The dry ice age

Gene Cooke III, owner of Cold Jet, explains why the company is obsessed with the possibilities of reclaimed CO2

Smart manufacturing: As manufacturers look to maximize the use of data analysis and create wider views of operations, their need for reliable networks increases

Automation: Industrial robots may be marvels of mechanical engineering, but they are still inherently ‘stupid’ - introducing more intelligence will unlock a raft of advantages

Sustainability: Three key factors impact a company’s bottom line and the right decarbonization strategy for an entire carbon footprint needs to address these

Issue 204 2022 www.manufacturing-today.com

Hello and welcome to the September issue of Manufacturing Today.

I was very interested to read George Konidaris’ feature in this issue, and his assertion that industrial robots are ‘stupid’. I admit the first picture I imagined was Tony Stark’s robot sporting its dunce’s hat as it stands in his lab! But of course what George means is that it takes tremendous effort to program an industrial robot ‘so that the stupid robot that actually does the work can stupidly repeat the same trajectory, over and over again, to get the job done’. This programming is done by a highly trained engineer, which makes industrial robots expensive and really only used in the creation of high-volume, high-value products.

Now imagine ‘if all you had to do was show a robot what a workpiece looked like and tell it what to do with its business-end - and then the robot would generate all the relevant motion itself, on the fly and at a high-speed, carefully avoiding not just the rest of the workcell but the other robots working in it too.’ George says we’re now breaking out of ‘decades-old doldrums’‘change is here - and you don’t want to be the last manufacturer to realize the benefits’.

Schofield Publishing Ltd

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road, Cringleford, Norwich, NR4 6AU, UK Tel: (312) 854-0123 Tel: 044 (0)1603 274130 www.manufacturing-today.com Please note:

2240 West Woolbright Road, Suite 402

Our cover story this issue shares some insights into the operations at Cold Jet. Today credited as the inventor of modern dry ice technology, Cold Jet specializes in the use of reclaimed CO2, and is recognized as the global leader in innovative dry ice technologies. We were fortunate to speak to Gene Cooke III, owner of Cold Jet, who shares that he business ‘continues to be obsessed with the possibilities of using reclaimed CO2 for cleaning and cold chain logistics’. For the full story, turn to page 22.

dry ice age

www.manufacturing-today.com l 1

Content

Sales

Libbie Hammond EDITOR libbie@schofieldpublishing.com | lhammond@finelight-media.com ON THE COVER

Chairman Andrew Schofield Group COO Joe Woolsgrove Editor Libbie Hammond Assistant Editor Mary Floate

Editors Daniel Baksi • Alex Caesari • Danielle Champ Editorial Administrator Amy Gilks Managing Art Editor Fleur Daniels Art Editors Paul Gillings • David Howard Charlie Protheroe Artwork Administrator Rochelle Broderick-White

Director Alasdair Gamble Business Development Director Philip Monument Head of Global Media Programs Mark Cawston mcawston@schofieldpublishing.com Operations Manager Adam Blanch Research Managers Michelle Fontaine • Natalie Griffiths Jo-Ann Jeffery • Ben Richell • Basil Sharpe Laura Thompson Editorial Researchers Victoria Burke • Mark Cowles Jeff Goldenberg • Melanie Joyce James Page • Wendy Russell Richard Saunders • Kieran Shukri Markus Wellington Advertising Sales Johanna Bailey • Mike Berger Jessica Eglington • James Fuller Will Gwyther • Alex Hartley Reid Lingle • Sam Surrell Marketing Manager Matt Bone Florida General Manager Ryan Finn Boston General Manager Joy Francesconi Subscriptions i.kidd@schofieldpublishing.com Administration Natalie Fletcher • Rory Gallacher Ibby Mundhir

by

advertisers within this publication do not necessarily coincide with those of the

to ensure that the information published is accurate, and correct at time of writing,

by

of such information can be accepted by the publisher. All rights reserved. The

and may not be copied, stored

retrieval

The opinions expressed

contributors and

editor and publisher. Every reasonable effort is made

but no legal responsibility for loss occasioned

the use

contents of the magazine are strictly copyright, the property of Schofield Publishing,

in a

system, or reproduced without the prior written permission of the publisher.

at: Manufacturing Today Magazine

@MfgTodayMag Follow us

Finelight Media

Boynton Beach, FL 33426, USA Tel:

778-2396 © 2022 Schofield Publishing Ltd Editor’s Letter

Gene Cooke III, owner of Cold Jet explains why the company is obsessed with the possibilities of reclaimed CO2 Issue 204 2022 www.manufacturing-today.com Smart manufacturing: As manufacturers look to maximize the use of data analysis and create wider views of operations, their need for reliable networks increases Automation: Industrial robots may be marvels of mechanical engineering, but they are still inherently ‘stupid’ - introducing more intelligence will unlock a raft of advantages Sustainability: Three key factors impact a company’s bottom line and the right decarbonization strategy for an entire carbon footprint needs to address these

(561)

The

6 Sustainability

Manufacturers need to create decarbonization strategies that address complex Scope 3 emissions, as this is critical to make sustainability profitable 10

Sustainable supply chain

When looking to revamp operations to achieve their net zero goals, manufacturers are faced with complex supply chain challenges. What are the sustainable answers? 12

Automation

Robots aren’t living up to their promise – they may be exquisitely engineered but they remain ‘stupid’. That is why robotics companies are looking at AI solutions 16

Smart manufacturing

As an industry that relies on communications, connectivity is key. Manufacturers can consider creating their own bespoke private network to enhance their operations

18

2 l www.manufacturing-today.com Contents

FEATURES 18 Cold Jet Morland 22 48 COVER STORY

Manufacturing news Updates and announcements from the manufacturing arena

INSIDE THIS ISSUE

www.manufacturing-today.com l 3 COMPANY PROFILES MiddleGround Capital Dixon Valve & Coupling Company LLC IQE Gat Creek Excool Active Power 26 34 54 30 42 60

...Contents continued Little Giant Ladder Systems LLC Whirlpool Glowforge Creative Composites ACI Building Systems Smart Start Inc Shop Vac National Composites 64 68 88 92 108 114 130 136

www.manufacturing-today.com l 5 Herrco Cosmetics Skyline Windows Will-Burt Portsmouth Aviation VA Technology Bundy Refrigeration Skymark Packaging Variohm Group 74 82 96 102 118 124 142 146

Green benefits

How the right decarbonization strategy makes sustainability profitable. B

6 l www.manufacturing-today.com

y Mauro Cozzi

www.manufacturing-today.com l 7

Sustainability

While the majority of manufacturers worry over the cost of cutting carbon, many proactive industry players are already seeing the opposite effect. These frontrunners are not only protecting their bottom line through decarbonization, they’re seeing it grow. But not every decarbonization strategy is created equal.

Decarbonization is the process that a business takes to reduce its carbon emissions. These emissions are broken down into three ‘scopes’: scope 1 (direct operations), scope 2 (purchased energy), and scope 3 (everything else in the upstream and downstream value chain).

In the manufacturing industry today, most companies focus on the first two scopes as they’re much easier to control. However, Deloitte estimates that for many companies, scope 3 emissions account for more than 70 percent of their carbon footprint. This is particularly true in manufacturing, where the extraction and processing of raw materials comes into play.

Not so long ago, creating a decarbonization strategy based on scope 1 and 2 emissions was enough to access the green premium so many strive for. But governments, regulators, and customers have matured in their understanding of greenwashing and are now critical of manufacturers who ignore the bigger picture.

Creating a decarbonization strategy that addresses complex scope 3 emissions across the supply chain is critical to make sustainability profitable. This is evident across three key factors that impact a company’s bottom line:

1. Risk mitigation

The CDP reported in 2021 that environmental supply chain risks will cost companies $120 billion by 2026, with manufacturing seeing higher cost increases than any other industry.

Regulation changes, carbon taxes, and resource scarcity pose significant financial risk to all manufacturers. But only those with visibility of their full carbon footprint, including their supply chain, are able to mitigate that risk and protect their profits.

Let’s say a carbon tax is being introduced in the country of a supplier. If the manufacturer doesn’t measure how much of their carbon footprint that supplier is responsible for, they have no way of knowing how much that tax will cost them until it’s too late to do anything about it.

Being aware of how environmental risk translates to financial risk is key to profitability. Coca-Cola disclosed to CDP in 2020 that 21 percent of the water used by its facilities came from ‘areas of high

8 l www.manufacturing-today.com

or extremely-high water stress’. This allowed the company to calculate that almost $1 billion of annual revenue was at risk in India alone.

Insights like these allow businesses to build a decarbonization strategy that adapts their supply chain to reduce environmental financial risk as much as possible.

2. Revenue growth

Around eight in ten consumers seek out socially or environmentally responsible products whenever possible and would switch brands to do so, according to Deloitte. But an increasingly carbon literate consumer base is demanding more scrutiny into how their products are being manufactured.

This consumer demand influences the outcome of tenders. The CDP reported that over 200 large purchasers with a combined $5.5 trillion in procurement spend are requesting thousands of companies disclose their entire carbon emissions.

Tenders are increasingly being decided by which company can prove they’re the most sustainable. A decarbonization strategy that doesn’t shy away from scope 3 gives the minority of companies that are capable of this the upper hand.

Sustainability

Axis, a property services partner in the construction space, uses its advanced carbon data to win bids and increase revenue.

“This data is winning us work when it comes to bidding and tendering processes,” explains Oliver Refson, Sustainability and Quality Manager at Axis. “Setting sustainability targets used to be a nice-tohave, but now it’s a mandatory requirement to get through the final stages of winning big contracts.”

3. Brand reputation

The Science Based Targets initiative (SBTi) claims that 79 percent of executives observed strengthened brand reputation after setting science-based targets in their decarbonization strategy.

These targets signal to customers, investors, and employees that their sustainability activities are credible, practical, and grounded in climate science. They prove that a company is not just going after the emissions it directly controls, but also the indirect emissions in its supply chain and beyond.

We’ve seen how customers respond in tenders when they believe that a product is more legitimately green than others in the market, but investors also favor environmental reputation.

Around 90 percent of institutional investors believe companies with high environmental and social reputations deserve premium share price valuation, and they agree that prioritizing these companies leads to better long-term returns.

The ability to attract and retain talent is also impacted by a company’s reputation on these issues. Seventy-five percent of millennials expect their employers to take a stand on addressing the climate crisis.

A science-led decarbonization strategy for the entire carbon footprint enables companies to unlock these critical business benefits and make sustainability profitable. The proactive manufacturers that are already doing this today have a significant head start. But these opportunities are out there for any company willing to tackle their supply chain emissions. v

For a list of the sources used in this article, please contact the editor.

