Considerations on the Development and Manufacturing of Generic Peptides

Patients Are Waiting: Speeding Time to Treatment in Rare Disease

Biotech Sector Survey: From Investment Confidence to Strategic Collaborations

Using Predictive Compliance Risk Analysis to Avoid FDA Penalties

Sponsor Company:

www.international-biopharma.com Volume 7 Issue 1 Peer Reviewed

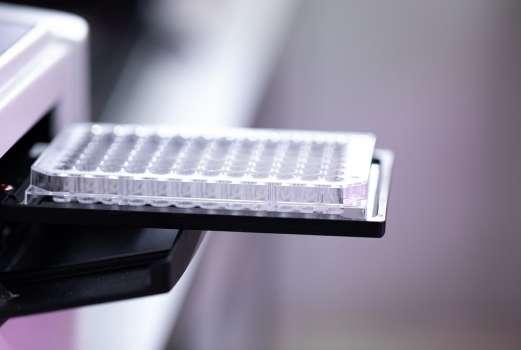

Stimulate your cell proliferation and productivity with Recombinant Insulin

Grow your cells with Recombinant Insulin

Are you working with biomanufacturing of therapeutic proteins or regenerative medicine and require highquality, animal-free, and reliable ingredients for your cell culture media formulation?

Recombinant Insulin from Novo Nordisk Pharmatech is produced by the world’s largest insulin manufacturer, Novo Nordisk. It is specifically manufactured for use in cell culture media, supported by a dedicated team of insulin experts, and securely supplied around the globe.

Learn more about our Recombinant Insulin and request a sample at novonordiskpharmatech.com

II INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

DIRECTOR: Mark A. Barker

INTERNATIONAL MEDIA DIRECTOR: Anthony Stewart anthony@senglobalcoms.com

EDITORIAL MANAGER: Beatriz Romao beatriz@senglobalcoms.com

DESIGN DIRECTOR: Jana Sukenikova www.fanahshapeless.com

FINANCE DEPARTMENT: Akash Sharma accounts@senglobal.co.uk

RESEARCH & CIRCULATION: Jessica Chapman info@senglobalcoms.com

COVER IMAGE: iStockphoto ©

PUBLISHED BY: Senglobal ltd.

Unit 5.02, E1 Studios, 7 Whitechapel Road, E1 1DU, United Kingdom

Tel: +44 (0)20 4541 7569

Email: info@senglobalcoms.com www.international-biopharma.com

All rights reserved. No part of this publication may be reproduced, duplicated, stored in any retrieval system or transmitted in any form by any means without prior written permission of the Publishers.

The next issue of IBI will be published in Summer 2024. ISSN No.International Biopharmaceutical Industry ISSN 1755-4578.

06 Biotech Sector Survey: From Investment Confidence to Strategic Collaborations

In the rapidly evolving landscape, ICON’s recently published biotech sector survey provides a roadmap through the intricacies of investment confidence, funding dynamics, and the pivotal role of strategic collaborations. The survey, conducted on ICON’s behalf by Citeline, included 133 respondents, predominantly located in Europe and North America, from small pharmaceutical and biotech companies, mid-size pharmaceutical and biotech companies, to large biotech or venture capital organisations. Dr. Chris Smyth, President, ICON Biotech explores the imperative of partnerships, delving into their role in funding strategies, and the increasing trend of pharma collaborations, even at the preclinical stage.

12 Extractables and Leachables for Inhaled Medicines

The structured approaches encouraged by the FDA, EMA, and other regulatory bodies require additional upfront resources compared to a more traditional approach. Performing an initial assessment of materials used in the product and developing a more thorough understanding of products earlier in their development allows more appropriate experiments on the higher-risk aspects rather than generic approaches covering all materials. Paul Hardman at Broughton, outlines the best way to optimise your extractables and leachables strategy.

RESEARCH / INNOVATION / DEVELOPMENT

20

Using Predictive Compliance Risk Analysis to Avoid FDA Penalties

In the complex landscape of global regulations, particularly within healthcare and pharmaceutical sectors, a robust compliance strategy is essential for maintaining the integrity of businesses amidst rigorous regulatory requirements. Organisations need to be both flexible and resilient, adept at navigating and anticipating the multifaceted and ever-changing aspects of global compliance standards. These standards are often stringently enforced by regulatory bodies, with the U.S. Food and Drug Administration (FDA) being one of the most prominent and rigorous. In this article,

responsible for any loss or damage incurred. This publication is protected by copyright.

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 1 www.international-biopharma.com

Senglobal ltd. Volume 7 Issue 1 – Spring 2024

The opinions and views expressed by the authors in this journal are not necessarily those of the Editor or the Publisher. Please note that although care is taken in the preparation of this publication, the Editor and the Publisher are not responsible for opinions, views, and inaccuracies in the articles. Great care is taken concerning artwork supplied, but the Publisher cannot be held

2024

& COMPLIANCE

04 Foreword REGULATORY

Contents

Hannah Crystal T. Jurolan and Joe Kalina at Xybion explain how companies can avoid FDA penalties using predictive compliance risk analysis.

THERAPEUTICS

28 Patients are Waiting: Speeding Time to Treatment in Rare Disease

Companies are overcoming challenges to develop, launch, and educate on new rare disease medicines faster. Rare diseases are no longer rare. Every year, people’s lives are upended by a diagnosis of one of 6,000-8,000 identified rare conditions, which collectively affect one in 17 people. Because a majority are genetic and appear early, more than half of these patients are children, and many are not expected to reach their fifth birthday. Chris Moore at Veeva Europe, explains the way to improve the treatment of rare disease.

MANUFACTURING & PROCESSING

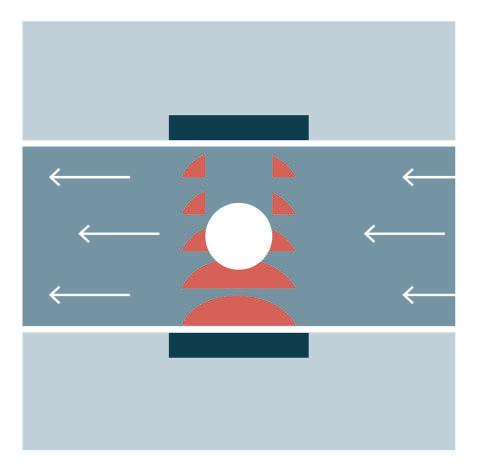

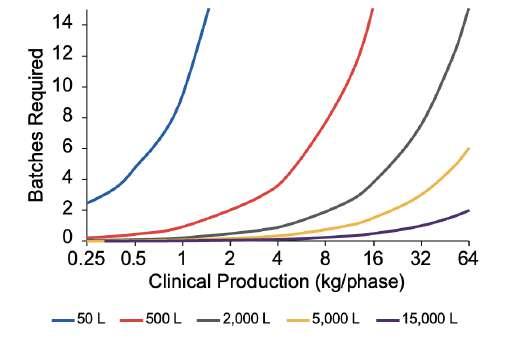

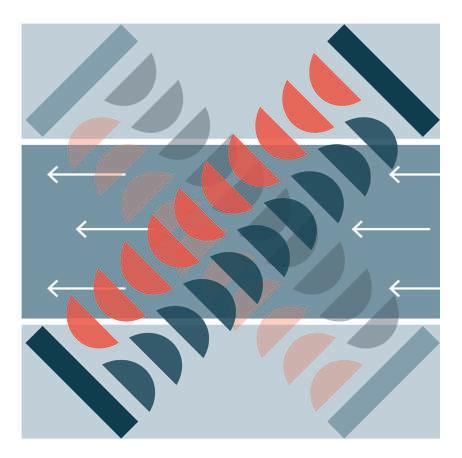

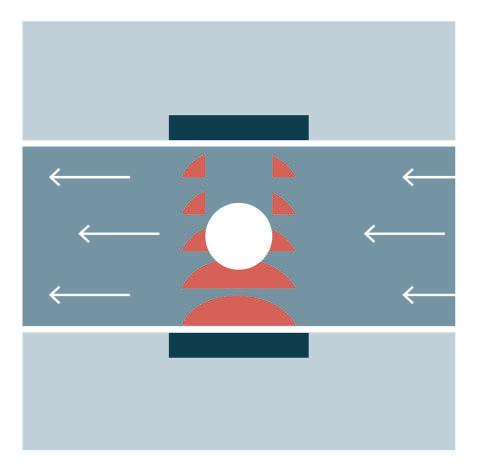

30 Elevating Biomanufacturing Efficiency with N-1 Perfusion Technology

In the dynamic world of biomanufacturing, the quest for improved efficiency and productivity continues to shape industry advancements. Among these innovations, the emergence of N-1 perfusion technology stands out as a pivotal milestone, offering a practical pathway to enhance production processes and boost overall efficiency. Sridevi Khambhampaty of Syngene outlines how this strategic approach aims to maximise the output of manufacturing facilities and streamline the timelines of production.

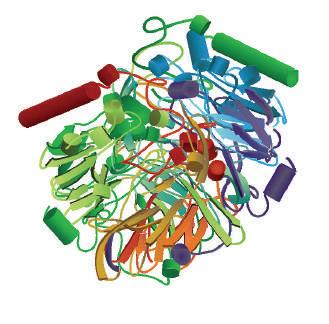

32 Considerations on the Development and Manufacturing of Generic Peptides

The development of generic versions of peptides such as Semaglutide, the drug substance inside Novo Nordisk’s blockbuster drugs like Ozempic®, Rybelsus® or Wegovy®, or Tirzepatide, the API in Eli Lilly’s Mounjaro®, has emerged as a significant area of interest and opportunity. However, generic companies face critical decisions regarding the choice between recombinant and synthetic semaglutide. The path chosen can significantly impact regulatory approval, safety considerations, and market competitiveness. Rafael Antunes at Aurisco Pharmaceutical outlines some considerations on the development and manufacturing of generic peptides.

