The construction of the new city in Mount Hampden is the talk of the town. It was delivered by many players who include National Crane & Equipment, offering a comprehensive suite of lifting solutions and earth moving machinery equipment rentals and sales. NCE helped with their regionally welldocumented expertise to bring up the Gwebi River Bridge. NCE boasts a diverse fleet of vehicles specifically designed to tackle lifting and access challenges in any environment – from cramped cityscapes to demanding construction sites.

Brown Engineering Group was also on the Gwebi River Bridge project. The giant company came in with their renowned wealth of experience in a project that is their first vehicle road bridge. The bridge is part of the dualization of the Old Mazoe Road from the Westgate roundabout to the Mvurwi turn off. Furthermore, several other construction industry players were involved in the construction of Gwebi River Bridge.

This monumental project is a testament to the powerful synergy between government vision and private sector expertise. At the heart of this transformation is Exodus and Company Pvt Ltd, whose role in dualizing and rehabilitating key road sections. The construction of the Gwebi River Bridge, further solidifies Exodus’s contribution to Harare.

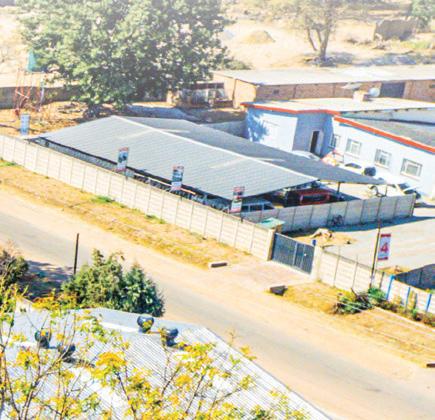

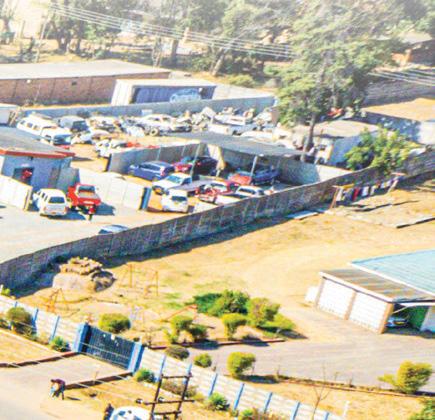

RadX Construction delivered the Paramount Garments warehouse in Msasa. RadX prides itself in delivering quality construction projects for clients across all sectors. The project sees the company reaffirming its place in the construction space with as it was swiftly and successfully completed.

Also working on the Paramount Garments warehouse was Gillfun Steel, who once again proved its eminence with a project that has redefined the manufacturing space of Harare. The company’s durable and quality reinforcement steel were used on this project.

Enjoy the read!

Structure and Design team.

PUBLISHER

Caast Media Group

MARKETING

Ashley Bangamu

Tinashe Mafiko

Newton Musara

+263 781 421 866

+263 781 512 568

+263 78 953 2918

DESIGN & LAYOUT

Blessed Mudzingwa

WEBSITE

Albert Chitumba

SOCIAL MEDIA

Natasha Munyukwa

JOURNALISTS

Michael Nott

Martin Chemhere

Farai Chaka

DISTRIBUTION

Joshua Govati Kudakwashe Gakaka

PHOTOGRAPHY Fotohaus

CONTRIBUTORS

National Cranes & Equipment

Brown Engineering

EMAIL marketing1@caastmedia.org ashley.bang@structureanddesign.co.zw

FIND US AT 31 Alexander Rd, Highlands, Harare

VISIT: structureanddesignzim.com and issuu.com/structuredesign for the digital editions of every issue

While every effort has been made to ensure the accuracy of its content, neither editor nor publisher can be held responsible for any omissions or errors: or for any misfortune, injury, or damages which may arise there-from. All rights reserved. Copyright 2024

Structure and Design Magazine: No Part of this magazine may be reproduced or transmitted in any form or by any means electric or mechanical, including photocopying or recording.

National Crane & Equipment with roots established in 1994 in Zimbabwe, now stands as the crown jewel, offering a comprehensive suite of lifting solutions and earth moving machinery equipment rentals and sales.

