20 minute read

PRODUCT SHOWCASE

WANT TO BE FEATURED? Send your latest product information to editorial@indmacdig.com

PRODUCTSHOWCASE

IMD's Product Showcase features the latest from some of the manufacturing industry's top suppliers.

Dynabrade Introduces New Line of Aluminum Housing Power Tools

Dynabrade, Inc.’s Newly refined Die Grinders, Disc Sanders and Drills are manufactured to ensure a lightweight tool. Excellent for or overhead or extended use. Each tool is manufactured with the rigidity and strength of a housing machined from a single piece of aluminum bar stock. Straight Line Die Grinders: Available in 25,000 and 30,000 RPM: These rear exhaust tools are widely used in aerospace manufacturing facilities for deburring and material removal applications. The straight-line design is ideal for applications in confined areas.

Right Angle Die Grinders: Available in 12,000 and 20,000 RPM: These rear exhaust tools provide greater torque under load when aggressive material removal is necessary. The compact size improves maneuverability and the precision gears provide enhanced durability and performance. An Extension Die Grinder is also offered. Available in 12,000 and 18,000 RPM, each tool features a ¼” collet. Ideal for use as both a Die Grinder and Disc Sander. Mini Right-Angle Drills: With eight models available with RPM’s from 900 to 5,000, each Drill features a Rotatable Head which is adjustable without tools. The head rotates in both a clockwise and counterclockwise direction; ideal for various drilling applications.

Pencil Die Grinder: Utilized in grinding and deburring applications where a high degree of precision is needed. At 100,000 RPM, the tool features low run out for smooth operations. The high RPM creates chatter free cutting and the top-quality bearings provide long tool life.

These new Dynabrade Aluminum Housing Air Tools are manufactured in the USA.

ABB Launches IRB1100 Robot And Omnicore™ Controller For Harsh Environments ABB is introducing a new harsh environment version of its IRB 1100 robot and OmniCore controller, designed with enhanced protection against water and dust. The entire body of the new IRB 1100 model has an IP67 rating, with all electrical components sealed against contaminants. This makes it resistant to water and provides the robot with complete protection from dust ingress. For manufacturers, the new IP67 protection rating will enable the robot to be used in applications generating substantial dust, water and debris including 3C polishing, wet grinding, buffing and deburring.

» For more information, visit www.abb.com IMD – The Industry’s Most Extensive Industrial Publication

Customized Safety Lifting Devices For Any Application

Safely Lifts Up To 500 lbs! Ergonomic Portable Lightweight Meets OSHA & ASME Requirements

Integrated Air Bearings Make Machinery Hover: Reposition, Relocate, Reconfigure on the Fly In today’s manufacturing environment, moving machinery to optimize floor space, flex for lean manufacturing, or position for optimum productivity is imperative. Embedding air bearings on OEM machinery provides manufacturers the ultimate capability to adapt and flex to ever-changing manufacturing configurations. Embedded air bearings can now be designed into the OEM equipment via an online toolkit available from AeroGo. Air bearing systems utilize compressed air to lift and float heavy machines, structures and tooling within their own footprint. Air bearing technology eliminates friction – making heavy loads easy to move – and it floats on the surface without damaging the floor.

800-4-SKYHOOK 800-475-9466 • 208-365-5770

New TwinCAT Analytics One-Click Dashboard from Beckhoff Provides Tools for Engineering 4.0 To reduce the once time-consuming process of dashboard creation down to a simple mouse click, Beckhoff has introduced the new TwinCAT Analytics One-Click Dashboard. The automated functionality in TwinCAT Analytics to convert analysis configurations into executable PLC code now also includes dashboard generation. With One-Click Dashboard, all it takes for users is a simple mouse click to generate an entire HTML5-enabled analytics dashboard based on the PLC code that is then loaded into a selected Analytics Runtime container. When the process completes, users receive a network address that they can use to access the dashboard in a web browser.

