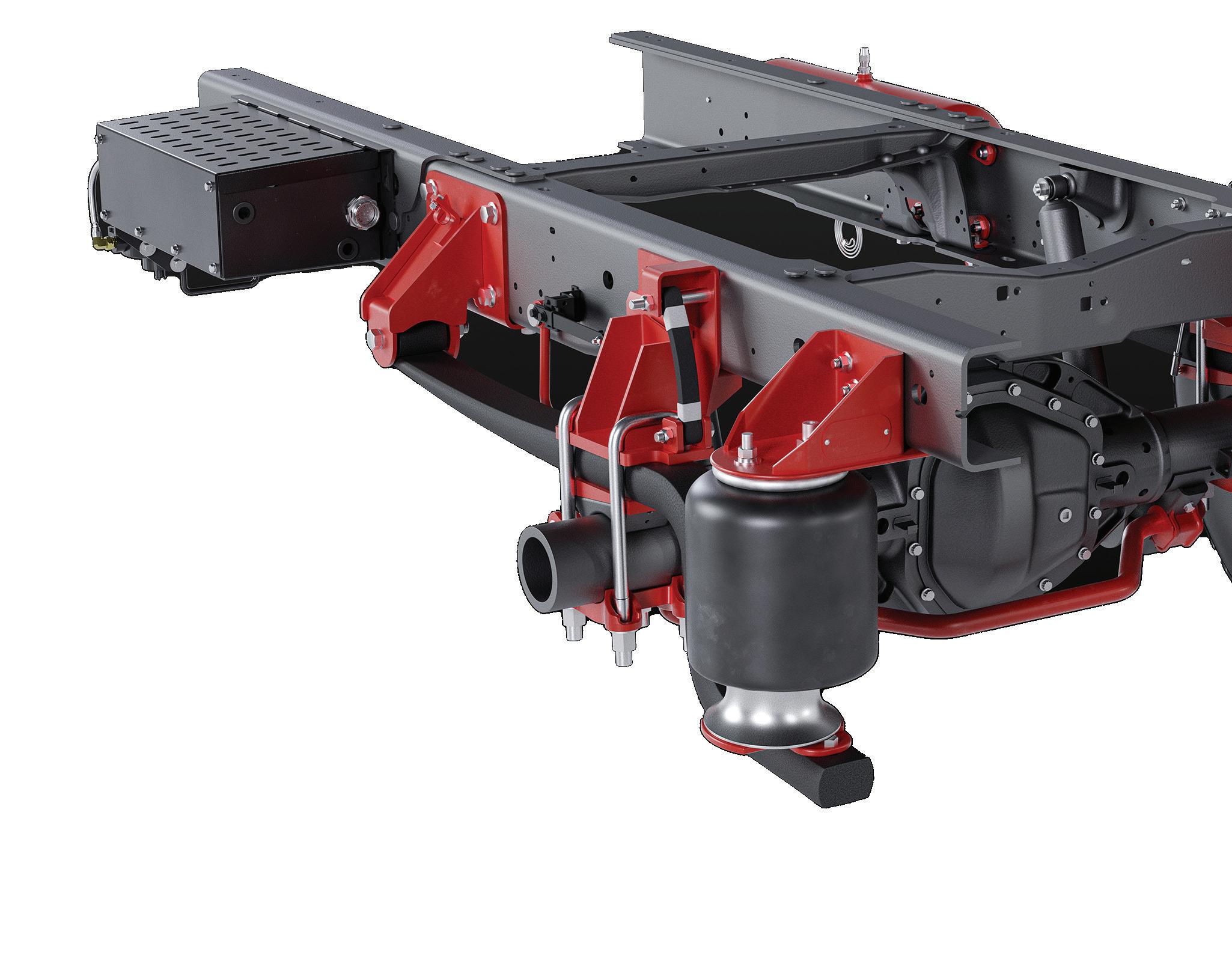

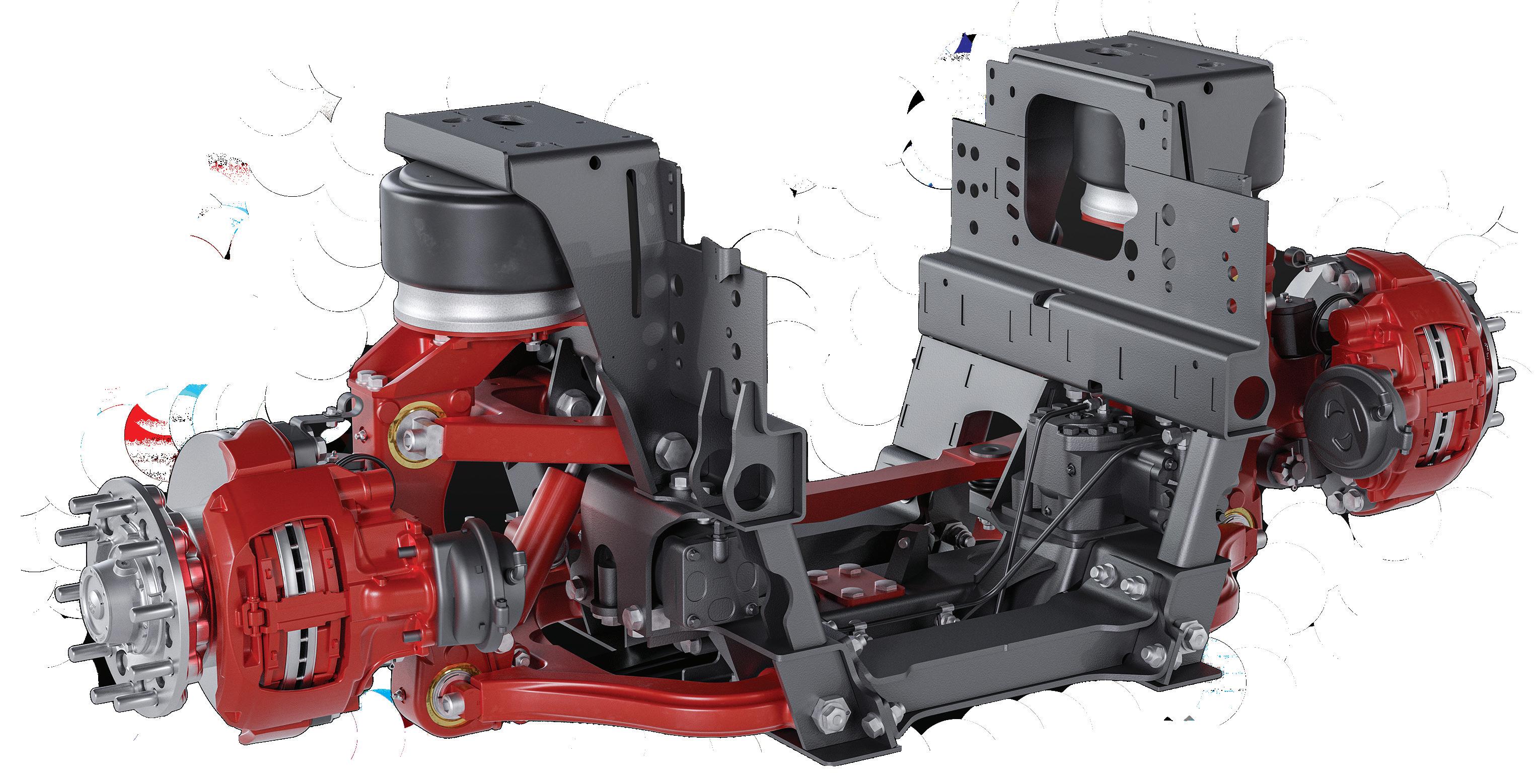

Reyco Granning

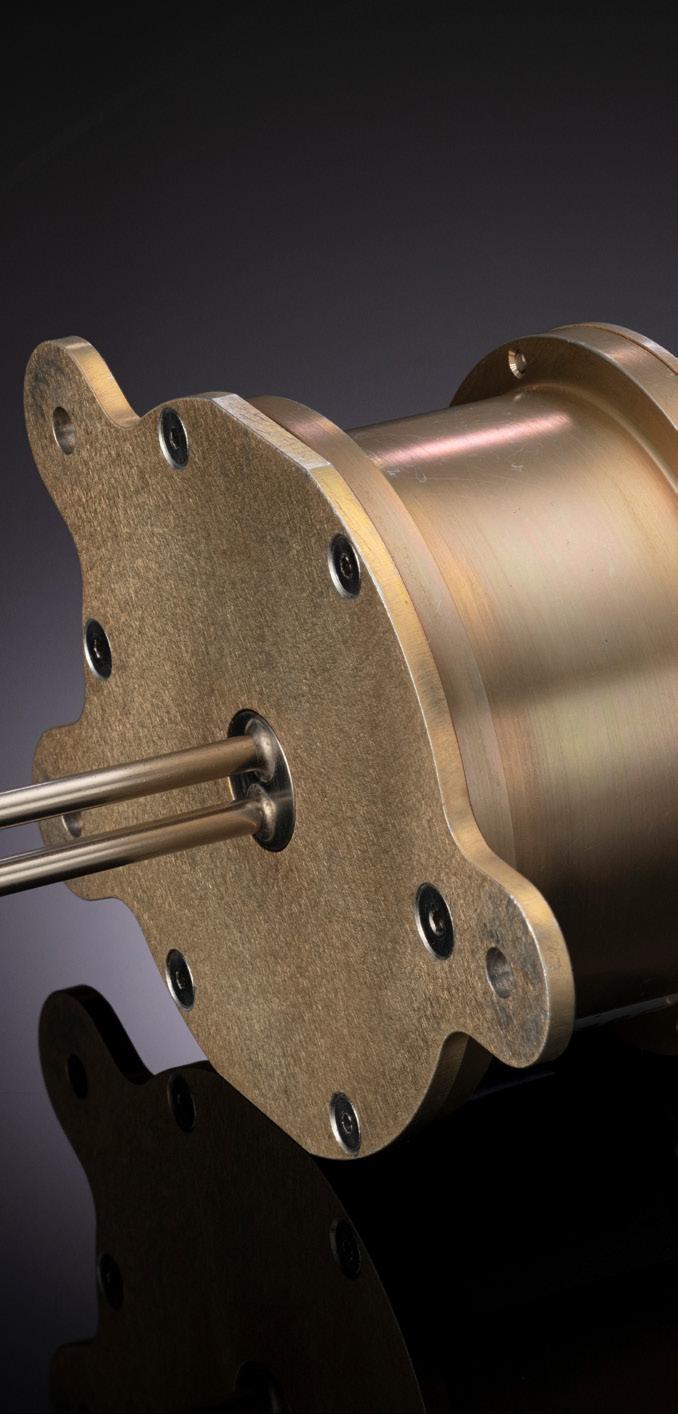

Reyco Granning Renold Dowty Propellers

92 98 102 110 manufacturing today manufacturing-today.com 5

Johnson Tiles

Elevation Labs HarcoSemco Rieke Office Interiors 116 120 National Composites 132 126 Contents 6

Freedman Seating Millerbernd Viewrail Vendors Exchange Belt Power 138 144 150 162 156 manufacturing today manufacturing-today.com 7

Cover Story 8

THE SWITCH LEADING

A Q&A with SMMT Chief Executive Mike Hawes

1.Can we focus our attention on yourself to start with – can you tell me about your own career so far, and what has brought you to this point at SMMT?

What do you enjoy most about the role?

businesses across the industry, and meeting them is what I enjoy most. There is nothing that replaces the insight and inspiration you get by going out and seeing the businesses – the products, the technologies and the people.

“ “

I ended up in the automotive industry by accident rather than design, but I haven’t regretted it for a moment. Automotive was the cross-section of a handful of sectors that I was interested in, having experience of transport policy and planning, government policy and research, and then corporate communications, before senior roles at Toyota and Bentley. Automotive is one of the most exciting, vibrant and challenging sectors to be in – the great thing is that it stirs emotions and people always have an opinion, positive and negative. There’s a wide range of issues, and it’s great to be in an industry that makes something – a set of consumer goods on which people depend. And there’s great people and

2. What are the biggest issues that need to be addressed in terms of electric vehicles and the move to EVs? For the customer, the biggest issue at the moment is charging. If you’ve got a driveway, you can charge at home, but if you don’t, you’re dependent on street charging, workplaces, supermarkets and so forth, and you’re going to be paying more money to do so. On-street charger provision needs to be improved, as well as charger reliability and availability, while VAT on public charging must be aligned with home charging at five per cent. Action is needed sooner rather than later. We need a nationally devised, locally delivered infrastructure plan that mandates higher levels of roll-out – in line with EV production targets and growing consumer adoption – to ensure that charging is available to all. Crucially, we need reliable infrastructure that is designed for all types of vehicles and road users, including disabled motorists, in the best locations across the UK.

...our biggest challenge is to drive down the cost of these vehicles...