TECHNOLOGY

42 Ensuring Image Integrity When Reviewing Western Blots

Western blots are frequently included in scientific papers to report results when analysing proteins in a sample. However, research shows that Western blot images are a common source of integrity issues, the publication of which can be harmful to journals. Here, Dr. Dror Kolodkin Gal at Proofig AI, explores the challenges editors and publishers face when reviewing Western blot images and suggests how to identify issues more effectively before publication.

APPLICATION NOTES

05 Simple Analysis of Impurities in Oligonucleotide Therapeutics Using a Single Quadrupole Mass Spectrometer

Oligonucleotide therapeutics have attracted attention in recent years as a new modality for drug discovery because they can be used to create disease-specific therapeutic agents and can be

designed easily by chemical synthesis. Shimadzu will analyse the level of Impurities in Oligonucleotide Therapeutics Using a Single Quadrupole Mass Spectrometer.

16 A Guide to Understanding and Performing all Appropriate Validation Steps When Adopting a New Endotoxin Testing Reagent

The adaptation of in-house endotoxin testing for a pharmaceutical or medical device manufacturer can be a daunting task. Many small-volume manufacturers find themselves in one of two common situations. Either they are utilising a contract testing organisation (CTO) and paying a great deal of costs, or they have adopted a solution that is set up by the manufacturer with much of the validation services outsourced. Timothy Francis at FujiFilm Wako Chemicals shows us a guide to understand and perform all appropriate validation steps when adopting a new endotoxin testing reagent.

24 Optimising Pharmaceutical Processes: A Guide to Lyophilisation Cycle Development

Lyophilisation, commonly known as freeze-drying, is a critical unit operation in the pharmaceutical industry used to preserve and stabilise both small and large-molecule drug products and biologics, including monoclonal antibodies, vaccines and peptides. Lyophilisation is a process that involves freezing a liquid drug product and then removing the frozen solvent via sublimation, providing a stable solid matrix of drug product and other excipients. Lyophilisation cycle development is not only a science, but an art; each drug product that comes into the laboratory presents unique challenges, and the design of a cycle requires an understanding of individual chemistry, characteristics, and interaction to yield a high-quality product in every cycle. While there are a myriad of tools and techniques to perform, the below is an overall guide to the lyophilization process, and some of the steps needed for success. Matt Bourassa at PCI Pharma Services guides us to lyophilisation cycle development.

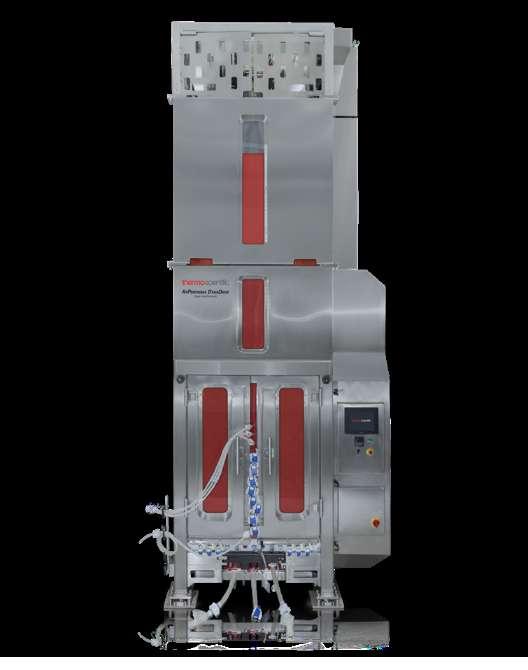

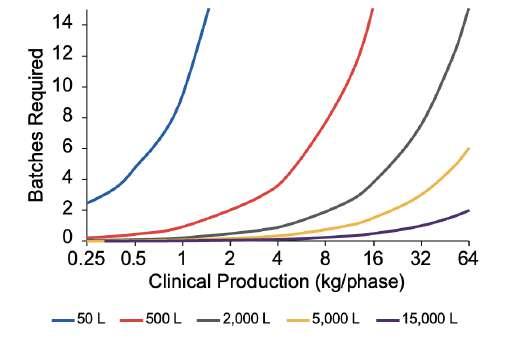

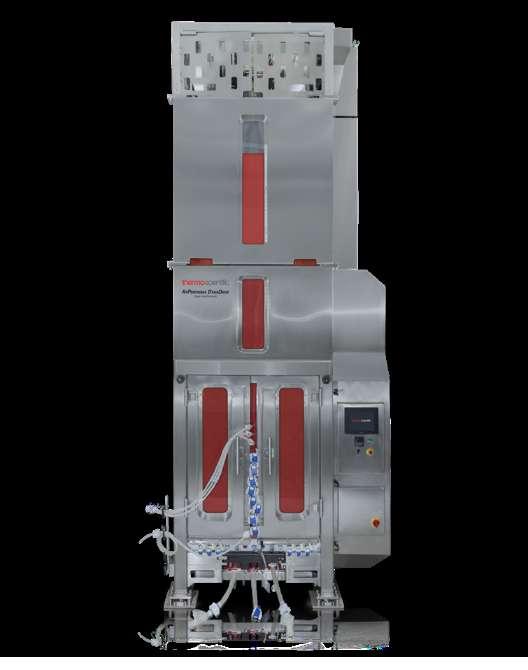

36 5,000L Single-use Bioreactors: The Next Generation in Biologics Manufacturing

The Thermo Fisher Scientific HyPerforma™ DynaDrive™ Single-Use Bioreactor line is suited for volumes ranging from 50L to 5,000L. Optimised for modern cell culture processes in a scalable, ergonomic design, the platform allows intensified, flexible manufacturing, enhanced by high-power input per volume, and better volumetric mass transfer performance. This article highlights the features and benefits of the DynaDrive™ SUB platform and explains how any new or existing facility can leverage the platform to achieve expected development and manufacturing objectives. From pre-clinical trials through commercialisation, manufacturers and companies looking to outsource their biologics can use the DynaDrive™ SUB to gain maximum efficiency and flexibility across a wide range of processes, cell lines, and molecules.

39 Enhancing Process Flexibility with Automated Filling

During the production and filling of highly complex biopharmaceuticals in cell and gene therapy, precise flow measurement and accurate air bubble detection play a crucial role. Flow meters and air bubble detectors ensure consistently high product quality to provide patients with effective and safe drugs. Using the example of the RoSS.FILL platform, developed by the Austrian company Single Use Support, ultrasound specialist. Nico Polley at SONOTEC explains how non-contact clamp-on flow meters and air bubble detectors can significantly increase the accuracy of automatic filling.

2 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

Contents

MISSION

#OneStopShop for stability and release testing

Since 1995 A&M STABTEST has been a household name for highest quality analytical services “Made in Germany” Our 340 strong team of dedicated specialists and stateof- the - art equipment get your projects done on time and in budget. We are your #OneStopShop solution for:

• Stability and release testing of small molecule and biological drug substances and drug products

• Analytical development and method validation

• mRNA -LNP ready methods acc. to draft USP guideline

• Dedicated cell-based potency assay group

• ICH- stability storage and logistics service

• Laboratory dedicated to inhaled drug testing (DPI, MDI, Nebulizer)

• GMP compliant LC -MS service for extractable and leachable testing, protein characterization, identification of unknowns and quantification of impurities and excipients

• Functional testing of container closure systems, prefilled syringes and injection devices (CCIT, force measurements)

• Analysis of ATMPs

A&M STABTEST; Kopernikusstrasse 6; 501026 Bergheim; Germany

#CONTACT www.am-labor.de anfragen.BM@am-labor.de

Although this is the first issue of the year, we are already well into 2024. And of course, I am far too late for a review of last year, but before we look forward and into this is issue of IBI, please just let me shine the light on last year’s FDA list of Novel Drug Approvals. In 2023 the pharmaceutical industry received FDA´s approval for 55 new molecular entities (NME), the second highest NME approval since 2015. I personally think this is remarkable for two reasons. First, how efficient the life science and pharma industry are in translating new scientific discoveries into live saving or at least live improving products. Second, the community behind transforming scientific discoveries into new drugs should be highlighted as a role model for a globalized society. In my role at A&M STABTEST I see many different companied from startup to big pharma and I am always amazed by the many different nationalities, cultural backgrounds, female/male working together to discover and develop great things. Looking at the state of the world today and the trend to a “My-Nation-First” mentality, I think we should highlight and openly celebrate what we can achieve, if we work together rather than cut ourselves of form others, only because they look different, come from a different cultural background or want to live their lives differently.

Looking at 2024 NME approvals, we already have 6 novel drugs (as of March 22nd, 2024) approved., already very good! New drugs need to be produced to make them available to the patients that need them. This issue of IBI again host different articled offering solutions and guidance for production challenges.

First of, is an interesting article by Rafael Antunes at Aurisco Pharmaceutical exploring the differences between recombinant production versus chemical synthesis of generic peptides and the implications for regulatory approval of a generic product produced by different means.

Thermo Fisher Sientific showcases their HyPerforma™ DynaDrive™ Single-Use Bioreactor, which offers great flexibility from 50 to 5.000 liters. Ideal for scale up from early phase demand to commercial scale production.

IBI – Editorial Advisory Board

• Ashok K. Ghone, PhD, VP, Global Services MakroCare, USA

• Bakhyt Sarymsakova – Head of Department of International Cooperation, National Research Center of MCH, Astana, Kazakhstan

• Catherine Lund, Vice Chairman, OnQ Consulting

• Cellia K. Habita, President & CEO, Arianne Corporation

• Chris Tait, Life Science Account Manager, CHUBB Insurance Company of Europe

• Deborah A. Komlos, Senior Medical & Regulatory Writer, Clarivate Analytics

• Elizabeth Moench, President and CEO of Bioclinica – Patient Recruitment & Retention

• Francis Crawley, Executive Director of the Good Clinical Practice Alliance – Europe (GCPA) and a World Health Organisation (WHO) Expert in ethics

• Hermann Schulz, MD, Founder, PresseKontext

• Jim James DeSantihas, Chief Executive Officer, PharmaVigilant

Lyophilization, it the process is setup well, is a great means to formulate biopharmaceuticals and small molecules alike. Lyophilized products can often be stored at higher temperatures, e.g., at 2–8°C or room temperature rather than frozen at -20°C or even lower. This decreases costs for warehousing and shipmen, but also increases availability of the drugs to places with less developed infrastructure. Matt Bourassa at PCI Pharma Services, gives a comprehensive guide to the techniques of lyophilization.

