Computational Design Portfolio

Parametric Bridge Analysis

Rhino Gh scripting

Dynamic Parametric Envelopes

Rhino Gh + Python Scripting

Ventilation Comfort Responsive Facade Generator

Grasshopper, Python, Ladybug, Mosquito, Arduinos, Sensors

The Robotic Touch

ABB robots, robot studio, grasshopper, rapid language

Robotic Zen Garden

ABB robots, robot studio, grasshopper, rapid language

Coverscape

Rhino, Grasshopper Kangroo physics plugin

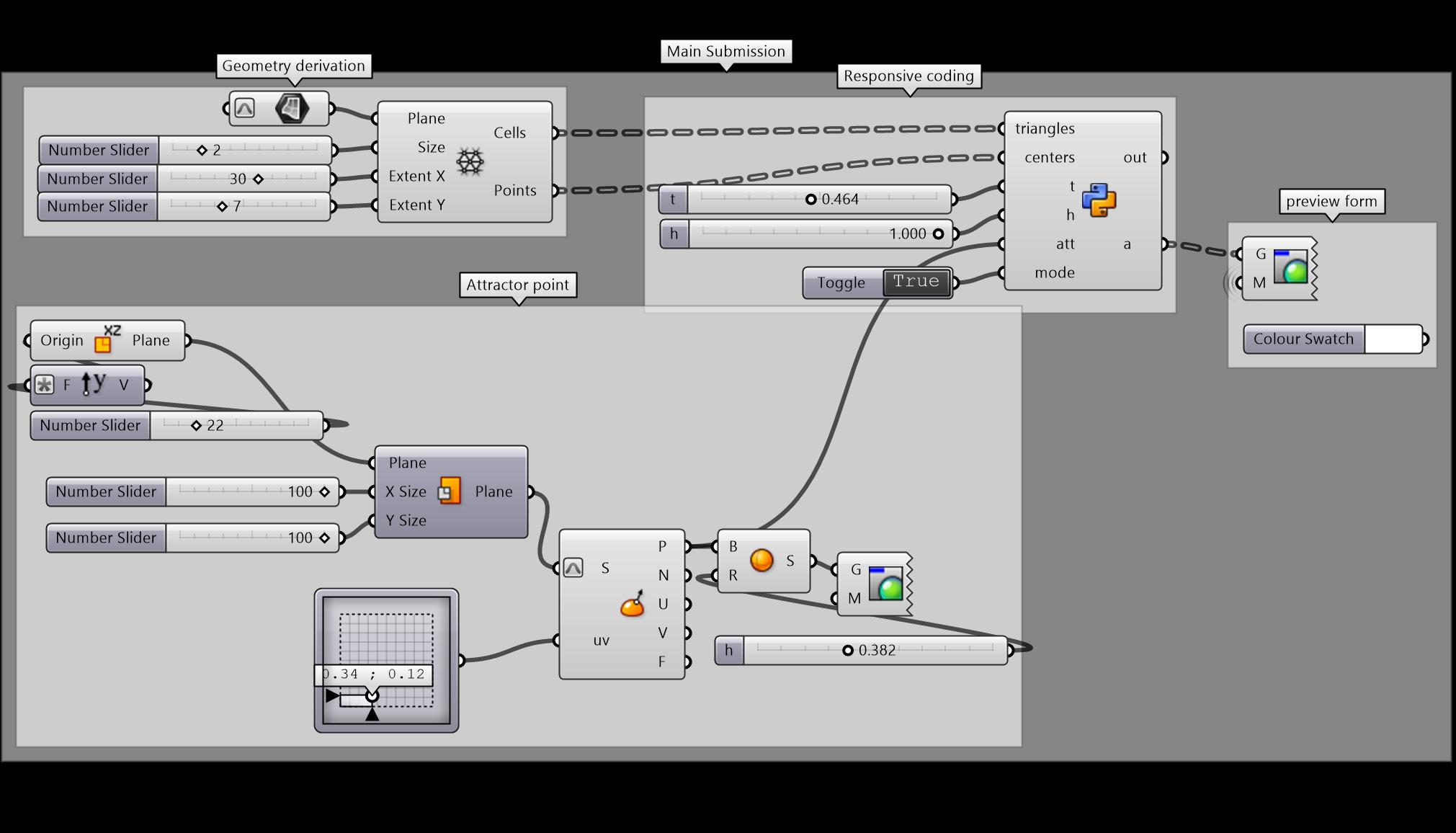

Responsive Facade Design

Rhino Gh + Python Scripting

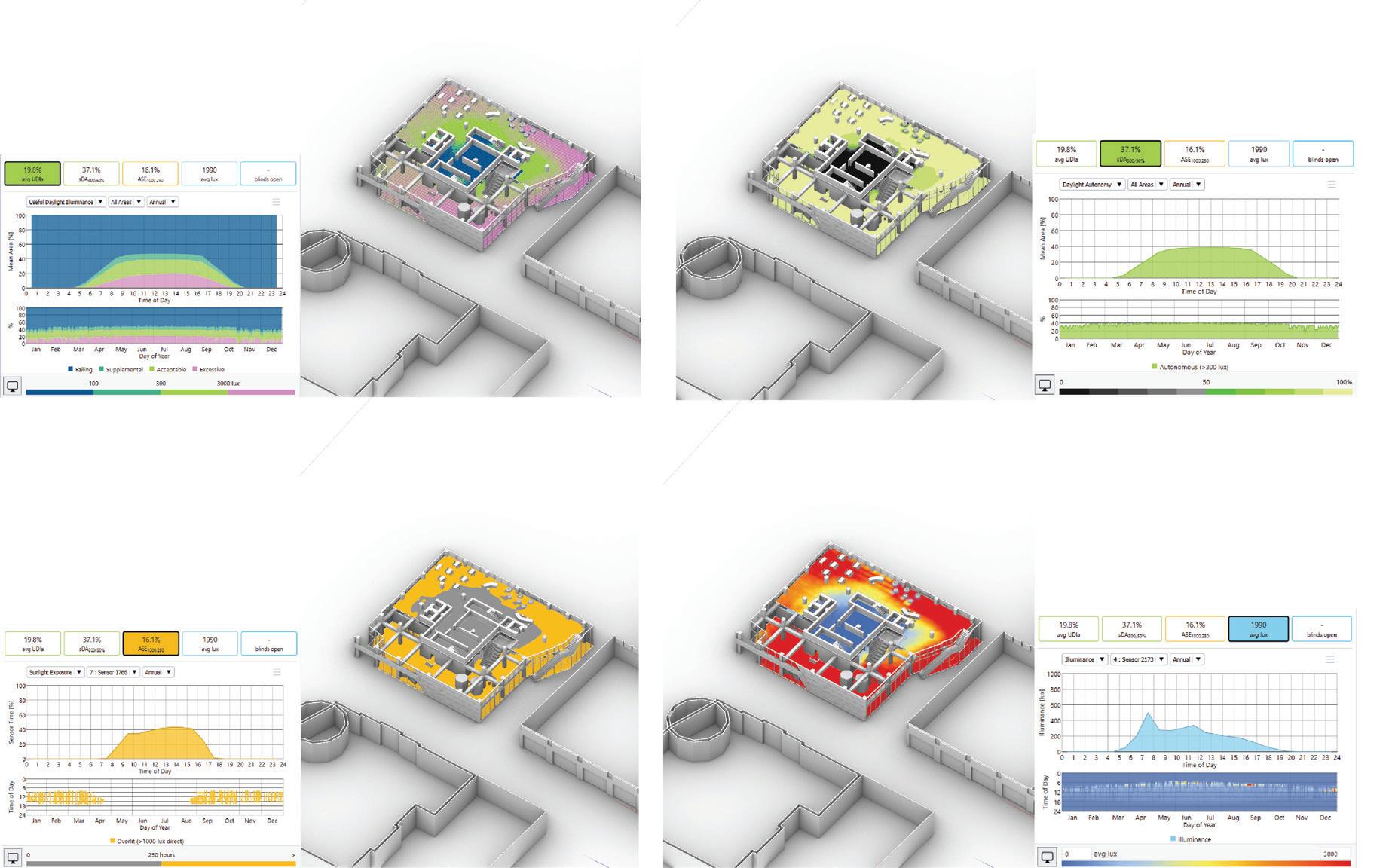

Climate simulation and analysis

Climate studio, Lady bug

Hybrid Design workflows

Rhinoww Grasshopper, Motion capture technology, Mocap

Architectural Intelligence

Runway ML, Meshroom, Unity, Rhino, Google earth studios

Stadium Design

Rhino, Grasshopper

Exposition Pavilion

Revit parametric designing

Parametric Truss

Year: 2021

Team: Individual

Type: Generative Modelling

Role: Design, modeling and visualization

Creating a system of script which updates complex assemblies with changing design iterations. The tectonic framing system enables parametric accordances which makes the deisgn process highly optimized. The Truss bridge system is made in a series of layers which has the flexibilty to mould itself according to the contextual paramters assigned to it.

The form follows a diagonal approach to construction where the tension members connect one step after the other. These members are then connected to one another by horizontal bracings. The system is anchored to horizontal rails via joints and suspension cables from either sides. The horizontal rails are connected to one another by sub criss cross truss system which helps distribute the load evenly and prevents buckling.

The script has changable parameters which include:

1. Parametric control of the truss height

2. Primary, secondary and tertiary structural systems

3. Members having cross sectional thickness

4. Parametrically resolved joints which change according to the movement of the attractor point. (python script involved)