» For more information, visit www.beckhoffautomation.com

Caldwell Vertical Clamp for Lifting, Turning Curved Loads The model TLC (turning, locking, curved surface), which lifts and turns from zero to 90 degrees, incorporates a vertical lifting clamp featuring a ‘lock open’ and ‘lock closed’ feature, facilitating attachment and removal from the load. A specially designed cam jaw is made to safely lift curved surfaces and flat plate. The product was first unveiled at the Associated Wire Rope Fabricators (AWRF) Product Information Exhibition (PIE) in Cleveland, Ohio last spring, as an enhancement to the manufacturer’s TL clamp, which itself is capable of turning a single plate or load from horizontal to vertical and back to horizontal through the same 90-degree arc.

» For more information, visit www.caldwellinc.com

Dillon Introduces Claw Jaws for Unrivaled Flexibility With Maximum Grip Dillon Manufacturing’s new Claw Jaws allow unsurpassed flexibility and maximum grip for turning applications. Dillon Claw Jaws are designed to bite into the workpiece providing increased holding power. The optimized clamping contour provides secure grip on the workpiece, while the jaw weight, its center of gravity, and cutting forces combine to minimizes jaw clamping force loss. Manufactured from 8620 steel for durability and long service life, an extensive product range is ideal for I.D., O.D., and bar clamping applications. The Dillon Claw Jaw system is available for most chuck brands. Optional rest buttons allow setting up different clamping depths.

Epson VT6L All-in-One 6-Axis Robot Wins “Product of the Year” Award at the Assembly Show

Epson Robots announced its VT6L All-in-One 6-axis robot won “Product of the Year” award in the Robotics category at the Assembly Show. Twenty finalists in the “Product of the Year” program displayed their latest cutting-edge technology and equipment. Epson’s VT6L All-in-One

6-Axis robot is a new entry level offering to the awardwinning 6-Axis line up. With a reach up to 900 mm and a payload up to 6 kg, this compact, easy to install robot includes next generation technology, is ideal for a wide range of simple applications and is offered at the ultra-low cost of $13,900.

Selectable Voltage Power Supply for Static Eliminators EXAIR’s new Gen4 Two Outlet Selectable Voltage Power Supply allows you to choose input voltages of 115VAC or 230VAC. Two 5kV stainless steel output connectors can energize two static eliminators. Applications using up to two Gen4 Super Ion Air Knives, Ion Air Guns, Ion Air Cannons, Ionizing Bars or any other EXAIR Gen4 static eliminator product can be connected to one power supply. Like all EXAIR Gen4 products, these two outlet power supplies are UL component recognized, CE and RoHS compliant. They also feature an electromagnetically shielded modular power supply cable which eases routing and connections.

» For more information, visit www.exair.com

GMTA Presents New Profilator Machines GMTA, the North American distributor of Profilator, has added new machines using the process modules it already supplies. Profilator

is suitable when customers require complex machining proceses

to be carried out effectively, efficiently and with high precision.

Today, an operator working on a modern machine expects a flexible

manufacturing process, short cycle times, reduced investment and

running costs. With these requirements in mind, Profilator offers

polygon & face slot machining, gear tooth pointing, chamfering

and deburring, gear and spline cutting, shifter stop machining and

Scudding ® . Gear cutting is used both for the Profilator rotative gear cutting with inserts and for hobbing.

» For more information, visit www.gmtamerica.com

1050°F Cabinet Oven From Grieve No. 1049 is a 1050°F (566°C), cabinet oven with two drawers from Grieve, currently used for annealing or normalizing processes at the customer’s facility. Workspace dimensions of this oven measure 39” W x 102” D x 51” H, with two drawers rated 250 lbs. loading with 36” wide x 78” deep x 15” high loading area. 800,000 BTU/hour installed in a modulating natural gas burner, while a 10,000 CFM, 7-1/2 HP recirculating blower provides horizontal airflow to the workload. This Grieve oven features 10” thick insulated walls comprised of 2” 2000°F ceramic blanket and 8” of 10 lb/cf density rockwool.