Timothy Francis at FujiFilm Wako Chemicals giving advice on what to consider and how to validate Endotoxin test when implementing new reagents.

Patients all over the word trust that the drugs they are receiving are foremost save and efficacious. This trust is built on the fact that pharmaceutical companies and their supplier have to adhere to a complex set of rules and regulations which are rigorously controlled and enforced by national and international regulatory bodies. As most pharmaceutical companies act globally, they have to adhere to the national regulations of the markets they are operating in, which can be quite different. Hannah Crystal T. Jurolan and Joe Kalina at Xybion showcase how a predictive compliance risk analysis can be applied to navigate the different changing regulation and avoid regulatory findings.

Data integrity in scientific publications is an important as researchers need to be trust that the information conveyed is accurate and untampered. Dr. Dror Kolodkin Gal at Proofig AI, explores the challenges editors and publishers face when reviewing Western blot images and suggests how to identify issues before publication.

Dr. Steven A. Watt, CBDO (Chief Business Development Officer) at A&M STABTEST GmbH

• Jeffrey W. Sherman, Chief Medical Officer and Senior Vice President, IDM Pharma.

• Lorna. M. Graham, BSc Hons, MSc, Director, Project Management, Worldwide Clinical Trials

• Mark Goldberg, Chief Operating Officer, PAREXEL International Corporation

• Maha Al-Farhan, Chair of the GCC Chapter of the ACRP

• Rick Turner, Senior Scientific Director, Quintiles Cardiac Safety Services & Affiliate Clinical Associate Professor, University of Florida College of Pharmacy

• Robert Reekie, Snr. Executive Vice President Operations, Europe, Asia-Pacific at PharmaNet Development Group

• Stanley Tam, General Manager, Eurofins MEDINET (Singapore, Shanghai)

• Stefan Astrom, Founder and CEO of Astrom Research International HB

• Steve Heath, Head of EMEA – Medidata Solutions, Inc

4 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

Foreword

Application Note

Simple Analysis of Impurities in Oligonucleotide Therapeutics Using a Single Quadrupole Mass Spectrometer

Oligonucleotide therapeutics have attracted attention in recent years as a new modality for drug discovery because they can be used to create disease-specific therapeutic agents and can be designed easily by chemical synthesis.

Typically, they are composed of oligonucleotides with about a dozen to several dozen bases (including modified bases). However, the development of analytical methods for quality assurance and standardization is still in progress. Quality control requires analysing impurities, such as by-products, unreacted residues, and degradation products, in addition to the principal components. HPLC-UV is commonly used for purity confirmation, but if impurities are detected, they must be checked to confirm whether they are known impurities or not. Mass spectrometry, which provides molecular weight information, is a valuable analytical tool in such cases. This application note describes an analysis of oligonucleotides and related impurities using an inert UHPLC system and a

single quadrupole mass spectrometer. Oligonucleotides and related impurities can be easily analysed using a Nexera XS inert UHPLC system and a LCMS-2050 single quadrupole mass spectrometer.

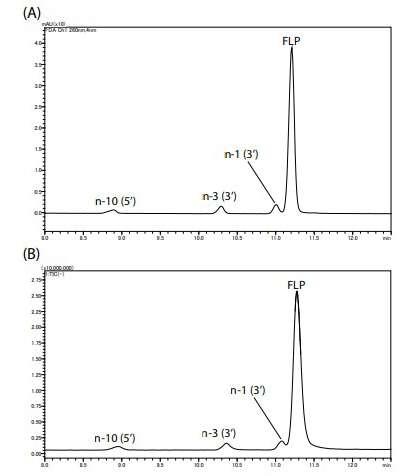

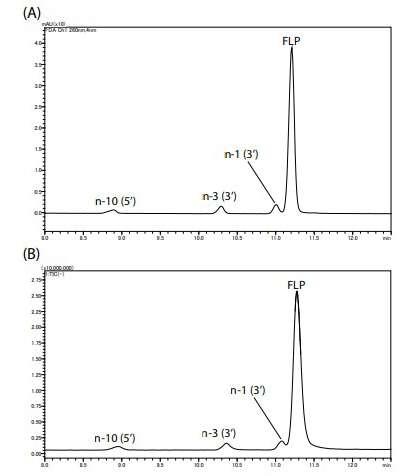

Figure 2 shows the UV (260 nm) and TIC chromatograms of the model oligonucleotides. Peaks were confirmed in the order of n10 (5’), n-3 (3’), n-1 (3’), and FLP. The mass spectra of impurities and FLP are shown in Figure 3. Multiply-charged ions (3 to 11 charges) were detected.

Marketing Communication Europe, Shimadzu Europa GmbH

Albert-Hahn-Str. 6–10, D-47269 Duisburg, Germany

Tel.: +49 (0)203-7687410

Email: shimadzu@shimadzu.eu

Website: www.shimadzu.eu

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 5 www.international-biopharma.com BIOPHARMACEUTICAL 5

Figure 3 – Mass Spectra of Impurities and FLP

Figure 2 – Chromatograms of Model Oligonucleotide (A) UV Chromatogram, (B) TIC Chromatogram

Figure 1

Regulatory & Compliance

Biotech Sector Survey: From Investment Confidence to Strategic Collaborations

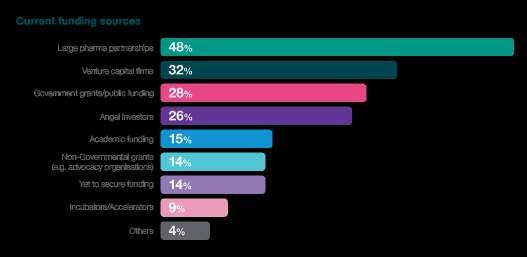

In the rapidly evolving landscape, ICON’s recently published biotech sector survey provides a roadmap through the intricacies of investment confidence, funding dynamics, and the pivotal role of strategic collaborations. The survey, conducted on ICON’s behalf by Citeline, included 133 respondents, predominantly located in Europe and North America, from small pharmaceutical and biotech companies, mid-size pharmaceutical and biotech companies, to large biotech or venture capital organisations.

A compelling narrative unfolds as we dissect the survey results, revealing the industry's resilience and determination despite funding challenges. We explore the imperative of partnerships, delving into their role in funding strategies, and the increasing trend of pharma collaborations, even at the preclinical stage.

Key Survey Findings: Stats and Implications

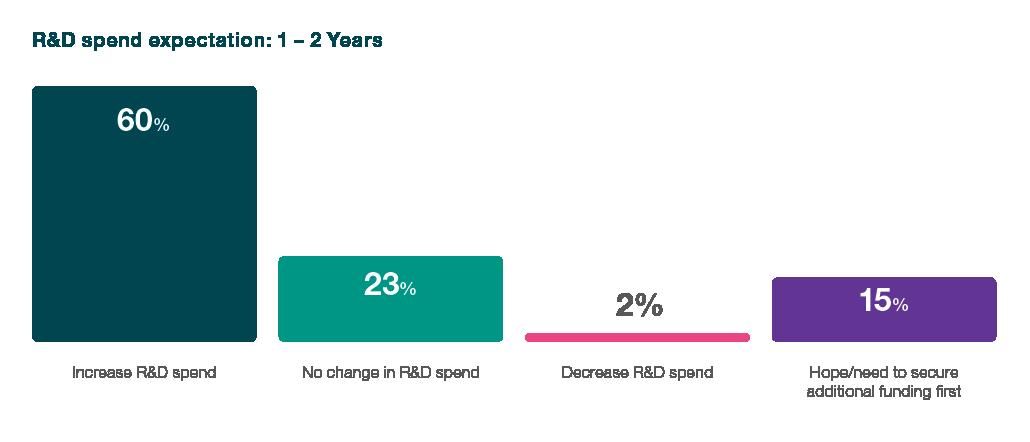

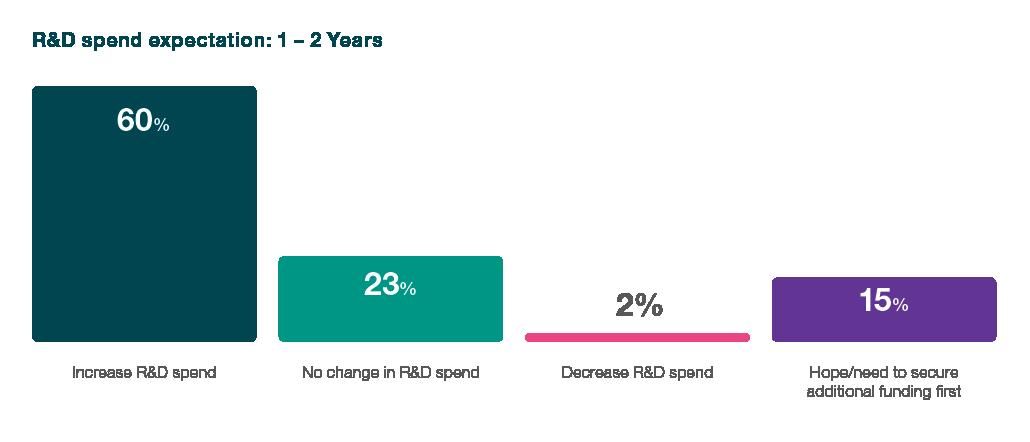

R&D Spending Expectations

The heartbeat of the biotech innovation lies in its Research and Development (R&D) endeavours, and the survey paints a vivid picture of the sector's commitment to pushing the boundaries despite financial headwinds. 60% of survey respondents expect to increase their R&D spending over the next one to two years, a testament to the resilience that permeates the industry. This statistic is a powerful indicator of the industry's faith in the transformative potential of its research initiatives and the impact these endeavours can have on shaping the future of healthcare.

