Mattsons remember, honor daughter with business

BY RAE LANZRATH STAFF WRITER

KENSINGTON —

What is in a name? Whether a farm, a person or a pet, a name is typically the first piece of information people know. For the crew at Taylor’s Market, the name is more than words.

In April 2021, Taylor Mattson died in a car accident at 16 years old. Nearly four years after her death, her memory lives on through her family, their farm and their business — Taylor’s Market.

“She would have loved this; she was all about family and doing things as a unit,” said Kerri, Taylor’s

mom. “It’s a great way to honor her.”

Taylor’s parents, Matt and Kerri, and brother, Zach, and Zach’s wife, Jenna, own and operate Taylor’s Market. They sell beef, lamb, pork and goat meat as well as goat milk and pet food products through their online store.

The Mattsons opened Taylor’s Market in June 2024. Their goal was to create a business that would provide locally raised meat in a user-friendly way. They said they

focus on selling in smaller amounts, using the internet and becoming a resource for their customers.

lived hers, Jenna said.

Prior to opening, something was missing from the business: a name. Zach and Jenna had the idea of using the business as an opportunity to memorialize Taylor.

“They came up with the name, and it just felt right,” Kerri said.

While the name is the family’s way of remembering Taylor, it also serves as their daily reminder to live their lives the way Taylor

“She was just one of those people that anyone could get along with,” Jenna said. “She had passion, and she loved what she did.”

Once the business officially opened, the family began selling small cuts of meat rather than traditional quarters or halves.

“In today’s economy, most people can’t afford buying a quarter or half of

Mattson page 2

Saturday, February 15, 2025

Published by

Star Publications

Copyright 2024

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6577

Fax: 320-352-5647

NEWS STAFF

Mark Klaphake, Editor

Mark.k@dairystar.com

Rae Lanzrath, Assistant Editor raeanna.l@star-pub.com

Tiffany Klaphake, Assistant Editor tiffany.k@dairystar.com

Emily Breth, Writer emily.b@star-pub.com

Sara Hoppe, Copy Editor sarastarpub@gmail.com

Carol Moorman, Writer carol@melrosebeacon.com

Natasha Barber, Writer natasha@saukherald.com

Ben Sonnek, Writer ben.s@saukherald.com

Hans Lammeman, Writer hans.l@star-pub.com

Story ideas send to: raeanna.l@star-pub.com

SALES STAFF

Robin Brunette, 320-293-5911 robin@saukherald.com

Missy Traeger, 320-291-9899

missy@saukherald.com

Tim Vos, 320-845-2700 tim@albanyenterprise.com

Mike Schafer, 320-894-7825

mike.s@dairystar.com

Neil Maidl, 320-292-4454

neil.m@star-pub.com

Jaime Ostendorf, 320-309-1988

jaime@star-pub.com

Bob Leukam, 320-260-1248 bob.l@star-pub.com

PRODUCTION STAFF

Amanda Thooft

Nancy Powell

Maddy Peterson

Cheyenne Middendorf

Karen Knoblach

Annika Gunderson

Nadiia Griepentrog

Deadlines: Country Acres will be published the first Saturdays of April, May, June, September, October and November, and the third Saturday of every month. Deadline for news and advertising is the Friday a week before publication.

ISSN: Print 2834-6440 Online 2834-6459

beef,” Kerri said. “We understand that the market has changed so much over the years, and it’s just not feasible anymore.”

Customers can purchase meat from the Barn2Door website, choosing pre-made bundles or customizing their order. They also can choose if they would like their products delivered, or they can set up a pickup time.

“More people are wanting to get homegrown products instead of going to the grocery store,” Kerri said.

showing dairy cattle.

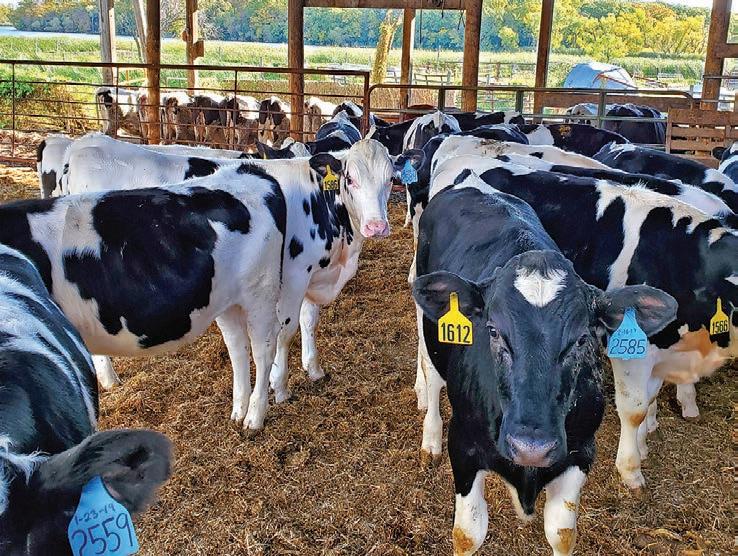

Kerri wears many hats, from being the farm’s bookkeeper to serving on the Pope County Farm Bureau Board. Rodger, Matt and Austin all work on the farm full time, where they grow around 2,200 acres of corn, soybeans, wheat and alfalfa and raise Holstein steers. Zach works for Jenniges Meat Processing in Brooten.

farm began before Rodger was born, and Matt grew up there as well. Along with the dairy, the Mattson family has raised cattle for custom-exempt butchering for more than 40 years. They sold the beef in quarters, halves or as whole animals.

“He’s able to butcher our animals, and they’re USDA (U.S. Department of Agriculture) inspected (at Jenniges) so we can sell it,” Jenna said.

“It works out really well.” Zach, Jenna and their daughter, Paige, raise sheep, goats and pigs at their farm down the road from Matt and Kerri. When she is not at the farm, Jenna works as a veterinary technician at H&H Veterinary Service in Benson. Jenna and Zach also make the deliveries and run the social media for Taylor’s Market.

“We’re the go, go, go in the business, and Matt and Kerri are the anchors,” Jenna said. “They slow us down and bring us back to reality. Zach and I are a bit more impulsive.”

Mattson page 3

While Taylor’s Market is relatively new for the family, farming is not. Matt’s parents, Rodger and Patty, ran a dairy farm until 2016. The

Publications bli ti “The newspaper of today is the history of tomorrow.”

The Mattson children — Zach, Austin and Taylor — grew up on the family farm, and all three kids inherited a passion for agriculture and farming from their parents. The boys both work in the industry, and Taylor participated in 4-H

software platform, the CropX soil sensor is part of the most agronomic farm management solution on the market today.