Introducing the Grizzly Model T31648 Metal Shrinker/ Stretcher Combo Pack Switch between metal shrinking and stretching operations without changing your tooling. Commonly used in autobody work, shrinker/ stretchers make curves in sheet metal by compressing, or "shrinking," it and expanding, or "stretching," your workpiece. With one dedicated shrinker and one dedicated stretcher, you can mount both tools to your workbench and switch between operations without having to change out your dies. All this for less than the cost of two separate tools. Workpiece capacity includes 16-gauge aluminum, 18-gauge mild steel, and 20-gauge stainless steel. The Model T31648 is covered by a one-year warranty.

C-FRAME PRESSES

• Heavy Gauge Steel Design • Press Bed bolted on, not welded, to prevent distortion. • Large press bed to accommodate a variety of tooling other than just punching. • Pump, motor, valve and reservoir are all easily accessible for maintenance. • Large rectangular tubes used at base of machine to give safe, instant portability.

WE CAN BUILD A CUSTOM MACHINE FOR YOU!

5806 Quality Ridge Rd | Coggon, IA 52218 Phone: 319.435.2378 | Fax: 319.435.2262 www.betenbender.com

Precise Grinding Through Stable, Symmetrical Design The development of the Multigrind ® CB XL design task included maintaining “small part” microns accuracy even on larger parts. The

solution was based on the award-winning, flagship Multigrind ® CB, a model designed from the beginning to be adapted and deployed for

future demanding grinding tasks. This new CB XL grinding center has

much of the same structural design as the CB, but with a “stretched”

X-axis and machine table. Due to its symmetric design, the Haas

Multigrind ® CB XL maintains stability and rigidity, regardless of part length. The effects of thermal growth are minimized because the

grinding contact point is always in the center of the “box” frame.

» For more information, visit www.multigrind.com

Hamilton introduces New Heavy Duty Casters & Wheels Built for 10-mph Speeds The new 10-mph speed-rated Spinfinity ® XC Casters and Renegade™ Wheels are designed for heavy industrial applications

with load requirement ranges from 1500 lbs. to 17,500 lbs.

Hamilton’s engineering department began the design of the

new Spinfinity ® XC Caster Series with mounting plate and inner raceways that are forged steel formed from one piece then precision

CNC-machined to provide a superior raceway for high-speed conditions. Next, engineers enhanced the casters with larger axles and massive double stacked precision ball bearings in the wheels to accommodate the higher speeds.

