Dynamic New Headquarters and Exhibit at PACK EXPO unveiled only weeks apart — pg. 6

New Technical Operations Manager is driven to win pg. 4

Check out our new home pg. 10

Dynamic New Headquarters and Exhibit at PACK EXPO unveiled only weeks apart — pg. 6

New Technical Operations Manager is driven to win pg. 4

Check out our new home pg. 10

Welcome to 2025. One year ago this month and after more than a year of searching, we found the right property to serve as our future home. It was just the start of what turned out to be a fantastic year.

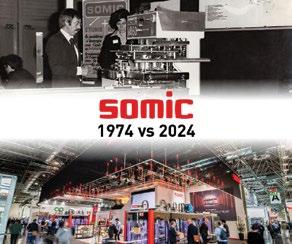

We recognized 10 years of success while celebrating our parent company SOMIC’s 50th golden anniversary. While we were busy designing our future home and taking care of day-to-day business, preparations began for our return to Chicago for PACK EXPO. Supplying North America with the best customized, Retail-Ready automated packaging machinery possible remains our top priority.

Let me tell you how that becomes easier to achieve this year.

Factory Acceptance Tests have been performed in Minnesota for several years and will continue to do so. We will be conducting six FATs in the first quarter this year, and the lion's share of these machines are being delivered to cheese and baking manufacturers.

We have also committed resources in anticipation of future growth by hiring additional staff across all departments. From the assembly line to our parts and service, sales support and HR departments, we are moving forward with a larger team to better serve current and future customers.

“The PACK EXPO visitors we spoke with are very optimistic about the future of automation.”

We were a three person operation when SOMIC Packaging first opened and began operating from a small office in suburban Chicago. It was thrilling to grow so quickly and move to a 13,000 square-foot office in Eagan four years later in 2018.

Rapid growth soon followed. We now have hundreds of end-of-line packaging machines operating at cheese, dairy, confectionary, meat processing, snack food, petfood and other North American manufacturing facilities. With 48,000 square feet of space to work with, every new machine sold in North America will now be assembled in Inver Grove Heights.

When we made the move in midOctober, we had 42 employees in a building which can accommodate twice that amount. We are being aggressive with our hiring and plan to have more than 50 employees by the end of this month. One important thing we did prior to the holidays was to bring Dave Billingsley on board as our Technical Operations Manager. When you read his story in this issue, you’ll understand why we hired him.

We needed to do this based on the success at PACK EXPO in Chicago two months ago. The show set an attendance record and many of the people who stopped by and visited with us were impressed with the new booth design and 434 machine.

Sept. 29- Oct. 1, 2025

Las Vegas

53%

have plans to build, expand or modify physical plant infrastructure

We had a very good mix of visitors with existing customers who have new projects in the works, and new attendees who spent a good amount of time learning about our case packaging technology. The show always opens on a Sunday and the lure of NFL games in the afternoon can be a distraction. But large crowds of people were lined up early each morning and we were quite busy every day throughout the show. The booth comments we received were plentiful and highly positive. Some were like, wow! A few mentioned how the booth and the 434 machine were consistent in their look and feel. It was precisely what we were looking to achieve, so mission accomplished.

Our demonstration of the next generation 434 spurred many conversations. We answered questions about its capability to run a variety of formats and layout flexibility, which the 434 is equipped to handle both. This includes multiple formats with quick and easy changeovers, and layout variations based on the frame and component modularity.

One thing that stood out and was quite apparent is the PACK EXPO visitors we spoke with are very optimistic about the future of automation. In many cases, they mentioned how it is an absolute requirement for their businesses to survive.

What was reassuring is the focus of the 434 is exactly where it needs to be with the four keys to success: flexibility, adaptability, ease of use and the low cost of ownership. We hit on all of these highly sought attributes for end-of-line packaging automation.

If you were impressed by what you saw when we demonstrated the 434 in Chicago, wait until you see what we have in store for PACK EXPO Las Vegas in 2025. But that’s a story for another time.

Respectfully,

Peter Fox, Chief Executive Officer

page: Retail-Ready Magazine is published by SOMIC Packaging, focusing on the Retail-Ready industry. We manufacture advanced mechatronic case-packing systems that collate, unitize and load cartons, trays, retail-ready packages, and wraparound cases.

See how SOMIC can bring new efficiencies to your packaging line.

+1.651.419.6050 us.somic-packaging.com

info@somic.us

on our

linkedin.com/company/ somic-packaging-usa

Dave Billingsley, Technical Operations Manager

“An employer once said he hired me because I don’t like to lose.”

