THE VOICE OF THE UK CONSTRUCTION EQUIPMENT INDUSTRY

SUMMER 2017

www.constructionworx.co.uk

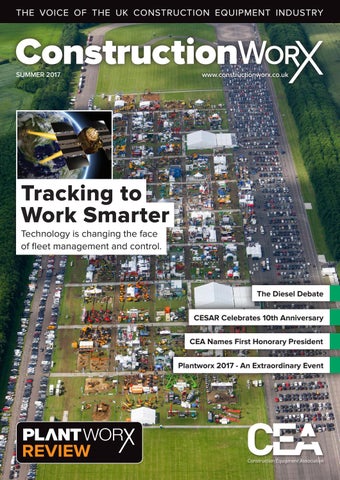

Tracking to Work Smarter Technology is changing the face of fleet management and control.

The Diesel Debate CESAR Celebrates 10th Anniversary CEA Names First Honorary President Plantworx 2017 - An Extraordinary Event

SUMMER 2017 1