» For more information, visit www.hamiltoncaster.com

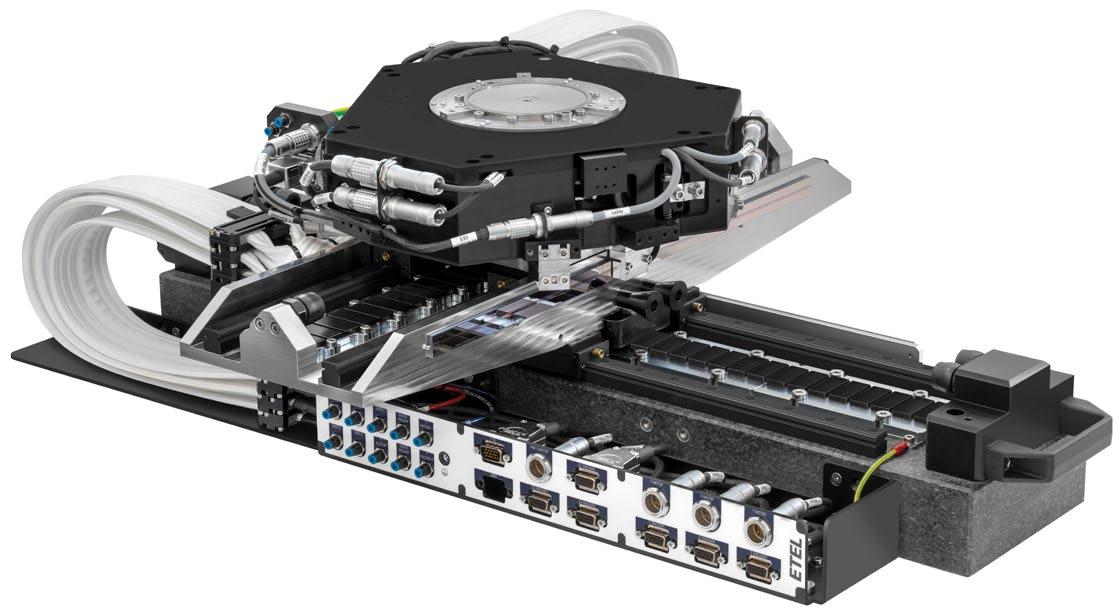

ETEL Expands Popular CHARON2 Motion Platform ETEL of the HEIDENHAIN Group has extended its motion systems product offering with the expansion to nine standard versions of CHARON2, its popular motion platform. The CHARON2 was originally designed in 2017 as an entry level platform to be flexible, scalable, modular and upgradable for semiconductor manufacturing applications. With these new additional configurations, the proven CHARON2 is now able to address any semiconductor use case as well as other markets with optimized cost, uniform performance and high reliability. The CHARON2’s modularity starts as a standalone X-axis and can be upgraded to a complete motion system of up to seven axes with the inclusion of the Z3TM module for tip-tilt.

Advanced tube measurement, new TubeShaper update Hexagon's Manufacturing Intelligence division announced today a much-anticipated update to tube design, analysis and production platform TubeShaper. This new version delivers important new functionalities to customers in tube and pipe manufacturing, including inspection of rectangle-section tubes and new reporting functionality. TubeShaper v2 also offers an innovative new licensing concept that makes it more economical for multiple users to share measurement results and bending plans across different locations. Under this new licensing concept, a new low-price ‘offline’ license allows production supervisors, engineers and designers to work on TubeShaper projects separately from operators measuring tubes on the shop floor so that more tasks can run concurrently, saving time as well as minimizing software investment.

» For more information, visit www.hexagonmi.com

UNRIVALED QUALITY REDUCE REWORK

“The Original” Dynafile®

Dynabrade Abrasive Belt Tools

Quickly grind and remove welds, deburr rough edges, and polish hard-to-reach areas. American-made quality tools are precision designed and manufactured, allowing for fast and efficient production with less rework.

Experience the ease of working with Dynabrade with free on-site demonstrations, excellent customer service, and products that are in-stock and ready for immediate shipment.

Dynafile® II

Pipe Belt Finisher

Dynafile® III

dynabrade.com

Hunter Industrial Releases New Digital Controllers for HVLS Fans Hunter Industrial, a division of the Hunter Fan Company, has released three new controllers today for each of its HVLS (high-volume, low-speed) fan lines—named the 350 Series, 430 Series and 700 Series. Hunter Industrial is proud to now offer network-capable controls across its entire HVLS fan lines. Purposefully designed for the user, each Hunter Industrial controller is a highly intuitive touchscreen that incorporates a “plug and play” design and allows for a hassle-free installation. Able to manage up to 30 fans at once, the 700 Series also features building management system (BMS) integration with an optional gateway, scheduling, zoning, password protection and fan diagnostics directly from the screen.

» For more information, visit www.hunterfan.com/industrial

Konecranes redefines heavy lifting with new M-series winch Konecranes next-generation heavy-duty winch offers improved hook approaches and flange mounted motors for positive motor to gearcase alignment that reduces component wear. M-series’ updated trolley layout improves safety while better facilitating inspections and maintenance with the use of convenient and safe trolley walkways. These design features, combined with Konecranes purpose-built, crane-duty Core of Lifting components have resulted in a winch that can easily be configured to fulfill the needs of various production processes. The M-series winch is available in capacities up to 70 metric tons, and CMAA ratings from D through F for service in a broad range of process duty applications.

