New dairy delights

Farmer Andrew de Groot and his father Aad de Groot are very happy with their new no-frills 26-aside herringbone on their Morrinsville farm. Even ‘Flax’ the dog congratulates Aad on the new build! Read about their successful project on pages 54-55. Photo: Clare Bayly.

New Farm Dairies is New Zealand’s most comprehensive guide for farmers planning a new farm dairy construction.

Showcasing a range of the newest dairy farm projects throughout the country. This gives farmers a vital, in-depth reference tool for their own dairy projects for years to come.

Distributing over 30,500 copies throughout New Zealand FREE to all dairy farmers and rural supplies stores, reaching all corners of the country’s vast dairying industry.

Nothing has changed!

Welcome to the 19th edition of New Farm Dairies – the annual supplement of Coast & Country News, which profiles new dairy builds around New Zealand.

This edition – a truly comprehensive study of 28 individual farm and/or dairy developments –arrives with spring.

In the last year – just like dairy farmers continually do – New Farm Dairies has faced change.

Sun Media publisher Claire Rogers, who owned the paper for 18 years with late husband Brian, sold New Farm Dairies and fellow publications Coast & Country News and The Weekend Sun to NZME in March 2024.

But rest assured – NZME sees the incredible value of this publication, which assists farmers in making one of the biggest on-farm investment decisions in their lifetime – a new dairy build or renovation.

And so, nothing changes. We’re still talking to dairy farmers who are finding and utilising new options to better the way they farm by interviewing – you guessed it – fellow dairy farmers.

New Farm Dairies gives those thinking of building new or upgrading facilities the chance to hear from fellow farmers to agricultural experts on the most up-todate information, products and services.

Everything from earthworks, building

construction, milking plants, to refrigeration, electrical needs to feed systems, equipment and storage facilities to animal housing feature in this guide.

Plus, the technology – that measures, monitors and manages nearly all aspects of a new dairy from the comfort of your home, office or the other side of the world in real time – keeps getting better.

There’s innovative ways to store and apply effluent, chill milk, run water systems that deliver efficiency and cost-savings – there’s even robotic milking systems.

Animal health, comfort and production continues to be at the forefront of new equipment and facilities – as is health and safety, and retainment of staff.

There’s no.8 wire ingenuity packed in, and bespoke ideas flavoured by previous years of this publication – as many farmers we interview have used New Farm Dairies as part of their research into crafting a new facility.

A big thank you goes to 2024’s contributors for welcoming us onto your farms and sharing your stories.

Those wanting to feature in next year’s edition – please get in touch today with our advertising consultant Lois Natta on 027 281 7427 or send her an email: lois.natta@nzme.co.nz Lois has project-managed NFD since it’s conception 19 years ago, and can help with all advertising needs. Be quick –space fills fast!

A microcosm of what’s happening on farm

On the face of it, New Farm Dairies promotes investments in the infrastructure which assists the New Zealand dairy industry. But it’s much more than that.

The clamour of opinion and conjecture reached a crescendo during the Covid years – a time when we were isolated from our friends, families and communities. The “news” tended to consist of daily reports of the devastation the pandemic was having around the world with predictions of its impact on our economy.

Most of the developments profiled in this 19th edition of New Farm Dairies were in their infancy during those times – the fact that those plans continued to percolate confirms the resilience that farmers are renown for.

That is what New Farm Dairies does –takes you down the farm race and into the homes and dairies of a small sample of farmers whose investments speak volumes for their confidence in the future of dairying. It provides you with insight to what is really happening on farm – direct from the farmers themselves.

Perhaps it was their geographic isolation from much of the noise that dominated the news which sharpened farmers’ focus on strengthening their farm’s infrastructure so it would be ready for the recovery. Or perhaps it was the simple reality of farming life that is inescapable – animals and land which needed to be cared for.

Whatever it was, this edition of New Farm Dairies bears witness to the confidence and optimism which has shaped our industry,

and which is, once again, raising it to a level of production and quality which is the envy of the world.

It’s a generalisation, but “cockies’” are a modest lot – they don’t go looking for profile and most of those profiled within these pages needed the wider perspective of the value their insight would bring to contemporaries, before they agreed to be profiled. But even then, in every case, their concession was attached to the profile being more about their commitment to building

a future for their families than to them as individuals. And, again in every case, they wanted to profile and acknowledge the expertise of the people who they opted to work with to realise the project.

Investing at the levels evident on these pages is a demonstration of belief, ability and bravery in the best of times – but following “the pandemic years” it is nothing short of exceptional. But that is an outside observation; if asked, each of the farmers profiled would say that each project was

undertaken after rigorous evaluation of every option and every aspect. “Expert” opinion was sought, and many yarns held over fellow farmers’ fences and yards talking about what worked, and what didn’t. It is also fair to say that past editions of New Farm Dairies were referred to for ideas on what could be done.

Another common theme to our stories is the team aspect which under-scored every project. In most cases loyalty was a driving

force, contractors appointed based on “past experience”. And that loyalty went both ways with the vast range of contractors –earthmoving, engineers, yard designers, builders, electricians, plumbers, milking supply companies, water and effluent specialists – collaborating and working with and around each other to deliver the dream. And the result is a palpable pride which is shared across “the team” – in the project and the part each has played, as much for the rewards it has delivered to their families, their businesses, their community and the dairy industry.

In summary, this edition of New Farm Dairies is a microcosm of what’s happening on farm; the resilience, optimism and, at the end of the day, bloody-minded determination to get ahead which no pandemic can dim. It also provides insight to some extraordinary innovations which are adding value, and which could equally have a place on your farm.

Clare Bayly

RIVERSIDE FARMS

An extra two hours a day…

The timing may have been less than perfect – but the team involved, and the result was.

Bruce and Katrina Warren, together with their son Danny his wife Sarah, put the finishing touches to their new 30-aside herringbone cowshed in the spring of 2022 – off the tail of Covid-19.

It was a tough time to push forward with a significant investment, but the family has ‘no regrets’ as they stand inside their heavily automated result –nestled at the base of Mount Taranaki.

Riverside Farms

They milk 315 F16

Friesians at Riverside Farms – averaging 430kgMS per cow – off 200 hectares – which includes 160ha effective with a 130ha milking platform. All of the young stock are carried on the property. It is rolling to steep country, culminating in some river rock that sits 274m above sea level – along Okato’s popular coastal strip – 20 minutes south of New Plymouth.

The dryland operation, outside of effluent irrigation, has 26ha available to make hay and silage. With a 2.5ml annual rainfall this part of the coast is also located in one of New Zealand’s lee wind zones. Lee wind zones are areas where the landforms create localised wind acceleration, resulting in higher wind speeds

than the rest of the region. The old 18-aside cowshed used to swallow five hours a day, and the cows often had to stand with their necks turned to fit into the bail. Bruce says when Danny returned to the farm after working as a builder for a decade, the former mechanic knew it was time to change things.

Playing into the decision was that they didn’t employ any staff – and that Bruce is a Type 1 diabetic, Danny’s wife a schoolteacher, and Katrina and Bruce along with their daughter Jasmin own and operate Sentimental Flowers in New Plymouth.

Automation a must

Automation was the secret sauce they needed, and they

were also mindful of staying ahead of looming potential environmental challenges. It put the decision into a ‘musthave’ territory. It also dictated a greenfield site for effluent management.

“When we purchased the top block, it was always in the plan to do something about the shed,” says Bruce. “The old shed was so close to the river; we knew we would have to address the effluent to safeguard the farm environmentally at some point.”

Danny says building had been a great early outlet and a foundation that allowed him to work for others and to pursue rugby. However, when he started to turn towards home the cowshed quickly came up in the conversation.

The views aren’t bad – both inside and outside this dairy.

Liam Gibson of SAG Earthworks Ltd has been an integral part of the site preparation for Riverside Farms’ new dairy. Liam also completes regular earthwork maintenance around the property and tracks for Danny and Bruce Warren.

RIVERSIDE FARMS

“It was so tiny,” says Danny. “I felt massive in it. I was hitting my head on the clusters, and it was made for Jersey cows.”

Fathers and sons

This farming family was never going to look outside their local connections for a new build. Notably, there were three father-and-son partnerships from three businesses in their community working alongside one another on the project through post-Covid challenges.

“As the dads, we can pull back a bit and let our sons make the calls,” says Bruce of the intergenerational relationships. “We put our point of view in if we’re not happy. But if it looks good, we all run with it.”