Over the course of a stellar career, Dave Billingsley has enjoyed success at every stop. For the majority of his 35 plus years of strategic operations management experience, the Minnesota native has consistently demonstrated an ability to turn vision into reality. Now he’s prepared to write the next chapter as the new Technical Operations Manager for SOMIC Packaging.

Reporting to CEO Peter Fox, Dave believes having a track record of success in the custom automated packaging equipment sector and with various manufacturing businesses made him an ideal fit for SOMIC.

“In roles ranging from Plant Manager and Director of Operations to CEO and President, I have led initiatives that improved quality, reduced costs and accelerated growth,” he explained. ”My hands-on leadership style, combined with a knack for building high-performing teams and inspiring them to exceed corporate targets, aligns perfectly with my new position.”

With ten people reporting to him, Dave will have multiple responsibilities beginning with production oversight where he will ensure the safety and well-being of staff members. In terms of project management, he will promote operational excellence while overseeing Factory Acceptance Test (FAT) machine commissioning.

He will also collaborate with SOMIC colleagues in Germany to maintain

process consistency, and concentrate on delivering the highest quality packaging equipment.

“In the early stages of my career, I was hired by a venture capital and equity firm to turnaround businesses that were struggling due to mismanagement,” recalled Dave about some of his accomplishments.

“These experiences allowed me to build a strong foundation in successful operational management. In each case, I helped these businesses transition from operating at a loss to becoming profitable. In most instances, I led them to achieve significant lucrative growth.”

The majority of Dave’s jobs have been with Minnesota companies. One recent position where he served as the Director of Operations resonates similar vibes to SOMIC Packaging’s move to its new Minnesota headquarters last October.

“My knowledge and guidance were crucial as we expanded the business. As part of my responsibilities, I oversaw the overall plant layout during our move to a second location, managing the production flow through the facility by using the L.E.A.D. (Lean, Efficient, Agile, and Data-driven) methodology.”

Those similarities played an important role for him to enthusiastically join SOMIC.

“During my research, I was impressed by the professionalism of the leadership team and the quality of the equipment SOMIC offers,” Dave said. “Meeting with the team in person confirmed my positive findings. I was excited about the opportunity to be involved from the ground floor as we expand the North American market, knowing my skills would be utilized to their fullest extent.”

Another positive Dave brings to SOMIC is his competitive nature.

“An employer once said he hired me because I don’t like to lose. And I don’t. I’m bringing this ‘refuse to lose mentality’ with me to SOMIC Packaging.”

His competitiveness stems back to when he was 15 and began driving race cars. That’s how he later met his wife, Mary. At one time, they promoted Monster Truck shows throughout the United States. Married for 33 years, they are the parents of Nick and Kelsey. And for the majority of weekends throughout the year, you’ll likely find the four at an automobile race track.

The family competes in races sponsored by the Porsche Club of America, one of the largest club race programs which conducts 32 race events yearly. Dave, Nick and Kelsey take turns driving their Porsche Cup Car and have been successful to the point where they were on the cover of PCA Club Racing magazine as a feature story in 2022.

“During my early racing years, I was hired by various teams across the U.S. to drive for them. My family was interested in racing and got heavily involved in the sport, especially years ago when the kids were old enough to start driving high-performance go-karts. I shifted my focus from being the sole driver to supporting and coaching them, including my wife. They all started driving the race cars, too.”

His focus now is squarely on quickly familiarizing himself with everything at SOMIC.

“My immediate goal is to leverage my skills and experience. I am confident in my ability to contribute meaningfully in a short amount of time as I am driven to win!”

Mr. Bonetsmuller’s inventive spirit and personality shaped the company in Amerang, Upper Bavaria for more than 40 years. He passed away on October 10, 2024 at the age of 83.

Manfred Bonetsmuller was a driving force in the packaging world after he recognized the great opportunities of automation for food production and founded SOMIC in 1974.

He continuously developed new technical innovations, and was quick to win customers from Germany and France with automated stacking, portioning, and wrapping packaging machines for the cheese industry. His willingness and know-how in response to individual customer requirements contributed enormously to the company’s further growth.

In the early 1980’s, he formed the decisive foundation for SOMIC’s continued success by developing the first carton erector. SOMIC would later offer complete packaging lines for dairies and became one of the leading suppliers in this sector.

From simple tray packers and lid tray packers to complex wraparound packers, SOMIC machines are now used in food, non-food and healthcare sectors. These are collected, grouped and positioned on a carton blank according to the requirements of the respective product. Once closed, these high-quality shelfready cartons offer optimal protection of the product during transportation and ensure an attractive presentation in the retail environment.

For the first time, products could be collected, grouped and packaged in one machine.