» For more information, visit www.konecranesusa.com

Multitasking QUICK TURN 200MSY from MAZAK The QUICK TURN 200MSY CNC turning center with Multi-Tasking capability brings together advanced technology, productivity

and value to deliver exceptional performance for shops large and

small. As an (MSY) configuration, this machine offers the greatest

versatility available in the QUICK TURN series. The machine features

milling capability and Y-axis functionality as well as a second

turning spindle to process parts in DONE IN ONE ® operations. Plus, the machine comes with the SmoothG CNC that features

MAZATROL conversational programming, complete with monitoring and diagnostics, and EIA-ISO programming as standard. For fully automated operations, the machine can be outfitted with a bar feeder or gantry robot loader

OnRobot Launches VGC10 Compact, a Highly Customizable Electric Vacuum Gripper OnRobot, a global leader in robotic end-of-arm tooling, announces the VGC10 compact electric vacuum gripper that addresses customer demand for a small but powerful and highly configurable gripper for nearly any application. Based on the design of the award-winning OnRobot VG10 electric vacuum gripper, the compact VGC10 is smaller and lighter than its larger cousin, so is ideal for constrained environments and smaller robot arms, but offers the same impressive payload of 15 kg (35 lb). The VGC10 provides fast out-of-the-box deployment but also offers unlimited customization, with easily changeable suction cup options and the ability to add or replace arms to fit highly specific application needs.

Combination Anvil and Bench Vise from Palmgren Designed differently than conventional style vises, Palmgren’s combination Anvil and Bench Vise features a horn, step, a hardened face and hardy hole. It comes with replaceable serrated jaws, pipe jaws and a precision machined slide bar. The anvil vise is perfect for flattening or forming a wide range of metals. This Anvil Vise from Palmgren is carefully machined to provide an exceptionally smooth working surface as well as secure safe clamping Now observing its hundredth anniversary, Palmgren is a C.H. Hanson brand.

» For information, visit www.palmgren.com

The “Red Zone Rebel” - The Ultimate Forklift & Pedestrian Safety Warning Light Forklifts have been around for many decades and have seen upgrades in their technology, yet forklift safety and operational lighting has remained somewhat in the dark ages. All that is changed with the introduction of the most advanced Forklift & Pedestrian Safety Warning Light on the market. Panacea’s new Red Zone Rebel incorporates the most recent advancements in LED Digital Technology and Magnetic Components that will help protect Forklift Operators and any pedestrians in the busy warehouse environment. The Red Zone Rebel is easily installed on the Mast using the included high-performance industrial strength magnets.

» For more information, visit www.panaceaco.com

The Leading Edge in Modular Ergonomics Proline has been a leader in workbench manufacturers providing world class production furniture since 1978. The aesthetics of their workbenches combined with the heavy duty, independent four leg design and the almost infinite selection of modular accessories have made many of their models the workbench of choice for production areas. Proline believes your production areas should be as professional as your office environment. They can custom paint their products to an existing corporate color for a professional look throughout a company’s facility.

