7 minute read

KEEP COOL AND CARRY

How 3D printing is providing enhanced comfort on Jack Wolfskin’s 40 liter 3D Aerorise Carry System.

In Northern Italy, the autumn sun beats down, casting a shadow high up against a massive grey cliff face. The view from the country’s largest lake below is just a tiny spec. You have to squint to see it. But as the hands stretch to grip and the lower limbs find whatever foothold they can, you can just about spot some movement.

Magdalen Hamel is two days into her week-long vacation at Lake Garda, where she is living the dream of any climber by scaling the mountains that overlook a body of water some 32 miles long and 10 miles wide. It is a spectacle she is taking in at every belay station on her multistage climb, an ascent in which she is debuting the first Jack Wolfskin product produced with the help of additive manufacturing (AM) technology.

As she recuperates from that climb, Hamel is back at the hotel, with headphones in ears and the 3D Aerorise 40 Carry System by her feet, answering questions for TCT Magazine.

We are nearly two years on from when Jack Wolfskin received the first samples of Carbon’s Digital Light Synthesis technology. The round, latticed pucks would soon evolve into ergonomically shaped pads that support the lumbar and shoulder areas on the back of a carry system that is now available for purchase.

“I think it was end of 2020 [when we started to use 3D printing] and close cooperation [with OECHSLER, a Carbon Production Network partner] started in ’21,” Hamel, Category Manager, Equipment

