All are critical factors for a well-run warehouse or DC. And all are enhanced by a properly marked floor.

Floor striping pairs with overhead barcode signs to organize bulk items for fast and efficient placement and picking. They divide spaces, highlight hazards, direct traffic and support OSHA safety guidelines, too.

Ready to earn your stripes? ID Label is one of the nation’s leading providers of floor striping services. We’ve also got you covered with custom engineered rack and LPN labels, signs and nationwide installation. Contact us today to request samples or a quote. 800-541-8506 • info@idlabelinc.com idlabelinc.com When We do The Barcodes, You Can Do More

04

Cross-border

AutoScheduler.ai explains how warehouse orchestration is a transformative approach to operations.

Catena

Ithink it’s safe to say we’ve all become Logistics Managers of Life.

Whether it’s ensuring the fridge stays stocked (Inventory Specialist and Order Fulfillment Manager), juggling pickup and drop-off for kids’ after-school sports and activities (Logistics Manager), replacing burnt-out lightbulbs and fixing broken toys around the house (Quality Control), returning goods to retailers (Reverse Logistics) or taking out the garbage (Waste Management), logistics is everywhere.

At some point, we’re all acting as the Buyer, the Planner, the Transportation Associate, the Shipper and sometimes the Engineer.

But outside out of our homes, there are people who hold down these positions for supply chain organizations. They’re tasked with keeping the product moving, keeping the trucks moving, ensuring the safety and efficiency of supply chains.

They’re the true Logistics Managers of Life.

That’s why the two awards featured in this issue—Top 3PL & Cold Storage Providers award (page

16) and Top Supply Chain Projects award (page 27)—are so important. Third-party logistics (3PL) and cold storage providers remain a key puzzle piece to building and nurturing partnerships, cultivating resilience and helping companies in the cold food space overcome supply chain disruptions. They exemplify all that represents Supply Chain Management and the art of moving product from Point A to Point B. Meanwhile, this year’s Top Supply Chain Projects focused on sustainability, automation, streamlining manual processes, enhancing traceability, mitigating risk and optimizing the overall supply chain— all pertinent facets to Business Logistics.

Everyone has a little bit of logistics in them. But to the winners of this year’s awards, congratulations for continuing to enforce safe food transport, cutting-edge technologies and sustainable sourcing.

Subscribe to our e-newsletter.

https://foodl.me/8x1hpx9a

EDITORIAL

Editor-in-Chief Marina Mayer mmayer@Iron.Markets

Managing Editor Alexis Mizell-Pleasant amizell@Iron.Markets

AUDIENCE

Audience Development Manager ...............................Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@Iron.Markets

Art Director Flatworld Solutions

ADVERTISING/SALES

Brand Director Jason DeSarle jdesarle@Iron.Markets

Account Executive Brian Hines bhines@Iron.Markets

Account Executive Jay Gagen jgagen@Iron.Markets

Account Executive Mark Pantalone mpantalone@iron.markets

IRONMARKETS

Chief Executive Officer.......................................................... Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter

VP, Marketing & Audience Development Ronda Hughes VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan

Corporate Director of Sales Jason DeSarle

Brand Director, Construction, OEM & IRONPROS Sean Dunphy

Content Director Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816

circ.FoodLogistics@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES Brian Hines (647) 296-5014 | bhines@Iron.Markets

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Food Logistics (USPS 015-667; ISSN 1094-7450 print; ISSN 1930-7527 online) is published 5 times per year in March/April, May/June, July/August, September/October, and November/December by IRONMARKETS, 201 N. Main Street, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI 53538 and additional mailing offices.

POSTMASTER: Send

201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • WWW.IRON.MARKETS

Downtown Atlanta, GA

November 12 & 13, 2024

TT Club debuted an active toolkit to assist members, partners and service providers in the development of relevant policies as they pertain to environmental, social, governance (ESG).

“The toolkit will develop over time to build a resource base of success stories of effective ESG strategies from across the cargo handling and supply chain sectors,” says TT’s managing director, loss prevention, Mike Yarwood. “This series of case studies provide building blocks to guide others in designing and embedding ESG policies and will be augmented as our experiences and those of our members and partners evolve.”

Scan the QR code to learn more https://foodl.me/h9yjkpnh

Microsoft launched new Microsoft Copilot templates, empowering organizations to build agriculture copilots with Microsoft Azure OpenAI Service. The copilot templates are an evolution of a previously announced agriculture LLM APIs , enabling more data source inputs and expand capabilities for broader use cases.

“AI and automation are helping farms of all sizes produce more while using fewer natural resources, and we’re starting to see how they can enhance decisionmaking on almost any plot of land,” says Ranveer Chandra, managing director, research for industry and chief technology officer, agrifood, Microsoft.

Scan the QR code to learn more https://foodl.me/1uio5872

From maintaining product integrity to ensuring regulatory compliance and improving operational efficiency, choosing the right cold storage warehousing solution is a significant investment with the potential to impact product inventory and integrity of the cold chain as a whole.

Charles Betts, national sales manager, Interstate Cold Storage says by taking the time to carefully evaluate operational needs, engage openly with potential partners and remain informed on market trends, your business can find a cold storage warehousing solution equipped with the power to streamline current operations while offering long-term scalability.

Scan the QR code to learn more https://foodl.me/c8g8dq68

Investments in temperature and humidity monitoring solutions are set to surge in the global food industry due to increasing traceability reporting demands. The implementation of the Food Safety Modernization Act (FSMA) amplifies this trend, mandating enhanced reporting protocols for various food products and impacting the entire U.S. food supply chain. In fact, ABI Research projects that worldwide revenues from food cold chain track-and-trace operations will surpass $7 billion by 2032.

“For cold chain management to be effective, it must be enabled by technological solutions, which are critical for maintaining the quality and safety of food products. The need for real-time monitoring across the food supply chain has been exacerbated due to the regulatory compliance requirements in North America and Europe. This includes all stakeholders from farmers and first-line handlers to logistics providers, food manufacturers, and retailers,” says Adhish Luitel, supply chain management and logistics senior analyst at ABI Research.

Scan the QR code to learn more https://foodl.me/e1tn5irm

TradeBeyond introduced artificial intelligence (AI)-powered supply chain traceability tools, allowing global brands and retailers to improve visibility and reduce risks in their supply chains.

“TradeBeyond’s customer base includes some of the world’s largest brands and retailers. For these businesses, manually reviewing thousands of documents and verifying their chain of custody is extremely inefficient,” says TradeBeyond CEO Michael Hung. “Our latest AIpowered traceability capability eliminates this challenge.”

Scan the QR code to learn more https://foodl.me/duuawgq6

Shippers and carriers are prioritizing climate change, sustainability and new partnerships while capacity is favorable, according to research compiled by Breakthrough . Volatile weather is impacting transportation. In fact, transportation leaders, including shippers and carriers, have shifted their priorities over the last 12 months against a backdrop of extreme climate events, geopolitical conflict, and heightened regulatory requirements. Both shippers and carriers named extreme weather events the top transportation challenge for 2024 amid an ongoing drought in the Panama Canal, intensified winter weather, and a highly active hurricane season.

Scan the QR code to learn more https://foodl.me/6ffqy2my

KOLTIVA launched EUDR Solutions, tailored for businesses seeking EUDR compliance, which mandates rigorous due diligence. This process includes extensive data collection on product origins; risk assessments on factors like country risk levels and forest presence; implementing risk mitigation measures such as audits and supplier support; and annual public reporting on due diligence systems.

“We view that the EUDR is more than a regulation; it’s a mission, a key element of the European Green Deal, driving climate neutrality by 2050. By adhering to the regulation, businesses contribute to the global fight against deforestation, a significant factor in climate ch ange and biodiversity loss. With the deadline approaching in less than a year, we reaffirm our commitment to assisting businesses in achieving compliance. We stand ready to provide expertise, technology, and services to ensure regulatory adherence while concurrently fostering a sustainable future,” says Manfred Borer, CEO and co-founder of KOLTIVA.

Scan the QR code to learn more https://foodl.me/furi4pjm

The food and beverage industry is one of the most high-stakes industries in manufacturing—one issue with quality can cause a domino effect so large that it takes down the reputation, and the revenue, of a brand. While FDA regulations help ensure food safety and quality for consumers, the always-evolving changes can be difficult for manufacturers to keep up with.

Tyler Marshall, head of strategic alliances and business development at Advantive , says in light of these challenges, many food manufacturers are turning to an enterprise resource planning (ERP) system to help stay up to date on the regulations and ensure safe production and delivery of food and beverages products for consumers.

Scan the QR code to learn more https://foodl.me/8anlqg88

To mitigate risks for truck drivers, it’s essential to emphasize comprehensive training on safe driving practices.