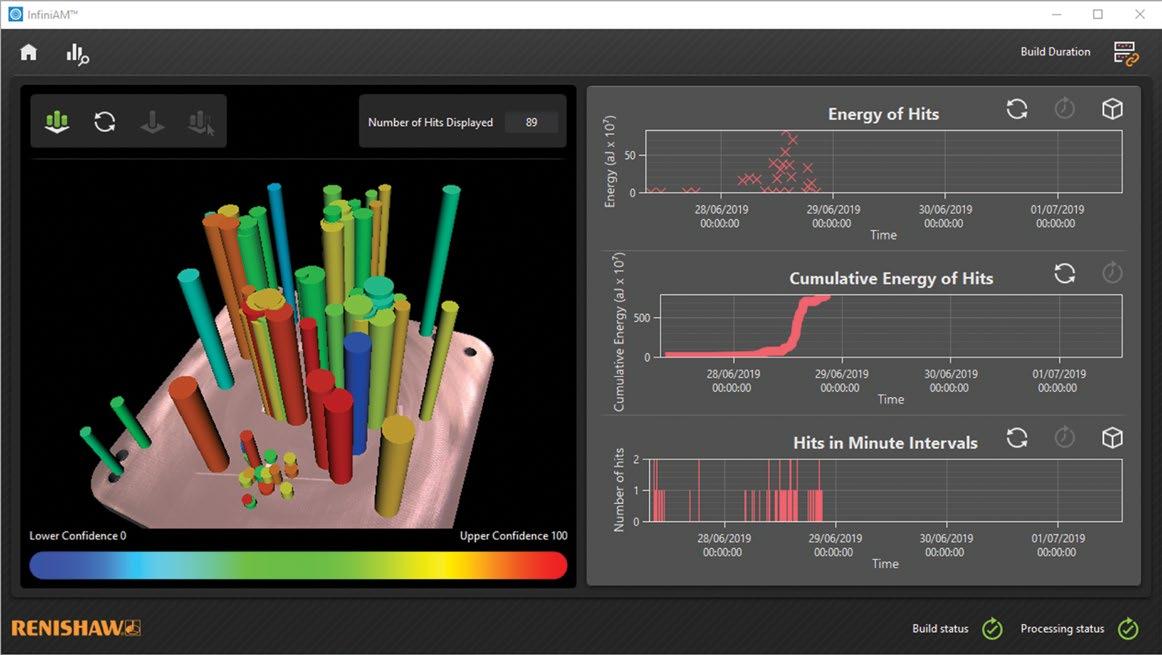

Renishaw Introduces New Software to Improve Additive Manufacturing (AM) Quality Renishaw recently launched its InfiniAM™ Sonic acoustic process monitoring software to complement its InfiniAM suite of additive manufacturing (AM) monitoring tools. InfiniAM Sonic enables engineers to detect acoustic events within the AM build chamber and turn this data into useful information about build quality. The software is the first of its kind in the AM industry. The InfiniAM Sonic package is installed into the RenAM 500Q system as a factory installed option and includes four acoustic energy sensors to detect vibration in the build. The sensors detect minute vibrations and collect the sound waves so that they can be heard, viewed and analyzed.

New FlyMarker ® mini STATION Tabletop Marking Unit The electromagnetic, 120-volt STATION is the newest addition to the FlyMarker ® mini series, which includes five generations of portable, battery-operated marking units. The all-in-one station

from Markator (Germany) features a capacitive touchscreen for ease of programming directly on the unit. Its large marking window (120 mm x 100 mm) and adjustable force settings deliver permanent dot peen marks on materials ranging from plastics to hardened steel (up to 63 HRC). The stronger force settings are designed to withstand surface treatments such as galvanizing and sandblasting.