“ “

Interview 9 manufacturing-today.com

For the industry, our biggest challenge is to drive down the cost of these vehicles, which is really difficult during supply disruptions, with the cost of raw materials and logistics going up. It’s a new technology too, so price parity isn’t likely to happen in the next year or two. But, gradually, as you get towards mass market, cost pressures and local assembly will drive down some of those extra costs, as will the availability of cheap, affordable and sustainable energy. Then, we will be well within that total cost of ownership benefit, meaning that buying an EV is a no-brainer, because the driving experiences are phenomenal.

3. A lot of focus goes onto electric cars but electric vans are growing in popularity – do you think more focus should shift to the commercial side? What are the barriers to adoption? What most people are talking about is what they see on the road, what they read about; and that is the rise of electric. Mainstream media and popular consumer titles will always report mainly on passenger cars, because their audience has the potential to have one of those on their driveway or parked on the street. But you mustn’t lose sight of commercial vehicles, because society depends on them for the provision of essential goods, the provision of services, filling the shelves and everything else. The paucity of

infrastructure for passenger cars is obvious but, despite the criticism, it is so much better than that for commercial vehicles. Certainly for HGVs, roadside charging is nonexistent. The industry is being challenged not just to decarbonise passenger cars but every single road transport segment, so the infrastructure, incentives, and affordability have to be there, across every region of the UK, from London to the Scottish Highlands.

4. When it comes to delivery and deployment, how are UK automotive manufacturers addressing the shift to EV? What is on their agenda for the next three to five years?

The UK is in many ways the same as any other manufacturing location: we must accelerate a transition from fossil fuels to decarbonised technologies. OEMs are investing to build the vehicles and we are trying to attract investment in gigafactories, because batteries need to be produced relatively nearby. For that you need cheap, renewable energy –because it’s the whole circular economy we’re looking at here – access to ports, availability of finance, a competitive investment environment and a strong domestic market. Invariably, about 20 per cent of what you produce tends to stay where it is. UK demand for EVs is accelerating dramatically and, despite a tremendous amount having been already invested, we need a lot more.

Cover Story 10

Interview 11 manufacturing-today.com

Cover Story 12

We have a relatively small window to attract these investments, because all major OEMs are moving towards new technologies at pace, making big bets on where they should be investing. The UK has to be on the shortlist, so we need a really compelling competitive proposition to attract them here. We have a lot to offer given the UK sector’s diversity, skill sets, R&D expertise and, potentially, significant amounts of renewable energy. There’s a lot in our favour, but everyone’s facing headwinds around logistics, supply chain, and availability and costs of raw materials. We need a framework for that investment especially for the supply chain which is as challenged as any other part of the sector to make the transition. But I am convinced we have a competitive offer. We just need to ensure we have political and economic stability as that is essential for long-term investment.

5. Do you think there needs to be more focus on educating and enticing customers into moving towards adoption of EVs? What holds them back? Public awareness of EVs has certainly shot up, but you need to turn that awareness or consideration into demand. That’s about cost of ownership. Recent changes to VED rules mean that EV users will pay road tax from 2025, and while it’s right that all road users should pay their fair share, the current approach will mean that the majority of EVs will be subject to the “expensive car premium”. With charging infrastructure lagging behind, there needs to be more not fewer incentives to encourage consumers to make the transition.

And this has to be a national transition; the popularity of EVs already varies across the UK: I live up north but work in London, and the conversations you have with friends about EVs are very different. In London, people tend to drive shorter distances and you can see EVs charging on the street, whereas in other parts of the country, such as more rural areas, you don’t see the vehicles or infrastructure, as readily possibly because people tend to drive longer distances. We have to make sure EV ownership works for everyone, especially motorists that don’t have driveways or don’t live in a city. We’re not doing too bad on the strategic road network, but once you get off that, all the evidence demonstrates charger provision is still a major issue.

6. EVs are also linked to both fuel prices at the pumps and the cost of energy – not just for charging EVs as electricity prices increase, but also for manufacturers as heavy energy users. Can you comment on how energy costs are impacting the automotive sector and the strategies manufacturers are introducing to deal with the issue? Unsurprisingly, rising energy costs are the number one concern for manufacturers. The UK pays, on average, 60 per cent more for energy than the rest of Europe, before the current price volatility. And these are the markets with which we are competing for inward investment. These steep energy costs are primarily a European issue, largely due to Russia’s invasion of Ukraine, so we must find a way to address these issues or else European manufacturing – not just the UK – will remain less competitive compared to other parts of the world. Every manufacturer, whether

“

“

Like other sectors and across Europe, we are facing an acute labour problem and are focused on filling the skills gap...

Interview 13 manufacturing-today.com

“ “

you’re in supply chain or an OEM, has been looking to reduce energy costs, which SMMT’s Sustainability Report demonstrates. But the low-hanging fruit has been picked many years ago so significant energy cost reduction measures are going to cost significant sums – at the very time the economic environment is so costly for manufacturers. Government can help, for instance providing business rate relief for these investments, else you end up “robbing Peter to pay Paul”.

7. On the manufacturing side – can you comment on the issues that manufacturers have been experiencing with the supply chain and if that is improving?

Supply chain issues have been incredibly difficult for everyone. The constraints on manufacturing are obvious: production

levels are 30 per cent off pre-pandemic 2019, which has led to the significant fall in the sales of new cars, vans and trucks. The issues don’t singularly lie with one component but semiconductor shortages have been a major factor, with the supply chain facing acute difficulties in terms of cash flow as a result of production volatility.

Do I think things improving? They’re beginning to. There is more optimism about next year, with supply issues expected to gradually ease as the year goes on, but the industry will be playing catch-up in terms of supply such that we could very well appear counter cyclical next year; we are forecasting production and registrations up 15 per cent in 2023, whilst the UK may well, regrettably be in recession. This is an indication of how severe the past few years have been and why

have to finally deliver recovery.

we

“ “

It is essential that we diversify Cover Story 14

“ “

8. How has the UK automotive manufacturing sector adapted following Brexit and what is the current outlook for Europe and international trade?

The industry was pretty united in its position going into the Brexit referendum: we would have preferred to remain, but this is not how the country voted. We are focused on making the deal we have work for us, and we fought hard to ensure the deal did all it could to safeguard the UK automotive industry. Indeed, the TCA offers opportunities for us –there is an automotive annex and provisions for the creation of technical working groups. But they have never met as, for that, you need a relationship of trust on both sides.

Manufacturers have had to persevere, and they have done a brilliant job so far. But there are still additional costs to bear. Moving goods, components and finished vehicles across the border into the EU costs more than it did – perhaps somewhere up to an extra five

per cent. And with the TCA requiring more stringent Rules of Origin requirements on EVs from 2024, threatening the continuation of tariff free trade for these goods, the EU and UK must make an honest assessment of local battery manufacturing capabilities and assess the risk to the sector and the delivery of shared decarbonisation targets.

Like other sectors and across Europe, we are facing an acute labour problem and are focused on filling the skills gap, investing in upskilling our current workforce. It’s better for us, better for our people, to do this. However, this will not solve our immediate problems. We need to get more talent into our sector.

It is essential that we diversify, reflecting the local communities in which we’re based and the broader society and customers we serve. We are not as diverse as we should be, nowhere near, and all the evidence shows that the more diverse your workforce and boardroom, the more creative, productive, innovative and financially successful a business is going to be.

Automotive is becoming increasingly more technologically advanced, and as such we are hoping to reposition the sector to entice more young people to join the industry. We may have been perceived as a metal bashing but it is no accident that we are facing production challenges not from a shortage of metal but computer chips. That tells you all you need to know about where the industry is headed.

There is also a wide variety of other trends challenging the sector; connectivity, automated vehicles, differing ways we purchase or own vehicles, changes in how we manufacture, and even changes in how we, as a society, approach mobility. It is a challenging time but also hugely exciting. ■

www.smmt.co.uk

9. Are there any other major trends or issues that you would like to cover or feel should be highlighted?

Interview 15 manufacturing-today.com

16

Thinking outside the box

Sustainability, according to Mats Lundberg, Head of Sustainability at Sandvik Group, is big. So big, in fact, that for many companies looking to incorporate sustainability into their business model, it can be difficult to know where to begin.

“It’s important to focus on critical areas,” Mats comments. “Within manufacturing, we traditionally talk about productivity. Translate that into the language of sustainability, and at its core, it’s about consuming less energy, using materials more wisely, and reducing waste. These are things that many companies have been doing for some time, but perhaps haven’t discussed in a sustainability context.”

Mats’ own journey into sustainability isn’t exactly conventional. A chemical engineer by trade, he initially specialized in materials, and worked as a postdoc, and then a scientist, at

the Risø National Laboratory for Sustainable Energy in Roskilde, where he played a key role in the development of materials for fuel cells and hydrogen applications. It’s through this role that Mats was connected with Sandvik, where he continued in research roles for seven years, and was responsible for leading the company’s installation of a hydrogen filling station in the Swedish town of Sandviken, 200 km north of Stockholm. Off the back of this success, Mats took the decision to focus his career within sustainability.

“The sustainability work at Sandvik has evolved tremendously over the last five years alone,” Mats reflects. “Today, we have a clear connectivity between sustainability and business, which coexist as two sides of the same coin. As part of our strategy, we’ve identified four key areas: circularity, climate, people, and fair play.

Sustainability 17 manufacturing-today.com

Mats Lundberg, Head of Sustainability at Sandvik Group, explains how sustainability is reshaping the manufacturing and engineering sectors

“Our goal as a company is to advance the world through engineering, and we can’t do that without making the world more sustainable,” he comments. “In pursuing these goals, we take a holistic approach that includes our own operations, but also looks downstream to think about our customers, and considers the upstream, looking at our suppliers – because the products we provide to our customers are the sum of everything up to that point. It means asking questions such as: what’s our footprint? How can we improve the type of materials we purchase? How can we provide better solutions for our customers? And finally, how can we measure the difference we make?”

As Mats insists, this last point is especially crucial. “You need to be able to prove your work with numbers,” he points out. “By applying metrics, it gives you a start point,

an end point, and you can place targets along the way. At Sandvik, we’ve said that we want to reduce our CO2 impact by 50 percent by 2030, and within that, we have targets for different pillars of our business, such as products and packaging. To achieve those targets, we need to collaborate with our key suppliers, integrating them into our decisions – beginning with small changes, and scaling them up continuously over time.”

Award-winning innovation

In June of this year, Sandvik announced the winner of its annual Sandvik Sustainability Award. The award is held in memory of Sigrid Göransson, a champion of social responsibility and improved working conditions within Sandvik – as well as the granddaughter of Sandvik’s founder, Göran Fredrik Göransson, and daughter of Anders Henrik Göransson,

18

the company’s incumbent CEO. First distributed in 2020, it celebrates the best innovations within Sandvik’s team to have demonstrated impact for environmental, economic, or social sustainability.

The winner of this year’s award was a cooperation between the two Sandvik business areas: Sandvik Mining and Rock Solutions, and Sandvik Machining Solutions. The teams, which consisted of Petter Nilsen, Dean Kangleas, Gary Tully, Annegret Bicherl and Thomas Zimmerl, successfully created a unique circular solution for the recycling of tungsten inserts, which are used in the production of modern mining drill bits.

“Drill bits typically consist of more than eighty-five percent tungsten, drawn from mineral that contains less than 0.5 percent tungsten,” Mats explains. “As a result, a large volume of material is required for the production of each insert, of which up to 30 could be included on a single drill bit. After drilling has taken place, lots of tungsten is left inside the body of the bit, which usually goes to waste.”