In conjunction with the technology to support it, creating a company culture that prioritizes safety over speed or deadlines can encourage truck drivers to prioritize their own safe driving habits. Managing editor Alexis Mizell-Pleasant uncovers why campaigns like Distracted Driver Awareness Month further the importance of staying focused and alert at all times while behind the wheel— truck driver or not.

Scan the QR code to learn more https://foodl.me/khukdg01

Food Logistics and Supply & Demand Chain Executive hosted SCN Summit: State of the Supply Chain, where Editor-in-Chief Marina Mayer sat down with industry experts and thought leaders to talk trends and technologies in the supply chain space and how they relate to the State of Today’s Supply Chains. Topics revolved around Generative AI, Company Culture, State of Transportation and more. Available on-demand!

Scan the QR code to learn more https://foodl.me/46ey44lb

Penske Truck Leasing unveiled Catalyst AI, an artificial intelligence (AI) platform that delivers real-time insight into fleet performance.

“Catalyst AI was born from our vision to harness the power of AI to meet the needs of today’s fleet managers,” says Ann Walsh, SVP of digital and customer data at Penske. “By integrating over 57 billion data points with AI, our patent-pending algorithm and industry expertise enables fleet managers to better optimize their operations using leading-edge technology.”

Scan the QR code to learn more https://foodl.me/t6oha6rg

Since March 26, when the Dali, operated by the Synergy Group and chartered by Maersk, collided with the Francis Scott Key Bridge in Baltimore, causing it to collapse, a series of disruptions at the ports have continued to surface.

To date, two alternative channels have been opened for vessel traffic, with a third one scheduled to open in May. These three channels should be able to handle much of the traffic into the Port of Baltimore. The current timeline for reopening of the main channel is by the end of May, according to project44 data.

Scan the QR code to learn more https://foodl.me/ba103rrz

The Women in Supply Chain Forum, set to take place Nov. 12-13 in Atlanta, is a premier networking event tailored to men and women in executive-level positions. This year’s theme, “Shattering Glass Ceilings: A Woman’s Impact on Supply Chain,” will bring together leading experts in the supply chain industry to discuss mentorship, self-advocacy, collaboration, closing the gender gap and what it takes to move the needle and pave the way for future female leaders in logistics. Register to attend!

Scan the QR code to learn more https://foodl.me/qeupw0wp

The LoRa ATL-1 wireless temperature monitoring system from Wireless Links allows for a simple plug-and-play setup that is easily scalable for cold rooms and refrigerated trailers.

Configured using Internet of Things (IoT), the LoRa ATL-1 Temperature monitoring and asset tracking device maintains a long rechargeable battery life. The solar-powered asset tracker for yard management features integrated GPS and a digital temperature sensor with 0.5°C accuracy around a half-mile radius, making it an ideal solution to track assets in the yard such as reefer trailers and other valuable assets located in large yards, depots, chassis and containers at seaports.

Scan the QR code to learn more https://foodl.me/cwhy9qxe

Plus launched PlusVision, AI perception software designed to be used in advanced safety systems, ADAS applications, and higher levels of autonomy.

“In the shift toward software-defined vehicles, software is getting more complex and needs to be decoupled from hardware in order to accelerate development efforts and feature updates over the air. We developed PlusVision as a flexible software solution with a future-proof architecture that can adapt to the evolving autonomy needs from SAE Level 0 to Level 4,” says Shawn Kerrigan, COO and cofounder at Plus. “OEMs and Tier 1s can integrate PlusVision with their own automated driving platform, combining PlusVision’s leading-edge perception capabilities with the product customization they desire.”

Scan the QR code to learn more https://foodl.me/6hpgy0h1

These days, supply chain disruptions aren’t just about port closures or bridge collapses or even severe weather events. Sometimes, the disruptions are merely just about the technologies themselves disrupting the way companies move product from Point A to Point B.

It’s these disruptive technologies that are altering the way organizations do business. They’re creating alternative means of connecting data, providing visibility, enforcing safety and more.

Case in point: Emerging technologies are reshaping the future of supply chain.

In fact, the growth of adoption of emerging technologies can be attributed to

several key factors, according to ChatGTP—a disruptive solution in and of itself:

1. Increased efficiency and productivity

2. Cost reduction

3. Competitive advantage

4. Data-driven insights

5. Scalability and flexibility

6. Enhanced customer experience

7. Regulatory compliance and risk management

8. Globalization and remote work

But many experts cite Internet of Things (IoT) as the most promising emerging technology solution for the cold food chain.

“The growth in IoT availability, as well as AI becoming more accessible, has improved

a lot over the last few years. However, now the biggest challenge is getting manufacturers and their workforces to select the most scalable and accurate technologies for specific business goals like boosting productivity, efficiency, sustainability, upskilling, etc.,” says James Newman, head of product and portfolio marketing at Augury. “Let’s examine productivity first. Productivity in the manufacturing industry is flat, at best, and rapidly declining, at worst, so what’s been done in terms of technology adoption up until now hasn’t helped enough. Organizations are looking for new ways to solve productivity challenges, and those are being compounded by the silver tsunami,

tor, professional services and customer experience, Sensitech.

“These tools enable improved traceability, transparency and real-time decision-making throughout the supply chain. The result? Enhanced quality control, reduced waste and a more robust food system,” Mathai adds. “For the food industry, success hinges on the ability of these emerging solutions to address real-world challenges. These challenges include supply chain blind spots, labor shortages, food waste, rising costs and inflexible processes. Technologies offering immediate results with a clear path for continuous improvement will have the greatest impact.”

Digitalization is also critical for tracking data, gaining insights and executing on performance.

“All too often business leaders have relied on out-of-date supply chain strategies and legacy technologies, leaving them blind to the magnitude of risk hiding in their third-party relationships. These risks can look like single-source dependencies, cybersecurity vulnerabilities, reputational risks, and geopolitical disruption, all of which can impact a business’s bottom line. So, by necessity, business leaders are now addressing these issues head-on with emerging technologies and data-driven workflows that provide better visibility into the business practices of

their supply chain partners,” says Nari Viswanathan, senior director supply chain strategy, Coupa. “Digitization has been critical for gaining these valuable insights. Through automation, digital tools, and new technologies like AI and digital twins, businesses can rethink how and where they produce and source from and better predict impactful events like droughts and flooding. While this does not eliminate risk altogether, improved scenario planning can reduce potential delays, lost revenues, expedited costs, and constant fire drills, which helps them better future-proof their supply chain.”

What’s more, innovations that combine proven technologies with rapid and cost-effective deployment to solve pressing business issues are driving adoption across the supply chain, says Owen Nicholson, CEO, Slamcore.

“For example, taking cutting-edge visual spatial intelligence developed for autonomous robots and retrofitting it to intralogistics vehicles delivers immediate gains in availability of accurate, real-time data to integrate into existing real-time location systems. Adding these modules to existing fleet vehicles addresses real-world business issues from scarcity of labor to productivity and efficiency enhancement, all of which establish compelling business cases for technological adoption,” adds Nicholson. or aging workforce. People with several decades of experience are retiring and workers with limited experience are joining. Now, manufacturers are wondering: how can they empower workers with 2-3 years of experience to operate like veterans with 25-30? The answer: adopt technology that works as an AI co-pilot. Plant teams can cut back on menial tasks because it will be easier to identify production issues like machines that need repairs or processes that happen outside of a desired range. By getting the insights they need to take quicker actions, workers can focus on higher-level tasks and decisions.”

Likewise, companies are focused on enhancing efficiency, reducing costs, optimizing supply chains and minimizing food waste, and emerging technologies like IoT, real-time monitoring and predictive analytics are transforming the food industry, according to Matt Mathai, associate direc-

To keep up with the ever-changing pace of the supply chain industry, manufacturers are developing solutions that leverage artificial intelligence (AI) to monitor temperature, streamline operations, automate manual processes and better translate data.

