1 minute read

Check Valves

SINGLE OR DOUBLE DOUBLEBackflow in homes is bad news, however, check valves can prevent it. We spoke to Richard Bateman, Product Marketing Manager at RWC, to find out about check valves and how they help.

Backflow is caused by differences in pressure between the mains supply and a water system and can lead to serious problems, such as contaminated water.

Because of its dangers, all five categories of the 1999 Water Supply (Water Fittings) Regulations for England and Wales require the installation of devices to protect against backflow. The most common devices are check valves, which ensure water flows one-way, stopping backflow re-entering and contaminating supplies. > CHECK VALVES

It’s vital to know where to install check valves, with placement needed as close to the risk point as possible. For example, in a fluid 2 category application where a mixer tap is “passing” and allowing hot back down the cold supply, the valve should be placed on the cold supply and as close to the tap as possible.

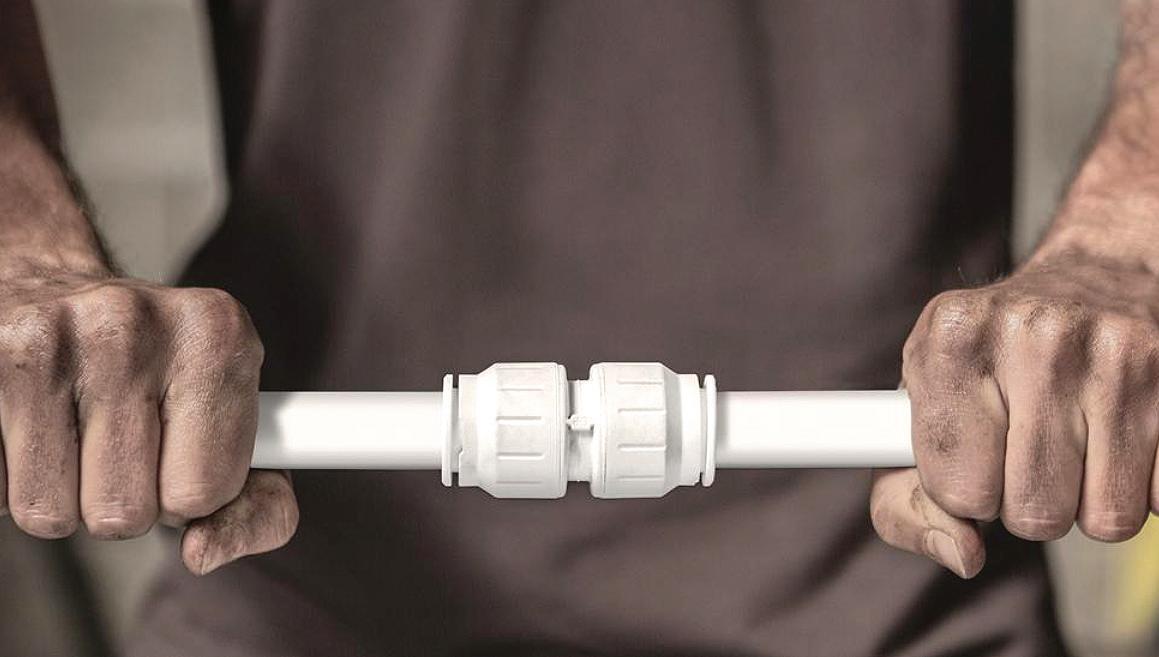

No matter the application, it’s important to prevent backflow from happening, which RWC’s range of single and double-check valves can do – including JG Speedfit, Reliance Valves and SharkBite. RWC say they are committed to providing the vital products and advice all installers need to prevent backflow.

Check Valve options

Single check valves - Type EA (verifiable) and EB (non-verifiable) – for fluid category 2 applications.

Double check valves – Type EC (V) and ED (NV) – for fluid category 3 applications.