From uncoated to laminated to UV or foils - Hero Print has you covered

AUSTRALIA’S BEST TRADE PRINTER

Breen Printing 57 Signageworld

Bright Print Group 58 Signarama Tuggerah

Cactus Imaging 59 SS Signs

Eckersley Print Group 60 SunPrint

Global Signs 61 Valiant Press

Grand Print Services 62 Vista Australia

Imagination Graphics 63 FESPA Australia

Kwik Kopy Australia 64 LIA

Lamont Print & Signs 65 VMA

MBE Parramatta 66 Messe Düsseldorf

Mint Imaging 67 David Fellman & Associates

Next Printing

Print Media Centr

HIGHLIGHTS: ASGA hosts social Bowls Day in

HIGHLIGHTS: FESPA Australia hosts annual Melbourne BBQ

HIGHLIGHTS: FESPA Sydney Social a huge resounding success

PRINT DIARY: A look at what’s on in the printing industry

CLASSIFIEDS: The Australian print industry’s biggest marketplace

Australia's one-stop destination for printable materials, press consumables, and printing & industrial equipment.

Our commitment to quality, sustainability, and innovation sets us apart.

Explore ecoporium, our online platform for eco-friendly packing solutions, and experience i_Consignment for e icient stock management.

Our Print & Packaging Consumables team boasts technical mastery, cutting-edge ink lab blending, and converting facilities.

We're not just products; we're your partner in bringing big ideas to life.

Welcome to the first issue of Australian Printer for 2025. I hope the past three months have been kind to you and your businesses.

The general sentiment, in our industry, so far this year has been one of optimism, even though challenges are still existent.

Printers, manufacturers, and associations alike have all identified silver linings to the challenges, saying they present new opportunities to tap into.

This bumper issue of the magazine takes a deep dive into industry insights in the Print Leaders Forum pages, where several of our thought leaders look back on the year that was and forecast what we can expect throughout the rest of 2025.

This issue also provides a peek into all the events that have happened so far this year – from the Durst Open House at Evan Evans, to Hunkeler Innovationdays, FESPA Australia socials and ASGA’s Vic Bowls Day.

We hope you enjoy your read of this special issue.

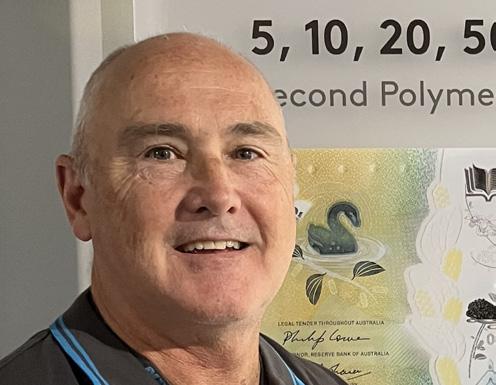

The local FUJIFILM Graphics Systems (FFAU) and FUJIFILM Business Innovation (FBAU) sales teams will soon merge, creating a single, go-to-market sales team.

In a letter to staff, FUJIFILM Graphic Communications senior general manager and head of Oceania Yoshitaka Nakamura provided an update of the changes taking place on 1 April, and then progressively until 1 April 2026.

“I would like to provide an update following the communication in November announcing the decision to implement a business unit responsible for the overall execution of both digital and analogue product offerings within the Graphic Communications space from FBAU and FFAU, with a focus on workflow software,” he said.

“I am pleased to advise a decision has been made to centralise the graphic communication sales function, which means we will be merging the FBAU and FFAU sales team under one leader effective 1 April 2025.

“By the end of FY25 (1 April 2026), we expect the FFAU sales function to come across to FBAU. The result will be one team led by Steve Fisher, head of graphic communications, FBAU.

“Centralising this business means we can more effectively offer customers our entire portfolio of graphic communications products and services, maximising value for them and our business.”

This change will also see the transfer of the wide format business from FFAU to FBAU.

FFAU will continue to have a focus within the graphic communications market as it continues to deliver analogue products (plate and chemical).

Fisher provided key messages around the new strategy, telling Australian Printer, “FUJIFILM Business Innovation Australia and FUJIFILM Australia are incredibly excited to be engaging the market with a single sales team, combining the graphics and communications function to elevate our selling and servicing, delivering the best possible outcomes to customers.

“Through this model, all of our high-quality analogue and digital offerings will be delivered through our singular sales team, providing a more seamless and better quality experience for our customers.

“This allows us to focus on the continued growth of solutions and services to support digital transformation.

“We are also continuing all support for FUJIFILM wide format offerings by the FUJIFILM teams for continuity for our customers.

“We look forward to continually evolving the rapidly changing landscape and providing our customers with everything from a graphic communications perspective.”

Managing Director

James Wells / 02 8586 6101 james@intermedia.com.au

Subscriptions / (02) 9660 2113 subscriptions@intermedia.com.au

Editor Hafizah Osman / 0431 466 140 hosman@intermedia.com.au

Subscription rate (5 issues) Australia $79 Printed by Hero Print Alexandria, NSW, 2015

National Sales Manager Carmen Ciappara / 0410 582 450 carmen@proprint.com.au

Design and Production Manager

Sarah Vella / 0406 967 559 svella@intermedia.com.au

Experience One Fujifilm at PacPrint 2025, stand B62. The one decision that makes the rest easy.

Put a smile on your face when you discover a world of possibilities. Meet our expert team and explore cutting-edge technologies designed to make print smarter and more profitable. From analogue to the latest digital presses, mono and colour print engines, and integrated workflows – we have it all. Join us and take your business to the next level with One Fujifilm. Because when print is simple and successful, everyone smiles. It’s worth the visit.

HP has launched two new presses globally, the PageWide Web Press T4250 HDR and PageWide Web Press T500M HD, that aim to redefine high-volume digital production.

Fuelled by the company’s continuous innovation in HP Thermal Inkjet Technology, these industrial presses address industry needs for solutions that deliver productivity, quality, and versatility in the direct mail, general commercial, and book publishing segments.

“At HP PageWide, we constantly pioneer advancements to ensure our customers remain at the leading edge of digital print technology that empowers their success,” PageWide Industrial vice-president and general manager Barbara McManus said.

“The industry-leading productivity, versatility, and quality of our new industrial presses provide our customers with powerful digital solutions to meet the needs of an evolving print market.”

HP A/NZ regional industrial manager Craig Walmsley highlighted the importance of these innovations for the local market.

Hong Kong-based printing company

Bannershop has suddenly closed its Australian business in western Sydney surprising many members of the local industry.

In a message published on the company’s website, Bannershop CEO, Anthony Choi, issued a short statement under the words, ‘Thank You For Your Support’.

“After 18 wonderful years of serving our customers in Australia, we have made the difficult decision to cease trading. We want to extend our heartfelt gratitude to all of our loyal customers for your support and trust over the years. Your patronage has meant the world to us, and we are truly grateful and thankful to your support. Thank you for being a part of our journey!” the statement said.

