CWX DIGITAL ONLINE ONLY

PREVIEW EDITION

PLANTWORX 2023

– THE PRODUCTS, THE COMPANIES, THE SHOW

PLANTWORX INNOVATION AWARDS

– THE AWARDS SHORT LIST

THE RISE OF THE HYDROGEN ICE

– PART 2 OF THE WOODROW REPORT

THE VOICE OF THE UK CONSTRUCTION EQUIPMENT INDUSTRY Construction Worx is an official partner publication for PLANTWORX

SUMMER 2023

THE OFFICIAL DIGITAL MAGAZINE OF THE CEA

The UK's Only Live Demo Construction Equipment & Technology Event in 2023 13-15 June 2023 East of England Arena and Events Centre, Peterborough.

Avoid the queues! REGISTER NOW for your FREE fast track entry badge app.plantworx.co.uk

With emerging technologies featuring alongside construction equipment, live demos, innovation and the latest in machine technology, the show will lead visitors into the future of construction.

For full details, visit www.plantworx.co.uk

FOR THE INDUSTRY, BY THE INDUSTRY

SUMMER 2023 WHAT'S INSIDE! THE OFFICIAL DIGITAL MAGAZINE OF THE CEA Global Market Outlook Chris Sleight of OHR analyses world market trends. 13 The long road to legislation Dale Camsell reports on long awaited progress towards common EU road regs. 68 UK equipment sales’ strong start Paul Lyons reviews the numbers so far in ’23. 66 The Plantworx Innovation Awards The Awards Short List. 61 The rise of the hydrogen ICE Part 2 of the Woodrow Report. 16 19 The products, the companies, the show CEA New Members A welcome to TVH and Lifos. 10 SUMMER 2023 03 ConstructionWorX DIGITAL

From the Chief Executive

Welcome to the Summer issue of Construction Worx. This issue is dedicated to Plantworx, which is just a matter of days away (13th – 15th June, East of England Arena Peterborough). We are delighted to report we have 300 confirmed exhibitors and there are a whole host of new initiatives for visitors to experience, which include the Get Connected Zone which is dedicated to connected technology, and the Awesome Earthmovers Operators challenge, where big prizes are being offered. We are also pleased to announce the National Highways and Costain teams are featuring in the Partner Zone, and they are looking forward to seeing all the new innovations at the show. There are more details in the magazine, whereas exhibitors’ can book an opportunity for a private audience with the teams to showcase new technology.

The Plantworx Innovation Awards Dinner event is at full capacity, with nearly 300 guests confirmed to attend. The evening (Monday 12th June) will provide excellent networking opportunities and celebrate the most innovative products to come to market. Not forgetting that The Dark Destroyer from the quiz show, the Chase, is set to host the event which will be very entertaining.

I would like to take this opportunity to thank Merlo for their generosity in sponsoring the drinks reception and also to Caterpillar, who have kindly sponsored the dinner, without your support we couldn’t have staged such a huge event – the largest dinner in the CEA and Plantworx history!

In addition, Construction Worx correspondent Peter Haddock talks to Group MD, Matthew Ayres from the Bennie Group and their collaboration with MachineMax. KGP’s Alex Woodrow shares the second part of his hydrogen feature, where he considers the outlook for H2-ICE (hydrogen internal combustion engine) based on the latest announcements from major OEMs in the commercial vehicle and non-road segments.

There’s the latest regulatory report from Senior Technical Consultant, Dale Camsell, and the latest market trends from CEA Data Analyst Paul Lyons, including a special feature on the Global Market, from our colleague, Chris Sleight, MD Off Highway Research.

One last note before I sign off, we are holding our very first Members’ Forum Meeting on Thursday 13th July 23 at ZF Automotive UK in Hockley Heath, Shirley. 10am – 15.30pm – more details will be emailed to you soon – but please save the date!

There is so much more to read in this bumper issue and we hope you enjoy the read. I look forward to meeting with some of you in person at Plantworx, where the CEA will have a guest lounge in Gilmores Bar – all members are welcome for refreshments – come and say hello!

PUBLISHER – Enigma Creative Unit 19 Omega Business Village, Thurston Road, Northallerton, North Yorkshire, DL6 2NJ. UK. W: www.enigmacreative.co.uk

EDITOR

Carney E:

AT LARGE Peter Haddock E:

SALES

Spink E: angela.spink@thecea.org.uk

SUPPORT

Oliver E: rob.oliver@thecea.org.uk The Construction Equipment Association (also trading as CEA) Unit 19 Omega Business Village, Thurston Road, Northallerton, North Yorkshire, DL6 2NJ. UK. T: +44 (0)20 8253 4502 E: info@thecea.org.uk W: www.thecea.org.uk THE OFFICIAL DIGITAL MAGAZINE OF THE CEA 04 SUMMER 2023 ConstructionWorX DIGITAL The Construction Equipment Association (also trading as CEA) is a company registered in England and Wales with company number 04930967. VAT number 243 3858 54. Registered Office: Unit 19 Omega Business Village, Thurston Road, Northallerton, England, DL6 2NJ. UK. © 2023 The Construction Equipment Association. Although care has been taken in preparing the information supplied in this publication, the CEA does not and cannot be held responsible for any errors or omissions and accepts no liability whatsoever for any loss or damage howsoever arising. Any views expressed do not necessarily represent those of the CEA.

CONTRIBUTING

Louise

louise@louise-carney.co.uk REPORTER

content@contentwithmedia.com ADVERTISING

Angela

EDITORIAL

Rob

Suneeta Johal Chief Executive Construction Equipment Association

Suneeta Johal Chief Executive Construction Equipment Association

CESAR ECV - Emissions Compliance Verification For more details on how you can use CESAR ECV (Emissions Compliance Verification) to help improve the air quality in and around construction sites in your area, please email us at enquiries@cesarscheme.org See us at Plantworx Stand: B-DB1 www.cesarscheme.org/ecv.php If it’s GREEN it’s CLEAN Easily identify clean construction within your local authority with ECV 5 EMISSI NS 7A53C 7A53C B-DB1 datatag.co.uk Powered by thecea.org.uk aea.uk.com Promoted by

Bennie Group get connected with MachineMax as data drives business growth

Understanding how each asset performs is critical to running a successful business when you operate a mixed fleet of over 500 machines, from large earthmovers to material handing units. With plant hire, contracting and equipment dealerships all part of the family run Bennie Group, there is a lot to manage for fourth generation Group MD, Matthew Ayres.

To find out more about its data journey Peter Haddock recently visited its head office in Northamptonshire on behalf of Construction Worx. He also helped the team connect some of its assets to the MachineMax telemetry driven fleet management solution they are rolling out across the business.

Matthew: "As a group we run quite a diverse fleet of equipment from the latest Cat D6 XE electric drive dozer to John Deere tractors, Bomag compactors, Volvo excavators and the Faresin all electric telehandler. And to keep all of these assets working hard, we have our own maintenance and repair workshops where we can perform major overhauls to equipment like our 2006 Cat 963C track loader.

"But like any business in our sector, to be successful, we not only need to ensure we have high levels of machine uptime, we also need to ensure machine utilisation levels are equally high. To do this, we recently restructured the group to pool our earthmoving, crushers, screeners and soil stabilisation equipment into our Bennie Plant rental business. This rents equipment to a range of customers and also now hires to our internal earthworks, ground engineering and soil stabilisation contracting division, Barton.

"This change paved the way to adopting a holistic approach to fleet management, allowing us to connect all of our assets. This also included those managed by our Bennie Equipment division, which specialises

06 SUMMER 2023 Construction

WorX DIGITAL

in material handling sales and rental. But we were still faced with the challenge of connecting each asset category into one solution to pull off the key data we needed, like operating hours, fuel burn, carbon emissions and location. And what surprised us, particularly with the material handling equipment, was how far behind the onboard telemetry systems and technology available for us to capture data was.

"This is one of the key reasons why we chose to work with MachineMax, as the business firstly can capture information from OEMs existing APIs through the GPS network. And secondly, if this is not possible, they have a very robust sensor with strong magnets that can be simply attached to a machine. This gives us a second option for not just the newer equipment that doesn't have APIs available, but also older units like our Cat 963C."

As soon as a machine from the Bennie Group is connected to the MachineMax platform, data is captured and fed into its cloud-based solution. Here it can be accessed from any connected smartphone, tablet or computer. There is even a mobile app that can be used by staff.

Matthew: "Collecting data is one thing, but turning it into useful information that we can act upon makes it so powerful. And this is where our digital journey comes together as over the past few years, we have upgraded our hardware and integrated other software solutions that streamline our business processes.

"This has already removed a lot of manual entry tasks where mistakes can be made and given us a much greater understanding of our business performance whilst enabling us to better integrate with our customers.

Knowing how impactful this process has been gave us the confidence to further accelerate our journey into other areas of the business. It also helped us to understand what we needed from an equipment solution which led to the MachineMax integration. What I really like about its approach is the simplicity of the dashboard solution it has created. It allows us to share the right information with our team in real-time and with customers in the future."

With the roll out of connecting machines underway, I wanted to find out from Matthew what the team was going to be able to do with the information collected from each machine.

Matthew: "As part of the process of finding a supplier to help us, we engaged with every aspect of the business and key customers to understand what information they wanted. For example, our maintenance team are interested in reviewing machine hours and planning in servicing and maintenance for our whole fleet. Whereas our

contracts team are more interested in looking at machine utilisation and fuel burn for the equipment working on a particular job site.