Danny adds: “It comes down to communication. You’ve got to be able to give and take”.

Danny leads day-to-day operations at Riverside Farms these days. His building background naturally put him in the

DAIRY WALL COATING SYSTEMS

building mix too. There are some bespoke designs – including a concrete ledge along the entire the AI race – because Danny and Bruce aren’t the tallest men in Taranaki.

The round yard includes interwoven holding pens with clever gate placements for safe drafting, and a hoof trimming crush with a powerful light that allows for safe handling or late-night vet visits.

Both father and son say the cornerstone of this build’s success came down to the people. It principally included Brian Hill Builders, Coastal Welders, Mitre 10 New Plymouth, Think Water New Plymouth and SAG Earthworks Ltd.

“We are so rapt with the team we put together,” says Bruce. “We picked who we wanted, and Brian Hill was our main touch base.

“All these guys sponsor the local community, so it all swings in roundabouts. We’ve known Brian for a long time. We knew his work, he’s built a lot of sheds, and now his son, Jono, is in the business too. It

was a no brainer.

“Steve Gibson contracting does a lot of work on our farm, and their team moved the dirt at the start.”

New grazable paddock

The new dairy is not only equidistant between Bruce and Danny’s homes, it was a strategic greenfield site that offered the most efficient effluent management.

SAG Earthworks Ltd carved off the top of a hill on-farm to add and compact an additional 2m.

Bruce says the father-and-son earthworks business – which also owns a local quarry – are familiar faces on their farm. Liam Gibson, 23, was integral to the site preparation.

“I think Liam has been in the digger since he was four,” smiles Bruce. “He’s an awesome operator and he also does our tracks around the farm. We never question him.”

Liam says taking fill from a “big, pointy

hill” was a good way to “kill two birds with one stone”. It’s given the family another grazable paddock.

Effluent big push

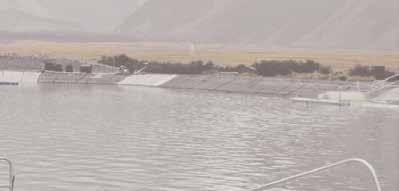

A weeping wall and the one million litre bladder that holds the effluent water has changed the environmental conversations – including negating dealing with excess rainwater in an open effluent pond.

“Although initially it wasn’t a cheap exercise to bring in the bladder from Italy, it’s a modern set-up that will still be compliant in 10 to 30 years,” says Danny. “A lot of traffic goes through this road. It’s a tourist route and instead of having a smelly, and massive pond, this now gives dairying a good name.”

Milking in the new cowshed takes 1.5 hours plus the wash-up, and the Automatic Cup Removers, the automatic teat spray in the exit, and the automatic wash have not only saved time but have added repeatable consistency. The herd’s Somatic Cell Count is 120,000.

Acraflex Dairy Wall Coating Systems save hours in cleaning, seal against bacterial build up and create a bright, hygienic working environment.

The A-team for the build included Bruce Warren, Andrew Wood of Coastal Welders, Danny Warren, Steve Bevan of Think Water, and builders Brian and Jono Hill.

A lot of thought went into the pipework that promotes cow flow.

RIVERSIDE FARMS

The in-shed feeding has also allowed the family to avoid production crashes when nature doesn’t play the game.

Think Water’s director Steve Bevan was responsible for installing the in-shed feeding, clusters, water conversations, the autodrafting, ACRs, auto-teat spray and he was also involved in calculating the storage and design for the effluent and the weeping wall.

“This is probably one of the most hightech herringbones we’ve done,” says Steve. “We’ve done a number of auto additions in other herringbone builds, but not always as a whole package.”

The revelation

Danny says the automatic wash has been the revelation. “Because when you’re milking by yourself, you can set the pre-rinse, the auto wash-up, and walk away – or be hosing down – and the plant switches itself off. You’re not worried about turning taps off when you leave, and every wash is the same. It’s allowed one person to do the job well and to do it quicker.”

One of the quiet achievers in this build is Mitre 10 New Plymouth, with trade account manager Heather Stewart saying she had wanted to work with Brian Hill for years. When she joined Mitre 10, she finally got her wish. Brian says Heather is exceptional to deal with.

“It’s all about better prices and good service,” says Brian. “Mitre 10 are our main suppliers because they are a great team to work with. They did really well on this build through a tough time.”

Cow flow

Coastal Welders’ Andrew Wood’s role started early in the planning process – in tight consultation with his clients – to make sure the yard design meets their needs

and achieves peak efficiency in cow flow. The fabrication and installation of the steel work is completed before the yard build starts.

Andrew says cow flow is at the heart of every successful project. After a lifetime in the business, he has a number of secret weapons which set his clients up for a positive and practical long game. He regularly collaborates with Brian Hill. The Wrangler crush is another staple that is worth its weight in steel. And Surfatex, which specialises in Acraflex dairy wall coatings – in addition to industrial coatings, anti-slip solutions and protective flooring –gives the dairy it’s easy-clean finish. Surfatex is the only licensed applicator of Acraflex from Taupo southwards, and its high-build paintwork is specifically designed to shield cowsheds from corrosion from manure and chemicals. It is guaranteed for a decade on a new build.

Lifestyle and opportunity

As Bruce looks around, there is a quiet but unmistakable pride in what his family has achieved after selling their house in town to buy a herd of cows and start sharemilking 35 years ago. The rest of Bruce and Katrina’s children include Marcus, who works as a landscape architect in Melbourne, and Michael, a Doctor of Political Science who works in the Wellington Ministry of Buildings.

With his health a constant management consideration – together with his desire to help Katrina and Jasmin with flower deliveries when they are busy – there is now some welcome flex in this operation.

Bruce says: “We also have a presentable and saleable farm that is compliant if we ever wanted to sell”.

Dianna Malcolm

Having full control of cows when treatment is needed is a welcome addition.

Getting supplies through Covid was navigated by Mitre 10’s Heather Stewart, centre, joined, from left, by Danny Warren, Ardie Warren, aged 5, Jono Hill, Brian Hill and Bruce Warren.

The automatic teat spray is taken care of in the exit.

Re-purposing saves thousands!

Matthew Lupton sliced a significant number of zeros off the price of his new dairy build when he replaced one of New Zealand’s oldest rotaries with a herringbone last year.

Driving into Collingwood Farms at Waverley, there is no doubt you’re pulling up to a brand new cowshed. What’s not so obvious is that there have been some clever inner decisions that allowed Matthew, 43, and his wife, Hannah, to create a new working space and exceptional cow flow on a greenfield site for an economic price which came in on budget.

This 32-aside herringbone dairy with De Laval Automatic Cup Removers has the latitude sewn in to expand to a 40-aside. For now, Matthew is milking 300 cows

on 120 hectares with an additional 60ha leased. The operation also carries 90 young and carryover stock, and 120-160 head of Hereford beef – with most sold at 100kg-120kg, with about 20 carried through one winter to be sold as yearlings. On-farm, they also make 400 bales of balage and 150-200 bales of hay.

Painful decision

Matthew was already working with Better Dairy Solutions when they started talking about a new cowshed.

“I’d bought the farm eight years ago, and we’d been battling away in the old dairy and dealing with constant breakdowns, [milk] grades, and it’d had been a struggle to get staff,” says Matthew.

“It was enclosed and dark – milkings took up to seven hours a day – and it was

often pretty stressful.”

Hannah is deputy principal of Waverley Primary School, and with their own young family, time is always a priority. Matthew called on his trusted service providers to find the solution. That included Darren Luff Contracting, Better Dairy Solutions, Bruce Clifton Builders, Dairy Technology Services, DeLaval and Surfatex.

It’s who you know

The ingenuity in this project came from whether to buy new or to re-purpose some of the existing plant.

“These guys have years of experience,” says Matthew. “You don’t build a cowshed every day, so it’s good to have their knowledge to reference.”

Better Dairy Solutions’ Gary Wallace and Gary’s son, Base, knew about a cowshed on another property that had been decommissioned six months earlier.

The old cowshed is a reminder of how far the Luptons have come.

Better Dairy Solutions’ Base Wallace makes sure everything is operating at the right settings.

COLLINGWOOD FARMS

“I mentioned it to Matt, gave him the valuation I’d put on it and stood back and let him work it out with them,” says Gary.

“Then we went in with Matt and his crew, gutted the shed, stripped it, and brought it back – and Matt got all the parts cleaned up.

“There is no reason why things can’t be retrofitted – a 100mm stainless milk line today is a 100mm stainless milk line forever.