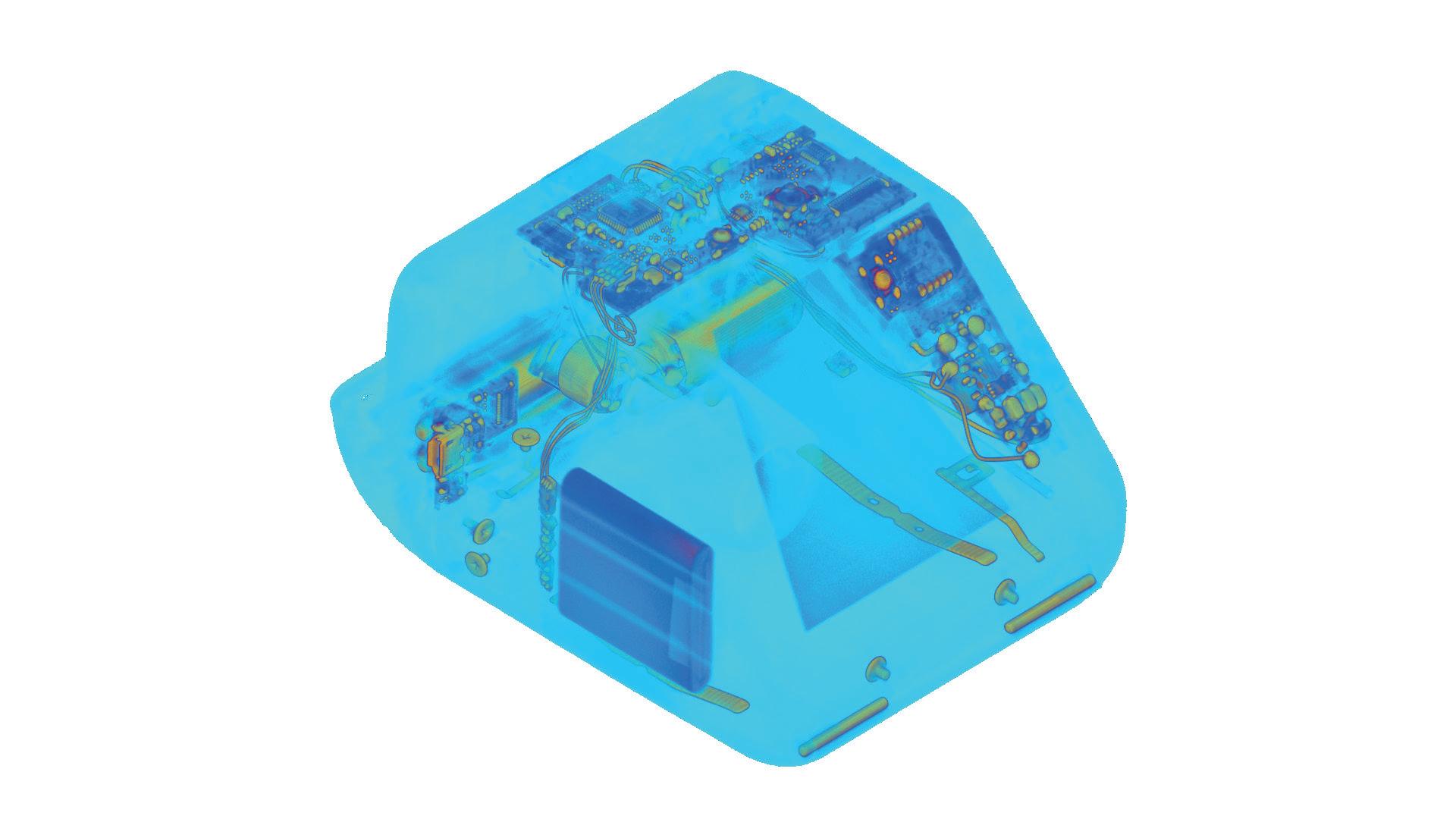

SHOWN:

JACK WOLFSKIN’S 3D AERORISE 40 CARRY SYSTEM WITH 3D PRINTED LUMBAR AND SHOULDER PADS at Jack Wolfskin, tells TCT. “It was our Innovation Manager that had the contact with Carbon and gave us the first sample. With this first touch, we were addicted, because we can combine so many material properties with only one material, which [translates] into using less materials. On a common carrier system, to get that comfort we

need a lot of different degrees of hardness and more firm or soft foams, EVAs, spacer mesh and the air mesh. And with only one material, we can [now] create an even better performance because it doesn’t collapse.”

Per OECHSLER’s Senior VP of Global Product & Technology Development Matthias Weißkopf, the service manufacturer expects AM to ‘significantly change the design of outdoor equipment and sporting goods in the coming years.’ Jack Wolfskin believes with the 3D Aerorise 40, it's leading the way on the former, while joining several other household names in leveraging 3D printing within the latter.

For the development of the 3D Aerorise 40 Carry System, the outdoor apparel company implemented a body mapping process which considered how the weight of the backpack needed to be distributed. The optimum distribution of weight and pressure, in addition to forming the ideal ergonomic shape, was important to ensure sufficient air circulation to enable cooling.

Printing four parts per build, Jack Wolfskin is putting the latticed pads

WORDS: SAM DAVIES

AND CARRY

into series production via OECHSLER, with the 3D Aerorise 40 already available via pre-sale. The four pads have replaced traditional foaming layers that cover the entire back panel and harness an open grid structure lattice that boasts thousands of rod-shaped struts. These struts have different vertical and horizontal strengths, with zonal cushioning offering different degrees of hardness throughout areas of the pads. Pads are firmer the closer they are to the back panel, and softer the closer they are to the skin for enhanced comfort. They're also firmer on the narrower side to support the back, as this is where the weight is concentrated, and softer at the wider ends to add comfort again. To ensure cooling ventilation, the degrees of firmness are infinitely variable.

These pads have been designed with

Carbon’s Design Engine and leant on the latticing capabilities that brands like Adidas, Riddell and

Rawlings have all benefited from.

“It was a 0 to 100 experience. This is an entirely new field for us,” Hamel says. “We see a lot of potential there so this is why we’ve been attracted so much by the pucks we got from Carbon. We touched, we squeezed it and we directly felt the benefit because the cushioning has so many density zones, it was smooth when we grabbed it and then we squeezed it, it got hard but it didn’t collapse. [Then we said],

‘hey, how can we translate it into benefits for our consumers?’ The consumer need is, for sure, always centre of our [thinking].”