"And when it came to customers, working on larger projects, the message was clear. They want to understand things like carbon emissions, fuel burn relative to activity, and idle time, all of which are critical moving forward. Having this information is particularly important when trying to measure productivity and efficiency. And, of course, with a significant increase in fuel prices, we will be working across the board to support key areas like operator training and realworld data-driven fleet management decisions.

"We see a greater movement into machine control to increase productivity and recognise that, in some cases, we will be able to compare running costs from one OEM brand to another. This, in turn, will inform our future equipment fleet purchasing and disposal decisions. Getting all our fleet connected is the next step that will make this all possible and, as we move forward, we will be able to use data to continue our business transformation. The ultimate goal is to use data-driven insights to deliver a better service to our customers whilst reducing our overall impact on the environment."

MachineMax is a key sponsor of the Get Connected Zone, alongside Plinx, in the Indoor Arena at the forthcoming Plantworx exhibition.

SUMMER 2023 07 ConstructionWorX DIGITAL

The future of green construction - how can the construction industry become more sustainable?

In this issue of Construction Worx we feature an interesting Q&A with Tom Hyde, Technical Support Manager for TotalEnergies UK. Hyde shares his insights on how the construction industry can embrace sustainability, discussing innovative technologies and methodologies.

Q: With the 2050 net zero deadline looming, it seems most of the industry has recognised the importance of taking climate action. What immediate steps are being taken (or should be) to achieve this?

A: Whilst recognising the problem is vital, good intentions are a drop in the ocean - the route to zero emissions will require decisive action.

One-third of global energy emissions in 2021 arose either directly or indirectly from the buildings sector, with around 6% of the global total coming from manufacturing construction materials, such as steel and cement, according to the International Energy Agency. In March, Green Alliance also found that the construction industry is the UK’s biggest user of non-renewable materials and generates almost two-thirds of the country’s total waste output.

Operators on site are having to adopt innovative solutions to ensure they are compliant and competitive. At the same time, the regulatory environment is shifting fast and reforms affecting the sector across every stage of the construction process are taking effect. For example, the 2021 Environment Act introduced measures to ensure that the resources companies are using in their operations are both sustainable and efficient, and has brought in detailed requirements in terms of waste management and biodiversity protection.

Q: What can machinery operators and industry leaders do to maximise operational efficiency whilst reducing their energy consumption and carbon footprint?

A: Companies looking to create immediate progress on their journey towards lower carbon emissions need to examine the ‘material’ components of a construction site.

Historically, lubricants have been seen as a something of a technical detail, but according to TotalEnergies’ research, the right lubricants can help significantly reduce fuel and energy consumption, providing substantive benefits including cost savings.

With construction equipment and machinery exposed to extreme conditions from dramatic variations in temperature to heavy loads, modern fluids designed to clean and degrease heavy machinery come with important benefits for workers and the planet. Alongside the functional benefits, it serves a sustainable purpose as keeping machinery working efficiently and for longer is less carbon intensive than frequently scrapping and replacing machinery. TotalEnergies’ Rubia 1000 and 2000 are great examples of engine oils suited to this purpose.

The right lubricant partner can support operators with maximising operational efficiency through technology. Data-driven predictive maintenance, such as predictive analysis and lubrication maintenance software, can increase energy savings by using

08 SUMMER 2023 ConstructionWorX DIGITAL

fuel economy type of lubricants along with specific low friction synthetic lubricants for certain applications. These may also provide improved lubricant lifetime, reducing material usage and waste.

Q: Whilst short term changes are essential, what steps can industry professionals and regulators take to ensure sustainable practices are adopted in the long term across all stages of the construction process?

A: Developing an industry-wide practice of transparency around carbon reduction goals will help embed the practices that will drive forward the sector’s sustainability agenda in the long term. By setting carbon reduction mandates at the planning stage of each project, industry stakeholders can ensure they are making the right choices to meet these goals.

Alongside project accountability is the need for stakeholders to apply the same reduction standards to their suppliers and subcontractors as to their own processes. TotalEnergies, for instance, has introduced a number of goals to support sustainable procurement practises including integrating environmental criteria in calls for tenders for priority categories, implementing an environmental audit framework for suppliers' sites, and ensuring that at least 90% of top suppliers have set targets for GHG emission reductions by 2025.

Q: Government regulations mean that site operations are required to have strong recycling credentials – how can lubricants and greases play a role in this?

A: To comply with biodiversity protection laws and waste management, site operations must prioritise products and materials which have established transparent recycling credentials - including the use of biodegradable lubricants & greases.

Operators can choose lubricants which not only meet the requirements of the major OEMs but which are fully biodegradable and formulated from renewable raw materials. These products can help reduce engine fuel consumption, while being suitable for use in sensitive environments, such as locations close to rivers, agricultural land or forests, with the risks associated with accidental leakages minimised.

Q: The UK Green Building Council has suggested that investing in a circular economy is one of the fastest ways to reduce carbon emissions and waste. How can this become a reality at a practical level?

A: Adopting material circularity could be one of the most impactful carbon reduction levers available to construction firms. It presents a specific opportunity to tackle ‘embodied carbon’ - the carbon emissions generated upstream before a building is completed such as emissions associated with materials.

Deploying renewable energy sources to power construction sites –where possible - is a practical opportunity for construction projects to reduce overall emissions. Design considerations such as the reuse of materials, increasing the use of recycled or partially-recycled materials, and retrofitting instead of demolition can also all assist in reducing embodied carbon.

Q: What role with the government play in the sectors’ net zero transition?

A: The UK government will play an active role in supporting the energy transition. Alongside the development and implementation of policies on the construction and operational emissions of buildings, the public sector as a buyer is increasingly prioritising ‘green’ tenders

The government is increasingly adopting a ‘carrot-and-stick’ approach to encourage companies to choose more sustainable routes through rewarding green efforts with subsidies - or closing opportunities to those not doing enough.

Therefore, it’s essential for businesses to evaluate every element of their construction toolkit – from overhauling the supply chain right through to more efficient mechanical maintenance. This means not only will they be ahead of the regulatory curve but could be in better positions to be awarded government-led infrastructure contracts. A focus on energy efficiency and reducing carbon emissions is not just financially smart, it is also imperative for the welfare of our planet and long-term business resilience. Carbon emission reduction will require a holistic approach, from macro-changes such as government incentives opting for renewable energy sources and re-using materials, to incremental changes that can be actioned in the short-term, such as choosing the most efficient products for operational maintenance.

SUMMER 2023 09 ConstructionWorX DIGITAL

NEW MEMBERS Welcome Aboard: Introducing Our Newest Members to the Association

In this edition of Construction Worx, we are excited to introduce Lifos and TVH, the latest additions to the membership roster at the Construction Equipment Association. Allow us to briefly acquaint you with our new members.

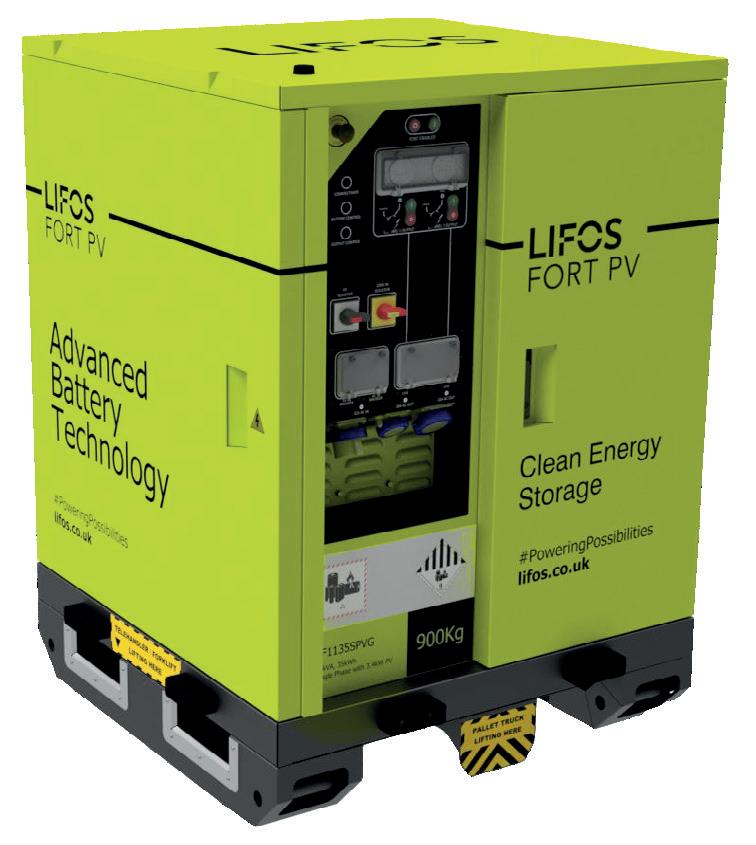

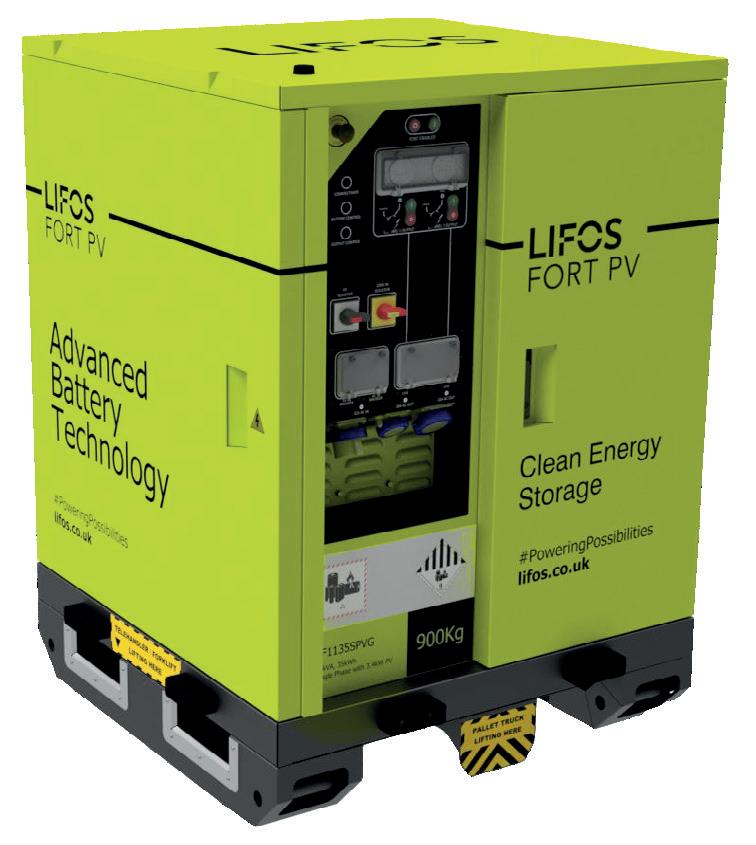

LIFOS Advanced Battery Technology Ltd based in Telford, design and manufacture a range of advanced solar battery storage systems.