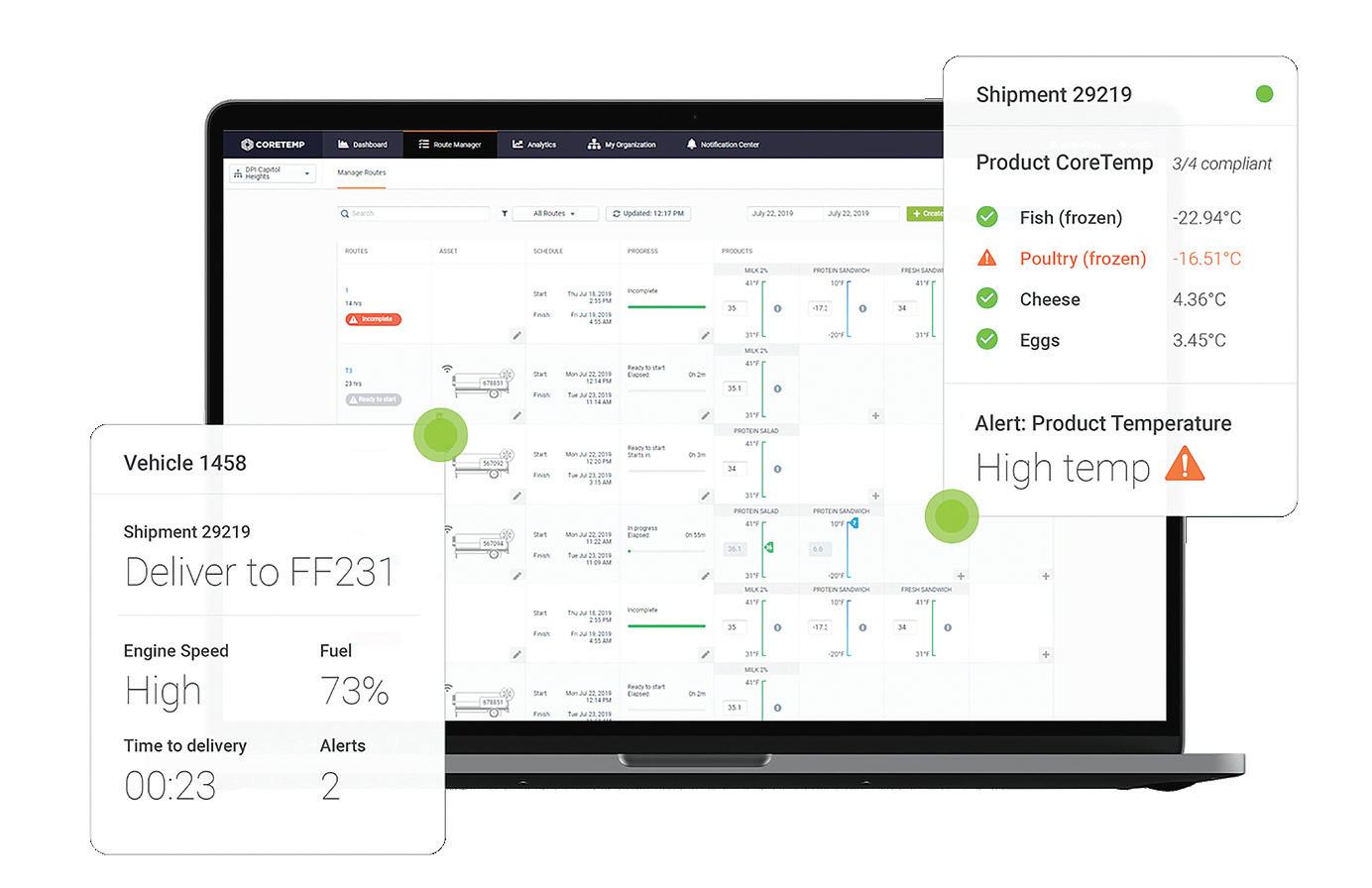

For example, EROAD continues to make significant developments to CoreTemp, which monitors core product temperatures and uses AI to drive actionable insights like early multi-layered temperature warnings, alerts per compartment, real-time route breakdowns, and performance scores.

“These advancements are disrupting how some of the largest North American brands are improving operational practices, quality standards, and minimizing product loss and damage,” says Travis Ross, solutions manager, cold chain and reefer, EROAD. “Our predictive reefer shutdown solution, powered by machine learning, continues to advance significantly, providing carriers with precise insights into the future condition of their refrigerated trailers over the next seven days. These insights are derived from a comprehensive analysis of alarm history, utilization data, and other relevant factors, progressing our ongoing mission to enable carriers to operate their fleets with optimal efficiency.”

EROAD also announced plans to develop new products and features using Microsoft’s generative AI to deliver innovative user experiences.

“Our predictive reefer shutdown solution, powered by machine learning, continues to advance significantly, providing carriers with precise insights into the future condition of their refrigerated trailers over the next seven days. These insights are derived from a comprehensive analysis of alarm history, utilization data, and other relevant factors, progressing our ongoing mission to enable carriers to operate their fleets with optimal efficiency,” adds Ross.

Augury partnered with DSV to introduce a new Parts-as-a-Service (Paas) solution that uses machine health for critical maintenance, repair, and operations production parts and equipment management based on real-time predictive maintenance insights.

“Now manufacturers can order parts when and where they need them, significantly reducing unplanned downtime and inventory carrying costs. With real-time machine insights and DSV’s inventory management solutions, manufacturers can stop buying a surplus of parts or waiting to buy parts after failures happen with all the risk that entails,” Newman says. Augury also partnered with HSB to expand its Guaranteed Diagnostics to include a production loss guarantee that protects manufacturers from unexpected downtime and production loss due to machine health events not detected by Augury.

“Deploying these emerging technologies allows manufacturers to gain real-time insights that can help them avoid waste that comes from machine malfunctions or process errors, which in turn helps reduce carbon emissions and improve worker safety,” he adds.

For its part, Grip launched a first-of-itskind order management system specifically focused on perishable direct-to-consumer (DTC). Powered by Grip’s shipping engine, which uses AI to decide the best way to send a box of refrigerated or frozen goods from Point A to Point B, “this technology was inspired by my time as head of logistics for frozen meat delivery subscription ButcherBox,” says Juan Meisel, CEO and co-founder of Grip. “I saw how we were spending millions of dollars a year trying to customize and run software for our logistics operation. I realized there was a huge gap in the market for software tailored to the unique challenges of shipping perishable products nationwide. Our

logistics engine analyzes factors such as temperature, major weather events, and carrier performance to provide package-by-package shipping recommendations. This level of insight was previously unattainable for most DTC brands due to resource constraints. We’ve also introduced large language models (LLMs) for internal and external data querying that allows us to service our clients better. You can essentially ask our OMS very complex data or logistics questions in natural language that allows us and our clients to understand our businesses better.”

In 2023, KNAPP’s first frozen shuttle installation went live at Shufersal in Israel. Operating down to -18°F, the operation allows for frozen “each picking” to support Shufersal’s digital e-commerce operation.

Earlier this year, KNAPP commissioned a comprehensive, multi-phase, mixed load palletizing solution at the Kroger Grand Lakes facility to include pallet AS/RS, shuttles, conveyor, KiSoft Genomix, KiSoft WCS and a high-velocity palletizing solu-

tion that allows Kroger to consolidate warehouse operations, reduce space used and deliver store-friendly pallets.

KNAPP also introduced Genomix to help fight the challenge of incomplete master data.

“Working closely with GS1, Genomix helps clients rapidly and cost effectively build a stronger quality of SKU dimensions and packaging characteristics (up to 60 elements). This helps ensure that SKUs that are not deemed ‘automation friendly’ are removed in order to avoid impacts to system performance,” says Greg Lary, senior systems manager, KNAPP Inc.

Also last year, Sensitech launched a new offering for monitoring outbound shipments through the SensiWatch platform. The real-time IoT solution empowers customers to take control of their outbound logistics through streamlined operations and reduced risk with vehicle-agnostic, self-deploying technology. Automated data capture and monitoring captures critical data throughout the delivery journey, including route optimization, product monitoring and real-time alerts. And end-to-end visibility and temperature control promptly address temperature deviations to optimize operational efficiency and minimize product spoilage.

“As the food industry becomes increasingly globalized, companies are seeking a competitive edge through technology. By leveraging these tools, they can differentiate their products, ensure superior quality and elevate the customer experience, ultimately staying ahead of the curve,” says Mathai.

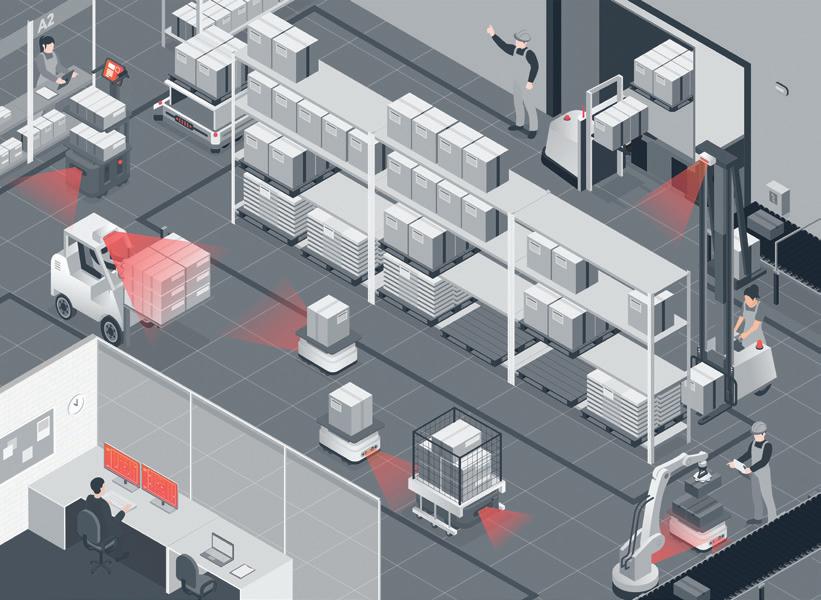

In March, Slamcore introduced Slamcore Aware, which packages cutting-edge visual spatial intelligence in a module that can be quickly and easily retrofitted to existing intralogistics vehicles.