He told Australian Printer, “The launch of the PageWide T4250 HDR and T500M HD underscores HP’s commitment to equipping Australia and New Zealand businesses with cutting-edge digital printing solutions. These presses are poised to meet the evolving demands of our print industry, delivering exceptional speed and quality”.

Designed for a wide variety of publishing, direct mail, and commercial print work, the T4250 HDR features fast speeds and consistent print quality, allowing customers to print more high-volume, high-coverage jobs.

The new 42-inch (106 cm) web press prints up to twice the productivity of its predecessor, the HP PageWide T485 HD, resulting in 20,000 B1 duplex sheets and over 200,000 letter-sized duplex colour pages per hour.

Combined with HP Optimizer, the press maintains high speed and quality on coated and uncoated media with weights ranging from 40 to 350 gsm. This press also comes

After 18 years of serving customers in Australia, Bannershop has ceased tradingCredit: iStock.com/MicroStockHub

Bannershop sponsored the South Sydney Rabbitohs over a four-year period from 2019 to 2022 and described itself at the time as “one of Australia’s leading large format digital printers” responsible for printing the club’s stadium and event signage.

“Bannershop prides itself on delivering the best value for money in the industry, a signage specialist catering for everything from retractable banners and posters to outdoor vinyl banners, window and vehicle stickers and exhibition display systems and graphic design service.

with the benefits of thermal inkjet technology – eight nozzle redundancy, user replaceable printheads, automated web-wipe cassettes, and on-press colour profiling.

The machine also keeps environmental sustainability in mind. HP Brilliant B70 Ink has low VOCs and reduces drying time, with up to 50 per cent less energy use than that of the T485 HD.

As for the HP PageWide Web Press T500M HD, it offers book manufacturers a purposebuilt solution to meet their clients’ demands for shorter run lengths, tighter turnaround times, and more frequent high-volume orders.

The 54-inch press is designed to use standard offset media and impositions, allowing operators to shift seamlessly between offset and digital print lines, reduce paper inventory, and streamline labour resources.

The 1000 fpm (305 mpm) speed rivals offset turnaround times and throughput by producing finished book blocks of variable trim sizes that move directly to the final production stage, saving time, labour, and floor space.

With reduced paper waste at start-up and between jobs with variable cutoffs, an optimised factory floor, and the complete elimination of offset aluminium plates, this press features the environmental advantages of industrial inkjet without compromising productivity or profitability.

“Bannershop has been heavily involved in supporting the Club at all levels, providing the highest quality products to showcase our various partners’ branding and provide the very best Red and Green match day experience,” Rabbitohs CEO, Blake Solly, said in 2022 when the company renewed its agreement.

“They have been wonderful partners throughout the challenges of the past three seasons, and we’re excited to have them on board once again.”

Bannershop launched its 2022 partnership by providing Rabbitohs Members and supporters with 10,000 free flags at the opening home game of the season against the Roosters.

Bannershop CEO Anthony Choi explained in an interview in 2015 that he started the business after studying in Australia and found the cost of producing a pull-up banner to be very expensive when he was seeking promotional materials for a project. With a belief that he could manufacture the banner cheaper, he returned to Hong Kong in 2006 and started Bannershop.

Koenig & Bauer A/NZ has welcomed the appointment of Koenig & Bauer AG CEO, Dr. Andreas Pleßke, as chairman of the drupa committee.

“We are super excited to be playing a part in shaping the future of print globally. Our focus on innovation, collaboration and sustainability will assist our Australian and New Zealand industry develop and be world leaders,” Koenig & Bauer A/NZ national sales manager Rayne Simpson said.

Pleßke said it is an honour to continue to actively help shape the development of drupa as chairman of the drupa committee.

“The world is changing rapidly – both in technical and political terms. Together with the committee we will ensure that drupa constantly develops further to also assert its pole position as a world-leading trade fair for print technologies in future and to orient the industry for the future,” Pleßke said.

Wolfgang Poppen, deputy chairman and managing partner, Freiburger Druck GmbH & Co. KG (bvdm) said, “drupa is the centrepiece of the industry, a place of innovations and technology launches. The coming months will be used intensively to further sharpen the profile of drupa’s position in 2028”.

Staying true to its four-year cycle, the next drupa will be held again in May 2028 – but this time, as a nine-day event that will only run over a single weekend. The event’s organiser, Messe Düsseldorf, said the decision to reduce the number of days was to adjust to the changing needs and expectations of exhibitors and visitors, and reflects the continued transformation of the industry. drupa 2028 will take place in Messe Düsseldorf from 9 to 17 May 2028.

As part of the further development of the world-leading trade fair, the strategic process towards drupa 2028 is already initiated. Alongside the proven trade fair format, innovative formats are being developed with a view to enabling even stronger networking within the industry.

Due to succession planning and personal changes, four new members were also included in the committee:

• Markus Hoffmann, executive senior vice-president, Leonhard Kurz Stiftung & Co. KG & chairman of the Printing and Paper Association in VDMA

• Marcel Martens, general manager Industrial Print EMEA Direct, HP Indigo & Pagewide, HP Industrial Printing

• Thomas Heininger, CEO, MBO Postpress Solutions GmbH & CEO, Komori International Europe

• Peter Voigt, managing director, Perfecta Schneidemaschinenwerk GmbH.

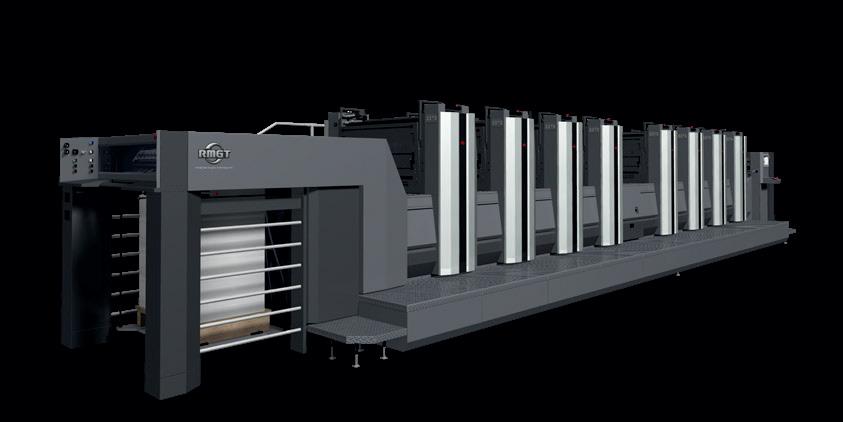

The widely acclaimed ROLAND 700 EVOLUTION litho press deploys an array of innovative technologies to give unprecedented levels of efficiency, productivity and print quality.

manrolandGoss - Australasia Tel: +61-2-9645-7900 info.au@manrolandgoss.com

IVE Group managing director Matt Aitken has described the financial performance of the company in the six months to 31 December 2024 as “a very solid result”.

IVE Group grew revenue to $507.8 million for the six months to 31 December with gross profit margin increasing to 48.5 per cent.

“All key profit metrics are up significantly. We have had strong margin expansion and further uplifted operating cashflow with working capital levels normalising and the balance sheet has been further strengthened with gearing continuing to sit below our internal target,” he said.