“Most of that other cowshed had a modern blower, milk lines, and its vacuum and milk pumps were up to spec,” says Gary.

“When we moved it over into Matt’s cowshed, we simply upgraded it to the size it is now. Matt’s decision to take on the background work that entailed has saved them thousands and thousands of dollars.”

The retrofitted items included the vacuum pump, the milk pump, 20 swing arms, three quarters of the milk line, the receiving can, the cooler – after it was reconditioned, stripped, repainted, and reassembled to match the rest of the plant.

They also re-purposed Matthew’s old hot water cylinder and vat. Their front 20 jetters are re-purposed. The back 20 are new. The front 20 clusters have the original shells, but a better claw bowl was added.

“You can still do things on a budget and get a new one-man cow shed. But there are some things within a new dairy – mostly things that revolve around technology –where we do advise choosing new,” says Gary.

Some things should be new

The ‘go new’ advice included the pulsators, the DeLaval MPC150 Automatic Cup Removers, the P3 automatic detergent dispenser, the bowls on the clusters, some jetters, and rubberware.

The MPC 150 ACRs are a simple, compact, and durable integrated inclusion which has helped whittle milkings down to an easy two hours morning and night.

“Probably the key things we like with the DeLaval ACRs is that we have a lot of programming options,” says Gary. “Our goal is to make them work as close to the way you would milk your cows yourself, and we have enough range within that technology to do that.

Matthew adds: “There is no doubt the ACRs and the autowash system itself have made milkings easy”. “On the auto wash there are not a lot of taps that need changing either, which is easy for staff.”

Dairy Technology Services, known as

DTS, was involved in the refrigeration decisions which also included working some of their magic blending the old with the new.

“We’ve been working with Collingwood Farm for many years, and we understood the farm’s refrigeration needs well,” says a DTS representative.

many years – and this isn’t the first time he’s completed a project for the family.

Collingwood

“Instead of installing a new fit-out, we were able to relocate the existing refrigeration equipment from the old shed to the new one, saving the farm a significant amount of money.

“DTS prides itself on delivering highquality refrigeration solutions that are both efficient and cost-effective. We only recommend buying new when it is needed.”

Darren Luff Contracting is one of the unsung heroes of this project and they regularly complete earthworks at Collingwood Farm. Like the ingredients in a cake – their work isn’t obvious once the shed is finished but that result hinges on their groundwork.

Positive experience

Matthew has known builder Bruce Clifton, of Bruce Clifton Builders, for

“Bruce is always really competitive on price, and he did a really great job,” says Matthew. “As soon as we got the consents through, his team just gunned it and worked rain, hail or shine.”

Farms Farms

Surfatex, which specialises in Acraflex dairy wall coatings, in addition to industrial coatings, anti-slip solutions and protective flooring is another daily hero.

The high-build paintwork includes seven coats of paint, creating a protective barrier which makes it easy to clean.

A new car

Next season Matthew will install in-shed feeding, lift cow numbers to 350, and aim for 130,000kgMS.

“Doing it this way doesn’t put too much pressure on us – and, as we can afford those additions – we will,” says Matthew.

“Every day, milking is like getting in a new car, and it frees up a lot of time for me to get on with other jobs or spend more time with my family.”

Dianna Malcolm

The new dairy has saved hours in the cowshed every day. Working in the old with the new is a clever way to stay on budget. Matthew Lupton says his new cowshed has exceeded his expectations.

This 50kW solar system includes 120 panels on north-facing ground-mounted racking. The initial investment is expected to pay itself back within six years.

A signature dairy at Stratford

Merging two herds through a centralised new cowshed on a Stratford dairy farm has transformed the dayto-day runnings for a third-generation family operation.

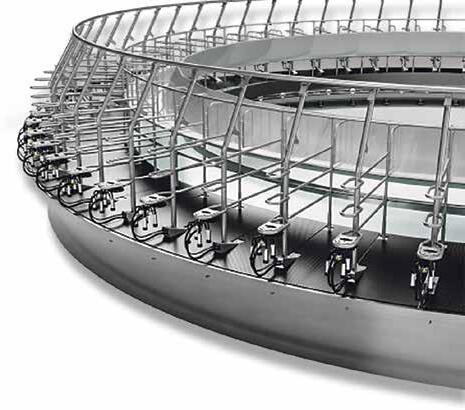

Cornwall Park Farms Ltd, owned by the Lightoller family, is a specific build because they didn’t spare the horses when it came to designing their 60-bail rotary.

Their first big move was to employ Gibson Construction to build it – the company’s first new dairy shed commissioned in Taranaki. Their other bold choices include incorporating solar panels, housing their milk vat, dedicating a room to their imposing 110kVA generator, and adding wider entry steps down to their cupping up area. Their accumulated detailed choices have contributed to an elegant finish, in a lightfilled cowshed for the Ngaere property, which milks 550 cows on 225 hectares for an average production of 520kgMS. The farm is owned and operated by Paul Lightoller, together with his parents, Jay and Raewyn, and Paul’s daughter Brooke, aged 18. The team also includes husband-and-wife duo, James and Carla Bugtong.

Two rolled into one

The family used to milk two herds through two cow sheds on adjoining properties

– through a 32-bail rotary which milked 350-head, and a 19-aside herringbone milking 200 cows. However, both dairies were fading fast, and the family decided to decommission them and invest in a single new solution on a centralised greenfield site.

Paul had seen and liked Gibson Construction’s work in New Farm Dairies, and so contacted its director Blair Atkinson, to talk through their options.

“When I called him, I didn’t realise they worked countrywide,” says Paul. “I was more after plans for a local builder. But Blair said he’d come down and have a look at it – and we visited some cowsheds they’d built, and it went from there.

“I’m not a builder, and it was the first time I’ve done anything like this. These guys do it all the time. I needed to look after what’s happening on the farm, and I wanted someone to oversee the build.”

Jay says: “We also wanted someone that when they started, they were here. We didn’t want them coming and going”.

Blair committed to step out of the office and project manage the build, even though it was three hours from his home. During construction the Lightoller family decided to combine their two herds in preparation for what was to come – milking 550-head through the 32-bail rotary – in a gruelling finale for their old dairy.

The new structure loomed as the promise of

The double backing gates mean they can split the herd, run the backing gate in reverse, and wash the yard more thoroughly with one pass a-piece. Photos: Cayden Searancke.

Proudly Taranaki owned & operated

things to come, and Blair says there was no stone left unturned in the new build.

“Everything is special and different,” smiles Blair. “We had a design we were using and then Paul changed everything.”

Paul counters: “What attracted us to Blair was the quality of his workmanship, and it allowed the whole process to progress nicely”. “There are no decisions I’m regretting at this stage. Everyone seems to be happy. We try and keep the farm nice. You spend a lot of time there, so you may as well have it nice and tidy.”

A roof over the vat

Housing the vat room was a departure from most of Gibson Construction’s clients.

“A lot of the time people want to save money by not covering the vats, but as you can see it does look good. It’s out of sight and these guys are out of the weather when they’re working. It was Paul’s idea to put the wall in as well.”

Paul adds: “It was something we chose to do”. ”It keeps a lot of the weather off that area, it means the chiller unit is covered, it gives us a covered parking area, and just finishes the build off nicely.”

DAIRY WALL COATING SYSTEMS

The wider steps – highlighted with Surfatex safety grip – were Brooke’s idea and they now have a ringing seal of approval from the whole team.

Extra ceiling height

The distance from the platform to the shed’s peak height is key to achieving a light-filled working space with meaningful airflow.

Gibson Construction routinely has an additional 800m to the apex of the roof than other contractors.

“We do it for the air flow, because it can get pretty hot in there once it’s full of cows,” says Blair. “Ideally, we aim for 4.2m from the operator floor to the centre of the knee joint with a 10 degree pitch to the roof.”

Cornwall Park Farms

Paul says humidity can be a problem in their region, and airflow in the cowshed was important – as is the shorter walking distance to the dairy. The cows used to have to walk up to 2km one way to the dairy. That same walk will no longer exceed 1.6km on any given day.

Their milking time now is two-and-a-half hours’ shorter every day –and, combined with the shorter walk, it opens the opportunity to lift production because there will be more available time for the cows to eat and to rest.

Blair says the Lightollers have been a pleasure to work with, and he’s proud of the finished article. “This is the standard that we

expect,” says Blair. “There is a reason these guys came to us and wanted us to build their shed.”

No high jumps!

