10 minute read

Reel Repairs Done by the Pro

Part 1: Restoring a corroded Penn 130ST

By Jonathan Williams

Advertisement

THE weakest link theory — “a chain is only as strong as its weakest link” — is something all anglers pay homage to every time they cast a line, swim a bait, troll a line or drop a bottom trace to the ocean bed.

All that stands between your trophy fish and the open ocean is one “I’ll take a chance” knot, trace or blunt hook. When you take that chance and your weak link fails, you’ll be left with the sound of your curses echoing in your ears instead of cheers of jubilation.

Your fishing reel is one of the most important links in the tackle “chain” between you and the fish. The modern fishing reel is extemely complex, especially the ones used in the extreme aspects of the sport such as marlin and tuna fishing and deep jigging. With dozens of moving parts being put under extreme strain in these situations your reel can let you down if it is not in perfect working order.

Gone are the days when a 12/0 Penn Senator was periodically doused with a bucket of cold sea water as its leather drag washers over-heated and began to smoke when the angler was fighting a beast of a marlin. Thanks to their space-age drag systems and the technologically advanced materials used in their manufacture, todays reels are both user friendly and reliable under all conditions.

There is a proviso, however, and that is that, like any other perfectly made machine, your reel needs a regular complete service and not just an after-fishing spray down with freshwater.

Every angler has experienced the nauseating feeling when he’s onto a big fish and his reel seizes, the drag becomes very rough and temperamental, an anti-reverse pawl fails to work or some other small part in its inner workings does not do what it’s supposed to do. It’s a horrible feeling!

Even if one stays attached to the fish under those circumstances, the enjoyment derived from using a well-tuned reel during a lengthy fight is lost. The difficult task of staying attached and somehow retrieving line becomes a stressful exercise and not the joy it was supposed to be.

Most anglers have tried the DIY exercise of servicing their reels which includes squirting a bit of Q20 onto the visible moving parts and then crossing fingers that they can get it back together again without a few leftover parts. Or if they can’t put it all back together again the reel and accumulated parts get put into a bag and taken to a reel repairer like me with an ardent plea to put it all together again as good as new.

As with servicing motor vehicles these days, servicing fishing reels requires someone with the knowhow, correct tools and access to necessary parts. Taking your reel to a professional reel repairer will give you peace of mind that when the reel is next put to use and you’re attached to a prize fish you’ll feel the smoothness of the drag, hear the clear scream of the ratchet, and when you turn the reel handle the line will wind on beautifully, leading to you landing the beast — provided you do everything else properly and there are no other weak links.

MY PROCESS

I have been repairing reels since I was in my 20s — first my own and then friends’ reels; this hobby eventually grew into a full time passion. This is what sets my work apart from the rest — reels are my passion, and this is evident in the manner I work on them.

I am now over 50, and over the last 30 years I have honed my skills and finetuned the process, gaining a wealth of knowledge and experience along the way. I can assure you that there is no substitute for experience when it comes to repairing reels.

Of course reels and technology constantly improve, so I have to adapt to keep up or get left behind the technology curb. Stagnation is therefore never possible as nothing stays the same.

I’m based in the Western Cape but service and repair reels from all over South Africa and the neighbouring countries, so reels are delivered by courier services or Postnet if clients are not close enough to drop them off.

When I get a reel it’s tagged with all the owner’s details and noted in a register so it does not get mixed up with anyone else’s reels. Being organised and having a working process is very important. It’s vital that the reels are stored on neat, clean shelving and do not lie on the floor as I often see. Keeping them free from dirt and dust is vital.

The first thing I do is assess the reel, then it’s stripped and checked for function or failure of parts. Each reel is fully stripped down to the bare shell, then the first cleaning process starts, after which it undergoes a second process in the digital ultrasonic cleaner. Once the reel is dried and totally cleaned fine checking starts, I replace any worn or damaged parts and finally it’s reassebled.

Each client is sent pictures of their reels when they’re stripped and again on assembly, and inbetween any problems are communicated and the cost of parts relayed. I am a firm believer in transparency and in keeping clients informed.

I also have accounts with the major reel agents in South Africa — Shimano. Penn and Diawa — to enable me to effectively and efficiently put reels back into commission wherever possible.

Once it’s all back together each reel is tested before getting a final clean being bagged before being dispatched to their delighted owners.

REVIVING A CORRODED REEL BODY

There are a few trade secrets I have learnt over the many years of removing corrosion and rust, and then treating that correctly. There are two items used to treat corrosion, both imported, which I regard as best practice for doing this and which remain trade secrets.

Over the years I have spent a small fortune on oils, greases and lubes testing to see what works best for me and my clients. Along the way I found the happy medium in terms of which products offers the very best performance and protection to my clients and their reels.

When servicing reels only the best oils, lubes and greases will do. I do not believe in using anything but the best products and best work methods too as these are expensive items and the commercial vessels and charter reels I maintain constantly take a beating as they work hard constantly.

A very corroded, salt damaged and neglected Penn 130ST reel.