Aitken confirmed IVE Group has ‘fully realised’ the cost synergies delivered to the business following the acquisition of the Ovato and JacPak businesses and fully integrated the Elastic acquisition that took place in May last year.

Here are the numbers:

• Revenue for the six months to 31 December was $507.8 million, up 0.4 per cent from $506.0 million in the same period a year prior

• Material gross profit margin of 48.5

Easy Signs director Andy Fryer has weighed in on US president Donald Trump’s decision to impose a 25 per cent tariff on steel and aluminium imports entering the US from 12 March, stating the proposed move will simply force the company and its competitors to slightly increase prices to adjust and maintain margins.

However, Australia is hoping to secure exemptions to the new taxes.

“While we are still awaiting further clarification on the amount of aluminium a product must contain to be included in the tariffs, we are working on the assumption that all of our imported aluminium products will be included,” Fryer said.

per cent was up from 46.2 per cent in the same period a year prior

• EBITDA was $74.1 million, up 12.6 per cent from $65.8 million in the same period a year prior

• EBIT was $51.4 million, up 23.4 per cent from $41.7 million in the same period a year prior

• Net Profit After Tax was $29.3m, up 29.1 per cent from $22.7m in the same period a year prior

• Net debt was $121.4 million, down from $131.0 million at 30 June 2024, reflecting continued strong operating cash conversion and greatly reduced restructuring costs, partially offset by peak working capital seasonality and capex associated with the packaging capacity build-out.

“If this is the case it will simply force us and all our competitors to slightly increase prices to adjust and maintain margins. The hardware components we import are not manufactured locally in the USA, so we have limited options.”

The company has revised its net profit for the full year (FY25) from $45 million to $50 million to a new guidance of $47 million to $50 million.

During the 1HFY25 call, Aitken also announced that IVE Group will replicate its Braeside supersite with a new 42,000sqm building at Kemps Creek in Western Sydney and will relocate its third-party logistics (3PL) business to a 32,000sqm facility in Dandenong South, Victoria.

Aitken said the new Sydney supersite expands the business into horizontal adjacencies, including packaging, to drive revenue growth and operational efficiencies.

“Four locations will come together at the Sydney supersite including the commercial print operations from Silverwater, Brand Activations from Granville, CX and Data from Homebush, and Paper Storage for print web offset from Warwick Farm,” he said.

“The site was chosen as it is close to key transport hubs as well as IVE’s Erskine Park and Huntingwood sites bringing together the Western Sydney teams.

“The benefits of the Sydney supersite include avoiding an additional $3.1 million per year in rental costs as well as provide operational efficiencies and a centralised strategic labour pool to optimise labour mix enabling flexibility across business units and reduce external labour hire.”

Easy Signs first opened its US operations with a $US2.8 million investment for a 6700sqm facility in March 2022.

Last year, Easy Signs was featured on the front page of the New York Times commenting on possible 400 per cent tariffs placed on aluminium components from China.

“We had been running into huge challenges with tariffs being applied on imported aluminium products such as pull-up banner stands, media wall frames and gazebos adding up to 370 per cent of the value of the aluminium,” Fryer said previously.

“This forced us to redirect containers that had arrived to the US from China, all the way to Australia,” Fryer said previously.

In September 2024, Fryer also mentioned that after doubling sales from 2022 to 2023, Easy Signs has experienced a further 50 per cent increase in sales as it grows to more than 50 staff members from its operations in Pennsylvania.

Redefine Commercial Printing Standards and elevate production with Next-Gen High-Speed Inkjet

PRODUCTIVITY

•High productivity

•560mm paper width

•High machine uptime

QUALITY

•New Inkjet 1200dpi PHs

•New saturated ink SC2

•Enhanced image quality

USABILITY

• Energy-efficient drying

•Easy operation

•Offset-coated papers

AGILITY

•Optimised integration

•Precision paper sensing

•Complete New Platform

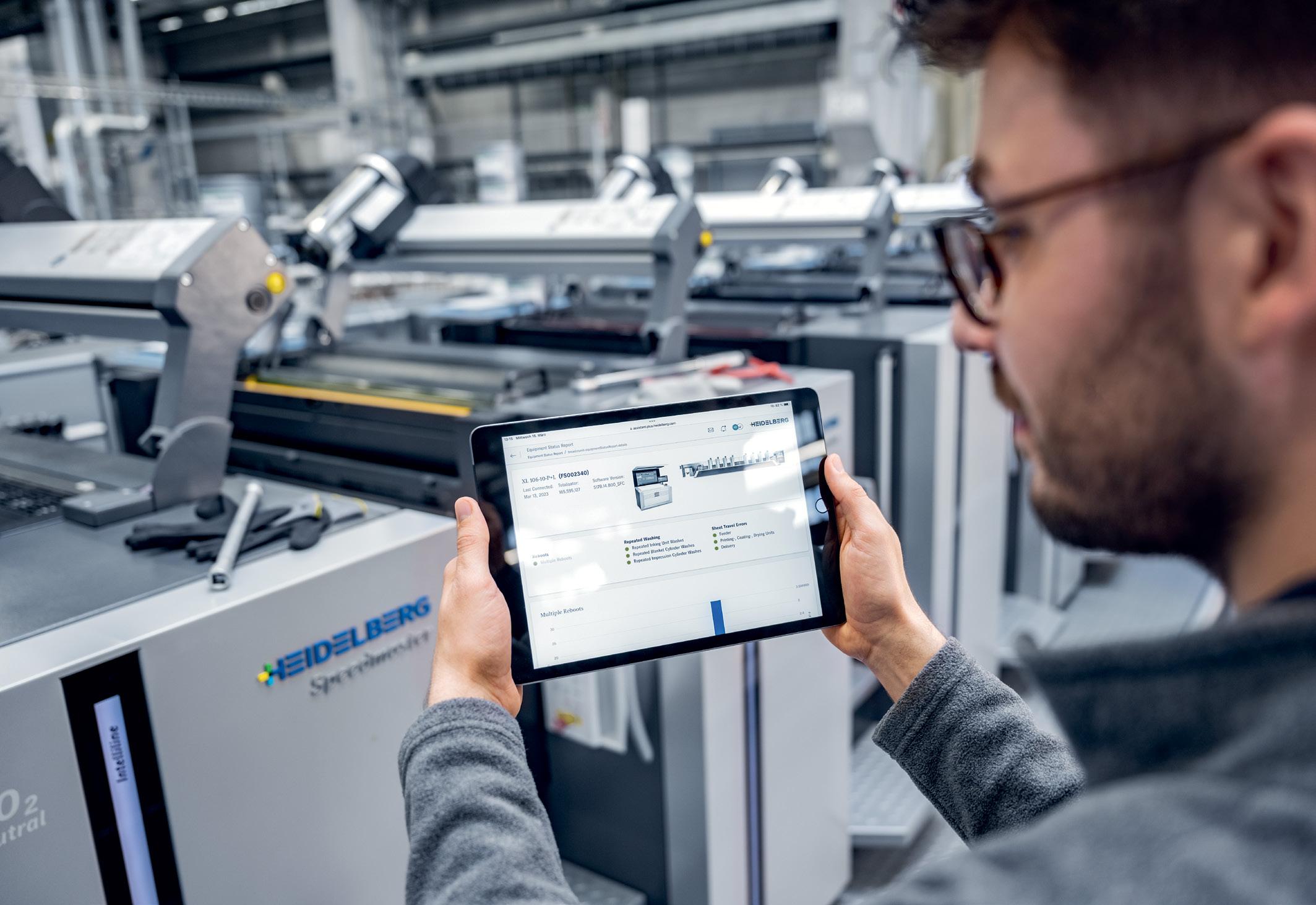

Heidelberg’s all-in-one digital Customer Portal is a reinvented production management solution that brings together all of the company’s apps into a centralised platform

Solving a business need can be a challenge, especially when it comes to getting short print runs produced cost-effectively. As operating a print shop is becoming increasingly complex, staying competitive means optimising the use of resources, materials, and time.