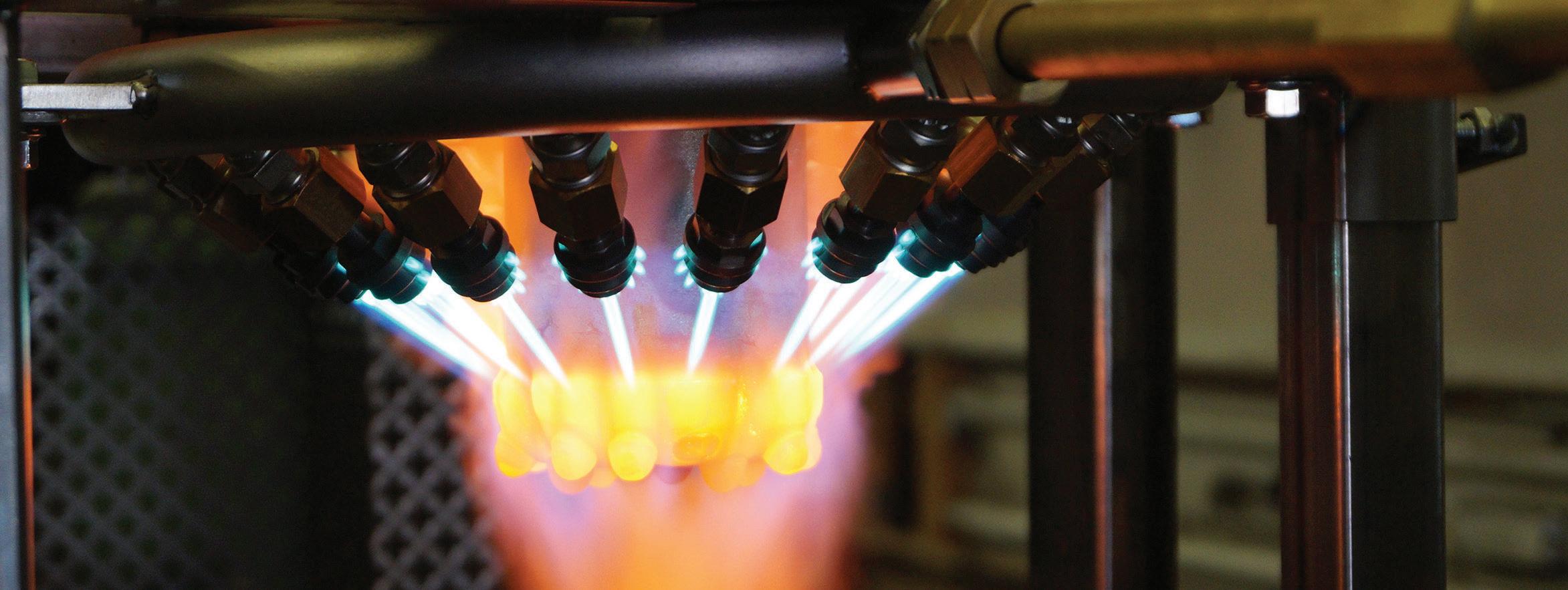

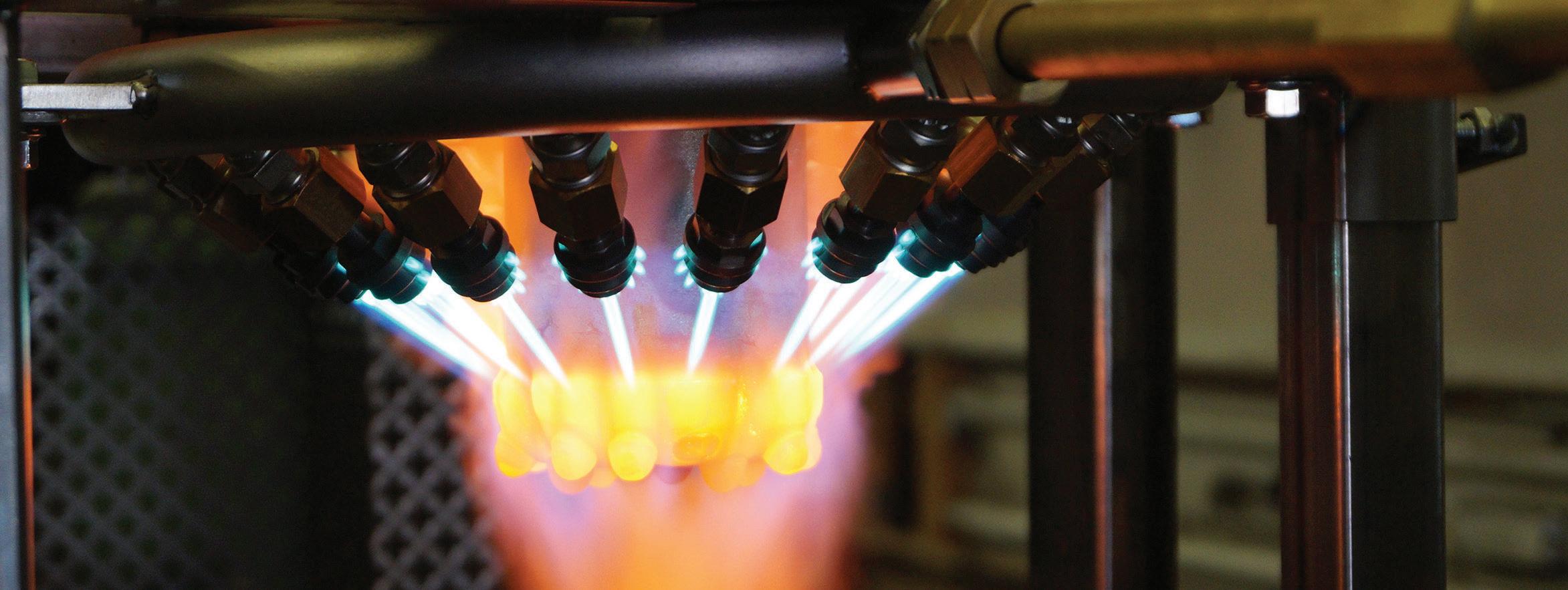

But the teams at Sandvik didn’t take that for an answer. “The question was, how can we separate the insert from the mining bit?” Mats states. “So, they bought a plasma burner and applied heat to the drill bit, which caused the tungsten to fall out. From this, we knew it was possible, but it still wasn’t an effective way to retrieve the tungsten. Instead, they began looking at induction heating, and the possibility of vibrating the drill bit in order to make the tungsten fall out – which they achieved.”

With the tungsten retrieved, the challenge facing Sandvik’s teams was to recycle the material back into the drilling process. That’s where Sandvik’s Mining and Rock Solutions team came in. “They ground down and refined the recycled tungsten in order to

produce tungsten and tungsten carbide powder,” Mats notes. “This can then be used for the production of new mining inserts, to give a circular production cycle.”

The method delivers a number of sustainability benefits. With a reduction in the use of virgin material, a greater proportion of tungsten can be supplied internally. This delivers cost savings, and reduces the need for supplier auditing. With the inserts divorced from the mining bits, outstanding steel can also be recycled locally, rather than transported across the globe. By introducing a separation process at individual mines, Sandvik also believes the solution can provide a reliable source of local employment.

“The beauty of this is that it’s already working,” Mats notes. “It’s been trialed in Australia and Sweden, and we’re looking to extend it to other parts of the world as well. We’re now developing a dedicated machine with induction heating that can be placed at the customer’s site to perform the separation process.”

Sandvik’s tungsten solution is set to reshape mining and drilling operations in the years ahead. But the manufacturing and engineering sectors can expect yet more innovation, be it new ways of capturing and deploying data, or an increasing embrace of digitization, that will pave the way for a more sustainable way of doing business. As the Sigrid Göransson Award reflects, it’s a future made possible thanks to the hard work and commitment of those within the industry. Or, as Mats describes them: “a few people thinking outside of the box to discover what’s possible.” ■

www.home.sandvik

“ “

“ “

19 manufacturing-today.com Sustainability

Sandvik’s tungsten solution solution is set to reshape mining and drilling operations in the years ahead

20

THE RIGHT APPROACH

Five key factors for manufacturing marketplace success

2022 has been a challenging year in manufacturing. Talent shortages, supply chain instability, struggles with the pace of digital transformation post-Covid, and economic and political instability have all helped put the squeeze on margins and slow down growth.

It’s no surprise that manufacturers should look beyond traditional approaches for growth and increased revenue. Setting up their own commerce marketplaces has been a manufacturing trend in 2022 and will continue in 2023 and beyond. But doing so is much more complicated than copying Amazon Marketplace and watching the orders flood in.

Manufacturer-driven marketplaces are infinitely more complex than B2C marketplaces, with more

sophisticated requirements for them to function effectively. Any manufacturer thinking of launching a commerce marketplace in 2023 should be mindful of the following key factors for success.

The emergence of B2B marketplaces

Marketplaces themselves are nothing new and have existed for decades. Some businesses, such as Etsy or NotOnTheHighStreet, are 100 percent marketplace propositions with zero inventory of their own. But B2B marketplaces are a more recent trend. The most recent analysis of the market was by Point Nine Capital, which revealed in 2020 that there were more than 300 B2B marketplaces in Europe –a stark increase from 20 in 2010.

Ecommerce 21 manufacturing-today.com

Approaching 2023, it’s likely that there are now far more. B2B companies are attracted by the potential for additional revenue streams, supercharging their way of doing business and creating wider ecosystems. And for manufacturers, it’s a chance to inoculate the business against some of the external pressures facing the industry right now.

1. Made-to-order is vital

A B2C transaction is straightforward. When the customer buys the product, the exact version of that product arrives with them within an agreed period, usually a few days. Manufacturing is not that simple, and most sales are conducted on a made-to-order basis.

Sometimes this means a manufacturer will only start making the product when an order has been placed. Frequently it will mean that product order comes with many specifications according to that customer’s needs. At others, it can mean there is a significant element of customization to the order.

A good example of this is in measurement methods. The US still uses non-metric measurements, so a European manufacturer selling to the US would need to be mindful of this. It boils down to configurabilitycustomers want a product to be configurable, and any manufacturer marketplace must be able to accommodate this.

2. Factor in non-standard pricing

Returning to B2C transaction models, there is never (or rarely) any haggling nor negotiations, and no requests for bespoke. The customer pays the vendor’s price, and both parties are happy with that. In manufacturing, that’s not the case.

Here, a customer will ask for a company’s best quote based on a number of different variables – quantity, quality, location and more. This non-standard pricing is known as a request to quote. It’s a very sophisticated feature that does not occur in retail or a B2C marketplace but is essential for a manufacturing commerce marketplace.

22

3. Interconnected systems

It’s rare for a manufacturer to produce a product that uses just one core material they hold a lot of in stock. Manufacturing is often complex, and many companies cannot deliver a finished product without using other products or materials from many other manufacturers.

This puts additional pressure on supply chains and is something that requires further sophistication in any manufacturer’s commerce marketplace. One major order can trigger a significant supply chain requirement, so it’s essential for the manufacturer’s systems to be interconnected. Procurement must sync with supply chain, IT and finance, or orders can stall.

4. Allow customers to order how they want

Bigger customers will order from many different places. An order can come automatically from a company’s ERP system or from HQ or one particular location. An order could be made directly from procurement or over the phone from another department.

The marketplace must be able to facilitate orders from a wide range of different interfaces, and it must meet each customer’s preferences. The answer to this is Headless Commerce architecture, which separates the front-end and backend of a commerce application.

It’s easier for developers to then create personalized experiences without having to make alterations to the back-end system. This allows customers to purchase products on their platform of choice and helps businesses approve orders using smart devices such as wearables or voice assistants.

5. Address change management

For any manufacturer to become a commerce business, they must be mindful of the need for change management. Manufacturers are usually sales-driven and may need help to get their sales teams to accept that there might be components in a deal that they don’t control.

There might even be sales made over the marketplace in which the sales team did not interact with the customer, so they don’t earn a commission. It’s a shift that will need addressing if a marketplace project is to be successful.

Manufacturer marketplaces are rich in potential for driving growth but are also highly complex, and any manufacturer must be aware of this or run the risk of their marketplace failing. Headless Commerce underpins any marketplace. This approach allows manufacturers the freedom to build a marketplace without constraints, improves the customer experience by decoupling the storefront from the back end and makes it much easier to add the sophisticated features that are integral to success. ■

a list of the sources used in this article, please contact the editor.

Alexander Graf is Co-Founder & Co-CEO

Berlin-based marketplace experts Spryker and author of the bestselling book, The E-Commerce Book.

Spryker is the leading composable commerce platform for enterprises with sophisticated business models and facilitates growth, innovation and differentiation. As a global platform leader for B2B and B2C Enterprise Marketplaces, Thing Commerce and Unified Commerce, Spryker has empowered 150+ enterprise customers around the world.

Alexander Graf www.spryker.com

of

For

“ “

...freedom to build a marketplace without constraints, improves the customer experience...

Ecommerce 23 manufacturing-today.com

“ “

24

Harnessing people power

The future is reliant on people, not processes, says Keith Tilley

Anyone involved in manufacturing will have heard of Industry 4.0 – the powerful concept of bringing smart technologies such as AI, the cloud, workflow automation, wearables and ‘real time’ data to manufacturing.

This use of digital technology to monitor and manage production processes is undoubtedly already impacting on the improvement of performance, by streamlining critical work processes and collecting and analyzing data for better decisionmaking. However, data doesn’t mean a lot without people to use it and in fact, the human element of smart factories has been somewhat overlooked.

For this reason, the next industrial revolution - Industry 5.0 – needs to be all about putting people back at the heart of industrial production, empowering employees to work in collaboration with technology that has been designed around the way they think and work.

Manufacturers must put people first and, rather than asking what can workers do with technology, asking what can the technology do for workers, instead?

But, where’s the best place to start?

...continually improve both workforce and customer satisfaction

“ “ Human resources 25 manufacturing-today.com

“ “

Pain points

A good place to begin is by identifying your workforce’s pain points and liaising with staff to get a deep understanding of their needs.

Examples could be inefficient reporting tools, or too much paperwork. By identifying these challenges and problem areas, you can identify ways to resolve issues and streamline processes that have been left behind in many of today’s smart factories, using the right technology to digitize workflows.

In taking this approach, we often see manufacturers reporting an increase in their team’s job satisfaction and team retention – something that’s critically important in today’s world - where the industry faces numerous challenges in attracting and retaining skilled talent.

The younger workforce, Millennials and Generation Z, are tech savvy and they want a workplace that enables them to integrate digital technologies into their roles, such as video learning or hands-free devices for example, rather than physical manuals or clipboards.

Technologies such as Assisted Reality (AR) devices can fulfil this demand, but they need to be connected to the workforce and the needs of the employee.