Dynamic Parametric Envelopes

Year: 2021

Team: Individual

Type: Generative Modeling

Role: Design, modeling and visualization

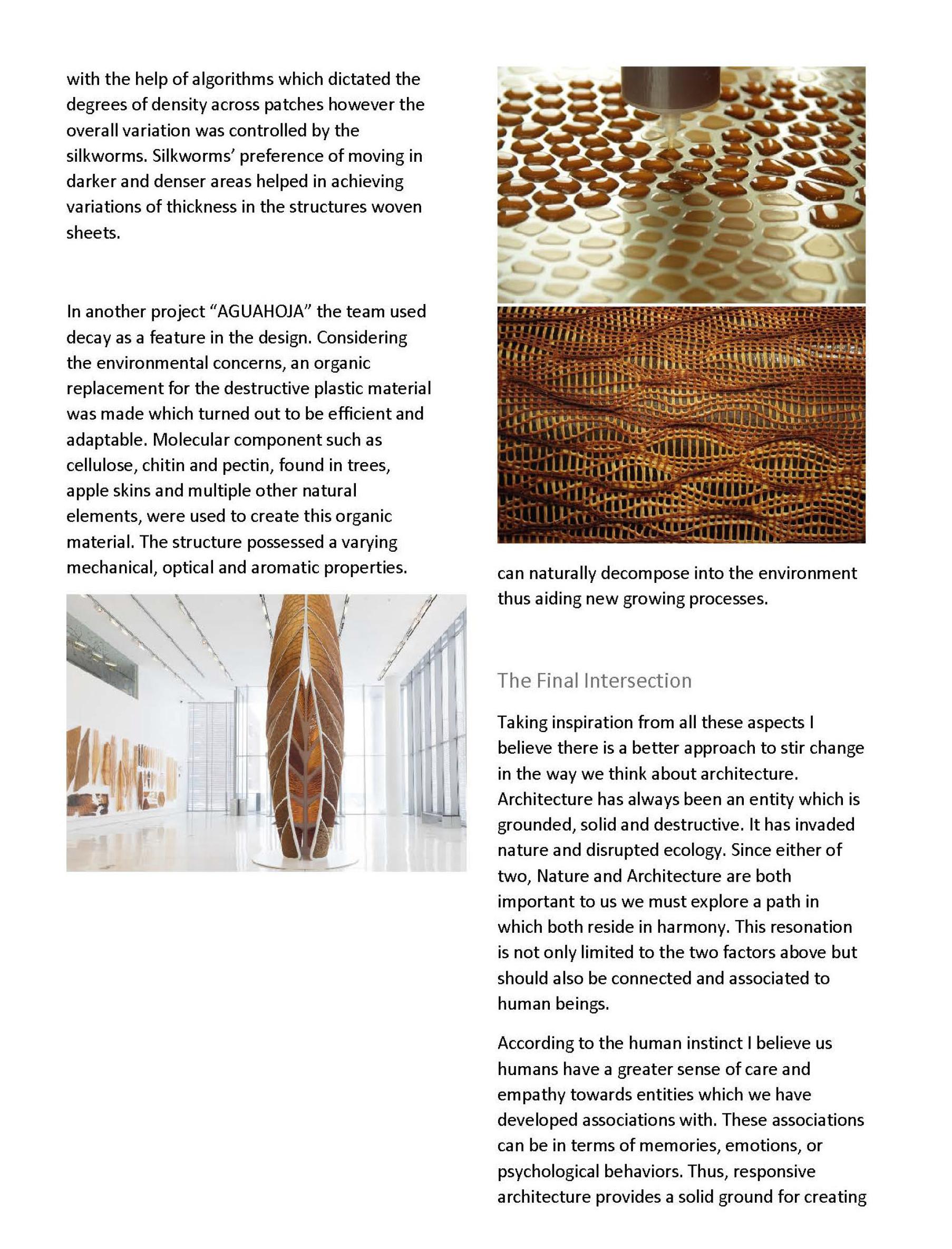

Developing a responsive building envelope which optimizes the workability of the facade system in terms of opening and closing of its facade panels.

The dynamic envelope is created in a series of layers. These consist of a double facade system. A secondary curtain wall with spider like hinges and joints together with a primary system at the front which has circular opening shades and a connection glass panel just behind the openings.

The concept was to enable the glass panels to become more opaque or transaprent according to the movement of the sun (attractor point).

The form follows a diagonal approach to construction where the tension members connect one step after the other. These members are then connected to one another by horizontal bracings. The system is anchored to horizontal rails via joints and suspension cables from either sides. The horizontal rails are connected to one another by sub criss cross truss system which helps distribute the load evenly and prevents buckling.

The script has changable parameters which include:

1. Parametric control of the truss height

2. Primary, secondary and tertiary structural systems

3. Members having cross sectional thickness

4. Parametrically resolved joints which change according to the movement of the attractor point. (python script involved)