Cozzi

Mauro Cozzi is CEO and Co-Founder of Emitwise, the carbon management platform for manufacturing businesses and supply chains to confidently understand, track and reduce their carbon footprint. Having raised over $17 million within three years, Emitwise combines 100 years of carbon accounting experience and machine learning technology to accelerate the climate action of the 3rd most carbon-intensive industry globally. By increasing the accuracy of scope 3 emissions, the platform empowers manufacturers and their supply chains to make carbon-led business decisions that lower risk, increase profitability and deliver ambitious climate action.

www.emitwise.com

www.manufacturing-today.com l 9

Mauro

A guide for manufacturers

Let’s begin by asking – what is a sustainable supply chain?

A sustainable supply chain isn’t just the environmental impact it has but it also refers to the holistic application of environmental, social, economic and legal concerns, including waste, carbon emissions, carbon footprint, labor conditions, health and safety and work exploitation.

The importance of supply chain sustainability

The supply chain makes up a large portion of manufacturers’ carbon emissions, but more sustainable supply chains, mean manufacturers can put into practice environmentally aware and eco-conscious ways of working that benefit the planet, reduce emissions and cost, and boost brand reputation.

Manufacturing supply chain challenges Increased costs

Economic factors have impacted the manufacturing industry. Rising costs for energy, labor, and raw materials, are having an impact on profit margins. Many manufacturers are struggling to set aside enough budget for investment in low carbon technologies as well as tackle the rising costs.

Monitoring complex supply chains

Complex supply chains can be challenging to manage. For example, a single product may have several different materials and several suppliers in place to ensure continued delivery in case one supply runs into any issues. When inter-connected, dependent supply chain changes, no matter how small, have a ripple effect on other parts of the supply chain.

10 l www.manufacturing-today.com

Many manufacturers are faced with complex supply chain challenges, particularly when they are looking to revamp operations to achieve their net zero goals. Dan Hulme explores how manufacturers can overcome these challenges

Lack of alignment in responsibility across supply chains

Manufacturers looking to switch to sustainably sourced and manufactured products, may find getting suppliers on board difficult or they may have to switch to new suppliers who can accommodate their requirements. Some overseas suppliers don’t yet understand the value of sustainability in the supply chain. This can make finding a sustainable supplier that can still produce cost-effective products difficult.

How manufacturers can build a sustainable supply chain

Identify sustainability issues within the supply chain

Manufacturers need to know what areas and processes of the supply chain could stand to be improved. However, there may be other

Sustainable supply chain

elements that aren’t so obvious such as hazardous chemicals produced by a factory within the supply chain.

Adopt a circular supply chain

Typical supply chains are linear. The materials are first sent to the manufacturer and then turned into a product, which is ultimately sold to the consumer and then discarded. This creates a huge amount of waste. By implementing a circular supply chain, waste can be reduced through recycling the products and sending them back to the manufacturer for reuse.

Reduce consumption

Transport is one of the largest emissions contributors and is a large part of the supply chain, alongside rising costs of fuel for HGV drivers. However, by investing in low emissions vehicles (LEVs) and electric vehicles (EVs) to reduce both costs and consumption, or through sourcing raw materials from businesses located in a closer proximity to the manufacturing site, most manufacturers can tackle this challenge.

Eliminate dead mileage

For some manufacturers eliminating or reducing mileage isn’t an option. The return journey also contributes to the ever-growing emissions and fuel costs. But there are ways to make the return journey more efficient; transporting materials back to the original base and / or hiring out these vehicles for a portion of the return journey, can also improve the Return on Investment (ROI).

Engage suppliers

None of this will be possible without engaging suppliers in plans to create a more sustainable supply chain. Those who do not have control over other operations within the supply chain (scope 3 emissions), may need to be firm and encourage suppliers to adopt more sustainable practices. This can be done by making it a regular part of conversations, explaining the positives and how they can benefit everyone. v For a list of the sources used in this article, please contact the editor.

Dan Hulme is Inspired PLC’s Carbon Consultant for the UK manufacturing sector. Inspired PLC is a UK market leading technology enabled provider of energy and sustainability advisory services. Since 2000, it has grown in scale and capability and is servicing over 3,400 UK and Irish clients across all sectors.

To enable businesses to respond to the climate emergency, it focuses on solving their toughest challenges. By managing data comprehensively, sourcing energy sustainably and reducing carbon efficiently, it allows clients to control costs effectively, make authentic ESG disclosures, improve their business performance, whilst powering their journey to net zero.

www.inspiredenergy.co.uk

www.manufacturing-today.com l 11

Dan Hulme

12 l www.manufacturing-today.com

Change is here

Despite what you might have read in the popular press, robotic automation is stuck; useful, but much too hard, because we’re still doing things the same old way. New AI technology is set to finally change that.

Industrial automation is one of the key reasons the world is getting better: widespread consumer access to an incredible range of astonishingly complex manufactured goods is only possible because of the scale and cost-effectiveness it supplies. Very few of us know how to build a microwave, and it would take even an expert weeks or months to craft all the parts from scratch by hand, but the average consumer can nevertheless walk into a store and buy one for less than $100.