Despite the funding challenges that have become an intrinsic part of the biotech landscape, the overwhelming majority expressing an intent to boost R&D spending sends a powerful signal. It signifies a collective determination to forge ahead with novel research, undeterred by the financial uncertainties. This optimistic outlook not only underscores the resilience of biotech professionals but also speaks to a broader narrative of belief in the value and impact of the biotech innovation on global health.

These statistics symbolise a commitment to progress and a belief in the industry's ability to overcome obstacles. The biotech sector is not merely weathering the storm; it is actively

charting a course toward a future where innovative solutions can address some of the most pressing challenges in healthcare. As the industry braces for an uptick in R&D spending, it positions itself ready and able to unlock new frontiers in science and medicine.

Challenges in the Funding Landscape

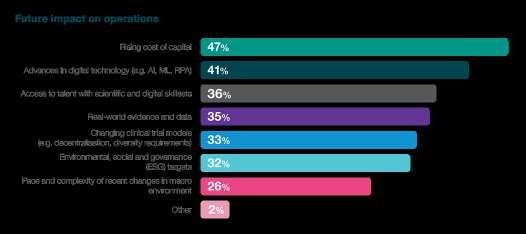

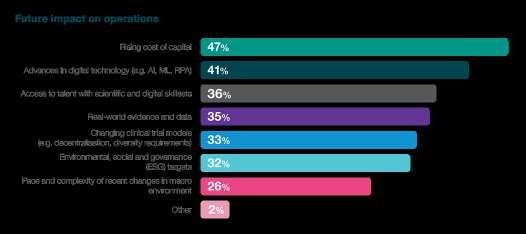

In the complex interplay between innovation and financial viability, the survey unearths critical insights into the challenges embedded within the biotech funding landscape. A significant 47% of respondents identify the rising cost of capital as a substantial influencer. This finding underscores the industry's acute awareness of its financial pressures, with the cost of capital emerging as a pivotal factor shaping future operations. As biotechs navigate this upward trajectory in capital costs, strategic financial planning becomes paramount to sustaining momentum in drug development.

Furthermore, the survey reveals that 35% of respondents consider cost management a barrier to innovation. This finding adds a nuanced layer to the funding landscape, highlighting the delicate balance between financial prudence and fostering innovation. The industry's drive to innovate and bring transformative therapies to market is apparent. Yet, the challenges posed by cost management warrant carefully calibrating financial strategies to ensure sustained creativity and progress.

The implication of these findings is significant – the industry is at a crossroads where the imperative to innovate collides with the realities of financial constraints. Biotechs must navigate a delicate dance, strategically allocating resources to foster innovation while managing costs effectively. This challenge underscores the importance of creative financial models, strategic partnerships, and efficient operational practices to ensure that the flame of innovation continues to burn brightly. In essence, these survey findings highlight the financial tightrope biotech companies walk, emphasising the critical need for thoughtful financial management in pursuing groundbreaking advancements.

Investment Confidence and Product Success

In an operating environment where financial milestones intersect with the promise of product success, the survey findings point to a strong level of confidence within the

6 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

PEER REVIEWED

Driving development and connecting commercialization of sterile and lyophilized drug products, we are dedicated to your success in bringing life-changing therapies to patients.

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 7 www.pci.com talkfuture@pci.com Your sterile drug product, our world. OUR END-TO-END BIOLOGIC SOLUTIONS INCLUDE:

Formulation & Lyophilization Cycle Development

Lyophilization and Sterile Fill-Finish Manufacturing

Aseptic Robotic Technologies

Analytical Support

Clinical & Commercial Labeling & Packaging

Refrigerated/Frozen Storage & Distribution

Lyophilization

• Sterile

•

•

•

•

•

and Sterile Manufacturing

Regulatory & Compliance

biotech industry. An overwhelming 93% of respondents express confidence in meeting their investment milestones, showcasing a robust belief in the industry's ability to secure the necessary financial backing for their endeavours. This high level of confidence signals optimism and a tangible assurance that the biotech sector can navigate the intricate landscape of investment despite the challenges posed by funding difficulties.

Moreover, an impressive 87% of respondents express confidence in the success of their products. Despite the complexities of clinical trials, financial uncertainties, and the evolving healthcare landscape, biotech companies are resolute in their conviction that their products will meet and exceed expectations.

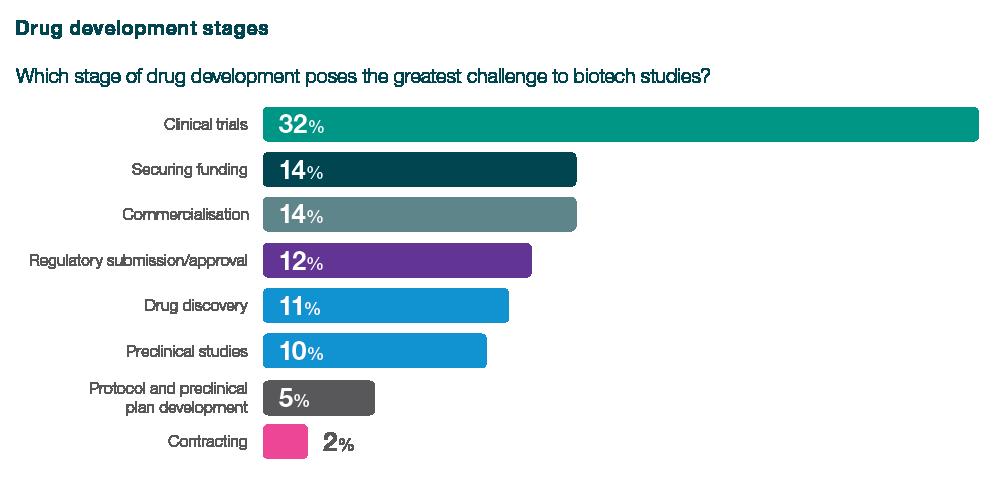

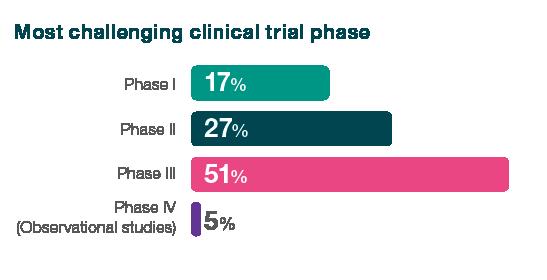

Clinical Trials Landscape

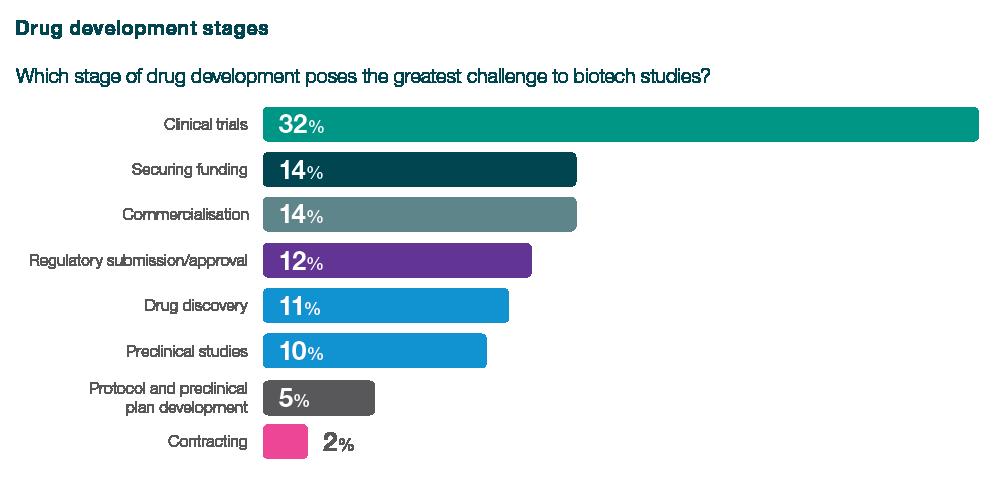

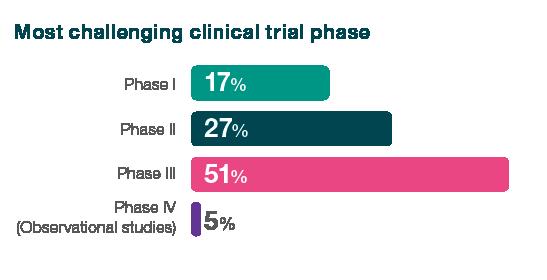

32% of respondents cited clinical trials as the greatest challenge for their organisation, with 51% identifying phase 3 as the most challenging period. Clinical trials topped the list of challenges, beating securing funding, which was cited as the top problem by just 14% of respondents, despite the current financing situation, emphasising the complexity and intricacies of this pivotal stage.

When asked about the clinical trial challenges they face, respondents said clinical trials are extremely costly, require significant expertise and coordination, are the most time-consuming element, and that candidates willing to volunteer for clinical studies are hard to find. Furthermore, they also cited difficulties due to differing laws in different countries.

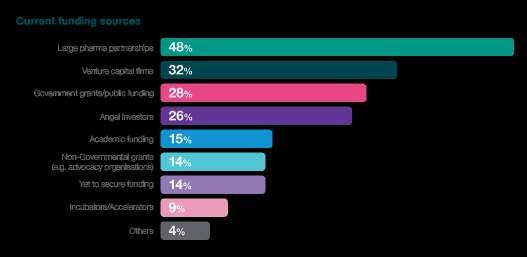

Partnering

The prominence of partnerships emerges as a strategic response to these challenges. A substantial 48% of respondents reveal that they are actively partnering with large pharmaceutical firms, signalling a recognition of the collaborative power established industry players bring. This strategic alignment with large pharma firms injects financial stability and provides access to invaluable expertise, resources, and an established infrastructure, potentially streamlining the clinical trial process.

