11 minute read

Bio-nanomaterials for development of health care textiles

21 COVER STORY BIO-NANO MATERIALS As seen in Fig 3.3, with increasing Reference concentration of Chitosan, bending length also increases. 2 – 3 % increase in bending length was observed in all concentration of chitosan. The increase in bending 1. Zitao Zhang, Liang Chen, Jinmin Ji, Yanliu Huang and Donghui Chen “Antibacterial Properties of Cotton Fabrics Treated with Chitosan” Textile Research Journal 2003 73: 1103 length is due to increase in stiffness 2. Md Ibrahim H Mondal, Firoz Ahmed, Md of fabric. Roknuzzaman, Md Nazmul Huda, Md Ahsan Conclusion Habib “Antimicrobial activity of chitosan and its derivatives exhausted cotton fabrics as ecoIn this study different concentra- friendly antimicrobial agents” Journal of Textile tion of antimicrobial agents were Eng Fashion Technol. 2020;6(3):77‒80 applied by pad-dry-cure technique and antimicrobial activity was evaluated against two bacteria i.e. S. aureus (Gram positive bacteria) and E. coli (Gram negative bacteria). The 3. Guneet Dhiman and J. N. Chakraborty “Antimicrobial performance of cotton finished with triclosan, silver and chitosan” Dhiman and Chakraborty Fashion and Textiles (2015) 2:13 anti-microbial activity increases 4. SEUNGSIN LEE, JEONG-SOOK CHO, AND with increase in concentration of GILSOO CHO “Antimicrobial and Blood RepelChitosan. After 10 gpl there is no lent Finishes for Cotton and Nonwoven Fabrics remarkable improvement in the an- Based on Chitosan and Fluoropolymers” Textile timicrobial activity. The maximum Research Journal 1999 69: 104 antimicrobial activity is archived at 15 gpl concentration which is 87.20 % for E. coli and 94.50% for s. aureus. There is no remarkable change observed in physical properties of 5. Mr. M. Parthiban, Dr. S. Gunasekaran & Silambarasan, Sakthi Srinivasan, Seetharaman, Karthika “Effect of nanosiver application on antimicrobial finishing” cotton fabric treated with Chitosan. 6. G.Thlagavathi, T.Kannaian, “Dual Antimicro7. DANIELA ENESCU “Use of Chitosan in Surface Modification of Textile Materials” Vol. 13,No. 6, 2008, pp. 4037-4048

8. Allan, C. and Hadwiger, L.A. 1979 “The fungicidal effect of chitosan on fungi of varying cell wall composition”. Exp. Mycol., 3: 285–287. [Crossref] , [Google Scholar]

Advertisement

9.Boguslaw ki,S.,Bunzeit,M.andKnorr,D.1990.“Effects of chitosan treatment on clarity and microbial counts of apple juice”.ZFL, Int. J. Food Technol. Food Proc. Eng., 41:EFS55 [Google Scholar]

10. Castellanos-Perez, N., MaldanadoVega,M.,Fernandez Villagomez G andCafferalMendez,S.1988. “An evaluation of the coagulating ability of chitosans from different crustacea species and fungi”. InChitin and Chitosan, Edited by:Skjak-Braek,G.,Anthonsen,T.andSandford, P. 567–576. London: Elsevier Applied Science

11. El-tahlawy, K.F., El-bendary, M.A., Elhendawy, A.G. & Hudson, S.M. (2005) “The antimicrobial activity of cotton fabrics treated with different crosslinking agents and chitosan” Carbohydrate Polymers, 60(4), 421–430.

Dr. S.S Kole, Dr. V.D Gotmare

Abstract: Textile Manufactures Department, VJTI Matunga-Mumbai incorporating both synthetic and biopolymers has increased considvelopment of healthcare products. The range of products available In the last few years, the nanoma- erably over the last few years, using is vast but typically, they are used terials have played an important conventional and nano-finishing in the operation theatre or in the role in the medical and healthcare route. In a near future, textile ma- hospital ward for the hygiene, care textile. Currently, woven and non- terials treated with biomaterial will and safety of staff and patients. The woven antibacterial fabrics are the perhaps be the largest application applications range from the simple most used applications in medi- in the area of medical and health- cleaning wipes to the advanced cal textiles segment, being used care textiles. The present paper is barrier fabrics used in operating to prevent infection or deodorize a comprehensive review on de- rooms. The demand for medical medical clothing. Today, the con- velopments in the nanostructured and healthcare textiles is on the upsumers’ attitude towards hygiene biomaterials for healthcare applica- ward trend as, a safe, healthy and and active lifestyle has created a tions. comfortable living environment. rapidly increasing market for a wide range of medical textiles, which has Introduction: This is important for the protection from the infection of pathogenic stimulated intensive research and An important and growing part of microorganisms has to be ensured. development. As a result, the num- the textile industry is the healthcare Many attempts are being made for ber of functional textiles with an and hygiene sector. Textile has al- the development of healthcare texantibacterial and antifungal activity ways played a vital role in the de- tiles with the use of verities of syn-