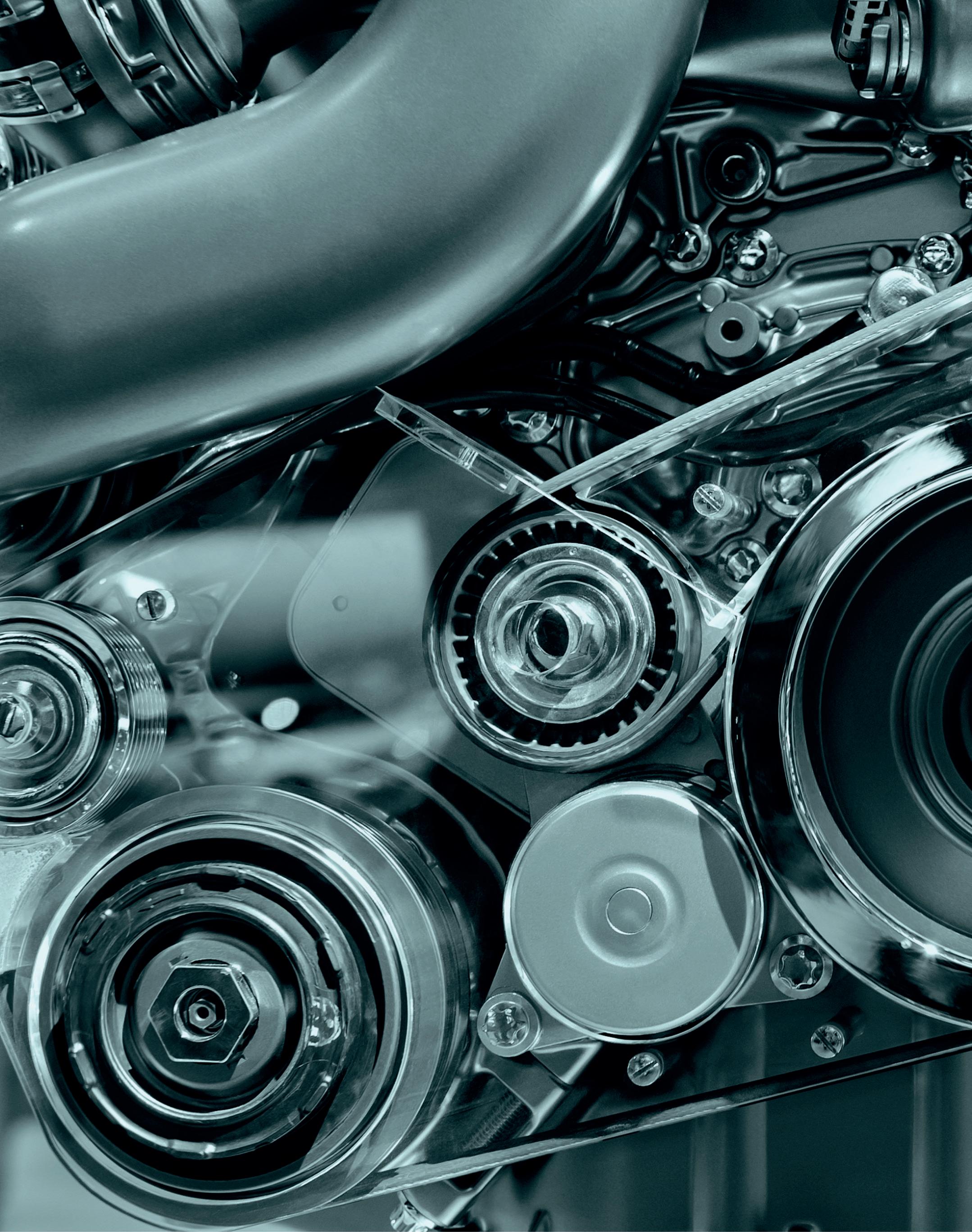

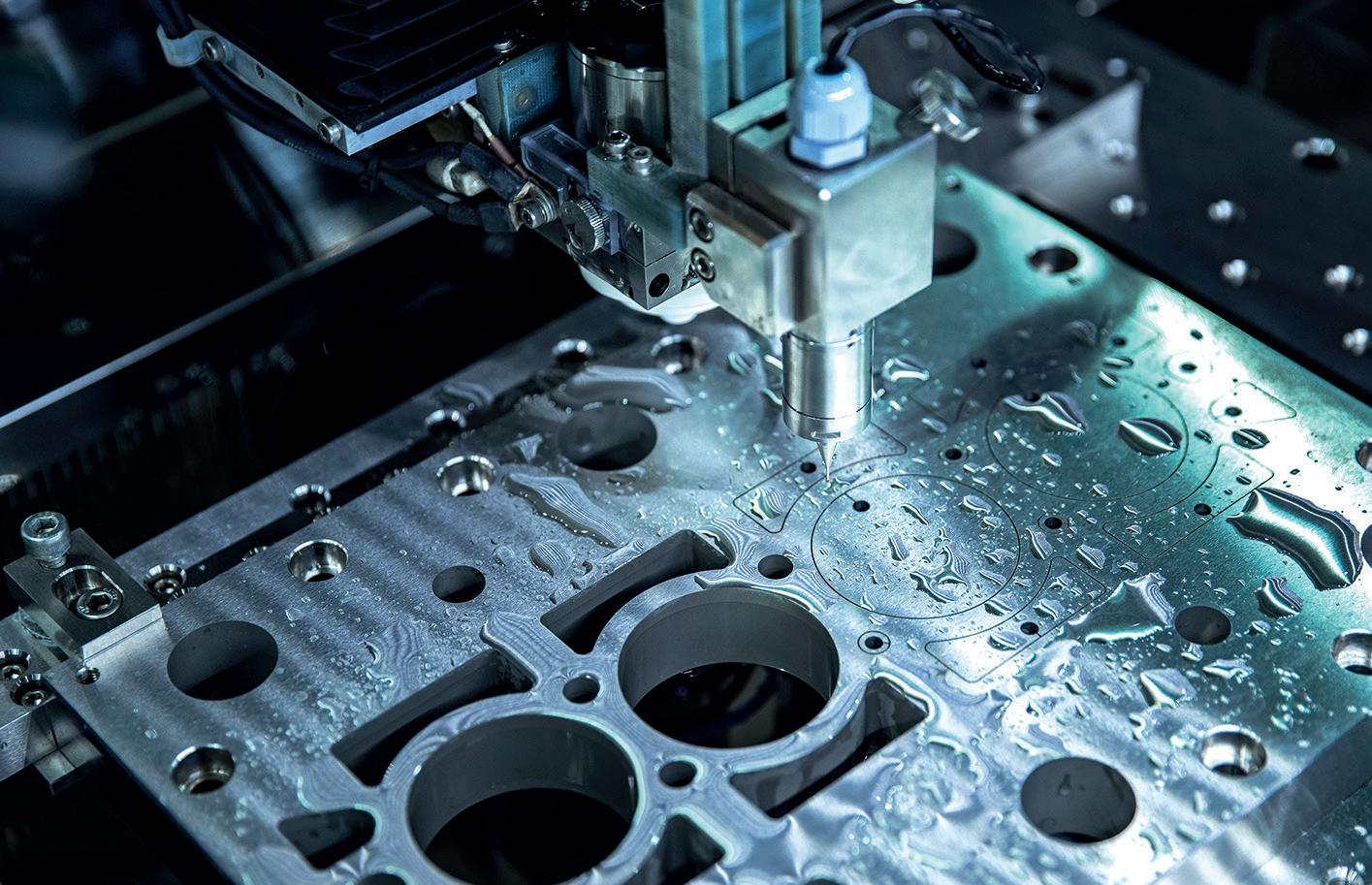

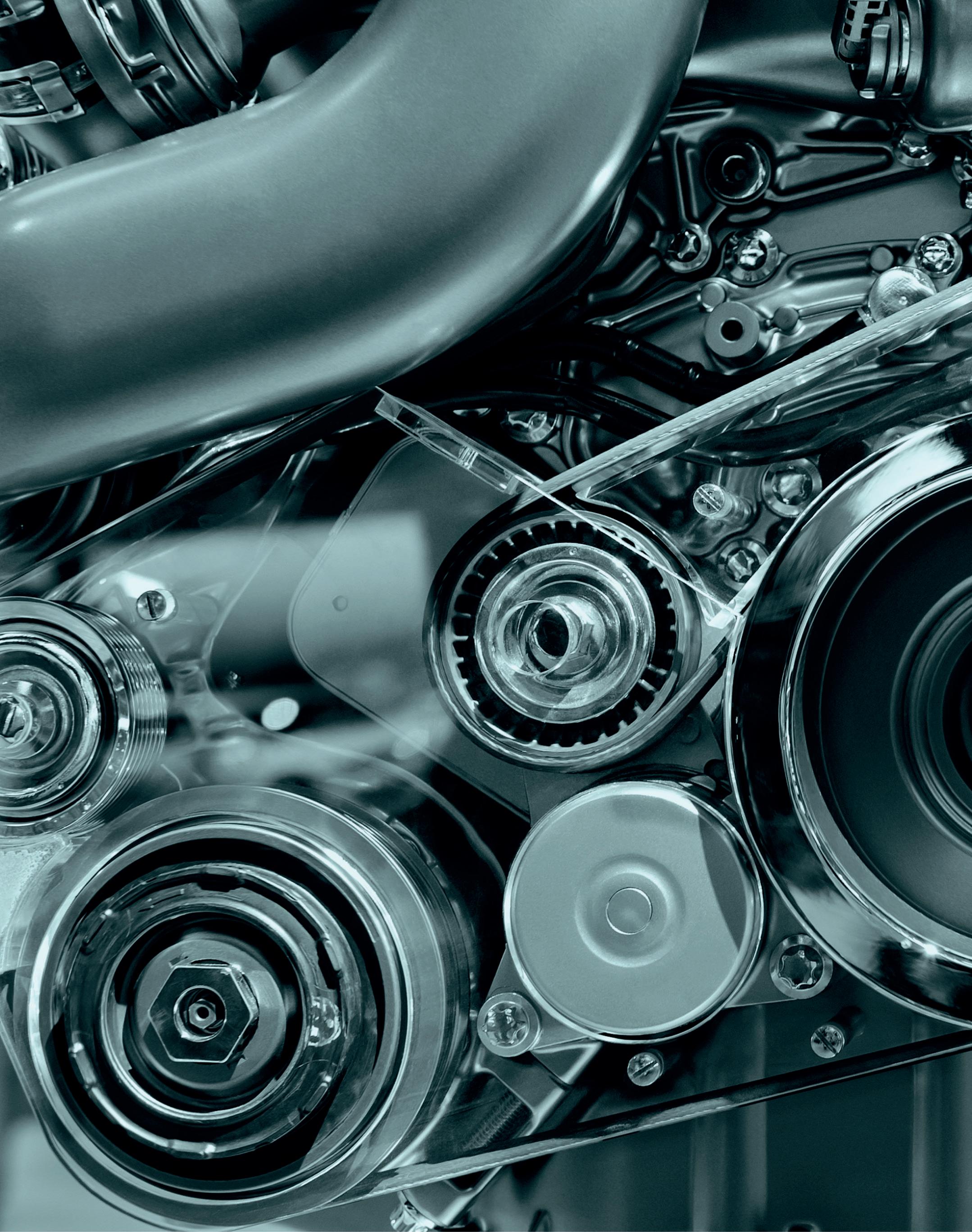

One tool in the industrial automation toolbox, however, is not living up to its potential. Industrial robot arms have done a lot of good for the world, but mass deployment has been restricted to the automotive and electronics sectors. Even in those industries, their contribution has been important but limited: most of the work assembling a car is still done by humans, with the robot contribution staying in the same lane for the past few decades. Today’s industrial robots are marvels of mechanical engineering, in most cases just as physically capable as a human, and much more precise. So why have they been stuck in the same gear (so to speak) for so long?

The primary reason is stupidity. Robots are stupid; exquisitely engineered, but stupid, and the average industrial robot sold today is

no smarter than it would’ve been 20 years ago. As a result, putting them to work is much harder than it should be. Today’s industrial workcell is a mechanical engineering marvel that expends tremendous effort to bring every workpiece to the exact same position (down to the millimeter) every time, over and over again, so that the stupid robot that actually does the work can stupidly repeat the same trajectory, over and over again, to get the job done. Not only that, but the trajectory itself must be engineered by hand, every rotation or adjustment planned and coordinated by a trained engineer. Repeatable patterns must be established and followed exactly, in order to avoid collision or disaster. The situation is even worse when multiple robots must operate in a single workcell; every move must be tightly timed and coordinated, a pre-planned high-speed ballet enacted in the dark, replayed endlessly without variation.

All that engineering is expensive, so much so that the ROI on an industrial robot only really makes sense for high-volume, high-value products. Industrial roboticists are so used to all these restrictions and all this complexity and all that cost, because that’s just the way things are done; it’s the way things have always been done. Robot workcells are complex because they have to be designed to get around the stupidity of industrial robots. We’ve been in this box for so long that we don’t even see the box anymore; we’ve just come to believe that this is all that robotic automation can accomplish.

www.manufacturing-today.com l 13

Automation

Unleashing the next phase of robotic automation. By George Konidaris

14 l www.manufacturing-today.com

Now imagine a person working on a factory line. A welder doesn’t need what they’re working on to be in the exact same place every time; it would be almost laughable if they were unable to adapt to their workpiece shifting a few inches to the left. Someone screwing bolts into a workpiece is perfectly capable of picking up a bolt from a big pile in a box. And three people working in the same space will take a little while to adapt, but very shortly will have learned to work around each other. You simply put people in a factory, give them some desks and the parts they need to do their jobs, and they figure out how to do the thing right. In short, humans are endlessly flexible, and most important for us here, they’re able to react to and deal with minor variations in the world around them.

This example suggests that the industry’s current focus on ever more precise robot arms, able to ever more quickly repeat preprogrammed motions down to the tenth-of-a-tenth of a millimeter, is not just misguided, it’s holding us back. We find ourselves squeezing the last few drops of ROI improvement from the things we can already automate. But we can instead break out of our box by designing robots with a little more intelligence. Not the chess-playing, schedulemaking, essay-writing kind of intelligence, but the simple practical intelligence of how to sense the world, and how to move around without smashing into it.

Just imagine if all you had to do was show a robot what a workpiece looked like and tell it what to do with its business-end - and then the robot would generate all the relevant motion itself, on the fly and at a high-speed, carefully avoiding not just the rest of the workcell but the other robots working in it too. Think of how much less expensive everything would be, how much easier and cheaper robot factories would be to build, how many applications robots would suddenly make sense for. All that in exchange for just the ability to move around in the world, as competently as even the simplest insect.

Unlocking this next stage of robotic automation will require the development of robot controllers capable of displaying the basic physical intelligence required to deal with the world as it is, rather than as it can be engineered to be (at great expense). A new generation of

robotics companies are, today, building on recent gains in AI technology to deliver just this, with the goal of making robots just a little less stupid and a lot more applicable, and so breaking the industry out of its decades-old doldrums.

Manufacturers - especially in these post-pandemic days where supplies are rare and demand remains high - tend to be very conservative towards new technologies, for the simple reason that they’re running businesses with low margins and hard throughput targets. It’s natural to not want to take too many risks when you have to deliver the things people use in their lives every day. But that conservatism is a dead-end, a recipe for finding yourself left behind. Now is the time for manufacturers to begin embracing new technologies - the type that can dramatically improve automation and have a long term effect on throughput, productivity, efficiency, and optimization - in short, your competitive advantage.