“Giving manually driven vehicles the ability to ‘see’ and map the space around them creates highly accurate, real-time spatial data that provides for better route-planning, task allocation, vehicle location and safety features.

As a technology that scales with the number of vehicles rather than the size of the facility, and which requires virtually no external additional infrastructure, Slamcore Aware is highly suited to large-scale, dynamic warehouse and factory settings,” adds Nicholson.

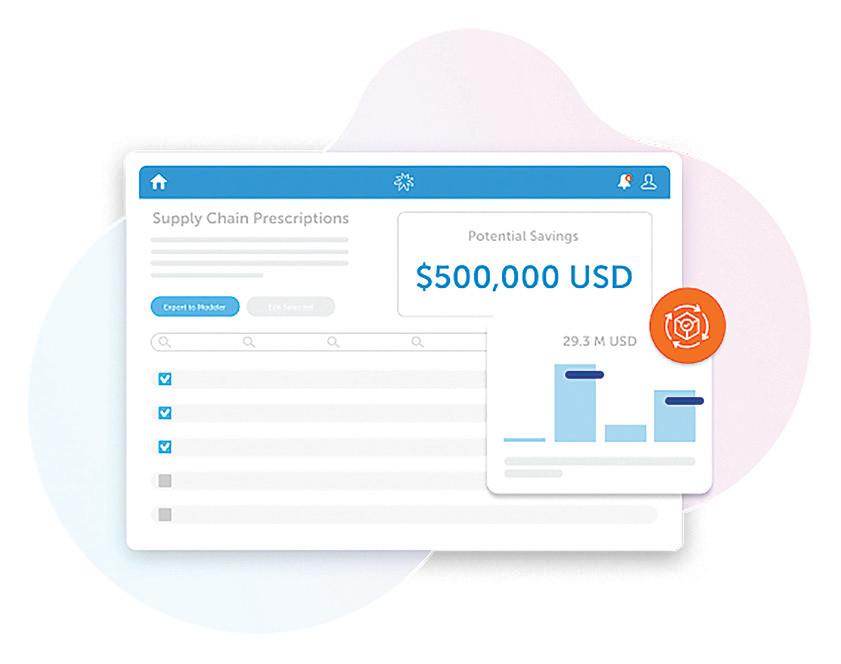

And, this summer, Coupa will launch Forecast Collaboration, which streamlines communication between buyers and suppli-

ers to better match supply and demand.

“Coupa has been leveraging AI for more than a decade and recently announced additional AI-driven automations that will support businesses by increasing payment automation, optimizing collaborative workflow processes, and creating deeper optimization capabilities. These new offerings help companies make smarter, more strategic decisions to improve business

• Over 18,000 Pallets of Racked Multi-Temperature Controlled Space Located in the Distribution Hub of Southern California

• Cold, Air Conditioned and Dry Storage for Dairy-Deli, Ready-to-Eat Meals, Juices & Smoothies, Milk and PlantBased Beverages, Yogurts & Spreads, Pharmaceuticals, Alcoholic Beverages, Food Ingredients & Packaging, Baking & Confections and CPG Goods

• Organic & Natural Food Products

• Flexibility, Cost-Efficiency and Superior Quality Customer Service

• Full-Service Transportation Services Managed In-House

• Wide Array of Value-Added Services Kitting & Heat-Shrinking Services

• Complete Product Monitoring with 24/7 On-Line Access. EDI, CSV, FTP, XLS, AS2

• E-Commerce Fulfillment Services

• SQF Level 2 GFSI Certification with Costco ADD with Excellent Scores!

• State Board of Pharmacy Licenses

• International Language Labeling

• Alcoholic Beverage Licenses, 14/17

A Thayer Group Company

8858 Rochester Avenue Rancho Cucamonga, CA 91730

Mailing: P.O. Box 1269, RC, CA 91729-1269

Phone: (909) 483-5841, Ext. 117

Fax: (909) 483-1792 www.dswdist.com • sales@dswdist.com

Slamcore Aware packages cutting-edge visual spatial intelligence in a module that can be quickly and easily retrofitted to existing intralogistics vehicles.

decisions and collaboration across the supply chain,” says Viswanathan.

What’s next?

For many companies, stepping out into the wilderness of selecting the right solution for your business can be daunting. Where to start? How to start? How do you know what solution is the best fit for your operation?

Sometimes it’s as simple as identifying the problem and then implementing the solution to fix it.

“Once a clear problem is identified, the next step is identifying the technology and the provider who can support your mission. There are too many industrial tech providers to count; you have to figure out which vendors can move the needle for your company and which vendors are just pushing marketing jargon. In the case of AI, when exploring a new solution, look at the algorithms and understand if they are built to do the job they are designed to do. Are they being continually re-trained across a large dataset, or are they custom-built for your limited dataset? It’s also important to poke holes in a vendor’s pitch. For example, if a company’s sales team claims an impressive stat about their accuracy - ask them to prove it,” says Newman.

Other times, this process involves the need to cultivate a willingness to delve into the operational details and be patient with the process.

“While technology generates data that may initially reveal challenges, that data is always actionable, offering opportunities

for significant improvements to profit and loss. Once willingness is established, it’s crucial to invest time in researching the best industry partners who can assist in optimizing key performance indicators (KPIs) related to cold chain,” says Ross.

Regardless of your current supply chain maturity level, gaining real-time visibility into your operations is the first crucial step, advises Mathai.

“Solutions that identify problem areas are the foundation for improvement. From there, organizations can leverage advanced analytics to drive operational transformations. Once on the path, we’ve seen customers continuously build upon their digital capabilities so they can better leverage tools like AI to drive growth and cost savings,” he adds.

Supply chain leaders and operators should also look at pain points, inefficiencies, and potential areas of improvement.

“Companies should not only ask themselves what they need to improve on, but also get feedback from suppliers on where they think a breakdown is happening,” says Viswanathan. “Some of the most impactful technologies for supply chains are business spend management software for improved transactions and supplier management, supply chain network design for managing constantly evolving supply-demand networks, IoT for real-time tracking and monitoring, and AI for predictive analytics. Ultimately, companies should prioritize technologies that align with their strategic objectives, offer tangible benefits, and demonstrate a clear return on investment for their supply chain operations.”

ture-controlled products.

“Accompanying this is the growth in demand for ‘ready-to-cook’ convenience meals. These market drivers have a direct effect on the need for emerging technologies and will result in faster adoption of new technology. We would expect a spike of investments into software and mechanics that can exist in a sub-freezing temperatures to help alleviate the labor void in this environment” says Lary.

Stockpiling and “just-in-case” inventory systems may always continue to be a “thing” in the grocery retail space.

“This is where AI and digital twin technology are going to be important, especially as we continue to see global warming have an impact on the food supply chain, something we’ve already witnessed in the dairy industry with a butter shortage last year,” says Viswanathan. “These technologies offer digital replicas of the physical supply chain that can help test scenarios and prevent disruption. While these technologies can’t prevent risk, they can allow businesses to plan around disruption and create solutions faster.”

But, what really is next? How will emerging technologies continue to reshape the cold food chain?

For starters, “the demand for increased visibility and transparency in food quality is only growing stronger—from consumers to production. Therefore, now is a great time to explore and embrace these emerging technologies and their potential benefits for the business,” says Ross.

The increasing preference toward fresh and perishable commodities continues to result in a sharp increase in the cold chain solutions needed to protect tempera-

This summer, Coupa will launch Forecast Collaboration, which streamlines communication between buyers and suppliers to better match supply and demand.

And, getting goods in and out of facilities on time, every time is critical.

“But these facilities are also constantly changing. Internal layouts expand, change, and are reorganized with accelerating regularity. Whatever technological systems you deploy must be flexible enough to cope with this constant change,” says Nicholson.