LIFOS recently launched an innovative solar PV battery storage system to help the construction industries transition to a diesel-free and low-carbon future.

The Lifos Fort PV range offers a renewable all-in-one solar battery storage system with 3 models from 12kWh, 23kWh to 35kWh. Each Fort comes packed with 18 solar panels providing 3.4kwh of green power, which can be quickly deployed either by using the fitted solar panel kick stand or the optional roof mounting kit designed specifically, for containers and welfare units.

Easy to transport and easy to use. The silent running Lifos Fort is perfect for noise-free night-time operating and will significantly reduce diesel generator costs and reduce carbon emissions.

The Lifos Fort is designed with safety in mind and comes with an integrated LiQ Battery Management software to monitor data on diesel usage, CO2 savings and solar power generation for easy ESG reporting. With a 5 year warranty included and the 7- year switch component replacement program, the Fort PV is a compelling longer life, lower cost energy storage solution.

With over 50 years of experience, TVH has built a reputation for quality, reliability and customer service. The company offers a one-stopshop for its customers, with a database of over 46 million part numbers, including 930,000 different references in stock, and supplies customers from over 180 countries.

TVH UK also offers a comprehensive range of services, including component repair and technical training. The company's expert technical trainers are equipped with the latest tools and technology to teach customers how to diagnose and solve equipment problems quickly and efficiently. The company is committed to sustainability, offering environmentally responsible products and initiatives to reduce its carbon footprint.

Based in Kidderminster, TVH UK serves UK customers with a comprehensive range of products and services. As part of the global TVH group, TVH UK has access to extensive resources and expertise to provide its customers with a truly comprehensive range of solutions.

Both TVH and Lifos will be exhibiting at the forthcoming Plantworx Construction exhibition.

10 SUMMER 2023 ConstructionWorX DIGITAL

Rugged and reliable hydraulic control in a traditional industry

Andy Peacock, Engineering Manager Mechanical of Webtec talks about maximising productivity in crushing and screening.

Traditionally, material crushing has been carried out in permanent locations with the material being transported to the crushing plant by heavy duty tipping trucks. In recent times however, mobile crushing plant has often proved to be more cost effective. Such equipment can be transported to its required location and then moved by means of wheels or caterpillar tracks to any convenient position. The same principles used in crushing and screening are now also applied to shredding, washing and recycling machines used to shred tree trunks, clean aggregate or sort waste into different streams for recycling. Mobile crushing plant may use either electro-mechanical or hydraulic drive for the main crushing mechanism but auxiliary functions are most often carried out by means of hydraulic cylinders and motors, which are ideally suited to operation in harsh working environments. Auxiliary functions can include such things as track and conveyor drives, conveyor folding and positioning, screen and deflector plate operation etc.

Webtec has a long history in screening and crushing

For over 40 years Webtec has supported crushing and screening OEMs with rugged and reliable hydraulic valves used to control the speed of actuators with varying loads, such as conveyor drive motors. The nature of the job means that motors can see rapidly varying loads but continuous steady throughput is still required to ensure that all machines work harmoniously together. To ensure this happens machine designers have put particular emphasis on using pressure compensated flow controls, for which the Webtec range is world renowned.

The Webtec range also includes, two port flow control valves, three port priority flow dividers and mono-block directional, flow and pressure control valves all widely used on crushing and screening machines as well as in countless other off-highway mobile machines.

2-port vs 3-port valves

The Webtec VFC Series of pressure compensated flow control valves will ensure that the actuator speed remains virtually constant over all load conditions. Once set, the weather-proof adjusting knob can be locked in position to avoid any inadvertent adjustment. When using a fixed displacement pump, the excess flow not required by a conveyor drive can be diverted to another machine function while maintaining a constant flow to the conveyor. This can be achieved by using a VFD priority flow divider from the Webtec range.

Alternatively, the excess pump flow can be directed to tank at a pressure only slightly higher than the conveyor drive pressure, rather than full relief valve pressure. This ensures maximum system efficiency with simpler, fixed displacement pump arrangements. If remote speed adjustment is required a proportional version of the priority flow divider enables an electronic signal to be used to vary the priority flow.

Monoblock valves

A flow divider can also be combined with a directional valve to enable the priority flow to be switched between two conveyor drives. The CV120 combines a single directional, flow and pressure control in one compact, simple-to-install unit, with the opportunity for multiple valves to be connected in series using a high-pressure carry-over function with a secondary relief valve. Despite its compact design the CV120 doesn’t compromise on functionality, using the same pressure compensated flow control technology as used in the VFD range.

Auxiliary valves

When the movement of two unequally loaded actuators needs to be synchronised, for example with track drives or conveyor positioning, the

SUMMER 2023 11 ConstructionWorX DIGITAL

FDC Series flow divider/combiner can be used to ensure equal flows to or from each actuator, irrespective of load. Certain functions on mobile crushers need to be interlocked to prevent dangerous or damaging situations. For example, operation of the track drive may need to be prevented unless a conveyor is moved to a transport position. The mechanically operated SV/DV 80 diverter valve can thus be used to prevent flow to a certain function unless mechanically actuated by the appropriate section of the machine.

Condition monitoring and predictive maintenance

For pumps and motors which operate for long periods of time, continuously monitoring their performance can provide an early warning of a potentially costly failure. The CTA flow monitor can be installed in the pump outlet line to monitor pump flow rate and/or in the supply line to a conveyor motor for example. By comparing the pump or motor flow rate with its rotational speed a rapid assessment can be made of the component’s state of wear and action taken before a catastrophic failure occurs. In addition, the CTA flow monitor can be observed remotely via the machine’s telematic system.

The RFS 200 flow hours counter is a new device which can be used as part of a preventive maintenance programme. Installed in the feed line to critical hydraulic components, it monitors their actual usage time thus enabling routine maintenance to take place when the component is approaching the end of its useful life.

Excavator mounted solutions

For short-term tasks such as demolition work, where the task involved does not warrant the use of a dedicated machine, crushing attachments are available which can be mounted onto an excavator boom and used to process smaller quantities of material.

The DHM Series hydraulic multimeter can be an invaluable tool, not only for system troubleshooting but also for optimising the set-up of attachments such as crusher buckets. It enables the measurement of flow, pressure, peak pressure and temperature and the unit can then transfer data wirelessly for automatic calculation of hydraulic power and volumetric efficiency. Also useful for system troubleshooting is the HPM7000 Series portable data logger. This unit has a variety of different modes with the ability to log up to 16 million measured values per test at a variable interval from 1 ms.

Many of the leading OEMs in the crushing and screening industry have therefore come to rely on Webtec products owing to their performance and reliability while operating under the harshest of conditions found in this industry.

FOR THE INDUSTRY, BY THE INDUSTRY 13-15 June 2023 East

For full details, visit www.plantworx.co.uk Register NOW for your free fast track entry badge. Avoid the queues by registering EARLY at app.plantworx.co.uk

The UK's Only Live Demo Construction Equipment & Technology Event in 2023

of England Arena and Events Centre, Peterborough.

12 SUMMER 2023 ConstructionWorX DIGITAL

With emerging technologies featuring alongside construction equipment, live demos, innovation and the latest in machine technology, the show will lead visitors into the future of construction.

Global market outlook

Construction equipment sales have fallen back form the unprecedented high of 2021. A soft landing is expected, but there are of course risks and uncertainties around this.

Global construction equipment sales hit a record high of nearly 1.3 million machines sold in 2021 as stimulus spending, job protection schemes and low interest rates drove a boom in economic growth after the sharp downturn of 2020.

That boom continued for most countries last year, the exception being China. Sales in the world excluding China grew 7 per cent in 2022, following on from a 19 per cent increase in 2021 in the same territories. In fact, sales could have been much higher were it not for the on-going supply chain issues and shipping bottlenecks (although shipping was getting back to normal by the end of the year).

In contrast, the Chinese market had a miserable year in 2022. Having boomed due to stimulus spending in 2020 and 2021, sales tumbled 39 per cent in 2022 due to the re-imposition of Covid lockdowns in numerous major cities, along with debt defaults and a general reset in the real estate market. The sharp dip in housebuilding was a particularly heavy blow for the construction equipment sector.

Despite the downturn in China pulling the global equipment market down by 2 per cent overall, 2022 still saw the second highest volume of machinery ever sold. Another positive was that order backlogs were so full and lead times so long at the end of the year in the world, excluding China, that it gave the industry confidence that good retail volumes would continue well into 2023, despite the weakening economic outlook.