Ventilation Comfort Responsive Facade Generator

Year: 2021

Team: Tabeer Tariq and Zhan Shi

Type: Scripting and GH tool development

Role: Linking data from sources, Coding and Facade development

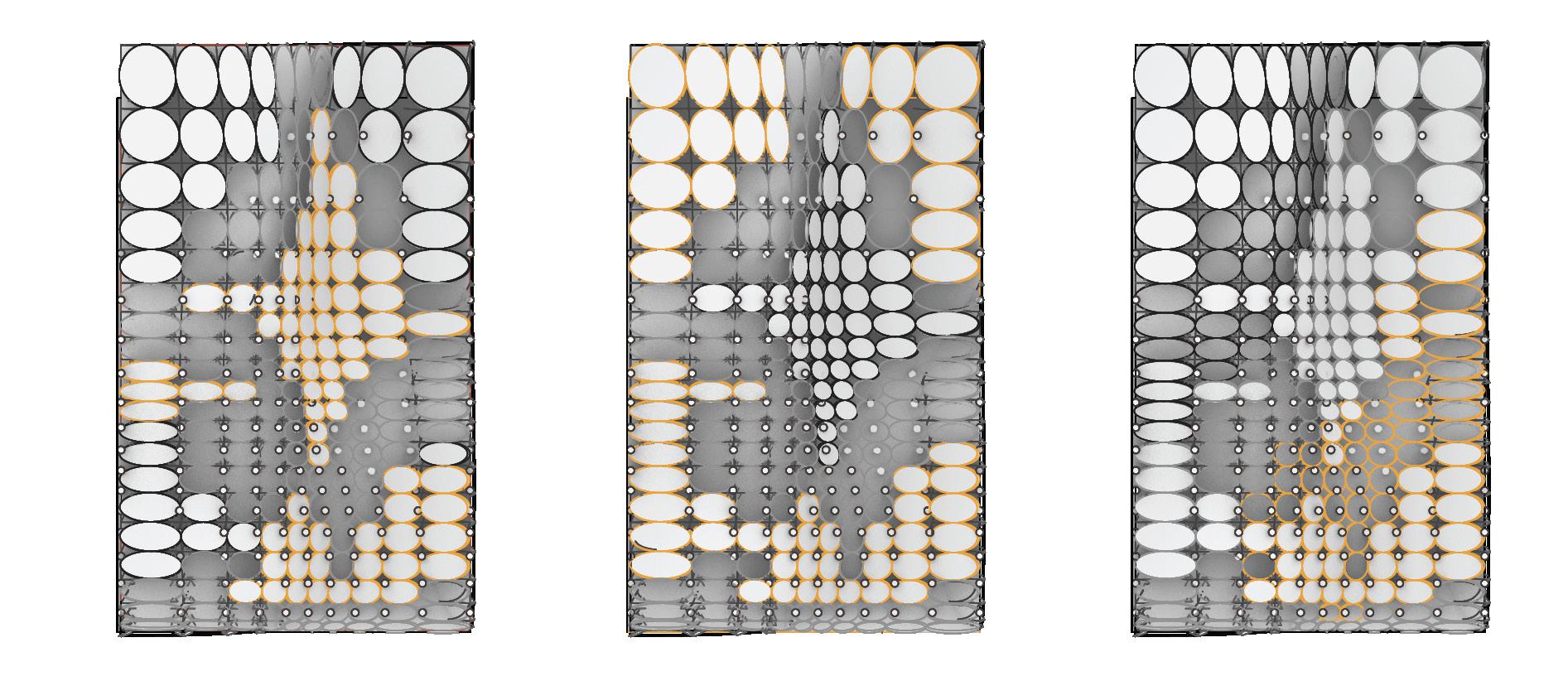

This tool is designed to provide architects with sustainable designs strategies, which analyze the environmental data and automatically generate a comfortable and responsive facade.

This grasshopper tool is designed to generate a responsive ventilation system which first collects climate data from websites. Compares the global data from ladybug to data from real time sensors. It then evaluates if the facade should be open and closed. The tool also controls the geometry of the facade panels in 2D and 3D as well as number of sensors required through out the space. The system also controls the angle of rotation and the variable gradient with which it should open and close.

The tool contains sub-components as shown in the image on the left. Location of the place can be changed for windrose and climate data. Efforts were made to make this prototype workable in real time as well so we connected an arduino and used a wind sensor to produce real time data. We linked physical model with the digital in Rhino grasshopper which worked in sync together. Both would respond and open and close together as the data would feed into it.

Sensor Generator Function

1. Randomly changing number of sensors

2. Apply the sensors on any types of surfaces

3. Showing the physical geometries of sensors

4. Changing the radius of the sensor geometries

Generating 2D panels with different shapes

1. Open and close based on the wind speed

2. Randomly assign two lines for the responsive facade.

3. Changing the density of the Panels.

4. Changing the opening orientation of the panels Changing maximum and minimum turning angle of the facade.