•Fully enclosed all-in-one soil sensing to cloud solution - built-in telemetry and power source eliminate the need for an extra device.

•The patent-pending spiral design the accuracy of soil data readings by preventing preferential water flow.

•A CropX sensor can be installed by anyone quickly - made even easier with a new tapered design, smaller spirals, and built-in installation rod slots.

CropX soil sensor data collection

Intervals of data measurement and transmission to the CropX cloud can be remotely configured and adjusted to each crop’s unique needs. The data is geo-tagged based on GPS coordinates creating geospatial time series for all measured data.

Moisture: Measurement of volumetric water content (VWC) values via ADR sensors. Moisture values are converted from electric impedance to VWC levels using a proprietary self-calibration method. Moisture values have an accuracy of +/- 0.5% across a range of 0-60% VWC.

Temperatures: Temperatures are measured with an accuracy of +/- 0.5°C (max) and an operating range of -10°C to +70°C. Each unit also measures the internal temperature of the unit above ground, which can help with increasing the precision of weather data.

Electric Conductivity (EC): Measurement in decisiemens/m, with an operating range of 0-5 decisiemens/m (bulk), representing the soil salinity level, which can be used to manage

BY BEN SONNEK STAFF WRITER

STARBUCK — Cen-

tral Minnesotans looking to source their in-home morning jolt may find an option closer to home than they might expect. For over five years, Liz and Mike Beaumia have been roasting small-batch orders of coffee beans at their farm near Starbuck and selling them through their business, Beau Coffee Company, which they run with their daughter, Mary (Beaumia) Jackson.

“Everyone deserves a good cup of coffee,” Liz said.

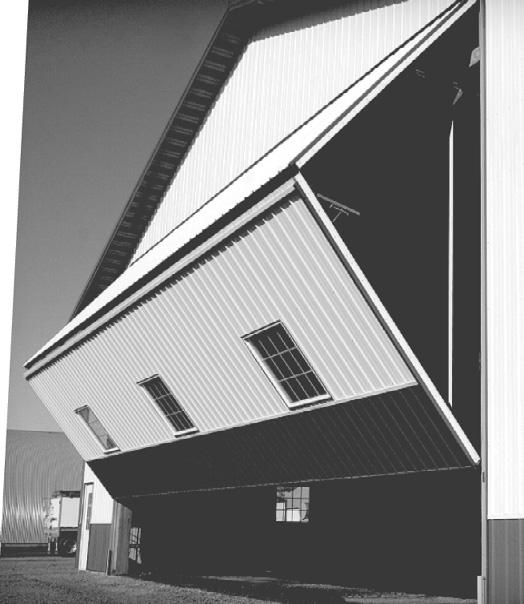

The Beaumia farm dates to 1922,

when Liz’s grandparents, William and Ida Anderson, moved to Minnesota from a Montana homestead to start farming and milking cows. The building where the Beaumias roast their coffee used to be a hay loft, initially refurbished so it could be used for storage.

Liz and Mike raised six children. Their daughter, Mary, attended higher education in Ely and worked for a couple of coffee shops there, one of which had a roastery. When she returned to the Starbuck area, she managed a mobile coffee kiosk.

“She fell in love with

everything coffee,” Liz said. “She would come home and talk to us about wanting to start a coffee business.”

Mike was about to retire after 20-plus years of working for 3M, and he did not plan on being idle afterward. He and Liz did not know much about coffee — outside of how much they enjoyed drinking it — but they looked into Mary’s idea.

“One guy told us, ‘If nothing else, you get to drink some really good coffee,’” Mike said.

The Beaumias began researching and taking classes at places such as

Roastery 7 in Brooklyn Center. They also did coffee tastings, finding out about the beverage’s variety of flavors.

“Wine … is still going to taste like wine,” Mike said.

Beaumia page 6

“Coffee, you can’t believe how many flavors there are.

… Even if the coffee is being grown in the same region, it varies from year to year.”

Liz, Mike and Mary kicked off Beau Coffee Company in 2019, making their first sale late in the year. Soon, the coffee kiosk owners sold them their kiosk, which the Beaumias continue to use today.

It was not long after Beau Coffee Company’s founding that it had to overcome its first major hurdle: 2020 and the novel coronavirus pandemic.

“It was rough for sure because there was just so

everything more difficult, but we did run the drive-up kiosk during the summer (and) did bean sales. It was such an uncertain time, but we got through it.”

Mary married in late 2021 and moved away from the area, but she continues to handle the business website, beaucoffeeco.com, and other online tools; Mike and Liz often run new ideas past her as well.

The Beaumias initially promoted Beau Coffee Company through social media and vendor shows, as well as simply getting out and talking to people. From there, they found a demand for what they had to sell. Customers typically place individual orders directly from them.

“It seems like a lot of places reached out to us,” Liz said. “The Neon Loon coffee shop in Starbuck — before they opened, (the owner) came to the kiosk and loved our coffee. … We started supplying

her with coffee. We weren’t exclusive suppliers, but she uses our coffee on a regular basis and sells our bags of coffee.”

If the orders are placed locally — including Starbuck, Glenwood, Morris, Lowry, Ashby and Alexandria — Liz and Mike also personally deliver their coffee beans, which sometimes comes as a surprise to new customers.

The Beau Coffee Company kiosk is usually out and about during warmer months, transported to special events to sell coffee and espresso drinks like lattes and mochas as well as cold brew and refreshers. The Beaumias have tried operating it in the winter, but that has not worked very well. This year, they plan to bring it to the Alexandria Shooting Park for the June 9-17 Minnesota Trap Shooting Championship and possibly Art in the Park in Alexandria.

The Beaumias have many customers who order regularly throughout the year. Their busiest times are normally in the summer, when the kiosk is active, and during the

Beaumia page 9

At our house, we like to laugh, so we listen to a lot of video clips of comedians and other internet personalities on social media. One of our favorite comedians is Jeff Foxworthy. He is known for his clean sense of humor and redneck jokes.

The other day, shortly after Jason and I were done listening to one of his “You Might be a Redneck” clips, I started thinking that there are a lot of funny ways to determine if you are a farmer or not.

Therefore, I present “You Might be a Farmer …”

farming

By Tiffany Klaphake

— If you have ever used bale twine as a belt for your pants.

— If you own more hats than shirts. If half of your clothing came free from businesses your family works with.