To put it simply, emerging technologies accelerate innovation because it allows

companies to move faster with more data, says Meisel.

“It increases the accuracy rate of decision making which allows the industry to reduce waste and service customers better,” he adds.

Oftentimes a supply chain disruption centers around an event, but sometimes, it also stems from the emerging technologies taking the cold food chain by storm, leveraging AI and IoT to mitigate risk, streamline operations, automate processes and more.

Note from the editor: Parts of the article were written by ChatGTP and sourced as such. The use of ChatGTP in this article or any article published by Food Logistics is not common practice but was merely an add-on to the emerging technology conversation.

For companies that haven’t implemented any form of emerging technology yet or are just starting their journey, here are some steps to effectively begin integrating these technologies, according to ChatGTP:

1. Assess business needs and goals

2. Educate yourself and your team

3. Start small with pilot projects

4. Prioritize based on impact and feasibility

5. Collaborate with experts and partners

6. Build a culture of innovation and experimentation

7. Invest in infrastructure and talent

8. Stay agile and adaptive

Deciphering which emerging technologies are best suited for a company’s supply chain requires a strategic approach and careful consideration of many factors. Here are some steps companies can take to make informed decisions, according to ChatGTP:

1. Assess pain points

2. Understand business objectives

3. Research the various emerging technologies

4. Evaluate potential impact

5. Conduct pilot projects

6. Engage stakeholders

7. Consider industry best practices

8. Invest in talent and training

9. Focus on data security and compliance

10. Monitor industry trends

Cross-border trade has become a cornerstone of economic growth around the world. Still, navigating the complexities of international logistics can be a daunting task for companies of all sizes. Luckily, third-party logistics (3PL) providers are increasingly revolutionizing the process of services to streamline and optimize cross-border operations.

Case in point: Cross-border trade presents a myriad of challenges, from varying regulations and customs procedures to transportation and warehousing complexities. Tony Esparza, VP of strategic operations at Hercules, details why the high volume of goods being moved across the northern and southern border is not new.

“U.S. imports from Canada have

increased at an annualized rate of around 4.23% over the last 27 years and reached $429.6 billion in 2023. Meanwhile, U.S.

exports to Canada have increased at an annualized growth rate of 3.69% over that same period, reaching $352.76

billion in 2023,” says Esparza. “Likewise, the value of goods imported to the U.S. from Mexico rose to over $475 billion in 2023 and imports from Mexico to the U.S. are expected to increase by 30-40% in the next 5 years, especially as interest in nearshoring continues to grow. While increased trade between the U.S., Mexico and Canada will positively impact businesses and the economy, it brings with it a range of cross-border transportation challenges that shippers must navigate.”

While 3PLs have undoubtedly simplified cross-border operations, they are not without limitations. One of the primary challenges is the fragmented nature of international trade regulations and customs procedures. Navigating these complexities requires a solid infrastructure.

“Within this already complicated ecosystem of regulations, different border crossings require different customs procedures. As a result, shippers must know the different requirements and procedures for northbound versus southbound freight, as well as for individual origin terminals. Shippers should not assume the requirements and procedures for transporting goods from the U.S. into Canada are the same as going from Canada to the U.S.; otherwise, they risk having shipments held up at the border,” says Esparza.

Additionally, these movements often entail longer transit times and higher costs compared to domestic operations. Jose Minarro, managing director for Sunset Transportation’s Mexico operations, explains transporting perishables over international borders introduces distinct challenges, necessitating tailored strategies to guarantee that these goods reach their destination in prime condition.

“The complexity of this task is heightened by the imperative for timely logistics, adherence to global regulations and the fragile nature of perishable items. Preventing spoilage and the spread of infections or diseases ranks high among concerns in cross-border perishable

transport. Items such as food, pharmaceuticals and flowers necessitate specific temperature conditions during their journey to avoid spoilage. Achieving this requires refrigerated containers (reefers) and continuous monitoring, significantly elevating both the costs and logistical complexity of transportation,” says Minarro.

A perishables’ shelf life is an emphasis on the need for prompt and timely transport. Delays risk the expiration of products before delivery to consumers, which Minarro says, leads to financial losses and unnecessary waste, therefore strategic logistics planning and expediting customs clearances are crucial for minimizing travel times.

At Romark, we blend personalized service with cutting-edge technology to create best-in-class logistics solutions for leading consumer packaged goods, pharmaceutical, and retail companies worldwide.

Our dedicated team delivers custom solutions using technical innovations such as AI-driven logistics platforms, state-of-the-art tracking systems, automated co-packaging machinery and automated warehouses.

We are also deeply committed to sustainability, leveraging the latest technologies to conserve resources, promote energy efficiency, minimize waste, and reduce carbon emissions.

Our clients get the best of both worlds: the precision and efficiency of advanced technology, along with the personalized service that only a committed team of experienced professionals can provide.

Partner with us today and strategically plan for tomorrow.

Technology has emerged as a gamechanger for 3PLs, offering innovative solutions to overcome traditional limitations. Utilizing transportation software and compliance solutions, Esparza describes, expedites the crossborder shipping process by automating documentation creation and submission while also reducing manual process time and errors.

“By automating the process, you avoid

needing to compile documents from multiple sources. It also ensures all necessary documents, containing complete and accurate information, are available to all stakeholders, when and where they need them. Advanced logistics software and digital platforms enable real-time tracking and visibility across the supply chain, allowing businesses to monitor their shipments at every stage of the journey,” says Esparza.

Technologies such as artificial intelligence (AI) and machine learning (ML) algorithms also hold immense potential

for enhancing transparency and security. Minarro says freight technology innovations, including the use of AI and advanced analytics to gain a competitive edge, are helping with optimizing routes, improving delivery times and enhancing overall efficiency in freight operations.

“Specific focus is on the adoption of digital solutions within the cross-border freight market. Key areas of investment include platforms for better tracking and management of shipments, as well as tools for simplifying customs clearance

and border crossing procedures. This emphasis on digitalization is aimed at making the cross-border transportation of goods faster, more reliable, and more transparent for many reasons, including freight fraud prevention,” Minarro explains.

For successful cross-border shipping of perishables specifically, Minarro describes the crucial feature of mastering several key practices.

“Understanding the regulatory landscape is paramount to ensure full compliance with international standards. Selecting the appropriate packaging, including cold packs and other materials that preserve freshness, is essential to maintain the quality of perishables throughout their transit. Timing the shipment to optimize speed and avoid potential traffic delays, particularly by choosing the most strategic days and times for shipping, can make a significant difference in delivery efficiency. Preparing all necessary documentation in advance streamlines the customs clearance process, and enrolling in trade facilitation programs may further expedite the movement of pre-approved, low-risk goods,” says Minarro.

“Performing thorough quality checks at various stages—before departure, during transit and upon arrival—is vital to ensuring that perishables meet the required standards from the point of origin to the destination,” Minarro continues.

“Additionally, staying informed about the current economic conditions, trade policies, and international relations is essential to navigating potential challenges in cross-border shipments. Finally, accurate and complete shipping labels are critical for complying with international shipping restrictions and facilitating a smooth transportation process for perishable goods.”

Looking ahead, the cross-border logistics sector is poised for contin-

ued innovation and growth. As global trade volumes continue to rise, the demand for efficient and reliable logistics solutions will only intensify. Effective cross-border transportation without delays relies on collaboration and coordination among importers, exporters, transportation providers, customs and border authorities and other stakehold-

ers, says Esparza. And while a challenging process no doubt, especially when cold monitoring is involved, there are steps shippers can take to set themselves up for success. With best practices in management and the implementation of technology, 3PLs can navigate cross-border shipping and expand their global reach into 2025.

Our investments in rail will move cargo through the Port of Long Beach more efficiently and with less environmental impact than ever before. We’re working to speed cargo to market and lower the cost of doing business.

From closures and the never-ending driver shortage to fighting labor costs and adjusting to electrification, it’s been quite the year for third-party logistics (3PL) providers. Yet 3PLs and cold storage providers remain a key puzzle piece to building and nurturing partnerships, cultivating resilience and helping companies in the cold food space overcome supply chain disruptions.

That’s why it’s important we honor and celebrate the top 3PLs and cold storage providers, both nationally and internationally.

Meet the winners of this year’s Top 3PL and Cold Storage Providers award.

Many of this year’s winners offer a variety of 3PL services,

with the top being LTL/TL (80% of winners), refrigerated trucking (79%), and truckload brokerage (77%), while many of the top cold storage services offered are cold storage (78%), cross docking (73%), warehousing/distribution management (72%) and fulfillment and EDI capabilities tied at 70%.

