2 minute read

RENISHAW

from TCT Europe 31.3

by TCT Magazine

On a particularly snowy day in a quiet Welsh village, a company is celebrating a milestone.

It’s been 50 years since Renishaw, now a global engineering firm, was formed off the back of an invention that would solve a tricky measurement problem for Rolls Royce.

Sir David McMurtry, now Executive Chairman of Renishaw, had designed and built a prototype touch-trigger probe for co-ordinate measuring machines (CMMs) used to measure the instrumentation pipes on the Olympus engines that propelled the Concorde supersonic aircraft. The invention was a success, and McMurtry, together with colleague, John Deer, now Renishaw’s Non-executive Deputy Chairman, believed this technology breakthrough could hold much greater commercial promise. After Rolls Royce agreed to licence the patent, but only to a limited liability company, the duo went and purchased an ‘off-the-shelf’ company and on April 4th 1973, Renishaw Electrical Ltd. was registered.

Cut to March 2023, we’re sat in a small meeting room in Miskin, opposite the space where Renishaw’s additive manufacturing (AM) systems are manufactured, waiting to hear from a panel of senior executives. There are whispers that McMurtry, who stepped down as Chief Executive in 2018 but is never too far away from the action, might make an appearance. Sure enough, he does, and his presence and bullish opinions on everything from sustainable business practices to nurturing engineering talent, captivate the room.

The conversation is far reaching and while today’s story focuses on the origins of a company that has its roots in industrial metrology and precision measurement, one thing is palpably clear: McMurtry is invested in the next generation of metal AM.

What this next generation will look like or unlock is not for today’s conversation but Louise Callanan, Director of Additive Manufacturing, has been tasked with leading and is careful not to give a micron of that progress away.

“In terms of the future, I suppose the most important thing really is to say that we're continuing to invest in AM in many areas - in our people, and in the technology,” Callanan told TCT.

When we meet, Callanan has been in the role for just over a year and still counts herself as a newbie to the AM industry. Yet she has built a long career at Renishaw after joining as a Graduate Design Engineer 26 years ago, and has always been aware of the technology’s benefits whether supporting development functions internally or facilitating very low volume production runs.

“It was just the excitement, from a development point of view of being able to quickly visualise your concepts, to be able to iterate those really quickly, and ultimately, to be able to accelerate the development process,” Callanan said.

Callanan’s tenure is a prime example – and there are several on the panel with similar stories – of how Renishaw seeks and maintains its talent, something she believes will be integral to this next phase of AM growth.

“I think that commitment to the future of AM means we can really start to attract and retain the right talent, the highest quality talent, which is massively important to the success of the future.”

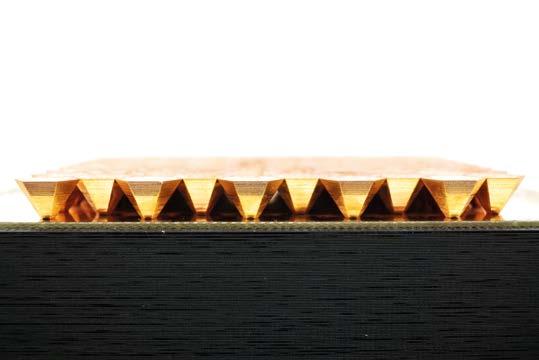

Renishaw first ventured into additive in 2011 with the acquisition of MTT Technologies, a UK-based manufacturer of laser melting systems, which McMurtry noted at the time for its potential in aerospace and medical markets. Today, Renishaw’s technology is used in everything from custom implants and neurological drug delivery systems to complex heat exchangers and aircraft assembly parts. Recently, the company announced the extension of one already successful partnership with British Cycling ahead of the 2024 Paris Olympics. The pair previously worked together to develop a track bike featuring metal powder bed fusion parts for the Tokyo Olympics and