And with the print industry becoming more digital now than ever, software is taking centre stage in a space that has traditionally been heavily skewed towards hardware.

With these factors in mind, Heidelberg has reinvented production management with its Customer Portal – a cloud based all-in-one digital portal that allows users to manage their operations effortlessly.

It provides easy access to production workflow apps, analytics, service and maintenance, shopping, administration, and a holistic 360-degree overview of a user’s

printshop. This enables businesses to simplify their operations with a single interface to access information and get support, streamlining their print shop responsibilities.

“With our digital tools and services, we are a pioneer in the digitisation of print shops around the world,” Heidelberg Australia national sales manager Dierk Wissmann said.

“The Heidelberg Customer Portal provides everything a user needs to run their print shop smoothly and profitably, helping them optimise their print shop’s efficiency, performance, and transparency.

“It is one customer portal with endless possibilities, and it lets users reduce touchpoints and achieve full transparency in their print shops. It is a powerful tool that users can use to identify and eliminate weak points in production more quickly, thus increasing their efficiency and performance.”

The portal houses up-to-date data, making it readily available at a user’s fingertips –enabling simple access from any device, anytime. The easy-to-use interface makes it convenient for a user to see what is important at the moment and allows them to have full transparency of their print shop so that they can take the relevant action immediately.

Since its introduction into Asia Pacific in 2023, there are more than 350 users regionwide – with businesses taking on this software platform growing quickly.

The wide range of apps offered through the Heidelberg Customer Portal include:

1. Analytics: Print Shop Analytics provides real-time evaluation of status and key performance indicators (Insights) including the possibility to benchmark the printing machines against others (benchmarking)

5. Administration: Users can enjoy the benefits of a thorough, quick, and easy overview of all their equipment and contracts. as well as integrated advice/ recommendations on how to improve the performance.

2. Production: Everything is located in one application to help users prepare, produce, and manage their production workflows. The Inventory Management App provides users with up-to-date information on consumables.

3. Support: Users can obtain a complete overview of their current service incidents and maintenance status, including the Online Training App to get access to helpful resources in an array of topics.

4. Shopping: Users can get direct access to the Heidelberg eShop with straightforward ordering processes and offerings that are customised to their equipment. They can also track

orders and get a full overview of all invoices (not available in all countries).

Dat a is presented as analysis, which can be read with just a few clicks on the modern dashboard

Improved efficiency and analysis of performance with insights is the key benefit of the Customer Portal.

Using the Insights app, printshops can see, in real-time, important key production figures which the app can then evaluate and interpret.

This analysis can be read with just a few clicks on the modern dashboard of the Insights app.

“Printshops will get real-time information about their pressroom and can quickly identify and eliminate weak points,” Heidelberg Australia technical sales and product manager, Darren Brookes said.

“Insights warns when set target values are not reached or problems occur within production that enable users to precisely narrow down where issues are occurring. These reports are then a basis for improvement with a focus on efficiency and improved performance in the pressroom.”

Benchmarking allows printshops to measure and track their performance within their market segment

Performance evaluations and comparisons with benchmarking is also another feature. For example, if a user is wondering how they’re performing in terms of waste with heavier substrates or how good their makeready times are in comparison to the competition for complex job configurations, the Print Shop Analytics app shows benchmarking in detailed reports. A user’s performance will be compared to their competitors within their market segment.

“Benchmarking also allows printshops to measure and track their performance within their market segment. Printshops will get real-time information about their pressroom and can quickly identify and eliminate weak points,” Brookes said.

“Insights warns when set target values are not reached or problems occur within production. This will make users more efficient and improve the performance of their pressroom.”

In addition, digital assistants help improve Overall Equipment Effectiveness (OEE)

with Performance Advisor Technology (PAT). Available as an app in Print Shop Analytics, the artificial intelligence PAT continuously analyses a user’s pressroom and machine data and, if necessary, automatically recommends solutions, just like a human consultant would do.

PAT offers practical suggestions for improvement, highlights strengths and potential savings, generates comprehensive diagrams and data, and gives specific recommendations. PAT also monitors the printing process, recognises deviations, and suggests suitable optimisation measures that will make a company more effective.

Efficient service ticket submission and tracking is also offered within the portal. A ‘traffic light’ logic design easily shows users the service status of their press and software modules (Prinect). The users can create a new ticket from a new issue directly via the app, using very few steps, including uploading a picture or video if necessary.

The status of the ticket can be easily tracked and with every update from Heidelberg’s service colleagues regarding the issue, users will directly get a notification and are able to chat with the experienced Heidelberg team.

Reduced maintenance effort through process efficiency and professional instruction is also achievable through Heidelberg Customer Portal. The Maintenance Manager is a software system that offers the complete maintenance documentation to a user’s dedicated Heidelberg machines.

Additionally, it supports the complete maintenance process administration including planning, due date monitoring and documentation of maintenance. These additional features are bound to a Heidelberg machine service contract.

Heidelberg has seen global success in the uptake of its Customer Portal platform.

Edmonton, Canada-based Burke Group of Companies Limited, is one of the companies that has successfully implemented the Heidelberg Customer Portal.

Aiming to be the best single source solution for its clients, the Burke Group of Companies has gone on to develop its print division into one of the top print production facilities in Canada by investing in the acquisition of other companies whose services add greater value for its current and future customers.

In line with providing an unparalleled and robust suite of solutions, the Heidelberg Customer Portal has enabled the business to continue providing a customer-first commitment.

“The new portal is a great tool. It would take hours to compile and analyse data that the portal provides in seconds,” the company said.

Another company that is a strong advocate of the Heidelberg Customer Portal is Emibra Brazil, a packaging company in Suzano, Brazil.

