2 minute read

Peterbilt Displayed Technological Advancements At World of Concrete

Peterbilt Motors Company displayed its lineup of vocational vehicles for the concrete industry at World of Concrete in Las Vegas, Nevada, held in January of this year.

World of Concrete (WOC) has been serving the global concrete & masonry construction industries for 49 years and provides opportunities to educate and connect industry professionals with resources and intelligence to make better informed business decisions.

Attendees visiting booth #C5148 in the Central Hall during the show at the Las Vegas Convention Center were able to see Peterbilt’s newest technological advancements, demonstrated on three customer trucks on display. These included a Peterbilt Model 567 with mixer body from Con-Tech, a Model 520 with a Concrete pumper from Alliance and a Model 548 with mixer body from Continental.

Peterbilt trucks come standard with VMUX electrical architecture that allows for quick and reliable body integration. This simplifies customization for customer needs in a manner that is consistent across all Peterbilt truck models. These trucks are powered by PACCAR MX-11 and PX-9 engines with class-leading performance, reliability and fuel economy.

In addition to the booth display, Peterbilt was excited to partner with Con-Tech and key suppliers, and donated a Model 567 paired with a bridge formula mixer to Concrete Industry Management’s (CIMs) 2023 auction. Auction proceeds benefitted CIM degree programs. SP

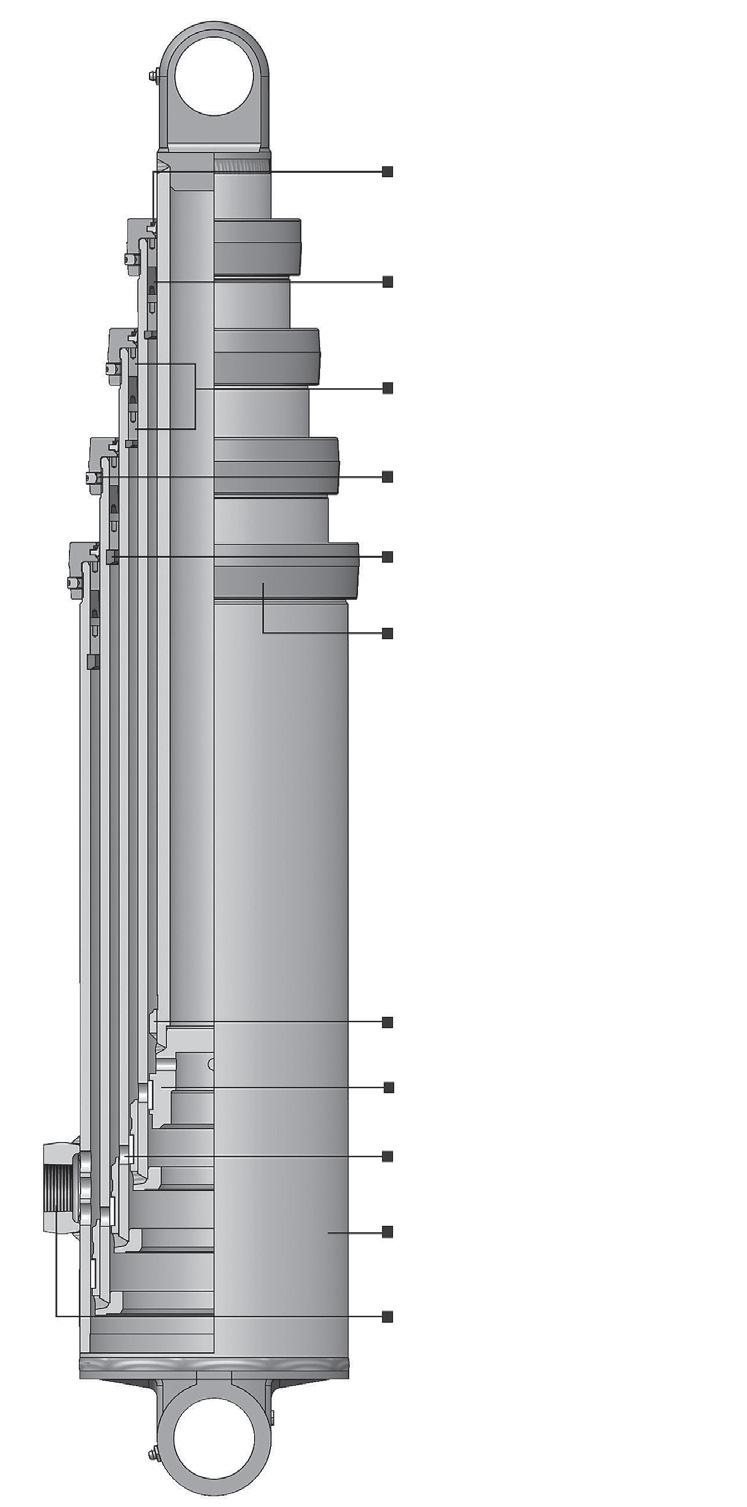

Individual Plunger Lifting Capabilities

alone,” Intagliata said. “From the tip to the tail of the trailer, from brakes to ABS to roll stability to other electronics and more, it’s an iterative process.”

Intagliata noted that the duo is currently wrapping up work on yet another project to help streamline and optimize trailer communica-

SEVEN BASIC SPECS:

4400 SERIES • AVAILABLE ACROSS WESTERN CANADA

Choose the Akaliko Canada 4400 Series single-acting telescopic cylinder with Chrome Plated moving stages to meet today’s rigid application requirements. CALL FOR PRICING AND AVAILABILITY TODAY!

tions. “We listen and engage. They’ll propose a functionality or request a solution, and our experts provide options and design ideas. We work together through development and testing while making sure we’re all staying on target to deliver what the Utility team is seeking.”

Both Bendix and Utility Trailer emphasize that Bendix safety technologies are engineered to complement safe driving practices: No commercial vehicle safety technology replaces a skilled, alert driver exercising safe driving techniques and proactive, comprehensive driver training. Responsibility for the safe operation of the vehicle remains with the driver at all times. SP

Source: Bendix

Self-Bleeding Design no air to bleed, which reduces labour/maintenance charges. Less Oil required to fill the cylinder. Less Oil = Less Weight or more payload. Threaded headnuts for added strength. Longer Bearing Length (overlap) for stability. Beveled stop rings and retaining rings for plunger centering.

Stock Models inventoried at five warehouse locations throughout the U.S. to meet your immediate requirements. Plus lifting capacity unsurpassed by other major brands in the industry and a Two-Year Warranty.