A Client-Driven Evolution

NCEs initial focus was on repairs such as hydraulics, engines, cylinders, axles and transmissions etc. Stemmed from a simple observation: clients needed rental equipment while their machinery was being repaired in the workshop.

This client-centric approach fostered the creation of NCE machine hiring division, a dedicated division catering to the growing demand for lifting and earth-moving solutions. Today, NCE boasts a diverse fleet of vehicles specifically designed to tackle lifting and access challenges in any environment – from cramped cityscapes to demanding construction sites.

Their team of specialists collaborates closely with clients to deliver customized solutions that prioritize safety, efficiency, and costeffectiveness for each project.

NCE: A Lifting Powerhouse Emerges

NCE stands out as the undisputed leader in lifting capacity across Southern Africa.

Their impressive fleet boasts a range of cranes, with capacities reaching a staggering 650 tonnes – the largest of its kind in Zimbabwe and the biggest number of crane fleet in Southern Africa. This unparalleled inventory guarantees they have the right tools for any job, from a single, critical lift to a complex, multi-phased construction project.

Unmatched Capabilities for Diverse Needs

NCE’s dominance extends beyond sheer capacity. They offer a truly comprehensive package to meet the specific needs of a wide range of industries, including:

Mining

Petrochemicals

Construction industry

General Industry

• Power Generation

• Renewable Energy

Project Management

Engineering Industry

• Plant and goods rigging

Their diverse fleet encompasses a vast array of equipment, including cranes, forklifts, telehandlers, lowbed trucks,

tippers, graders, bulldozers, front end-loaders, TLBs and other specialized machinery. This allows NCE to cater to the unique lifting requirements of each project they undertake.

NCE’s team of highly skilled and experienced professionals goes beyond simply providing equipment. They offer a complete suite of lifting solutions, encompassing:

Mobile cranes of varying capacities

• Access platforms for reaching previously inaccessible areas

Heavy lifting expertise for even the most challenging loads

• Project engineering to ensure seamless integration of lifting solutions into the overall construction plan

• Complete lifting solutions, encompassing every aspect of the lifting process

Safety remains paramount for NCE. They prioritize a risk-free environment for their employees, clients, and the project itself. This unwavering commitment to safety ensures peace of mind for all stakeholders involved.

NCE have a well-established reputation for excellence. Their collaborative efforts with industry leaders like Brown Engineering on the new parliament bridges leading to Mount

Hampden exemplify their capabilities. Their portfolio further extends to prominent projects for Delta, Dairy Board, Zimplats, Mimosa, Triangle and numerous other industry giants.

Unmatched Lifting Capacity: NCE boasts the largest crane fleet in Southern Africa and forklifts in Zimbabwe, ensuring they can tackle any lifting challenge.

Customised Solutions: Their team collaborates closely with clients to develop a solution tailored to their specific needs and project requirements.

Safety-First Approach: NCE prioritizes safety above all else, creating a secure environment for everyone involved.

Commitment to Sustainability: NCE actively seek ways to minimize their environmental footprint.

The Future of Lifting Solutions is Here National Crane & Equipment stands as a testament to the whole nations.

With their unparalleled equipment portfolio, expert team, and unwavering commitment to safety and efficiency, NCE is poised to remain the driving force for innovative lifting solutions in Southern Africa for years to come.

The Operations director had this to say about NCE “we are dedicated to all businesses wanting to make it in Zimbabwe and Southern Africa at large, we strive to be the one shop for all your machinery hire”.

With great reviews from existing customer’s testimonies on their capability and capacity NCE is poised to be a flagship and epitome of great industry standards, as we head in the future of growing our region and continent.

Company is driven on the following mantras:

OUR MISSION

(i) To provide quality service to the mining, the forestry, agriculture, manufacturing& the construction industry.

(ii) Using latest techniques, state of the art equipment, information technology systems, to increase returns to all stakeholders.

(iii) To project maintenance and mechanics through a professional dedicated and motivated team.

