59 minute read

A HARD LESSON

Laura Griffiths speaks to CREATE Education about the reality of implementing 3D printing in classrooms.

I’m teaching a 3D printing class today!” “No way! Which printer are you using?” “The school photocopier.”

“Huh?”

“We’re printing net shapes out of paper and then photocopying them.”

“…That’s not technically 3D printing.”

That, or words to that effect, describe a recent conversation I had with a friend who also happens to be a primary school teacher. Living amid the additive manufacturing (AM) bubble, where the drum for 3D printing in education is constantly being banged, the exchange sent me straight back to my own school days where ‘Information Technology’ class meant one PC shared between a class of 30 and each student taking turns to type up a hand-written book report with a basic word processor. I couldn’t have imagined that one day I’d be using one daily to write articles about a technology that was once considered science fiction, saving them to something called ‘the cloud’, and subsequently uploading via the internet for the world to see.

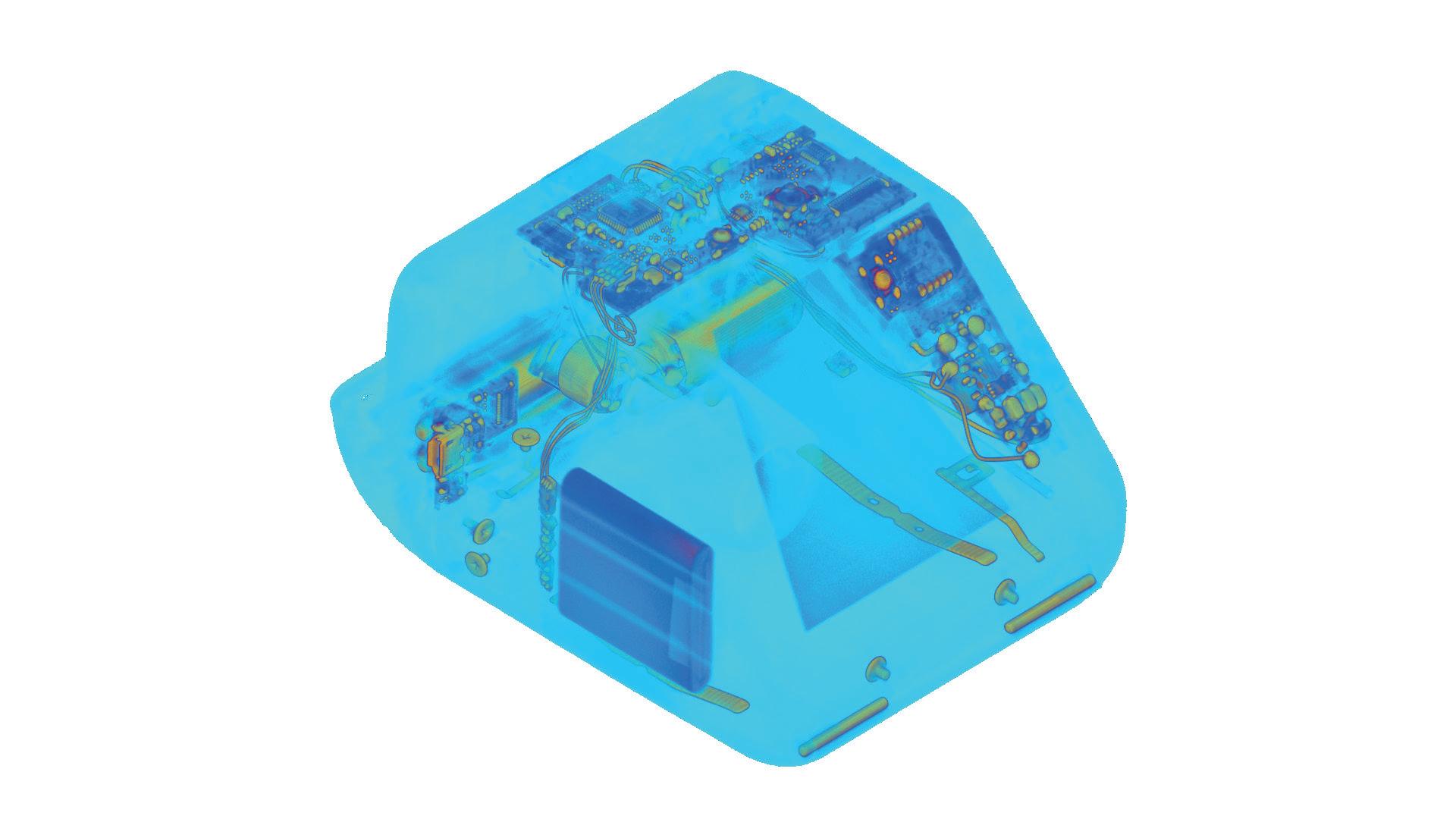

SHOWN:

APPLICATION FOCUS IN THE CLASSROOM

world, and the skills required to use it, are becoming increasingly difficult to ignore.

TEACHING THE TEACHERS The skills gap, however, is still very much a reality and the charge to close it requires support, not just for pupils that will one day be entering industry but for the teachers expected to lead those lessons. Unfortunately, it’s not as easy as installing a 3D printer in a classroom.