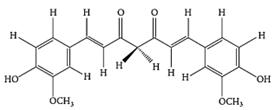

thetic and natural chemicals. So far, a number of chemicals have been employed to impart antibacterial activity to textiles. These chemicals include inorganic salts, organometallics, iodophors (substances that slowly release iodine), phenols and thiophenols, onium salts, antibiotics, heterocyclics with anionic groups, nitro compounds, urea and related compounds, formaldehyde derivatives and amines [1]. However, many of these chemicals are toxic to humans and cannot easily degrade in the nature and causes skin irritation problems [2]. High volume of research has been reported on application of synthetic and natural antimicrobial agents on textile substrates, especially on cotton using conventional and nanotechnology methods, as cellulosic materials offers ideal environment for microbial growth. It is necessary for human beings to wear antimicrobial finished textile products for healthy life style [3]. Today, the application of nanotechnology in the textile has taken an upward trend, for the development of textile products for various applications and has real commercial potential for the textile industry. This is mainly due to the fact, that conventional methods used to impart different properties to fabrics often do not lead to permanent effects, they will lose their functions after laundering or wearing. Nanotechnology can provide high durability for fabrics. Nano-particles have a large surface area-tovolume ratio, thus presenting better affinity for fabrics and leading to an increase in durability of the function. In addition, a coating of nano-particles on fabrics will not affect their breathability or hand feel. Application of nanoscience and nanotechnology-related textiles can play an important role in the medical sector. Currently, woven and non-woven anti-bacterial fabrics are the most used applications of nanotechnology in the medical and healthcare textiles segment with incorporation of both synthetic and natural polymers, being used to prevent infection or deodorize medical clothing, wound dressing and bedding. The nanotechnology-based products are used in the medical sector to cover a range of antibacterial textiles with a broad spectrum of antimicrobial activity. Textile materials treated with nanomaterials in the form of nanoparticles, gels and nanoemulsion are functional to prevent mite sensitization in atopic dermatitis; antimicrobial wound dressings, patient dresses, bed linens or reusable surgical gloves and masks [4] .Nanoemulsion and Nanogels for Healthcare Applications: Nanoemulsion are the class of disperse systems consisting of two immiscible liquids. The liquid droplets (the disperse phase) are dispersed in a liquid medium (the continuous phase). Several classes may be distinguished: oil-in-water (O/W), water in-oil (W/O) and oil in-oil (O/O). To disperse two immiscible liquids, one needs a third component, namely, the emulsifier. The choice of the emulsifier is crucial in the formation of the emulsion and its long-term stability. Nanoemulsion is submicron emulsion with mean droplet diameter ranging from 100 to 500 nm. They are thermodynamically stable and translucent dispersions of oil and water with a droplet size in the range 100-600 nm. Nanoemulsion is prepared by low-energy spontaneous titration methods such as Phase Inversion Temperature (PIT) emulsification, by phase inversion composition or by high shear forces using highpressure homogenizers or ultrasonic generators [5]. The various natural material like curcumin and neem are used for imparting the antibacterial properties in the textile material with various forms. The activity of these materials on textile substrate is limited because of their poor aqueous stability. The solubility can be enhanced by preparing the stable nanoemulsion [6]. The activity of nanoemulsion on textile material is depends on the type of oil used, method of preparation of nanoemulsion, active content in the emulsion etc. The oil in water nanoemulsions are commonly used in the textile since textile materials shows more affinity to the water rather than oil [7]. Similarly, like nanoemulsion the nanogel containing the active agent is used in the designing of textile drug delivery systems. The nanogels are prepared using dispersion agent and the properties of nanogel like spreadability and viscosity depends on the type of gelling agent used. The nanogel containing the therapeutic value is applied on the spunlace nonwoven samples using hand lying technique, this type of material used in the healthcare applications [8]. Application of Curcumin for Wound Dressing Curcumin or diferuloylmethane with chemical formula of (1,7-bis(4hydroxy-3- methoxyphenyl)-1,6heptadiene-3,5-dione) and other curcuminoids constitute the main phytochemicals of Curcuma longa L. (Zingiberaceae family) rhizome with the common name of turmeric [9]. The structure of curcumin is shown in the Fig 1. The presence of polyphenolic compound and variety of biological activities in the structure has been gained significant attention of researches all over the world for various applications [10]. Curcumin finds application in the feild of textile of medicinal applications especially wound dressings. But, application of curcumin is limited in textiles because of its poor aqueous solubility. The extraction and formulation of nanocarriers loaded with active curcumin is being used to design cotton based wound dressings. The dressing materials treated with stable nanoemulsion containing active drug of curcumin shows exceptional performance with respect to antimicrobial activity, skin irritation study and biocompatibility [11].