Customer satisfaction is our business philosophy. We are committed to:

(i) To promote and maintain sustained growth and profitability for all stakeholders

(ii) Establish and maintain long-term beneficial relationships with customers

(iii) Continually enhance and maintain customer satisfaction through providing quality and efficient service.

(iv) To remain the leading machinery hire and dealer in Zimbabwe and the entire Africa.

(i) Efficiency and professionalism

(ii) Continual product support and improvements

(iii) Good corporate leadership

(iv) Honest, Integrity, Professional standard, development concern

(v) To be a preferred supplier of quality branded products and services.

In the spirit of Ubuntu, NCE has opened a program that grants accounts to new customers with minimal requirements needed to start trading today with zero deposit needed Ts & Cs apply.

Text by Michael Nott | Photos by Fotohaus

Although the Brown Engineering Group has a wealth of experience in many diverse areas of the engineering, construction and manufacturing industries the Gwebi River Bridge is their first vehicle road bridge.

The bridge was commissioned by the Ministry of Transport and Infrastructure Development as part of the dualisation of the Old Mazoe Road from the Westgate roundabout to the Mvurwi turn off.

It’s part of the government’s drive to develop infrastructure in line with the policy framework for Vision 2030.

It will improve travel time, increase motorists’ safety as well as providing easier access to the New Parliament. The bridge was designed by ZICAD

Engineering Consultants, leaders in the field of Mechanical, Electrical and Project Management Services (MEP), with the Ministry of Transport and Infrastructural Development as the client.

The design follows the specifications set out by the Ministry of Transport and Infrastructure Development Part JD which deals with bridge construction.

Brown Engineering Group was selected to supply the steel works. Exodus and Company are constructing this section of the new dual carriageway and are also doing the civil works for the bridge.