— If you learned to drive a tractor before you learned to drive a car.

— If you check the weather forecast several times a day.

— If you make yourself feel better about rain or snow because it will benefit the crops.

— If the main reason you go for a run is because you hear the cows are out.

— If you get excited about a rainy day because it is the only day you have off.

— If having dirt, grease or poop on your clothes is normal.

— If you still have remnants of straw in the back of the family car from the county fair last year.

— If you talk about farming when out with friends.

— If you talk about farming at family gatherings.

— If you talk about farming at church.

— If you talk about farming at weddings.

— If your truck or tractor doubles as your office.

— If you are more distracted by the neighbor’s crops growing than your phone while driving.

— If a family vacation or a day off consists of attending a farm show, county fair or state fair

— If you can name the livestock species of a farm by the smell of the manure.

— If your wardrobe consists of good clothes and barn clothes.

— If family get-togethers are scheduled around chore time.

Farming is the one occupation I know where it is not weird to talk about your job all the time. We could be at a high school sporting event, church or Christmas Day celebration and all the farmers are talking about farming. It might just be that here in central Minnesota because this area is full of farmers, and most of our neighbors, my family and Jason’s family are farmers. But these are just a few of the things I have noticed about farmers that most others would find odd.

Growing up, I assumed most of these habits were normal, as my family members were farmers and many of our friends and family were farmers. As I got out on my own, I realized many of these habits were customary to just the farming community. After being married to a farmer, I have noticed even more of these habits as I have gotten to know more and more farmers.

Jokes aside, farming can be a stressful occupation, and it is important to laugh and remember what is important at the end of the day. Whether your cows get out at midnight, the kids bust a bunch of bales while playing in the hayloft or they forget to turn off the nozzle on the bulk tank when trying to get milk to feed the cats, it might not seem funny at the time, but looking back, it brings a smile to your face.

It might be odd when you think about it, but it also shows the level of dedication and passion farmers have. It truly is a lifestyle and not just a career choice. And I, for one, am very grateful for their dedication.

become friends, and we try to do our best for them.”

holidays, when people are having family gatherings and looking for unique gifts.

Beau Coffee Company gets most of its beans from Café Imports out of the Twin Cities, sourcing beans from around the world. The Beaumias prefer to air-roast their beans, which they have found gives a more consistent roast. Even so, no two roasts are the same.

“When you change crops, it can be from the same origin, but it can roast a little different,” Mike said. “We do a lot of testing as far as flavor samples; we get samples, roast them and pick not just the ones we like but the ones we think customers will like.”

The Beaumia farm’s refurbished loft keeps the temperature stable for better roasts.

“We really baby our beans,” Liz said.

The beans are bagged after they are roasted and cooled. The Beaumias’ goal is to roast beans as close to the time of sale as possible, so the roast is fresh. Because of this, they mostly operate on a roast-to-order basis, and they try to have the process done within 48 hours of delivery.

If customers have suggestions for how their orders are roasted, Mike and Liz are glad to hear them.

“We want to take care of our customers,” Liz said. “We’ve enjoyed the people we’ve gotten to know; they

So far, most of Beau Coffee Company’s customers have not wanted bitter coffees, and one of the most consistent pieces of feedback the Beaumias have received is that their beans make smooth coffee.

“That’s what we want, too,” Liz said. “(Mike) is careful not to over-roast coffees. … When people compliment us, it means a lot.”

The coffee also retains its flavor better after it cools down.

“If I’m out traveling and buy a coffee, it might taste good at first, but as it cools down, I’m not liking the flavor of it,” Liz said. “That’s something else people have mentioned — that, as (our coffee) cools down, it’s still good.”

Having been roasting coffee for over five years, the Beaumias have been amazed not only by the sheer variety of coffee that is out there but also by the supportiveness of their customers, with clients hailing from North and South Dakota, Wisconsin, Utah, Missouri, California, North Carolina, Mississippi, Florida and Texas among others.

“(With) some people, we don’t have any idea how they discovered us,” Liz said.

No matter where the customers are from, the Beaumias are more than willing to seek out new coffee types and give them an experience they would otherwise miss.

“We have really good customers and really good people,” Mike said. “They appreciate what we’re doing.”

BY RAE LANZRATH STAFF WRITER

Danielle Douvier is a natural-born educator. She spent seven years working as a special education teacher for the Minnewaska Area School District. This school year, she has taken a break from teaching in a traditional classroom setting to teach from Morning View Acres, a

farm she operates with her husband.

“I wanted to explore more options with the farm,” Danielle said.

Danielle has been teaching classes for both adults and children on a variety of topics, including how to make sourdough bread, herbal teas or soap. She also promotes the concepts of small-scale agriculture and self-sufficiency.

She and her husband, Travis, live on 33 acres near Glenwood with their three children, Lucian, Winston and Iris. The family raises livestock, grows a large percentage of their food and makes an array of different products.

Travis and Danielle began farming in 2016 because they wanted to be self-sufficient, teach their children the importance of agriculture and provide safe and healthy

food for their family.

Travis grew up on a dairy farm near Brooten and wanted their children to grow up in a similar atmosphere.

“The hardworking values that you’re taught on a farm can’t be learned anywhere else,” Travis said.

Danielle did not grow up on a farm but spent a large part of her young adulthood traveling and working on farms on the West Coast and in Latin America. Danielle said she found inspiration and healing in the sensory-rich experiences of farm life and growing and preparing food.

“We rely so heavily on buying what we need (that) we often miss out on the benefits of doing it for ourselves,” Danielle said.

Since then, Danielle has

Douvier page 12

Great Plains keeps raising the bar when it comes to seeding performance in a box drill. The legendary BD7600 features an industry-leading box capacity, a durable, field-tested design, and the innovative Great Plains Metering System for greater accuracy across all seed types, from traditional to cover crops.

at Morning View Acres near Glenwood.

Douvier teaches a variety of courses to adults and children.

(Below) Eggs are gathered Jan. 20 at Morning View Acres near Glenwood. The farm has around 30 chickens.

She said her goal is to inspire others to live simply, develop a relationship with the earth, and experience the satisfaction of creating for themselves. When Danielle is not teaching classes, she is busy being a mom.

spent many years practicing self-sufficiency skills. As she learned, she realized she could use her educational background to help others.

“Our kids understand where their food comes from,” Danielle said. “They witness it firsthand, and they help me plant and harvest.”

One of the key values Travis and Danielle try to instill in their children is the importance of utilization and not being wasteful. The family only raises as many animals as their land can support. They use the vegetables they need and share or sell the rest. Danielle saves seeds from vegetables so she can plant them the next year and uses fat from her cattle to make tallow products.