When it came to the yard work, Cornwall Park Farms had an easy choice to make. Preston Engineering is based 15 minutes from the farm and was already doing work for them. Director Gary Preston is a skilled engineer with the trophy cabinet to prove it. He says it’s always

Acraflex Dairy Wall Coating Systems save hours in cleaning, seal against bacterial build up and create a bright, hygienic working environment.

Paul Lightoller and Gibson Construction’s Blair Atkinson understood each other’s vision.

Brooke, Raewyn, Jay and Paul Lightoller are joined by their employees at front: James and Carla Bugtong.

positive to work at Cornwall Park Farms –and the notable difference in the engineered yardwork was that they added an additional rail on the holding yards, yard, and backing gates – taking them all to 1.6m high –300mm higher than usual.

“I think if they think they can jump, they might,” says Gary. “This isn’t as high as we normally do, but it makes everything extremely safe.”

They also installed double backing gates, with the scrapers and jets fitted –which were made in-house by Preston Engineering.

“It seems to be the way farmers are going now in Taranaki,” says Gary. “They are enjoying the double backing gates, because they can split the herd, run the backing gate in reverse, and they both wash the yard more thoroughly in the one pass.”

The other difference was the decision to add eight spring-loaded man gaps.

“It’s not common, but it’s definitely more beneficial than the squeeze gaps,” says Gary. “If there is a squeeze gap, heifers will sometimes try and get through, or if the farmer has eaten too many pies, it can be hard for them to get through. Being

spring-loaded means it’s safe and easy for everyone.”

Solar panels

Another new addition is the solar panels at the farm’s entry, feeding power directly to the cowshed. The 50kW system includes 120 panels on north-facing groundmounted racking. Solar One’s Regan Fairley says this is company’s first dairy installation. He says the initial investment is expected to pay itself back within six years, and the panels and racking are covered by a 25-year product warranty.

Regan sees massive relevance for dairy farms given their high energy demand.

“The biggest struggle for us is getting the information to the farmers, so they see the numbers and data and understand how it can help their business,” says Regan.

Paul says the solar decision seemed logical.

“I can’t remember if I saw some advertising or not, and there was an initial outlay. But we could see the benefit it could have a few years down the track. Our power bill at the cowshed was around $2500 a month so it will be interesting to see how that plays out.”

Paul says one thing they hoped not to use was the generator. “It’s a big unit, and originally it was going to be outside, but the room we decided to put it in didn’t have much use, and it made sense to use it because it was going to be in a cramped position by the vats.

“Now, it’s out of the weather and hopefully that generator will be a waste of money and we won’t have to use it.”

Reducing effluent

Davieth Verheij, of AgFirst Engineering, completed the full effluent system infrastructure together with Delaval Coastal Agri Services and supporting contractors Viking containment, and Gibson Construction. It completed the pond, irrigation and

green water recycling design, supply, and build – in addition to designing and supplying the electrical control system. It also completed all council consenting to make sure the system was compliant.

The effluent system is made up of four key system components. The stone trap and solids bunker removes solids through a stone trap and solids storage bunker. A key feature of this component is the AgFirst solids retention screen, which holds the wet solids in the bunker – allowing them to drain and dry.

The effluent storage pond is 40m x 40m x 4m deep, with a total holding capacity 4,181,000 litres. It is lined with Viking Containment High Density Polyethylene. Third on the list is the green water recycling. Its 11kW green water washdown

Covering the vat helps keep the sun off it and makes the finish tidier, and allows everyone to work in the space comfortably regardless of weather.

Carla Bugtong putting cups on in the new dairy.

The effluent storage pond is 40m x 40m x 4m deep, with a total holding capacity 4,181,000L.

system draws from the top of the effluent pond, reducing dairy shed water use by approximately 70 per cent. It equates to a water saving of 30m3/day – or 9,150,000L per annum. By reducing the effluent, it –in turn – saves Paul 458 irrigation hours a year, including saving power, time, water and money. Lastly, the effluent Irrigation comprises an industry leading AgFirstdesigned 7.5 kW pond stirrer, a 7.5 kW Wangen PC pump and a Weta low-rate travelling rain-gun irrigator.

Feed a priority

Feed pinches on the shoulders of the season meant that in-shed feeding was always going to be a priority for the family to sustain production and their days in milk, regardless of the season. PPP Industries was responsible for installing it.

“We had already been in-bail feeding for four years in the old dairy,” says Paul. “It keeps our production more consistent through the season to fill in the gaps outside of our pasture growth. We can get dry in summer here, so we do feed turnips and grass silage in late-summer and autumn.”

Lights out

Mike Robinson, of Robinson Electrical, has always done Cornwall Farm’s electrical work and roughly 30 per cent of his business is dairy-related. This job was his first brand new install in seven years, and a baptism of fire with the extensive automation involved.

irrigation system, for example.” The detail continues right down to the lights all having sensors which automatically switch on when someone comes in.

Milking is certainly a breeze now

Percy Contracting was responsible for the earthworks, Preston Engineering manufactured the yardwork, and Hunt Farm Services took care of installing the Waikato plant, which included a concrete platform. The Wrangler hoof trimming system completed the install.

The way forward

“It was just a matter of doing my homework,” says Mike. “With the solar power we also set up timers to run as much as we can during the day when the sun is out to take advantage of that, like the

Paul says they never hesitated to choose a rotary after working in one for three decades, but he also wanted to make the most of the technology that was available.

“A rotary is what we know and it’s a good way of milking a lot of cows reasonably quickly.

“Like everyone says, this build is about

futureproofing the operation and having a shed that will attract quality staff.

“It’s also about capturing technology that we can use to make informed management decisions around what we’re trying to do.”

Paul says the new working result – which started up for the first time in March – is everything they hoped it would be.

“Milking is certainly a breeze now because the new shed has made it so

straightforward,” says Paul. “It’s an absolute pleasure and milking is certainly a one-person job. But because the facility is expansive, we do like to have an additional person there to help with cleaning up at the end of milking.

“From the outset it hasn’t missed a beat. We’d been told to expect teething problems, but everything has gone pretty smoothly.”

The Lightoller family didn’t spare the horses when it came to designing their 60-bail rotary.

The expansive yard includes an additional rail which is 300mm higher than most yards.

The ceiling is 4.2m from the operator floor to the centre of the knee joint, with a 10-degree pitch to the roof.

Dianna Malcolm

Going robotic

In just six weeks a Taranaki herd achieved what it has taken overseas herds two years to achieve.

When the Greensill family first contemplated converting their conventional Taranaki dairy farm to robotic milking they were told that, anecdotally, cows could take months – if not years – to transition to being in control of the decision to go to the cowshed to be milked.

Within six weeks of commissioning the new robotic milking barn on their 28-hectare property, cows were “voluntarily and consistently coming up to the barn to be milked,” says Layne Greensill.

The Greensill family – farm owners Layne and daughter Helen Loren, who is farm manager, and son Lachlan operate two farm properties in the Oakura district.

Layne says they’d been milking 250 cows at their nearby 80ha property, and 70 cows on the 28ha farm.

“We needed two new cowsheds across both properties and so, eight years ago, we decided to concentrate milking on

the smaller home farm, converting the 80ha farm to drystock.

“That change was enabled by a huge amount of research – starting in New Zealand and then extended in Europe – which confirmed that converting the home farm to robotics and running just 100 cows would enable us to equal or better the production we’d been doing, under conventional systems, on both farms,” says Layne. “It was also cheaper to go robotic than construct a rotary or herringbone dairy with corresponding levels of technology.”

Robotic-ready cows

Farm manager Loren Greensill says deciding to go robotic “affected our genetic strategy and we began breeding ‘robotic-ready cows’ – cows with fabulous, even udders and quick letdown. They also had to have good feet because, with an average 2.5-3 milkings per day, they spend more time walking and standing on concrete – milking and eating.”

Loren says their past production averaged 480kgMS under a conventional system “but our goal in the 2024/2025 season is 650kgMS per cow”. “A lot of that production increase will be down to the new milking system, and our ability to feed them in the barn during the lower grass growing times of the year.”