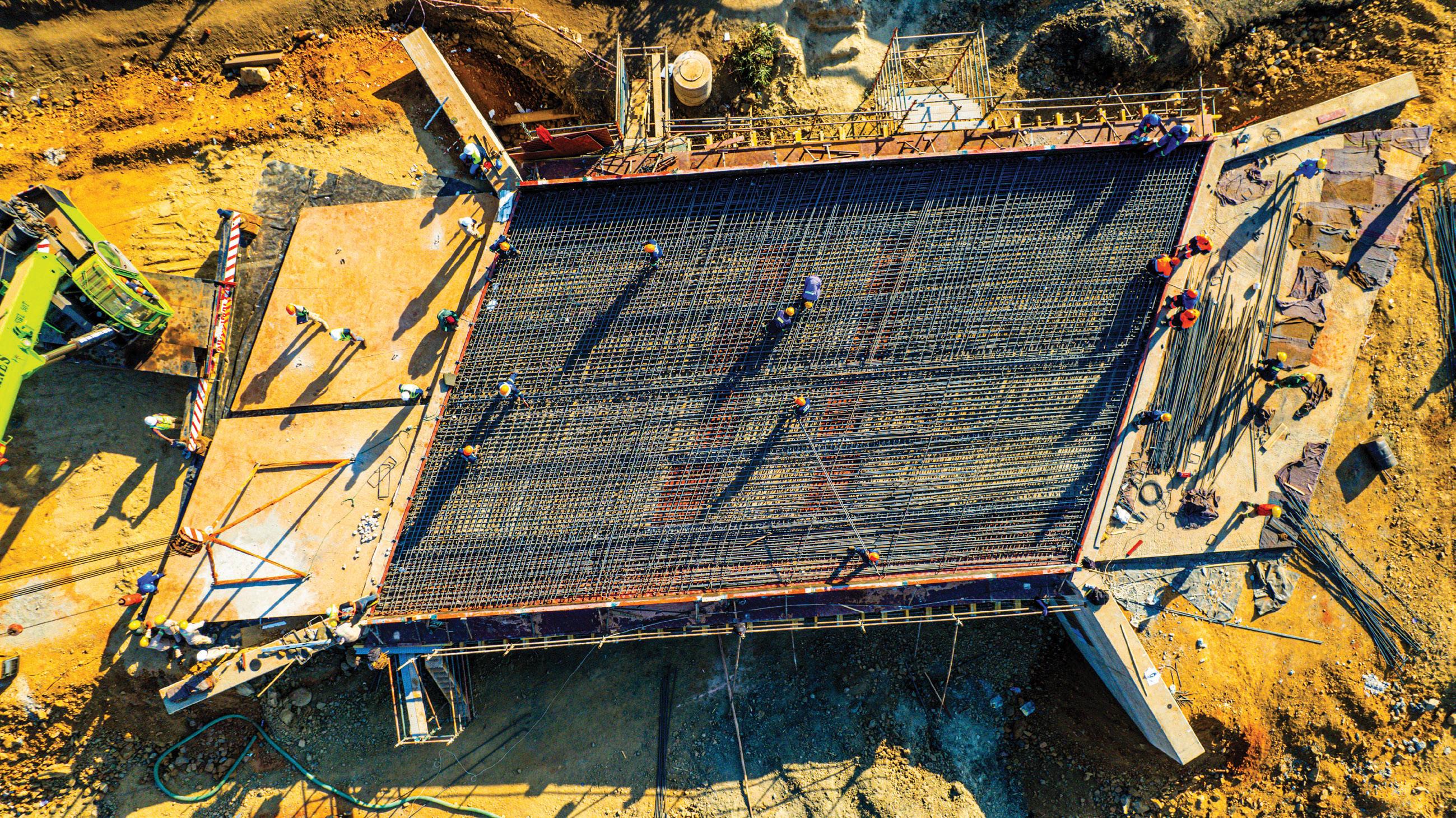

The bridge has a 20-meter clear span above the river. The steel girders, which were custom manufactured and fitted by

Brown Engineering Group, sit on top of the massive concrete wall type abutments on either side of the river built by Exodus and Company.

The steel girders are fixed to the abutments by elastomeric bridge bearing pads of steel and rubber which let the steel shift slightly to accommodate expansion and contraction.

There is a 40mm gap at either end of the girders to allow for movement.