The factory floor of five years from now is not going to look like it does today. They will be less expensive, more reliable, and more flexible. Change is here - and you don’t want to be the last manufacturer to realize the benefits. v

George Konidaris

www.manufacturing-today.com l 15

Automation

George Konidaris is the co-founder and Chief Roboticist of Realtime Robotics, a Boston-based startup that helps companies deploy smart automation faster, reduce cost, and improve productivity. He is also an Associate Professor of Computer Science at Brown, where he is the recent recipient of an NSF CAREER award, young faculty awards from DARPA and the AFOSR, a DARPA Director’s Fellowship, and the 2020 IJCAI-JAIR Best Paper Prize. Realtime Robotics technology generates collision-free motion plans in milliseconds for industrial robots and autonomous vehicles. Its solution empowers robots to function together in unstructured and collaborative workspaces, as well as to react to dynamic obstacles the instant changes are perceived. Its solutions expand the potential of automation. www.rtr.ai

Smarter communications

Manufacturers are moving to smarter and more automated operations to stay efficient, competitive and profitable, and there are many support systems in place to facilitate this.

Earlier this year, the UK government announced a £50 million data innovation hub as part of the £300 million UK R&I Made Smarter Innovation Challenge, to support manufacturers with the development of digital technologies to help to boost productivity, growth and sustainability.

The connectivity problem

In an industry which relies on communications - whether its backend business systems, production-line sensors, automated vehicle guidance apps, or team members across a site – connectivity is key.

For many manufacturers, it’s vital that communication networks are secure, simple to manage and, above all, always-on. But even the smartest of manufacturers will struggle with coverage not-spots, dropped connections and high cost, complex systems.

Typically, the largest manufacturing sites will often face the bigger issues. The scale and complexity of these sites means that conventional public networks and WiFi options often struggle to meet connectivity needs.

Facilities that are based in rural, hard to reach, or more remote settings will also face difficulties as public mobile coverage can be limited; whilst operations that are based in urban areas are forced to compete with thousands of consumers and businesses for wireless bandwidth.

Unreliable connectivity has created a communications gap for businesses around the country that are looking to maximize the use of

16 l www.manufacturing-today.com

With the Government’s new data innovation hub set to accelerate digital technology in manufacturing, Mick Goulding explores the role of connectivity and private networks in securing sites, protecting people and supporting digital transformation in manufacturing

their data analysis and create a deeper and wider view of operations to increase efficiency. One area that manufacturers can be smarter with regards to their communications is by building and deploying their own private mobile network.

What is a private network?

Private networks are bespoke 4G or 5G mobile communications networks that help meet the specific needs of manufacturing sites, applications and existing coverage challenges. They provide guaranteed, always-on connectivity, tackling unplanned outages and ensuring operational continuity.

The private network system is designed around the specific needs of manufacturing sites and existing coverage challenges to offer a range of operational applications, like real-time data, that enhance worker safety and allow for in-depth asset tracking.

Enhancing safety

Private networks also enable a range of applications to support workers on site. For example, personal health devices can be used to

Smart manufacturing

continually monitor and provide health checks in hazardous or highstress environments. Where hazardous materials may be used, digital sensors connected via the network will constantly assess air quality and detect contaminants to prevent potentially harmful toxins impacting worker health.

Better connectivity will also enhance video surveillance and provide more accurate geolocation monitoring to track the location of assets, removing people from perilous locations entirely through task automation and remote control.

Tackling downtime

Unplanned downtime, which has the potential to lead to significant and costly delays, is an ongoing challenge for the manufacturing sector.

The low latency, high bandwidth, round the clock guaranteed connectivity of a private network provides manufacturers with the opportunity to enhance their connectivity and boost applications like data analysis. This allows for a deeper and wider view of operations, enabling real-time site monitoring and remote operations, which makes tackling downtime and increasing efficiency within the industry easier.

Transforming operations

Along with tackling downtime and ensuring worker safety, private networks provide manufacturers with the ability to utilize transformational digital technology, and upgrade key applications, including data analytics, asset tracking, automation, predictive maintenance and asset localization.

Faster connectivity will provide enterprises with detailed data analytics, enabling the monitoring of operational communications in real-time. This smart sensor data, in combination with machine learning, allows machinery to make swift and informed operational decisions.

Enhanced connectivity means manufacturing can also be made more efficient with asset tracking and asset localization, which enable autonomous vehicles and software guidance systems to provide 360° situational awareness of mobile assets, improving production lines by using geolocation to increase traceability of parts and tools.

Once situated on-site, machines and robots can be automatically and independently monitored, enabling the removal of manual repetitive tasks, with predictive maintenance ensuring the operational continuity of key assets to create smarter manufacturing production.

With levelling up high on the UK’s agenda, the manufacturing sector has a pivotal role to play in boosting productivity, creating skilled jobs and supporting local economies. Key to success will be secure, enhanced connectivity, and the industry must act now to ensure it has the capacity to apply novel digital solutions to manufacturing challenges. By leveraging initiatives like the government’s data innovation hub, the industry can invest in private networks and become a frontrunner in the race towards smarter production and Industry 4.0. v

www.cellnextelecom.co.uk

www.manufacturing-today.com l 17

Mick Goulding is Commercial Director, Enterprise at Cellnex UK. Cellnex is Europe and the UK’s largest and fastest-growing independent owner and operator of neutral wireless telecommunications and broadcasting infrastructures.

Mick Goulding

Mint condition

Rockwell Automation Inc., the world’s largest company dedicated to industrial automation and digital transformation, is working with The Royal Mint to design, build, and commission a facility to safely recover valuable metals from electronic products.

E-waste is one of the fastest growing waste streams with less than 20 percent currently recycled worldwide. The Royal Mint is using patented chemistry to recover more than 99 per cent of gold and other materials from electronic waste contained within the circuit boards of discarded laptops and mobile phones.

Building on a 15-year relationship with The Royal Mint, Phil Hadfield, UK Managing Director at Rockwell Automation says: “We are proud to continue our working relationship with The Royal Mint to create a new source of high-quality precious metals for the business and help with the global challenge of electrical waste.”

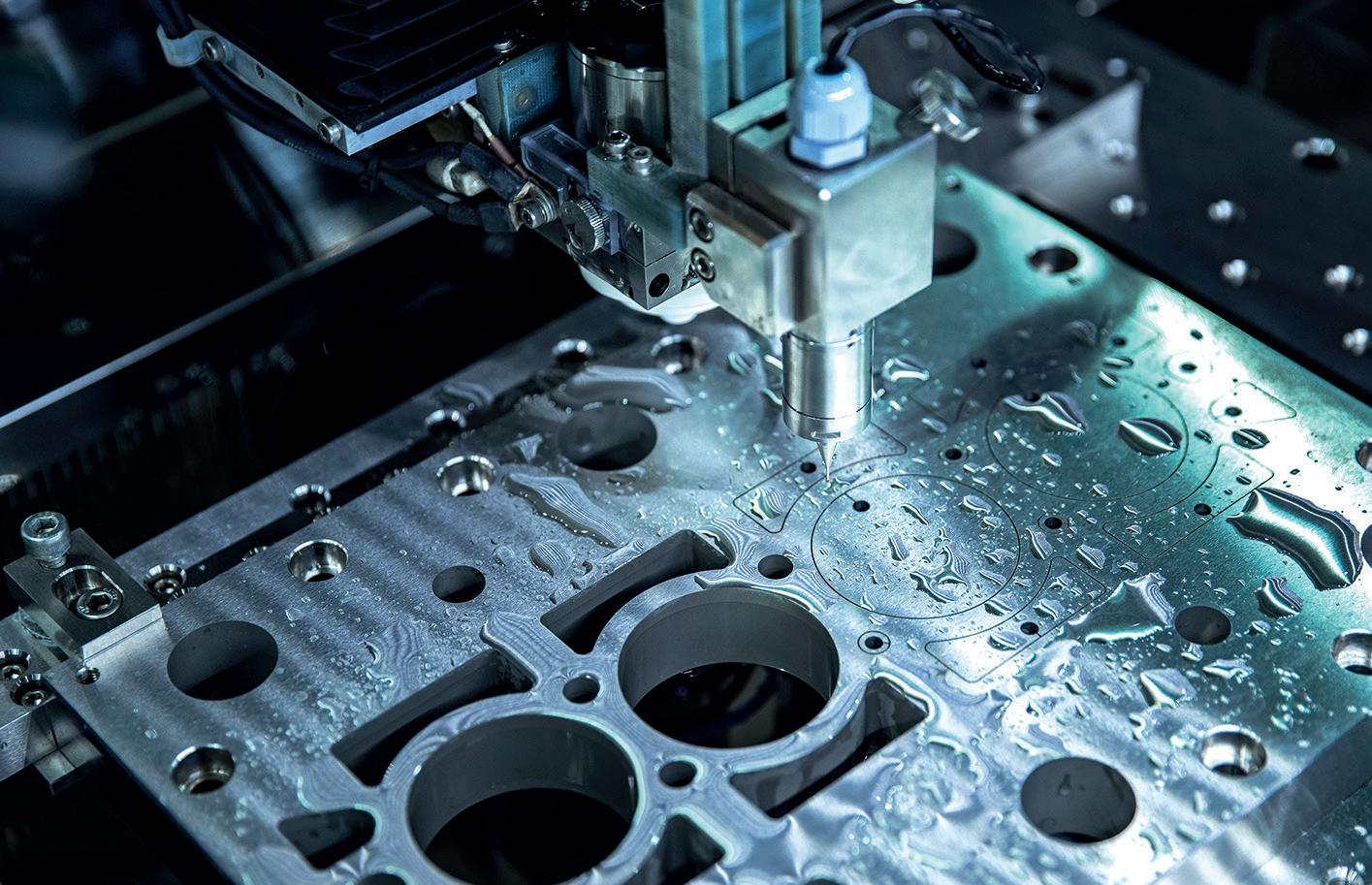

Precision molding

Profile Plastics has become a TactoTek licensee, with rights to design and produce In-Mold Structural Electronics (IMSE) solutions that use TactoTek intellectual property, creating a complete IMSE supply ecosystem in North America.

Profile Plastics is an established supplier of precision Film-Insert-Molded (FIM) parts to global automotive OEMs, and their tier one and two suppliers.

According to Nat Svela, VP of Sales at Profile Plastics: “Our customers are asking for solutions that integrate cosmetics, structure, and electronic functions, including capacitive touch and lighting, into a single part - TactoTek’s IMSE technology delivers that integration. Because it’s a single-piece injection-molded solution, IMSE designs minimize parts and assembly.”

Marko Suo-Anttila, SVP Engineering at TactoTek, highlights that: “Profile Plastics is one of the pioneers of FIM and has decades of experience. This is the ideal background to become IMSE- capable, quickly and efficiently.”