For example, AR devices can be integrated with digital workflow software and attached to safety helmets, enabling employees to easily use voice commands to watch short training videos, access manuals, view mechanical drawings, look up spare parts and access other materials critical for training – even in high noise environments.

AR heads-up displays make it appear as though the worker is looking at a seveninch display. A front-facing camera can be used to make video calls and show a remote expert back at HQ any problems that a trainee experiences – which leaves them ‘hands-free’ to get the job done.

By working with your team to identify these needs and requirements and seeking out the right technology to help streamline processes, manufacturers can create real value for workers – as well as boosting productivity.

The connected workforce

As I’ve said, the key to digital transformation success is to combine people, processes and systems harmoniously, so, when it comes to Industry 5.0, it’s not a case of implementing technology once and moving on. Optimizing processes is essential, of course, but it’s not enough on its own.

26

The move to put people back at the center of industrial production means ensuring continued engagement and satisfaction with technology, gathering feedback and learning from the processes put in place; the human elements that today’s smart factories often miss.

Integrating digital technologies with humancentric processes, such as reporting and training, enables data that wasn’t previously available to be collected and analyzed, identifying ‘human bottlenecks’ such as gaps in training requirements, different methods used by staff to carry out tasks, and varying recording and reporting techniques, across the workforce.

It also offers the potential of digitally capturing and recording all the human processes needed to keep the smart factory running, such as machine set up, quality assurance inspections, equipment maintenance and repairs, fulfilling compliance requirements more effectively by using photos and video evidence, as well as time stamps and a log of who did each process.

This connectivity between employees and technology reduces inefficiencies and enhances productivity levels, engaging with the workforce to continually improve both workforce and customer satisfaction –something that is vital, yet missed by many

companies rushing to digitize critical industrial processes, overlooking the requirements of people at the heart of their businesses.

People first Industry 4.0 technologies are vital in keeping our manufacturing industry competitive and resilient – especially against today’s backdrop of socio and economic difficulties. However, without a connected workforce, these technologies cannot meet their full potential.

The human workforce needs to be the industry’s focus as we move into 2023 and beyond, putting the needs of our people – not just our processes – at the very center of what we do. ■

Keith Tilley is CEO of workflow automation specialist, Intoware. Intoware is at the forefront of digital workflow automation. Its flagship product ‘WorkfloPlus’ was the first software developed for mobile use to take advantage of both Mixed and Augmented Reality. Accessed via mobile, tablet, desktop and wearables, WorkfloPlus empowers connected workers to save companies time and money whilst ensuring quality and accountability.

Keith Tilley www.intoware.com

Human resources 27 manufacturing-today.com

ARE YOU SECURE?

Pathway to success in Industry 4.0: building up smart factories’ cyber defense

By Dr. Aarthi Krishna

Today’s digital revolution is turning factories into the new frontier of cyberwarfare.

Last year, manufacturing became the most attacked sector by cybercriminals, putting intellectual property, product quality, and even employee safety in jeopardy. Yet, according to our report by the Capgemini Research Institute, cybersecurity in smart factories isn’t a C-level concern. While being connected to the cloud or the internet is unlocking operational efficiency, resilience, and productivity, the increased connectivity creates a significantly larger attack surface area and entry points for attackers to exploit.

Combining this with the use of legacy machinery, designed before cybersecurity was even a consideration, manufacturers have been left exposed to a plethora of cyber threats. Leaders must now address the complex security questions being raised if they are to protect their business moving forwards.

Growing attack surface

The sheer scale of Industrial Internet of Things (IIoT) connections and Operations Technology (OT) devices is overwhelming manufacturers – in fact, the number of IIoT connections is expected to reach 37 billion by 2025, while the total number of connected devices worldwide is set to triple to 24.4 billion by 2030.

According to our report, a vast majority (78 percent) of organizations have little to no visibility over these devices at their smartfactory locations. And there the problem lies. If organizations want to seize the advantages offered by Intelligent Industry, it goes without saying that risk areas must be identified quickly, and a high-level of visibility is essential to establishing and mediating a potential cyber incident.

Employees – who are often the first line of defense – are also the weakest link in smart factories, seen by attackers as the most vulnerable entry point. Since the pandemic, issues of ‘shadow IT’ have arisen as workers opt for more discrete IT systems that bypass the shortcomings of central IT systems. To resolve this, firms have brought in vendors and partners to manage shadow IT issues, creating an even larger surface area for attackers to exploit. While decentralized defense software will be effective if selected well, misconfiguration will only multiply the ports of entry for attackers.

28

Unengaged boardroom is not cyber-aware

More than half (51 percent) of industrial organizations believe that the number of cyberattacks on smart factories is likely to increase over the next 12 months. However, the heightened awareness of cyber risks doesn’t necessarily translate to preparedness. The same report found that nearly half (47 percent) of organizations did not even see cybersecurity in smart factories as a C-level concern.

This disconnect between leaders and the C-suite is problematic because it affects everything from budget allocation to how quickly organizations respond to an attack. Employees are often credited as the weakest link because they are the only unpatchable piece of the security framework. And people are ill-equipped in this area. Less than half (48 percent) of organizations state their smart-factory employees are trained to deal with the impact of an attack through connected machinery. To minimize the potential for cyber breaches to turn into fully fledged attacks, employees must be trained to spot the early warning signs of a potential attack to allow for quick response.

Cyber security

of the overarching concept and another with deep knowledge of specific security considerations. This is clearly a major issue as it is essential to have people who truly know how to manage the new threats presented by the connected industry.

Manufacturers must invest in training experts and cybersecurity leaders who can oversee the implementation of comprehensive Industry 4.0 security measures, as well as spearheading the upskilling program for employees. Those that cannot get this off the ground quickly should consider partnering with an organization equipped with expertise and end-to-end services to manage it.

“ “ “ “

Intelligent Industry promises vast benefits and unlimited possibilities, powered by new and emerging technologies. Smart factories will lead the way forward for manufacturing, but without securing the increased digitalized environment, organizations are still putting their business interests at risk. All advancements can be reset in a blink of an eye if security is not properly infused into the systems, and only organizations that adapt to survive can realize their true potential. ■

For a list of the sources used in this article, please contact the editor.

Navigating the labor market

A notable reason for this is the global shortage of cybersecurity professionals – which is even more acute in the smart-factory specialism. In 2013, there were 1.5 million unfilled cybersecurity jobs; today that extends to an estimated 3.5 million.

As things stand, more than half (57 percent) of organizations experience difficulties hiring the right skill sets, exacerbating the issue to new extremes.

Whether it’s 5G or quantum computing, every new technology requires two kinds of specialists: one group with a deep knowledge

Dr. Aarthi Krishna www.capgemini.com

Dr. Aarthi Krishna is Global Head of Intelligent Industry Security at Capgemini. Capgemini is a global leader in partnering with companies to transform and manage their business by harnessing the power of technology. The Group is guided everyday by its purpose of unleashing human energy through technology for an inclusive and sustainable future. It is a responsible and diverse organization of over 350,000 team members in more than 50 countries.

Intelligent Industry promises vast benefits and unlimited possibilities...

29 manufacturing-today.com

News in Brief

Community connection

Leading global specialty minerals company, ICL Group, recently joined Conflux Co-Learning, the nation’s first co-learning space which solely serves manufacturers and distributors. The membership-based organization creates content, connections, and space, so leaders can navigate and grow in a rapidly changing industry.

“We are proud to now be a member of Conflux,” says Bryce Tinker, Carondelet Plant Manager and US Manufacturing Director for ICL Specialty Products. “Conflux is truly a growth-oriented community, and we look forward to reaping all the benefits that our membership will contribute to our plant’s upcoming expansion.”

Pre-owned perfection

Kia has been named the winner of the 2023 Vincentric Best Certified Pre-Owned (CPO) Value in America award in the Passenger Car category.

“Kia’s success in this important segment of our industry has continued to grow, and we’re now poised to continue thanks to these awards from Vincentric,” says Steven Center, COO & EVP, Kia America. “We recognize many of our customers look to our Certified Pre-Owned vehicles as a more affordable entry point to our line-up and these accolades prove Kia to be one of the best Certified Pre-Owned brands in the industry.”