As Hamel stands on the balcony of her hotel room, she picks up the 3D Aerorise 40 to demonstrate the energy return capabilities of the pads, outline their rhombus shape, and indicate how the formation and stretchiness of the pads facilitates air circulation and reduces the temperature on the user’s back.

After making those gesticulations, Hamel has now placed the bag out of shot and is demonstrating the diagonal movements hikers make on their trails.

“When you are on a hike, you’re always in this diagonal movement,” Hamel says, pushing her right limbs forward and left limbs back, before swapping over to mimic a hiker. “We want to make sure that our customers can carry their load very easily. It is also about load control. This was the main story for us because usually the consumer needs to decide, ‘do I need a ventilated backpack with the usual gap we have at the back, but the load is a little far away from the back, or will we go for a body contact carrier system to have very good load distribution, but I don’t have this great ventilation?’ Here, it comes in both.”

Considering the actions of the consumer in this detail, and supplementing it with body mapping, is how Jack Wolfskin came to best place the pads on the back of their carry system. After the parts are printed by Oechsler and put through the necessary post-processing steps, two symmetrical pads are placed in the shoulder region of the backpack and two symmetrical pads are placed in the lumbar area. They work to support the areas of the body that come under the most pressure from the load the hiker or climber is carrying on their back.

By 3D printing the pads, Jack Wolfskin has been able to reduce the weight of its carry system, improve the ventilation, and provide a temperature reduction brought on by friction in the pressure zones of up to 5°C. In working with OECHSLER, Jack Wolfskin is also reinforcing a commitment to engineering products in Germany with manufacturers located nearby.

“We are pleased to support Jack Wolfskin in the development of the Aerorise backpack series,” Weißkopf commented. “With our expertise in additive manufacturing, we have been able to significantly improve the product features of the backpack for the benefit of the customer. We see significant growth potential for 3D printing development and series production in these areas.”

Jack Wolfskin does too. Throughout the product development process, the company went through ‘countless iterations’ with OECHSLER to arrive at the ergonomically shaped final designs. They started with the round pucks, moved towards rectangular shaped pads, and then came to the rhombus-shaped components with a seam allowance attaching them to the back panel.

With close links to OECHSLER, the Aerorise 3D 40 is now in series production and is already getting rave reviews from users. Feedback to Jack Wolfskin has included, ‘I feel cold when I’m wearing it,’ ‘I can’t feel anything at all after a minute,’ and simply, ‘so cool.’ Hamel, who will make her way back up the mountains surrounding Lake Garda tomorrow, is similarly impressed with what her and her team have developed. And, of course, is already looking forward. “There are so many opportunities,” she finishes. “We would really like to understand [3D printing] much better, much more in the future. This really will be a game changer in our industry. We see that additive manufacturing can give us a lot of benefits in the research and development part, for sure.

“I think it will take time to get it set on a manufacturing base to make it accessible to a wider range of consumers, but we, as a brand, are absolutely convinced that the consumer is aware of it and will see the benefits. And we’re also proud too that we are one of the first brands that already have taken the first step and we are already live with that product.”

SHOWN:

THE LATTICE SHAPES CONSIST OF THOUSANDS OF STRUTS AND WORK TO ADD COMFORT, REDUCE WEIGHT, AND PROVIDE COOLNESS

M AEROSPACE RTC

Thebest3Dprintingfortheindustry

G N N T I R I P D 3 S G I E L O O N C H T E

-MJF -SLS -SLA -FDM -DMLS -POLYJET -DED MORE THAN 70 MATERIALS

We have composite materials, metals and thermoplastics. OTHER

SERVICES -CNC Machining -Injection Molding -Laser Cut -Water Jet