The strategic role of partnerships in clinical trials is indispensable. In an environment where challenges are acknowledged, partnerships with large pharma firms and specialised CROs become tactical manoeuvres and strategic imperatives. These collaborations stand as a testament to the industry's recognition that the complexities of clinical trials demand a collaborative approach. They are committed to leveraging shared expertise, resources, and capabilities, thereby enhancing the efficiency, quality, and, ultimately, the success of clinical development endeavours. In essence, the clinical trials landscape outlined by the survey findings underscores the pivotal role of partnerships in navigating the intricate journey from research to regulatory approval.

Additionally, 41% of respondents express a preference for medium to large CROs when it comes to clinical development. This preference underscores the industry's reliance on specialised service providers, emphasising the value of working with CROs with a global presence and comprehensive service offerings. It also suggests that strategic collaborations with CROs play a crucial role in managing the intricacies of clinical trials, leveraging their expertise to optimise trial design, patient recruitment, and data management.

8 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 9 www.international-biopharma.com

Regulatory & Compliance

Looking Forward

When examining the findings of ICON's biotech sector survey, a comprehensive narrative emerges, painting a vivid portrait of an industry that survives and adapts amidst funding challenges. From R&D spending expectations to navigating the intricacies of the funding landscape and clinical trials, a resilient spirit permeates the biotech sector. Despite financial headwinds, the survey illuminates an industry-wide commitment to advancing innovation, as evidenced by a resounding 60% of respondents who anticipated increases in R&D spending.

The challenges embedded in the funding landscape, particularly the rising cost of capital and the delicate balance required for cost management, underscore the financial tightrope biotechs navigate. Yet, these challenges are not insurmountable. The industry acknowledges the imperative to innovate and is compelled to allocate resources, fostering creativity while managing costs effectively and strategically. The survey findings point to this financial balancing act, emphasising the critical need for thoughtful financial management to propel groundbreaking advancements.

Strategic partnerships emerge as a linchpin in overcoming challenges in the clinical trial landscape. A substantial 48% actively partner with large pharmaceutical firms, recognising the collaborative power they bring. Furthermore, 41% prefer medium-large CROs for clinical development, highlighting the industry's reliance on specialised service providers. These partnerships go beyond tactical manoeuvres; they are strategic

imperatives, reflecting an industry-wide commitment to collaborative approaches that enhance efficiency, quality, and the ultimate success of clinical development.

The survey outlines the challenges biotech organisations face and paints a portrait of an industry that is adapting to address them. The transformative potential of strategic partnerships, the unwavering confidence in innovation, and the commitment to navigating financial complexities can support biotech companies in their important work of driving innovative and scientific advancements of much needed medicines.

Dr. Chris Smyth

Dr. Chris Smyth is President of ICON Biotech. Dr. Smyth has 30 years' operational and therapeutic experience, most notably in biotech, MedTech and oncology. Prior to ICON, he spent 10 years in IQVIA Biotech, where he held EVP Oncology and Chief Operating Officer roles before assuming global leadership as President of the division. Dr. Smyth also previously led global clinical operations for 8 years at an oncology biotech company, Antisoma. Dr. Smyth holds a Bachelor of Science degree in Biochemistry from the University of Kent at Canterbury, a PhD in Reproductive Biology from the University of Edinburgh Medical School, and an MBA from Henley Management College.

10 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

MICROBIAL

CONTRACT DEVELOPMENT AND MANUFACTURING OF BIOPHARMACEUTICALS

Richter-Helm is a Germany-based GMP manufacturer specialized in products derived from bacteria and yeasts, with a proven 30-year track record.

Count on us to flexibly provide a comprehensive range of services and customized solutions. Clients worldwide have already benefited from our commitment to good manufacturing practice and total transparency. Our work focuses on recombinant proteins, plasmid DNA, antibody fragments, and vaccines.

Richter-Helm consistently works to the highest standards of pharmaceutical quality.

Contact us

+49 40 55290-801 www.richter-helm.eu

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 11 www.international-biopharma.com

MORE ABOUT OUR SERVICES AND CAPABILITIES

LEARN

PRODUCTION? ARE YOU LOOKING FOR EXPERTS IN

Extractables and Leachables for Inhaled Medicines How risk assessments can improve E&L strategies

Regulatory agencies such as the U.S. Food and Drug Administration (FDA) and European Medicines Agency (EMA) are encouraging a more structured approach to product development, such as using Quality by Design (QbD) principles.

The structured approaches encouraged by the FDA, EMA, and other regulatory bodies require additional upfront resources compared to a more traditional approach. Performing an initial assessment of materials used in the product and developing a more thorough understanding of products earlier in their development allows more appropriate experiments on the higher-risk aspects rather than generic approaches covering all materials.

Benefits of Performing a Risk Assessment

Extractables and leachables (E&L) risk assessments are valuable processes that can identify and highlight the risks of potential leachables from both the container closure system and the manufacturing processes. The risk assessments also include the level of risk that leachables might present to user safety and product quality.

By performing a risk assessment, manufacturers can better understand the product, whether a medical device or the container closure system, and the manufacturing processes. Identifying risks and scoring them based on that understanding allows for subsequent E&L studies to be more focused. Therefore, decisions around the E&L aspects of the project can be more appropriate.

Risk Assessment Lifecycle

Quality risk management is a systematic process. The lifecycle can be split into Assessment, Control, and Review stages, and there should be regular communication with stakeholders throughout the lifecycle. A typical quality risk management process is described in ICH Q9 with a flowchart, and it is a good place to start when designing a strategy. An initial assessment can be performed based on previously mentioned tables and decision trees from the FDA and EMA guidelines. This can inform stakeholders early in the assessment about the studies that might be required for the project.

The first step of the process is the Risk Assessment, which is further divided into a series of sections:

• Risk Identification involves identifying the parameters that might affect the leachables by reviewing and brainstorming processes and materials.

• Risk Analysis collates information to understand identified failure modes.

• Risk Evaluation uses information gathered during the Risk Analysis to score the failure modes.

• Risk Control covers where the risks are either accepted or

Inhaled Medicines

In the UK, pressurised metered dose inhalers (pMDIs) are a commonly prescribed treatment for the 5.4 million people with asthma and the 1.2 million with chronic obstructive pulmonary disease (COPD). A 2019 study found that based on a sample of 85 patients, switching from dry powder inhalers (DPIs) to pMDIs was associated with decreased asthma exacerbations and improved asthma control. Despite alternatives such as DPIs being available, pMDIs still represent the foundation of asthma control in the UK.

pMDIs consist of a drug formulation (in suspension or solution) with a closure that delivers the required dosage efficiently and consistently. A pMDI usually consists of a pressurised canister that contains the active substance and propellant and is capped with a metering valve, along with a plastic holder consisting of the actuator, mouthpiece, expansion chamber, and mouthpiece.

Compared with other pharmaceutical products, pMDIs have a much greater risk of the packaging impacting drug delivery. The formulation includes the API in a hydrofluorocarbon (HFC) liquified gas, which acts as an effective solvent for leaching. Furthermore, pMDIs often consist of multiple materials and plastic components with a range of polymerisation catalysts, antioxidants, pigments, and slip agents used in their manufacture that may leach, all of which may carry varying toxicological risks.

experimental studies are planned based on mitigating risk appropriately.

• A Risk Review reassesses the failure modes and re-scores them following any risk mitigations. Risk review can also be part of lifecycle management.

Extractables Studies

Having identified the risk parameters, manufacturers can design their E&L studies accordingly. Extractable studies are chemical analyses that expose a sample of the container closure system or part of the manufacturing system to selected solvents and conditions that either simulate the product formulation or aggressively extract from (but do not destroy) the material to inform the potential for leachables under normal use. Extractable studies can help assess the risk of leachables in the finished product and help design the leachables studies.

Extractable studies are intended to identify potential leachables from a material. Several solvents are used to extract substances from components; the range of solvents should span a range of polarities and pH that may be observed in the finished product.

Solvents commonly used are water, isopropyl alcohol (IPA), and hexane to span solvent polarity. These can also be

12 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

Regulatory & Compliance

Global CRO: Pioneering Your Journey From Discovery to Delivery

• Central Lab: Kitting, Logistics, and Biostorage With Virtual Sample Inventory Management

• Biospecimens: Curated Inventory and Analysis With Advanced Biobanking

• Preclinical: Advanced Cell-Based Assays and Target Validation

• Genomics: Single-Cell to Multiplex Studies

• Bioanalytics: Immunogenicity and PK Testing

• Immune Monitoring: Comprehensive Cell Phenotyping and Profiling

• Tissue and Liquid Biopsy: Rare Cell and CTC Isolation and Analysis

• Clinical Trials: Design, Strategy, and Full-Spectrum Support

• Diagnostics and CDx: Regulatory Consulting, Companion Dx, and NGS

• Data Sciences: Biometrics and Biostatistics via QuartzBio® precisionformedicine.com

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 13 www.international-biopharma.com