Clever cleaning

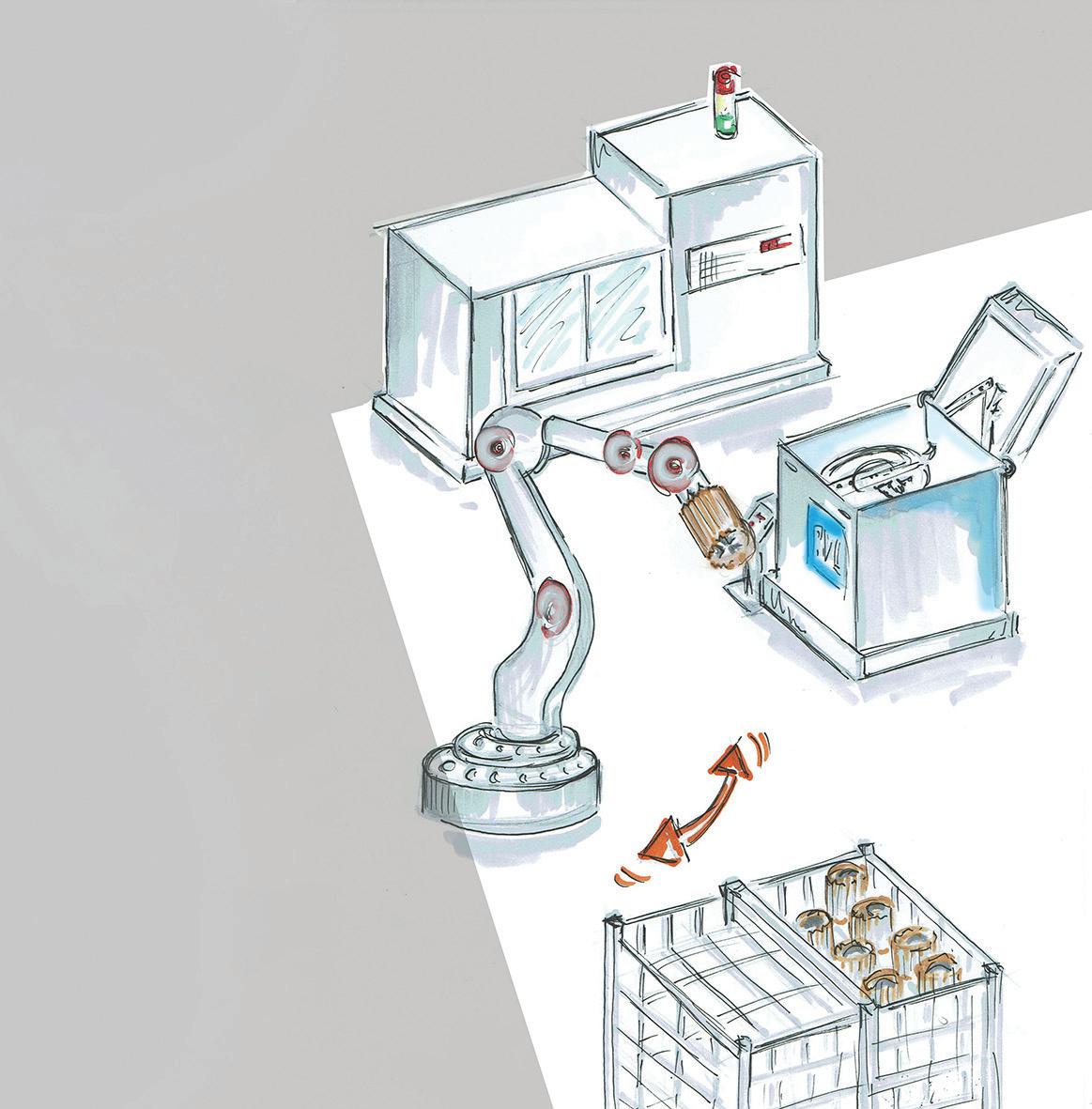

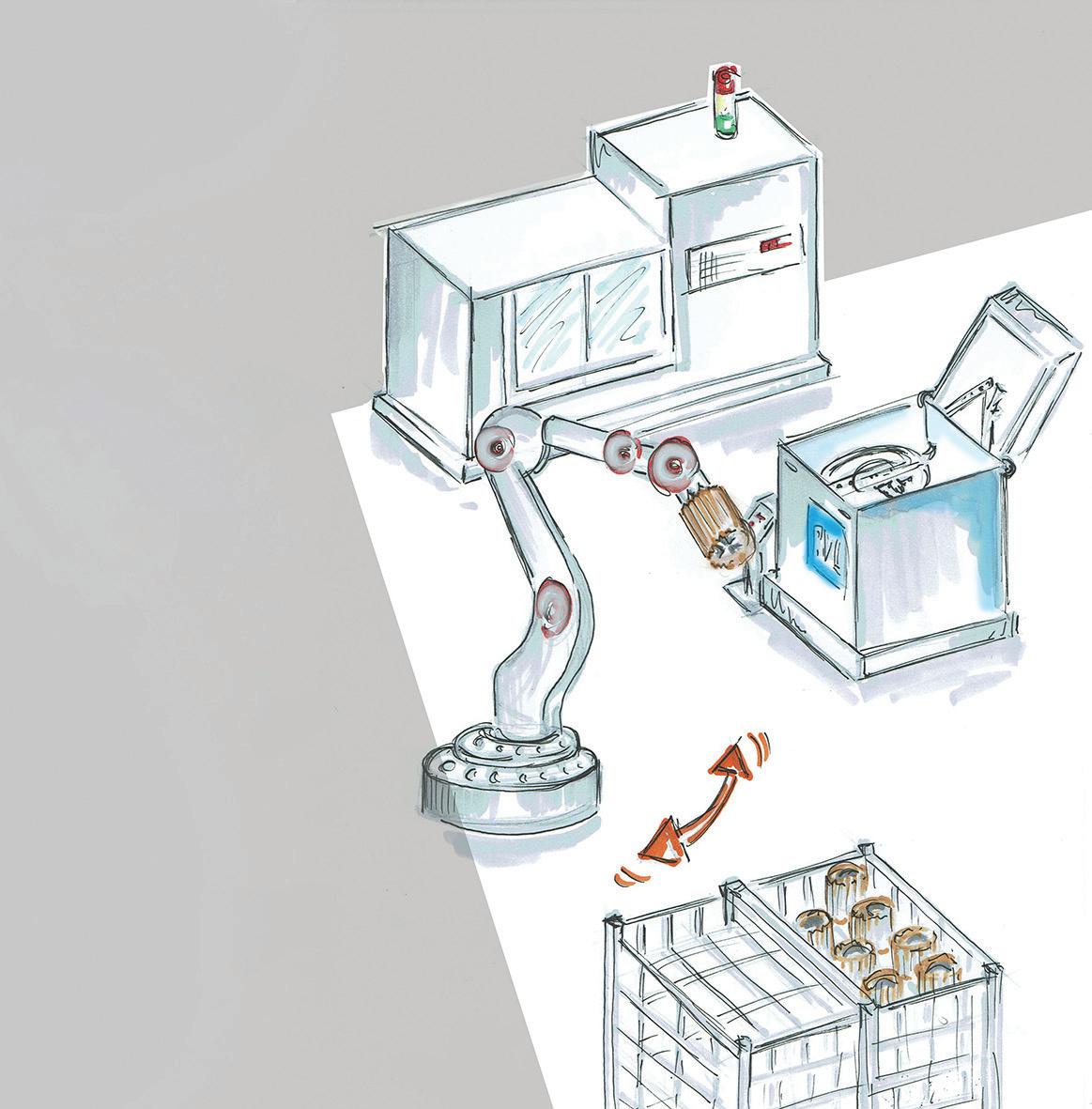

BvL announces the design of a manufacturing cell where the machining center and cleaning system are supplied by a robot. Several automotive suppliers use decentralized cleaning in their production to reduce personnel hours and costs, however, these solutions do not have to be complex and expensive.

The OceanRW cleaning system from BvL is a small, conventional single-tank cleaning system that uses the turntable principle.

“It is important to us to design the perfect cleaning system for customers,” explains Bernd Menke, Sales Manager at BvL Oberflächentechnik. “The entire process, the logistics and also the automation play just as important a role as the satisfaction of the system operators. In this case, we were able to implement the perfect process with a small cleaning system: an optimum solution that is neither too complex nor too expensive – all while relieving the employees in production.

“BvL can implement a great variety of solutions and integrate these in the customer’s production line. Our consulting and competence benefit greatly from a wide range of experiences,” he explains.

30

Smooth operator

A new short-term solution is available for businesses with urgent filtration needs, providing nationwide rapid deployment capabilities.

One-stop engineering and filtration specialist, Axium Process, has announced the launch of a range of separation systems developed for urgent liquid processing concerns. The UF2Go is the second option available for hire, joining the RO2Go reverse osmosis plant to provide a complete filtration solution.

The UF2Go and RO2Go systems have been designed to meet industrial scale demand for most types of liquid processing requirements - with environmental concerns top of the list.

Built on tried-and-tested technology used by multiple leading brands, the UF2Go is a versatile system suited to many different industries, including manufacturing, pharmaceutical, food, beverage, dairy and water recycling. Designed for rapid deployment and minimal operator training, each system can be up and running in a matter of hours following installation.

Industry News manufacturing-today.com 31

Exclusive Feature 34

QUALITY, NOT QUANTITY

Through Creation Technologies’ focus on serving OEMs within just three industries, it has doubled its revenue

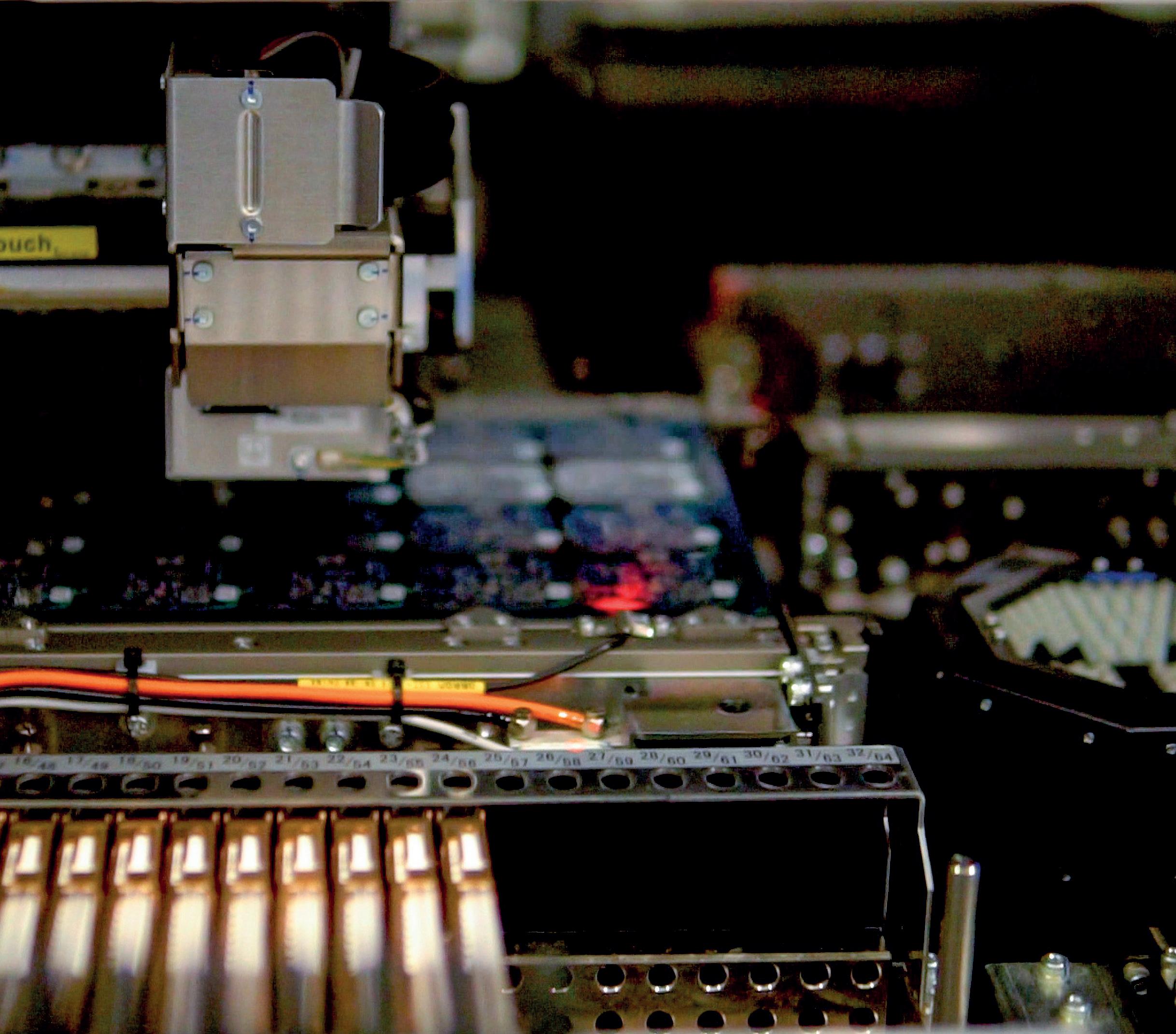

As a specialty Electronics Manufacturing Services (EMS) provider, it could be all too easy to spread oneself far and wide into as many markets as possible. However, this is an industry that respects qualitative work, over quantitative, which is exactly how Creation Technologies (Creation) has amped up its reputation over the last three decades. Established in Vancouver, in 1991, the company focuses all of its energy into three main verticals: aerospace and defense, medical devices, and tech industrials, and employs 4400 people across its fifteen locations. These include bases in China, Mexico, Canada and the US, which consist of 14 manufacturing facilities, three global materials sourcing groups, a design center and a rapid prototyping center.

Creation Technologies manufacturing-today.com 35

▼ Stephen P. DeFalco, Chairman and Chief Executive Officer

Stephen P. DeFalco, Chairman and Chief Executive Officer, only joined the company in 2019 but has already made a significant impact on its operations. His strategy for growth has seen the business’ revenue double over the last three years to around $1 billion annually, however he anchors Creation’s success in something far longer standing than his own initiatives: “When the founders of Creation set out, they put together a specific set of values for the company. These core principles focus on serving customers, delivering top quality and reliable work, and treating employees properly. It’s fair to say, they’ve stood the test of time.

“It’s a real privilege to lead a company like this,” he continues. “We have an exceptional team of employees around the world and a wonderful customer base. Getting to see the products we have built, out there in the world, in hospitals helping patients, defending our troops in the field and supporting our industrial economy, it really is a fantastic job. It offers a ringside seat to some of the most exciting innovations globally.”

Selective acquisitions

In terms of expansion, Creation practices a methodology that relies on strategic, datadriven decisions. The company’s clientele is the driving force behind this; it listens

to their needs and invests wherever it will benefit both parties the most. With regards to acquisitions, the business is looking to be more than your typical tier one company, as Stephen explains: “We want to create the first scaled specialty EMS company, unlike the tier ones that are currently around that, yes are very big but, try to be everything to everyone. That’s not our goal whatsoever, we shall still remain specialized within our three key verticals. Most of our growth comes from how happy we make our clients, and the continued increase in business that it brings, which is also the basis that we consider for acquisitions.

Exclusive Feature 36

When looking at a potential company, we screen it based on who and what size its customers are and what programs it implements in supporting them. Over the last three years we’ve been successful in finding three that have slotted in perfectly with our strategy: Applied Technical Services (ATS) in Seattle, IEC Electronics in Rochester, and Computrol in Boise.”

Best practices

It’s not so much a case of expanding the company’s markets, but more so deepening its involvement within them.

Creation also prides itself on harnessing the ideas and policies of its acquired enterprises and sharing them across the entire board. A prime example of this was the company-wide adoption of the quarterly bonuses ATS awarded its hourly-paid manufacturing workers, upon reaching their targets. There was a direct correlation between the program’s implementation and an increase in not only the quality, delivery and efficiency of production, but also a genuine interest, on the employee’s behalf, in the health of the business.

manufacturing-today.com 37 Creation Technologies

Exclusive Feature 38

A simple formula

Stephen’s mantra is to quote less and win more, and he believes in being selective when choosing the right Original Equipment Manufacturers (OEM) to work alongside. Another cornerstone of his leadership style is his hands-on, interactive approach with employees. The company’s working culture is high on the agenda, as he details further: “The formula is simple, on the employment side. We create an environment in which people can come to work and want to do a great job. We make a point of listening to their ideas and always respecting their points of view, especially when it comes to ways in which we can improve the company or their time with us. Our culture really thrives on serving customers. There were a number of people struggling with mitigating the ongoing supply chain issues, whilst trying to provide the best level of service they could, which we all know

can be incredibly draining. In response we have upgraded our processes and systems through investments and provided further management in our customer relations. We’ve always been a very intimate company when it comes to our clients and they appreciate our transparency and open communications.”

In growing towards a larger version of its current self, Stephen cites the theme for the first half of 2023 to be agility. With the current market climate, it’s difficult to take the regular approach of locking in a three-year plan and getting straight to it. With the ongoing supply chain issues and increases in delivery times, Creation will be focusing its energy on the shortest possible turnaround of components into products, and readying itself for the quickest responses to market changes. ■

www.creationtech.com

manufacturing-today.com 39 Creation Technologies

Exclusive Feature 40

CUSTOM CONVEYANCE

The story behind CHL Systems’ partnership approach to custom food processing equipment

CHL Systems (CHL) designs, builds and installs the systems and equipment that move, make and pack the products that feed our communities. A familyowned company, CHL has enjoyed over 65 years of business, and is under third generation management. With roots in service, repair and installation of equipment in food, pharmaceutical and general manufacturing facilities, CHL has grown to encompass full design engineering and manufacturing capabilities. Today, most of its custom design-and-build business operates within the food processing industry and focuses on improving processes that ultimately make products safer and better, offering added value to customers.

With an illustrious career in manufacturing, and six years’ service at CHL, Mike Giagnacova, CEO, sits down with Manufacturing Today to discuss past and present operations, as well as future plans.