Off-Highway Research’s forecast is for a 7 per cent decline in global sales in 2023.

This is a slightly steeper downturn than envisaged a year previously, due to the weakness of the Chinese market. Stripping China out of the equation, the remaining countries of the world will only see a 5 per cent downturn overall.

Off-Highway Research would still classify the 2022-2025 downturn as a soft landing. Only single-digit year-on-year falls in equipment sales are expected, and the volume of machines sold throughout the forecast period should stay above 1 million units per year. Prior to the current up-swing, such a volume was only achieved twice before.

Chris Sleight Managing Director Off Highway Research

Chris Sleight Managing Director Off Highway Research

SUMMER 2023 13 ConstructionWorX DIGITAL

Global sales of construction equipment by region, 2017-2026*(Units)

EUROPE

Construction equipment sales in Europe rose 4 per cent in 2022 to 216,861 units. This increase from 2021’s already high level of 208,288 machines sold maintained the market at a high level, and comparable with the previous record set in 2007.

The strongest growth in 2022 was seen in the larger markets of Southern Europe – most notably Italy, which saw sales rise an impressive 18 per cent, while Spain’s 17 per cent growth was also well above average. France also performed well with an 8 per cent rise in sales, thanks to broad demand for both heavy and compact equipment.

Growth in the UK was more subdued at 4 per cent, but the volume of equipment sold was the highest ever seen. Meanwhile the German market declined 1 per cent, but this must be seen in the context of the extraordinarily high number of machines which have been sold in the country in the last four to five years.

Off-Highway Research’s forecast for Europe is essentially for the market to stabilise at a high level. Although single-digit percentage annual declines in sales are expected for the next three years, the market is forecast to remain above 200,000 units over the medium term. Prior to the current peak, a volume above 200,000 machines sold was only achieved once before for a single year in 2007.

A slowdown in housebuilding due to rising interest rates represents a threat to compact equipment sales. However, Europe’s infrastructure markets are strong, which should stimulate sales of larger earthmoving equipment.

NORTH AMERICA

North America was the pick of the major markets last year, with an 8 per cent increase in sales to take demand to a record high of 318,855 machines sold. Compact tracked loaders are now firmly established as the most popular equipment type in the region and mini excavator sales have also grown to a significant level. Sales of these machines have largely been at the expense of skid-steer loaders and backhoe loaders.

Although a modest 1 per cent decline in sales is expected this year, the market will still enjoy the second highest volumes ever seen. The long lead times for equipment mean that suppliers are confident of sales well into the third quarter of the year, even though rising interest rates are starting to cool-off the housing market.

While this is expected to lead to a fall in sales of smaller equipment types, infrastructure investment is on the rise in the region, thanks in part to the stimulus plans which were put in place during the pandemic years.

OUTLOOK AND RISKS

The global forecast is for a soft landing, with modest downturns in sales over the next three years, but with volumes remaining at historically high levels. This is broadly based on the premise that infrastructure investment is maintained and that although interest rates are rising, they will only slow residential construction, rather than push it over a cliff.

However, there are risks to the forecast and they are almost entirely on the downside. Inflation was a serious issue throughout 2022 and although improving, it remained too high in early 2023. Add to that the war in Ukraine, which continues to heighten inflationary pressures worldwide and is therefore also exerting upward pressure on interest rates.

There have only been two previous peaks when global equipment sales exceeded 1 million units – just prior to the global financial crisis when the market overheated and then again in the early 2010s, driven by stimulus in China. In both cases, annual sales of more than 1 million units of equipment were only sustained for one year – 2007 and 2010.

But 2023 is likely to be a sixth consecutive year of annual sales in excess of 1 million units. When a slowdown in activity comes, excess young equipment in fleets around the world could be a barrier to new machine sales, exacerbating the slowdown for the industry.

On the other hand, a prolonged period of historically high volumes is not necessarily a problem. Construction equipment sales always grow worldwide over the long-term as the global population grows and with it the requirement for buildings and infrastructure. There are also demographic changes which drive the adoption of machinery such as skills shortages and higher wages for manual labour, as well as the retirement of the construction industry’s aging workforce.

Forecasting is a challenge at the best of times, but even more so when in uncharted territory.

For more information about their services, visit www.offhighwayresearch.com

Global sales of construction equipment by type, 2021 (Units)

Global sales of construction equipment by type, 2021 (US$ million)

14 SUMMER 2023 ConstructionWorX DIGITAL

Moving Intelligence and UK's AMI Group Ltd: A Powerful Collaboration in Security and Tracking

The CEA is delighted to welcome Moving Intelligence as a new member of the Association.

Moving Intelligence is passionate about protecting construction companies against the ever-increasing threat of theft. With an estimated £1 million in equipment stolen from construction sites every week, the company provide tailored security solutions to help keep your business one step ahead of criminals. Its innovative solutions are designed to provide peace of mind and protect your business from the costly effects of theft.

Moving Intelligence has joined forces with UK-based security and tracking specialist, AMI Group Ltd. The acquisition marks an important step in the Dutch brand’s UK strategy. Founded in 2004, AMI Group Ltd. is a leading developer and supplier of advanced location and security solutions. AMI Group’s technologies secure over £350m of equipment in the UK alone, including excavators, generators, engines, and vehicle fleets. The company is built on family values and has an exceptionally good customer service record, characteristics that fit Moving Intelligence well.

Patrick Horst, CEO of Moving Intelligence commented on the acquisition:” We are delighted to welcome AMI Group into the Moving Intelligence family, enabling us to take the next step into the B2B market. Together we will continue to push the boundaries of our market both nationally and internationally.”

Peter Stockton, Operations Director at AMI Group added: “Moving Intelligence is the perfect fit for our business and more importantly our customers in the UK. The acquisition gives our team access to a strong and exciting portfolio of products and further strengthens our development and technical expertise. We’re heavily focused on executing a seamless transition for our customers and partners, whilst venturing on an exciting journey within a larger international organization.”

Volpi Capital is also very pleased with the progress and growth of Moving Intelligence. “With this third acquisition, the number of employees has grown to over 100 people and there is also an expansion of the services they can provide. Moreover, the total combined number of assets under management grows to 115.000, compared to 55.000 at the time of initial investment by Volpi and Surmount, in less than two years. That is a unique achievement, which we are very proud of.”

Moving Intelligence and AMI Group Ltd. are looking forward to the cooperation and growth this takeover will bring about on both sides.

Below is a link to the Moving Intelligence website: www.movingintelligence.co.uk

NEW CEA MEMBER

SUMMER 2023 15 ConstructionWorX DIGITAL

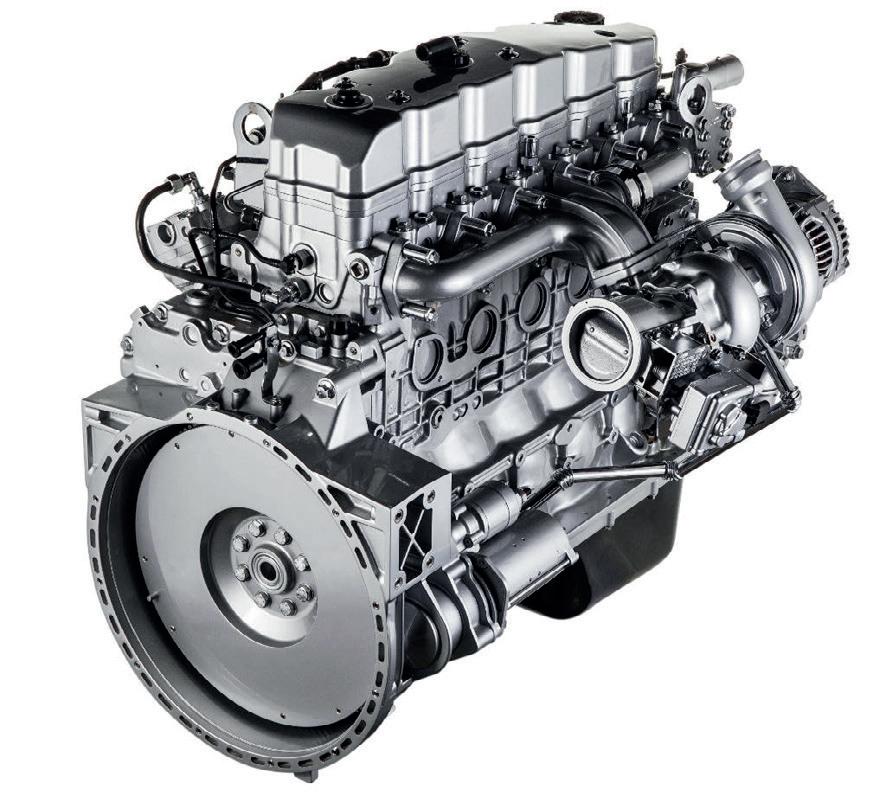

Hydrogen Outlook Continues: The Rise of the Hydrogen ICE

In the first part of this series on hydrogen we explored some of the key trends surrounding the topic. In this second part, we will consider the outlook for H2-ICE (hydrogen internal combustion engine) based on the latest announcements from major OEMs in the commercial vehicle and non-road segments. We will also discuss what this might mean for technology and provide a market outlook.