The first challenge, as Sonya Horton, Education Product Manager at CREATE Education Project, a UK-based organization that enables schools, colleges and universities to access 3D technologies and training, told TCT, is that there simply isn’t a requirement to teach it as part of the school curriculum.

“There’s one reference in the entire curriculum that says students should have an awareness of new and emerging technologies, such as 3D printing, but there’s no requirement to be able to use it, to do 3D modelling or to learn any of those skills,” Horton explained. “The reality is that many schools don't do it at all. The ones that want to do it, that see we should be preparing our kids for jobs and for industry, the ones that get it, then often have very, very little support from the senior leadership teams.”

The UK’s national curriculum does list ‘design and technology’ and ‘computing’ amongst its compulsory subjects from as early as key stage 1 (children aged 5 to 6) but Sonya argues, given there’s no prerequisite for schools to prioritize 3D printing, “students can go through their entire school life never encountering 3D printing technology.” It’s even less encouraging in later stages of education, where ‘design and technology’ is demoted from the core subjects list, along with arts, humanities, and modern foreign languages, of which schools are only required to provide one. For ‘design and technology’, there are multiple factors working against its adoption in the curriculum: expensive equipment, a lack of funding support for qualified technicians, external pressures of league tables, and exam results that often mean D&T becomes ‘just another thing’ to worry about.

“It's understanding that this just isn't another piece of technology that's going to come and go because [teachers] have been bombarded with technologies over the years,” Horton said. “They always seem to have to learn something new and then it disappears but this technology, as we know, is being used throughout industry and it's growing, it's here to stay. Actually, if we're not skilling up our kids to be able to use this technology, we're

putting them at a serious disadvantage in future careers and that's even from a very young age. Why should kids do it? Because this is going to be part of their world. It's going to be everywhere. It already is. I was at TCT [3Sixty] just before the pandemic and I saw the launch of the [adidas] trainers with 3D printed midsoles. I was shopping on Friday and guess what I saw a pair of? It's crazy. So, it's about the fact that it's not going away. It's vitally important.”

LESSON PLAN Setting up a printer is one thing, learning to design for one is another, and that’s before figuring out how to apply that to a classroom of 30 children. CREATE Education offers training packages to educators, ranging from one-hour remote courses for every machine sold, designed to walk teachers through the setup, to hands-on half and full-day courses.

“It's finding schools to actually have the budget to pay for the training but also to get those teachers out of the classroom for a day,” Horton said. “If they do that, we found that they have the most success because they've been there, they've done it, they've had hands-on for a day, gone through the process, learned the software, made something, sliced it, 3D printed it, set up the printer, they know how to do it, so they can walk away and do a project with the kids because they can replicate what they've done in their journey. But they’ve also got lots and lots of ideas for other projects that they can do with the kids, linked to the curriculum that will tick all those boxes that they need to tick.”

Often, interested schools will approach CREATE Education directly but Horton shares that the organization does a lot of outreach work to engage schools, and is currently working with associations like the Design and Technology Association to run programmes and encourage adoption within primary schools. It’s everything teachers need to hold their hands through a six-week loan, enough to run an entire project end-to-end. The persisting challenge, Horton noted, is time.

“I am a former teacher so I think that helps to build trust amongst the teachers because you're not just the technology person,” Horton said. “The feedback from the training is almost overwhelmingly positive because it's hands on, it gives them the tools to just have a go. But the teachers do recognize that they’re still going to have to invest a little bit of time, but it gives them that starting point and they see why and how, and because they know where to start and take something away that they can do immediately with their classes, it gives them that sort of that motivation, and that impetus to actually do it.”

Change is happening but without the backing of government, that shift is usually spurred by the enthusiasm of individual champions and teachers who see the value in bringing this technology into their classrooms. To guide them, CREATE Education offers a range of resources on how to implement 3D printing throughout the curriculum, including guides and project ideas on how to apply it across various subjects and help tick the required boxes.

Andrew Allshorn, founder of AT 3D-SQUARED, is one such champion and a CREATE Education ambassador. That includes going into schools and supporting the Inspired Minds classroom at TCT 3Sixty, which gives hundreds of children the opportunity to learn about 3D technologies every year. Allshorn shared how his approach means inviting not just design and technology departments, but teachers across the board, from history to cooking, so they can see for themselves how 3D printing spans much further than technology labs. “When I first did it, I put one in a local school and I said, 'I want the science teachers, I want the geography teacher, I want the cooking teacher, I want everybody in here to see what this thing can be,'” Allshorn explained. “The important thing is we need to find how to get that into curriculum and how to get the teacher engaged.”

Horton added: “There are innovative schools, there are schools that are pushing the boundaries, that are doing some really good stuff, because they get it and the senior leadership get it. They are supporting those design and technology departments to do some amazing stuff.

“What we need is not just 2 or 3% of secondary schools doing that, we want 100% of secondary schools doing that. It's about investment and understanding how important this technology is for future careers.”