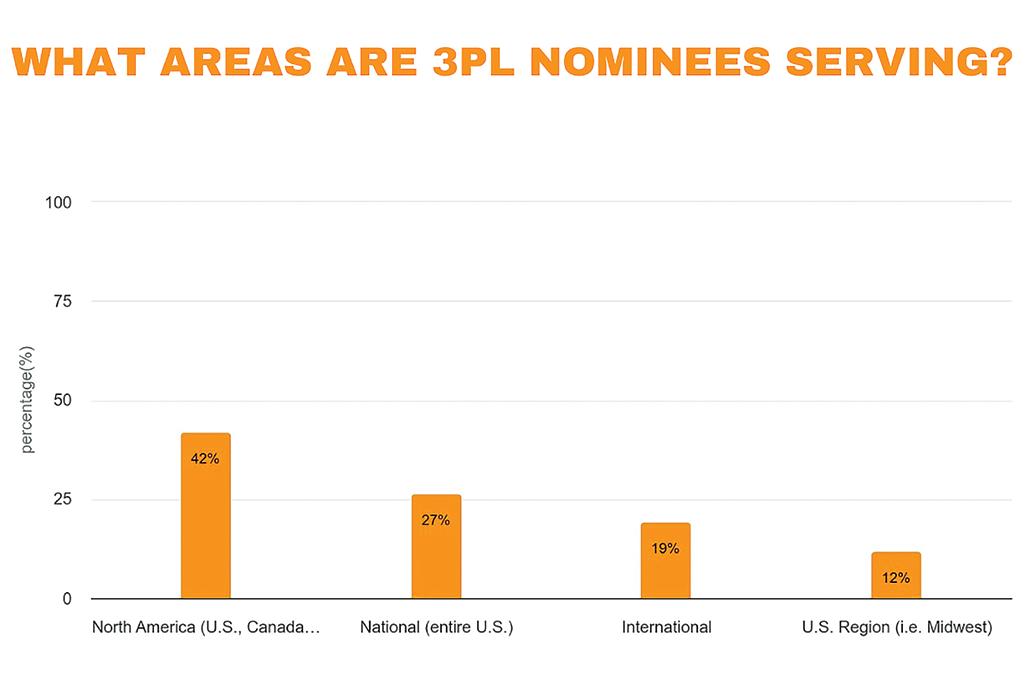

And, 42% of companies service North America.

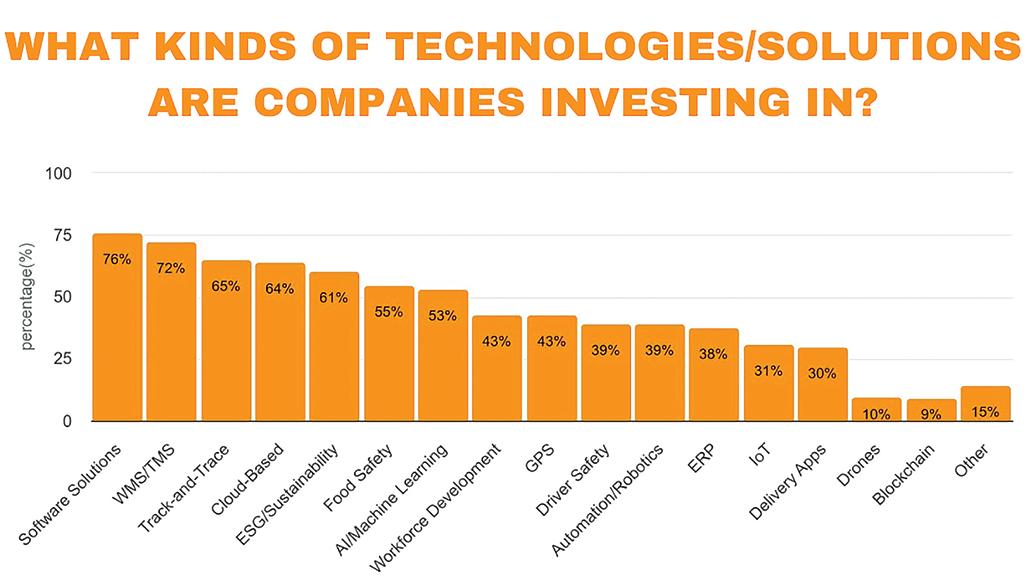

Seventy-six percent of the winners plan to invest in software solutions this year, with 72% investing in warehouse management systems/transportation management systems (WMS/TMS). This is indicative of how forward-thinking these 3PLs and cold storage providers are, and how despite disruptions and other challenges, they continue to forge ahead.

Let’s meet the overall winner for Top 3PL and overall winner for Top Cold Storage. OVERALL TOP 3PL WINNER:

Truckstop

https://truckstop.com

Truckstop, this year’s overall Top 3PL winner, is a trusted partner for carriers, brokers, and shippers, empowering the freight community through a platform of innovative solutions for the entire freight lifecycle to increase efficiency, automate processes, and accelerate growth. This year, Truckstop introduced new security enhancements for brokers using its RMIS system, aimed at improving safety and trust within networks. These advancements include a sophisticated identity verification process that requires carriers to validate their identities annually or upon ID expiration by comparing their government-issued identification against a real-time photograph. Additionally, an enhanced multi-factor authentication (MFA) feature protects against compromised credentials, facilitating secure and smooth access to both Truckstop and RMIS platforms. Dedicated to innovative technology that enhances the freight process, Truckstop also announced new patent filings, including one for generative AI in freight solutions; and introduced Load Alert Notifications, which allows carriers and brokers to access legitimate freight and trusted capacity more quickly and at scale. Other noteworthy achievements include Truckstop’s acquisition of the FreightFriend platform; and developing an exclusive partnership with Carrier Assure to enhance carrier vetting within the RMIS platform. This partnership represents a significant step forward in improving the efficiency and reliability of carrier onboarding and monitoring and showcases a commitment to advancing industry standards.

Stoecklin Logistics

www.stoecklin.com/en-us

To meet evolving e-commerce demands and ensure freshness and quality, Stoecklin Logistics, a leading provider of automated material handling and warehouse storage systems and this year’s overall Top Cold Storage Providers winner, continues to deliver innovative logistics solutions to more than 1,200 customers worldwide. In 2023, the company launched the Stoecklin CasePicker, designed to help minimize waste in fresh food distribution. The gripper allows different returnable and disposable containers to be picked immediately after one another, can operate in freshness zones ranging from 39.2°F to 57.2°F and can handle up to 135,000 cases of fresh fruit and vegetables a day. Further reducing energy waste, Stoecklin’s AGV and forklift fleets are equipped with energy management solutions that include energy recovery, IT-supported journey optimization, adaptive dynamics and minimization of emission sound pressure in rack handling and conveyor systems. Additionally, Stoecklin Logistics is helping leading cold storage companies achieve long-term success with solutions that ensure simple modular integration to reduce manual labor and promote healthier working environments.

Here are some additional standouts:

DSW Distribution Centers, Inc.

www.dswdist.com

DSW is a 51-year-old, family-owned food-grade, multitemperature-controlled 3PL specializing in perishable food products, beverages, organics, pharmaceuticals, and general commodities. DSW is SQF Level 2 GFSI-Certified with a Costco Addendum with Excellent Rating Scores, and is USDA NOPOrganic Certified, Alcoholic Beverage Licensed and holds over 12 State Board of Pharmacy Licenses. DSW packs VIP variety packs and shrink packs and trays for over 40 customers worldwide. It maintains alliances with other companies for port drayage, customs brokerage and freight forwarding, national transportation and distribution centers, and provides full LTL/ TL transportation services, retailer compliance programs, website shopping cart e-commerce fulfillment, international export labeling, EDI/XML/CSV/FTP automation, heat-shrinking and more.

MoLo, a service of ArcBest, provides best-in-class truckload brokerage services across North America, connecting shippers and carriers to deliver products when and where they’re needed. Backed by ArcBest’s asset-based system, MoLo offers the capacity to scale and keep supply chains moving and businesses growing. ArcBest’s asset-based system includes ArcBest’s dedicated fleet, the Panther expedite fleet, ABF Freight equipment, and company-owned flatbeds, trailers, dry vans, rail containers, and refrigerated trailers. In addition to an account team built around their needs, customers can always reach MoLo’s 24/7, after-hours and weekend operations support teams.

https://romarklogistics.com

Romark Logistics is a comprehensive, technology-driven logistics company, providing innovative, tailored supply chain solutions. With roots dating back to 1954, Romark has expanded strategically, encompassing more than 10 million square feet of owned or managed industrial real estate in key locations throughout New Jersey, Pennsylvania, Georgia, Texas, California, and Arkansas, with an additional 12 million square feet through a joint venture with Woodmont Industrial. Embracing early adoption of cutting-edge automation, technology, and e-commerce solutions has further elevated its top-tier service, catering to fast-moving consumer goods, pharmaceutical, and food and beverage companies. As part of its ongoing sustainability initiatives, Romark earned the Supplier Leadership on Climate Transition (Supplier LoCT) GHG Scope 1, 2, and 3 Footprint badges, highlighting the company’s dedication to reducing its environmental impact, conserving resources, and assisting clients in achieving their green objectives. Romark optimizes warehouse operations for maximum efficiency and service excellence by leveraging leading-edge technology such as robotics. Advanced systems like very narrow aisle environments (VNAs), autonomous mobile robots (AMRs), and automated guided vehicles (AGVs) enhance warehouse processes. Romark utilizes drone inventory management to provide real-time insights and enhance inventory tracking accuracy. And, through strategic partnerships with the New Jersey Innovation Institute, technological advancements, and a focus on sustainability, Romark demonstrates its broader commitment to harnessing technology and innovation to drive industry-leading solutions.