Engine Developments

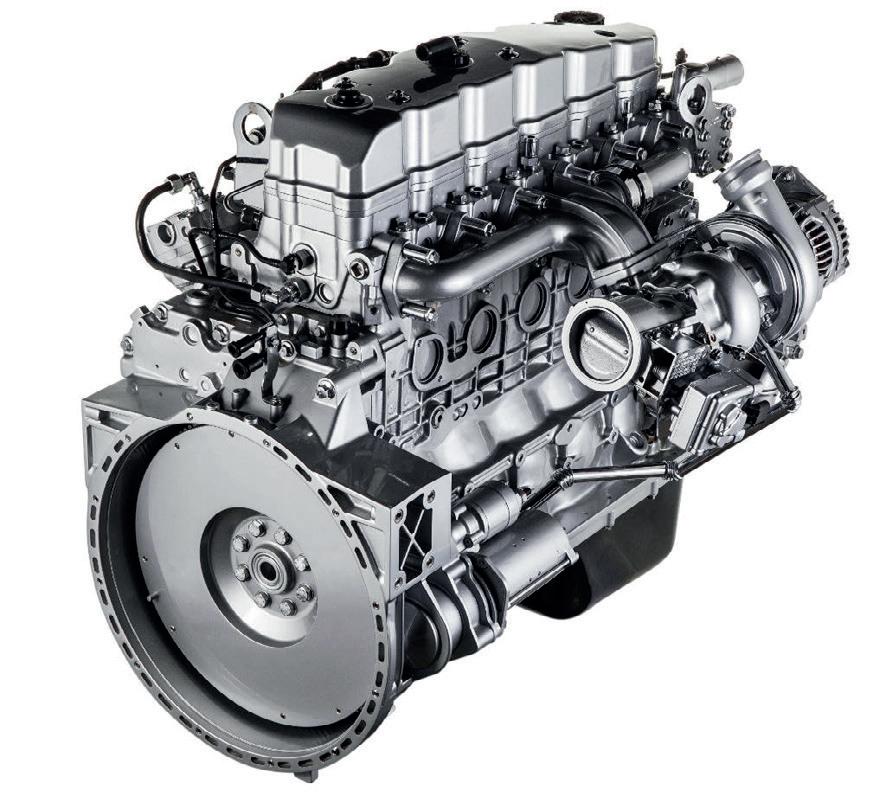

At Bauma in November of last year, we witnessed the unveiling of several hydrogen engines, including Liebherr’s H964 XL four-cylinder and H966 six-cylinder engines. In March’s Conexpo in Las Vegas, the number of engines on display was even greater and included those from suppliers who were absent at Bauma.

The engine-dominant hall at ConExpo featured JCB’s 4.8-litre AB H2 engine and Cummins Fuel Agnostic X15H 15-litre engine (unfortunately not named the Chimera engine), which boasts three heads for diesel, natural gas, and hydrogen variants. The other two engine OEMs not present at Bauma, Deutz and the newly renamed HD Hyundai Engine (formerly Doosan), displayed their 7.8-litre and 11-litre hydrogen engines respectively. Kubota's 3.8-litre engine was also showcased, with the company announcing that it would not be limited to PowerGen applications as previously stated at Bauma.

Both Cummins and JCB are heavily investing in these new engines, as well as test and development facilities in the UK. Therefore, it will be crucial for hydrogen burnt in ICEs to be considered a Net Zero fuel in future UK legislation for both non-road and commercial vehicle applications. With the European Commission now including H2-ICE in its new heavy-duty CO2 proposals, the technology is expected to play

a key role in reducing carbon emissions in heavier applications. The US EPA also announced that H2-ICE, with "neat" hydrogen (not including diesel pre-injection), will be counted as zero emissions. Recent work being completed by the Advanced Propulsion Centre and Cenex for DESNZ will likely recommend H2-ICE as a major pathway for low carbon for NRMM (non-road mobile machinery).

JCB Engine Cummins X15 Fuel Agnostic

The debate between early IDI (in-direct injection) and DI (direct injection) fuel systems for these engines will play out by segment. Early engine models are expected to use IDI port fuel injection, for which the technology and manufacturing readiness is higher. These engines may have lower specific power and lower overall efficiency but will cost less. For these smaller engines, the lower demands may offer an acceptable trade off between performance and cost. For larger engines, the adoption of DI may come a couple of years later. With larger engines having higher durability requirements, the longer lead time will allow for more demanding development and testing.

Development continues to accelerate, driven in part by commercial vehicle applications. Recent symposiums in Vienna and Gothenburg

16 SUMMER 2023 ConstructionWorX DIGITAL

have featured presentations on the future of hydrogen, particularly in relation to aftertreatment for on-road legislation, following the announcement of Euro 7 earlier this year. Under European legislation, hydrogen engines will likely be considered net-zero if they produce less than 5g CO2 per t/km at a vehicle level, with the residual largely comprised of burnt lubrication oil. However, in California, the most stringent emissions region for NRMM by 2030, the ban on heavy-duty trucks will not allow for hydrogen internal combustion engines (ICE). It remains to be seen whether this ban will be adopted for California’s non-road zero-emission rules that are currently under development.

While fuel cells are widely adopted across the commercial vehicle segment, their adoption is likely to be more limited in NRMM. Many OEMs have stated that the H2-ICE is a more durable approach for the demanding NRMM duty cycles. However, fuel cells could still be interesting for smaller applications, such as materials handling and small construction applications. For larger applications, the fuel cell is being tested in port handling, articulated and rigid dump trucks for mining and quarrying.

Due to the pace of investment and legislators' zeroemission approach, it is expected that all major OEMs across the commercial and NRMM segments will have at least one hydrogen engine in their portfolio and available for sale commercially between 2025 and 2028. The first low volume products are expected to come to market in 2024. By 2030, multiple models will be available across OEMs and segments.

In KGP’s latest xEV forecasts for the CV and non-road segment, over 70,000 new vehicles and machines could use H2-ICE, increasing to over 1 million by 2050. However, because these will be higher fuel-use applications, greater than 10% of new machine demand could be H2-ICE based. In all scenarios, a shortfall will still need to be met by using low carbon diesel, such as HVO in the short term and potentially E-Diesel/ Fischer-Tropsch-Diesel (FTD) in the longer term.

The major challenge for hydrogen remains the availability of green hydrogen, which will be necessary for net-zero emissions. However, the infrastructure and supply are still under development, and initially, less carbon-intensive forms of hydrogen may supplement green hydrogen. The cost of hydrogen is also an issue, as TCO models suggest that less than £4/kg will be needed to make it cost-competitive, and this largely depends on renewable energy and curtailed electricity to produce green hydrogen. The ongoing analysis at KGP will assess the fuel mix for both new machines and the existing population (aka parc) of machines in use.

Future challenges will include meeting the demand for hydrogen and finding solutions to get it to the site. Part three of this series in July will consider the hydrogen demand outlook and the solutions being considered to get it to the site.

SUMMER 2023 17 ConstructionWorX DIGITAL

Part 2 of Alex Woodrow’s special report on hydrogen power. Alex is Managing Director of KGP – providing powertrain and related energy data, analysis and consultancy worldwide.

18 SUMMER 2023

PREVIEW

Get Ready for Plantworx 2023: The Ultimate Showcase of Construction Equipment and Technologies!

Attention all construction industry Professionals! Brace yourselves as Plantworx 2023 is about to hit the ground running. This year's event will be the ultimate "one-stop-shop" for the latest and greatest construction equipment and technologies. The fifth biennial construction machinery exhibition is set to take place from June 13-15, 2023, at the popular East of England Arena and Events Centre in Peterborough.

SUMMER 2023 19

In today’s world, face-to-face business events have taken on a new level of importance, as evidenced by the record-breaking visitor attendance at this year’s Conexpo Con/Agg exhibition, in Las Vegas. Plantworx 2023 is no exception and is the event of the year that you cannot afford to miss. With a plethora of innovations and new zones, visitors will witness cutting-edge market offerings and the latest technology pipeline developments.

Rob Oliver, Executive Director of the show organisers has recently shared his insights on Plantworx 2023. He stated, “Plantworx is back and bustling, following the successful Conexpo event and the UK’s Executive Hire Show. We are promising a wide range of new to the market products from an array of leading OEMs. As the industry witnesses a surge in companies embracing electric-powered solutions and making strides in hydrogen technology, Plantworx 2023 is set to be the most impressive edition yet. It is the showcase for groundbreaking machines and cutting-edge innovations that will propel the construction sector into the future.”

Many of Plantworx’s 300 plus exhibitors will be making their show debut.

The event will be graced by industry-leading machinery original equipment manufacturers (OEMs) presenting their electrification strategies for off-road vehicles and equipment. Visitors can expect to be blown away by the exhibits. Manty stands will feature live demonstrations from renowned brands, such as Hitachi Construction Machinery, and the Chinese heavyweights XCMG (who will be at Plantworx for the very first time). Other big names on the list include Caterpillar, Hidromek, Hydrema, Hyundai, SMT (Volvo), Takeuchi, Sany, Sunward Europe, Liugong, Mecalac, Yanmar Compact Equipment, Kubota, Develon (formerly Doosan), Bobcat, AVANT, BOMAG, Brokk UK, RSP Suction Excavators, Merlo, Manitou and many more.

Plantworx is also set to showcase the latest advancements in engine and battery technologies, Xerotech With Hibernium® and Lifos have been shortlisted for Plantworx Innovation awards and will be exhibiting for the first time. Atlas Copco is a regular exhibitor at Plantworx, this year its showing its ZBC Battery Storage System, which is also shortlisted for an Innovation award.

Xerotech’s Hibernium® is a highly customizable battery technology that allows users to select their preferred energy content, operating voltage range, physical dimensions, and even battery cell chemistry. What’s more, there are no design or engineering costs involved, making it an attractive option for one-off prototyping projects.