It’s electrifying

EV Technology Group Ltd. has entered into terms with MEPC Silverstone Park, securing a 90,000 squarefoot industrial lease at the historic motoring site. The new facility comprises EV Technology Group’s EV Centre of Excellence, and has been constructed by MEPC as part of its latest 265,000 square-foot development at Silverstone Park.

This follows the recent announcement of the proposed acquisition by EV Technology Group of Fablink Group Holdings Limited, a tier one contract manufacturer in the United Kingdom, which operates seven manufacturing and assembly sites with over 750 employees. Fablink operates its Streamline Automotive Division, which services the increasing demand in the UK for contract vehicle assembly services, especially in the Electric Vehicle (EV) sector. The new Silverstone facility will allow EV Technology Group and its subsidiaries to rapidly expand EV manufacturing and assembly capacity, supporting its vision of electrifying iconic brands.

As EV Technology Group looks to expand its house of brands, this state-of-the-art facility will be home to the company’s electric vehicle engineering and development hub.

Wouter Witvoet, CEO and Founder of EV Technology Group, says: “Silverstone has been the home to many iconic motoring stories - and our future electrifying iconic brands here will be part of its next chapter. The site’s location puts us in the heart of the booming UK EV industry, and will allow us to scale manufacture and assembly of electric brands such as the iconic MOKE.”

Modern refurbishment

Sustainability is at the heart of a partnership between robotics and automation specialist FANUC UK and machinery refurbisher, Electron Engineering Services Ltd (EES). By retrofitting a cutting-edge FANUC CNC into a lathe for a subcontract machinist, as well as a FANUC digital spindle motor and drive, servo drives and new electrical interface, this legacy machine has been upgraded ready for the digital age.

As well as boosting productivity by delivering improved functionality, faster programming and enhanced reliability, the partnership is helping to cut waste by breathing new life into old machines, repurposing them for today’s smart manufacturing needs.

Based in Halifax, West Yorkshire, EES has been refurbishing machinery for over 30 years. “The majority of the machines we refurbish – that we essentially remanufacture – are actually of a higher build quality than many of their more modern counterparts,” explains Richard Vogel, EES Sales Director. “They are of robust, predominantly high-integrity cast-iron construction, and would have been at the cutting-edge of technology when first commissioned.

“The refurbishment service we provide brings these machines in line with modern day requirements, while ensuring that the brilliant engineering that went into them in the first place isn’t discarded. This includes making sure they are compliant with modern standards and regulations.”

Manufacturing

18 l www.manufacturing-today.com

News

NEWS IN BRIEF

“LET’S MAKE IT MORE COMPLEX” SAID NOBODY, EVER

Our suite of software is the simplest to intergrate, adopt and use. It’s time to experience SMARTER HR, PAYROLL & FINANCE.

MHRGLOBAL.COM

22 l www.manufacturing-today.com

Gene Cooke lll

The dry ice age

Since its launch in Loveland, Ohio, way back in 1988, Cold Jet has been focused on developing environmentally sustainable solutions. The company’s original mission was to replace the use of toxic chemicals within aircraft coatings, recognizing what was then a compelling ecological need for the reduction or elimination of the use of chemical solvents. “Methylene chloride was the base chemical then used by various militaries around the world for the maintenance of aircraft,” reflects Gene Cooke III, owner of Cold Jet, speaking to Manufacturing Today. “To investigate the use of solid CO2 or dry ice as a medium to remove coatings from aircraft surfaces, we formed a partnership with McDonald Douglas, then a major American aerospace manufacturing corporation and defense contractor.”

It was during that process of discovery that Cold Jet identified a set of manufacturing opportunities to minimize or eliminate the use of chemicals in cleaning applications, with the potential for application across a host of industries, from food processing to automotive manufacturing. “For the next 30 years, we pursued the belief that CO2 could be used for surface preparation and cold chain logistics,” Gene explains.

Along the way, Cold Jet has been bolstered by multiple investments, including its acquisition of IceTech in 2016, a leading manufacturer of high-performance and reliable dry ice blasting and dry ice production equipment, and automated solutions. Founded in Denmark in 1998, IceTech had supplied equipment to more than 180 countries around the world at the time of its purchase by Cold Jet, both directly, and through a network of more than 30 distributors. Many of the IceTech staff remain within Cold Jet, which is today credited as the inventor of modern dry ice technology. Specializing in the use of reclaimed CO2, Cold Jet’s dry ice is formed through the capture of waste CO2 from industrial and biogas facilities, prior to its conversion into a commercially viable cooling and cleaning medium. In this way, the company is able to reduce greenhouse gas emissions, while delivering a product that is water and chemical free.

“We’re currently undertaking a large project with a manufacturer headquartered in Cincinnati, looking to completely eliminate the use of water throughout their manufacturing process,” Gene indicates. “Water is one of the most precious resources in 2022, and its use for cleaning process equipment is unnecessary when it could instead be redeployed far more effectively.”

Vital solutions

Today, Cold Jet is the global leader in innovative dry ice technologies. The company boasts three primary manufacturing facilities across the globe: in Cincinnati, Ohio; Bramming, Denmark; and Poznan, Poland. A further seven sales and service facilities are located across Europe, Japan, China, Mexico, and Canada, as part of an operations footprint that spans 13 different countries in total, and which gives Cold Jet the capability to provide worldwide support for its clients. Across its facilities, the company currently produces a total of eight primary environmental cleaning and surface preparation systems, together with six primary dry ice manufacturing systems and a suite of compatible accessories and configurations. But Cold Jet isn’t stopping there, and recently announced its CONNECT technology, a core intelligence, customer service, and support platform designed to sit across both its business segments.

“We’re very excited about Cold Jet CONNECT,” Gene admits. “The concept is simple: data is the currency of 2022, and we need to be able to provide it in real-time to the customers who are operating our equipment, and to the service organizations who support it. For instance, we work with a manufacturer in Missouri, US, who operates four facilities, producing a wide range of refrigeration systems for brands including 7/11 and Subway. They use about 50 of our dry ice blasting systems throughout their assembly facilities to remove the overspray of foam that can occur during production. With CONNECT, we can provide them with data from any individual set of equipment, on any single manufacturing line, on any given day, or we can summarize data from across the totality of their equipment.

www.manufacturing-today.com l 23 Cold Jet

More than 30 years ago, Cold Jet placed its faith in the potential of dry ice as a cold chain logistics medium. Today, that faith is being repaid with a flurry of new contracts, fueling the company’s ambitious expansion plans

“With that, they can understand and develop best practices,” he continues. “It can unlock the answer to why facility A might be performing differently to facility B, thereby empowering the customer to take better decisions to achieve more efficiencies. The aim is to tie 100 percent of the use of our products into real-time data monitoring and report generation.”

The company is also investing heavily in its own systems as it seeks to maintain its cutting-edge capabilities. “We’re working on moving from a Kanban manufacturing system to a fully integrated MRP system for all our facilities around the world, which is a huge undertaking,” Gene reveals. “We’re also including an automated barcoding system for all our materials, components, or sub-assemblies. Because we produce our dry ice manufacturing system in Denmark, which is then sold in

the Americas and Asia, there’s a significant volume of inter-company trading that needs to take place to satisfy local taxing laws and accounting standards. We need to plan how much inventory we have in Shanghai, Stuttgart, or Seattle. Barcoding is a way to optimize our operations, helping us to understand exact costs, and then to generate proper invoices, all without generating delays for the customer.”

Cold Jet has experienced significant success in recent years, with annual year-on-year growth of 15 percent. It’s come at a time when much of the manufacturing industry has suffered, as the arrival of the Covid-19 pandemic saw customers close their doors, and demand for products and services dwindle. Cold Jet’s ability to avert this downturn is thanks, in large part, to the company’s vital role in the transportation and distribution of much-needed vaccines.

“We have a reputation when it comes to the delivery of dry ice manufacturing solutions to a multitude of customers,” Gene emphasizes. “Thanks to that, Pfizer was able to find us in June 2020 with a very pressing need, while its vaccine was still under development. Since then, we’ve worked with Pfizer at its primary manufacturing facilities in Brussels, Belgium and Kalamazoo, Michigan, while also working at their primary distribution sites in Pleasant Prairie, Wisconsin.”

Building partnerships

Perhaps unsurprisingly, it’s a partnership that has seen Cold Jet rapidly expand its footprint within the biopharmaceutical and life sciences sector. “The messenger RNA that Pfizer utilized as the primary protein in its vaccine requires preservation at ultra-low temperatures,” Gene comments. “Dry ice was determined to be the perfect transport medium, with respect both to the need and the volume of goods that needed to be distributed all the way from the point of manufacture, through to ultra-low temperature shipping containers, and further on to the point of inoculation. We’ve worked hard to be an excellent supplier to Pfizer, and that’s allowed us to acquire even more business with companies throughout the world, such as Thermo Fisher Scientific.”

Although Cold Jet’s partnership with Pfizer helped to see the company through what might otherwise have proved a difficult time, there remained obstacles to be overcome. In order to meet the demand of Pfizer and others for dry

24 l www.manufacturing-today.com

Moving forward, we hope to be able to extend our capabilities, transitioning away from the supply of dry ice production machines, and adding a level of expertise in the totality of the use of dry ice as a transport medium, across volume, sizing, and packaging. In doing so, we’ll be able to minimize our waste footprint, while offering a more comprehensive service for our customers

ice, the company relied on the health of its own global supply chain.

“We have two primary product lines: environmental cleaning and surface preparation, and dry ice manufacturing systems,” Gene states. “The former is split between Cincinnati and Poland, the latter between Cincinnati and Denmark, plus a number of proprietary sub-assemblies. Working with our base in Scandinavia, mainland Europe, and the US, we’ve really developed relationships at the local, regional, national, and multi-national levels, which has set us on track to surpass $100 million in revenues in 2022.

“Part of that is culture,” he adds. “At Cold Jet, we are more collegial and collaborative, and less formal than some other companies might be, and we translate that into our supplier relationships. We’re not looking for last dollar negotiations, we’re looking to build business partnerships that enable us to be responsive to our customer base, but also respectful of the business objectives of those suppliers. That means availability of the right material, at the right time, takes precedence over cost per unit and payment terms.”

It’s been a remarkable journey for Cold Jet, and for Gene. Reflecting on the company’s growth from its initial start-up phase, he credits much of its success to the engagement and dedication of his employees. “It all began with a

few cowboys who were willing to place a bet on the future of our business,” he says. “Now, as of the end of July 2022, we have 291 full-time colleagues around the world, and we’re set to exceed 300 by the end of September. The challenge from here is to continue to create the same level of engagement today that we had when we were just ten or 15 in number. We need to add more disciplines and processes, with replicability and scalability; that’s a fine line to tread.”