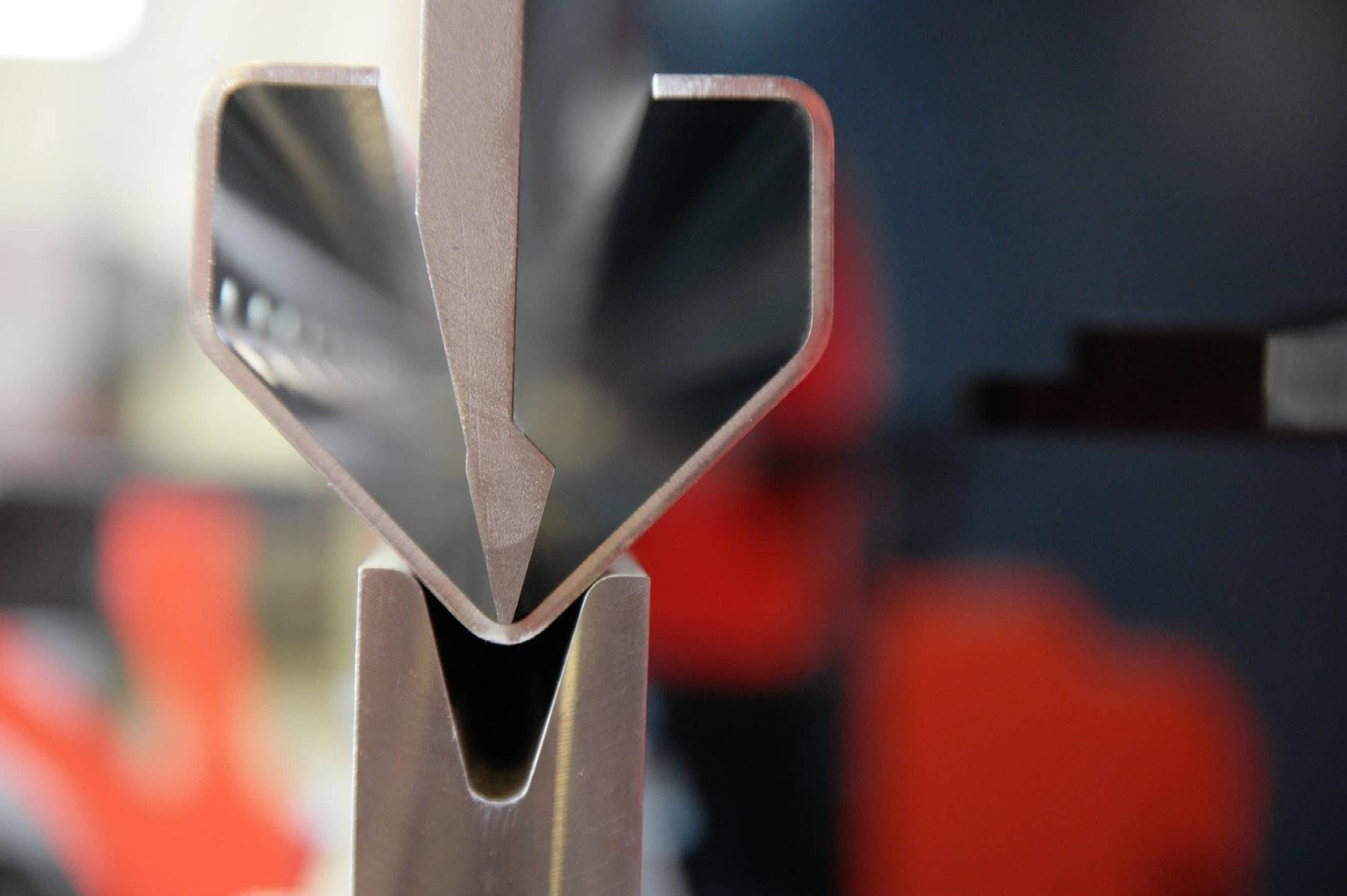

Brown Engineering custom manufactured the girders in three sections welded together to create a kind of I-beam 1.3 meters high.

The extra-long welds, using the sub-arc welding technique, were particularly difficult and demanding to achieve. Each girder is made up of two sections – one 8 meters long and one 12 meters long – to make up the 20-meter span.

The welding was inspected and approved by two independent engineering companies, ZICAD and Probitas Engineers to verify and approve their structural integrity.

Between the steel girders Exodus and Company will install pre-cast concrete panels fixed to the shear lugs which Brown Engineering Group manufactured on their girders.

The lugs function to fix the concrete panels to the steel. On top of the precast panels will be a concrete deck with a final asphalt layer on top.

Each of the steel girders manufactured and fitted by Brown Engineering Group weighs just over 17 tonnes.

They were manufactured in two parts, comprised of 12 meters and 8 meters, to form the required 20-meter span, as well as for ease of transportation and handling.

The longer section weighs 10 tonnes and the shorter section 7 and a half tonnes. They were loaded onto Brown Engineering Group’s truck using a 20 tonne crane and a 160 tonne crane on site to lift the girders in to position.

Because of the enormous weight involved the girders were transported one at a time. Once on site they were assembled with 20mm splice plates and M30 bolts with a total of 106 bolts on each girder.

Brown Engineering Group purchased a special electronic Newton-Meter Torque wrench to guarantee the bolts were correctly tightened to the highest specifications.

The girders were painted with corrosion resistant epoxy to ensure an extended life span of at least 100 years. The design also includes future proofing the structure to accommodate climate change issues like flooding or extreme weather fluctuations.

The procurement and fabrication took one month and the installation took a week. Once completed the bridge will have concrete stanchion parapets and steel railings for safety, supplied in conjunction by Brown Engineering Group and Exodus and Company.

There will also be a single lane for pedestrian access.

Although this will be Brown Engineering Group’s first vehicle road bridge they have provided the pedestrian bridge at Eastgate Mall.

They are currently supplying the steel work for many warehouses across the country, and the continuing development of a range of upmarket shopping malls.

They are also involved with the construction of the exciting new waste-to-energy project undertaken by Geo Pomona Waste Management, so their portfolio is impressive and diverse.