AM Community Shows Off at RAPID + TCT Solving Problems and Giving Back AM Community Shows Off at RAPID + TCT

John E. Barnes Suzy Marzano

Suzy MarzanoChair of the Additive Manufacturing Senior Manager Industry Development and Senior Manager Industry Development and Technical Activities Technical Committee (AMTC) for SME Technical Activities SME Managing Director of The Barnes SME Global Advisors and CEO/ Founder of Metal Powder Works

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

The recent RAPID + TCT conference, which was held May 17–19 in Detroit, is proof positive as to how far AM has come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

This edition of Voices AMplified features two leaders who leverage their experience, insights, and talents to improve the way we, as a communi3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall ty, get the best out of additive manufacturing (AM). hosted by the Medical AM Advisory Team.

The first article explores how a harmonized workflow can Other highlights included the winners of the 2022 SME link software and equipment needed to 3D print compoAdditive Manufacturing Community Awards: Slade Gardnents. Bryan Crutchfield, vice president and general manager ner, founder of Big Metal Additive (Industry Achievement); of Materialise North America, shares how he and his team worked during the pandemic to solve a problem faced by VELO3D and IMI Critical Engineering (Aubin AM Case Study); many software developers-limited interoperability due to the and Virginia Tech students Daniel Chirvasuta, Nathanael proliferation of numerous, standalone products. And it’s clear High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and that his mission is to move the industry forward. As part of Nicolas Tomanelli (Digital Manufacturing Challenge). the feature, Crutchfield, who served as a volunteer advisor on To help foster the next generation of innovators, the SME SME’s AMTC for six years, shares that the Materialise team is Education Foundation’s Bright Minds Program welcomed not out to dominate the 3D-printing realm. It’s the opposite. nearly 1,000 middle and high school students to RAPID + TCT. Because closed systems are a path to stagnation, manufac- There also was a special networking lunch for young profesturing workflows must “be digital in nature, and also automat- sionals and a Career Forum Panel. The initiative is led by Ellen ed as much as possible.” And that requires giving customers Lee and Jennifer Coyne, who are both advisors on the Additive the choice to use world-class technology through an open Manufacturing Technical Community Leadership Committee. software platform. SME Media also interviewed dozens of AM leaders during

The second feature profiles the esteemed career of Sheku RAPID + TCT as part of its Voices AMplified initiative that Kamara, Dean of Applied Research at the Milwaukee School showcases the people behind the technology. This month’s of Engineering (MSOE), who was recently re-appointed as a Voices AMplified report profiles two such visionaries: Olga volunteer advisor to SME’s AMTC. Kamara came to the U.S. Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology in 1996 from Sierra Leone. As we look back on his journey of learning, he shares that his greatest joy has been in teaching advances, AM’s growth is fueled by a host of engaged others about what is possible through AM. To that end, Kacompanies, organizations, and dedicated professionals, all mara and his MSOE colleagues worked with industry leaders of whom are energized and passionate about developing, to create the Additive Manufacturing Body of Knowledge implementing—and sharing—new ideas and best practic- (AMBOK), as well as a wealth of training materials to serve es throughout a collaborative community of innovators. as a technology road map for manufacturers. In the article,

The recent RAPID + TCT conference, which was held Kamara also shares his view on the limitless problem-solving May 17–19 in Detroit, is proof positive as to how far AM has powers of technology, and how important it is to help others. come in recent years. The 31st edition of the industry’s marA few years ago, he and his friends organized a dialysis clinic quee event featured more than 400 exhibitors, hundreds of in his homeland, which helped community members get the critical care they needed without having to travel or relocate speakers and expert panelists, dozens of technical sessions, to other countries. Kamara not only talks the talk, but he networking opportunities, and attendees from 38 countries. walks the walk.

The AM community took center stage throughout the As Chair of SME’s AMTC, I recently met in person at IMTS show. This includes the passing of the baton in two key with our committee to plan the next 12 month, and it is going leadership positions. John Barnes assumed the chair of the to be exciting. We brought on five fantastic people who are Additive Manufacturing Technical Community Leadership all experts in their area making the AMTC a well-rounded, Committee, succeeding Christopher Williams; and Sarah diverse team. Our promise to the AM community is to do Rimini now chairs the Medical AM Advisory Committee, what we can to lift up and promote the industry through the succeeding Amy Alexander. I’d like to thank Christopher and Industry Achievement Award, our Career Forum series, the Amy, who provided exemplary leadership and vision during Dick Aubin Case Study Award, and assisting SME with its their tenures, and welcome their replacements. forward momentum in AM. We have several new ideas in the

John, who heads The Barnes Global Advisors and Metal works. It’s going to be a great year at the AMTC! Powder Works, has been involved in metal additive manufacturing throughout a distinguished career. He’s led teams that qualified the aerospace industry’s first series production metal AM parts, and developed a pilot metal production facility.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

Although their movie counterparts possess awesome superpowers, the 3D-printed Baby Yodas (at left) and Groots (right) that Olga Ivanova gave to visiting high school students are unable to do so much as dissipate electrical charge--but they’re still very popular with the kids.

According to Materialise, its RapidFit smart cubing system empowers automakers to speed up their engineering and development processes, as in the Aston Martin prototype shown here.