Data Sciences Biospecimens, Biostorage, Sample Protection IV, Transfusion Administration Clinical Trial Support Commercialization Circultaing Tumor Cells (CTCs) Protein Molecule DNA RNA Assays Flow Cytometry Sample Collection Sample Collection II Sample Processing Data Solutions Online Management, Tracking, and Reporting Biobanking Regulatory Global CRO Manufactiring Specialty Labs Central Lab Services Data Sciences Biospecimens, Biostorage, Sample Protection IV, Transfusion Administration Liquid Biopsy Tissue Custom Biospecimen Collections Circultaing Tumor Cells (CTCs) Protein Molecule DNA RNA Sample Collection Sample Processing Solutions Cells Clinical Site Training Global Shipping and Logistics Local Logistics Supply Chain Management Online Management, Tracking, and Reporting Global CRO Manufactiring Specialty Labs Central Lab Companion Diagnostic Blood, biofluids and derivatives Kitting, Custom Kit Production Liquid Biopsy Tissue Custom Biospecimen Collections Cells Clinical Site Training Global Shipping and Logistics Local Logistics Supply Chain Management Global CRO Manufactiring Specialty Labs Central Lab Services Companion Diagnostic Blood, biofluids and derivatives Kitting, Custom Kit Production Liquid Biopsy Tissue Custom Biospecimen Collections Cells Clinical Site Training Global Shipping and Logistics Local Logistics Supply Chain Management Global CRO Manufactiring Specialty Labs Central Lab Services Data Sciences Biospecimens, Biostorage, Sample Protection Companion Diagnostic Blood, biofluids and derivatives Kitting, Custom Kit Production Liquid Biopsy Tissue Custom Biospecimen Collections Circultaing Tumor Cells (CTCs) Protein Molecule Sample Collection Cells Clinical Site Training Global Shipping and Logistics Local Logistics Supply Chain Management Online Management, Tracking, and Reporting Global CRO Manufactiring Specialty Labs Central Lab Services Data Sciences Biospecimens, Biostorage, Sample Protection Companion Diagnostic Blood, biofluids and derivatives Kitting, Custom Kit Production Liquid Biopsy Tissue Custom Biospecimen Collections Circultaing Tumor Cells (CTCs) Protein Molecule Sample Collection Cells Clinical Site Training Global Shipping and Logistics Local Logistics Supply Chain Management Online Management, Tracking, and Reporting Biospecimens Specialty Labs Companion Diagnostics Clinical Trials Central Lab Services Data Sciences

Regulatory & Compliance

modified to span a relevant pH range. Solvents that simulate your product's formulation can also be used.

It should be noted that some regulatory agencies recommend three solvents, e.g., polar, non-polar, and semi-polar. Standard extraction techniques typically considered are reflux, sonication, autoclave, and solvent soaking; each has advantages and limitations. When choosing the extraction technique, consideration should be given to the objectives of any extractable study, i.e., aggressively extracting compounds from the sample without degradation of compounds extracted or damage to the material. Characterisation of the extract solutions is principally carried out using mass spectrometry techniques because of their sensitivity, selectivity, and low sample requirement; examples are headspace GC-MS for volatile species, direct injection GC-MS for semi-volatile species, LC-MS for non-volatile species and ICP-MS for elemental species.

Every effort should be made to identify extractable compounds above a previously determined analytical evaluation threshold (AET) using spectral libraries, test mixes, and trained analysts' expert knowledge and experience. Guidance such as USP <1663> and ISO 10993-12 are good places to start when designing extractable studies, and the risk assessment process allows studies to focus on the highest-risk areas. Following an extractables study, a toxicological assessment of the observed extractable species is required to inform whether any species must be targeted in long-term leachables studies due to their toxicity risk.

Leachable Studies

Leachables studies are chemical analyses of the finished product. Leachable studies can detect the release of compounds that are either washed from the surfaces of the container closure system or manufacturing equipment, or migrate from materials into the product under normal storage conditions.

Leachables are a potential risk to product quality and patient safety. Leachables studies are often run as part of a long-term stability program to observe the levels of migrating species over the product's intended shelf life. Depending on the product being tested, the sample matrix can introduce complexity to a leachable study compared to an extractables study, impacting both sample preparation and ease of analysis.

Formulation excipients such as flavours or drug substances can interfere with detecting the often trace level leachables, affecting the method sensitivity requirements. Simulant formulations, which simulate the final formulation's physical properties but may omit certain ingredients to aid the analysis process, are an option if sample preparation techniques cannot reduce interference. However, the use of simulant formulations must be robustly justified.

Storage of samples is typically based on ICH Q1A stability guidelines, and methods used can be targeted to analytes of concern, as determined by Toxicologists. Targeted methods must be validated as fully quantified or limit test methods (to ICH Q2), with limit test methods being justified if confidence exists that leachables will not be observed above a certain level. Extractable studies are routinely performed using clean solvents. Therefore, when product formulation is introduced in leachable studies, unforeseen leachables may occur due to the action of

formulation ingredients or the interaction of these ingredients with previously observed potential leachables; this may result in leachable compounds being observed in the leachables studies that were not observed during extractables studies. These new leachables would not be detected if only specific targeted methods were employed in leachables studies.

As methods for targeted analysis are commonly based on the screening methods used for the extractables study, it is good practice and recommended that screening capability be retained during leachables studies.

Risk Review

A toxicological review of the data generated during E&L experiments is essential to the E&L risk assessment. A toxicological review of the materials and ingredients contributes significantly to the quality of the risk assessment.

Toxicological experts' contributions include assessing the materials and ingredients before the risk identification process and advising appropriate sensitivity levels for analytical methods to inform the leachables study design. Following any leachables studies, the Toxicologists assess the leachables compounds and levels observed and play a critical role in informing the group whether the risk has been reduced or possibly increased due to results.

Regulatory agencies have shown an increased requirement to show aspects of QbD when developing new products. E&L risk assessments demonstrate knowledge of the product and its manufacturing process, contributing to applying QbD principles during a product's development. They also focus efforts on E&L projects, which can be expensive when performed inefficiently. By following the risk assessment process, only required studies are performed, and these studies can be designed to de-risk several failure modes.

Working with a science or regulatory consultancy can help you design and implement an effective E and L risk assessment. Broughton has extensive experience of developing tailored E and L studies that combine technical and analytical expertise with integrated toxicological consultancy and regulatory compliance. To find out more and to speak to one of our scientific experts, visit the Broughton website at www.broughton-group.com.

Paul Hardman

Paul Hardman is Managing Consultant, Chemistry at Broughton. He has 10 years of experience in developing inhaled pharmaceuticals; across API particle engineering, formulation development and scale up, and device design including interaction with the formulation to enable products to target either systemic absorption or local effect in the lung. He is passionate about product quality and understanding a product's chemistry, from product design to its intended function, how the chemistry changes over time, and assessing any special features. Paul is currently leading studies related to product chemistry across a wide range of consumer and medicinal products at Broughton.

14 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

Application Note

A Guide to Understanding and Performing all Appropriate Validation Steps When Adopting a New Endotoxin Testing Reagent

Limitations of Common Endotoxin Testing Solutions

The adaptation of in-house endotoxin testing for a pharmaceutical or medical device manufacturer can be a daunting task. Many small-volume manufacturers find themselves in one of two common situations. Either they are utilising a contract testing organisation (CTO) and paying a great deal of costs, or they have adopted a solution that is set up by the manufacturer with much of the validation services outsourced.

A potential limitation of these methods is cost. Utilising a CTO is appealing to low-volume manufacturers. However, it can be a limitation to expansion as testing costs increase with volume. A system that does not allow versatility in reagent usage can lock the client into manufacturers’ costs and price increases.

However, an even bigger drawback to both situations is the lack of testing control and feedback that the user receives for each method. The disadvantage to the convenience of a contract testing service is the increase in time to results as well as greater limitations on the frequency of testing monitoring. In-house testing can provide results in an hour or less if needed. This nearly real-time feedback on the quality of the manufacturing process is invaluable to the trend monitoring of the manufacturing process.

Dangers of an Improperly Performed Analytical Methods Validation

Real-time feedback can be provided by seemingly attractive solutions. Some solutions utilise outsourced verification data provided by the manufacturer. This provides the convenience of having preparatory tests being done offsite – outsourcing much of the validation. However, a great limitation of this method is that the routine testing takes place in a different location with different analysts, accessories, and accompanying instruments, which may not fully support the verification test requirements stated in USP chapter 85: “To assure the precision or validity of the turbidimetric and chromogenic techniques, preparatory tests are conducted to verify that the criteria for the standard curve are valid and that the sample solution does not interfere with the test. Validation for the test method is required when conditions that are likely to influence the test result change.” Although an outsourced standard curve may technically check the requirements, it assumes that changing “conditions that are likely to influence the test result” is not a factor between the different locations, personnel, equipment, and accessories in and with which the validation testing and the routine testing takes place.

Although routine test monitoring includes the PPC and recovery rates at the testing location, the concern about the offsite verification data is not unfounded. Why would the

USP require suitability verification if redundant information is obtained during routine testing? The information obtained during routine testing is not for validation but to monitor daily test conditions. A validation performed in the same conditions as the actual test, including location and analyst, is imperative when setting up in-house testing.

Invalid results in routine testing presume an accurately validated test method to reveal issues in reagent preparation, contamination, and instrument failure. However, repeated failure of routine results can be caused by improperly determined testing parameters found using data obtained away from the in-house testing location. Being caught in this situation can cause undue stress on the clients as they face regular actionable results to investigate, retest, and report. The challenge of changing testing methods does not present itself as a feasible solution because much time and money are invested in the test method. However, this leads to the crucial blunder of passing off systematic test method errors such as random user mistakes or environmental contamination.

The solution: the user needs to perform the verification correctly onsite. What may feel like an unattainable goal due to the complexity of process validation, however, is simplified by the simple fact that the test is already considered to be validated. All that is required of a user is to verify that the already validated endotoxin test is suitable for the onsite products. The purpose of this document is to provide the user with the correct regulatory citations and guidance needed to give confidence in understanding the requirements of validation for the Bacterial Endotoxin Test according to USP compendial methods and advice, and FDA guidance.

Process Validation

Page 4 of the FDA’s “Guidance for Industry: Process Validation: General Principles and Practices” states, “Process validation is defined as the collection and evaluation of data, from the process design stage through commercial production, which establishes scientific evidence that a process is capable of consistently delivering a quality product.” When a pharmaceutical or medical device manufacturer thinks of “validation,” this all-encompassing definition is what comes to mind. The somewhat vague definition is what allows the scope of process validation to apply to every area of the drug or device manufacturing process. However, the document does provide a clean division of process validation into two distinct categories. Page 10 states, “Process validation includes facility validation and process performance validation.”