Meanwhile, Lifos is set to impress visitors with its Fort renewable power system in a box. This complete power system is easy to transport and deploy and can be fully hybridized with its own solar panels, genset, or wind turbine. With the Lifos Fort, users can save money on diesel charges and lower their energy emissions in any circumstances.

The Atlas Copco Power Technique ZBC Battery Storage System is a modular energy storage solution designed to minimize fuel usage and carbon emissions for construction operators. It operates in hybrid mode, reducing emissions by up to 50%, and can eliminate up to 100% of CO2 emissions when used with renewable energy sources. The system produces no noise and requires minimal maintenance.

These new battery technologies are a promising development in the world of renewable energy and are sure to be a highlight of Plantworx.

The digital revolution is in full swing, and a deluge of technology and connectivity companies are hitting the market. These technology solution providers are working tirelessly to achieve an allencompassing connected site.

It’s not just about the excavator; it’s about the telematics, cameras, and sensors that work together seamlessly to enhance the excavator’s functionality. The data collected by these systems provides contractors and fleet owners with real-time insights into their equipment’s performance and health. Through a single platform, contractors and fleet owners can monitor the location, usage, and health of their equipment, all in one place.

Plantworx 2023 has attracted a host of these businesses, including equipment management platform experts MachineMax, ABAX Telematics and Plant Tracking, as well as connectivity solutions company Plinx and Onwave, who is showcasing Onwave Locator (OWL),

Xerotech With Hibernium®

20 SUMMER 2023

Yanmar Compact Equipment

which is a SaaS application, developed by Onwave to aid customers with the dissemination and communication of hazard and work site information to remote workers.

Safety is also an essential consideration in the construction industry. With the inherent risks that come with building and infrastructure projects, safety measures must be put in place to protect workers, the public, and the environment. Companies including Spillard Safety Systems, Xwatch Safety Solutions, GKD, SiteZone, Leica, and Prolec are at the forefront of providing innovative safety solutions to the construction industry.

All of these companies will be showcasing their latest safety solutions at Plantworx 2023, Leica and Xwatch will be announcing a world-wide first with a recent collaboration that first debuted in Las Vegas. With such innovative solutions on offer, it is clear that safety will continue to be a top priority for the construction industry.

Spillard will be showcasing its AI Human Detection System (HDS), which has been shortlisted for a Plantworx Innovation Award. GKD, SiteZone are other companies that are dedicated to improving safety in the construction sector. Their range of products includes proximity detection systems and access control solutions that help to prevent accidents and unauthorized access to construction sites.

The award-winning Official CESAR Scheme is set to once again emphasize the criticality of security and demonstrate how its multilayered security marking technologies can thwart criminals who seek to target plant and machinery. Additionally, Datatag ID (who operate CESAR for the CEA) will be unveiling KIST, a web-based administration portal.

This portal has been crafted to enable effortless creation, management, and administration of assets such as tools, vehicles, and equipment, using existing phone and tablet technology to scan QR

codes or unique identification numbers. Each asset is assigned to a user or parent asset, for instance, a tool to a storage location or a vehicle, upon creation. With the CESAR or Micro-CESAR security label providing each asset with a unique identifier, an audit trail can be established to document the asset’s movement and allocations, facilitating tracking and management of the asset’s complete lifecycle, from acquisition to periodic maintenance and phase-out from inventory. This increased transparency in asset management leads to greater accuracy and accountability across a fleet of assets.

Sustainable welfare cabins are an innovative solution for providing comfortable and environmentally-friendly temporary accommodation in remote or challenging locations. These cabins are designed to meet the needs of workers who require on-site accommodation and facilities, while also minimizing the environmental impact of their operations. Two award-shortlisted companies in this space are Boss Cabins and Genquip Groundhog who will be showing their latest green innovations at the show.

The versatility of a machine is often determined by its attachments, Mr. Oliver elaborated on the significance of excavators in the contemporary construction landscape, likening them to the ‘Swiss Army Knife’ of the industry. He described them as the ‘Polymath’ of construction.

Plantworx 2023 has a record number of attachment manufacturers exhibiting. Leading brands such as Auger Torque, Digga Attachments, Digbits, Arden Equipment, Worsley Plant and BPH Attachments will showcase their latest products, alongside the top tiltrotator companies like Engcon and Steelwrist.

Machine control and guidance systems have become the norm on most site machinery, whether factory or retrofitted, and Plantworx 2023 is not left behind. Nasco Digtec’s iDig 2D & 3D will demonstrate the very latest in dig technology.

Pre-register for Plantworx and avoid the queues

Plantworx 2023

Hitachi Construction Machinery

SUMMER 2023 21

Lifos

Plantworx Get Connected Technology Zone: Driving the Future of Construction Equipment

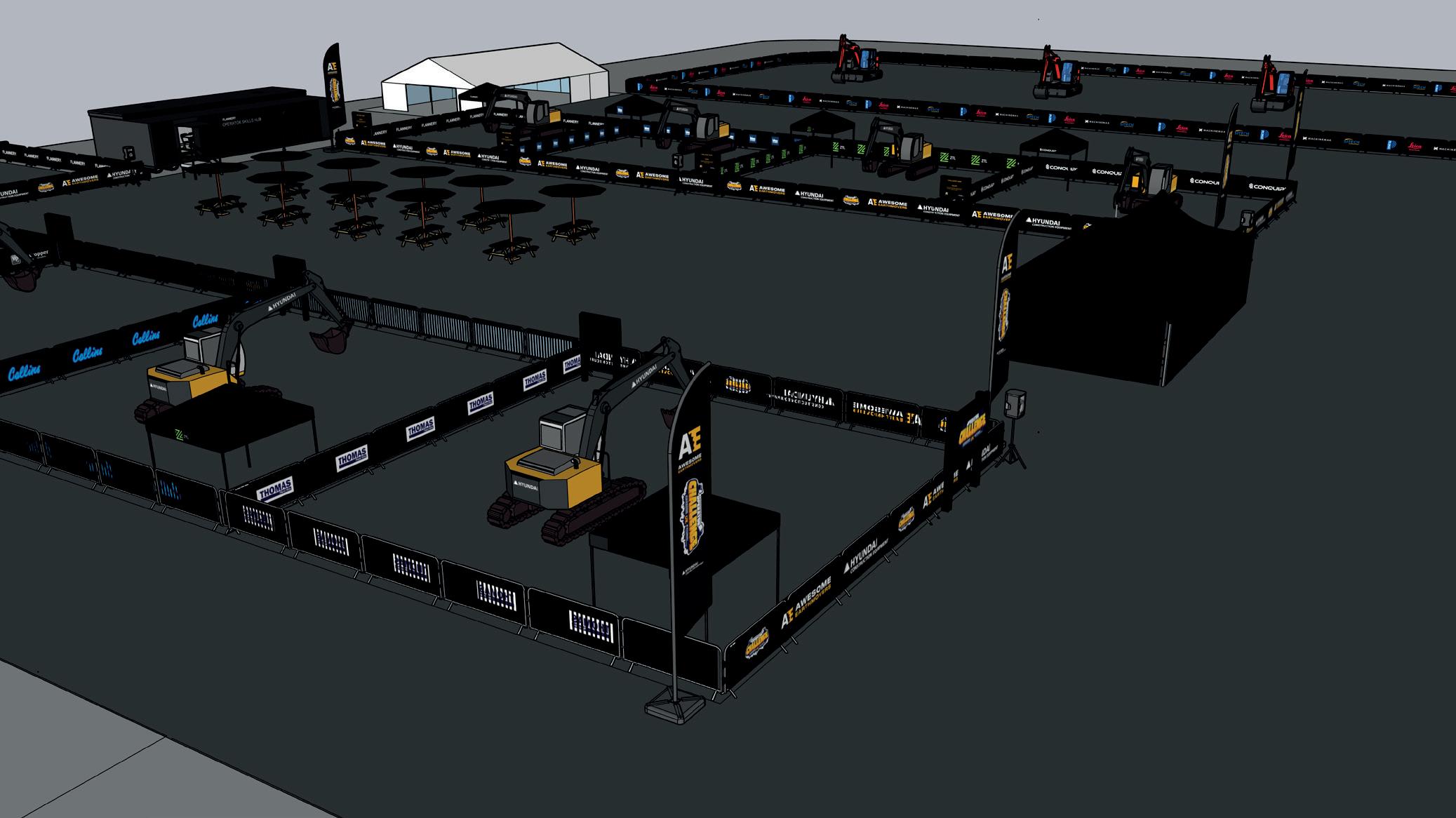

The construction industry has come a long way in the past few decades, and technology has played a significant role in that progress. From machine control to telematics, GPS systems, and safety systems, technology has transformed the way construction sites operate. To showcase the latest advancements in construction equipment technology, Plantworx is launching the Get Connected Technology Zone, a dedicated space for technology providers in the construction equipment sector.

The inaugural Futureworx exhibition in 2022 was a massive success, demonstrating the industry’s appetite for new technology. As a result, the Futureworx team has been asked by leading construction innovators to recreate an element of this event at Plantworx. The Get Connected Technology Zone will showcase the technology and innovation that will drive productivity on construction sites, leading us into the construction site of the future.

The new ‘sell out’ zone will bring together companies that have new and innovative ways of delivering solutions. The focus will be on the people-plant interface, telematics, the connected site, and safety systems. Indoor companies such as Ongrage Machine Control, Unicontrol, Sitech, Sodex, Plinx, MachineMax, GKD, and FTC are amongst exhibitors in the Get Connected Zone.

The outside exhibitors include Conquip, Hyundai Construction Equipment Europe, and Thomas Plant These exhibitors will demonstrate their products in action on “working machinery,” which will have the technology previously installed. Exhibitors will arrive ready “to plug and play,” demonstrating the ease of integrating new technology into existing construction equipment.