“Out of respect, I don’t want to throw away things that could be used,” Danielle said.

She teaches classes for adults focused on sourdough bread, seed saving, soapmaking, plant propagation, herbal tea preparation and herbal medicine making. She also runs Wild Child Earth Camp, a children’s camp started in 2014 with Melrose Community Education. The camp offers a combination of nature education and traditional skills, like how to start a fire by hand, identify edible plants and harvest clay from the subsoil to build with cob, a mixture of clay, sand, straw and water.

The family has 14 beef cattle, about 30 chickens, and, this year, two sheep. The family alternates the years they raise sheep and pigs so

Douvier page 13

from page 12

they have a variety of meat available. They also gather eggs from their chickens, incubating some to refresh their flock and butchering some for meat.

“We’re not trying to push out the (highest number) of animals,” Travis said. “We raise enough for ourselves, and we sell the excess.”

They sell their heifer calves at weaning and keep steers for feeder cattle. While most are Highland cattle, some are crossed with British Whites or Holsteins.

their animals. They also have a high-tunnel greenhouse, a garden, many fruit trees and berry bushes.

“They don’t have fancy genetics,” Danielle said.

“But they do well on the grass-fed diet, and they’re very docile around the kids, which is most important.”

The Douviers grow hay on about 11 acres to feed

“I try to diversify what is grown on the land as much as possible,” Danielle said. The family grows many traditional vegetables along with perennial crops like asparagus, hazelnuts, gooseberries and Jerusalem artichokes, also called sunchokes. Danielle uses the produce in many ways, from grinding corn for flour to hot peppers canned to make hot sauce.

Another lesson the couple has taught their children is to be independent and helpful on the farm.

“They just jump in and help, and we don’t have to tell them,” Travis said. “They have the ability to see that something needs doing, and they do it.”

Danielle’s journey began with growing produce and has now developed into

teaching her kids and others around her. Both Danielle and Travis hope to continue to share lessons of self-sufficiency with youth education groups, families and anyone else ready to get their hands dirty.

“When I began doing all of this, I realized it’s really not that difficult,” Danielle said. “I enjoy being able to show others that they can do it, too.”

BY RAE LANZRATH STAFF WRITER

BELGRADE — Smaller communities sometimes lack the opportunities presented in larger ones. Residents of rural towns in central Minnesota may be lucky to have a grocery store, a few restaurants or a strip mall.

Dave and Jessica Reigstad wanted to change this for their community and recently built and opened Smilin’ D Arena & Events, a horse-riding arena and event center between Belgrade and New London.

The arena is 100 feet by 200 feet, with 22-foot side walls. The riding area itself is 90 feet by 180 feet.

The riding area is kept at a lower temperature than the rest of the arena because cooler weather is better for both horses and cattle, Dave said. Jessica wanted to make sure there

were amenities, like a place for riders to warm up and for people watching to be comfortable. So, a fireplace was added near the bar.

The first floor of the building contains a bar, heated bathrooms, the fireplace and seating for attendees. The second floor contains pop-up shops for local vendors, a second smaller bar, announcer booths and a 360 degree walkway.

“We have a few local shops that have items for sale so people can shop in between events,” Dave said.

There is a large, four-sided TV screen above the riding area and chutes for cattle.

The arena is situated on 7.5 acres, with a large parking area to accommodate horse trailers and trucks. There is an unloading area for cattle to be ushered into the building through a large garage door, which makes it easy for both the handlers and the animals.

Construction on the arena started in January 2024, and the first event was held in September 2024.

Reigstad page 16

“It was originally going to just be a shell of a building for our family to ride in,” said Dave, who also owns a construction company. “It was 50 degrees in January with 35 guys looking for work, so we decided to insulate it. Then we added the bar, and it just started happening.”

In the few short months the arena has been open, the Reigstads have hosted around 40 events, which typically center around horses. Ranch rodeos, barrel races, cattle sorting, riding clinics and draft horse pulls are just a few. Upcoming events include a reining practice, a kid’s rodeo, more riding clinics and several ranch rodeos.

“We are always looking for differ-

ent events,” Dave said.

Horse events are not the only possibility for the arena. Pit bike races also have been a success, with more happening in the future. There also was a concert scheduled in January.

“It’s just grown really rapidly,” Dave said.

While Smilin’ D Arena & Events may be new, the Reigstads have been in the horse industry for nearly 20 years.

Dave and Jessica have four children, and their son, Brady, was obsessed with horses when he was little, Dave said. For Brady’s second birthday, he was given a saddle and boots.

“Jessica said one day, ‘We’ve got to get this boy to the country,’” Dave said.

Reigstad page 17

Competitors ride horses Jan.17 at Smilin’ D Arena & Events near Belgrade. Nearly 40 events have been held in the arena since it opened.

Shortly after, the family moved to a property in rural Kandiyohi County and purchased a horse. That was in 2006.

“We bought our first horse, then our second, then our third, and then we built an arena,” Dave said.

The Reigstad’s kids were involved in various school activities, and they strayed away from horses for a few years. The youngest child, Grayce, is now a senior in high school, and the couple

decided to get back into the industry.

“She enjoys it, too,” Jessica said. “So, we just have gotten back into it.”

Prior to Smilin’ D Arena & Events opening, it has been over 30 years since the New London area has had a rodeo arena. In the 1980s and 1990s, there was an arena not far from where Smilin’ D Arena & Events is located that held outdoor rodeo events, Dave said.

By opening Smilin’ D Arena & Events, the Reigstads have provided a facility for local riders to utilize and compete.

“This is horse country out here, and there wasn’t anywhere like this,” Dave said.

BY RAE LANZRATH | STAFF WRITER

SPICER — Since 1986, many things have changed. But one that has not is Dale Hegstrom’s passion for gunsmithing.

Hegstrom has been a gunsmith for nearly 40 years. From building custom rifles to repairs to inventing new equipment, Hegstrom has created a booming business in his hometown — Little Crow Gunworks. He grew up in the New London-Spicer area, and after traveling for 20 years, returned home in 2006.

Little Crow Gunworks has been open since 2007, providing customers with a variety of products and services.

Over the years, Hegstrom has developed several pieces of equipment and tools that are now sold around the world. One of his many creations is the World’s Finest Trimmer, or the WFT, which is used to trim down rifle casings.

“It’s used for reloading cartridges,” Hegstrom said. “You have to trim them back because they expand from firing.”