Looking towards the long term, Gene is intent on the need for the company to remain driven in its ambition. “We continue to be obsessed with the possibilities of using

reclaimed CO2 for cleaning and cold chain logistics,” he concludes. “Moving forward, we hope to be able to extend our capabilities, transitioning away from the supply of dry ice production machines, and adding a level of expertise in the totality of the use of dry ice as a transport medium, across volume, sizing, and packaging. In doing so, we’ll be able to minimize our waste footprint, while offering a more comprehensive service for our customers.” v

Cold Jet www.coldjet.com

Services: Dry ice solutions

www.manufacturing-today.com l 25 Cold Jet

The industry insider

MiddleGround Capital is a private equity firm wise beyond its years. Formed of leading industry professionals, the company is taking a unique hands-on approach to investment, with a focus on driving higher ESG standards across its portfolio

Although only established in 2018, MiddleGround Capital (MiddleGround) is the product of years of experience. A private

equity firm specializing in the business-tobusiness industrial and specialty distribution sectors, its founders worked together for more than a decade in middle market private equity

investing, prior to MiddleGround’s founding. Currently, investing out of both its mobility and flagship second fund, the company takes an operationally focused approach to value

26 l www.manufacturing-today.com

creation, partnering with its portfolio companies to support long-term growth strategies.

But MiddleGround isn’t your run-of-themill investment firm. With a board comprising

MiddleGround Capital

leading industry professionals, the company possesses the insider knowledge required to navigate industry trends and exploit market niches with greater agility than general investors.

Direct access to major CEOs, as well as influential customer connections, further drives MiddleGround’s ability to identify high-growth companies.

www.manufacturing-today.com l 27

MikeBridge

“We have real-world industry experience,” confirms Mike Bridge, Director of ESG and Data Analytics at MiddleGround, speaking to Manufacturing Today. “Our operations team comprises 25 individuals who have lived within the challenges that these companies are facing.

“We have experience ranging from former hourly line workers to operations executives from major OEMs. In fact our founding partner, John Stewart, started his career installing bumpers on Toyota Camrys. Our DNA is factory floor experience.”

Investing in what we know

Headquartered in Lexington, Kentucky, MiddleGround launched its first fund in August 2019, with a value of $460 million. In June

2021, this was followed by its flagship second fund, worth $800 million. It’s been a tricky few years for businesses, with the arrival of the Covid-19 pandemic in early 2020, followed by supply chain shortages, and the war in Ukraine. But amid these uncertain times, Mike argues that businesses are looking for a change – a factor that is driving healthy deal flow for MiddleGround. “In particular, we’re seeing an uptick in smaller and family-owned businesses coming to market,” he comments. “Although we’re only halfway through the year, we’ve already exceeded the deals we received in 2021, which puts us on track for a recordbreaking year.

“The manufacturing deals we’re seeing are typically tighter processes; they’re asking buyers

to come to the table with more,” he continues. “They are not just looking for capital, they are looking for partners to help solve problems. That means our research-intensive approach, oriented around a particular thesis, has paid dividends, as has our operational expertise. We’re able to position ourselves well because we’ve already underwritten and understood the market trends at a macro-level.”

One such deal arrived in November of 2020, with MiddleGround’s acquisition of Shiloh Industries, Inc., a global innovative solutions provider focusing on lightweighting technologies. The move fits neatly within MiddleGround’s mobility thesis, and further echoes the company’s stated commitment to ‘invest in what we know’. The company’s

28 l www.manufacturing-today.com

The ESG team attends investment committee meetings to discuss the risk and opportunities identified in our ESG screening process. We assess every portfolio company on a common set of 15 key performance indicators, including governance, worker welfare, environmental stewardship, energy use, waste, safety indicators, board makeup, and more

seventh platform acquisition from its first fund, it was the second automotive deal to be sourced, subjected to due diligence, and closed during the Covid-19 pandemic.

“Our automotive experience gives us the knowledge of where the industry is going when it comes to EVs and lightweighting, for which Shiloh had a really excellent portfolio,” Mike reflects. “At the same time, we have the capability to identify where we can add value to that company beyond others. That spoke well to the sellers, and was the basis on which we were able to close the deal.”

An ESG-led approach

As it looks to build its reputation for valueadded investment, MiddleGround is aiming high. In June 2020, it became the first sub-billiondollar AUM company to sign the Principles for Responsible Investment (PRI). As Mike explains, it’s a topic “near and dear” to the company’s heart. “When we look for new investments, we identify transitional assets,” he indicates. “That might be companies who traditionally struggle to adhere to ideal working conditions, or those who are poor stewards of the environment, where we believe we can bring improvements.”

But ESG isn’t an add-on for MiddleGround; it’s a central part of the company’s investment criteria. “The ESG team attends investment committee meetings to discuss the risk and opportunities identified in our ESG screening process,” Mike goes on. “We assess every portfolio company on a common set of 15 key performance indicators, including governance, worker welfare, environmental stewardship, energy use, waste, safety indicators, board makeup, and more. We’ll compare that to our internal data and available information to understand where a company sits in relation to its peers, and set targets better than that. Many of our investments are precisely that: helping companies to know where they are in that journey, and being a resource for them to plot a path within ESG. It can be intimidating to get started, but we encourage everyone to get on board because it can make a substantial difference.”

As Mike is well aware, it’s one thing for companies to have an ESG policy. It’s quite another to execute on that policy. “Nowadays, that’s not enough,” he emphasizes. “You need to be able to set targets, track and measure your performance, and prove what you’ve achieved.”

Crucially, MiddleGround’s emphasis on ESG is founded on the belief that an ESGled approach can deliver operational and process enhancements. That, in turn, drives

the return on investment. “We’ve been in the shoes of operators, and we understand that enhancements are driven by supporting shopfloor workers and leaders first and foremost,” Mike argues. “We place a strong focus on culture, whether it’s through boot camps, the setting up of production management systems, or engaging factory workers directly and listening to their ideas.

“One company in our portfolio produces galvanized steel eye beams for the solar market,” he goes on. “At the time of our due diligence, the working conditions were inadequate – there was a lack of bathrooms, a lack of protection, a lack of a proper rest area. Whereas some firms might be scared of that investment, we immediately installed temporary facilities after acquisition, before investing $2 million into permanent facilities, and another $1.6 million into equipment upgrades. By visualizing targets for the employees and encouraging motivation, we were able to reduce a $16 million backlog in less than ten weeks. We were even able to take 35,000 pounds of unnecessary waste that was formerly going to landfill, and repurpose that for the production of minerals for cattle –both saving the company $200,000 annually, and protecting the environment.”

So firm is MiddleGround’s commitment to staff welfare, in 2021, the company mandated a minimum hourly wage of $15 per hour across all its North American businesses. More than 500 members of staff had their pay increased as part of the initiative, but MiddleGround isn’t satisfied. The company is now planning for a so-called ’25 by 25’ initiative, targeting a minimum compensation package of $25 per hour by the year 2025.

“We feel that giving our staff $10 per hour relative to employees in an industry such as fast-food hospitality is a good target area to be, in respect to the skills and expertise present among our workforce,” Mike notes. “We’re going to continue to evaluate that every year. It’s an investment in our people that we’re not afraid to make.

“At the same time, we’ve built out our own internal automation team, stacked with industry veterans, whose responsibility it is to identify which jobs are low value-added, and to automate those,” he continues. “That includes loading and unloading machines, repetitive work, or perhaps those jobs which involve a high ergonomic burden. Then, we’re able to repurpose the staff to other areas of the business, thereby increasing operator efficiencies.”

For Mike, it’s important for companies like MiddleGround to share this expertise when it

comes to ESG. “Collaboration makes the world a better place,” he states. “We’re happy to compete head-to-head, but we believe we have a responsibility to impart what we’ve learned, and to listen to how others have succeeded in order to improve ourselves.”

International expansion

Moving into the latter part of 2022, MiddleGround is set to make further investments in its ESG team. “We’ve already brought onboard our Vice President of ESG, Madelyn Tutewiler, who brings a wealth of experience from the oil and gas industry,” Mike notes. “Together, we’ll look to build out our next industry thesis, centered around ESG, with a view to launching an ESG fund in the early part of 2023. We’re also in the process of building a five-year strategy for ESG, and educating our team company-wide about its importance.”

An international expansion is on the cards, as MiddleGround gets ready for the opening of its new Amsterdam office, scheduled for early 2023. “We already have a number of European facilities,” Mike notes. “The Amsterdam office will enable us to better support those, while opening up a new investment base. We currently have just over 80 members now, and we expect to be closer to 100 by the end of the year as we look to expand our team internally.

“MiddleGround will continue to be a front runner when it comes to implementing real change,” Mike concludes. “We’re going to continue to invest in our core thesis and stay on top of industry demands. At the same time, we’ll look to systematize our playbook, while also incorporating flexible tools to evaluate risks and opportunities. Above all, our focus remains on executing the actionable deals that come through our pipeline.” v

MiddleGround Capital www.middlegroundcapital.com Services: Private equity firm www.manufacturing-today.com l 29

MiddleGround Capital

Go with the flow

Committed to customer service and innovation, Dixon Valve & Coupling Company, LLC strives to delight its customers every day. With an extensive product range and expanding global reach, the organization has one foot firmly in the future

Dixon Valve & Coupling Company (Dixon) was founded in 1916 by Howard W. Goodall. A premier manufacturer and supplier of hose couplings, valves, dry disconnects, swivels, and other fluid transfer and control products, Dixon has enjoyed steady growth throughout the decades. The business continues to add new products and services to its offering that align

with its value proposition, and it endeavors to be the easiest organization with which to do business by delighting its customers every day.

Dixon’s growth can largely be attributed to a drive to find solutions for its customers. From its beginnings serving customers operating within the oil and gas industry to branching out into a variety of different markets over the decades, the organization’s product offering is

30 l www.manufacturing-today.com

ever-evolving. From food and beverage to fire protection and transportation, being able to penetrate a wider range of markets has helped Dixon enhance its customer base.

Today, the business boasts over a 1100page catalog, showcasing a variety of product lines. This wide range of products appeals to distributors, who can rely on Dixon as a onestop shop for their needs. With an extensive

distribution network throughout the U.S., Dixon strives to ship the majority of orders the same day they are received.

As Bob Grace, President of Dixon Valve, explains, “we work really hard to help our customers and support them, before, during, and after the sales process.” To be able to achieve this level of customer care, the organization places huge importance on

employee training. From virtual and in-person training sessions to company-wide webinars, employee training to achieve exemplary customer service helps to set the organization apart from its competitors.