» For more information, visit www.RocklinMFG.com

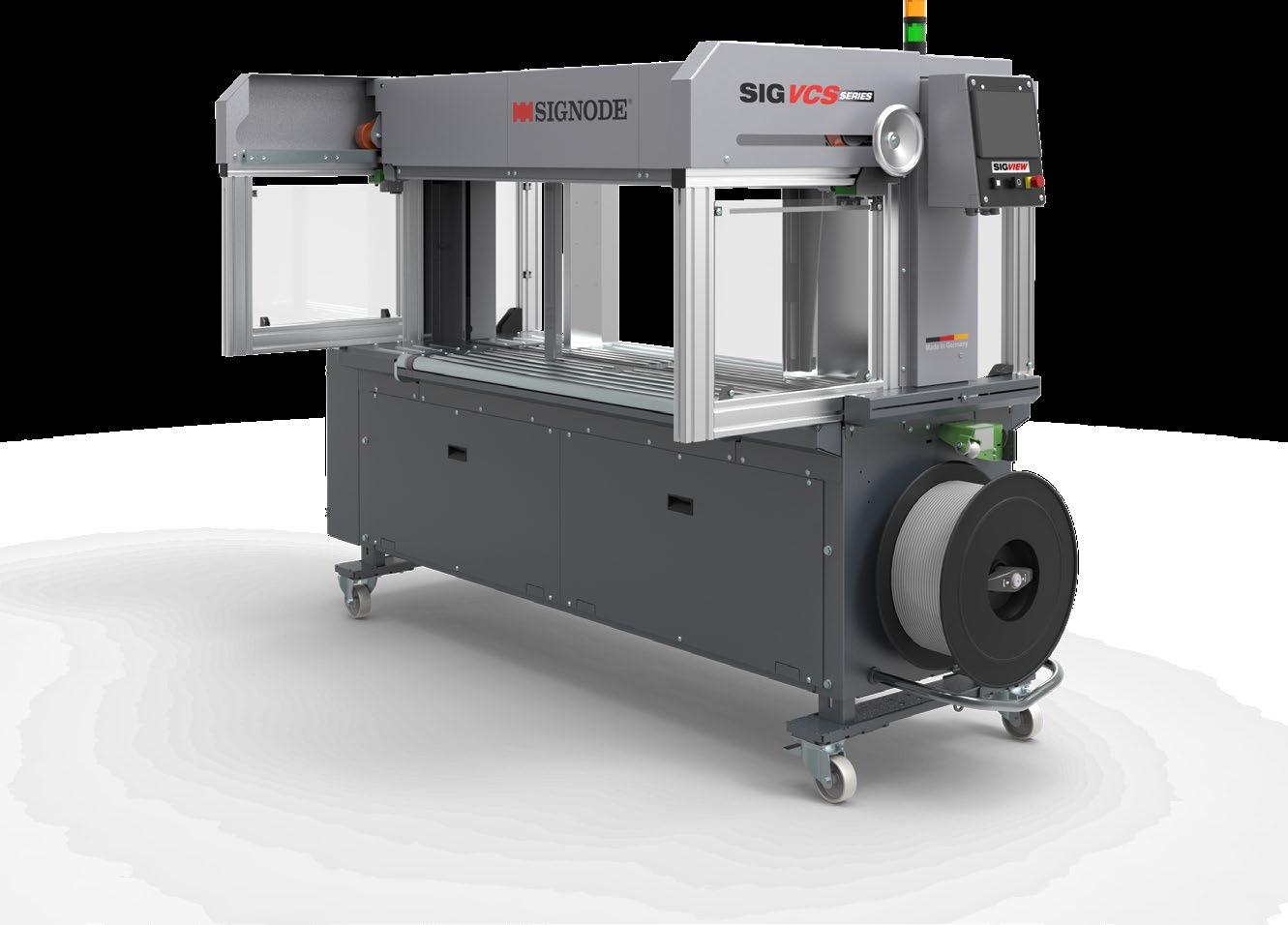

The SIG-VCS Automatic Corrugated Cross Strapping and Squaring Bundler The SIG-VCS is designed to strap standard folded boxes and provide high-speed bundling, squaring and strapping for variable package sizes and configurations. With precise bundle compression and consistent strap tension and placement, it produces up to 25 squared bundles per minute for single strap applications. The SIG-VCS has flexible features like adjustable strap tension up to 10 levels and a control panel that stores up to 2000 different bundle combinations, making it easy to integrate into any operation with ease and a promise of maximum productivity.

» For more information, visit www.signode.com

Tormach Introduces 1100MX And 770MX Servo-Driven CNC Mills, And Upgraded Pathpilot Cnc Control Console Tormach Inc. has introduced its latest CNC Mills, the 1100MX and 770MX, as well as an updated PathPilot Operator Console. The new MX series are servo-driven versions of the company’s best-selling two mills, the 1100M and 770M, which were introduced in 2018. The new MX series of machines feature an added encoder to the spindle for rigid tapping, a BT-30 spindle, and servos for the X, Y, and Z axes. The servos provide much faster performance with maximum speeds up to 10,000 rpm and feed rates as much as 2.5-3x faster than the M series machines.

Verti-Lift Enhances Safety, Ease, and Productivity Verti-Lift presents a complete line or Ergonomic Equipment for Elevated Work Heights. In the world of manufacturing and assembly, some oversized products require work to be done at an elevated height. Verti-Lift’s Double Scissor Lift & Tilt Tables allow operators the ergonomic flexibility to work at an elevated work height. Whether it’s an assembly cell, an automated line, or part of a manufacturing process, some oversized products require work to be done in the vertical position. The Verti-Lift’s Double Scissor Lift & Tilt Tables allow an operator to work from an elevated position and platform for greater ergonomic access to the product.