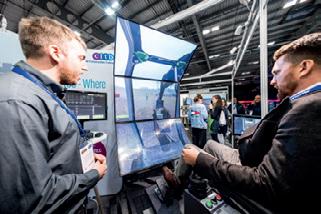

Training Meets Technology: The Simulation Zone Transforming Construction Skill Development at Plantworx 2023

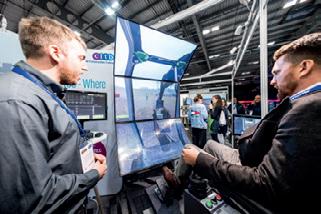

The Simulation Zone at Plantworx, a cutting-edge training platform for construction professionals, is making a triumphant return for 2023 after its debut in 2019. This innovative and interactive zone offers an opportunity for novices and experienced operators alike to upskill and learn machine control systems, advanced technologies, and gain insights into the world of construction.

Plantforce Rentals, a pioneer in simulation training, is once again spearheading The Simulation Zone. The company has introduced this groundbreaking technology to tier one contractors on major infrastructure and rail projects, including HS2 and the nuclear project at Hinkley Point C.

Plantforce has partnered with leading industry players like Trimble and Leica Geosystems to provide visitors with a comprehensive and immersive experience. In the Simulation Zone, participants can test their skills using the latest technologies and work together to overcome construction site challenges in a virtual environment.

The Simulation Zone at Plantworx 2023 is open to all visitors, regardless of their experience level. With the guidance of immersive training experts, participants will navigate the virtual world of simulation technology and experience first-hand the benefits of this innovative approach to skill development.

In addition to showcasing the future of the construction site, Plantworx 2023 will also highlight the key challenges facing small and medium-sized construction sector companies in the areas of immersive technologies and data. The event will provide an excellent opportunity for attendees to learn about new technologies and the ways they can benefit their operations.

From June 13th to 15th, 2023, the East of England Arena and Events Centre in Peterborough will be buzzing with excitement as industry leaders, manufacturers, and enthusiasts come together to showcase the latest equipment, technologies, and techniques in the construction industry.

22 SUMMER 2023

What’s new at Plantworx 2023?

Plantworx 2023 aims to discover, showcase, and explore technologies and innovations that will promote sustainability and efficiency at construction sites now and for the future.

Sunward’s stand will serve as the launch platform for multiple new products, such as the SWE 155UF medium short tail excavator and the SWE 20FED, a two-ton fully electric mini excavator. The SWE 20FED is especially suited for urban construction sites with strict emissions and noise regulations due to its lithium-ion battery and three-phase asynchronous motor.

Visitors can also explore Sunward’s popular and iF award-winning series of short-tail excavators, including the SWE 25UF mini and SWE 60UF compact models. The SWE 155UF medium short tail excavator, with its 16-tonne weight, 90 kW/2200 rpm Cummins engine, and highperformance Hengli hydraulics, will be showcased as well.

Sunward will display its SWTL4538 compact tracked loader and a scissor lift to complement its ‘construction’ lineup. Plantworx will see the premiere of Sunward’s SWA 16JE electric articulated boom lift, designed for low maintenance and low total ownership costs.

The company will also exhibit its variety of attachments, such as hydraulic quick couplers, augers, sorting grapples, buckets, breakers, and Steelwrist tilt rotators.

Aquajet is a top Hydro demolition robot company and is part of the LIFCO group along with Brokk. These robots are much faster and safer than traditional hand lancing methods and Aquajet’s machines can be programmed and autonomous. The new Aqua cutter 750V features a patented infinity lance system that runs in a continuous figure 8 motion, resulting in a more even finish and improved productivity. It also has

A Plantworx first

For the first time in 2023, Gaz Evans Models (GEMs) will be exhibiting at Plantworx. GEMs specialises in creating top-notch scale models and accessories for the construction, demolition, and recycling sectors, offering these models at surprisingly reasonable prices. With permission from original equipment manufacturers (OEMs), GEMs produce all its scale models and attachments in-house. The process begins with obtaining drawings from the OEMs, then creating a hand-built master model using either plastic card or 3D printing. These

parts are cast in high-quality white metal, cleaned, assembled, painted, and detailed by GEMs themselves. Their products cater to OEMs, plant dealers, and collectors.

GEMs also offer customised models and dioramas, perfect for company foyers, events, and client gifts. They can modify base models with company signwriting and colours, adjust booms, and add attachments. Models can even be placed on plinths for special presentations.

Gaz Evans Models (GEMs)

Sunward

Aquajet

SUMMER 2023 23

Brokk

a patented EDS system that maintains its distance from the work, reducing pump diesel consumption significantly. The Aquajet 750V with infinity won the Swedish Hydro demolish awards in late 2022.

On the Excavator Forklift stand visitors will see a new Excavator Forklift attachment, which has been patented, and can be easily attached to micro or mini excavators, converting them into forklifts capable of lifting pallets weighing between 1000kg and 2000kg. The attachment comes with an adjustable pressure relief valve on the lift cylinder, ensuring that the maximum fork capacity is approximately the weight of the excavator. The lift is powered by the hammer service and controlled by the hammer pedal, while tilt is controlled by the dipper lever.

In addition to forklift capabilities, the attachment also includes a 1000kg x 750mm reach jib with a hook height of 2.6m for handling bags and slung loads. A 200mm lift and carry version is available for use when high lift is not required. The attachment also features an

articulated axle that allows one wheel to be 150mm above the other, providing excellent roughsite performance. The Excavator Forklift attachment offers landscapers and small builders a labour-saving solution for their work sites.

Rotar Engineering has introduced an innovative new product, the Fully Integrated Quickcoupler Adapter, specifically designed to overcome the shortcomings of the industrystandard Symmetrical Quick Coupler. This revolutionary product is a game-changer, offering a “Plug & Play” solution that eliminates the need for adapter plates, extra engineering costs, and installation of hydraulic lines. The adapter is fully dedicated to the original components of the quick coupler manufacturer – Oilquick, Steelwrist, or Lehnhoff – and comes with an optimized centre of gravity, weight reduction, and lower fuel consumption.

The Fully Integrated Quickcoupler Adapter features a 3D hydraulic routing design, OEM manufacturing, and integration of all components and hydraulic lines, making it more reliable and easy to maintain. Furthermore, the adapter’s sleek design eliminates visible hydraulic hoses, giving it a clean and polished look. Overall, this product offers several benefits over the Symmetrical Quick Coupler and promises to be a game-changer in the industry.

Construction companies now have a cost-effective and efficient

UPGRADE TO THE

Visit us at: Stand Number: D-K10

Excavator Forklift Rotar Engineering

ULTIMATE.

way to reprocess and recycle small-volume construction rubble and debris into usable aggregate and hardcore, thanks to the new Auger Torque Cone Crusher Bucket. This simple and effective attachment can be easily mounted onto 3-10 tonne excavators, and it is specifically designed to crush and reprocess a variety of construction waste materials. These materials include general clay construction bricks, light concrete walling blocks, hollow concrete ‘breeze blocks,’ concrete pavers, asphalt, and more.

The Auger Torque Cone Crusher Bucket is highly effective at crushing to an output produced material size of around 40-70mm, making it ideal for a wide range of applications. These include foundation laying, track and yard surfacing, landscaping, roadways, and using as a base layer below poured concrete or filling a disposal skip most efficiently.

This innovative attachment not only minimizes extra deliveries and encourages waste reuse but also cuts down on fuel consumption, emissions, and landfill waste. As two satisfied customers have attested, the attachment can save up to £1000 a day in rubble and skip hire costs while enabling efficient on-site recycling

Watch the Cone Crusher in action: https://youtu.be/o7uajB9VUv0

Auger Torque is also proud to promote the new offering to its portfolio, the Kinshofer Drum Cutter range. Originally a Kinshofer product, Auger Torque is excited to take over the manufacturing, development, sales and support for this attachment range globally. High quality design, manufacturing and parts guarantee high performance levels in the toughest of environments, as well as submerged operation in water of up to 25m depth.

SANY Heavy Machinery, one of the latest OEMs to embrace the battery-electric drive revolution, has taken a significant step towards sustainable development with the launch of its SY19E mini excavator. SANY Heavy Machinery’s fully electric excavator is a game-changer, offering zero emissions, reduced noise levels, and various other benefits over traditional combustion engines.

The SY19E’s state-of-the-art lithium iron phosphate battery technology surpasses lead-acid batteries in terms of performance and is less toxic to produce and recycle. It contains no hazardous or toxic chemicals, rare metals, or heavy metals such as cobalt, nickel, or lead, which are commonly found in other battery types.

With up to 3,500 full charge cycles, the battery technology provides a

Auger Torque

Auger Torque

Auger Torque

Auger Torque

KX085-5: THE 8-TONNE STANDARD NEW The ultimate in operator comfort, efficiency, and high productivity. Talk to your Kubota dealer today to find out more. www.kubota.co.uk

The Kubota KX085-5 is equipped with a host of built-in operational and safety technologies as standard, including engine auto-stop, intuitive control systems, an integrated rear-view camera and much more. Add a new ultra-quiet, spacious cab, and it all adds up to our most productive 8 tonne mini excavator ever.

longer lifetime, reducing environmental impact compared to other batteries that require replacement throughout the machine’s life.

The SY19E also includes an auto-idle function that reduces motor energy consumption after five seconds of control inactivity, as well as energy-saving LED lights throughout the cab and boom, and a state-of-the-art touchscreen monitor.

