10 minute read

PROCESS

Replace Manual Process, Protect Products, Cut Cost

Pipe, Valve and Fitting Distributor Eliminates Injuries with Automated TAB Wrapper Tornado Orbital Wrapper

Pipe, valve and fitting distributor City Pipe & Supply, Odessa, Texas, has eliminated cuts, scrapes and other reportable incidents that occurred in the packaging and shipping department by replacing its manual stretch-wrapping method with the automated TAB Wrapper Tornado orbital wrapping machine. Cutting workers' compensation claims to zero, the orbital wrapper features patent-pending technology that wraps plastic film 360 degrees around and under the pallet and its load while raised on a forklift to create a sturdy, unitized load in less than one minute, even when wrapping City Pipe & Supply's large, heavy, and oddly shaped products for the oil and gas industry.

The new wrapping system replaces the company's manual method, which required two workers to wrap the load by hand while raised on a forklift, passing the film roll back and forth and trying to keep the products in place without tearing the film, knocking the product off the pallet, or bumping their heads working under the pallet. “Nobody enjoyed doing this job, including me,” says Charlie Justice, vice president of City Pipe & Supply. “Now, everybody loves the TAB Wrapper Tornado and nobody wants to go back to wrapping by hand.” Justice purchased the TAB Wrapper Tornado model with an 80-inch wrapping ring for his busiest facility and has since purchased four more with 80” and 100” wrapping rings to automate the process in other locations. “The TAB Wrapper Tornado has

eliminated injuries and turned a dangerous job into one that our people actually enjoy doing,” says Justice. “I would recommend it to anyone as an upgrade from wrapping pallets by hand.”

Touch-Screen Controls with Built-In Training Guides Included as standard equipment at no extra charge, the touchscreen HMI features a clear, colorful, visual menu structure with built-in training guides for intuitively easy setup, operation and preventative maintenance. The video training guides present operating instructions on screen at the machine rather than in print, on DVD, or online for fast learning, superior retention and convenient review at any time. Setting the wrapping parameters based on the pallet load, replacing empty stretch-film rolls, and understanding the designed-in safety features are among the instructional videos included.

Developed to enable entry-level workers to safely manage the wrapping function, the new touch-screen control panel is included on all three TAB Wrapper Tornado Perfect Storm models and on custom models.

conveyors at the infeed with a proprietary sensor array that recognizes the presence of a pallet load to be wrapped. The TAB Wrapper Tornado Perfect Storm automatically feeds the pallet load from the accumulation zone onto the infeed conveyor then into the center ring for wrapping and to discharge in a continuous process, automatically adjusting the wrapping to the dimensions of the pallet load. With multiple accumulation zone extensions available, the orbital wrapping system enables lift truck operators to unload and stage multiple pallet loads for wrapping then tend to other tasks without waiting for loads in process to be wrapped and without stopping to run the system.

Introducing Portable Machines At Modex from March 9-12, 2020 in Atlanta, Ga., TAB Industries plans to introduce their portable TAB Wrapper Tornado orbital wrapping machines that may be moved safely without requiring a lift truck. Featuring durable casters and mounting brackets, the optional portability package was developed to ease movement around warehouses, production lines, shipping departments, and other locations. Workers simply turn a crank to lower the casters onto the floor and raise the machine off the floor to allow smooth movement from one location to another. Once in place, the casters may be raised in seconds and the machine lowered onto the floor, ready to plug in and operate.

Offered in addition to the built-in fork tubes included as standard that allow movement by forklift, the portable TAB Wrapper Tornado stretch-wrappers are ideal for packaging and material handling managers interested in automating the wrapping process at multiple assembly lines and other locations without investing in multiple machines. By moving the machine to the product, the portability package reduces product handling and minimizes the risk of damage to products in process.

Visit TAB Industries at Modex Booth #2124.

For a free brochure or more information, contact:

TAB INDUSTRIES, LLC

2525 N. 12th Street, Reading PA 19605 Phone: 610-921-0012 info@tabwrapper.com www.tabwrapper.com.

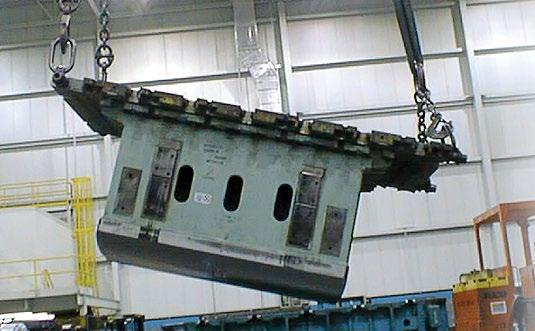

HOIST RINGS ACTEK

200% PROOF LOAD TESTED EACH RING HAS SERIAL NUMBERS ORDERS SHIPPED SAME DAY RATED LOAD 400 LBS - 250,000 LBS

P i v o t s 1 8 0 °

Forged Street Plate™ Swivel Hoist Rings Side Load Hoist Rings Hoist Ring Kits

S w i v e l s 3 6 0 °

Drop Forged Hoist Rings Mold Handler™ Swivel & Pivot Hoist Rings

Forged Swivel Hoist Rings

Round Base Swivel & Pivot Hoist Rings

ISO 9001

ACTEKMFG.COM 800-752-7229 | SALES@ACTEKMFG.COM

NEW ALUMINUM HOUSING TOOLS

Dynabrade, Inc. is proud to introduce a new line of Aluminum Housing Air Tools. Newly refined Die Grinders, Disc Sanders and Drills are manufactured to ensure a lightweight tool. Excellent for overhead or extended use. Each tool is manufactured with the rigidity and strength of a housing machined from a single piece of aluminum bar stock.