The ammunition used in rifles are brass casings, with the bullet inside the casing. When the gun is fired, the casing falls next to the shooter and the bullet is shot out at the end of the gun. For years, people have collected the casings after they have been fired and reloaded them.

Prior to the WFT, people had to manually trim down the casings. Now, they can simply adjust the trimmer to the size they need and attach it to a drill.

“It works like a pencil sharpener,” Hegstrom said. “You feed the casing into it, and it shaves it down.”

Little Crow Gunworks produces trimmers for many different caliber rifles and sells them online across the U.S. and internationally. Hegstrom’s trimmers also are available through big-name stores like Scheels and Amazon.

Hegstrom page 20

“When I came up with it, I wasn’t even thinking about manufacturing it,” Hegstrom said. “We started making them and put them online, and it just took off.”

The Little Crow Gunworks website was created as an avenue to sell more trimmers. Since they had an online store already, Hegstrom started including some of his other inventions, too.

“There were tools that I had designed that I was using in the shop, and I just threw them on there to see if they’d sell,” Hegstrom said.

The Brass Annealing Mandrel, or the BAM, is another tool that Hegstrom sells online. His son, Robert, works in the store and was the motivation behind the manufacture of the products.

“I was using them

for other things in the shop, and we started making them so Robert could learn how to run the lathe,” Hegstrom said.

The BAM is a small tool used to heat casings during the reloading process. Brass annealing is a practice that heats the casing to prevent cracking and improve the consistency of the casing. The BAM attaches to a drill and holds the casing in place while it is heated with a torch, making the process safer and easier.

Hegstrom also has created a number of tools that aid in the assembly of automatic rifles. Kits sold online allow customers to build their own automatic rifles and customize them as they want. The tools that Hegstrom sells help customers during the building process.

“You have to as-

semble all the parts, so I just came up with tools to make that easier,” Hegstrom said.

Another one of the tools Hegstrom invented is a barrel wrench. The wrench is used to take barrels off guns, making it much easier for people to switch barrels or clean theirs.

“No one else made a tool that worked well, so we figured it out,” Hegstrom said.

While the development and manufacturing of his inventions occupy around 80% of his time, Hegstrom said the rest of his time is spent working with customers and their rifles.

Hegstrom helps customers figure out what modifications they need to make to achieve their goals. Whether it is a new scope, barrel or stock, Hegstrom can put together exactly what people need.

“They’ll say, ‘I want a prairie dog hunting gun,’ and we put a new barrel, a new stock and a new trigger on it,” Hegstrom said.

Hegstrom page 23

(pictured with their daughter, Eden) Freeport

Tell us about your farm. Our operation is a partnership between Jeremiah, his dad and his younger brother. We milk 150 cows and finish our own dairy steers. Everything is bred through artificial insemination. We farm 600 acres growing corn, alfalfa and grass hay.

How did you meet and when did you get married? We met while attending Ridgewater College in 2013. We started dating in 2017 and married in the fall of 2020.

What are each of your roles on the farm? Jeremiah is the herd manager, does all the morning milkings and milks the evenings when the hired hand is off. He does most of the breeding and some shop work alongside his brother and dad. With fieldwork, everyone has a job they typically do. Amber does morning calf chores and then helps with the remainder of morning milking, and she then wrangles the 2-year-old for the rest of the day. She does a small portion of the breeding and will jump in and help with fieldwork or other tasks if/when needed.

What is the biggest challenge of working with your spouse? Dealing with differing opinions on how something is done or how to go about fixing a problem.

What is the best part of working with your spouse? Getting to spend some parts of the day together, whether that is milking or eating meals as a family.

What is the best piece of marriage advice you were ever given or would give someone else? Communication is so, so important. Nobody can read your mind. That goes for marriage and relationships in general, not just when you work together.

What is your favorite task to do together on the farm? Doing the morning milkings together. We can talk about what’s going on that day, both with the farm and with our family and friends.

Tell us about your farm. We have around 35-40 feeder cattle; they are in three size groups from started calves to finished weight. We grow a little bit of hay, but otherwise, we don’t do crops. Ken’s dad bought the property in 1976, and it’s just down the road from the original farm. We have two kids: a son and a daughter. Our son lives across the street from us, and our daughter and son-in-law live in Tennessee.

How did you meet and when did you get married? We met in April 1989 at a local tavern in Alexandria. We married May 29, 1992.

What are each of your roles on the farm? Ken does all the daily chores for the cattle; he feeds them and does all the other work. Susie works off the farm part time, but does all the booking for butcher dates, works with customers, does the bookwork and helps unload hay or feed.

What is the biggest challenge of working with your spouse? Trying to compromise and work together can be hard. Susie is scared of the cattle once they are fully grown, so she doesn’t like working with them as much. It’s also hard when she works all day at her other job but then has to come home and help with chores or whatever job needs to be done.

What is the best part of working with your spouse? On Sunday mornings, in the summer, we take an hour or two to weed the garden. It’s our quiet time together that we get to just spend outside with each other. It’s still doing something productive, and it makes the garden grow better, but it’s our time together.

What is the best piece of marriage advice you were ever given or would give someone else? Find someone who you can work with and who will work with you. You might not always get along or agree on things, but you have to be able to compromise and find a solution.

What is your favorite task to do together on the farm? Our “date nights” used to be delivering meat to our customers. We had a lot of customers down by St. Cloud, so we’d go on Friday nights and deliver meat and then get supper together. Now, we don’t do that as much, but we ride side-by-side together a lot around the farm and down the streets and just wherever. We also go camping quite a bit.

Tell us about your farm. We farm north of Rose City. We have five children aged 10-20: Quenton, Carson, Graham, Benjamin and Greta. We have one part-time employee who helps with crop production. We are farming around 800 acres, raising corn, soybeans, rye and alfalfa. We raise British White and Angus cattle, including 50 cows, and finish out most of the calves to sell directly to the consumer. We also have 400 ewes, Katahdin and Dorper hair sheep and a small flock of registered Columbia ewes.

How did you meet and when did you get married? We met as children in 4-H. Will was also friends with my brother through school, so we knew each other a little that way. We started dating in high school after hanging out at a party. We got married Oct. 11, 2003, and have been married for 21 years now.

What are each of your roles on the farm? Will’s role on the farm is feeding and managing cattle and hogs, planting and harvesting crops, producing grass and alfalfa hay, hauling grain, and doing machinery repairs and farm maintenance. Becky’s role is managing the sheep operation, rotating animals through pastures, doing daily sheep chores with the children, managing all the bookwork and record keeping, running the farm-to-table meat business, making meat deliveries, and going to farmers markets.