Harare's urban landscape is undergoing a dramatic transformation, with the Gwebi River Bridge standing as a prime example of the city's infrastructure renaissance.

This monumental project is a testament to the powerful synergy between government vision and private sector expertise.

At the heart of this transformation is Exodus and Company Pvt Ltd, whose role in dualizing and rehabilitating key road sections has significantly improved traffic flow and overall road safety.

The construction of the Gwebi River Bridge, a cornerstone of this broader initiative, further solidifies Exodus's contribution to Harare's progress.

Beyond road improvements, the project extended to beautifying and upgrading Old Mazowe Road, a vital thoroughfare connecting key points like Westgate, Mt. Hampden, Loop Road, and the new Parliament Building. The Gwebi River Bridge itself is a marvel of engineering.

ZICAD Consulting Engineers provided the visionary design, ensuring the structure's functionality, safety, and aesthetic appeal.Their meticulous attention to detail and commitment to sustainable development are evident in the bridge's harmonious integration with the surrounding environment.

B&S played a pivotal role in bringing the design to life through their construction expertise. Their focus on reinforcement and decking was crucial in creating a bridge that is both sturdy and durable.

By meticulously reinforcing the bridge's structure and crafting a safe and resilient surface, B&S ensured the bridge's longevity and efficiency.

The project also benefited from the expertise of Brown Engineering and National Cranes & Equipment in erecting the bridge's steel structure, as well as the contributions of Fourways Concrete and Acsend Concrete for concrete supply.

Additional support from companies like Mike Appel, Hitbay Sanitation, CBF, and Adelcraft provided essential specialized services for the project's success.

The Gwebi River Bridge stands as a symbol of Harare's progress and a testament to the power of public-private partnerships.

It is a collaborative effort that showcases the combined expertise of engineers, designers, and construction experts working together to create a landmark infrastructure that will serve the city for generations to come.

This successful project underscores the immense potential of public-private partnerships in driving infrastructure development. By combining government vision with private sector efficiency,

Zimbabwe has demonstrated its ability to deliver transformative projects that will benefit the nation for years to come.