With a focus on technological evolution, financial solidity, and valuing people, Emibra goes beyond simply supplying packaging. Its mission is to offer customised solutions that meet the needs

Some of the benefits of the Heidelberg Customer portal include:

• Improved efficiency and performance through real-time production data analysis via the Insights app

• Performance evaluations and competitor comparisons with benchmarking reports in the Performance Benchmarking App

• Automated improvement suggestions through AI-powered Performance Advisor Technology (PAT), offering optimisation recommendations

• Simplified service and maintenance processes with clear service and maintenance tracking

• Reduced maintenance effort through efficient process management and professional instructions in the Maintenance Manager

• Transparent shopping processes with direct access to the Heidelberg eShop and order tracking

• Comprehensive production management via apps such as Inventory Management

• Cloud-based platform for easy, anytime access to important data and applications from any device

of customers in various segments, many of which are long-standing partners, with more than 40 years of collaboration.

By using the Heidelberg Customer Portal, the company has been able to remain faithful to the values that it has always been guided by – innovation, quality, and sustainability. The portal offers a solution to Emibra Brazil’s customers that adds value and strengthens partnerships.

“The new Heidelberg Customer Portal is a strategic innovation that expands our ability to make informed decisions at management level. By providing us with actionable data-driven insights, it not only elevates operational effectiveness but also allows us to identify opportunities for growth and longterm improvements,” the company said.

As evidenced by these companies’ successes, Wissmann said, “Take your printshop to the next level with Heidelberg Customer Portal”.

The Heidelberg Customer Portal addresses several major pain points for print shops, including:

• The lack of real-time production visibility – It offers real-time insights and analytics, helping identify inefficiencies and bottlenecks quickly

• Complex workflow management – The platform streamlines production processes and inventory management, making it easier to handle multiple tasks

• Performance benchmarking –Print shops can compare their performance to industry peers, which is difficult to do manually

• Service and maintenance inefficiencies – The portal simplifies service ticket submission and tracking, along with predictive maintenance, reducing downtime

• Manual performance optimisation – The AI-driven Performance Advisor Technology (PAT) app provides automated recommendations for continuous improvement, eliminating the need for manual analysis

• Cumbersome procurement processes – Direct access to the Heidelberg eShop simplifies ordering and tracking, reducing administrative effort.

The event saw the showcase of the Vanguard VK300D-HS high production flatbed LED UV printer, which Evan Evans bought from Durst Oceania last year

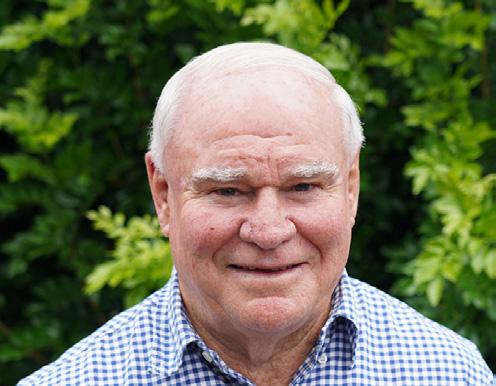

Durst Oceania recently hosted its first local Vanguard Open House at Melbourne-based printer Evan Evans, providing visitors with an opportunity to see the Vanguard VK300DHS machine in operation.

Evan Evans installed the Vanguard VK300D-HS high production flatbed LED UV printer last year shortly after the brand was launched in Australia following the Fespa Global Print Expo in Amsterdam.

Evan Evans owner Roger Cameron said, “Durst Oceania has been a supporter of us for a long period of time. Today is the first time we have opened our doors to people in the trade. For us, this is not only about showcasing Vanguard, but also showcasing our capabilities”.

The event also reinforced that Durst has solutions for all levels of the market and not just top-tier, high volume customers.

Durst Oceania managing director Matt Ashman said, “Durst Oceania has been in business for five years. We now sell equipment big and small across Australia, New Zealand, and the wider Oceania region. We, at Durst Oceania, are growing – so much so that we’re doubling down on the Vanguard and Durst Oceania brands.

“Because of this growth, we will be moving into a new facility in Melbourne later this year, amplifying the support we provide the industry.”

The Vanguard Digital VK300D-HS is the impressive high speed version of our six-time award winning VK300D series.

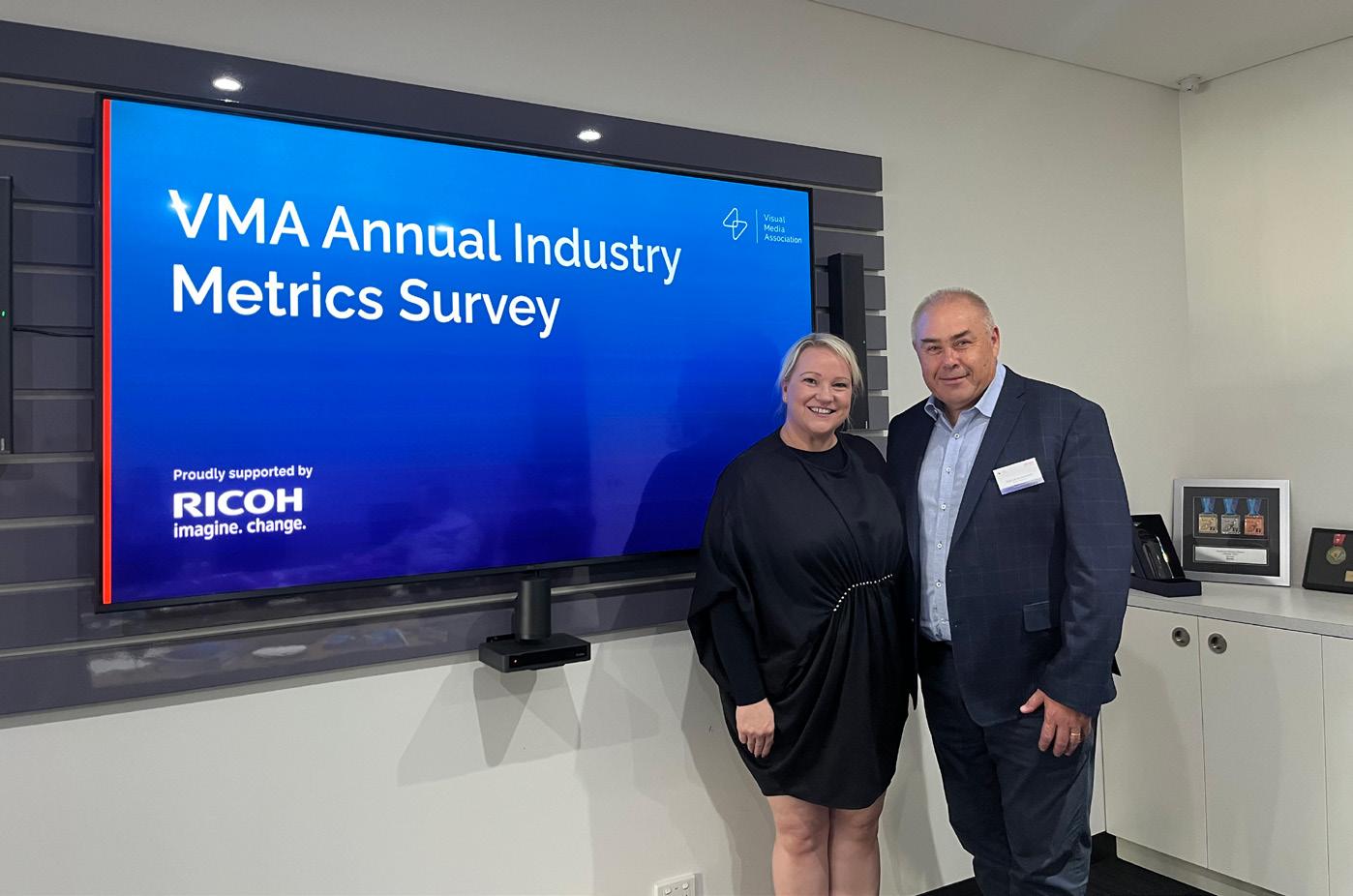

The Visual Media Association said the data from the survey is crucial for the industry as it aims to help local business owners with their planning and forecasting

The Visual Media Association (VMA) has released findings from its 2024 Annual Industry Metrics Survey and recently hosted a roadshow across the country to present the findings.