What is the biggest challenge of working with your spouse? The biggest challenge of working with your spouse is managing stress. During hard times, we have to remember we are on the same team, and we need to go through the challenges of supporting each other. Sometimes, we can let the farm consume us, so we try to get off the farm and take time to have fun together. There is life outside of farming.

What is the best part of working with your spouse? The best part of working with your spouse is being together all the time; it is very rewarding. We are very close and best friends. We have a lot of fun together while we are working.

What is the best piece of marriage advice you were ever given or would give someone else? Be uplifting and compliment your spouse. Try to find positive things to say to them. Be on the same team. During times of stress, stick together. Communicate goals and dreams.

What is your favorite task to do together on the farm? Our favorite time on the farm is lambing time; we spend a lot of time together in the barn, and having so many lambs born is really a bright spot in our year.

from page 20

Hegstrom has been working in the industry since 1986 and has experienced significant changes throughout the years.

“When I started, every gun had a wood stock,” Hegstrom said. “Now, there aren’t enough hours in the day to work on wood stocks.”

Today, most of the guns brought into the shop have synthetic stocks made from fiberglass or carbon fiber materials.

Another shift in the industry has been the advancement of scopes and rangefinders. Scopes became more popular in the early 2000s and have since become mainstream.

“We have scopes that can shoot 1,000 yards,” Hegstrom said. “Twenty years ago, how would you know what 1,000 yards was without pacing it off or having a surveyor?”

Some of Hegstrom’s customers are local, some travel from across the state, and some travel from around the country.

“Spicer is becoming a destination for this stuff,” Hegstrom said. “We have three shops in town already and a fourth opening up.”

from page 25

are now. … (British White’s) breed traits were their mothering and their milk ability, and they were originally a dual-purpose breed.”

One of Traeger’s cousins raised and showed a British White cow, butchering it afterward, and Traeger liked the meat. She decided to keep raising those cows, and her cousin kept showing them and winning ribbons.

The British White breed traces back over 3,000 years to Vikings referencing the white cows with black markings.

“There are around 13 different breeds in the world that have the striking color British Whites have,” Traeger said.

In England, British Whites were owned almost exclusively by British nobility until the late 1800s. The cattle came to America in 1940, when Winston Churchill sent five cows and a bull to a Pennsylvania prison as seedstock to prevent their potential eradication by Nazi Germany, which was known to destroy a country’s national treasures upon invasion. Eventually, after moving and crossbreeding, the

C

Traeger

breed’s purity in America was restored in the 1970s.

“We got some of our bulls from the guy who originally imported the stock (to re-purify the breed),” Traeger said.

“We have some foundation stock still here that’s closely related.”

Rolling Hills Cattle Company currently has about 70 acres, and Traeger leases about 2,000 more acres of pasture. She maintains between 100 and 150 cows as well as some bulls, and the number has stayed steady over the last 20

years.

The British White breed is known for their meat quality along with their low-stress temperament. Because the cattle are so calm, they do not get sick easily, resulting in more tender meat. While the breed can do well with grain feed, Traeger keeps her British Whites grass-fed so they can be more efficient and fertile in a shorter time frame.

“People think of grass-fed beef as that dry, tasteless, veal-looking meat,” she said. “(With British Whites),

we’re talking marbling equal to corn finished. … We try really hard to get our animals as finished as possible.”

Rolling Hills also provides British White semen, for which the demand is growing nationally and internationally.

“When a person has a herd that is superior in phenotype and genotype, more and more people are going to want to add that to their herd,” Traeger said. “As we continue to work on only producing top bulls, that’s going to grow. With all due respect to

all the other big operations, they don’t have the meat quality to back it up.”

The operation of Rolling Hills Cattle Company prioritizes making the land better, which Traeger does by keeping a low footprint while reintroducing nutrients into the soil.

Pasture rotation is one method Traeger uses, preserving the roots of the grasses and letting them rest so they grow back faster.

“When my grandpa was farming, to him, it was important to leave it better than he found it,” Traeger said. “As a generational family, we’re all engineers; we can’t help ourselves. So, we’re always trying to look for ways to do this better. … Having a pasture that

*Offer ends 2/28/2025. Available at participating and eligible dealers only. Offer may vary by product type, series, model and select units in dealer’s current inventory. Must take delivery from dealer stock by 2/28/2025. Offers available on new equipment in US and Canada only. Some restrictions apply. Length of contract and rate may vary. Monthly payment subject to change. Prior purchases not eligible. See dealer for details. Financing provided on approval of credit by authorized Bobcat finance providers to well-qualified buyers. All finance programs and rates are subject to final approval by the applicable Bobcat finance provider and are subject to change at any time without notice. Administrative fees may apply. Offer not available to government accounts, national accounts and municipal/utility bid customers. Bobcat Company reserves the right to extend or discontinue any of these programs at any time without prior notice.

from page 26

looks like a golf course isn’t always the best practice for the land.”

Some of the grazing done by Rolling Hills’ herd is for research by the government on a pasture owned by the U.S. Fish and Wildlife Service. The studies have demonstrated British White cattle are less picky eaters than other breeds, which is closer to how animals graze in the wild.

“They go in before the cattle come in and look at the different plant species, what the size of the plant is,” Traeger said. “We graze the cattle in there for the prescribed period of time they want and then the people doing those studies come back after those cows leave — or even while the cows are there — and look at what the cows are eating and what stage they eat it at. They have found the British White cattle will eat things other cattle won’t touch.”

The meat produced by Rolling Hills Cattle Company is processed at United States Department of Agriculture plants so it can be shipped across state lines and be sensitive to customers with food

C

available Jan.

states.

allergies and histamine issues. By Traeger’s estimation, the meat has gone to at least 20 different states coast-tocoast, and she also sells at farmers markets in the Twin Cities. It is harder to sell closer to home, where people tend to be better connected to local beef sources if they do not produce beef themselves. But she does not mind; by selling farther afield, she brings money back to use in her community.

Traeger hears back from customers all the time.

“I have people who will not buy beef anywhere else, and they’ve

been loyal customers for over 10 years,” she said. “They might’ve come to the farm store or farmers market, they may have found me elsewhere on one of my websites; they try (the meat) and are like, ‘Your hamburger never tastes like hamburger. It’s like ground steak.’”

Not only do people love the meat, but on tour days at Rolling Hills Cattle Company, they also love the cows.