The heart

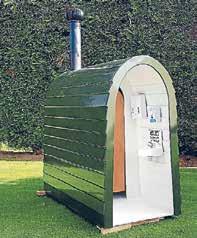

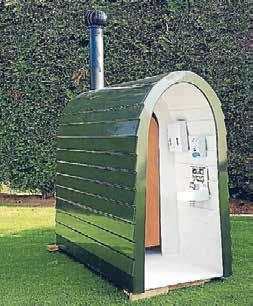

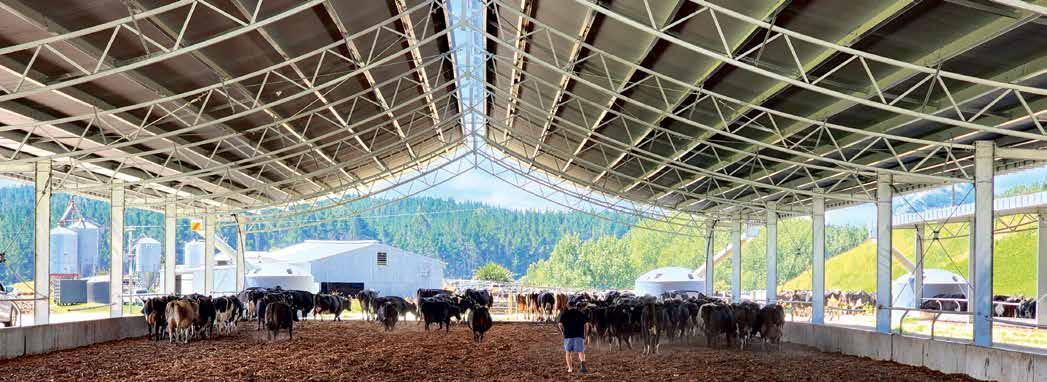

Layne says the new eight-bay barn on a raised site in the centre of the farm is “literally the heart of the business, housing the robotic milkers, feed and drafting lanes with room for a wintering barn”.

Layne and Helen’s son-in-law Rhys Longstaff, of RLC Contracting, commenced earthworks in September 2022 and the shed was commissioned one year later in December 2023.

Specialists in the design and building of dairy wintering sheds, Winton Engineering supplied the new barn which was erected by Layne and Helen’s eldest son, Nick Greensill’s NSG Construction. And it was operational when

New Farm

Dairies visited in May 2024 with fitout continuing for service rooms, and auxiliary pens and animal bedding.

All concreting was carried out by Freestyle Concrete & Earthmoving of New Plymouth. Pipework for the new dairy was supplied as part of the Lely package, featuring Texas-style one-way gates, and was installed by Layne working with local Tataraimaka business

The Garage.

Robotic system

Layne says their plan is to ultimately milk 180 cows across three robots “but we started with two”.

Lely’s area sales manager Graham Petrie says the Lely Astronaut A5 robotic milking system, coupled with the Lely Astronaut management system, revamps the traditional system with

The new barn sits proudly on a central site overlooking the farm.

tailored milking “and an incredible amount of insight/data to maximise each cow’s potential”.

“At any time we can see yield in litres, protein percentage, milk fat percentage, liveweight every time they stand on the scales, Somatic Cell Count, milk conductivity and rumination and get alerts for mastitis etc.”

Graham Petrie says natural milking and free cow traffic are not only about the cow’s freedom to choose when to eat, drink, rest or be milked – “they are also about the cow’s wellbeing and comfort during milking”.

“A layman’s overview of the process is the cow voluntarily comes to the barn and approaches each robot – which either admits her for milking or, in the case of her having been milked within a set time period, sends her through and back to the paddock without access to the feed lane.

“Once accepted, the cow enters the

milking zone and the robot commences pre-milking, assuming normal vacuum when the cow lets her milk down.

"Her liveweight is measured as she milks. Each cow is fed a prescribed diet while milking and, once finished, gains access to the feed lane.”

Graham says again, each cow decides when she leaves the feed lane, passing through a drafting gate which directs them to one of three grazing areas – which are preplanned and entered by Farm Manager and nutrition specialist, who is Loren.

“Automatic washing of each robot takes place two hours in every 24 hour period.”

The Lely Astronaut robotic milking system was installed by Bromley Dairy & Pumps of Feilding, which is the Lely franchise in Taranaki and Manawatū.

Ben Bromley of Bromley Dairy & Pumps says his team installed the robots and some of the vat and cooler plumbing. “All milk lines are insulated and milk is taken down

to four degrees Celsius before it goes into the vat.”

All plumbing, sumps, concrete culverts, gates, washdown and the new effluent system – including sand trap – were installed by AJD Plumbing of New Plymouth. Feed systems and pumps were installed by Moa Milking & Pumping of Inglewood.

The transition

Transitioning the cows to the new environment as the barn was nearing completion, Layne says the team spent a week prior to commissioning letting the cows come up and go through the shed “and have a nosey and get comfortable and then another week being here twice-a-day”.

“The first week of milking we reduced available feed in paddock to increase their interest in coming to the barn to get a feed,” says Layne.

“Our feed supplier tailored a particularly enticing feed mix for the robot and they soon learned that they needed to walk into one of the two robots before they would be fed and then they also got unrestricted access to feed in the raceway.

“Within six weeks we didn’t have to get a single cow out of the paddock – they were all coming up to be milked of their own volition. The cows are happier, quieter and milking like champions. We couldn’t be happier.”

“Effluent made easy”

Ben Bromley says Bromley Dairy & Pumps responds remotely to any issues and ensures same-day service if required.

Alec Dravitski of AJD Plumbing is the son of friends of the Greensill family.

Clare Bayly

Interior of the barn showing cows in feed lane on the left, the exit drafter/weigh scales to the cow’s right, two robotic milkers, additional yards and room for development of wintering barn.

The Greensill family: Lachlan, Helen, Layne and Loren Greensill.

Family’s dreamcome true

The dairy taking shape inland from Rahotu in Taranaki, in June 2024, is a tribute to a family legacy of dairy farmers and, fittingly, the first of its kind in New Zealand.

In 1911 Rob Willcox’s great grandfather purchased the original 140 hectare farm known as the “bush block” while farming on the coast at Rahotu since 1898. “So we’ve got a lot of history here,” says Rob. Rob’s grandfather purchased the bush block from his father’s estate in 1928 but unfortunately suffered a massive stroke in 1940, meaning Rob’s father had to leave school and help his mother – who had come to New Zealand as a war bride in 1919 – to run the farm as his older brothers were away fighting in World War 2. This was the start of a very strong feminine role in the running of the farm.

Rob’s father Frank purchased the farm in 1959 from his father’s estate after running the farm with his brothers. Rob and his wife Gwen came home to the farm in 1971 and in the 1980s began taking over the farm. Their daughter Tina Worthington joined them in 2007. In 2012 Rob, Gwen and Tina formed Willcox Farms Ltd, all three being shareholders.

Three years ago Willcox Farms Ltd was able to purchase the neighbouring farm from the long-standing Fleming family, taking the

farm up to 317 hectares. Tina, her cousin Scott Chadwick and his wife Jacqui run the home farm and contract milker Buddy Sharpe runs the new farm.

Rob says the old shed “was an internal rotary and there was a 40-aside herringbone on the new farm”. The expiry of effluent consents in 2025 and new Fonterra regulations led us to take on the massive decision to build a new dairy in the middle of the combined farms, halving the distance the cows have to walk.

‘Start to finish’

Rob says the family has a long association with Brian Hill builder and approached him to design and build the new dairy. Brian recently sold the business to his son Jono but remained involved in most aspects of the design and build. Corbin Mills was on-site foreman.

Willcox Farms

client. The Willcox dairy has a larger footprint, providing a spacious interior for the platform and service rooms. “The building has a steel portal frame with timber purlins, a colour steel roof and freezer panel walls,” says Jono.

Brian Hill Builders has been building in the Taranaki region for 50 years, Jono saying they are ‘start to finish’ builders doing everything from design to building including concreting across the spectrum of needs –residential, commercial, agricultural, and repairs and maintenance.

“We have a range of designs for dairies which we then tailor to suit the needs of each

Mitre 10 New Plymouth Trade has a long-standing trade relationship with Brian Hill Builders and was the chosen provider to supply products needed to construct the Willcox dairy. That relationship enabled the close collaboration needed to ensure everything was ordered and delivered on time.

Mitre 10 New Plymouth supplied all structural steel and mesh used in the floor through to all yard areas along with steel for the blockwork in the pit and access areas,

and structural timber ply for the building platform and all fixings. Framing and roof structure timber and correct bracing components with all associated fixings were also supplied on time and to spec.

First for NZ

Entrenching the legacy philosophy, the new dairy will be a showpiece for a revolutionary milking system from DeLaval – the first of its kind in New Zealand.