The Annual Industry Metrics Report, supported by Ricoh Australia, captures salary benchmarks, skills and training levels and shortages, employment demographics, customer group breakdowns, certifications, operational practices, and perceived challenges.

“We need this data for our industry. This data helps business owners with their planning and forecasting. If you’re considering new investments – what should I be investing in? What are others investing in? Where am I sitting when you look at financial benchmarks? Where am I sitting with salary benchmarking? These are things that really help your businesses, and the more data we get the more we can build in on it,” VMA CEO Kellie Northwood said.

According to the VMA report, industry employment figures represented stability across most sectors since last year’s Annual Industry Metrics report. In 2024, total industry employment is 229,113, a modest decrease from last year’s 229,194.

“This is an incredibly strong number. We still sit as one of the largest manufacturing

employees in the country. What’s also interesting is that despite recent consolidation of our industry, we are increasing in the number of businesses recorded under the ABS as ‘print or visual media related services’ businesses, with a rise from 4414 businesses recorded in 2023 to 4435 in 2024,” Northwood said.

“We remain a male dominated industry, but that number is coming down. It was 64 per cent in 2023, as compared to 58 per cent in 2024. We have more women joining the industry, which is terrific, and what we’re also seeing, which I am really excited by, is that our industry is one of the fastest growing for female apprentices.”

A notable finding in the survey was the increased number of apprentices in the industry, with 77.78 per cent of businesses currently employing one or more first year or stage 1 appreciates, compared to 38.46 per cent in 2023. More than 75 per cent of businesses currently employ one or more second year or stage 2 apprentices, compared to 53.85 per cent in 2023.

“In 2023, our apprenticeship numbers were quite low, but we’ve since seen this surge,” Northwood said.

“What we’re also seeing is that we’re attracting talent from different cohorts. One industry that is struggling [for employment] in Australia is graphic design.

One of the largest cohorts of apprentices coming into pre-press and print are now coming from the design channel. There just aren’t enough jobs for designers in this country.

“A lot of design is being offshored, and we have great, talented people who have an eye for creativity and understanding of the software. So, if you’re looking for apprentices and not sure where you can attract them, have a think about your local design college.”

Key findings from the 2024 VMA Annual Industry Metrics Survey:

General industry trends

• Total industry employment is 229,113, reflecting the largest sovereign manufacturing employer in the country

• 4,435 (4,114 in 2023) businesses are registered as print or visual media businesses across Australia, with most businesses being in New South Wales (28.75 per cent) and Victoria (28.75 per cent)

• 67.50 per cent of businesses operate across a single site

• 86.25 per cent of companies are privately owned and operated

• More than a third of industry businesses reported $500,000 to $3.5 million in annual turnover

• Only 17.5 per cent of businesses reported less than $1 million in turnover

• 37.5 per cent of businesses reported $1 million to $5 million in annual turnover

• 37. 5 per cent of businesses reported $5 million to $50 million in annual turnover

• 17.5 per cent of businesses reported less than $1 million in annual turnover

• 7.5 per cent of businesses reported $50 million to $100 million in annual turnover

• 57 per cent of businesses said labour is the highest cost to their business

Quoting jobs and workflow

• Email ordering (59.95 per cent) is the predominant avenue in which job orders are received. Direct sales orders are also common (27.09 per cent), followed by external EDI or API connection (15.33 per cent) and e-commerce/web to print (14.82 per cent)

• 34 per cent of businesses report

average job size has increased; however, 19.74 per cent report job size declined significantly

• 62.5 per cent of volume trends are linked to seasonal campaigns, such as Easter, Christmas, or sporting events

• 41.07 per cent of volume trends are linked to education and government, such as elections, budgets, or school terms

• Four in 10 businesses are collecting payment owing within 30 days

• 84 per cent of average job size are under 1000 units, with 30.6 per cent being under 500 report offering commercial print – digital to market

• 42 per cent of businesses are looking to invest in new equipment and upgrades to expand service offerings

• Diversification investment is reported to occur mostly in the next one to two years with 43.09 per cent reporting this focus

• Packaging, warehouse, and logistics and finishing are the three top growth areas (this is the second year that packaging ranks the highest in diversification investment)

• In 2023, promotional products, merchandise, and wide format ranked as the top three. 2024 reports these sectors are receiving investment, however, warehouse and finishing is pushing ahead

• 83.52 per cent of employees are full-time (80.11 per cent in 2023)

• 16.14 per cent of employees are part-time (16.34 per cent in 2023)

• 7.21 per cent of employees are casual employees (12.94 per cent in 2023)

• 4.07 per cent are contracted employees (4.37 per cent in 2023)

• 38.75 per cent of companies currently employ less than 10 employees

• 26.25 per cent of companies currently employ 11 to 30 people

• 12.5 per cent of companies currently employ 51 to 100 people

• 64.91 per cent of industry employ men, while 38.63 per cent of industry employ women and 8.33 per cent employ non-binary people

• Finding candidates with the right skills is the biggest challenge for the industry (68 per cent) and a further 47.3 per cent report finding job-ready candidates is challenging

• 77.78 per cent currently employ one or more first year/stage one apprentice (38.46 in 2023)

• 77.78 per cent currently employ one or more second year/second stage apprentice (53.85 per cent in 2023)

• 55.56 per cent currently employ one or more third year/third stage apprentice (30.77 per cent in 2023)

• 33.33 currently employ one or more fourth year/fourth stage apprentice 30.77 per cent in 2023)

• 2.44 per cent of companies pay 100 per cent to the award (10.29 per cent in 2023)

• 26.83 per cent of companies pay five to 10 per cent above the award (38.24 per cent in 2023)

• 39.02 per cent of companies pay 11 to 20 per cent above the award (36.76 per cent in 2023)

• 21.95 per cent of companies pay more than 20 per cent above the award (5.88 per cent in 2023)

• 51.35 per cent of businesses hold no certifications

• 27.03 per cent of businesses are ISO9001 certified

• 24.32 per cent of businesses are FSC certified

• 8.11 per cent of businesses report carbon mapping

• 8.11 per cent of businesses are SGP certified

• 16.22 per cent of businesses have other certifications

• 18.92 per cent of businesses are ISO 14001 certified

• 8.11 per cent of businesses are PEFC certified

• 8.11 per cent of businesses are APCO certified.