From automotive to medical, Bryan Crutchfield suggests additive

From 3D-printed figurines for students to “quantum dots” and nanocomposites, manufacturing will get more done using streamlined, harmonized workflows Olga Ivanova is a force to be reckoned with in the AM universe

Striving for Paging Dr. OHarmony Kip Hanson

Contributing Editor Kip Hanson

Bryan Crutchfield

Advisor, SME AM Olga Ivanova Master networker Technical Community Leadership Committee Vice President & RAPID + TCT General Manager Director of Technology Materialise North America Mechnano

Olga Ivanova has 3D-printed plenty of interesting parts during her time in manufacturing. Rocket nozzles. Turbine blades and impellers. Neonatal tracheostomy tubes. There are more, which we’ll get to in a moment, but to Star Wars fans, it’s the Static Dissipative Yoda that’s most intriguing.

“We printed a bunch of Yoda and Groot (Guardians of the Galaxy) figurines for high school students who visited our facility recently,” said Ivanova, director of technology at Mechnano, an additive manufacturing materials

Contributing Editor After the economy tanked during the Great Recession, Bryan Crutchfield was more than ready for a change. “I’ve been in the Detroit area for developer near Phoenix. “It’s our way of getting young my entire career and spent roughly 20 years of that with people interested in additive manufacturing.” a Tier 1 automotive supplier,” he said. “So even though I love the industry, I’d ridden it right to the bottom by Padawan Learning then and wanted to do something else. That’s when a She’s quick to point out that those educational giverecruiter approached me looking for someone with oper- aways were made of a gray-colored base resin, not the more ational and sales experience to fill a position in the addi- expensive static dissipative material (which is black) that she tive manufacturing industry. It sounded good to me.” spends much of each day working with—and yes, which she occasionally uses to print Yodas that are just as resistant to electrical charge as they are to the Dark Side of the Force.

That opportunity landed him at 3D-printing product and service provider Materialise NV, where Crutchfield now serves as the vice president and general manager for the company’s North American headquarters in Plymouth, Mich. He also sits on the board of Leuven, Belgium-based RapidFit NV, a Materialise company specializing in automotive tooling design and manufacturing, and Link3D Inc. of Lafayette, Colo., developers of Materialise’s SaaS-based CO-AM software.

“With the acquisition of Link3D, Materialise brings to market a neutral AM platform that not only supports our

AM Community Shows Off at RAPID + TCT

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

The recent RAPID + TCT conference, which was held May 17–19 in Detroit, is proof positive as to how far AM has come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

technology, but also that of third-party developers and, at some time perhaps, even our competitors’ software solutions,” Crutchfield said. Suzy Marzano Senior Manager Building Interoperability Industry Development and

He suggested the AM industry has long needed a Technical Activities SME harmonized workflow that encompasses all aspects of the 3D-printing process. This begins with what Crutchfield refers to as content creation—the importation and potential cleanup of a CAD file, for example, or using point-cloud data from a 3D scanner to construct a viable model of a part or part feature. Supports, meshes, and lattice structures might then be added, the part nested with others that use the same material, and the build file sent to the 3D printer for processing. After leaving the build chamber, parts enter what many call the “dirty little secret” phase of additive manufacturing—postprocessing—which depending on the technology, includes CNC machining, vapor polishing, heat treatment, and other operations.

Whatever the process and however many steps are needed, though, each should be part of a harmonized workflow that links all of the software and equipment required to 3D print a component. “Our CO-AM platform accomplishes all this and more,” Crutchfield noted. COVID has helped create the platform. During the pan-AM Community Shows Off at demic (and even before), Materialise worked on a problem that eventually plagues any company that develops software: the proliferation of multiple, standalone products suffering RAPID + TCT from limited interoperability. Materialise “refactored” its It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology software, connecting each module with a series of application programming interfaces (APIs) to create comprehensive workflows that it now offers to the industry. advances, AM’s growth is fueled by a host of engaged “Additive once belonged only to service bureaus and companies, organizations, and dedicated professionals, all prototyping-only applications,” Crutchfield explained. “Those of whom are energized and passionate about developing, barriers have slowly melted away as AM has moved into implementing—and sharing—new ideas and best practictraditional manufacturing, where it assumes its well-deserved es throughout a collaborative community of innovators. role as just one more tool, albeit an important one.

The recent RAPID + TCT conference, which was held “But this movement is going to require an even highMay 17–19 in Detroit, is proof positive as to how far AM has er level of interoperability,” he continued. “We and other providers will need to provide seamless connectivity to ERP come in recent years. The 31st edition of the industry’s marsystems, for example, as well as the MES platforms used in quee event featured more than 400 exhibitors, hundreds of CNC machine shops and plastic injection molding houses. speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories. Suzy Marzano Senior Manager Industry Development and Technical Activities SME

Automotive assembly fixtures like the one shown here make heavy use of carbon fiber and 3D-printed components.

Although their movie counterparts possess awesome superpowers, the 3D-printed Baby Yodas (at left) and Groots (right) that Olga Ivanova gave to visiting high school students are unable to do so much as dissipate electrical charge--but they’re still very popular with the kids.

A technician keeps an eye on production at one of Materialise’s many print farms.

Each of these systems should talk to one another in a smart, digital way.”

The Best Mousetrap

As Crutchfield is quick to point out, this is not some attempt to rule the 3D-printing software universe. Just the opposite. He and the Materialise team, all the way up to founder Fried Vancraen, believe that closed systems are a path to stagnation. “The world’s going digital, and because of that, manufacturing workflows—additive or otherwise—must be digital in nature, and also automated as much as possible,” Crutchfield said. “But you need to have an open architecture and an open mindset to do that. What’s more, you must be humble enough to realize that you don’t always have the best mousetrap.”