DeLaval’s technical specialist for Oceania, Graeme Middlebrook, says Flow-Responsive milking speeds up the milk-extraction by lifting the vacuum level when high milk flow is available and then reducing level again once high flow has ended.

“This replicates what happens in nature when a calf’s initial sucking stimulates

The new 60-bail E100 DeLaval rotary platform features DeLaval ComfortBails where wires, pipes and technology are integrated into the design of the bail.

let-down and prevents the inevitable trade-off between udder-health and productivity that occurs in a traditional fixed vacuum level over the entire milking process.

“DeLaval has been producing FlowResponsive milking systems overseas for many years, there are two in Australia and this is the first in New Zealand,” says Graeme.

“Pulsation and vacuum respond to the milk flow in real time and adjust accordingly. To stimulate the cow for milk release at the start and then to balance how quickly milk is released with how quickly the milking machine can harness it.

“Farmers know that flow changes during milking – milk release timing and speed varies from cow-to-cow and this unique system tailors vacuum and pulsation to each and every cow in the herd.

“Additionally, the system senses when flow reduces at the end of milking and accordingly tails off – preventing overmilking,” says Graeme.

Rob says Flow-Responsive milking appealed on at least two fronts – animal welfare and speed of milking. “Stimulating and responding to each cow’s milk flow reduces

The exterior of the dairy has taken shape with internal fitout taking place.

or eliminates the contribution of milking machines to teat damage, and potential mastitis, enabling her to reach her potential and increasing her health and life in the herd. Overall milking time is 20 per cent faster than traditional systems.”

Flow-Responsive milking is just the start of the DeLaval ‘firsts’ installed in the new dairy by Coastal Agri Services of Opunake.

Clusters first

Coastal Agri Services’ Simon Foley says the new Willcox dairy features the revolutionary DeLaval Evanza clusters which come with TopFlow claw and a unique cartridge replacing the traditional liners making milking faster and more efficient.

“The new 60 bail E100 DeLaval rotary platform features DeLaval ComfortBails

DAIRY WALL COATING SYSTEMS

Acraflex Dairy Wall Coating Systems save hours in cleaning, seal against bacterial build up and create a bright, hygienic working environment.

where wires, pipes and technology are integrated into the design of the bail.

“The dairy has a high degree of automation with DeLaval’s MA200 automatic cup removers, body condition score camera, on-deck teat spray and Delpro FarmManager.

“The new dairy also features DeLaval Sort Gates which when combined with the DelPro herd management system efficiently drafts cows according to drafts set either before or during milking.

“Cupping will be effortless in the new dairy thanks to a milker platform the height of which can be adjusted to suit the height of the

milker,” says Simon.

There are no bail restraints in the new dairy as culling has taken place to remove slow milkers. Rob is confident this will be complemented by Flow Responsive milking “which will mean the cows milk out well, and faster”.

Andrew Wood of Coastal Welders built the galvanised steel portals for the building along with consulting to design and fabricate the yarding. Cow flow was paramount in this, and any yard design work. The backing gates feature wireless solar panels which send a signal to solenoids to turn on the water which drives the gate. The design of the yards saves water and hosing time, if any is needed. Personal safety was also important in the design, keeping stock separated from the operators.

Left: The Willcox family: Jacqui and Scott Chadwick, Rob and Gwen Willcox with Marni, and Tina Worthington.

The dairy features DeLaval’s MA200 automatic cup removers, body condition score camera, on-deck teat spray and Delpro FarmManager.

A minimalistic approach to concrete areas and containment was a priority.

The interior walls of the dairy are coated with the seven-layer Acraflex paint system applied by Surfatex 2019 Ltd, providing a hard-wearing, easily cleaned surface. Tina’s husband Bryan Worthington fitted out the farm office and kitchen with joinery.

Animal handling, veterinary and AB facilities include a Wrangler Cattle Crush, which can quickly and simply be adjusted to accommodate varying size cows, will add comfort and efficiency to the treatment of lame cows.

Effluent research

Rob admits he probably put as much research into a new effluent system as he did to the new dairy, duly appointing Davieth Verheij from AgFirst Engineering in collaboration with DeLaval Coastal Agri Services to complete the full dairy effluent system design and build on a greenfield site close to the new dairy.

Effluent from the dairy flows to a weeping wall system via a rainwater diverter. The AgFirst weeping wall design was constructed from custom-built precast concrete panels by Brian Hill Building. The weeping wall design provides passive solids separation via gravity with no moving parts. It also offers significant solids storage for targeted land application only twice per year. This simplistic design provides peace of mind for troublefree effluent management by removing the risk of solids build-up in the pond and risks commonly associated with effluent solids and irrigation equipment.

From the weeping wall the filtered effluent flows by gravity to the new lined effluent pond.

Trapezoid pond

The pond is built in the shape of a trapezoid to suit the landscape, minimising earthworks requirements and maximising land use. Rob expresses appreciation to Jonathan Price from Campbell Contracting for digging the pond with help from his father John, who came out of retirement to operate a hired 30 tonne digger. Typically, a square pond would be desired for pond stirring efficiency. However, as the solids are removed by the weeping wall, regular pond stirring is not required. This is a big saving on system operating costs.

The new pond has a total volume of 4,800,000L and was lined with High Density Polyethylene by Viking Containment. The HDPE liner has a 20-year product warranty and comes in 8.0m wide panels, which allows efficient deployment and installation.

The seam welding process is also unique incorporating an air channel within the seam, which can be pressure-tested to ensure its integrity.

All welding and testing is documented in a comprehensive Quality Assurance Report. Viking Geoladders were incorporated to provide safe access for emergency evacuation

of the pond or for maintenance when servicing pumps or control equipment.

Irrigation design

A large part of the effluent system design is the effluent irrigation system. A Wangen progressive cavity pump reticulates effluent around the property with effluent applied to land via the AgFirst ‘Weta’ Low Rate Travelling Rain gun irrigator. The Weta achieves large irrigation volumes at low rates and is the only irrigator in the world that simply maintains its selected travel speed – no matter where it operates on the farm –ensuring a controlled and uniform nutrient application. The irrigation system was built by AgFirst Engineering and installed and commissioned by Coastal Agri Services.

When New Farm Dairies visited in earlyJune 2024, the start of calving the 750-cow herd was just six weeks away, so the building site was a hive of activity as contractors focused on getting it operational well before the target date.

The whole family say completion of the dairy will be a dream come true.

Futureproof farm

“This is a family farm,” says Rob. “Three generations of my family have farmed this land and our hope is that our investment in this new dairy will futureproof the farm and hopefully ensure that future generations of our family continue to live and farm in Rahotu. This is our legacy.”

Tina agrees. “My cousin, Scott, and his wife Jacqui, are as passionate and committed to the farm as I am. “I’ve also got a couple of kids who I hope will eventually join me on the farm so the future’s bright – thanks to Mum and Dad’s forsightedness and commitment to the family.”

Tina is not fazed by the prospect of transitioning the herd to the new dairy.

“They are used to being milked and fed in a rotary, albeit an internal rotary – where the cows face outward – so we understand there will be a settling phase. But I’m sure the allure of on-shed feeding will resolve that.

“We plan to run the entire herd through the dairy a few times before they calve – hence while calving is due to start July 15. We are aiming to start running cows through around the beginning of July.”

Clare Bayly

Weeks before the dairy was completed, the construction team found time to stop for a photo.

Even from a distance the Te Hou Farm’s new 80-bail rotary is imposing – and the team responsible for it remain intensely and collectively proud of the fresh heartbeat it’s given this Rangitikei operation.

Located 12km from Bulls, Te Hou Farm milks 1600 cows – with 300 autumncalving – on 1324 hectares, which has a 580ha milking platform.

Production is 520kgMS per cow, which equates to between 800,000 to 832,000kgMS for the season.

They are split into three herds based on age, weight, and stage of lactation, in addition to a sick herd.

Te Hou Farm is managed by Jarred Clode, who relocated from Hinds in Mid-Canterbury in 2017, bringing with him new ideas for one of the biggest single-site dairy producers in the lower North Island.

As the partnership has acquired neighbouring properties, the business model has steadily changed for Jarred and its owners, Ngā Wairiki Ngāti Apa from Marton with 67 per cent, and the Ātihau-Whanganui Incorporation owning 33 per cent.

In 2020 Jarred’s role expanded to operations manager, and it was clear to him at that point the 50-bail rotary was holding the farm back.