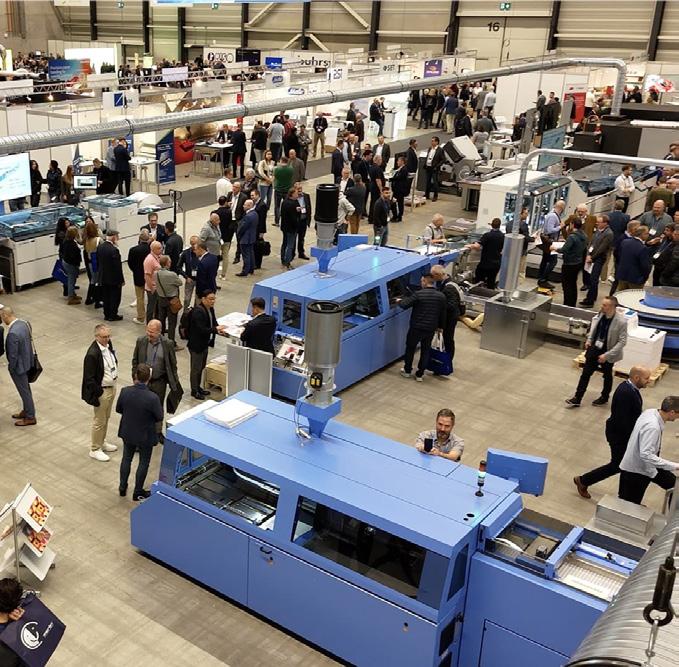

The event, which recently took place in Lucerne, Switzerland, offered attendees a chance to see the latest and greatest in digital print, inkjet, and finishing technology

The 15th edition of Hunkeler Innovationdays 2025 presented the latest and greatest in high performance digital print, inkjet, and finishing technology. With an interdisciplinary concept, the event stood out as an exciting and knowledgeable place to network and connect.

The biennial event, held in Lucerne, Switzerland, was Hunkeler’s first since its acquisition by Müller Martini. It offered live demonstrations, interactive exhibits, and in-depth discussions with industry experts in high volume digital printing technology.

Canon leads the way in digital transformation

For Canon’s customers and prospects, Hunkeler Innovationdays was a chance for them to experience ‘The Power to Move’. There were several opportunities to get hands on with the latest Canon technologies in commercial printing, and discover how companies have used its innovations to redefine the possibilities of print.

Canon reaffirmed its commitment to commercial print by displaying the latest digital print technologies and shared how its automated, end-to-end solutions deliver the efficiency, flexibility, and quality required for sustainable growth.

From live examples of how Canon supports print service providers in identifying new business opportunities, to defining matching strategies and business models, and how to select tailored workflow and press technologies to accelerate digital transformation, Canon offered a roadmap to success.

Products on display included:

• The ProStream 2000 production printer – an industrial-scale inkjet printer that allows for greater flexibility, fast-setup times and high-quality output. It prints at up to 133m/min and has a print quality of up to 1200dpi by 1200 dpi. It also protects the environment through reduced energy consumption, optimal paper usage, and maximises productivity via an improved product platform.

The machine also prints on a variety of applications including books, medical leaflets, travel books, business statements, and newsletters. It prints on a wide range of media including uncoated, matt, silk, and gloss coated offset media and on inkjet papers up to 300gsm.

• The Canon varioPRINT iX3200 –a high speed, high uptime, high value digital colour press. Canon’s sheetfed inkjet technology offers a streamlined production workflow and stable performance, with little to no setup time.

At its core, the varioPRINT iX3200 delivers ultra-fast production speeds of 9120 SRA3 duplex images per hour, high uptime (more than 90 per cent) with automated efficiencies, and minimal labour involvement. That all adds up to an attractive total cost of ownership and streamlined production.

• PRISMA Cloud Services – an easyto-use central web platform that allows users to access their PRISMA cloud-based workflow applications and print management tools 24/7.

Part of the software, PRISMA Home allows users to take their print operations to new levels of efficiency and allows them to self-activate applications

and manage users, subscriptions and devices wherever they are.

Fujifilm showcases its Jet Press 1160CFG inkjet press

Fujifilm’s new continuous feed inkjet press, the Jet Press 1160CFG, was featured alongside several integrated inkjet solutions as the company demonstrated how strategic partnerships are helping to add value for customers.

In line with the Hunkeler Innovationdays 2025 theme, ‘Connect’, Fujifilm partnered with several vendors to demonstrate the full capabilities of its inkjet solutions.

The Jet Press 1160CFG took centre stage on the stand. Launched at drupa 2024, the Jet Press 1160CFG is a high-speed full-colour continuous feed inkjet printer. The printer is equipped with a newly developed ‘Paper Stabiliser’, designed following vigorous R&D and analysis of paper characteristics during high-speed continuous feed printing.

The conditioning unit enhances productivity, production efficiency, and print and finishing quality by regulating the amount of moisture in the paper before printing. With the enhanced drying technology, the press delivers highspeed printing of 80 meters per minute –even on thick and thin coated paper.

Fujifilm showcased the press in collaboration with Hunkeler’s finishing equipment to produce high quality promotional postcards live at the show. Additionally, a joint demonstration with Meccano Tecnica highlighted the possibilities of Fujifilm’s inkjet technology for high quality, flexible, short-run book production. Finally, Fujifilm showcased instant switching capabilities between books of varying sizes and pagination, in collaboration with Horizon and its StitchLiner technology.

In addition, Fujifilm had on show its integrated inkjet solutions. Integrated inkjet is an approach that custom-integrates an inkjet print engine into an existing press or other print equipment. Fujifilm’s inkjet integration experts were in attendance to demonstrate the many ways this can be done.

Fujifilm’s inkjet print engines on display at Hunkeler Innovationdays included the 42K Printbar System and the Mini 4300 Printbar System, which can be placed in various locations of the process including in places where finishing alone typically resides.

Fujifilm has integration products for a wide range of printing including monochrome, four colour, extended gamut, jettable functional fluids, and spot varnish embellishment.

“Our participation underscores Fujifilm’s commitment to innovation and collaboration, in keeping with the ‘Connect’ theme of this year’s show.

The Jet Press 1160CFG is a milestone product for Fujifilm,” Fujifilm EMEA head of digital press solutions Taro Aoki said.

“There is nothing else like it on the market, particularly with its advanced paper stabiliser. We have been market leaders for continuous feed inkjet in the Asia Pacific region for some time and we’re now delighted to be bringing this technology to the European market.”