Enabling customers to use best-in-class technology through a brand agnostic and open software platform only drives the industry forward, Crutchfield added. Unfortunately, getting to this point has taken longer than he and others at Materialise expected. Vancraen calls it “the slow revolution,” and as someone who’s been in AM since its earliest days, he should know.

Crutchfield agrees. Though he’s equally eager to see 3D printing assume its rightful position as “just one more tool” on the production floor, he’s resigned to the fact that this will take time. “Anyplace it offers a unique solution, that’s where it will continue to provide its greatest value.”

Holding the Line

Speaking of production floors, Crutchfield’s years with Materialise have brought him full circle. Where his initial role with the company was the support of a factory they’d opened to 3D print components for the medical industry, automakers are now among Materialise’s largest customers. Ford Motor Co., for instance, has deployed “fairly large teams” to understand where and how AM will bring the value Crutchfield just mentioned. In fact, he recently sat alongside Ellen Lee, the leader of one such Ford team, on SME’s Additive Manufacturing Advisory Council. “I think a lot of folks look at automotive companies as these stodgy, set-in-their-ways manufacturers, but I can tell you from personal experience that some of them—Ford included—have extensive experience within AM,” he said. “They’re pouring resources into proofs of concept. They’re building out workflows, determining the rules of engagement, and laying the foundations for future growth. And along the way, they’re finding all kinds of small wins.”

Paging Dr. O

Olga Ivanova has 3D-printed plenty of interesting parts during her time in manufacturing. Rocket nozzles. Turbine blades and impellers. Neonatal tracheostomy tubes. There are more, which we’ll get to in a moment, but to Star Wars fans, it’s the Static Dissipative Yoda that’s most intriguing.

“We printed a bunch of Yoda and Groot (Guardians of the Galaxy) figurines for high school students who visited our facility recently,” said Ivanova, director of technology at Mechnano, an additive manufacturing materials

From 3D-printed figurines for students to “quantum dots” and nanocomposites, Olga Ivanova is a force to be reckoned with in the AM universe Olga Ivanova Master networker RAPID + TCT Director of Technology Kip Hanson Mechnano Contributing Editor developer near Phoenix. “It’s our way of getting young people interested in additive manufacturing.”

Padawan Learning

She’s quick to point out that those educational giveaways were made of a gray-colored base resin, not the more expensive static dissipative material (which is black) that she spends much of each day working with—and yes, which she occasionally uses to print Yodas that are just as resistant to electrical charge as they are to the Dark Side of the Force. October 2022 | sme.org 37

AM Community Shows Off at RAPID + TCT

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

The recent RAPID + TCT conference, which was held May 17–19 in Detroit, is proof positive as to how far AM has come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

One area of particular interest to automakers is service parts. Crutchfield explained that, as with the aircraft and defense industries, manufacturers are required by law to assure spares availability for a set number of years. The Suzy Marzano Senior Managerchallenge here is they either A) need to maintain minimum Industry Development and inventory for parts they might never sell or B) assure that the Technical Activities tooling necessary to make these legacy parts is available SME when requested.

Most in the AM community will immediately recognize that 3D printing is a perfect way out of this quandary, a fact that automakers have also come to realize. The question then becomes how to leverage this capability most effectively. Said Crutchfield, “No manufacturer wants to break into a production line to make a handful of spares, so what better solution than to 3D print them?”

But because the approval process for any vehicle component is quite lengthy, some automakers are now evaluating dual qualification—one for the high-volume, conventionally produced parts and another for 3D-printed spares. This approach eliminates the inventory and tooling concerns mentioned earlier while making it possible to “print on demand,” quite possibly on a localized, point-of-need basis. “If automakers or any other manufacturing sector can AM Community Shows Off at produce spares in an additive manner and still meet form, fit, and function requirements,” Crutchfield said, “it’s definitely a win-win for all concerned.”RAPID + TCT It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology The Virtuous Circle Some might wonder, “What’s taking so long? Service bureaus began 3D-printing parts before many of today’s advances, AM’s growth is fueled by a host of engaged mechanical engineers and product designers were born. Why companies, organizations, and dedicated professionals, all hasn’t 3D printing become as mainstream as conventional of whom are energized and passionate about developing, manufacturing technologies?” But that’s not a fair criticism, Crutchfield cautioned, noting that CNC machine tools have implementing—and sharing—new ideas and best practicbeen in use for more than 60 years and yet are still seeing es throughout a collaborative community of innovators. significant, ongoing improvements.

The recent RAPID + TCT conference, which was held Similar analogies exist for plastic-injection molding May 17–19 in Detroit, is proof positive as to how far AM has machines, stamping, and forming presses, as well as metal come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories. Suzy Marzano Senior Manager Industry Development and Technical Activities SME

Depowdering falls among 3D printing’s “dirty little secrets” category of secondary operations.

Paging Dr. O

Olga Ivanova has 3D-printed plenty of interesting parts during her time in manufacturing. Rocket nozzles. Turbine blades and impellers. Neonatal tracheostomy tubes. There are more, which we’ll get to in a moment, but to Star Wars fans, it’s the Static Dissipative Yoda that’s most intriguing.