Facility Validation

Facility validation will fall completely out of the scope of Bacterial Endotoxin Testing. The Bacterial Endotoxin Test only has a few direct, basic facility requirements such as climate control and adequate shelter from direct sunlight. However, a site that is manufacturing a product to endotoxin-free standards

16 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

will need facility validation. Page 10 of the FDA document states, “Proper design of a manufacturing facility is required under part 211, subpart C, of the cGMP regulations on Buildings and Facilities. It is essential that activities performed to assure proper facility design and commissioning precede PPQ.”

Although not dealt with directly in BET validation, it is crucial that this portion of process validation is completed before the Process Performance Validation (PPQ), which includes endotoxin testing, proceeds. However, a client that is looking to implement the BET as a new test or a replacement of a previous technique should not need to change anything regarding their existing Facility Validation.

Process Performance Validation/Qualification (PPQ)

The Bacterial Endotoxin Test is one of the pieces that make up the PPQ. Page 11 of the FDA guidance on process validation explains that PPQ is the general name given to the combined validation of “the actual facility, utilities, equipment (each now qualified), and the trained personnel with the commercial manufacturing process, control procedures, and components to produce commercial batches. A successful PPQ will confirm the process design and demonstrate that the commercial manufacturing process performs as expected.” One can think of the PPQ as the aggregate of all method validations needed for the quality control checks in the manufacturing process. On page 13, the guidance explains that PPQ includes “the validation of analytical methods used in measuring the process, in-process materials, and the product.” Of course, one of these analytical methods is the Bacterial Endotoxin Test.

Analytical Method Validation (Non-compendial Analytical Procedures)

The manufacturer must provide a method of validation for every test they are using. The requirements for this validation are now outlined in the FDA guidance on “Analytical Procedures and

Methods Validation for Drugs and Biologics.” Page 7: “Analytical method validation is the process of demonstrating that an analytical procedure is suitable for its intended purpose. The methodology and objective of the analytical procedures should be clearly defined and understood before initiating validation studies.” The document provides a detailed description of potential objectives and tests to perform to ensure an analytical method is performing to its intended purpose. USP 1225 parallels these requirements: “Validation of an analytical procedure is the process by which it is established, by laboratory studies, that the performance characteristics of the procedure meet the requirements for the intended analytical applications.”

It is at this point that many users of the Bacterial Endotoxin Test misunderstand the requirements for adopting or converting to a new test reagent. Because they either outsource the entire test itself or portions of the validation for in-house testing, they believe that adopting a new in-house test reagent and equipment will require them to perform a completely new Analytical Method Validation. However, because the Bacterial Endotoxin Test is a compendial method outlined in USP 85, the FDA considers the Bacterial Endotoxin Test to be an already validated test method. As a result, users do not need to perform an Analytical Method Validation but can proceed with a Compendial Analytical Verification.

Compendial Analytical Verification/Verification of Compendial Procedures

When either adopting a new or pre-existing reagent in a compendial procedure, this step of Compendial Analytical Verification is what is required of the user. The FDA document states, “The suitability of an analytical procedure (e.g., USP/ NF, the Official Methods of Analysis of AOAC International, or other recognized standard references) should be verified

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 17 www.international-biopharma.com 17

Application Note

under actual conditions of use. Information to demonstrate that USP/NF analytical procedures are suitable for the drug product or substance should be included in the submission and generated under a verification protocol.” There is no need to validate the method itself, to determine its adequacy for the test, or even to perform a comparison study with an alreadyexisting method (although that is often valuable for internal evaluation).

The requirements are simply to verify the suitability of the method for the specific drug under actual conditions of use.

The USP chapter 1225 details what this compendial verification may look like, “Verification requirements should be based on an assessment of the complexity of both the procedure and the material to which the procedure is applied... Only those characteristics that are considered to be appropriate for the verification of the particular method need to be evaluated.” Although this may seem ambiguous, leaving the question open of how much of the Analytical Methods Validation steps need to be adopted for the BET test verification, the USP clearly outlines what is needed. USP chapter 1085 specifies that for

the Bacterial Endotoxin Test, this verification of compendial procedures includes analyst qualification, consumable qualification, equipment and instrument qualification, and method suitability qualification.

Analyst Qualification, Consumable Qualification, Equipment, and Instrument Qualification

These three portions of the BET verification are the preparatory tests needed to be in place before the method suitability qualification. The following from USP 1085 regarding analyst qualification, “training for performing any BET involves demonstration of acceptable proficiency for both sample preparation and assay method(s).” For consumable qualification, “use apparatus that is shown to be free of detectable endotoxin and does not interfere in the test.” For equipment and instrument qualification, “all instrumentation and equipment used in the performance of an LAL test... should be qualified using proper scientific standards and according to approved protocols. Incubating plate or tube readers should reference a user requirement specification (URS), an installation qualification (IQ), an operational qualification (OQ), and a performance qualification (PQ).”

18 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1

Application Note

Application Note

When providing proof of these qualifications, calibration certificates, CoA’s, and IQ/OQ/PQ documents are attached to the method of suitability testing for the product.

Method Suitability Testing

Finally, the actual verification required for a new user of the Bacterial Endotoxin Test is Method Suitability Testing. This is found in both USP 85 and expanded on in USP 1085 and includes the calculation of the endotoxin limit and MVD, the assurance of the standard curve test, and the interfering factors test. It is this process that is outlined in the following attachments. The new client has the assurance that the Bacteria Endotoxin Test is already considered to be validated when using an FDA-licensed reagent such as PYROSTARTM ES-F. They also have the assurance that these considerations found in USP 85 are all that need to be addressed when either adopting a new test method or switching test methods.

If a user is concerned that switching between gel clot reagent to a quantitative reagent or switching manufacturers in reagent or instrument will require them to perform a PPQ since one of their analytical methods has changed, then they can be assured by the words in the opening paragraph of USP 85 that from a regulatory standpoint, nothing has changed in terms of their Analytical Methods Validation: “There are three techniques for this test... Proceed by any of the three techniques for the test.”

Conclusion and Introduction to the Following Documents

If you are considering changing your LAL reagent or technique due to failed results with a previously outsourced validation or to adopt a better BET technique, you have the assurance that the FDA and the USP consider this a simple change in the reagent. If you are considering adopting the LAL reagent for BET testing, you have the assurance that the FDA and USP already consider the method you are adopting as compendial. Once this is understood, your confidence can arise that you are following a fully compliant and compendial method. To aid in your risk assessment and preparation for performing the appropriate suitability assessment based on the USP and FDA requirements, FUJIFLM Wako provides a full range of endotoxin-specific LAL reagents. FUJIFILM Wako can support your validation by providing example procedures and reports that can then be used as a part of the submission of a successfully validated Bacterial Endotoxin Test.

REFERENCES

1. FDA. Guidance for Industry: Process Validation: General Principles and Practices

2. FDA. Analytical Procedures and Methods Validation for Drugs and Biologics

3. USP <1225> Validation of Compendial Procedures.

4. USP <1226> Verification of Compendial Procedures.

5. USP <1085> Guidelines on the Endotoxins Test

6. USP <85> Bacterial Endotoxins Test

Timothy Francis

Timothy Francis is the Senior Technical Specialist for the LAL Division of FUJIFILM Wako Chemicals U.S.A. Corporation. He comes into the Technical Specialist role with 5 years of experience teaching the natural sciences at a college level. He is proficient at taking the complex, technical aspects of a topic and breaking them down into clear, understandable pieces that all connect back to the big picture. He draws upon this experience to provide professional technical support and training for the PYROSTAR™ line and to help you with your technical needs.

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 19 www.international-biopharma.com 19

Using Predictive Compliance Risk Analysis to Avoid FDA Penalties

In the complex landscape of global regulations, particularly within healthcare and pharmaceutical sectors, a robust compliance strategy is essential for maintaining the integrity of businesses amidst rigorous regulatory requirements. Organisations need to be both flexible and resilient, adept at navigating and anticipating the multifaceted and ever-changing aspects of global compliance standards. These standards are often stringently enforced by regulatory bodies, with the U.S. Food and Drug Administration (FDA) being one of the most prominent and rigorous. Insights into developing a strategic framework for identifying and mitigating compliance risks is critical in today's dynamic business landscape, where violations of regulations can lead to severe repercussions, far beyond minor setbacks, potentially jeopardizing the future of regulated businesses.

The Challenge of Disparate Quality Systems

In the intricate world of healthcare and pharmaceuticals, ensuring regulatory compliance across a complex network of operations is paramount.

The integration of diverse and complex quality systems, often resulting from mergers and acquisitions, poses significant challenges for effective risk management in the pharmaceutical and healthcare industries. These fragmented systems can create inconsistencies in the compliance infrastructure, leading to vulnerabilities that are challenging to detect and more challenging to rectify. This fragmented approach to quality system integration can undermine the overall effectiveness of compliance efforts, exposing organisations to regulatory risks and potentially eroding public confidence in their commitment to safety and quality.

Uniting Global Quality Management Under Predictive Compliance

In response to the challenges posed by disparate quality management systems, enterprises in the healthcare and pharmaceutical sectors are increasingly adopting predictive compliance risk analysis. This advanced approach offers a cohesive and strategic method for managing regulatory obligations without the need for extensive overhauls of existing systems.

Predictive compliance goes beyond merely reducing the likelihood of non-compliance; it enhances operational efficiency and refines the precision of internal audits. By centralising oversight across various locations and implementing forwardlooking measures, organisations can achieve a compliance framework that is both robust and flexible, ensuring resilience in the face of regulatory audits.

The Role of Predictive Risk Analysis in Compliance

Predictive risk analysis represents a transformative approach

to managing compliance obligations. Far from being merely an assemblage of advanced technological terms, predictive compliance risk analysis signifies a fundamental shift in strategy – from a reactive stance, addressing compliance issues as they arise, to a proactive one, aimed at foreseeing and mitigating potential breaches before they materialise.