» For more information, visit www.verti-lift.com

SAFETY IS OUR BUSINESS

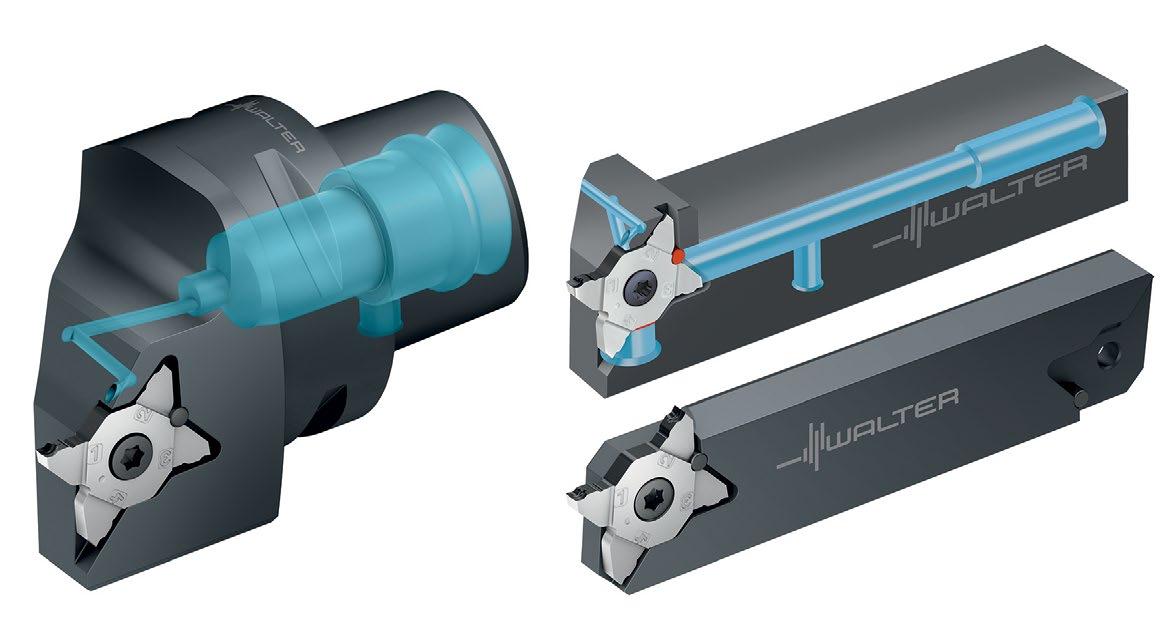

Walter expands its MX system with Walter Capto TM toolholders, opening a new range of applications Walter has added Walter Capto™ toolholders and insert widths to its Walter Cut MX grooving system. Capto toolholders feature enhanced rigidity and modularity, while the tapered polygonal shape handles both torsional and bending forces with ease. This interface can be used for lathes, and for turning/milling centers. With the new Walter Capto™ monoblock tools (C3–C6), the MX system can now also be used on machines with Capto interfaces. In addition, new parting blades are introduced to work with automatic lathes and multi-spindle machines. Walter has completed the range with new grooving inserts and toolholders for larger insert widths.

» For more information, visit www.walter-tools.com

Made in USA ASME B30.26 Compliant

H.E. 360° NE W

5:1 Design Factor

Special Configurations Available Upon Request 200% Proof Load Tested

LEARN MORE at www.adbhoistrings.com | 800.423.4425

Wildeck, Inc. to Showcase Suite of Access Products at MODEX 2020 Wildeck’s portfolio of access products includes stair crossovers, modular platforms, access ladders, pallet access gates, stairs, rolling ladders, work stands and aerospace/specialty products. Two products of especial interest to MODEX’s 2020 show attendees are Wildeck’s stair crossover products and Finger Gates. Wildeck’s crossover products improve access and mobility around material handling/automated systems (like conveyors). Wildeck’s Finger Gate is a durable steel gate that easy integrates into any facility and provides a strong, protective barrier at elevated work levels.

Follow us on facebook @americandrillbushing 5740 Hunt Road | Valdosta, GA 31606