“We printed a bunch of Yoda and Groot (Guardians of the Galaxy) figurines for high school students who visited our facility recently,” said Ivanova, director of technology at Mechnano, an additive manufacturing materials

casting equipment. The latter has enjoyed far greater productivity thanks to AM—remember, one of the first commer-

Although their movie counterparts possess awesome superpowers, the 3D-printed cial uses for stereolithography in the early ’90s was making

Baby Yodas (at left) and Groots (right) that Olga Ivanova gave to visiting high school students are unable to do so much as dissipate electrical charge--but they’re still very 3D-printed patterns used in investment casting. In addition, popular with the kids. many sand-casting shops are now using a form of binder

From 3D-printed figurines for students to “quantum dots” and nanocomposites, Olga Ivanova is a force to be reckoned with in the AM universe Olga Ivanova Master networker RAPID + TCT Director of Technology Kip Hanson Mechnano Contributing Editor developer near Phoenix. “It’s our way of getting young people interested in additive manufacturing.”

Padawan Learning

She’s quick to point out that those educational giveaways were made of a gray-colored base resin, not the more expensive static dissipative material (which is black) that she spends much of each day working with—and yes, which she occasionally uses to print Yodas that are just as resistant to electrical charge as they are to the Dark Side of the Force. October 2022 | sme.org 39

jetting to produce molds and cores from digital models. “Compared to traditional manufacturing technologies, AM is barely out of its toddler years,” Crutchfield said. Whatever the relative maturity, efficient additive manufacturing requires a robust workflow, he reiterated, adding that the lack of which has made 3D printing more cumbersome and therefore slowed its adoption to some extent. Achieving this, however, means that everyone must work together, from the material providers to the equipment manufacturers. “There aren’t any interoperability standards yet, and all of the 3D printers pretty much march to the beat of their own drum in terms of data formats and communication protocols,” he said. “As such, people must often rely on brute force to get hardware and software to work together.” A similar statement applies to feedstocks—even though they might have the same chemical characteristics and powder morphology, titanium from one supplier is different from titanium from another supplier, a factor that directly influences 3D-printing processes. “This is what I mean by AM still being in its infancy, in that there are so many challenges yet to conquer,” Crutchfield concluded. “But with every high-value application or unique engineering challenge solved by additive, it gains new ground. OEMs invest more into research and development, the industry makes additional efforts at standardization, and there’s greater market pressure to reduce operating costs. “We’ve seen this trend over the past five years or so, and I expect it will only intensify going forward. I like to think of it as a virtuous cycle that will continuously strengthen AM’s place in the Bespoke implants like this one are a huge win for 3D printing and patient alike. manufacturing industry.”

AM Community Shows Off at AM Community Shows Off at RAPID + TCT RAPID + TCT

Suzy Marzano

Suzy Marzano Senior Manager Industry Development and Senior Manager Technical Activities Industry Development and SME Technical Activities SME

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

The recent RAPID + TCT conference, which was held May 17–19 in Detroit, is proof positive as to how far AM has come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Talking to Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during the Dean RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, Sheku Kamara came to the United States in 1996. Having studied mechanical engineering at Fourah Bay College, a constituent of the University of and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed prodSierra Leone, he’d left his troubled homeland several ucts. He also chairs the Direct Digital Manufacturing Advisory years earlier and moved to Germany with a scholarship Team and moderated a panel at RAPID + TCT. through the German Academic Exchange Service, or Carl and Olga represent the spirit behind Voices AMplified. Deutscher Akademischer Austauschdienst (DAAD). And I hope you enjoy their stories. when the chance came to attend the Milwaukee School of Engineering (MSOE) in Wisconsin as a graduate student, Kamara jumped at it. He’s been there ever since.

Kip Hanson Contributing Editor

“They were one of the first schools to adopt additive manufacturing with funding from the NSF (National Science Foundation) and had a true rapid prototyping center,” Kamara said. “At that time, folks might have had experience with SLA (sereolithography) or FDM (fused depositon modeling), but they rarely knew multiple technologies. MSOE allowed students to work with all of the leading types of 3D-printing equipment and it still does. It was a great opportunity.”

It was so great that Kamara stayed on after earning his master’s degree. Within two years, he was responsible for

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

Sheku Kamara stands at an open house before the 3D printers named Bart, Dave, and Marie, speaking quee event featured more than 400 exhibitors, hundreds of with a visiting student about additive manufacturing. speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

Looking back on a long career of learning,The AM community took center stage throughout the sharing, and always trying to do your best.show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, Sheku Kamara succeeding Amy Alexander. I’d like to thank Christopher and SME Technical Advisor Amy, who provided exemplary leadership and vision during Dean of Applied Research at the Milwaukee School their tenures, and welcome their replacements. of Engineering

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

Paging Dr. O

Olga Ivanova has 3D-printed plenty of interesting parts during her time in manufacturing. Rocket nozzles. Turbine blades and impellers. Neonatal tracheostomy tubes. There are more, which we’ll get to in a moment, but to Star Wars fans, it’s the Static Dissipative Yoda that’s most intriguing.

“We printed a bunch of Yoda and Groot (Guardians of the Galaxy) figurines for high school students who visited our facility recently,” said Ivanova, director of technology at Mechnano, an additive manufacturing materials

the additive manufacturing lab, and today is MSOE’s Dean of

Applied Research.