Services

Engineering Design

Project Management

Engineering design services

Structure And Civil Engineering

Contract Administration

Design

Design-Build Coordination

Field Quality Control

Municipal Engineering And Certification

Office Block Design

Shopping Centre Design Transport Planning

Traffic Impact Studies

Road Transport Facilities

Engineering Structures Bridges, Railways And Viaducts

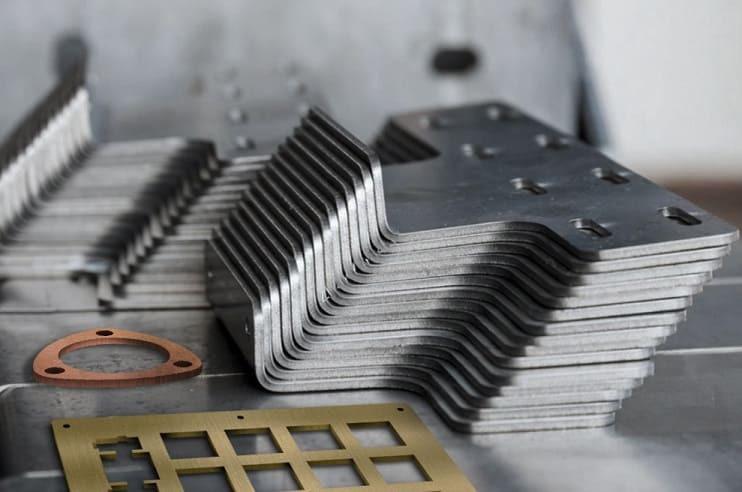

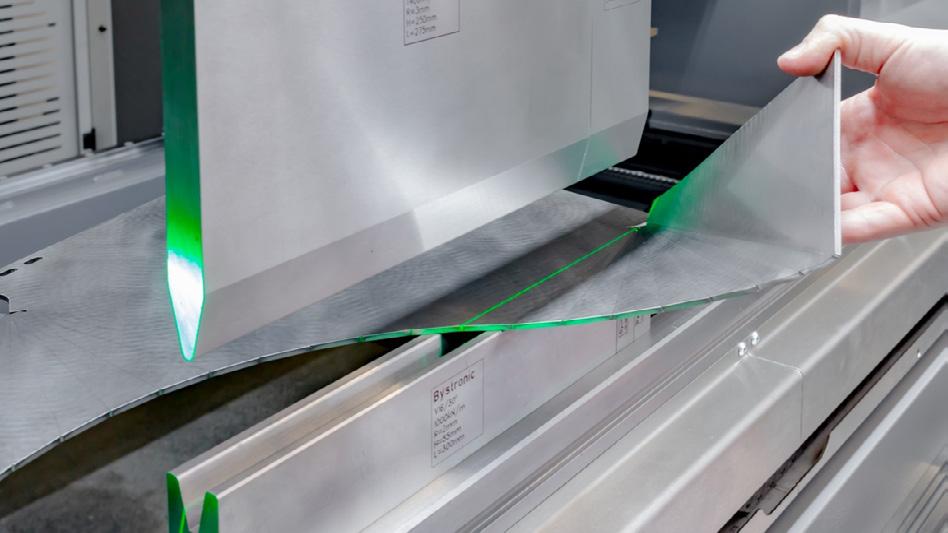

Good quality steel plays a crucial role in laser cutting for several reasons:

Consistent Cutting Performance: 1.

High-quality steel ensures consistent material properties, such as hardness and composition Consistency leads to predictable cutting results, minimizing variations in cut quality and reducing the risk of defects.

Reduced Heat-Affected Zone (HAZ): 2.

When laser cutting, the heat generated by the laser beam affects the surrounding material.

Good quality steel has uniform composition, which results in a smaller HAZ.

A smaller HAZ means less distortion, better edge quality, and improved precision.

Minimized Residue and Contamination: 3

Inferior steel may contain impurities, which can lead to slag or dross formation during laser cutting

High-quality steel produces cleaner cuts with minimal residue reducing post-processing efforts.

and optics to extreme conditions

Using good quality steel reduces wear and these components, prolonging their lifespa

5. Cost Efficiency:

While high-quality steel may have a higher cost it pays off in the long run

Text by Farai Chaka | Images By Photohous

Throughout Southern Africa, RadX Construction prides itself in delivering quality construction projects for clients across all sectors (including Industrial and Commercial, Hospitality and Residential, Mining and Oil & Gas, Construction Camps and Infrastructure). RadX’s expertise includes civil and building construction, engineering design, project management, quantity surveying, architecture and design-build solutions. The company’s track record speaks for itself and has resulted in some of the world’s largest blue-chip companies placing their trust in the company.

RadX Construction has reaffirmed its place in the construction space with the swift and successful completion of a warehouse project in Msasa. The warehouse is designed to house three shops, with the main anchor being Paramount Garments.

Starting on January 2, 2024 and reaching full practical completion by May 31, 2024, this project is a peak exhibition of RadX's exceptional capabilities. Throughout the project, RadX Construction maintained a close working relationship with the client, Paramount Garments.

Regular site visits and constant communication ensured that any changes or decisions were handled promptly and collaboratively. Decisions were easy, and the client was very hands-on," notes project manager Daniel Machibaya. "We were part of the design stage and any changes were discussed openly.

This team effort made the project seamless and enjoyable. "

The primary objective of this project was to construct a state-of-the-art warehouse for Paramount Garments within a budget of $1.2 million USD.

It features a flat, sloped roof and is situated on a property spanning 4113 square metres with the building footprint covering 1777 square metres and an additional 2177 square metres dedicated to paved areas.

The scope of work was extensive, including excavations, earthworks, formwork, reinforcement, concrete works, brickwork, plastering, carpentry, joinery, ironmongery and painting.

All of this was handled painstakingly from the installation of aluminium doors and roller-shutter doors up to the intricate brick dressing and suspended ceilings. The project faced several challenges, particularly the timing of the start date during the annual construction holiday.