Expanding global reach

Dixon’s strategic objective is to create solutions that make products safer, longer lasting, and always available to customers. As a company with strong roots in the U.S., it has always been important to be close to the customer base; both from a manufacturing and a distribution perspective. The company’s growth and site locations are a result of organic, U.S.based acquisitions and expansions. Existing manufacturing sites have been embedded over the years to continue to offer the knowledge, expertise, and necessary infrastructure for operational efficiency and excellence. In terms of distribution center locations, Dixon’s choices have been driven by a desire to serve the customer base from a local network.

Over the years, the business has exploited opportunities for global expansion as they’ve arisen. Following a UK acquisition in the 70s, the business opened up to the European market and has since expanded into France, Germany, and the Middle East. In 1996, the organization acquired Australian manufacturer, Minsup, which is now known as Dixon Asia Pacific and has grown to incorporate five locations across Australia with operations in both China and Singapore. This impressive growth has enabled product diversification within the global arena.

From distribution to product innovation, Dixon is driven by the needs of its customers. “We work with our customers, who are distributors, and we work with end users, to highlight challenges and ascertain requirements,” expounds Bob.

www.manufacturing-today.com l 31

Company, LLC

Dixon Valve & Coupling

Dixon evolves its product offering in response to industry trends and demand. One such line are products for use in cryogenic applications. With the acceleration away from traditional fossil fuels and a move towards cleaner solutions, Dixon has seen an increase in the demand for products for the storage and transportation of Natural Gas (NG) and Liquid Natural Gas (LNG). NG and LNG are cooled to cryogenic temperatures to become liquids allowing for economical shipping and storage. LNG is used in vessel fuel bunkering, at fueling stations for on-highway and off-highway vehicles and for peak shaving at power plants and pipeline systems when energy demand is high. Dixon’s product mix has evolved to include couplings and valves that incorporate seals able to withstand the temperatures necessary for those applications. This market is snowballing

and Dixon intends to keep pace.

Like most businesses, Dixon felt the immediate repercussions of the pandemic. Following the uncertainty and downturn however, operations began to stabilize; parts were needed, and demand started to increase. “Within a year of the start of the pandemic, we were ramping business back up,” stated Bob. “We had a pretty good advantage over organizations more reliant on overseas products. With in-house manufacturing capabilities and our three foundries, we benefited from greater control over our supply chain. This reduced reliance on external suppliers gave us a competitive edge.”

The aforementioned foundries, which are owned by the parent company The Dixon Group, are located in Quarryville, Pennsylvania, and Winnipeg, Canada, with the most recent

acquisition, in Dayton, New Jersey. Many of the products Dixon makes start with a foundry casting which enables greater control over processes and end-product quality. Richmond, the latest foundry acquisition, was a long-term supplier. With an excellent working relationship, it was logical for the business to join the group and expand its global reach into alternative markets.

With the addition of a 100,000-squarefoot facility that houses its Boss manufacturing division, Dixon now has ten manufacturing operations. Boss is home to Dixon’s legacy brands, including Air King® couplings, King combination nipples, LPS Frac fittings, Holedall® , and King Crimp®. The state-of-the-art facility has enabled Dixon to manufacture with increased efficacy and efficiency.

“The world will always have the need for industrial goods, so there will always be a need to manufacture products, but how they are manufactured and where is the question,” says Taylor Goodall, President of The Dixon Group, “so we plan to continue to invest in our employees, automation, and facilities to make this possible.”

Dixon is proud of its culture and is intentional in its expectations of employees. Rather than merely signposting its mission and vision,

32 l www.manufacturing-today.com

Dallas, North Carolina, U.S. location

Each of our manufacturing divisions have a dedicated group of engineers working on specific product lines. The future for us is new products and new markets, and we are optimistic

the organization works to embed its core operational values. Each quarter, all 1700 employees come together in small groups for company-wide training on a range of pertinent topics, from safety and wellness to financial results. “The organization is far easier to manage when we’re all on the same page,” states Bob. “We know how important it is to treat each other with respect and it will always be that way. Our values center on six pillars; respect, responsibility, caring, citizenship, trustworthiness and fairness.”

Driving efficiency

Moving forward, Dixon will continue to focus on its supply chain and manufacturing facilities in a bid to boost inventory levels back to pre-pandemic status. Equally, the business continues to review its markets; making sure all opportunities are optimized. Customer buying habits have changed, inevitably in response to recent supply chain shortages and many customers want to boost inventory levels to weather potential future storms. Dixon will do its best to meet those expectations, alongside innovating and expanding its product portfolio.

Indeed, innovation is a long-term plan. Dixon is proud of its innovation center, created in honor of its pioneer founder, Howard W. Goodall, and his son Richard B. Goodall. In dedication to the father-son duo, company engineers research and develop new concepts, materials, and products for use in the market. “Each of our manufacturing divisions have a dedicated group of engineers working on specific product lines,” explains Bob. “The future

for us is new products and new markets, and we are optimistic.”

Looking to the future, automation and lean operation are essential. Continuous improvement is imperative for operational optimization; helping to reduce waste, remove bottlenecks, and ultimately implement solutions. “For example, if we review a process that may have been in operation for the last ten or 20 years, we would take new equipment and technological advances into consideration when evaluating efficiencies, set-ups, cycle times, and tooling within the arena of continuous improvement,” explains Phil Wilson, Vice President of Manufacturing.

Dixon’s focus on automation is a response to the world changing and the current manufacturing climate challenges, particularly

in terms of labor shortages. Tools, such as an automated loading cell for example, would enable the reallocation of labor from one area to another. Alongside this, it’s equally important to improve training opportunities and upskill the existing workforce. “Additionally, we will be working to align and benchmark our manufacturing processes,” continues Phil. “Whether in the form of a process improvement or in automated equipment, lean operation is certainly helping us to drive efficiency, positively impact quality responsiveness, and contribute to reduced lead times.”

The future looks bright for Dixon. It aims to do bigger and better things for both the organization and its people, while continuing to delight its customers every day. v

www.manufacturing-today.com l 33 Dixon Valve & Coupling Company, LLC Headquarters Chestertown, Maryland, U.S.

www.dixonvalve.com/en/home Services:

manufacturer

Dixon Valve & Coupling Company, LLC

Valve and coupling

Conducting the market

34 l www.manufacturing-today.com

Deep dive into IQE: the UK based company at the foundation of the global semiconductor industry

David Bishop

www.manufacturing-today.com l 35 IQE

On the open market, there were no boundaries when it came to technology; but those days are changing.” That is David Bishop, Head of Global Supply Chain at IQE, the world’s leading designer and manufacturer of advanced compound semiconductor technology. He sat down with Manufacturing Today to reflect on the company’s evolving commercial interests, cutting-edge innovations, and science fictionlooking future.

“In the last three-to-four years, global trade wars between the US and China have changed everything,” he begins. “When I first joined IQE, you could procure raw materials all over the

world without issue; you could have suppliers in any region. That is just not the case anymore. In today’s market, you have the US putting constraints on China; the latter, moreover, will not buy anything that has content from the former. These two titans of technology and industry are truly butting heads. The US, for instance, has started using Export Control Classification Numbers (ECCNs) to restrict selling US-created content to restricted entities.”

As David explains, that sent shockwaves through the business. Every piece of equipment and every material that IQE owned or bought had to be ECCN compliant. However, if working with a client on the restricted entities list, the

process had to be inverted; the company could not use anything with certain US content or certain ECCN-classifications. On a micro level, some customers from China would often stipulate that no raw materials from the US were to be used in products being shipped to them.

“It was a total nightmare,” he admits. “But we have overcome this. Our supply chain is unique in that all our raw materials are very high in purity, predominantly coming from columns three and five on the periodic table. We take those materials and work our magic on them in a reactor and grow layers.”