Although their movie counterparts possess awesome superpowers, the 3D-printed Baby Yodas (at left) and Groots (right) that Olga Ivanova gave to visiting high school Kamara explained that MSOE is a private university students are unable to do so much as dissipate electrical charge--but they’re still very whose focus is experiential learning. As a result, the school popular with the kids. has more labs than classrooms, giving students ample time to work with their hands. MSOE also stays quite close to the AM industry and regional businesses, an attribute that is “pretty unique.” From the very beginning, Kamara said,

No Experience Necessary

Aside from a drive to learn and a newly discovered love of 3D printing, Kamara had another important thing going for him in those early days. Ironically, it was a quality that few of us would brag about: no manufacturing experience. “I encountered people who knew all about machining or plastic injection molding who would tell me, ‘No, you can’t do that, or that will never work.’ But I had no preconceived notions, so it was only natural for me to put forth solutions they might never consider.” Before his promotion to Dean, Kamara spent nearly two

From 3D-printed figurines for students to “quantum dots” and nanocomposites, decades proposing such solutions, some unorthodox, others

Olga Ivanova is a force to be reckoned with in the AM universenot. He supported dozens of companies and several hundred students during their additive manufacturing journeys, first as

MSOE’s manager of operations and then as the director of its

Rapid Prototyping Consortium. Through it all, his greatest professional joy has been Olga Ivanova teaching others about AM, in many cases helping them to Master networker unlearn what they already knew about conventional manu- RAPID + TCT facturing so they can more effectively leverage 3D printing’s Director of Technology Kip Hanson Contributing Editor unconventional capabilities. Kamara noted that the aerospace and medical industries Mechnano were early adopters of 3D printing because it makes customization easier and provides greater design flexibility than traditional manufacturing methods. But what manufacturers developer near Phoenix. “It’s our way of getting young haven’t yet wrapped their collective heads around is all the people interested in additive manufacturing.” untapped potential that AM brings to the table, if only users had the necessary tools and sufficient knowledge. Padawan Learning She’s quick to point out that those educational give-

The Body of Knowledge aways were made of a gray-colored base resin, not the more To meet this last need, Kamara and MSOE have expensive static dissipative material (which is black) that she worked with other industry leaders to develop the Additive spends much of each day working with—and yes, which she occasionally uses to print Yodas that are just as resistant to electrical charge as they are to the Dark Side of the Force. October 2022 | sme.org 41

Manufacturing Body of Knowledge (AMBOK), as well as the training materials needed to bring others up to speed more quickly, thereby expediting AM’s further development. The effort was (and remains) a collaboration between MSOE, America Makes, SME’s Tooling U-SME, the National Coalition of Advanced Technology Centers (NCATC), and Technician Education in Additive Manufacturing & Materials (TEAMM), which together form the Additive Manufacturing Leadership Initiative (AMLI).

The group released its first version of AMBOK in 2006 and, as noted, continues to build on its work. “AM is constantly evolving,” he said. “For example, there was no automated post-processing back then. 3D-printed parts were all finished by hand. Nor were there hybrid CNC machine tools, which combine additive and subtractive processes on a single platform.” He laughed: “Where does that fit into a book on 3D printing? That’s why we have to go back and revise it every few years, because, from a standards perspective, the constant state of flux can be quite challenging to keep up with.”

Despite these challenges, AMBOK is a vital tool. It has provided manufacturers with a technology roadmap and, just as importantly, given students a benchmark by which to measure themselves: Tooling U’s Fundamentals of Additive Manufacturing Certificate. “I taught the initial classes for that certificate and still teach the review course. It’s something I greatly enjoy doing,” Kamara said.

He apparently enjoys writing, also. Together with consultant and former MSOE professor Kathy S. Faggiani., Kamara recently published the Fundamentals of Additive Manufacturing for the Practitioner, part of the Additive Manufacturing Skills in Practice series, “Additive manufacturing is my passion.”

Impossible Possibilities

Passionate or not, Kamara suggested that we’re just getting started with 3D printing. “People often ask me, ‘What are the limitations of this technology?’ My response is that we simply don’t know. Not only are the materials and equipment constantly evolving, but we can’t yet design for its many possibilities.”

He held up his cell phone to illustrate this last point. “If I were to print this or any other object, it would have fairly consistent material properties throughout. That’s a good thing. But what would happen if I changed the properties in this

AM Community Shows Off at RAPID + TCT

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

The recent RAPID + TCT conference, which was held May 17–19 in Detroit, is proof positive as to how far AM has come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

AM Community Shows Off at Suzy Marzano Senior Manager RAPID + TCT Industry Development and Technical Activities SME

It’s official. Additive Manufacturing is thriving and continues to gain momentum with successes across diverse applications. In addition to ongoing technology 3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applications. The panel was one of several during a special town hall advances, AM’s growth is fueled by a host of engaged companies, organizations, and dedicated professionals, all of whom are energized and passionate about developing, implementing—and sharing—new ideas and best practices throughout a collaborative community of innovators.