Machibaya remarks, "We started the project on January 2, cutting short our annual construction holiday to ensure that all stub columns were in place by the time the steel structure was ready for erection.

We also had to manually pour about 85m³ of concrete on-site since the main pre-mix concrete suppliers were closed."

The busy location on Mutare Road also posed logistical challenges but RadX seems to have turned this into an advantage.

"We wanted the project to be a practical marvel for passers-by, which would help in marketing our company and what it stands for – BUILDING TRUST," Machibaya adds.

Despite the complexities of the project, RadX Construction successfully managed the budget, making only minor adjustments. Machibaya explains, "There were some minor additions at the deck on shop one and at the rainwater sump, but nothing that significantly altered the scope or budget.

The client was very hands-on, and we maintained constant communication to ensure any changes were seamlessly integrated."

One of the standout features of the warehouse is its face-bricked exterior and interior, giving a different texture and a rustic industrial feel.

Coupled with the structural steel, it ties in nicely to create a modern yet industrial look. RadX Construction has also equipped this warehouse with impressive sustainability features.

The roof hosts a substantial solar farm with about 72 solar panels, seeing to it that the warehouse predominantly runs on solar energy, with the electrical grid serving as a backup only when necessary.

An intricate rainwater harvesting system complements this green energy initiative. Rainwater collected from the 1777-square-metre roof is directed into a sump, which then pumps it into a 228,000-litre water ZimDam reservoir.

Notably, three-quarters of this reservoir’s capacity is dedicated solely to fire safety, a precautionary measure following a previous fire incident in one of Paramount's warehouses in 2023. Additionally, a separate 5,000-litre tank is used for further rainwater harvesting.

RadX Construction's success on this project is also thanks to the strong partnerships they maintain with various suppliers and contractors.

The architectural vision was drawn by Mark Sanderson of Draftworx Design while Brown Engineering handled the roofing.

Pomona Bricks supplied the pavers, Tiger Bricks provided the bricks and long-time collaborator Gillfun Steel supplied the reinforcement steel.

Derick Kambarami of InfraDesign and David Gutu of David Gutu and Associates formed the consulting team.

Products and Services

Cutting and Bending

Steel Sections

Roofing Sheets

Palisade Security Fence

Quality Tank Stands

Scaffolding Hire

Steel yourself for success! We’re your one-stop shop for everything steel, plus the accessories to cut, prep, weld, and conquer your project.

13 Shepperton Road, Graniteside, Harare, Zimbabwe www.gillfunsteel.co.zw

sales@gillfunsteel.co.zw

Text By Farai Chaka

Gillfun Steel has once again proved its eminence with its recent involvement in the construction of Paramount Garments' expansive warehouse in Msasa. It is their durable and quality reinforcement steel that was used on this project.

Gillfun Steel offers a wide range of products, including steel tubes, sheets and domestic and industrial steel, as well as related paints and hardware.

Their main product is steel in various forms and sizes and they provide an onsite cut-tolength service for long steel products, seeing to it that materials are customised to specific project needs, minimising wastages and helping builders stay on schedule.

At Gillfun Steel material delivery is a top priority. They have a sizable fleet of trucks at their disposal which leads to timely deliveries which in turn keeps projects on track and minimises delays.

This gives building contractors such as RadX Construction assurance that their steel will arrive like clockwork and definitely not after frantic calls to suppliers. This level of efficiency is what you need for a smooth construction.

This is not the first time Gillfun has worked with RadX Construction on a project. Gillfun Steel has a strong relationship with RadX Construction, supplying reinforcement steel on many of their projects.

They have worked together on several big projects beginning with the TM Marondera project in 2019, Unifreight Gweru, Zuva Petroleum service station, Driptech’s Samora Avenue/Glenara branch and the CUT RAG Processors warehouse in Willowvale.

Trust Gillfun Steel. With Gillfun Steel, you are choosing a steel merchant who has been known for supplying quality sustainable steel for over twenty two years now.

Experience their excellent service and join the many satisfied customers who have since made them their go-to supplier.

We would like to congratulate Paramount Garments on the successful completion of their Msasa Branch.

We look forward to partnering with you in the future!