“Strangers can walk amongst my cows, and they’re more likely to lick your pants than take off (running),” Traeger said. “It goes back to the gentleness of the breed.”

Holtz will receive her chapter degree this year and plans to receive her state degree next year.

“Not many people receive their state degrees as juniors,” Arndt said. “She has enough hours and has done the work, so she will get hers her junior year.”

From doing daily chores to breeding the pigs, Holtz manages her herd mostly on her own. She said her parents help her some, but for the most part, she does it alone. She spends countless hours researching boars to find the best match for her sows and determining traits to focus on in the breeding program.

“I try to artificially inseminate them, but I’m not very good at it, so I have a boar to breed them, too,” Holtz said.

Holtz has 17 breeding sows. Their piglets are sold to local 4-H participants or to a neighbor as feeder pigs.

“Our neighbor buys all my extra pigs,” Holtz said. “It’s nice because he has a constant flow of pigs coming

in, and I have somewhere for them to go.”

Holtz sells pigs to around 10 families as show animals. Some of the families are local and some travel from other counties for the animals.

“Not everyone can afford to go buy a fancy show animal,” Holtz said. “I just want them to still have an opportunity to show a high-quality animal.”

Holtz began raising pigs in 2023. She said she wanted an animal that was smaller than a cow, so she began with sheep.

tle, sheep and pigs living in their barn.

Once the 4-H families have purchased their piglets, Holtz decides if she wants to show one of her own animals or purchase a new one. She said she always makes sure her customers get the best animals to show, and she does not worry about her own showing as much.

“My sister did a lot with sheep, and I wanted to do something different,” Holtz said.

“I try to go to the county fairs that they’re shown in so I can see them,” Holtz said. “They did really well at the Douglas County Fair last year, and that was really exciting.”

The pigs joined the family’s farm shortly after, and now they have cat-

Holtz helps local 4-H clubs in more ways than supplying show animals; she also offers educational opportunities. Holtz brings her animals to Cloverbud activities to teach the younger children about pigs.

“They get to hold the babies, but they’re learning, too,” Holtz said.

Along with showing pigs, Holtz shows cattle as well. This year, she traveled to Denver, Colorado, and showed in the National Western Stock Show.

“I’m excited to keep raising animals and showing,” Holtz said. “I keep trying to do better each year.”

Kurt Herickhoff 320-760-8183

Gregg Weller 320-808-3041

Owen Rajdl 320-815-0676

Byron Fischer 320-815-0233 www.centralmnseeds.com

The students are not going to stop with just a dozen homemade flagpoles.

BY TIFFANY KLAPHAKE STAFF WRITER

PIERZ — A dozen flags gently wave with the wind in front of the Pierz Healy High School every year on Veteran’s Day thanks to a small group of local FFA members.

Katlyn Gotvald, a Pierz Healy FFA member and chapter sentinel, spearheaded the project at the beginning of the 2024-2025 school year. Gotvald, with the help of three or four other FFA members, made 12 flagpoles using disc blades and T-posts.

“We (the chapter officers) are a part of the flag folding ceremony (on Veteran’s Day), but we wanted to add something to the school to show our support for the veterans,” Gotvald said.

Isabelle Dulude, Pierz FFA chapter reporter and part of the team that assisted on the project, agreed.

“The overall goal is to show our support for the veterans — not just on Veteran’s Day but throughout the year — by flying the flags on other holidays,” Dulude said. “To have the flags in front of the school, we are showing our support.”

Besides the Veteran’s Day program, the flags will be displayed on Memorial Day, Fourth of July and Labor Day to represent the continuous support of veterans and their families.

“The goal is to get enough (flagpoles) to go along the whole school from the elementary school to the high school,” Dulude said. “The plan is to make a dozen each year. It will take a couple of years to get them all done.”

Gotvald was enrolled in a welding class and a construction class and used that time to work on the flagpole project under the direction of Ms. Pat Tax.

“We wanted to use resources we already had,” Gotvald said.

Among the materials on hand were the T-posts, which were used as the poles. Disc blades, which were the bases of the flagpoles, were not readily available.

“We asked farmers in the area if they had any spare discs that they could donate for the project,” Dulude said. “So, we were able to get those donated.”

The T-posts were welded to round tubing to make the poles more stable. The posts were then cut and welded to the disc blades. The students ground down the sets until they were glossy and then spray-painted them black. Then, Gotvald and her team drilled a hole at the top of the fence post to attach a wooden dowel to a bolt so the flag

height can be adjusted. A flag can then be attached to the wooden dowel.

“One feature we wanted to include was to make them easy to store,” Gotvald said. “Each section comes apart to make it easier to store in the shed outside at school, and the flags are stored inside the school.”

As Veteran’s Day approached last November, Gotvald received assistance from fellow FFA members, such as Dulude, to finish the project.

Together, they were able to finish the 12 flagpoles in time for the Veteran’s Day program at the school.

The morning of Nov. 11, 2024, Gotvald and fellow FFA members placed the new flagpoles and flags out in front of the school to welcome and show their support of the military. Members of the public and veterans who showed up for the annual Veteran’s Day program were the first to see the flagpoles.

FFA chapter officers fold a flag as part of the Pierz Healy High School Veteran’s Day Program. That day, as is tradition, Gotvald, Dulude and their fellow officer team folded the flag for the program in front of the student body, veterans and members of the public.

It has been a long-standing tradition that the local

Now, the Pierz Healy High School can show support towards veterans on not just Veteran’s Day but throughout the year by displaying flags on their one-ofa-kind flagpoles.

BY EMILY BRETH | STAFF WRITER

SAUK CENTRE — When it comes to leadership, FFA and trying new things, twin sisters Katie and Samantha Gregory are always up for the challenge. The sophomores showed this when they ran for chapter officers and earned a place on the team.

“They work together really well,” said Tami Gerads, Sauk Centre FFA advisor. “They help push the other officers to be better as well and are both great leaders.”

This is Samantha’s first year on the officer team. She is serving the chapter as historian. Katie ran two years ago. She served her first year as reporter and her second as secretary, a position she was re-elected to serve again this year. Samantha said being on the team together, the girls bounce ideas off each other, help to flesh out thoughts and turn ideas into groomed plans.

“It is special to be on the officer team working with Samantha,” Katie said. “FFA is something we share a common interest in and bond over. We both have traits that if (one) is lacking, the other can make up for it. We have personalities that work well together.”

Samantha agreed.