This proactive methodology is grounded in the application of data analytics, machine learning, and other predictive technologies to analyse vast arrays of data for early signs of potential compliance risks. By harnessing these insights, organisations can transition from traditional, often cumbersome compliance models to more dynamic, real-time monitoring and response frameworks. This not only enhances the ability to maintain continuous compliance across various regulatory environments but also significantly reduces the likelihood of infractions that can lead to financial penalties, reputational damage, and operational disruptions.

Moreover, the adoption of predictive risk analysis in compliance processes redefines the benchmarks for regulatory adherence. It establishes a new norm that is not only anticipatory but also exceedingly precise, enabling organisations to tailor their compliance strategies to the specific risks and requirements of their operational contexts. This level of specificity and foresight in compliance management fosters a culture of compliance that is embedded within the operational fabric of the organisation, rather than being an external imposition.

In essence, predictive risk analysis in compliance is not just about avoiding penalties; it's about instilling a forward-thinking ethos that permeates every layer of an organisation's operations. It underscores the importance of strategic risk management as a cornerstone of sustainable business practices, ensuring that organisations are not merely reacting to regulatory landscapes but are actively shaping their journey through informed, data-driven decisions.

Key Components of Predictive Compliance Risk Analysis

Predictive compliance represents a sophisticated convergence of multiple disciplines, transforming traditional compliance frameworks into proactive, resilient systems. This advanced approach to compliance management is founded on a strategic amalgamation of data collection, analytics, and focused risk mitigation efforts.

• Establishing a Robust Data Foundation: The efficacy of predictive compliance begins with the meticulous collection of relevant data. This foundational step involves identifying and aggregating critical information sources, ranging from internal audit findings to historical regulatory inspection outcomes. The objective is to streamline the data acquisition process to ensure that it is both comprehensive and efficient, avoiding the pitfalls of data overload or irrelevant data capture.

20 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1 Research / Innovation / Development

PEER REVIEWED

UniSafe® Platform

Delivering the future with safety and simplicity

Developed around UniSafe®, our platform meets the needs of you, our partner, and your varying patients’ needs both now and in the future.

Proven, on market, in patient use

Fully industrialised and ready to supply

Coming soon

Want to know more?

Coming soon

Visit ompharmaservices.com/ibi-march2024 or email pharmaservices@owenmumford.com

UniSafe® is a registered trademark of Owen Mumford Ltd. ©

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 21 www.international-biopharma.com

A spring-free, passive safety device for 2.25mL pre-filled syringes, designed for simple assembly and use.

2024 OMPS/ibi/ad/ob/0324/7

A spring-free, passive safety device for 1mL pre-filled syringes, designed for simple assembly and use.

A reusable companion auto-injector for UniSafe® 1mL.

A reusable connected companion auto-injector for UniSafe® 1mL.

• Harnessing Analytical Insights: Once data is collected, the next step is to transform this raw information into meaningful insights. This transformation is achieved through the application of advanced analytics, utilising tools and platforms that employ statistical models, machine learning algorithms, artificial intelligence, and data visualisation techniques. The focus here is on interpreting the underlying patterns and indicators within the data that could signify potential compliance risks.

• Strategic Risk Identification and Mitigation: The true value of predictive compliance lies in its ability to proactively identify risks and prioritise them based on their severity and probability to occur. This requires a discerning approach to data analysis, one that goes beyond mere aggregation to a nuanced understanding of the data's implications in inspections. By focusing on key risk areas in an automated predictive compliance solution, organisations can allocate their resources more effectively, concentrating their efforts on mitigating the most significant compliance risks.

Benefits of Predictive Compliance Risk Analysis

The implementation of predictive compliance risk analysis offers a comprehensive array of benefits, underpinning a philosophy where preemptive action is invariably more effective and less costly than remedial measures. These benefits extend beyond mere regulatory adherence, enhancing operational efficiency, credibility, and financial health of organisations.

The essence of predictive compliance lies in its capacity to anticipate and mitigate regulatory risks before they escalate into significant issues. This proactive approach provides

organisations with a critical advantage – time. Time to identify, assess, and address potential compliance gaps before they result in severe regulatory repercussions.

The traditional approach to compliance – often characterised by a scattered allocation of resources in response to emerging issues – can be both inefficient and ineffective. Predictive compliance introduces a paradigm shift towards strategic resource allocation. By leveraging data-driven insights to pinpoint areas of highest risk, organisations can concentrate their efforts and resources more judiciously. This targeted approach enhances the efficacy of compliance programs and contributes to overall operational efficiency, reducing wasteful expenditure and focusing on areas that yield the highest return on investment.

An organisation's compliance framework is a critical component of its corporate integrity and reputation. Predictive compliance strengthens this framework by embedding a culture of continuous improvement and vigilance. Beyond evading penalties, predictive compliance is about embodying a commitment to the highest standards of regulatory compliance and ethical conduct.

Implementing Predictive Risk Analysis in Your Organisation

The integration of predictive risk analysis into an organisation's compliance framework is a sophisticated process that unfolds progressively, requiring meticulous planning and execution.

Assessing Organisational Readiness and Establishing Realistic Expectations

The initial phase in adopting predictive risk analysis involves

22 INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY Spring 2024 Volume 7 Issue 1 Research / Innovation / Development

Research / Innovation / Development

a thorough assessment of the organisation's current state and readiness for such a transformative initiative. This crucial step encompasses evaluating existing compliance frameworks, technological infrastructure, and the organisational culture towards risk management. It also involves setting realistic expectations and aligning them with the capabilities and potential impact of predictive risk analysis. This stage is about ensuring a solid foundation, both in terms of infrastructure and mindset, to support the subsequent steps of implementation.

Selecting and Implementing Appropriate Technology

Technology serves as the backbone of predictive risk analysis, facilitating the collection, analysis, and interpretation of vast datasets to identify potential compliance risks. This step involves a comprehensive review of available technological solutions, including data analytics platforms, machine learning tools, and compliance management systems. The selection process should prioritise technologies that align with the organisation's specific requirements, scalability, and integration capabilities, ensuring they complement existing systems and processes.

Conducting a Pilot Program

Before fully integrating predictive risk analysis across an

organisation, conducting a pilot program is advisable. This controlled approach allows for the testing of processes, technologies, and team dynamics on a smaller scale, providing valuable insights into the system's effectiveness and areas for improvement. The pilot phase is instrumental in identifying potential challenges and refining the approach before broader implementation, thereby minimising the risk of large-scale issues and ensuring a smoother transition to predictive compliance models.

Embracing Predictive Compliance: A Strategic Imperative

In an era marked by rapid regulatory changes and heightened expectations for corporate accountability, the ability to foresee and address compliance risks proactively is more than just an operational benefit – it's a critical differentiator that can set the foundation for sustainable growth and innovation.

In regulated business environments, the transition to predictive compliance is not just a strategic move; it's a visionary one. It signifies a shift from reactive problem solving to a forward-thinking mindset that values preparedness, operational integrity, and adaptability. For enterprises ready to embark on this journey, predictive compliance offers a path to meeting the regulatory demands of today and thriving in the regulatory landscapes of tomorrow.

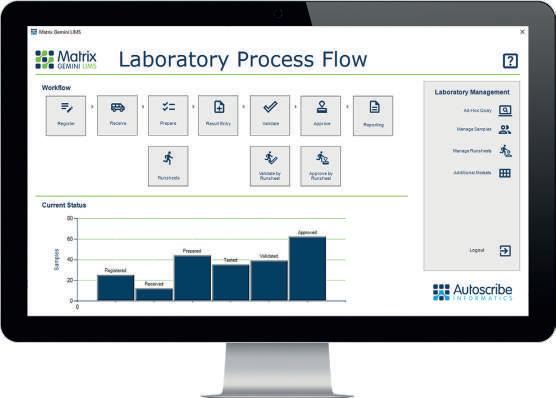

Hannah Crystal T. Jurolan

Hannah Crystal T. Jurolan has carved a niche for herself in the intersection of life sciences and technology and is currently the Assistant Marketing Manager at Xybion. With a robust background in biosystems engineering, her expertise bridges the gap between intricate biological systems and cuttingedge technological solutions. Over her three-year tenure at Xybion, Hannah has been instrumental in shaping the marketing strategies for Laboratory Information Management Systems (LIMS), leveraging her technical acumen to inform laboratory leaders of the latest LIMS technologies.

Email: hjurolan@xybion.com

Joe Kalina

Joe Kalina, MBA has distinguished himself as a leading figure in global LIMS marketing, spearheading the development of innovative new systems, notably a LIMS designed for managing COVID-19 tests. His comprehensive expertise spans across all areas of marketing including SEO, branding, demand generation, web development, and more. During his four-year tenure as Director of Marketing at Xybion Digital, Joe expanded the horizons of SaaS marketing and LIMS technology, transforming Xybion LIMS into an award-winning brand and co-authoring several industry guides with Hannah Jurolan that equip forward-thinking scientific leaders with the knowledge to harness the latest advancements in modern laboratory technology.

Email: jkalina@xybion.com

INTERNATIONAL BIOPHARMACEUTICAL INDUSTRY 23 www.international-biopharma.com

Application Note

Optimising Pharmaceutical Processes: A Guide to Lyophilisation Cycle Development

Lyophilisation, commonly known as freeze-drying, is a critical unit operation in the pharmaceutical industry used to preserve and stabilise both small and large molecule drug products and biologics, including monoclonal antibodies, vaccines and peptides. Lyophilisation is a process that involves freezing a liquid drug product and then removing the frozen solvent via sublimation, providing a stable solid matrix of drug product and other excipients. This method is particularly suitable for heat-sensitive molecules, as it dramatically mitigates hydrolysis degradation found in liquid product, is more product-sensitive and practical than other drying methods, and avoids the difficulties of multi-component powder filling.