“To give some background about what we do at CHL,” Mike says, “we design, build, and install the systems and equipment that move, make and pack products that feed our community, and our nation.” In any processing

facility, there are products that need to be moved, whether raw materials or finished products, and that’s where CHL comes in, he explains. “We design and install the equipment and conveyance systems that move the product. This can be for a 500,000-square-foot brand-new facility, for example, or a replacement system where limited space is a constraint.”

Turnkey solutions

Additionally, in a processing facility, there are products that need to be made, such as pork or poultry products, or dog food. “In that processing, there’s some custom equipment that needs to be made to process the raw ingredients

CHL Systems manufacturing-today.com 41

into the finished product, so we will work with the customer to design custom machinery if that is what’s needed,” Mike says.

In every processing facility, the final step is packaging the product for shipment. “From weighing and packing to palletizing, we also design, supply and install equipment that puts the final product into its packaging and moves it out the door,” he explains.

Because each customer is unique in terms of product and facility, it’s crucial for CHL to champion a partner approach to customer relationships. “We don’t just sell a piece of equipment for the customer’s process line,” Mike explains. “We work with our clients from the outset to help design or integrate exactly what they need, install it on site, and then ensure it does exactly what it’s required to do.” This approach is key to ensuring a successful project and often leads to longterm relationships, he says. “We like to engage customers for the long-term in order to establish a level of trust and rapport. In this way, we develop a good understanding of our customers’ needs, and can provide solutions from a turnkey system to advanced robotics.”

Partnership approach

An example of the value CHL places on customer relationships is demonstrated in the work it recently completed for Bell & Evans, which now boasts a nearly 500,000-squarefoot world-class poultry processing plant that harvests live birds all the way through to the finished product for shipping. As Mike details: “Of course, there were many key players involved in that project, but it’s important to note that it took less than 20 months to get the production plant up and running. The only way this was accomplished was because there were such strong partnerships in place. We have dealt with some of the key players for a long time. This familiarity and trust, coupled with a great group of contractors, was pivotal to promoting a team environment to deliver this facility in record time.”

Exclusive Feature 42

“ “

We have been in business

65

Taking the poultry plant as an example, Mike goes on to discuss the role of technology and automation in manufacturing operations. “In a facility such as a poultry plant, there is a considerable amount of hard automation: machines that do straightforward, repetitive physical tasks. Within automation however, there are different levels, and this is where Artificial Intelligence (AI) can come into play. To incorporate AI, it’s crucial to have a full understanding of what you are trying to accomplish to be able to build the appropriate algorithms that make accurate decisions on the production line. From decisions surrounding quality control to picking and packing, the finer levels of AI are only just beginning to gain traction. It is the future, but it’s a little further down the road. When compared to hard automation, it’s far more complicated to take a non-regimented process, add layers of decisionmaking to changing scenarios, and then create an automated process out of that,” he explains.

As is the case for the majority of businesses, other, more pressing considerations have taken center stage over the last couple of years, and particularly so, in terms of supply chain issues. “We are starting to see some stabilization of certain components,” Mike notes, “but obviously, there have been price increases, and some items are still difficult to get, particularly electronic components. For us, the vendors that we use are essential, and we pride ourselves on bringing the same level of partnering to our supply chain as we do to our customer relationships. In terms of the Bell & Evans project, despite the fact that it occurred at the height of the pandemic, our strong network of vendors and contractors worked with us to accomplish our goals within an aggressive timeline and difficult circumstances.”

This partnership approach also filters through to the company culture. “Our culture here is very family-oriented, and localized,” Mike

“ “

says. “As we’ve expanded, we’ve added employees from different areas of the country, and, while they may not be in the main office, they do feel part of the team. We’re proud that our culture transcends our four walls.”

Tackling the challenges

Part of this culture is to create a sustainable business for the future. “We have been in business for 65 years,” highlights Mike. “Sustainability is the key to ensuring another 65. The methods and the means we use to manufacture are increasingly efficient and environmentally friendly. We are a family-owned company that has transitioned to a board of directors model, a move designed to ensure the longevity of the company. As I consider the future of CHL, I am encouraged to see the level of engagement by our younger generation of staff members and am excited about the impact they will have in the years to come.”

Looking to the future, CHL aims to continue doing what it does best: helping organizations within the food industry face the challenges of producing higher volumes, at a superior quality, while being more efficient and sustainable.

As Mike concludes: “The biggest challenge for us can sometimes lie in educating our customers, so that they understand how automation can be used, what the long-term cost benefits are, and how it can best fit their unique needs. If partial automation or robotics are a better fit, we will offer that as a solution, and provide full turnkey services, including installation and training. A big part of our success is partnering with our customers to truly understand their production goals and what automation options can work for them.” ■

www.chlsystems.com

for

years

CHL Systems manufacturing-today.com 43

44

SPREADING TO EXPAND

Econ Engineering currently supplies eight out of every ten gritters on the UK’s roads today

Econ Engineering manufacturing-today.com 45

Jonathan Lupton, Managing Director, started out as an apprentice straight from school, working around the trucks for his father’s company, in 1985. He rose organically to the position that he holds today, continuing the family ownership of Econ Engineering (Econ) into a second generation.

Jonathan’s father (Bill) was the son of a farmer, and in his younger years developed and launched, the first tractor mounted hedge cutter, which was designed and manufactured in the farm yard’s outbuildings. As Bill sadly hadn’t patented his design, it was copied by a competitor and as a result he took the decision to sell the business to another company, shortly after. This enabled him to

focus on his next idea, and as such Econ was founded in 1969, as a means to manufacture his latest innovation: a road salt spreading gritter, following a harsh string of winters and the establishment of the country’s earliest motorways.

Mainstay of the business

In 1970, Econ built its first road gritter, which was operational by the winter of 1972. By 1978, the company had outgrown its initial premises and moved to a larger site nearby, still in Ripon, where it has remained until this day. The following decade was powered by growth, and saw the acquisition of the business’ largest competitor, Atkinsons of Clitheroe. Atkinsons were also in the gritter market but manufactured

46

a range of agricultural equipment too, which opened up a new sector to Econ. This diversification allowed the company to grow greatly, but in the early 1990s, the decision was made to sell the agricultural side of the business and fully focus on the winter maintenance aspect of the business. Throughout this decade, Econ designed and produced the widely successful Hot Box: a vehicle body that features either one or two, gas heated hopper chambers to

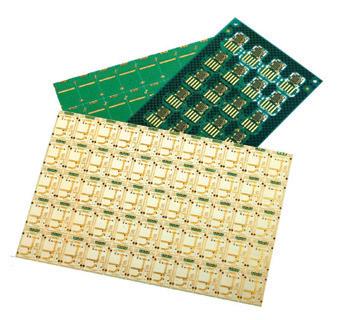

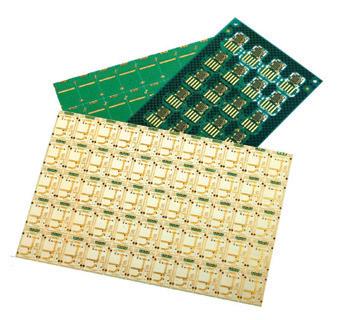

GSPK Circuits Ltd

GSPK Circuits Ltd has been supplying the global electronics industry with printed circuit boards for over 50 years. Our experience over that time, and the expertise we have gained, has provided us with the capabilities we need to provide you with quality engineering and manufacturing processes. Proud of our history, we are incredibly excited about the future.

maintain the temperature of its contents, which allows for round the clock road repairs. Alongside this, it also started to manufacture a range of modular body equipment and unibodies, enabling customers to use their trucks as gritters in the winter or as regular road maintenance vehicles during the summer months. Regardless of these innovations, Jonathan still cites the company’s biggest seller, the gritter, as being the one it’s known best for.

At GSPK Circuits, we are committed to developing specialist PCBs for your individual applications. We take pride in the fact that we always react with a ‘can do’ attitude. Every project is approached with the manufacturing process in mind. We are aware that your needs will be different from the next, so we deliver tailored solutions and products to suit your requirements.

Econ Engineering manufacturing-today.com 47

“Even today, the permanently mounted gritters are still the mainstay of the business – eight out of ten winter service vehicles on UK roads are Econ units. We launched our gritter hire fleet back in 1998, which consisted of seven trucks that first winter. We doubled the size of our fleet from 70 to 140, literally overnight, back in 2005, through the acquisition of our main competitor in the rental market –MHS Vehicle Hire. They went out of business, so we managed

“ “

to incorporate their gritters in time for the launch of our new control system at that point. Fleet expansion has been high on our agenda ever since, and currently we have over 1000 hire vehicles in service and have also opened a service center this year in Sowerby, Thirsk.”

Servicing and assistance

Econ is the market leader for the two primary sectors it operates within: winter and highway maintenance. This niche approach is partially responsible for the company’s great success. Without spreading itself too thinly, it can really focus on what’s important, which in these industries, according to Jonathan, is servicing and assistance with excellent customer service.

.

. . currently we have over 1000 hire vehicles in service and have also opened a service center this year in Sowerby, Thirsk 48

“

“

Continued customer support is crucial to Econ’s model, and is what sets it apart from its competition, as it relies heavily on repeat business. As a family owned entity, and selfproclaimed ‘safe pair of hands,’ any local authority that signs up to an eight or nine year contract can rest assured that Econ will be there to look after their equipment.

As a result of the company’s reputation, the business has continued to see incredible growth despite the state of the market and economy over the last few years, as Jonathan details: “There are two main factors attributing to the growth we have experienced over recent years. Firstly, the buoyancy of the road repair market. This doesn’t just include road repairs and such, it’s also affected by the initiative to install fiber optic broadband up and down the country. Driving around the UK now you see a vast amount of roadworks going on; the contractors of these sites are all responsible for ensuring that certain key performance indicators are met when the roads are returned to normal

use – leading to greater reliability on the specialist equipment required and services in which we’re well versed. Secondly, the international semiconductor shortage is affecting the manufacture of commercial chassis. This means that there’s a large number of customers turning to the hire of vehicles in the meantime, which has resulted in our fleet being exceptionally busy. We’re really seeing the success of focusing on niche, select markets and in turn being able to provide the absolute best service possible.”

Expansion of capabilities

With such great growth, comes even greater means for innovation. Econ is currently working on a prototype for the first electric, highway vehicle solution, which could be released as early as January. The new technology will emit zero emissions, an enormous benefit to local authorities looking to reduce their carbon footprint. Due to certain limitations concerning range and charging, Jonathan believes that the

Econ Engineering manufacturing-today.com 49

“ “ “ “

product will be more prevalent within cities than the countryside. Regardless, he sees the electric era to be a reasonably short one, functioning mostly as a stepping stone towards hydrogen fuel cell and combustion solutions.

Besides fleet innovation, Econ has reinvested huge resources into its production facilities and infrastructure this year alone. In opening the new £7 million service and engineering site in Thirsk, the company’s HQ in Ripon has gained a huge amount of floorspace for further

The beauty of Econ is that we are privately owned. We are able to make quick decisions and exercise the utmost dynamism when responding to changes in the market

