7 minute read

Peterbilt & Platform Science Build A New Ecosystem Of Connected Products

Peterbilt announced that it will develop a new ecosystem of connected products for its industry-leading vehicles.

The initiative will be under the umbrella of the cooperation agreement recently signed between Platform Science, Inc. and Peterbilt parent company PACCAR Inc.

The new services will leverage Platform Science’s Virtual Vehicle™ platform which enables customers to access fleet management functionality, ELD capabilities, truck-specific navigation and third-party applications directly from their vehicles.

Peterbilt leverages technology and innovation, and will jointly build this industry-leading ecosystem to take our connectivity services to the next level. “Today’s customers demand the highest level of uptime and complete integration with their existing fleet management solution” commented Jason Skoog, Peterbilt general manager and PACCAR vice president.

“SmartLINQ and the PACCAR Solutions portal have provided a solid foundation to build this next-generation solution” Skoog added.

“With Virtual Vehicle, truck buyers can eliminate barriers to innovation, production, and safety and customize in-cab experiences with technology solutions that best meet their needs,” said Jack Kennedy, cofounder & CEO, Platform Science. “For more than 80 years, Peterbilt has built world-class vehicles that maximize safety, performance and uptime, combining innovative technology with enduring craftmanship. We are proud to collaborate with their team to integrate the Virtual Vehicle platform into their trucks and deliver the most cutting-edge truck technology to meet their customers’ every need.”

The Platform Science ecosystem will eventually allow for third-party apps to be downloaded and managed remotely or directly on the truck interface, eliminating the need for costly and time-consuming aftermarket hardware wiring and installation. “The new services will leverage the existing connectivity solutions of our heavy- and mediumduty truck platforms” added Bart Lore, senior director Global Connected Services, “thanks to the new app ecosystem, Peterbilt vehicles will take a quantum leap integration to existing fleet management solutions” added Lore.

The new suite of services will launch in 2024 with class 8 Models 579 and 567 and the medium-duty Models 548, 537, 536 and 535. Multiple service packages will be available depending on the truck model and intended application. SP

Source: Peterbilt

Magnet Transport Group Relies On Kenworth W990s

Mark Miller has always had a passion for entrepreneurship. It’s what led him to start a new business venture, Magnet Transport Group in 2020, following 34 years of owning and operating an industrial cleaning, painting and epoxy flooring company.

“My dad was a truck driver, and I drove a truck for several years after high school before entering the industrial cleaning industry. When I grew my cleaning business (Performance Industrial) to the point it could operate without me, I started driving trucks parttime for my friend Greg Liebl, owner of High Road Transport. I’ve always had an interest in heavy equipment and enjoyed the opportunity to travel the country as a driver,” Miller said.

“At age 63, I wasn’t ready to retire, but I was ready for a challenge in starting a new business. So, in 2020 I sold Performance Industrial to my son Bill and daughter-in-law, Karen, and started Magnet Transport Group with my stepson Drew (Trombley),” Miller said.

According to Miller, warehousing, construction and other commercial industries in Upstate New York requiring transportation services were growing rapidly, creating the perfect market conditions for Miller and Trombley to enter the trucking industry.

During the fall of 2020, the Kingsbury, New York-based company purchased its first truck – a Kenworth W990 equipped with a 76-inch midroof sleeper, 505-hp engine and 18-speed automated transmission from New England Kenworth – Burlington, Vermont. Magnet Transport Group specializes in hauling oversized loads on flatbed and step-deck trailers in all 48 states and also transports general freight in dry van trailers throughout the Northeast. Miller gained valuable experience hauling oversized freight while previously working for High Road Transport.

For Miller and Trombley, the decision to start a company with Kenworth’s latest long hood was an easy one. “Drew and I have both driven W900s in the past and we really liked that model and the quality of trucks Kenworth produces,” said Miller. “We also have some friends that own trucking companies and operate Kenworths and they advocated for us to go in the direction of buying a Kenworth. When it came down to choosing the model, as a new company, we wanted to build a uniform fleet with new model trucks. And since we like the classic style of trucks, the W990 made sense. We expected it to be a step up from what we experienced driving the W900, and it sure is.”

