2 minute read

TRRG Invest in Online Process-Quality Initiative

TRRG Invest in Online Process-Quality Initiative

EXPORT PROCESS IMPROVEMENT

The last year has seen TRRG’s export team working hard to develop and embed an online process quality initiative into the manufacturing processes of our global network of dealers.

One key objective was to implement a PreDelivery Inspection (PDI) system commensurate with TRRG’s manufacturing sites across Europe, the aim from the outset being to ensure that the customer experience is the same regardless of where a client procures a TRRG product and that the build quality at our dealers is identical to that of a TRRG subsidiary built product.

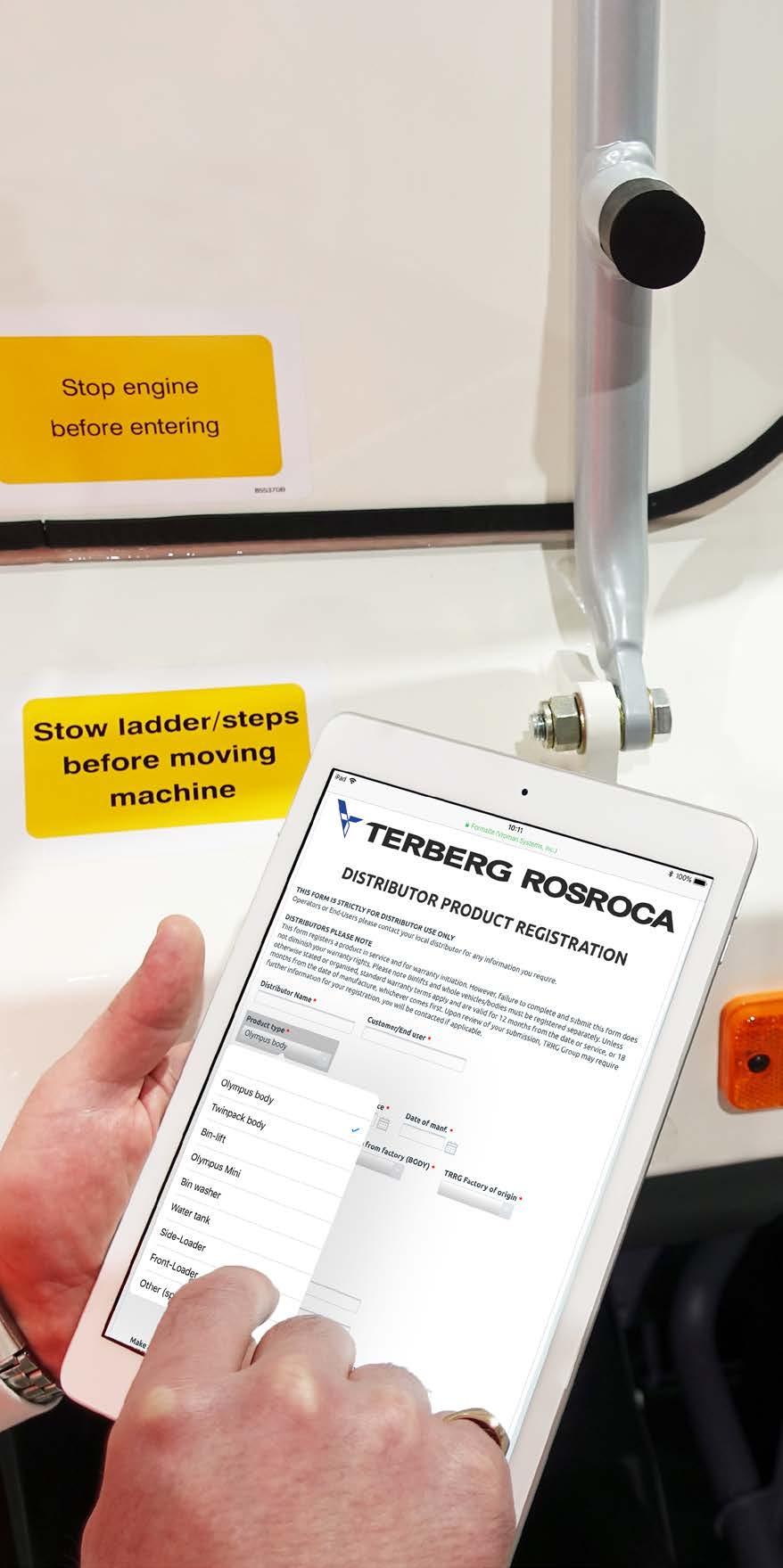

The initiative doesn’t just encompass the PDI process, it also includes an online warranty registration and warranty claims process. With multi-device compatibility, the system can be used across mobile, tablet and desktop devices and protects against errors, ensuring that any repair or parts are correct for the equipment.

Jeremy Boanson-James, Export Technical Manager for TRRG has been leading the charge to implement the initiative at all dealers and has so far received a great reaction.

He said: “I’ve been visiting our dealers and assisting with training to help employ the system for all TRRG vehicles leaving its production lines.”

“All dealer staff have been very welcoming of the system and have been excited to introduce it into their production process.”

“Thanks to the design of the system, admin and workshop staff can complete forms whilst walking around the vehicle.

“The system is a vast improvement for our export operations as it collates records and imagery in one system for vehicles starting operation around the globe.!

The first dealer to receive training for our new system was Excel Industries in Dubai, with the help of the Process Engineering department at Ros Roca, Spain who was able to offer an invaluable insight into the processes at our Spanish facility. Pierangelo Marfella from Excel Industries said:

“The support we receive from TRRG and the systems they have helped us implement are a superb enhancement to our manufacturing process. We feel more confident in the product quality of what we produce locally for TRRG clients and look forward to continued success”

In line with TRRG’s continuous improvement ethos, Jeremy Boanson-James visits each dealer three to four times per year and ensures they are equipped with everything they require to build TRRG product, backed up by office based support via email, skype and telephone.

Where long term visits are requested or necessary our export team may spend up to a month living and breathing the manufacturing process at a dealers. We ensure that critical elements such as work instructions, specialist tooling,

service information, software, process control measures and welding instructions are aligned with our subsidiaries. We’re proud to offer this complete service to ensure that our dealers feel fully supported and integral to the our global team, this full factory support is guaranteed by our growing export department.

With the forecast for our dealer network to build over 280 units over the next 24 months, our online process quality initiative will help ensure that our global customers have a positive TRRG dealer experience.