Jarred presented the idea to his board that building a new cowshed on a greenfield site would be a logical and efficient choice. He wanted to mirror a cowshed he had worked on in Canterbury. The board supported the decision – and a monumental shift was initiated.

“Our milkings used to take five hours a day,” says Jarred. “The old cowshed was just…old, and there was a lot starting to go wrong with it and I knew if we were staying, we would have to change things.”

That shift included demolishing the

50-bail rotary – because that site was still central to the farm – and transitioning the entire herd into a 36-aside herringbone, which they had inherited on a neighbouring 100ha buy for the duration of the build. The earthworks had been completed a month earlier. They then had to endure another switch back to the new rotary at completion.

“It was a lot of cows and a lot of stress on the staff at that time,” remembers Jarred with a grimace.

During that time, Jarred and his wife, Bronwyn, also welcomed their son, Will. It has made the last three years a blur of action, decisions, and work for Jarred, aged 40, and his team of five dairy staff, a drystock head stockman, two calfrearers, and administration staff which includes Bronwyn.

Milkings clipped by three hours Managing the new construction within a cowshed that operates 365 days of the year has been a testament to their

APB Electrical’s senior sparky Barry Penny-Baker and chief executive Andrew Boustridge.

Dairy Technology Services’ Aaron Evans says Te Hou installed a Glycol chiller and vat wraps.

Steve Bromley, of Bromley Dairy & Pumps, was responsible for the water tanks and stainless steel plumbing for water for the plant.

commitment. The final result is they have lifted cow numbers, and shortened milking times by three hours a day.

“The greatest thing is the time and the efficiencies of cow flow with the new yard, and cow comfort,” says Jarred. “I’ve replicated some things from a cowshed I worked at in the South Island at Rangitata Dairies, which is a little different to North Island dairies.

“We have included a big open 5m apex here at the North face. That was one of my biggest pushes, because it offers better light and ventilation. We also allowed a 3m overhang for more shelter at cups-on and at cups-off.

“We added a massive sprinkler system on the yard, and we have more space in the yard. The cows like the shed better. It’s brighter, lighter and the technology is great too. It’s all auto plant, vat, and floodwash with the auto yard clean on the backing gate. Everything adds up to time savings, efficiencies, and consistency.”

Being able to preserve their 2018-built feed pad, effluent system, and exit from the old dairy and merge it into the new build was a welcome saving – in addition to their Wrangler hoof-trimming set-up.

From the ground up

The enormity of the earthworks is one of the big early impressions on the driveway approach. They had to lift the site by 3m to allow enough room for the drainage and effluent management. It meant ground zero on the new cowshed was at the same level as the roofline of the old cowshed.

The earthworks fell to Sutherland Contracting. Alan Sutherland says when his son, Logan, dumped the first 24-tonne dump trailer-load he realised the enormity

of the mission.

“The challenge was the sheer size of it,” says Alan. “Logan did thousands of loads for two months non-stop. I think he saw the same butterfly and the same rabbit in front of him every day for the entire time.”

Alan adds that establishing the foundation turned into so much more.

“It brought a lot of us contractors together in various things and built relationships that we’ve carried on post-build. We were all sort of locals, but we hadn’t worked this closely for this long before.

“There were definitely a lot of laughs. We did pull some late nights, and the odd evening a little fairy lady [Bronwyn] came out with a few meals. Normally when we do a contract, we do it, and that’s it.

“But for this one we were fully involved throughout, so we got to see the completed job. Every time I come here now; I think about how we built it.”

Jarred says they chose a Waikato plant and Moa platform for a straight-forward reason: “Because they build a basic, easymaintenance, good shed”.

The Orbit 5500 concrete platform installed by Moa Rotary Platforms features an automated lubrication on a double beam with nylon rollers. The 100mm deep reinforced concrete deck has a 2.7m platform – which is ideal to protect machinery, and for better cluster alignment and application – a heavy duty galvanised sub-frame and Automatic Cup Removers. The outward sloping deck allows for easy entry and exit and sends manure to the outside of the platform.

Modern technology

Steve Bromley, of Bromley Dairy & Pumps, at Feilding says they were already servicing Te Hou’s existing machines. He was also responsible for all of the water tanks, and the stainless steel plumbing for water for the dairy plant.

“The cool thing about it is that the platform and the milking plant are from the same people, and it’s a tried-and-true New Zealand-made product that is very reliable,” says Steve.

“It’s also very customer-focussed. We like that. The features of the Waikato ECR-S

[Electronic Cup Removers] are the new touch buttons where the light reflects what’s going on with the milk and you can see that at a glance from a distance.

“They also include the ‘lift-to-start’ function; it controls the cow restraints and the SmartSPRAY at the end of milking.”

Steve says the whole idea of this plant is to go forward with modern technology.

“The shed is the blueprint for every new shed now. It also has a multi-port centre gland, so all the milk, compressed air, wash water and teat spray goes through underneath the platform. Running over the top is increasingly an OH&S [Occupational, Health, and Safety] issue, and bird problem.”

Steve is particular about his workmanship and favours stainless steel and medium density alkathene pipe with a 50-year rating.

“I like a nice job, and farmers are paying a lot of money for their new sheds so why shouldn’t it be nice, reliable, and easy to service?” he asks. “The water here is very hard on galvanised pipe, so we were mindful of that.”

Te Hou Farm Te

Jarred Clode and wife Bronwyn holding their son Will, with the Te Hou team of Dillan Baird, Glenn Cuenca, Brad Curtice, Jasmine Thomas, and Rachael Laurenson.

80 bails of new technology

The farm is 70 per cent irrigated by five centre pivots – the biggest one covering 65ha. The paddocks have all been subdivided into six to nine hectares, and the cows receive 1.2 tonne of supplement a year, fed on the shoulders of the seasons. The cowshed includes individual in-bail feeding and auto-drafting.

Wrapping up chilling

Chilling milk has become a clever and innovative area to be involved in. Dairy Technology Services’ Aaron Evans says Te Hou pays significant attention to how it handles their product. Not only did they invest in vat-wraps for the 21,000L and two 30,000L vats, they also installed a Glycol chiller so the milk hits the vat at six to eight degrees Celsius, and is chilled to 4.5 to five degrees Celsius by the end of milking. Vat wraps can drop vat refrigeration energy consumption by up to 25 per cent, by reducing the vat’s environmental heat-gain.

“It’s all good to get the milk into the vat cold,” says Aaron. “But exposed stainless steel heats up pretty fast on a summer day, and it takes a lot of power to keep that milk cool without the vat-wraps.

“We find the chiller won’t start at all during the daytime if the vats have those wraps on them. They also help with the temperature pull-down, because the vats don’t have the heat load from the sun on the stainless steel. We can wrap any vat, of any size.”

Aaron says the rising price of refrigerant gas now makes investing in new units the smart choice if the units are aged 10 years or older. For Te Hou, everything was new. “We’re the last ones here at the end of the

project to install this part of it, so there is always pressure then to get everything up and going before the shed starts. It’s always nice, when everything is lined up, and it looks neat and organised.”

Power it up

This was a monster installation for the electricians on-site, APB Electrical. The company’s chief executive officer Andrew Boustridge says APB Electrical had worked with Te Hou for eight years in day-to-day runnings and was happy to be involved in the new build.

“It’s a great achievement to be standing here at the finished cowshed with it in full swing,” says Andrew. His words are echoed by senior electrician Barry Penny-Baker. “Knowing what the previous cowshed was like to where they are

today is so different by leaps and bounds,” says Barry. “Everything is now plug and play. The challenges were putting the infrastructure into the ground prior to pouring the concrete. Within that we were anticipating the future – so instead of running two conduits, we run three because at some stage we all know there will be another addition. We try to always do that, but it’s not always allowed for in the budget. This time it was.”

What is he most proud of?

“Everything. This is the first cowshed of this size for me. To come away and the first day and everything worked great was a big tick.”

Barry says the size of the project meant the team had plenty of time to get to

know one another. Standing beside the 110kVA generator with the cows behind him, he reflected on the experience.

“You can’t go into a project like this not being able to work together. There is no room for big attitudes. We will be here for ongoing repairs and maintenance and general upkeep to keep this huge enterprise going.”

The only thing that is not automated at this point is the cows don’t have collars, and heat detection is still manual.

Surfatex, which specialises in Acraflex dairy wall coatings, in addition to industrial coatings, anti-slip solutions and protective flooring plays a big role in keeping this cowshed safe and clean.