Since purchasing its first W990, Magnet Transport Group added a W990 day cab in 2021 to better accommodate growing regional delivery demands. Trombley is the full-time driver of the W990 day cab and the company hired its “first” driver this past summer. Before, Miller and Trombley would split time operating the W990s.

“Now that we have a fulltime over-the-road driver and Drew handling regional driving, I have more time to focus on growing the business,” said Miller. “We’re very active in prospecting new customers in our area to work with; developing working relationships with other trucking companies in Upstate New York; and in browsing load boards for freight to haul. Our goal is to add another W990 next year and add several more trucks in the following years to meet demands. As we grow the fleet and hire more drivers, Drew will phase out of his role as a primary driver and spend more time running the business.”

Prior to joining Magnet Transport Group, Trombley drove for a regional beverage carrier where he gained valuable driving experience. Over the course of his career, he’s driven a variety of trucks including Kenworth W900s. According to Trombley, the layout of the cab and driving experience of the W990 compared to the W900 is a significant step up.

“I have a lot more legroom driving the W990 compared to the W900 and the seats are more comfortable,” said Trombley. “The visibility over the front of the hood and through the side mirrors are noticeably better as well, which makes it an easier and more enjoyable truck to drive.”

On the road, Trombley credits the W990s improved turning radius and fuel economy over the W900 as key performance differences between the two models. “By design, the W990 is more aerodynamic than the W9 and we definitely notice the W990’s improved fuel efficiency at the pump,” said Trombley. “The new model also seems to have a smoother, sharper turning radius, which is especially helpful in navigating tight jobsites and industrial facilities.”

Magnet Transport Group was an early Kenworth W990 adopter, and there weren’t many on the road when the company started operating its first one. “Now we see quite a few of them,” said Miller. “We receive compliments all the time about the look of our trucks, which are a direct representation of our company. We keep them nice and clean to support our image as a quality and professional company.”

As Magnet Transport Group has its eyes set on growth, Miller said that the W990 will be its choice of truck to continue building its fleet.

“Just like some people become tied to one car brand, like Ford or Chevy, Drew and I are now Kenworth people,” said Miller. “We look forward to the opportunity to continue to grow our family business and the W990 will definitely be a part of it.” SP

