3 minute read

RENISHAW IS READY

from TCT Europe 31.3

by TCT Magazine

tour. I’m waiting for the inevitable ‘no photos, please’ but instead, Renishaw has laid bare its production bay featuring rows of RenAM 500 systems in various stages of completion.

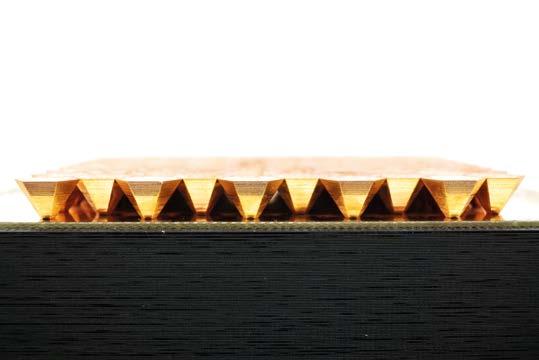

The RenAM 500 is Renishaw’s flagship machine. It can be equipped with one or four 500W lasers across its 250mm x 250mm x 350mm build platform, but all configurations adopt the same gas flow system, safety and precision digital optics, and smart connectivity capabilities. While eight, even 12-laser systems are now not uncommon in additive (Callanan doesn’t reveal if this next generation will follow a similar trajectory), Renishaw was one of the first companies to introduce a multilaser system of this size back in 2017 and has quietly iterated on features like automatic and flexible powder and waste handling options, and intelligent software solutions ever since.

“We know that we don't want to rest on our laurels and we do need to make sure that we remain competitive,” Callanan said. “And that means that we need to continue to ensure that we're also delivering quality parts in a cost-effective way. So we're continuing to work on projects to improve the usability, and to improve the productivity of the current 500 platform.” untold, the ‘where’ is not so closely guarded. Last Summer, Renishaw announced an investment of around 65 million GBP to almost double the footprint of its Miskin site and help meet its weighty Net Zero emissions targets. Its ambitions include the development of 400,000 sq ft of lowcarbon buildings that will house a new production hall for its AM machines. We’re invited to get a peek from the top floor of its current site that’s currently tightly packed with an orchestra of machining, electronics, precision and large equipment assembly operations downstairs.

“Our strap line is ‘apply innovation’ and I think it's definitely more than just a strap line,” Callanan said. “It's something that's completely embedded within the company and it gives us that ability to challenge the status quo, to always be pushing technology innovations forward and really looking at the future in terms of the long term.”

What that means for additive in particular, we’ll have to wait and see, but Callanan says its success in AM won't be just about the machines.

2022 Commonwealth Games, securing seven Olympic medals in the process, and now plan to increase the bike’s speed with an enhanced design.

“I think the common thing with all of those [partnerships] is that companies may operate in different industries but they're partners to us who share that same passion for technology and quality, that passion for innovation,” Callanan said. “I think that's really what makes those partnerships work very well together. There's a lot of mutual respect for each other's area of expertise.”

Taking a walk through Renishaw’s facility feels like getting a covert behind the scenes

The RenAM 500 Flex has been designed to allow for easy switching between material types and was first put to work at the UK’s Digital Manufacturing Centre to verify its capabilities in a commercial production environment. In November, the Royal Air Force announced it would be using the system to produce custom-built structural aircraft components for rapid repairs and advanced component manufacturing, a first for the organisation.

“One common vision for everybody in AM is the adoption of additive manufacturing as a viable high volume production technology,” Callanan said. “And we're no different there, certainly from a next generation perspective. That's where we're really focused and really looking to make a step change in that productivity benefit and cost per part and looking to open up that additive technology to more applications.”

While the ‘what’ and ‘when’ around Renishaw’s next move in additive remains

“We're a part of the Renishaw family, we can offer that end-to-end process and I think that really is where we bring something different than anyone else. So whilst AM seems relatively new, for Renishaw, we're in our 12th year at this stage, so we're not really the newbies anymore, and our long-standing history shows that we have got that track record of sticking with new technologies that we believe in. We're just a member of the Renishaw team. That's how we see it, we see it being an area that will continue to grow, and we will definitely establish ourselves at the table alongside our more traditional manufacturing technology product lines, industrial metrology and position measurement. But I think the key thing for us is the overall success and growth of Renishaw, which we're very confident about.”

1. The UK’s largest AM event

With nearly 200 exhibitors confirmed for the show floor, TCT 3Sixty is the UK’s definitive and most influential additive manufacturing event. In addition to expanded portfolios from technology providers like Laser Lines, which will be bringing along Stratasys' Selective Absorption Fusion, Stereolithography and P3 polymerisation machines, you can expect to hear from newcomers like Makertech3D and Defiant3D who will both introduce new hardware.

2. “More than just machines”

As Robert Pitts, sales manager at Tri-Tech 3D, explains, “Establishing a successful AM process is about more than just machines.” Technical support is important to help guide the process of choosing and implementing the right AM technology, and while all important machines from the likes of Formlabs, XJet and Markforged will be present on booths from 3DGBIRE, Additive-X, and more, the floor will have plenty of expertise on offer from experienced teams ready answer your questions.

3. World’s best FREE AM conference

The TCT 3Sixty conference is an absolute must wherever you are on the additive adoption curve. Filled with application stories from real end-users like Collins Aerospace and LEGO Group, the latest research from University of Birmingham and Anglia Ruskin University, and market