The manufacturing of the excavator is also eco-friendly, as SANY produces it in a lighthouse factory recognized by the World Economic Forum. This reduces material waste, energy consumption, and greenhousegas emissions throughout the production and manufacturing process.

Also, making their UK debut at the show are two brand new Sany wheel loaders, the SW305 and SW405 models with their bucket capacity of 2.3/3m³ and an operating weight of 14.5/18 tonnes respectively. The new generation of wheel loaders from Sany use with well-known components including Kawasaki pumps and ZF transmission and fully equipped as standard including a 360-degree camera, keyless entry,

The new ESE 8 will be taking centre stage at Plantworx 2023 on the RSP Suction Excavator stand C-ND4 & C-ND3

Lloyd Gardener, Director of RSP UK, said of the launch, “We are delighted to be bringing the ESE 8 to the UK market. As a global company, it’s our mission to invest in our technology, innovation and products to ensure they represent the best solutions for our customers and our industry.”

MTS Suction Systems are introducing the new MEGA-AIR compressor system option to their DINO range of suction excavation systems and will be exhibiting the unit mounted to a DINO12 Suction Excavation System.

MEGA-AIR fitted to the DINO range provides more air pressure and volume enabling higher performance air-lances to be used which in turn enables harder grounds to be loosened more quickly and efficiently. MTS have proven the MEGA-AIR technology on their DINO equipment used in North America successfully competing against wet systems that utilise high pressure water to break harder ground.

Russell Fairhurst, the MD of MTS Suction Systems UK Ltd states ‘MEGA-AIR widens the scope of operation of MTS systems enabling not only operation in harder ground conditions, but also improving ground loosening in all conditions which has the knock-on effect of enabling ground to be removed as lower fan speeds and therefore more economically’.

Leica Geosystems part of Hexagon announce ‘game-changing’ innovative 3D collision safety solution integration with Xwatch Safety Solutions. This can be seen in action on the Xwatch stand at Plantworx.

Leica Geosystems and Xwatch Safety Solutions have jointly developed a new solution to safeguard construction assets and infrastructure on site. The two systems are connected together by a Can

single joystick steering and 3rd function hydraulics.

RSP UK has launched their new and innovative Suction Excavator in the ESE 8 – mounted onto a Mercedes Benz AROCS with an 8m3 container. The new model is set to transform and optimise suction excavator use within the industry. The dual tipping and 20% increase in the working range versus other models make this first in its class.

The technology was launched at Bauma in October 2022 by RSP Germany and the first-ever unit has been brought to the UK this month.

bus communication channel to create one of the world’s first solutions for safety and productivity in a 3D world.

This system is unique to Xwatch and Leica. The revolutionary combined solution will allow users to create or import 3D avoidance zones above and below the surface area, directly within the Leica MC1 machine control software.

The operator can quickly create or import avoidance zones in the incabin Leica MCP80 panel, which will then trigger the hydraulic functions of the excavator to slow down or even entirely stop once approaching

RSP UK

26 SUMMER 2023

MTS Suction Systems

these danger zones.

It’s also very easy to use for the operator and has the ability to ‘kill’ the motion of the machine’s tracks so it cannot breach environmental sites, power cables, drainage.

Other critical avoidance areas include overhead obstructions such as powerlines, underground services, and operations in close proximity to pedestrian walkways, live carriageways and public roads.

This solution is made possible by combining the state-of-the-art Leica MC1 machine control software and the top- of-the-line XW5 Series from Xwatch Safety solutions.

The Spillard Safety Systems’ AI Human Detection System was launched last year at Futureworx. This system is capable of identifying

lithium-ion batteries provide enough power for a full day of paving. Charging options include the standard eight to 10-hour normal charge rate or an optional two-hour fast charge system.

It features the simple-to-operate GOMACO-exclusive G+® control system with a full function radio remote control that puts all machine operations in the hands of the operator. Travel control, manual threepoint grade control, cross auger directional controls, vibrator control dial, warning lights, and emergency stop are all located on the remote’s control panel. The CC-1200e is also equipped with rotary-sensored slew drive steering on its front wheel assemblies allowing smoother paving, easier control, and maximum turning capability with the ability to slipform a 24 inch (610 mm) radius, depending on the mould profile.

humans through their shape, form, and characteristics. When a person enters a pre-determined restricted or exclusion zone, the system sends audible and visual alerts to the machine operator.

What makes this system unique is its ability to present the detected data in three ways. Firstly, the data is displayed clearly on a zonal display and communicated to the operator through spoken words. Secondly, an external speaker informs the detected human to “move away,” which significantly changes the behaviour of banksman, machine controllers, and workers by moving away to a safe distance. Thirdly, safety managers receive video telematics information on a bespoke, GDPR compliant platform for training and further investigation into predictive behaviour.

The video telematics data provides visual verification of the human detection made. Furthermore, high idling, excessive fuel burn, shockrelated braking, or acceleration events can also be measured and verified. Based on this information, operators and project managers can make informed decisions on what needs to be changed on the site to make it safer and reduce all-round costs.

This year GOMACO will introduce the world’s first battery-powered slipform curb machine, the CC-1200e, to the UK market, at Plantworx.

The GOMACO CC-1200e electric curb machine is equipped with a power dense 48 VDC lithium-ion battery pack. The result is a paver with zero-exhaust emissions, reduced vibrations, and zero engine noise. The

Avant Tecno, a renowned expert in loader technology hailing from Finland, has recently launched two new models in its 600 Series that boast of an upgraded engine. The 645i and 650i models are considered the most powerful loaders in their respective size classes worldwide, as per the company. Even though these new machines have similar dimensions and lifting capabilities as the previous 600 series models, they come with a more powerful engine. These models feature Kubota’s 33kW/44hp diesel engine, which provides ample power and torque for high pulling force and speed-intensive work. Avant claims that its competitors lack machines as efficient as these in the same size range.

The EU Stage V emission standard for non-road mobile machinery requires a catalytic converter and a particulate filter for diesel engines above 19kW. Avant is the first manufacturer to introduce such loaders with the specified size class in the market. The 645i has a single-speed Kubota V1505CRT diesel engine, while the 650i features a two-speed version of the same. The four-cylinder 1498cc turbocharged common rail engine delivers a power output of 33kW/44hp, and the oxidation catalyst and particulate filter handle exhaust aftertreatment, without the need for any additives like AdBlue.

Leica Geosystems

Leica Geosystems/Xwatch

GOMACO

SUMMER 2023 27

Avant Techno

Takeuchi UK has added a new model to its 3-Series excavator range, the TB350R short-tail swing compact excavator. This is the company’s first short-tail model in the five-tonne class, and it has a rear swing overhang of just 75mm and weighs 5095kg. The excavator has a maximum dig depth of 3575mm, a dump height of 3945mm, and a ground reach of 5925mm. The machine is powered by a Stage V ready engine with 32.4 kW and a four-pump hydraulic system, providing a bucket breakout force of 37.3kN.

The TB350R comes standard with the Takeuchi Fleet Management (TFM) telematics system, which provides owners and operators with machine health vitals and condition, run time (hours), machine location, remote diagnostics, scheduled maintenance reminders, and customisable alert settings. The excavator will be launched in the UK at Plantworx.

Straight from Bauma, making a major presence will be the new TB395W, Wheeled excavator, widely anticipated by the plant industry in the UK. The new TB395W will be demonstrated to the max in the Takeuchi Dig Zone and static on the Takeuchi stand, so all visitors will have a chance to get a close look at the redesigned ergonomic 3-series style on one of the most compact wheeled excavators available.

The brand-new battery powered TB20e mini excavator will be taking charge of Takeuchi Time, a timed operator challenge where visitors can win daily prizes. The competition is hosted by Dave Vickers @ diggingwithdave2023 and tests operators precision skills and speed on the newest fully electric Takeuchi.

Visitors can expect to meet the Bobcat T7X Compact Track Loader, which Bobcat say is ‘your window into the future of the compact equipment industry.’ With the introduction of the zero-emissions Bobcat T7X, the manufacturer is shaking up the industry again.

The T7X is completely battery-powered and equipped to outperform its diesel-powered counterparts. The heart of the T7X is its powerful, 62-kilowatt lithium-ion battery. Each charge can support common daily work operations for up to four hours of continuous operation time and a full day of operation during intermittent use. After a recharge, the T7X is ready to do the tough work again. Unlike other compact loaders, the T7X doesn’t rely on a hydraulic system to transfer power to the machine’s work group. Instead, it features an electrical drive system consisting of electric motors and ball screw actuators.

DEVELON, formerly known as Doosan Construction Equipment, will be exhibiting for the first time in the UK. Several of the products on display are being seen for the first time in the UK. These include the new DX63-7 6 tonne and DX85R-7 8 tonne mini-excavators in the Static section of the stand and the new DX250WMH-7 material handler in the Demonstration area.

Together with the DX62R-7, the DX63-7 is one of two new 6 tonne mini-excavators from DEVELON, completing the roll out of the next generation of machines from the company, Despite offering an 8% increased torque of 26.5 kgm/rpm, the D24 engine still provides a 7% decrease in engine fuel consumption.

Alongside the DX63-7, DEVELON is showing the new DX85R-7 8 tonne mini-excavator for the first time in the UK at Plantworx 2023. The DX85R-7 reduced tail swing (RTS) excavator utilises a newly improved upper structure platform offering increased durability and

robustness and a different boom swing cylinder layout resulting in an increased boom swing angle of 60o

Equipped with an MG22 Sorting Grapple, the new DX250WMH-7 25 tonne Stage V compliant material handler is being demonstrated by DEVELON for the first time in the UK, for use in the solid waste, recycling, demolition and forestry industries.