The recent RAPID + TCT conference, which was held May 17–19 in Detroit, is proof positive as to how far AM has come in recent years. The 31st edition of the industry’s marquee event featured more than 400 exhibitors, hundreds of speakers and expert panelists, dozens of technical sessions, networking opportunities, and attendees from 38 countries.

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed hosted by the Medical AM Advisory Team. Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gardner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge). To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee. SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM. Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT. Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

section here by adjusting the laser speed or power? I don’t know, because there’s currently no software that allows me Suzy Marzanoto design for this, even though the machine could physically Senior Manager do it.” Industry Development and

But why would someone want to do such a thing? After Technical Activities SME all, one of the central tenets of product design is consistency and predictability—won’t capabilities like these lead to a Wild West-like world in which nothing is certain?

Not so fast. As a counter example, Kamara cited a Boeing 787, an aircraft he flies in frequently. Its wings are composed of an aluminum structure covered with carbon fiber and epoxy resin. None of these materials is terribly strong on its own, but when laid down in alternating, precisely oriented sheets and fastened in a strategic manner, they’re able to carry an aircraft weighing more than half a million pounds. By mastering 3D printing’s innate ability to alter material properties on the fly, he predicts, manufacturers will one day be able to “program” their wares with specific desirable characteristics. “Take the Nylon feedstock used in powder bed fusion printers. If I lower the laser energy during the build process, I can make a part that’s porous, almost like a sieve. But by putting a lot of energy into the Nylon, I can seal it up tight. Combining these two sintering techniques with the right polymer might produce a composite-like material that is both exceedingly strong yet porous and lightweight.” It also creates other opportunities. For instance, Kamara continued, “automotive engineers struggle to devise failure points in their vehicle designs—in other words, if my car crashes, I want it to crumble in a certain way. If you can precisely control and adjust your material properties throughout different regions of a 3D-printed part, functionality like this might become very easy to deliver.”

A Helping Hand

When not writing books or dreaming up lofty goals for additive manufacturing, Kamara donates his time to other manufacturing-related causes. Most recently, he served on

Meet Sheku Kamara, Dean of Applied Research at the Milwaukee School of Engineering (MSOE).

Although their movie counterparts possess awesome superpowers, the 3D-printed Baby Yodas (at left) and Groots (right) that Olga Ivanova gave to visiting high school students are unable to do so much as dissipate electrical charge--but they’re still very popular with the kids.

This manifold is just one of many parts that Sheku Kamara has 3D printed during his decades at MSOE, first as a student and now as dean.

Paging Dr. O

Olga Ivanova has 3D-printed plenty of interesting parts during her time in manufacturing. Rocket nozzles. Turbine blades and impellers. Neonatal tracheostomy tubes. There are more, which we’ll get to in a moment, but to Star Wars fans, it’s the Static Dissipative Yoda that’s most intriguing.

“We printed a bunch of Yoda and Groot (Guardians of the Galaxy) figurines for high school students who visited our facility recently,” said Ivanova, director of technology at Mechnano, an additive manufacturing materials

Olga Ivanova is a force to be reckoned with in the AM universethe boards of the Wisconsin Center for Manufacturing and Productivity (WCMP), a manufacturing extension partnership (MEP) center sponsored by the National Institute of Standards and Technology (NIST), and the Wisconsin Manufacturing Extension Partnership (WMEP) for a total of nine years. Olga Ivanova Again, the goal was to promote AM’s successful adoption, Master networker this time with small to medium enterprises. In one notable RAPID + TCT case, Kamara helped a medical device company develop a Director of Technology Kip Hansonpre-surgical planning process to aid surgeons in hip re- Mechnano Contributing Editorplacement surgery. For more than 18 years, the process has helped thousands of patients with custom implants recuperate faster. “This is a great example of what companies can do with a little guidance and the time to investigate alternative developer near Phoenix. “It’s our way of getting young technologies,” he said. “There are just so many opportunities people interested in additive manufacturing.” like this out there.” Kamara has also has served as a RAPID + TCT Event Padawan Learning Advisor since 2004 and was selected to join SME’s Additive She’s quick to point out that those educational giveManufacturing Technical Community Leadership Committee aways were made of a gray-colored base resin, not the more last year. And with funding from the NSF, he and MSOE col- expensive static dissipative material (which is black) that she league Subha Kumpaty provided an opportunity for several spends much of each day working with—and yes, which she occasionally uses to print Yodas that are just as resistant to electrical charge as they are to the Dark Side of the Force. October 2022 | sme.org 43

U.S. students to conduct research focused on rapid prototyping for biomedical applications and the linking of materials science with cutting-edge bioengineering for practical applications at the Non-Ferrous Materials Technology Development Center (NFTDC) in Hyderabad, India.

He also keeps an eye on his homeland. He’s donated several 3D printers to the Directorate of Science, Technology and Innovation and the Milton Margai College of Education and Technology (MMCET) for them “to wrap their heads around” and was involved in starting an additive manufacturing group in Nigeria.

“Life in Sierra Leone has gotten better since I left but it remains a very difficult place,” Kamara said. “A few years ago, some friends and I helped put together a dialysis clinic there. The country did not have one, and people would have to travel to other countries for treatment, which at that time meant moving away. Now, some of them have a chance to stay home. So it’s a struggle, but I’m old enough to know that what’s most important in life is to do your best, always tell the truth, and try to help others. That’s all you can do.”