A.N. Deringer Inc. | www.anderinger.com

Air Cargo, Customs Brokerage, Drayage Service, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking

AJC Logistics | www.ajclogistics.com

Customs Brokerage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Intermodal, LTL/ TL, Ocean Carriers, Refrigerated Trucking, Truckload Brokerage

Allen Lund Company, LLC | www.allenlund.com

Drayage Service, Freight Forwarding, Intermodal, LTL/TL, Truckload Brokerage

Americold | www.americold.com

Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Arcadia Cold Storage & Logistics | www.arcadiacold.com

Drayage Service,LTL/TL,Multi-Vendor Consolidation,Refrigerated Trucking

Arrive Logistics | www.arrivelogistics.com

Bulk/Liquid Bulk Transportation, Cross-Border (Mexico & Canada), Customs Brokerage, Drayage Service, Drop Trailer, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Open Deck, Rail, Refrigerated Trucking, Truckload Brokerage

Atlanta Bonded Warehouse | www.atlantabonded.com

Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Fuel Savings Program, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Belts Logistics Services | www.beltslogistics.com

Drayage Service, Intermodal, Last-Mile, LTL/TL, Truckload Brokerage

Best Bay Logistics | https://bestbaylogistics.com/

Bulk/Liquid Bulk Transportation, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

BlueGrace Logistics | www.mybluegrace.com

Air Cargo, Customs Brokerage, Drayage Service, Freight Forwarding, Fuel Service-Managed Transportation, Intermodal, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

BM2 Freight Services, Inc | www.bm2freight.com

Bulk/Liquid Bulk Transportation, Drayage Service, Freight Forwarding, Intermodal, Last-Mile, LTL/ TL, Refrigerated Trucking, Truckload Brokerage

Brown Integrated Logistics | www.brownintegratedlogistics.com

Dedicated Contract Carriage, Drayage Service, LTL/TL, Truckload Brokerage

C.H. Robinson | www.chrobinson.com

Air Cargo, Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

Candor Expedite | www.candorexp.com

Air Cargo, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Last-Mile, LTL/ TL, Refrigerated Trucking, Truckload Brokerage

Capstone Logistics | www.capstonelogistics.com

Direct-Store Delivery, Drayage Service, Fuel Service-Managed Transportation, Intermodal, LastMile, LTL/TL, Rail, Refrigerated Trucking, Truckload Brokerage

CJ Logistics America | https://america.cjlogistics.com

Air Cargo, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

Cold Storage Solutions | www.coldstoragesolutions.com Last-Mile, Refrigerated Trucking

Corporate Traffic Logistics | www.corportetraffic.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Dedicated Contract Carriage, Drayage Service, Freight Forwarding, Intermodal, LTL/TL, Rail, Refrigerated Trucking, Truckload Brokerage

Covenant Logistics | www.covenantlogistics.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fleet Leasing, Freight Forwarding, Fuel Savings Program, Intermodal, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Coyote Logistics | www.coyote.com

Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Intermodal, Last-Mile, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

DSW Distribution Centers, Inc. | www.dswdist.com

Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Last-Mile, LTL/TL, MultiVendor Consolidation, Refrigerated Trucking, Truckload Brokerage

EASE Logistics | www.easelogistics.com

Air Cargo, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Intermodal, Last-Mile, LTL/TL, Refrigerated Trucking, Truckload Brokerage

East Coast Warehouse & Distribution Corporation | www.eastcoastwarehouse.com

Dedicated Contract Carriage, Drayage Service, Fuel Savings Program, Last-Mile, LTL/TL, MultiVendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Echo Global Logistics | www.echo.com

Air Cargo, Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Intermodal, LastMile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

England Logistics | www.englandlogistics.com

Freight Forwarding, Fuel Savings Program, Intermodal, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

FlexCold, LLC | https://flexcold.com

Customs Brokerage, Drayage Service

FST Logistics | www.fstlogistics.com

Bulk/Liquid Bulk Transportation, Dedicated Contract Carriage, Drayage Service, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

Genpro Inc. | www.genproinc.com

Intermodal, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Grip | https://gripshipping.com

Air Cargo, Last-Mile, LTL/TL, Multi-Vendor Consolidation

Hub Group | www.hubgroup.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

J.B. Hunt Transport Services Inc. | www.jbhunt.com

Air Cargo, Bulk/Liquid Bulk Transportation, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Fuel Savings Program, Fuel ServiceManaged Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

Jarrett | www.gojarrett.com

Air Cargo, Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fleet Leasing, Freight Forwarding, Intermodal, Ocean Carriers, Rail, Truckload Brokerage

Johanson Transportation Service | www.johansontrans.com

Air Cargo, Consulting, Cross Docking, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Drop Trailer Programs, Expedited, Freight Brokerage, Freight Payment/Auditing, Hazmat, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, NVOCC, Ocean Carriers, Ocean Freight Forwarder, Oversized/Overweight, Pool Consolidation, Rail, Refrigerated Trucking, Reverse Logistics, Routing/Scheduling, Transloading, Transportation Management, Truckload Brokerage

Kenco | https://kencogroup.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Lindner Logistics, LLC | www.lindnerlogistics.com

Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Freight Forwarding, LTL/TL, Refrigerated Trucking, Truckload Brokerage Lineage | www.onelineage.com

Customs Brokerage, Dedicated Contract Carriage, Drayage Service, Intermodal, Last-Mile, MultiVendor Consolidation, Rail, Refrigerated Trucking Longship | www.longship.us

Bulk/Liquid Bulk Transportation, Direct-Store Delivery, Drayage Service, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Matson Logistics | www.matsonlogistics.com

Direct-Store Delivery, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Over-Dimensiona/Heavy Haul/Breakbulk/Special Project Cargo Rail, Refrigerated Trucking, Truckload Brokerage

Maverick Transportation, Inc. | https://mavericktransportation.com

LTL/TL, Refrigerated Trucking, Truckload Brokerage

MegaCorp Logistics | www.megacorplogistics.com

Air Cargo, Bulk/Liquid Bulk Transportation, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fuel Savings Program, Intermodal, Last-Mile, LTL/TL, MultiVendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

MoLo Solutions | www.shipmolo.com

Carrier Fleet Management, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Expedited Truckload, Hazmat Transport, High-Risk/High-Value Freight Program, Refrigerated Trucking, Specialized Equipment Truckload, Trailer Pool/Drop-and-Hook Services, Truckload Brokerage

Nexterus | www.nexterus.com

Customs Brokerage, Drayage Service, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, MultiVendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

NFI | www.nfiindustries.com

Air Cargo, Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Intermodal, LastMile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

ODW Logistics | www.odwlogistics.com

Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Intermodal, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

OTR Transportation | https://loadotr.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Direct-Store Delivery, Drayage Service, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

Penske Logistics | www.penskelogistics.com

Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Fleet Leasing, Freight Forwarding, Fuel Savings Program, Intermodal, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Perishable Distributors of Iowa (PDI), a Hy-Vee subsidiary | https://contactpdi.com/index.php

Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, LTL/ TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

PLS Logistics Services | www.plslogistics.com

Bulk/Liquid Bulk Transportation, Drayage Service, Intermodal, LTL/TL, Rail, Refrigerated Trucking, Truckload Brokerage

Prosponsive Logistics | https://prosponsive.com

Air Cargo, Customs Brokerage, Drayage Service, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

Quality Custom Distribution | www.qualitycustomdistribution.com

Direct-Store Delivery, Last-Mile, Multi-Vendor Consolidation, Refrigerated Trucking

Quality Distribution LLC | www.qdislc.com

Direct-Store Delivery, Drayage Service, Freight Forwarding, Last-Mile, LTL/TL, Truckload Brokerage