Triangular 2d unit logic Triangular 3d unit logicChanging panel densities

Changing panel orientations

Arduino physical response facade model

When the wind speed is higher than 0.5 m/s. This responsive system will be started in sequence.

When the wind speed is higher than 0.5 m/s. This responsive system will be started at the same time.

Data was collected from EPW files and real time arduinos, compared and linked into Facade generator to operate.

The Robotic Touch

Year: 2022

Team: Tabeer Tariq, Yujeong Seo, Thomas Brennan, Abiola Morakinyo

Type: ABB Robotic fabrication

Role: Design, digital simulation, coding, physical implementation

The project revolves around creating a tool and framework of anchor points to weave a fibrous material using the robotic arm and rotating table. Ideally this will result in a lightweight form that can be part of an assembly making an occupiable space. This will involve testing of:

1. Tool designs that focus on controlling tension and maneuverability around the frame and anchors.

2. Multiple forms of frames leading to the most interesting and modular result.

3. Different approaches to anchor points using hooks or bolts, finding what would most effectively work with the robots.

4. Fibrous materials with different properties such as nylon string, yarn, or twine.

Relevance and Importance

1. Utility in “clean” architecture (no chemical processes)

2. Lightweight components that could act as shading devices or structurally performative pieces

Implementation Strategy

Proper tension of thread strategy undisturbed path of robot

To maintain the straight and firm shape of the model, giving a proper tension of the thread is the most important. Without using resin, we should design not only the right frame and anchor but also the end of robot arm tool.