STRAIGHT LINE DIE GRINDERS: Available in 25,000 and 30,000 RPM: These rear exhaust tools are widely used in aerospace manufacturing facilities for deburring and material removal applications. The straight-line design is ideal for applications in confined areas.

RIGHT ANGLE DIE GRINDERS: Available in 12,000 and 20,000 RPM: These rear exhaust tools provide greater torque under load when aggressive material removal is necessary. The compact size improves maneuverability and the precision gears provide enhanced durability and performance.

PENCIL DIE GRINDER: Utilized in grinding and deburring applications where a high degree of precision is needed. At 100,000 RPM, the tool features low run out for smooth operations. The high RPM creates chatter free cutting and the top-quality bearings provide long tool life.

These new Dynabrade Aluminum Housing Air Tools are manufactured in the USA.

STEEL HOUSING DIE GRINDERS

Dynabrade’s line of Steel Housing Die Grinders feature high quality steel housings, ideal for heavy-duty applications where durability is required. This line of Die Grinders is available with either .5 hp or .7 hp Air Motors. Each tool features a rubber grip housing to insulate the operator from vibration and cold air transmission. Each tool also comes standard with a 1/4" collet, but can easily be changed to a 3/8" or 1/8" collet with available collet inserts. The tools are available in either 20,000 RPM or 24,000 RPM in front and rear exhaust designs. Standard and extension models are also offered. Rear exhaust models can also accept overhose assemblies for reduced sound levels and/or exhaust redirection. A 20,000 RPM extension model is also available with a 3/8"-24 thread; ideal for use with Cone/Plug Grinding Wheels. These tools are made for heavy-duty applications. Examples of target markets would be Shipyards, Foundries, Steel Fabrication and Welding Operations. Made in the U.S.A.

.4 HP DIE GRINDERS

Dynabrade’s line of .4 Hp Die Grinders are ideal for precision grinding, deburring and blending on a wide variety of materials. These air tools, compact and lightweight, are available in RPM ratings from 950 - 30,000 and feature a composite overmold housing, which reduces tool vibration and cold air transmission to the operator. Additionally, each tool includes a muffler, which dramatically reduces sound levels in the workplace. The .4 Hp Die Grinder tools series is available in either straight-line, right angle or 7° offset handle designs. Choose a specific style of Die Grinder for the type of job you are doing. Additionally, the tools are available in geared or gearless models. Geared Die Grinders have higher torque levels while gearless tools offer reduced maintenance and downtime. Front and Rear Exhaust models are also offered. The .4 Hp Die Grinder Series powers optional carbide burrs and mounted points for deburring, grinding, etching, cleaning and more. Additionally, different size collets and collet inserts are also offered. Made in the U.S.A.

EXTENSION DIE GRINDERS

Dynabrade’s line of .4 Hp Extension Die Grinders allow for efficient work within long pipes, castings, and other places where an extended reach is needed. The .4 Horsepower straightline air tools are available in either a front or rear exhaust air motor and run at 25,000 RPM. The new tools are available in two different shaft lengths; 3" Extension Models or 6" Extension Models. These .4 Hp Extension Die Grinders allow the operator to extend into work pieces and reach previously inaccessible areas. Each .4 Hp Extension Die Grinder features a safety-lock lever to prevent accidental start-up of the tool. Also, the tools run as low as 72 dB(A) to further reduce sound in the workplace. The .4 Hp Extension Die Grinder powers optional carbide burrs and mounted points for deburring, grinding, etching, cleaning and more. Made in the U.S.A.

PENCIL GRINDERS

Dynabrade’s line of Pencil Grinders is ideal for precision deburring and metal removal on investment castings and other materials. It is also excellent for use on toolings, dies, molds, production parts and much more. The Pencil Grinder features a lightweight, ergonomically designed, vibration-free handle, ideal for reducing operator fatigue. Available in speeds of 65,000, 50,000 and 35,000 RPM, the high-speed air motor is controlled with a patented governor, providing constant speed under load. The efficient air turbine design uses a maximum of only 8 SCFM at 90 PSI, 5 SCFM at idle. The Pencil Grinder has a precision, high tolerance, low run-out collet. Run-out is a true .002 @ 1" from face. An easy change collet insert is available in three sizes; 1/8", 3/32" and 3mm. Additionally, the tool features a guarded collet with tactile warning to keep fingers close to the workpiece and away from the collet and burr. The tool also features a super flexible air hose for maximum agility. The tool is ideal for use on Metal, Plastic, Composites, Precious Metals, Titanium, Fiberglass, Glass, Precious Stones and various Non-Ferrous Metals. Made in the U.S.A.

VARIABLE SPEED PENCIL GRINDER

Dynabrade’s Variable Speed Pencil Grinder allows you to easily adjust the speed from 0 – 60,000 RPM to suit a variety of grinding applications. This Pencil Grinder offers precision deburring, finishing and engraving with an easy, adjustable speed flow control. Simply set your speed with the touch of a dial. The tool remains at the desired speed until the operator changes it. The tool features a high quality air-line, an overhose assembly that helps direct air away from the operator, and an Ergonomic Tactile Grip for a non-slip, comfortable operation. The tool also has an easy one-touch push button for easy on/off operation. A convenient Spindle Lock has a “thru-hole” for quick accessory change. No need to struggle with two wrenches. This tool is ideal for use with Turbine Blade Manufacturers, Tool and Die Shops, Machine Shops, Investment Castings, Jewelry, Medical Implants and various Composites Markets. The tool includes a 3mm collet and accepts Carbide Burrs and Mounted Points. Made in the U.S.A.

No obligation demonstrations on these and any product in the Dynabrade line are available. Please call 1 - 800 - 828 - 7333 or visit www.dynabrade.com for details.