50

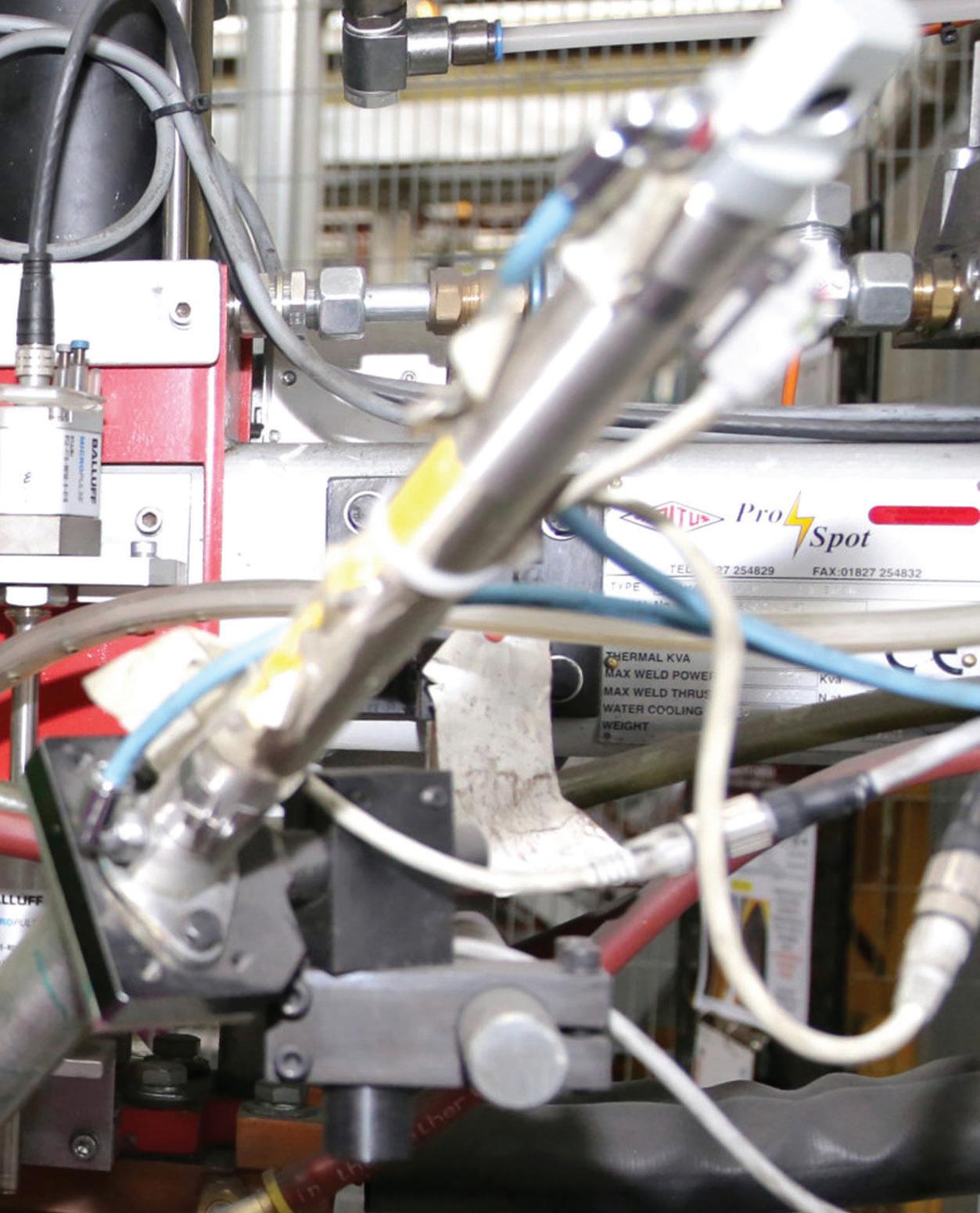

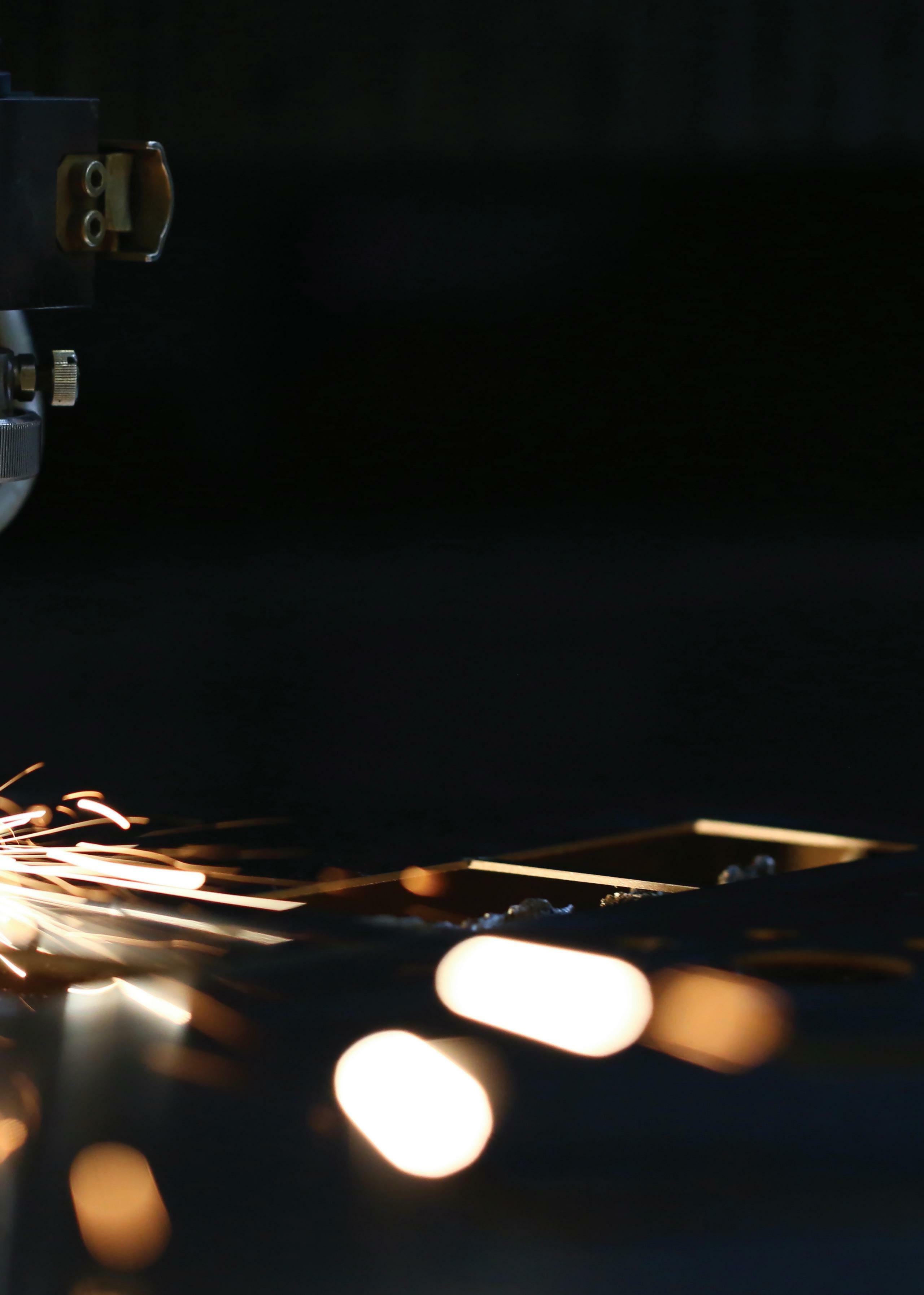

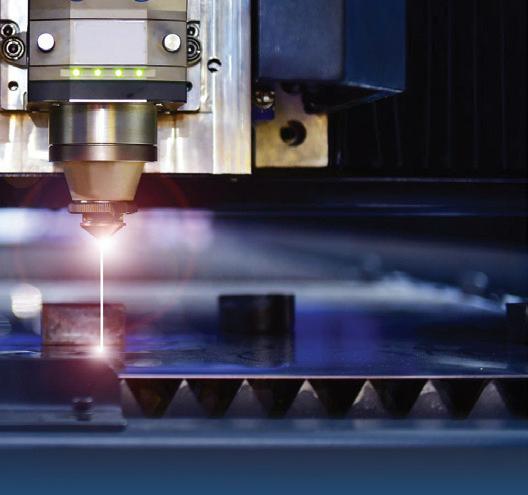

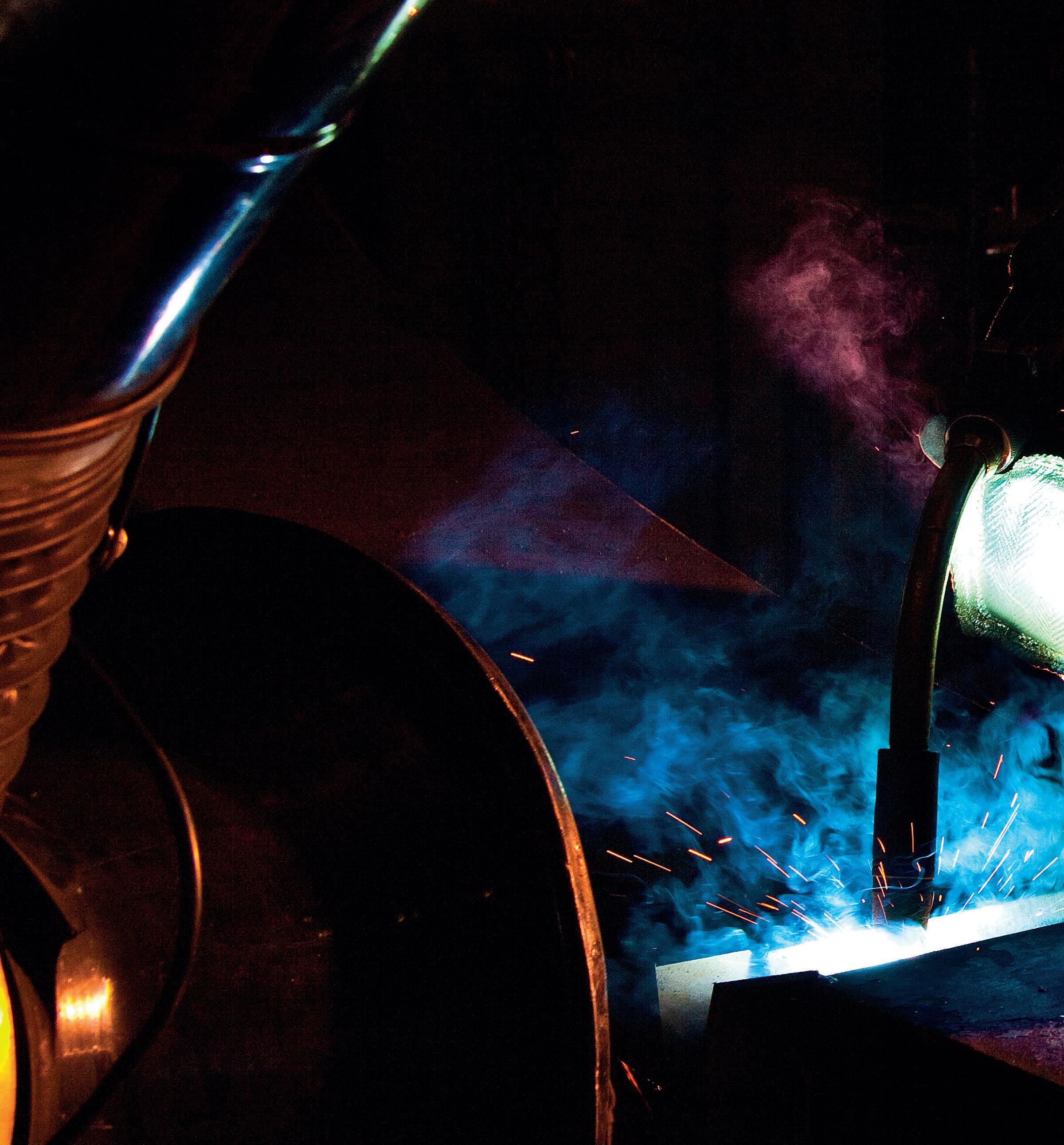

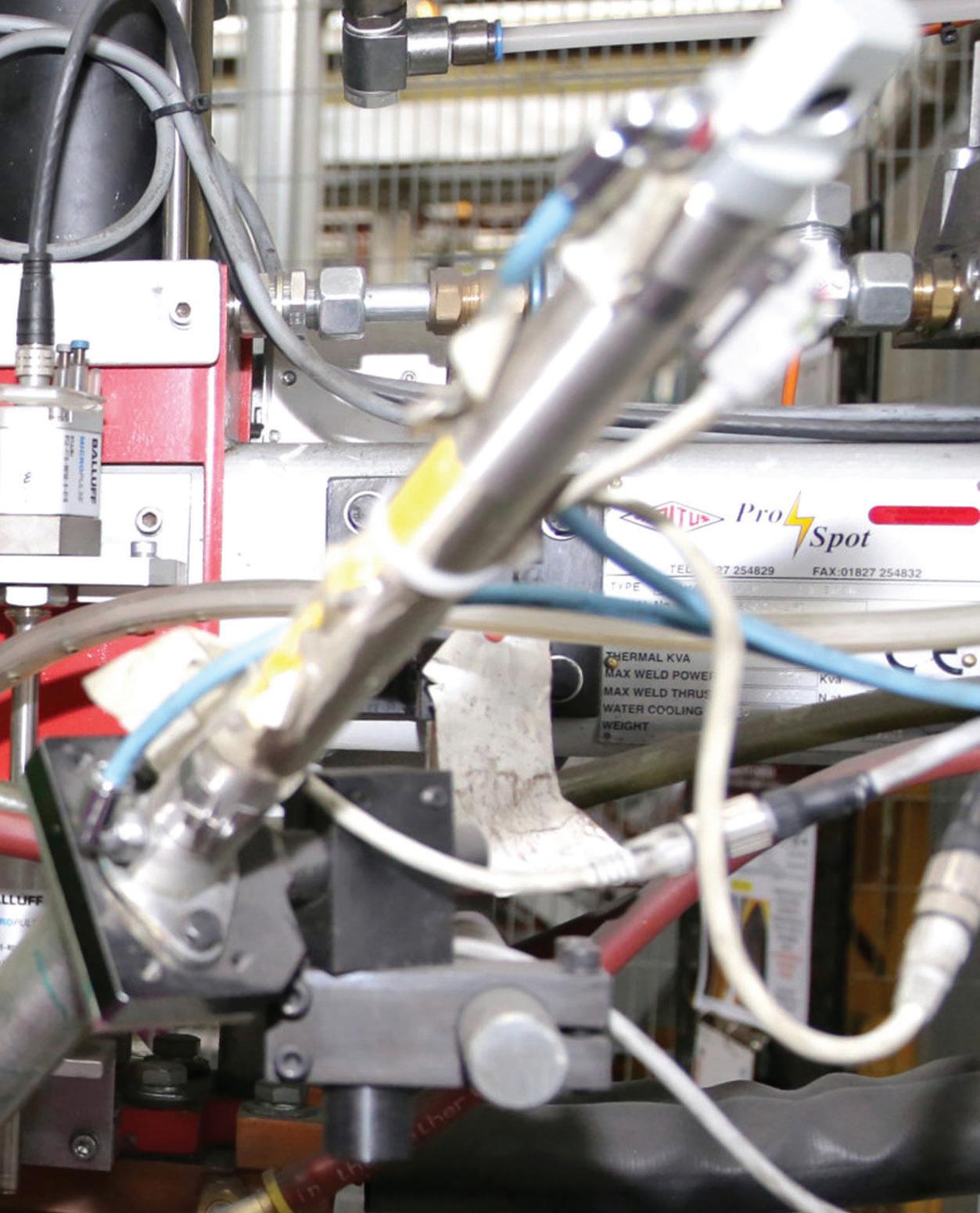

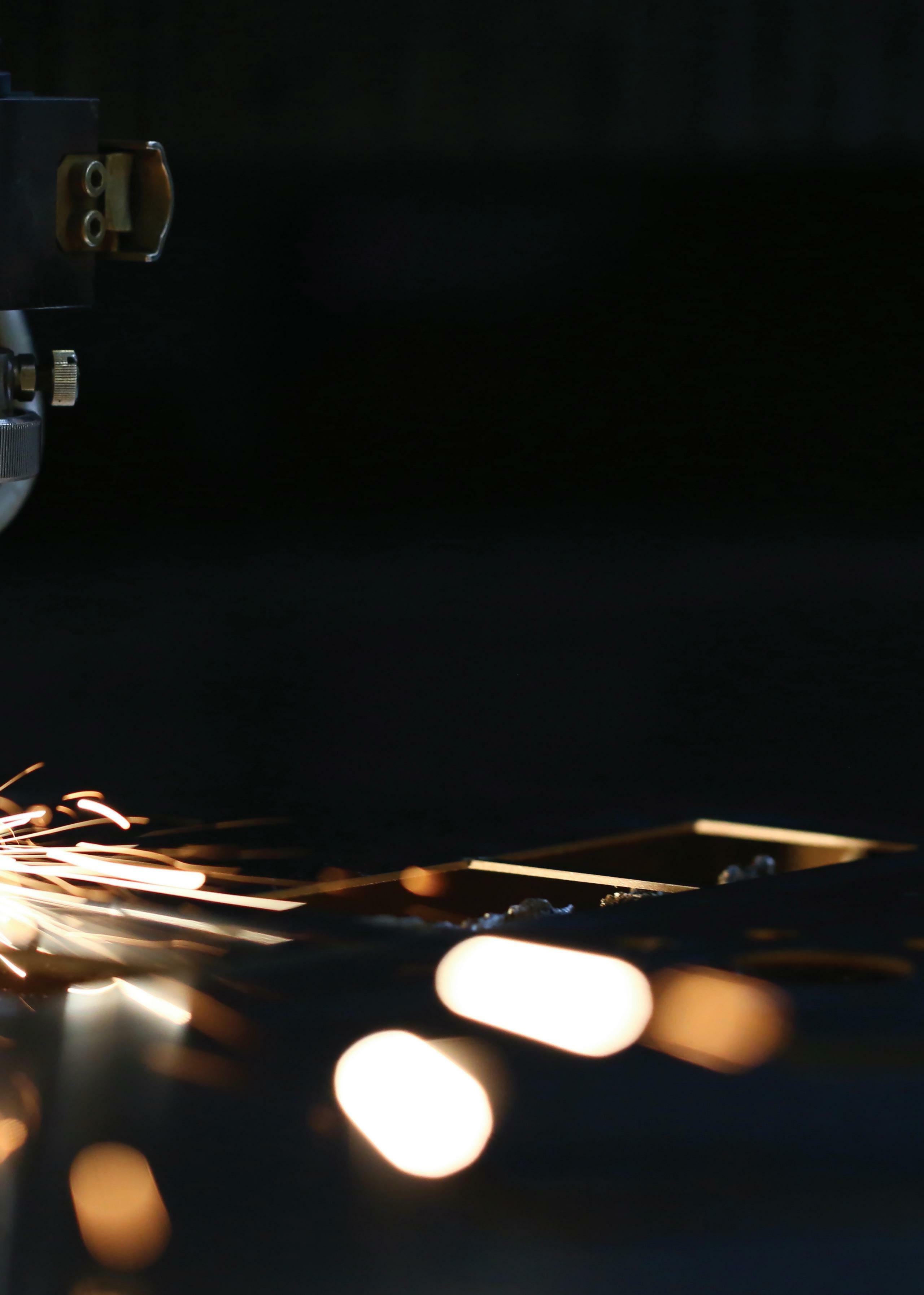

expansion of its capabilities, as Jonathan explains: “Our 90,000 square-foot facility is set on just six acres of land; meaning the internal expansion available to us, by relocating the service center elsewhere, has been instrumental in our reinvestments in technology. We have implemented a new £850,000 laser cutter and purchased a team of robotic welders. Everyone is aware of the current labor shortage throughout all industries, which Econ iss now tackling with automation. The new robotic welders have increased production of a large number of products, freeing production hours for more involved processes undertaken by our

skilled workforce. Alongside the purchases of these two key pieces of equipment we have ordered two new presses that are due to be fitted around Christmas, replacing those we’re currently using, which will increase our production efficiencies.

“It’s difficult to say where the future lies from here on out,” he concludes. “As mentioned, the road repair sector is currently incredibly buoyant but we can’t rest on our laurels that this level of requirement will continue. The beauty of Econ is that we are privately owned. We are able to make quick decisions and exercise the utmost dynamism when responding to changes in the market. It’s what has fueled our growth up until now and will continue to do so for many years to come.” ■

www.econ.uk.com

Econ Engineering manufacturing-today.com 51

52

CARE, FOR ALL

Using industry experience to increase its technical know-how, Medstrom is developing care where it’s currently lacking

The establishment of Medstrom Ltd (Medstrom) was resultant of the management buy-out of a service business called Hillrom in 2010, by a confident team with over 120 years of experience. For the first eight years, Medstrom focused on managing the 19 contracts it had inherited from its predecessor; working to deliver, refine and improve the longstanding services Hillrom had offered. The team gained a great deal of experience during this period, which not only broadened its knowledge base, but ultimately led to it manufacturing the products it had previously been distributing.

Rachel Apsey, Commercial Director, talks Manufacturing Today through the motivation behind this change in direction: “Our day-to-day learnings were a major force behind our move towards inhouse manufacturing. Two key factors in regard to harm coming to patients, which were increasingly highlighted by our NHS customers, were the development of pressure ulcers and the fall-risks posed by the traditional style of hospital beds. To solve this, our research and development team and I came together to design a new format

Medstrom manufacturing-today.com 53

– one that could be lowered to a safe enough height to prevent harm caused by falls and raised high enough to save the hospital staff from back issues. As an ex-nurse and midwife, myself, I wished to reiterate this issue where possible – back injuries cost the NHS something in the realm of £400 million per year.”

Customer engagement

Today, Medstrom is one of the largest providers of total bed management services to the NHS and has over 25 percent of the UK’s acute-care bed and mattress fleet. It supplies its specialist products and services to over 150 hospitals across the UK and Ireland, which includes hospital beds, critical care beds, pressure area care and bariatric support. The early days of the company were far humbler though, as Rachel explains: “Although we are now producing what is heralded as the best bed on the market, which customers cite to be reducing

falls by 60 percent – we literally started out manufacturing in an empty shed.

“The main way in which we innovate is by engaging with our customers,” she continues. “In applying my nursing background, I always say that for every product we send out into the world, there will be a patient. We monitor patient outcomes closely and discuss with our consumers what does and doesn’t work, the NHS being one of the key drivers behind this. A good example is how post-COVID we have a lot more patients suffering with long-term lung conditions who require intensive care beds – making this product far more critical. Another is the increasing number of patients being admitted with mental health related issues, which has stimulated a new development of ours, a mental health bed that will be going into production early next year. This will offer the full functionalities of existing electric beds, but without the use of excessive cables that can pose a ligature risk to patients suffering with suicidal tendencies.

Addressing challenges

“The critical part for me is the continual market research in order to obtain the latest insights into the clinical environment, as it’s ever-changing. Five years ago, patients weren’t falling out of bed at the same rate that they do today – 700 every day in the NHS alone. Patients are increasingly getting older, frailer and overall, more vulnerable, which is also increasing the risk of pressure ulcers. Our diets, as a nation, have suffered in recent years meaning we are physically getting bigger. When a patient arrives at A&E, who is unable to fit in a typical hospital bed, they end up sitting in an ambulance waiting for the delivery of an appropriate product for far too long. This stigma removes them of any dignity and is simply not acceptable. We not only produce a four-foot-wide bed that supports