Considering the limitation of movement of the robot, we will design the path that is not disturbed by the robot itself. This path should be worked well with the turntable and supplier.

Implementation Strategy

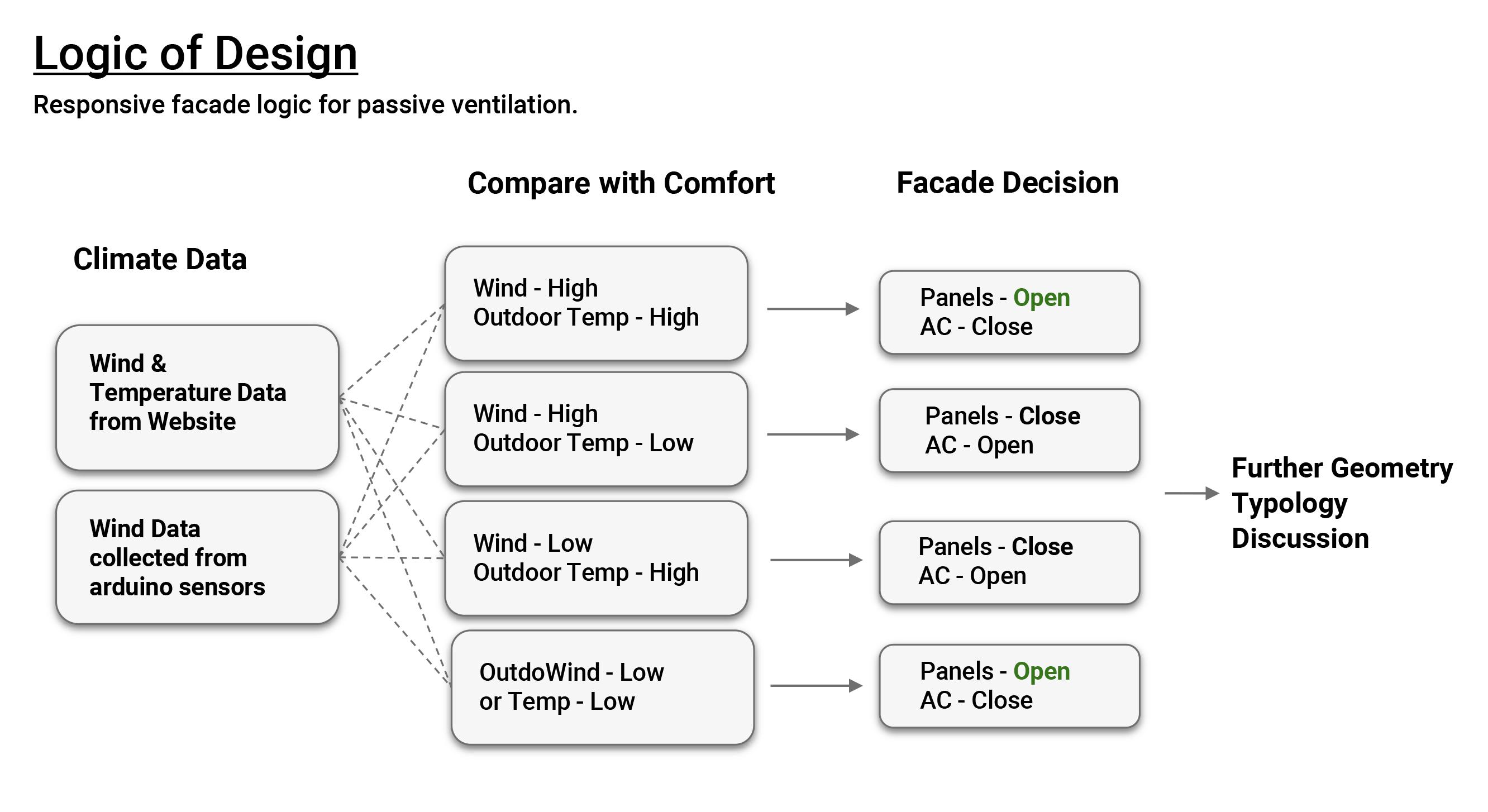

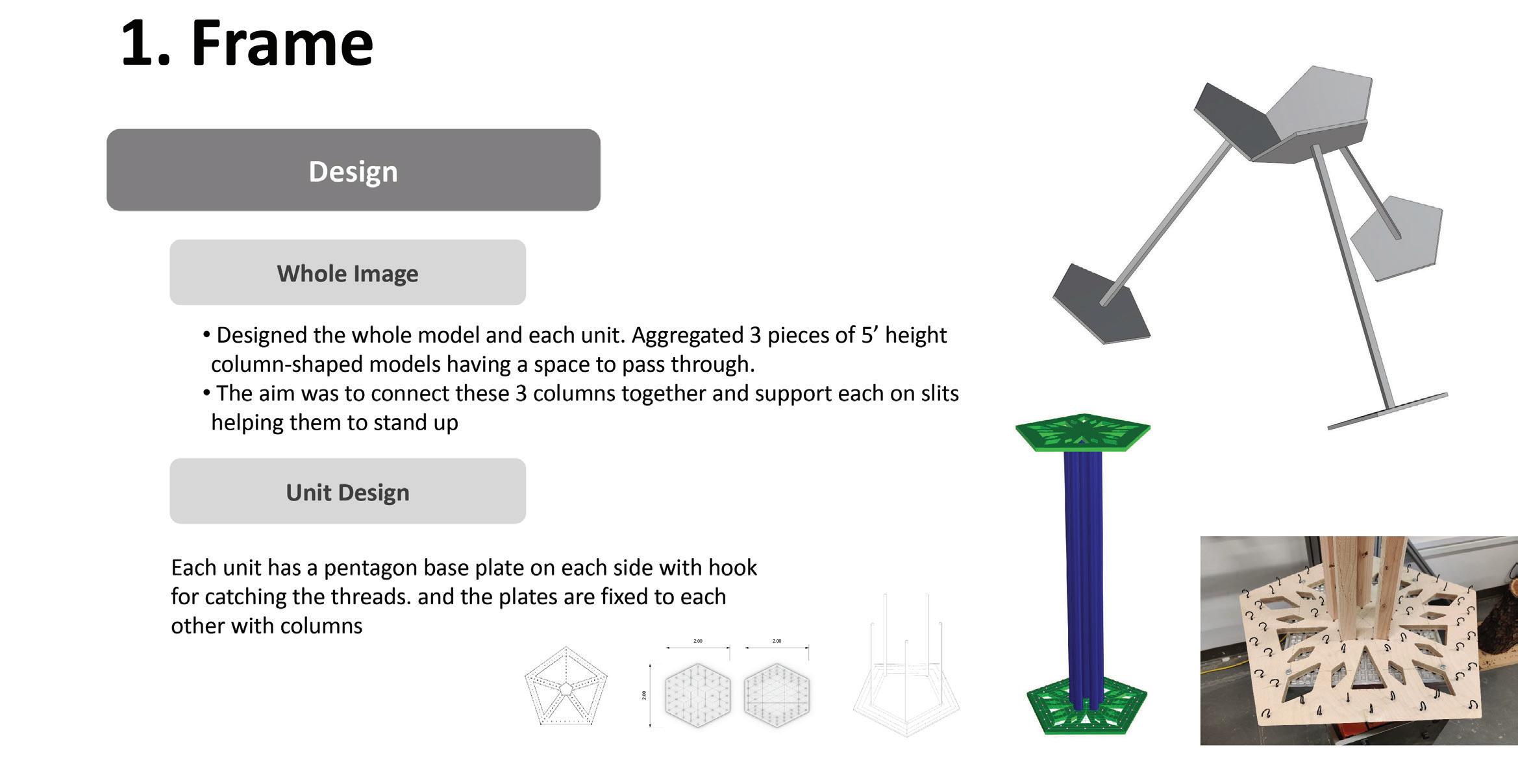

Design

Whole image

Designed the whole model and each unit. Aggregated 3 pieces of 5’ height column shaped models having a space to pass The aim was to connect these 3 columns together and support each on slits helping them to stand up

Unit Design

Each unit has pentagon based plate on each side with hook for catching the threads, and the plates are fixed to each other with columns

Process Creation

Each unit has a pentagon base plate. The base plates were produced with the assistance of the cnc router, cutting the pieces from plywood as well as precisely drilling the holes for hooks to be inserted The plates were also designed with cutouts to reduce weight as we create a more appealing look.