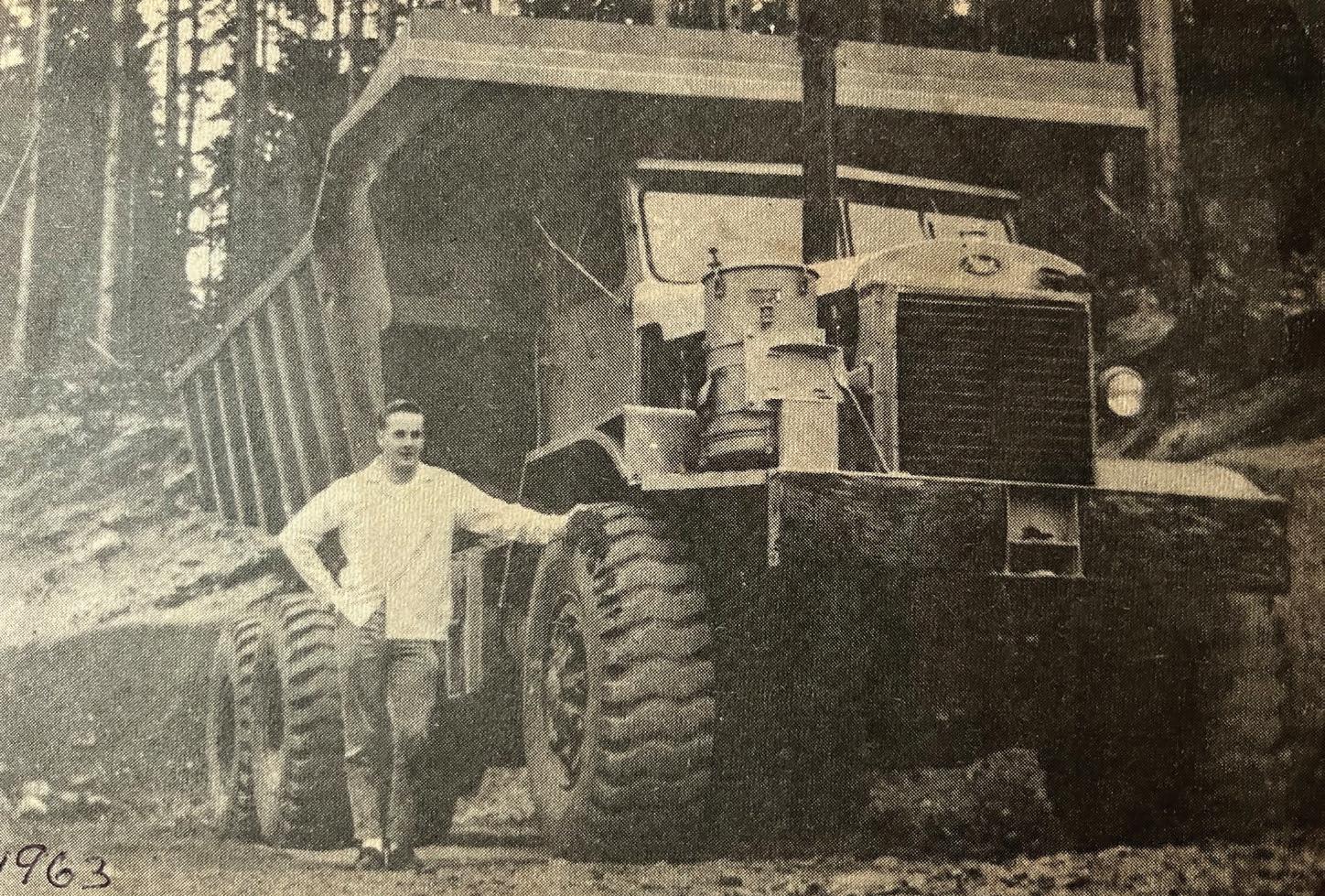

For this story, I’ve consulted with Ian McCallum who worked for Nories in the 50’s and 60’s, driving all these trucks. Ian had pamphlets, newspaper clippings and pictures about these trucks.

Norie Bros. obtained six war surplus Mack trucks. They had 671 Jimmy motors and came with a bare minimum cab. Just a seat and a bit of a roof. Nories had cabs and fenders added at Norm Copley’s shop at Mill Bay. Number 1 & 2 were gravel trucks. Numbers 3, 4 and 5 were log haulers and from what I can determine #6 never left Copley’s shop. One of the gravel trucks had the box removed and a tank added to make a fire truck.

Nine foot bunks with about two foot stakes and straight pipes out of the exhaust manifold. Living in Elk Bay in my fifth year, I could hear them coming along the beach road which sent me scrambling to my big rock where I could watch them dump.

Nories purchased a used

34 ton Mack Dump Truck, powered by a Cummins NVH-1200 Diesel engine.

Possibly this truck came from a mine in Quebec. The truck was completely rebuilt from the ground up—the cab was moved forward four feet and the engine was overhauled and moved forward about eleven inches. Turbocharg-

They also acquired #8 which had a six cylinder Cummins engine. They left this as a gravel truck, hauling ballast, the Eimco rock drill could fit in the box and it was really handy putting stuff in when moving camp.

Henri Norie was pretty proud of his #7, he asked my Dad how it was working out. Dad said, “Well Henri it can haul a heck of a lot of wood, but the trailer is so heavy that it’s a struggle to lift the trailer off with the TL 11.” chased two new Pacific P16s that came with self-loading trailers. Pacific had used a hydraulic ram to load the trailers. This style never really caught on because it was a pretty big job switching trailers if you had a problem. of the hill above the big switch-back. Hopefully I can get it stopped.” When we got there the front wheels were hanging about thirty feet in the air. This was a close call! SP ers were added. A Twin Disc Converter-Transmission package was installed with the transmission mid-ship mounted for flexibility and accessibility. When rebuilt it would haul 20,000 boardfeet of logs or GVW of 120 tons. One load at Port Neville had 26,000 board feet on board.

Number 9 was obtained and rebuilt at Copley’s shop same as number 7, except it only had a half shack for a cab. Henri Norie designed a self loading trailer using a winch to load the trailer. Could have been the first one designed for big logging trucks. It worked really good for backing into steep landings. Back right up to the loader put the trailer down and ready to load. No more trying to get the truck to back up to hook up the trailer on the slippery bark and mud. Lots of times you would have to pull it up with the straw-line from the yarder. Later on, Nories pur-