54

up to 75 stone, but we also offer a delivery service within a couple of hours, depending on the contract in place. Right product, right patient, right time is our strap line.”

Medstrom’s production facility in the East Midlands was developed throughout 2019. Matt Stonton, Capital Operations Director, and a small team, were tasked with transforming the aforementioned ‘shed’ into a clinical manufacturing center, capable of producing 4000 beds per year. The plant employs Lean principles, applied from Matt’s time working within automotive, aerospace and pharmaceutical engineering. Thus far it has managed to increase its annual output by over five times since its first year of production.

Addiotionally, the Medstrom Academy was established in early 2020, with the aim of supporting its clientele in the implementation of its products. The purpose-built space showcases the range of solutions that the company offers in meeting the clinical challenges of patients

Medstrom manufacturing-today.com 55

and caregivers, with a number of physical learning experiences. These include empathy and age simulation suits, which are designed to replicate the body morphology and physical impairments of plus-size or ageing patients, among other educational and visual tools. It also offers a number of Continuing Professional Development (CPD) accredited courses that cover the definition of a pressure ulcer, the science of surfaces, the consequences of immobility and the mitigation of bed-related injuries.

Future progression

Given the manufacturing plant’s inaugural run took place in July 2019, Medstrom was required to hit the ground running when the Covid outbreak escalated, as Rachel details further: “I’m pretty sure Matt worked 24/7 for the first six months of the pandemic; we manufactured as many beds as possible then

started sourcing products from overseas too. It was a frantic time. Unlike the majority of our competitors, we didn’t furlough any of our staff. Covid was a real concern for us, as a board of directors, as around 80 percent of our team are frontline staff. With having everybody working, we had extra support for all of our technicians, nurses and trainers every step of the way, but we still had to consider how to protect them as they were heading into hospitals. We hosted a great deal of education and training surrounding social distancing and the virus, and I can proudly say that we never had a single person contract Covid through work. “Teamwork plays a crucial part in everything we do,” she adds. “Matt developing a new bed is obviously important, but without the clinical advisor guiding him, it may not meet the correct standards. Similarly, without the technician installing it, how can the nurse utilize the bed in treating

56

a patient? For these reasons, we try to ensure that our network of differently skilled people, operates as one. We want to create a long-term sustainable future for all of our employees, as the company wouldn’t be where it is today without everybody we’ve got on the ground, at every level.”

On top of its success within the UK, Medstrom currently serves customers in Italy, Switzerland and the Netherlands, and is awaiting FDA approval to move across into the US market as well. According to the company’s US-based Non-Executive Director, there are multiple distributors waiting for its product range to land on American soil. Besides transatlantic growth, the future of the company is very much engrossed with continuing to meet the ever-changing needs of patients near and far. As Rachel concludes: “Bottom line; improving patient outcomes is our main mission. Within that, we’re looking

to expand our range further, maintain our communication with customers and clinicians and continue to be there to provide answers through innovation and products.” ■

www.medstrom.com

Medstrom manufacturing-today.com 57

Discover Boss Design’s beautifully upholstered solutions for commercial spaces

58

Like a BOSS

With absolute quality at its core, and a meticulous eye for the details that really matter, Boss Design (Boss) has been manufacturing furniture for nearly 40 years. The company was established in Dudley in 1983 and has focused on redefining spaces within the commercial sector. Boss prides itself on being a productcentric business, analyzing problems to provide stylish and effective solutions.

Boss began the transition from a UK business that served an entirely UK market, to an international enterprise in 2004. Mark Barrell, Design Director, describes this period of Boss’ history as both challenging and incredibly formative, as he elaborates: “By 2008, we had somebody based out in the Middle East for the first time. We were selling furniture in the region well before that and it appeared that there was an opportunity to achieve a lot more with

Boss Design manufacturing-today.com 59

a physical presence on the ground. This set the tone for our operations going forward and we bought a furniture manufacturing business in the US five years later. Ever since, we have been working hard on extending our reach within the US – on reflection, it may have been our biggest challenge to date.

“Our venture across the Atlantic was partially due to the activity of our existing clients, typically the largest banks, power companies and infrastructure providers in the world,” he continues. “Going back 15 years, it was commonplace for global businesses to purchase the furniture they needed for their UK projects from a UK company, as they would from a US company for their projects