The recent developments in the ishing of Textiles--A Review, AATCC

applications: a review. Journal of Advanced Research, 6 (2), 105–121. 8. Ferreira M.C, Tuma P. (2006). Complex wounds. Clinics, 61,571– 578. 9. Kurkov. (2010). Parental delivery of CDs effects on drug binding, APPS Pharmaceutical Science Technology, 11, 1152-1158. 10. Lee J.E, Park J.C. (2001). Characterization of UV-irradiated dense/ Fig 1. Structure of Curcumin porous collagen membranes: Morphology, enzymatic degradation Conclusion Developments in Antimicrobial FinMedical Journal, 42, 172–179. and mechanical properties, Yonsei nanostructured bioactive material such as nanoemulsion and nanogels in the field of healthcare textiles has opened a new sustainable market due to their unique properties such as biocompatibility, biodegradability, nontoxicity and antimicrobial activity, which have attracted 11. Gotmare, Vijay D., Sushant S. Kole, and Rajani B. Athawale (2018). Sustainable approach for development of antimicrobial textile material using nanoemulsion for wound care applications. Fashion and Textiles5.1, 1-13. Review, 4-22. 3. Jeong, S.H. (2005). Synthesis and characterization of silver/chitosan bio nanocomposite by chemical reduction method and their antibacterial activity, Polymer Fibers, 40, 543. 57BRAND UPDATE 12. C. A. C. Ara´ujo, L. L. Leon.( 2001). Biological activities of Curcuma longa L, Memorias do Instituto Oswaldo Cruz, 96,723–728 208. much scientific and industrial interest. Understanding the antimicrobial and antifungal activity of various biomaterials and its assessment is 4. Y. W. H. Wong . (2016). Selected applications of nanotechnology in Textiles, AUTEX Journal of Research, 6, 58-95. 35 Years of Continuous Improvements Over the past 35 years, U.S. cotton has made significant improvements in growing cotton responsibly. To continue the progress, the Trust Protocol has ambitious national goals for 2025. By this date, the Trust Protocol aims to have more than half of all U.S. cotton production included in the program. 13. T. Rudrappa, H. P. Bais . (2008), Curcumin, a known phenolic from Curcuma longa, attenuates the virulence of Pseudo monasaeruginosa PAO 1 in whole plant and animal pathogenicity models, Journal of Agricultural and Food Chemistry, 56, 1955–1962. important to meet the specific requirements of the end consumers. materials and methods described in details through this paper help toestablish material's potentials and within the field of medical textile usage. References 5. Ali M.S, Alam M.S, Alam N. (2014). Preparation, characterization and stability study of dutasteride loaded nano emulsion for treatment of benign prostatic hypertrophy. Iran Journal of Pharmaceutical Research, 13, 1125‒1140. 6. Krasner D, Kennedy K.L. (1993). “Achieving a transition towards agricultural sustainability requires broad public and private partnerships and a vital part of my work at The Nature Conservancy includes looking at ways to collaborate with key agricultural stakeholders,” said Dr. Kris Johnson, Deputy Director of Agriculture, The Nature Conservancy, North American Region and U.S. Cotton Trust Protocol Board Member. “Informed by science-based targets, the Trust Protocol provides evidence of and encourages continuous improvements in U.S. cotton production.” For more information, please visit https://TrustUsCotton.org, and visit us on social media. About the U.S. Cotton Trust Protocol In a period of ever greater supply chain scrutiny and a growing demand for transparency, the U.S. Cotton Trust Protocol will set a standard for more sustainably grown cotton. It brings quantifiable and verifiable goals and measurement to the issue of responsibly-grown cotton production and drives continuous improvement in key sustainability metrics. 209. 14. Kurkov. (2010). Parental delivery of CDs effects on drug binding, APPS Pharmaceutical Science Technology, 11, 1152-1158. 1. Gao, Y, Cranston, R. (2008). Recent Advances in Antimicrobial Treatments of Textiles. Textile Research Journal, 78, 60-65. 2. Purwar.R., Joshi.M. (2004). Recent The ABCs of wound care dressings. Wound Management, 66, 68–69. 7. AHMED, Enas M. (2015). Hydrogel: preparation, characterization, and The Trust Protocol underpins and verifies U.S. cotton’s progress through sophisticated data collection and independent third-party verification. Choosing Trust Protocol cotton will give brands and retailers the critical assurances they need that the cotton fiber element of their supply chain is more sustainably grown with lower environmental and social risk. Brands and retailers will gain access to U.S. cotton with sustainability credentials proven via Field to Market, measured via the Fieldprint Calculator and verified with Control Union Certifications. The U.S. Cotton Trust Protocol is overseen by a multi-stakeholder Board of Directors comprised of representatives from brands and retailers, civil society and independent sustainability experts as well as the cotton-growing industry, including growers, ginners, merchants, wholesalers and cooperatives, mills and cottonseed handlers.

Tired of searching good talent ?

Want to hire quality staff and skilled worker with specific domain knowledge?

We have a solution online with domain expert MEET YOUR PERFECT EMPLOYEE

Register FREE , add your position and skill requirement and get going! Jobseeker will get in touch with you very soon.