Romark Logistics | https://romarklogistics.com

Air Cargo, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/ TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Ryder System, Inc. | www.ryder.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, E-Commerce/Omnichannel Fulfillment; Fleet Leasing, Freight Forwarding, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

Saddle Creek Logistics Services | www.sclogistics.com

Air Cargo, Dedicated Contract Carriage, Direct-Store Delivery, Fleet Leasing, Fuel ServiceManaged Transportation, Intermodal, LTL/TL, Rail, Refrigerated Trucking, Truckload Brokerage Sheer Logistics | www.sheerlogistics.com

4PL/Managed Transportation Services, Customs Brokerage, Direct-Store Delivery, Fuel ServiceManaged Transportation, Intermodal, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

Simple Logistics | www.simplelgx.com

Direct-Store Delivery, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Soren Transport, Inc. | https://sorentransport.com

Air Cargo, Continuous Moves, Dedicated Contract Carriage, Cross-Border Freight, Direct-Store Delivery, Drayage Service, Expedited Freight, Final Mile, Freight Forwarding, Fuel Savings Program, Fulfillment Solutions, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Peak-and-Surge Capacity, Project Logistics, Refrigerated Trucking, Reporting and Analysis, Specialized/Custom Freight Carriage, Storage/Warehousing Procurement, Supply Chain Consultation, Truckload Brokerage

SpartanNash | www.spartannash.com

Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Freight Forwarding, Freight Solutions Management, Intermodal, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

States Logistics Services, Inc. | www.stateslogistics.com

Air Cargo, Continuous Moves, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fleet Leasing, Freight Forwarding, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

Syfan Logistics | https://syfanlogistics.com

Customs Brokerage, Dedicated Contract Carriage, Drayage Service, Last-Mile, LTL/TL, Refrigerated Trucking

Taylor Logistics Inc. | https://taylorlogistics.com

Dedicated Contract Carriage, Intermodal, LTL/TL, Multi-Vendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Total Distriburion, Inc. | www.totaldistribution.com

Bulk/Liquid Bulk Transportation, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Total Quality Logistics | www.tql.com

Air Cargo, Bulk/Liquid Bulk Transportation, Customs Brokerage, Direct-Store Delivery, Drayage Service, Freight Forwarding, Intermodal, Last-Mile, LTL/TL, Ocean Carriers, Rail, Refrigerated Trucking, Truckload Brokerage

Transervice Logistics Inc. | www.transervice.com

Bulk/Liquid Bulk Transportation, Customs Brokerage, Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Fleet Leasing, Freight Forwarding, Fuel Savings Program, Fuel ServiceManaged Transportation, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Transfix | www.transfix.io

Dedicated Contract Carriage, Intermodal, Last-Mile, LTL/TL, Truckload Brokerage

TransLoop | https://transloop.io

Bulk/Liquid Bulk Transportation, Dedicated Contract Carriage, Drayage Service, Fleet Leasing, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Triple T Transport, Inc. | https://triplettransport.com

Continuous Moves, Direct-Store Delivery, LTL/TL, Refrigerated Trucking, Truckload Brokerage

Truckstop | https://truckstop.com

Customer Relationship Management, E-Commerce, Freight Payment, Internet of Things, Load Planning, Mobile Technology, Supply Chain Management, Supply Chain Visibility, Systems Integration, Transportation Management Systems, Truckload Brokerage

Universal Pure | www.universalpure.com

High-Pressure Processing Solutions

Weber Logistics | www.weberlogistics.com

Dedicated Contract Carriage, Direct-Store Delivery, Drayage Service, Last-Mile, LTL/TL, MultiVendor Consolidation, Refrigerated Trucking, Truckload Brokerage

Werner Enterprises | www.werner.com

Bulk/Liquid Bulk Transportation, Continuous Moves, Dedicated Contract Carriage, DirectStore Delivery, Drayage Service, Fleet Leasing, Fuel Savings Program, Fuel Service-Managed Transportation, Intermodal, Last-Mile, LTL/TL, Multi-Vendor Consolidation, Rail, Refrigerated Trucking, Truckload Brokerage

Zipline Logistics | www.ziplinelogistics.com

Air Cargo, Drayage Service, Intermodal, Last-Mile, LTL/TL, Rail, Refrigerated Trucking, Truckload Brokerage

A.N. Deringer Inc. | www.anderinger.com

Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Order Assembly, Pick/Pack Assembly, USDA/FDA Inspection, Warehousing/Distribution Management

AJC Logistics | www.ajclogistics.com

Cross Docking, EDI Capabilities, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Americold | www.americold.com

Blast Freezing, Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Arcadia Cold Storage & Logistics | www.arcadiacold.com

Blast Freezing, Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/ Distribution Management

Arrive Logistics | www.arrivelogistics.com

Consulting, Cross Docking, EDI Capabilities, Public Refrigerated Warehousing, Storage

Atlanta Bonded Warehouse | www.atlantabonded.com

Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/ Distribution Management

Brown Integrated Logistics | www.brownintegratedlogistics.com

EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/Recalls, Storage, Warehousing/Distribution Management

Candor Expedite | www.candorexp.com

Blast Freezing, Consulting, EDI Capabilities, Packaging, Pick/Pack Assembly, Reverse Logistics/ Recalls, Storage

Capstone Logistics | www.capstonelogistics.com

Consulting, Cross Docking, Fulfillment, Inventory Management, Kitting/Assembly, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/Recalls, Storage, Warehousing/Distribution Management

CJ Logistics America | https://america.cjlogistics.com

Blast Freezing, Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Cold Storage Solutions | www.coldstoragesolutions.com

Blast Freezing, Cross Docking, Inventory Management, Public Refrigerated Warehousing, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Corporate Traffic Logistics | www.corportetraffic.com

Consulting, EDI Capabilities

Covenant Logistics | www.covenantlogistics.com

Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/ Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

DSW Distribution Centers, Inc. | www.dswdist.com

Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/ Distribution Management

East Coast Warehouse & Distribution Corporation | www.eastcoastwarehouse.com

Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Multi-Vendor Consolidation, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Echo Global Logistics | www.echo.com

Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Packaging, Pick/Pack Assembly, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

England Logistics | www.englandlogistics.com

Freight Brokerage

FlexCold, LLC | https://flexcold.com

Blast Freezing, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

FST Logistics | www.fstlogistics.com

Consulting, Cross Docking, E-Commerce/Nesting/Retail Fulfillment, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Grip | https://gripshipping.com

Consulting, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/Recalls, Storage, Warehousing/Distribution Management

Hub Group | www.hubgroup.com

Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/ Distribution Management

International Cold Storage, Inc | www.international-cold-storage.com

Cross Docking, Storage, Warehousing/Distribution Management

J.B. Hunt Transport Services Inc. | www.jbhunt.com

Cross Docking, Fulfillment, Inventory Management, Multi-Vendor Consolidation, Pick/Pack Assembly, Reverse Logistics/Recalls, Warehousing/Distribution Management

Johanson Transportation Service | www.johansontrans.com

Consulting, Cross Docking, EDI Capabilities, Multi-Vendor Consolidation, Reverse Logistics/Recalls, Storage, Warehouse/DC Location Services, Warehousing/Distribution Management

Kenco | https://kencogroup.com

Blast Freezing, Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Körber Supply Chain | www.koerber-supplychain.com

Consulting, Fulfillment, Inventory Management, Packaging, Pick/Pack Assembly, Storage, Warehousing/Distribution Management

Lindner Logistics, LLC | www.lindnerlogistics.com

Blast Freezing, Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Lineage | www.onelineage.com

Blast Freezing, Cross Docking, EDI Capabilities, Fulfillment, High-Pressure Processing, Inventory Management, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Matson Logistics | www.matsonlogistics.com

Cross Docking, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Packaging, Pick/Pack Assembly, Public Refrigerated Warehousing, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

MegaCorp Logistics | www.megacorplogistics.com

Cross Docking, EDI Capabilities, Reverse Logistics/Recalls, USDA/FDA Inspection

Nexterus | www.nexterus.com

Consulting, Cross Docking, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Pick/Pack Assembly, Reverse Logistics/Recalls, Storage, Warehousing/Distribution Management

NFI | www.nfiindustries.com

Consulting, Cross Docking, EDI Capabilities, Fulfillment, Inventory Management, Kitting/Assembly, Multi-Vendor Consolidation, Order Assembly, Packaging, Pick/Pack Assembly, Reverse Logistics/ Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

ODW Logistics | www.odwlogistics.com

EDI Capabilities, Fulfillment, Inventory Management, Public Refrigerated Warehousing, Reverse Logistics/Recalls, Storage, USDA/FDA Inspection, Warehousing/Distribution Management

Penske Logistics | www.penskelogistics.com