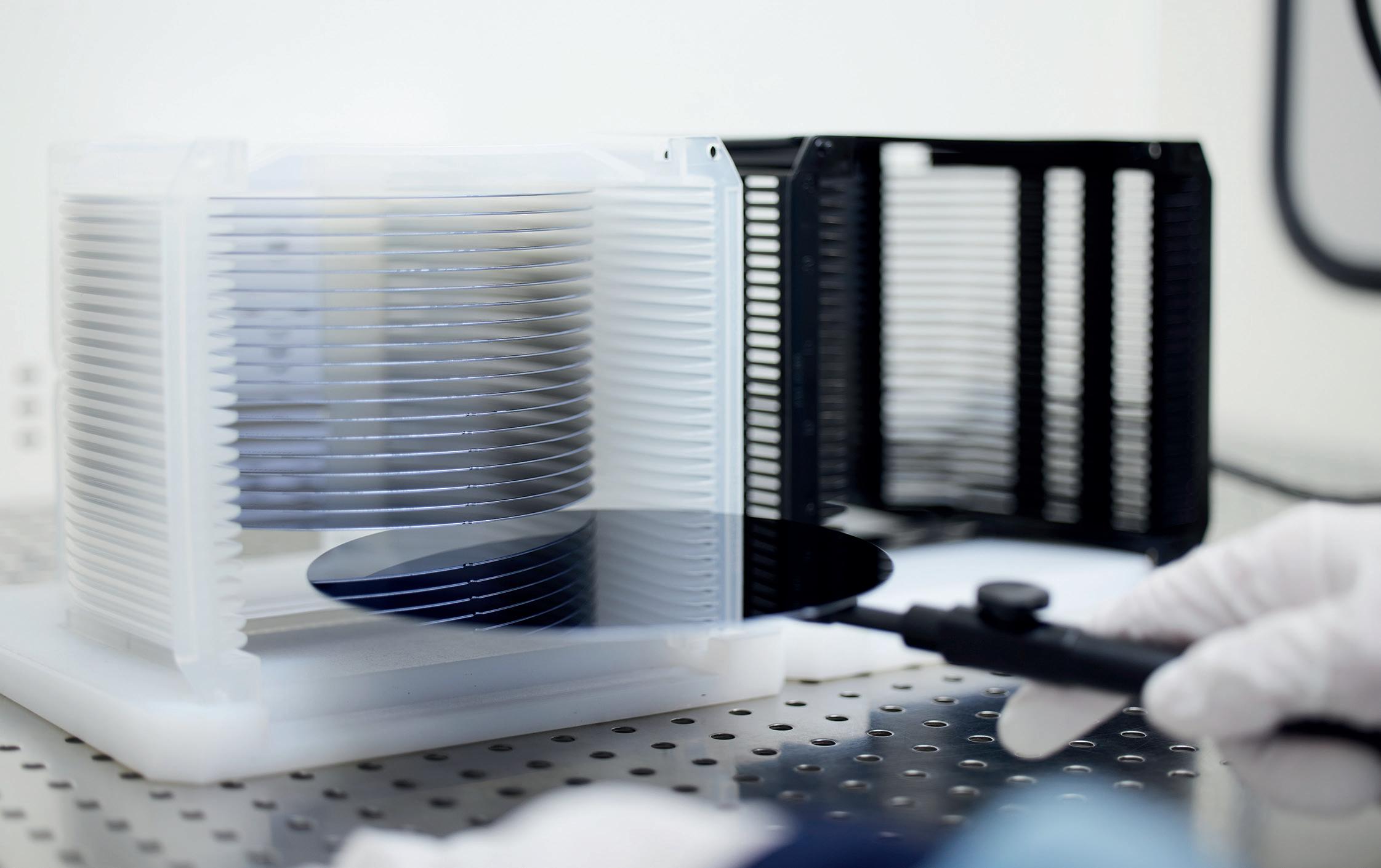

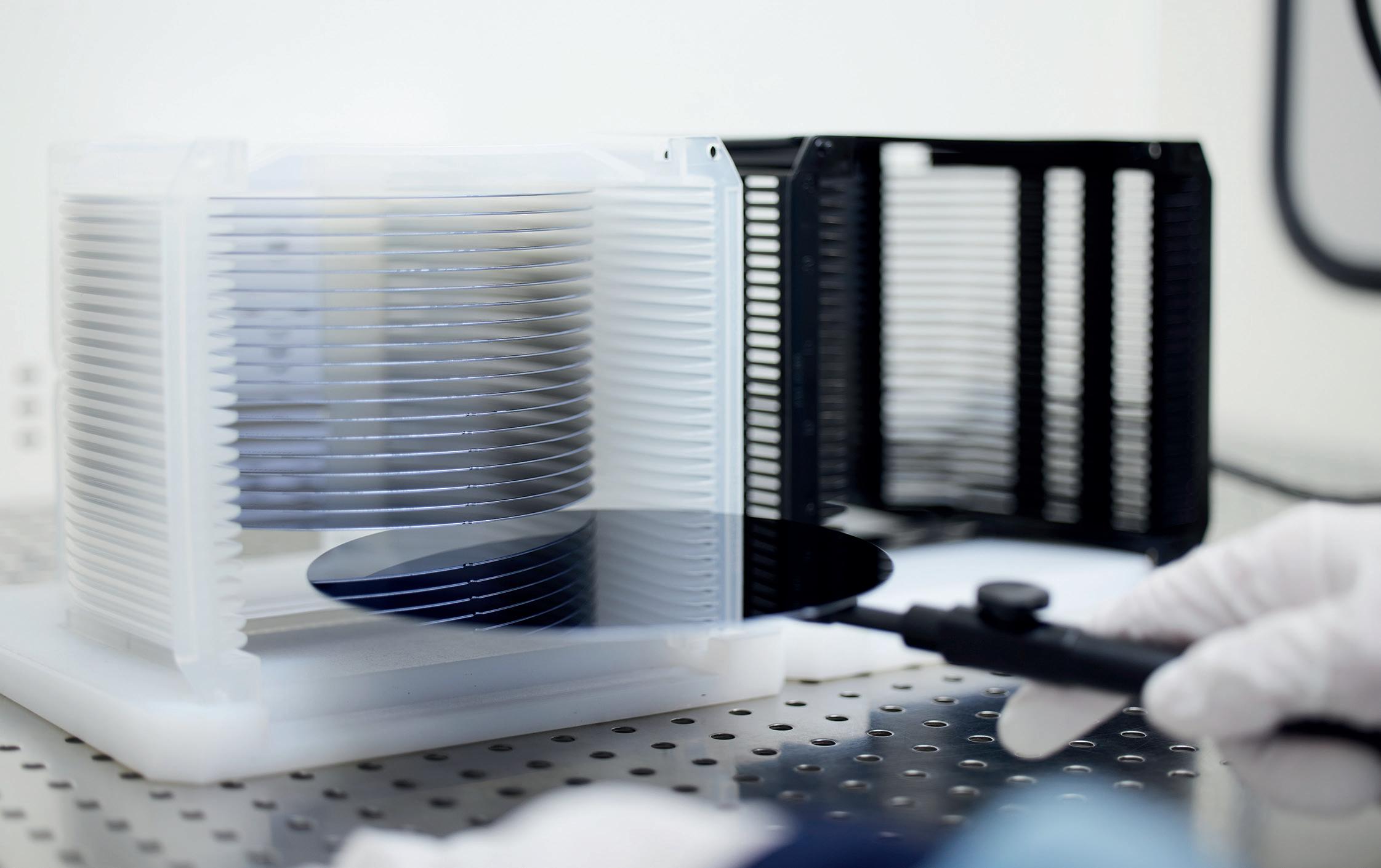

It all sounds very science fiction. “That is just the start!” David laughs. “We buy a substrate, a crystal that is grown, sliced, and polished so that it has a crystal lattice structure on it. This allows us to grow the epitaxy layers on top of it; the substrate provides the foundation since without it the structure would fall apart. With that in place, we can grow up to 400 layers; each layer being a micron thick, and by growing up to 400 of them, we are able to create the device characteristics required to enable an extensive range of technologies on the marketplace.

“The one technology we enable that most people would recognise is 3D-sensing

36 l www.manufacturing-today.com

IQE

The next big revolution for us is going to be electric and driverless vehicles. These kinds of technologies will require a lot of compound semiconductors, especially on the autonomous driving front – I would go as far as to say that it will be led by compound semiconductors

technology,” he details. “With that function, high-end phones can utilize facial recognition software. We were the pioneers of that technology, and the only company that could create the device characteristic in 2017 when it was launched on the first mobile phone handsets to have this functionality. To return to the science behind it all, as mentioned, we grow a 400-layer structure, and each is a micron thick, giving us a total of 400 microns – equivalent to about one third the thickness of a grain of sand! Together with the substrate, we can produce a six-inch wafer (or one disc), that is capable of producing 12,000-to-15,000 devices. These are not much bigger than a grain of sand.”

And it goes further. Within those chips are about 1400 vertical-cavity single-emitting lasers, each generating a single 950 nanometer laser, and these are the pieces of technology we look at when, say, unlocking our phones via facial recognition software. “These operate through an emitter-to-receive model,” comments David. “The lasers are emitted by the phone, bounce back off your face, and send data to the phone. Therefore, it can work out the imagery it is sensing in 3D. It is, in short, mind-blowing.”

IQE’s story dates back to 1988 when its first Metal Organic Chemical Vapor Deposition (MOCVD) operation began in Cardiff, Wales, under the name of Epitaxial Products International (EPI). What then followed was consistent year-on-year growth, with the firm primarily servicing optical communications

38 l www.manufacturing-today.com

markets with its diverse range of photonic products (light emitters and detectors, such as lasers, LEDs, and photodetectors, for example). Transitioning to the IQE name, the company continued to design and manufacture epiwafers using a process called epitaxy, as previously explained by David.

Through that process, the company is able to manufacture RF epitaxial wafers, photonic epitaxial wafers, substrates, and nano-imprint services, among other integral technological items. IQE remains a leading force in a variety of markets, including wireless (smartphones, tablets, computers), power control (power suppliers, electrical vehicles, LEDs), photonics

CS Clean Systems (UK) Ltd.

(lasers, optical sensors), and infrared (nightvision, thermal-imaging). To facilitate these commercial endeavors, in 2017, IQE announced its new, state-of-the-art mega-foundry in Newport, Wales, measuring over 30,000 square meters.

Talking cars

As David reflects: “Our founder, Drew Nelson, had this vision, back in 1988, that compound semiconductors were going to be the next revolution after silicon. Silicon has its limits; you can only go so far with it because there is a natural limit to the material’s capability. Drew saw that the silicon industry could not go any

CS Clean Systems (UK) Ltd. are a key supplier for the IQE Newport Mega Foundry, covering all the toxic gas abatement needs for this facility. Top-of-the-range CLEANSORB® CS200PD PRIMELINE DUAL Systems have been supplied for 24/7/365 continuous point-of-use toxic gas abatement for the exhaust lines from MOCVD Reactors in a demanding production environment. Fully passive CLEAN-PROTECT Abatement Systems are installed for the removal of toxic gases in the event of an emergency release. CLEANSORB® LABLINE Systems are in use for gas cabinet vent purge detoxification. These products are regularly serviced and maintained by CS UK’s Service Team.

further; however, fortunately, he also realized that compound semiconductors could unlock a range of new technological enhancements.

“Our initial and largest market remains the wireless market,” he reveals. “Most handsets will have some form of IQE content in them – and that does not just mean mobile phones. Inside your handset is a bunch of hardware; it started off with 2G, then 3G and 4G, and now you have 5G (or, simply, the amount of data being transmitted to the phone). For each type, a device will require a chip: one 2G chip, one 3G chip, one 4G chip, and now one 5G chip. Four in total, all managing wireless frequencies differently; if one is weak, then the next one down the list picks up the signal.

“Unlike the radio, however, when signals drop in and out, the user experience is not impacted because the chips self-manage all the frequency modulation,” David continues. “This is the world IQE started off in, and it has exploded since then. Now people are talking about 6G. It is unbelievable! We have a large share of the market, with more than half of devices featuring our technology.”

www.manufacturing-today.com l 39 IQE

Though the wireless market has been a commercial mainstay for the firm, it has not been averse to branching out into other sectors. More recently, for instance, IQE has been active in healthcare, automotive, and power management markets, as well as developing technology for aerospace and security applications. “The next big revolution for us is going to be electric and driverless vehicles,”

explains David. “These kinds of technologies will require a lot of compound semiconductors, especially on the autonomous driving front – I would go as far as to say that it will be led by compound semiconductors.

“For example, vehicles might have sensors for Light Detection And Ranging (LiDAR),” he goes on. “In fact, to make a car truly autonomous you would probably need to add about 70 LiDAR

sensors; although you sometimes see cars with giant cameras on them now, these will actually be tiny in comparison. I doubt you would even notice them! Linking that in with 5G connectivity, which we discussed earlier, all autonomous vehicles could hypothetically communicate with each other. That would mean that, if an accident has occurred further down the road, the cars ahead can communicate with those at the back; they will then be able to take avoiding action to mitigate risks associated with dangerous situations. All before a human driver could even see it coming! It is like something out of science fiction, but the technology is available – in fact, it is here today.”

Promising products