He opened new market segments when SOMIC developed a compact cartoning machine that combined two systems. This meant that for the first time, products could be collected, grouped and packaged in one machine. With this innovative technology, more product shapes such as cups, tins, bags, folding cartons and others could be processed, which enabled the company to expand into more sectors and countries.

The basic modular principle of SOMIC’s end-of-line packaging machines he developed are still one of the keys to the company’s success today. It allows maximum output on the smallest footprint and can be individually adapted to any packaging task.

With his inventive spirit and passion for always offering customers the best packaging solution, he grew SOMIC from a four person business to a globally active mechanical engineering company.

He was instrumental in having the company expand to North America with SOMIC Packaging in 2014, and another production facility was added when SOMIC Haag was acquired in 2019. In December 2023, subsidiary SOMIC Packaging Asia Pacific Co. Ltd., expanded SOMIC’s reach to Asia when it opened in Thailand.

The packaging industry has lost an ingenious and inspiring developer, and industry legend. The SOMIC team intends to honor his life’s work and spirit by continuing to develop groundbreaking packaging solutions that are “engineered to perform.”

77,500

47,816

2024 attendee registrations in total attendance

43%

67% of Current Attendees New to the Show that have Significant or Final Purchase Power

Two weeks after beginning the arduous task of moving the North American headquarters six miles down the road to our spacious new building on Courthouse Blvd. in Inver Grove Heights, Minn., we debuted a brand new booth design in Chicago at PACK EXPO International.

It’s an exciting time for all of us at SOMIC Packaging.

This PACK EXPO was one for the record books. The show set an alltime record with more than 77,500 visitors and exhibitors attending the four day event from November 3-6. The majority of the people who stopped by our booth were impressed with the new booth design. It recognized SOMIC’s golden anniversary and all of the achievements that have made us an integral part of the Packaging industry.

“Our demonstration of the next generation 434 spurred many conversations.”

Peter Fox, Chief Executive Officer for SOMIC

Visitors were impressed with the versatile 434 next generation case packer.

Demonstrating our continuous upwards progress, it reinforces the commitment made to the design and development of cutting edge, retailready case packing solutions.

This 434 machine was sold to a multinational cheese packager who has since installed it at one of its Midwest facilities. Operated each day of the show, it was poetry in motion.

We demonstrated its capability to handle up to 34 cases per minute during a single cycle. The custom formats allow for packing flat sachets, stand-up flexible pouches, or a wide array of cans, cups, trays, jars, bottles, tubes or blister packs. With single and multi-row grouping and multi-layer stacking, format adjustments are now 70% faster.

The versatile case packer provides more case sizes and larger arrangements for the grouping of end-of-line, tray, and carton packing products. A standard 434 has decentralized servo technology suitable for the machine’s modular design. Functional units can be individually adapted for any customer requirements and future applications.

New features earned high praise from booth visitors. The machine’s supply unit is more user-friendly as it contains all noise-intensive components which dramatically reduce sound levels. The combined SOMIC QuickChange automatic adjustment system scored big points. It prevents incorrect operation and allows for faster and easier format changeover.

Also earning kudos was the new frame construction with a 180-degree opening to improve accessibility, and machine height safety doors. The ideal ergonomic conditions and LED corner lighting for better visibility will help operators during their cleaning and maintenance sessions and to make easier format changes.

a new home.

From the assembly line to our parts and service, sales support and HR departments, we are moving forward with a larger team to better serve current and future customers.

After two years of searching and planning for the right location, we moved into our new North American headquarters in mid-October. The spacious 48,000 square-foot new building at 8270 Courthouse Boulevard in Inver Grove Heights, Minn. more than triples the 13,000 square feet of space at our previous office in Eagan.

Some of the design choices implemented in this building were influenced by parent company SOMIC’s corporate headquarters in Amerang, Germany, including the use of large glass windows to allow for natural lighting.

Besides a manufacturing area that is larger than an Arena Football League field, the building contains a separate section for the warehousing of critical parts and consumables. The current floor arrangement provides over 10,000 square-feet of administrative space, and another 8,000 square-feet on the second floor has been designated for future office requirements.

We employed more than 40 people when the move took place, and the building can accommodate up to 80 on-site employees.

Big enough for expansion, but nowhere near the size of our ambition.

In the fall of 2024, SOMIC Packaging relocated to a larger North American headquarters in Minnesota. With this move, we’re expanding the possibilities in the packaging equipment industry, and future-ready innovation invigorates our way forward. We’ll be assembling our next-generation equipment here to get our customers up to speed faster. We’re hiring more technicians and service staff to keep customers running efficiently. And all this is just the beginning. Not only are we anticipating the future in our new facility, we’re creating it.

Learn more about SOMIC Packaging’s latest equipment and customizable solutions for your business. Call 651.419.6050 or visit us.somic-packaging.com