“We always have each other,” Samantha said. In eighth grade, Katie knew she wanted to be an officer and have the opportunity to try new things within FFA and help others find everything there is to be offered. She also likes to share information about the sisters’ mutual passion.

“I wanted to … help inspire other people and teach them about something I love: agriculture,” Katie said. “I wanted to help people and be somebody who has good leadership skills and guides others to go for their dreams.”

Before joining FFA, the girls already had a strong

connection to agriculture as their parents, Allan and Angie, operate a hobby farm with a range of ever-changing animals and their grandparents, Kenny and Delores, have a beef farm.

“My grandpa has helped inspire some of that in me because I help at the farm a lot,” Samantha said. “Just seeing him when he is so proud of me and doing chores and stuff, it makes me feel good. (FFA) has grown (my interest in agriculture) a lot more.”

Katie agreed.

Before joining FFA, the girls already had a strong connection to agriculture, as their parents, Allan and Angie, operate a hobby farm and their grandparents, Kenny

“We definitely had a solid foundation of being in agriculture just through our grandparents,” Katie said. “FFA has definitely helped us pursue that and dive specifically into our own interest.”

Within FFA, they explored different avenues, finding their niche. Samantha competed in a range of FFA career development events from food science and floriculture to fish and wildlife and small animal vets. She also got involved with different activities the chapter put on, like FFA Week, a petting zoo and Ag Safety Day.

Katie has similar experiences with the FFA activities and attended Chapter Officer Leadership Training and Fall Rally. She competed in some of the same CDEs but also competed in leadership development events such as extemporaneous public speaking and creed speaking.

While Samantha did not join the team as soon as

her sister, it is not preventing her from suggesting ideas and getting in the action to help keep the chapter moving forward.

“Katie kind of convinced me (to run for office), but I also thought I had some good ideas that could help our chapter grow,” Samantha said. “I feel like I have good leadership skills that I could apply by being an officer and make our chapter an inviting place.”

Katie said she is excited to see her sister fill her role as an officer and to see what kind of ideas she will come up with. Both girls agreed they are glad to be a bigger part of FFA and give back to the chapter.

Through their time in FFA, they have learned many positive things about agriculture and the importance of leadership in any given situation.

“Leaders are very important because they are people who will help others find what they are here for and see past their expectations to fully achieve what they can do,” Katie said. “Leaders are speakers, listeners and kind of have all the traits to help people.”

Serving as an officer, the twins said, is a great accomplishment, and they are glad to be doing it side by side.

“Being on the officer team truly means the world to me because of the opportunity to try something new,” Katie said. “I can tell my leadership skills have grown tremendously. Looking at seventh-grade me to now, there is a big change.”

The sisters said they would encourage anyone to at least give FFA a try because it is not just about farming.

“If you are on the fence about it, just go for it,” Samantha said. “I wasn’t sure (about being on the officer team) and that’s why I didn’t do it when Katie did. Now that I did it, it has been so much fun.”

BY RAE LANZRATH STAFF WRITER

West Central Area High School and Ashby High School have joined forces to create a farm-to-table program for their schools.

Both schools grow produce for school lunches and the food shelves and share a mobile meat-cutting trailer. Courses are offered at both schools to educate students on growing, processing and preparing produce and meat products.

main focuses: meat and produce. During one semester, students at Ashby work with the produce while the students at West Central are learning about meat. When the semesters switch, the courses switch as well.

The schools share the mobile meat-cutting trailer they received through grant money from the Minnesota Department of Agriculture. The trailer is 8 feet by 35 feet and contains a cutting table, a walk-in freezer, a meat grinder, sinks and packaging equipment.

and more recently has developed a hydroponic grow room in the school basement. The produce is donated to the local food shelf. The school has donated 1,500 pounds of apples, squash, pumpkins, green beans, tomatoes, cucumbers and plums over the course of the year, Oestreich said.

The program was started by Eric Sawatzke, Bonita Oestreich, Eleora Mathiowetz and Meadow Christenson. Sawatzke teaches agriculture at West Central and Oestreich and Mathiowetz teach agriculture at Ashby. Christenson works for Minnesota GreenCorps.

“The students do everything,” Oestreich said. “They grow the produce, harvest and process it and prepare donations for the food shelf.”

The program has two

“Butchering and meat cutting is an important trade,” Sawatzke said. “If we’re able to give students the foundation, they may be able to use that in the future.”

The West Central High School built a greenhouse and has developed a hydroponic growing system in which lettuce is grown and donated to the local food shelf. They also grow sweet corn on 2 acres each year, which they donate to the food shelf. The program grows apples to donate as well.

courses and FFA and was instrumental in the development of the greenhouse program. In her current position at Minnesota GreenCorps, she operates an 11-month assignment to assist the two schools in developing the program.

“As ag teachers, we couldn’t do it on our own,” Sawatzke said. “With her help, we’re able to grow the program and perfect those practices.”

The courses teach the students about the cuts of meat and offer hands-on learning on butchering meat and processing it properly. The goal of the program is to donate meat to the local food shelf, as they do with produce.

The Ashby High School has had an apple orchard and school garden for years

The students participate in every step of the process, from planting seeds to delivering to the food shelf. Sawatzke said by doing this, students learn practical skills as well as the importance of giving back to their community.

“They bring the food to the food shelf, so they can see the impact of what they’re doing,” Oestreich said.

Some of the produce is delivered to the food shelf fresh and some is freezedried. The students wash, cut and freeze-dry the apples as part of the class.

The food that is not donated to the food shelf is processed in the classroom and used as learning tools for the students. The students have made a variety of products including pies and other homemade goods using the produce grown in the greenhouse.

Christenson taught the students how to make a homemade pie crust as a way to continue their education on being self-sufficient.

Christenson is a former West Central High School student who graduated in 2022. When she was a student, she participated in several agriculture

eady d ntal pment ouse her

The greenhouses and meat-cutting trailer were purchased using grant money from several different agencies and programs. Prior to partnering with Ashby, Sawatzke had already begun the greenhouse project. He applied for several different grants and participated in local fundraising events to raise money.

The partnership between the schools began in 2021 after a conversation at a football pep rally. The West Central and Ashby schools had already combined to create one football team, and they made it to the state tournament. The agriculture teachers from Ashby sat next to Sawatzke at the pep rally and, after some discussion, decided to join forces and apply for the meat-cutting grant.

This is now the second school year of the courses, and the plans for the future are bright. Sawatzke and Oestreich both have several ideas to expand the program to more in-depth courses, donating more products and continuing to educate as many students as possible.