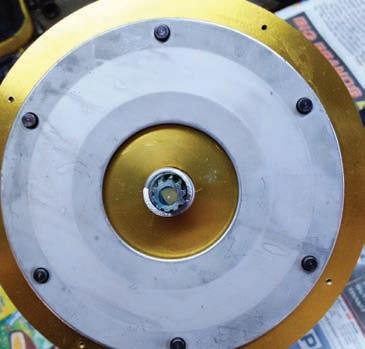

Drive plate outer.

Right side plate assembly.

Left side plate assembly.

Spool with ratchet plate and rusted spool bearing.

Cleaned spool and floating drag washer.

Cleaned right side spool and pinion gear.

Cleaned left side plate assembly with the anti-revese dogs and bearing.

Final cleaned and assembled 130ST.

REFURBISHING A PENN 130ST

Although they may look badly damaged a lot of it is just surface-deep and it’s amazing how well good quality reels like this can be restored.

On arrival the reel is checked for the general condition, then for damage, malfunction, possible failure wear of parts as well as corrosion damage. In other word a comprehensive assessment is done prior to stripping, and then further assessment is done once it’s opened up.

If the stripped reel’s parts are badly worn they are replaced on assembly to ensure reliable functioning.

Corrosion, and specifically galvanic corrosion, is always an issue on reels, especially on the areas where stainless steel parts are mated to aluminium parts such as the reel seat areas and screw areas. These are most prone to galvanic corrosion which is a reaction caused between dissimilar metals when saltwater ions react with the combination of these two different metals.

When saltwater gets into the inside of a reel one can expect the same scenario, especially when the saltwater (corrosive by nature) has dried in place.

Saltwater intrusion into the carbonfibre drag stacks will create problems when it’s left to dry there as it forms salt crystals once dried. This can damage the carbon weave and score the stainless steel drag plate they mate with, affecting the butter-smooth drag needed to reel in big fish.

Left unchecked and not correctly addressed, this will require replacement of the drag stack and possibly the drag pressure plate — an expensive exercise. Often, over time, this corrosion migrates into the left side plate of reels, causing more damage there also.

I find that the most neglected areas on tuna and marlin reels are the insides of handle knobs, the insides of the drag areas and the insides of the spool assemblies and gear shafts. The latter is not easy to access and requires a full strip-down to lubricate it.

Once the reel is fully stripped it’s cleaned with the ultrasonic cleaner. I find this weapon in my arsenal indispensable, along with my Myford precision lathe.

I use a double process of cleaning for every reel to remove as much of the dirt, corrosion and rust as possible. It is more time consuming and labour intensive, but I’ve found this is the best way to service them.

PREPARING YOUR REEL FOR USE AFTER SHORT-TERM STORAGE

If your reel has been serviced within a year you are fine to just take it out of storage and fish it — provided it was serviced correctly. Oil points such as the handle post (knob), clutch lever assembly and the clicker; they can always benefit from a drop of oil if the reel has been standing for many months on a boat or in storage.

If it’s a brand new reel you shouldn’t need to do anything to it before going fishing as manufacturers do their best to ensure reliability straight from their factories.

PREPARING YOUR REEL AFTER LONG-TERM STORAGE

When reels have been stored for six or 12 months inbetween marlin seasons, for instance, if saltwater has been left on the spool this will weaken the line, possibly causing the loss of a trophy fish. I would recommend replacing this line or at the very least the top shot, especially if it was exposed to any sunlight. There’s nothing worse than incurring the cost of going to sea, hooking a trophy fish and then losing it due to line failure.

If reels have been stored for this length of time one would need to check that the drag functions correctly from strike to sunset and then back to free spool.

The spool and main shaft have to be free turning when in free spool, just in case corrosion or rust has gotten to the bearings or the main gear shaft has become dry. This is especially true on most Tiagras (20 to the 80W models) and Penn Internationals (normally up to the 70 models and some older 80 models) where the main shaft turns inside a gear sleeve and not bearings alone.

PREPARING YOUR REEL FOR STORAGE

Before storage rinse the reel lightly with the clutch lever (drag lever) engaged so water does not get into the carbon washers and drag stack. Do not use a high pressure hose to wash it down as this pushes salt and debris into the insides.

After rinsing it fully back off the drag lever (free spool) so you do not weaken the drag tension washers. Let this air dry for three to four days in a place where it gets a breeze to dry the insides fully.

After this the reel seat area can be sprayed directly with some silicon spray. The rest of the reel can also be sprayed with this or some Tackle Guard and then this can be wiped off by cloth. Do not wipe the silicon spray off the reel seat area; you want to leave it on there to help prevent corrosion.

A reel cloth bag can be used to protect the reel from dirt and dust; the cloth bag is better than a plastic bag as it allows any moisture to evaporate and will not keep it trapped, thus encouraging corrosion.

Even when your reel looks dry often the abour or bottom of the spool under the line is still wet with moisture, and if it’s covered in plastic this will encourage corrosion.

A little bit of care goes a long way towards keeping your reel in good working order, but if it’s fallen into a state of disrepair don’t just throw it out — most of them can be rescued.