Process: Assembly

The hooks are inserted and plates are fixed at a distance of 5ft from the surface with 5 radically placed central columns.At this times holes are added to the base plates to allow them to be attached to the rotating table

Problem and Solution

During simulations we found out that robot was out of range so we divided the weaving pattern into 2 portions of the column for easy accesibility

Received suggestions for improvements based on maintaining thread tension and thread feeding

Made suggested changes and redesigned thread tension method and thread feeding mechanusm. With a soring feeder shape like a pen, we can set the exact location of the thread feeding

Initial tests showed that the amount of tension resulted in the spring being bent out of the intended TCP, losing the accuracy to reach the targets.

Completed final version of the end of the arm tool. Tension showed that the spool holder and the feed spring provided enough tension to eliminate slack, but not too much that it bent the spring out of place. The spring feeder was set into a solid wood base to better maintain a constant TCP.

Method

Proper Tension

Connecting hooks to a long distance (vertical connection: farthest)

Undisturbed path

From inner hook to outer hook

Problem and solution

Singularity

Weaving target points were very close to the robot and it would result in singularity in order to reach them so points were separated in 2 groups and their direction of planes were shifted and altered according to requirement

Exact Position

Digital model and physical model have a slightly different dimension in cutting process. Even though we measured physical model and several points, it was hard to set exact location of the path. We completed it with human-robot collaboration. The hooks can be chnaged in direction manually to adjust for robotic simulation paths

Proper location and Direction

[Hook Direction], Face outside(bottom), upward(column)

Iteration

[Rotating Table], 72 degrees rotation for each side

Code Based Workflows

Challenges and next steps

Tool rigidity and ensuring that it did not hit the frameor hooks. Getting the angles just right so the robot arm doesnot hit the frame and lead to singularity errors. Reconciling digital model and codes with the irregularities of the physical frame.

The next steps include refining the robot movement to have even more precision, as well as constructing more frames in order to link them together into an occupiable soft structure.

Robotic Zen Garden

Year: 2022

Team: Tabeer Tariq, Hari Vardhan, Shray Tripathi

Type: Sand morphing with Robotics

Role: scripting, simulation and implementation

Coverscape

Year: 2022

Team: Tabeer Tariq, Yumeng, Emma, Racheal, Tara

Type: Real time sound simulation for a HCI apple proposal

Role: scripting, coding the and simulation from sound output to interactive geometryStatus: Completed

Responsive Facade Design

Year: 2022

Team: Tabeer Tariq,

Type: Automating using GH scripting, python

Role: scripting, simulation and implementation

Climate Simulation Analysis

Capturing Sketch by Motion sensors

Examine if the motion capture can retain the characteristics and shape made by hand

Using gestures having different intensities as the sketcg is made

Follow similar recurring pattern

We aimed to capture the movement of drawing an object and translate hand gestures into an abstract installation

Algorithmic extension: Arraying, Repetition and extrusions

Analog: Digital Artifacts

Steps of constructing the rigid body device using MoCap Braced 3 smart markers with a glove and assigned it to the rigid body. This glove was then worn and used to draw on paper. The motion capture data was exported as a CSV File, Imported into Grasshopper where the points were further extruded

Architectural Intelligence

Year: 2020

Team: Tabeer Tariq,

Type: Runway ML, Meshroom, Unity, Grasshopper, Google earth studios

The project explores the generative and creative potiential of AI in the notion of human Machine collaboration. It samples artistic influences from fields such as painting sculpting, fashion and media art and implements them into architecture objecr using ML alogrithms. Here the human curates the process where as machine generates the model and shapes.

The process includes sampling images site and artistic influence using Runway ML, deriving formal data analysis using Meshroom and then modeling it using Rhino and grasshopper.

Stadium Design

Year: 2021

Type: Grasshopper scripting

Exposition Pavillion

Year: 2019

Team: Tabeer Tariq, Sameen Javed

Type: Revit workflow, creating families and parametric modelling

Intersection of responsive architecture and material ecology

Cybernetics systems integrated with nature and human experience