The high-build paintwork includes seven coats of paint, creating a protective barrier which makes it easy to clean.

For Jarred – now in his eighth season with Te Hou – the changes have completely changed his day-to-day life and made it easy to retain team members.

“The board were very supportive throughout and took everything I’ve suggested and never turned anything down. I’m really grateful for the faith they’ve shown in me.

“The cowshed is awesome, our team love it, and we are all very excited for what the future holds for the herd and for our business.”

Alan Sutherland, of Sutherland Contracting, had to lift the greenfield site by 3m to allow room for drainage and effluent management – here he gives perspective to the earthworks.

The new operation houses an 80-bail rotary on this Rangitikei farm, 12km from Bulls.

Steve Bromley, of Bromley Dairy & Pumps.

Making days

When Jim, Dave and Emily Malone tore down their cowshed, they looked at each other and took a deep breath…because the clock was ticking.

They had eight weeks to rebuild a 30-aside herringbone before calving started, Emily was pregnant, and there weren’t a lot of Plan Bs.

The couple milk 270 cows in an equity partnership on 93 effective hectares with Dave’s father, Jim, at Sanson about 30 minutes west of Palmerston North.

To create the window, they needed to achieve the build, they dried off three weeks early and dropped the start of their spring calving back by 10 days.

“That demo moment when you’ve no longer got a cowshed was pretty confronting,” admits Dave. However, there were some enviable professional advantages within this family when it came to the rebuilding. Emily is a draftsperson for Resonant – multi-disciplinary engineering and surveying services. Dave was a former residential builder who’d come home eight years earlier when his mother, Elaine, was fighting cancer. It has tied the three together in a partnership founded on deep respect and care.

Fiscally responsible

None of them wanted to over-capitalise on the flood-prone property, but they all wanted a classy result that would make their working days easier. Their old cowshed was born as an eight-aside in 1963, before stretching into a 12, 14, then 20-aside by 2000 under Jim’s stewardship. Dave was ready for the next step.

“I’d been milking for eight years, cupping up and daydreaming about what I’d change,” says Dave. “We’d looked at heaps of sheds around the area as we got more serious about it and plucked ideas from everything.

“But the biggest thing for us was – if we were going to do it – we needed to do it once, and we needed to do it right.

“This wasn’t about potential resale; it was for our future sanity. We had made the commitment to be here, and we decided to take on some debt and do it properly.”

The initial plans came in over budget, and instead of cutting corners the three of them rolled up their sleeves and did a significant amount of the grunt work themselves – painting late at night, laying conduits through the weekend, running alkathene and water lines, hooking up hoses, and completing brickwork together.

A game-changer

Emily proved to be a game-changer and a big saving for the partnership with her connections and knowledge in the planning. She handled all the council consents, which were more complicated because they are on a flood-prone property. It allowed them to spend less than they had originally asked the bank for. They did drop two storage rooms from the build to save costs. “Looking back now, I’m glad we didn’t put them in. We didn’t need them,” says Dave.

The new toilet almost got flushed too, but its inclusion has been a popular save.

“The toilet was an additional $12,000 because it needed a full septic system,” says Dave. “We didn’t realise how much of an inconvenience it used to be for everyone who came to the farm that there was no toilet available at the cowshed.

Steve Bromley of Bromley Dairy & Pumps, farmer Dave Malone with wife Emily holding Archie, Jim Malone, and Alf Downs Contracting Ltd’s Johan Hayward.

The new bridge was a necessity.

Two stone traps save time during hosing down.

easier

“It’s been a surprise just how useful that single decision has been for the operation.”

Teamwork

The main team involved in the build included Rural Building Engineering, Alf Downs Contracting, and Bromley Dairy & Pumps. They started May 20, 2023, and the new cowshed was completed by July 25, 2023.

Milking still takes 2.5 hours, but the stress levels are gone – and there are some nifty personalised design hacks in this cowshed.

“We’ve saved a labour unit,” says Dave. “Before we had to have two people milk because we had to push every row in. That was the main reason we needed to change. In the old shed the wall was literally at the end of the cows’ noses, and they just didn’t want to go in.

Emily adds: “We do have weekend relief staff, and the new shed has also definitely made getting staff easier”.

The new cowshed is six metres wide with a 1.5 metre pit, Electronic Cup Removers, and it is now a one-man job. Cow flow is seamless, and production is 20 per cent ahead this season. They deliberately didn’t install a wing wall on the exit. Dave says it works well because there is a direct line of vision for the cows exiting the cowshed to the paddocks. Three windows in the wall in front of the cows is also a nod to allowing more light into the structure. The Wrangler crush forms the end of the AI race.

Dave says their contractors were impeccable. RBE also put in a new bridge over the creek directly out from the cowshed because the old bridge was in the way of the new build.

“We didn’t realise how bad that bridge was until we pulled it down,” says Dave.

“RBE did a fantastic job across the board, and they were so organised. We know they have built 90 per cent of the sheds in this area in the last 30 years. That’s why we picked them. They had everything prefabricated, ready to go, and they pulled finger when they needed to.”

Smart installation

Steve Bromley, from Bromley Dairy & Pumps, was responsible for the plant and he made lots of practical suggestions and didn’t waste anything. Right down to the simple things like making sure they had multiple taps so they could easily deal with water challenges, and stainless-steel TriFerrule clamps for durability, and easy access to the pumps for any repairs.

“When we pulled everything out of the old cowshed, we were careful how we did it and we put it all in the hayshed,” says Emily. “Steve worked out what could be re-used, and we got rid of the rest. We re-used all our claws, pulsators, and milk pump.”

Dave adds: “We upgraded to a Blower Vacuum pump with a variable speed drive one”. “It matches the airflow, so we are using less power. Our power bill has dropped slightly. I expected it to rise, because we have gone from a 7.5KW

Stainless steel collars around the galvanised pipe will add life to the cowshed.

The power is all neatly packed away, but accessible.

The attractive dairy has made finding relief milkers much simpler.

An ingenious and simple drop-down lane design has allowed a two-for-one use with Malmak Ltd’s drafting race doubling as an AI race.

Getting the right results

pump to a 15KW pump. We have a new vacuum pump, new washdown pump, a new farm pump, a new filter, and a double-bank cooler to meet regulations. Our milk is going into the vat at 10 degrees Celsius and the chiller is off within an hour of milking.”

The inner workings of a cowshed were in Steve Bromley’s wheelhouse, and the Waikato distributor is thrilled with the result. The herd’s Somatic Cell Count is at 105,000.

“It’s almost a new plant and Dave, Emily, and Jim did a great job of keeping everything organised and moving forward,” says Steve.

Installing Waikato ECR S Automatic Cup Removers have been a popular inclusion for Dave too.

Steve also notes that the backlit touch switches on each cluster give a quick and clear visual on each cow’s milking status from any position in the pit.

Surfatex, which specialises in Acraflex dairy wall coatings, in addition to industrial coatings, anti-slip solutions and protective flooring was also in the mix. Glen and Leianne Sinclair own Surfatex’s lower North Island franchise.

The high-build paintwork usually includes seven coats of paint, which stops manure and chemicals breaching its protective barrier. It is guaranteed for a decade on a new build.

Malmak Farm’s old shed also had Acraflex dairy wall coatings, and Dave didn’t hesitate to choose Acraflex again, because it had stood the test of time.

Lightbulb moment

Their electrician choice was a slightly off the grid for cowshed builds. Alf Downs Contracting used

to do a lot of work on cowsheds but the 70-yearold Marton-based business – with 36 staff – has become well-known for its expertise in industrial, commercial, and domestic factory maintenance, Programmable Logic Controllers computerised systems, lighting and lines. At one point, it was New Zealand’s biggest street lighting contractor.

“We’d had one-off sparkies over the years, and having a bigger firm in the mix was part of our thinking so if we have a call out, we can get someone,” says Dave.

Their on-site electrician was Johan Hayward, who says it was a pleasure to be involved. Alf Downs’ manager Ashley Williamson acknowledged the impact of the group’s teamwork.

“It made a big difference having Dave who was so hands-on,” says Ashley. “Their communication was great. Dave knew exactly what he wanted, where he wanted it, and how he wanted it. Together with Steve’s knowledge as a milking systems specialist, it’s worked out perfectly.”

Steve adds: “It’s always good when someone wants to be involved, and we were thrilled Dave, Emily, and Jim gave us the project, and put their trust in us”.

Sliding doors

Jim reflected quietly that his life could have looked very different at this point.