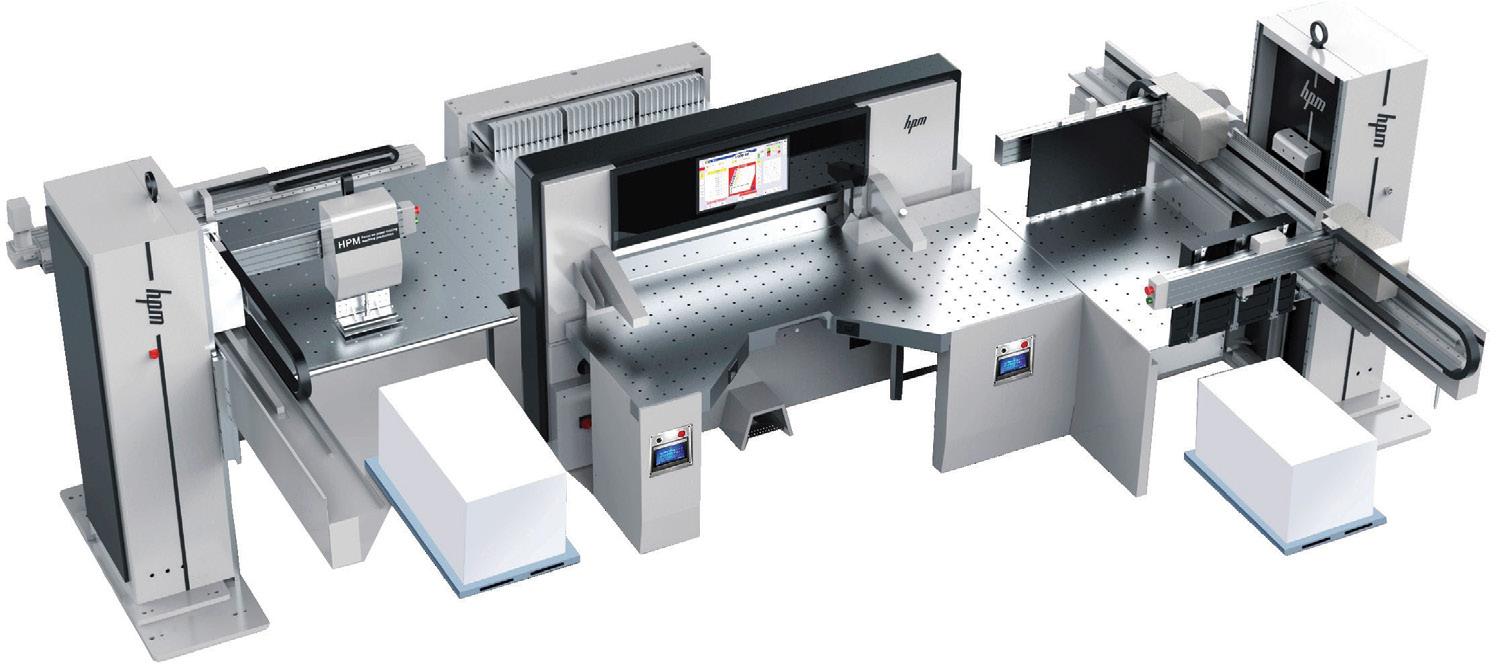

Heidelberg unveils new Stahlfolder

Heidelberg took the wraps off its new Stahlfolder TH 56/66 models for automated end-to-end production in digital printing in a world first at Hunkeler Innovationdays 2025.

The Stahlfolder TH 56/66 Fireline for nearline postpress operations in digital printing enables highly automated processing of digitally printed sheets in a single operation, all the way through to the finished cut and folded print product.

Cutting, creasing, and folding all take place in just one pass.

The Stahlfolder TH 56/66 Fireline is also fully integrated into the Prinect workflow. As a result, the system can be preset automatically based on the job parameters from Prinect and with no operator intervention.

The standard programs stored in the system cover a wide range of different end products. The possibilities with the Jetfire 50 include A3 and A4 posters trimmed on all four sides for full-bleed motifs, four-page pamphlets (A4 portrait plus A5 portrait and landscape), and

eight-page A6 products with concertina, parallel, or letter fold. To minimise the number of system changeovers, Prinect groups similar orders into batches, and these jobs are then completed one after the other on the Jetfire 50 and the Stahlfolder TH 56/66 Fireline.

The company also showcased its digital ecosystem for end-to-end production based on the new Jetfire 50 at Hunkeler Innovationdays. The Jetfire 50 is based on inkjet technology from Heidelberg’s cooperation partner Canon and marks its expansion into industrial digital commercial printing.

“In the industrial printing context, efficient and highly automated postpress operations are vital if production departments are to process a large number of highly diverse orders efficiently and ensure the profitability of digital print production. That makes our new Fireline postpress solution a key addition to the Heidelberg digital ecosystem, taking us a big step closer to end-to-end print production,” Heidelberg chief technology and sales officer Dr. David Schmedding said.

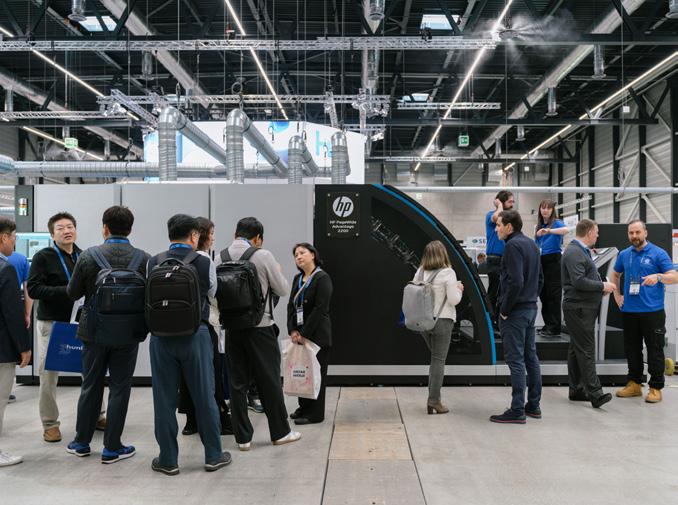

HP proudly demonstrates its PageWide Advantage 2200

HP took to Hunkeler Innovationdays to introduce a smaller, cost-effective new configuration for its HP PageWide Advantage 2200 web inkjet press. The new configuration features a single-zone drying system and a passive web cooling module, allowing customers to print mono and full colour jobs efficiently across a wide range of uncoated and coated applications.

Designed for PSPs whose primary print offering includes uncoated media, the new configuration offers the opportunity to expand into high-value commercial print applications on offset coated media.

While optimising total cost of print, the press has the capability of printing colour jobs up to 244m/min with PageWide’s powerful new Performance Economy Color print mode. Built on a modular platform, the new configuration can be upgraded with additional drying and web cooling, to enable PSPs to scale capabilities as their business grows.

“Our customers value the flexibility of the modular HP PageWide Advantage 2200. The digital press enables PSPs to offer print solutions that meet customer needs and growth aspirations for their business,” HP PageWide Industrial vice-president and general manager Barbara McManus said.

“With the new single-zone dryer configuration with passive web cooling, more businesses than ever can access a unified platform that supports diverse printing applications and differentiate themselves from competitors with high value jobs, all in one easy to upgrade press.”

HP also demonstrated its fastest integrated book production solution at the show, printed with both HP Indigo Liquid Electrophotography (LEP) and HP PageWide Thermal Inkjet (TIJ) printing technologies.

The fully integrated book production line was orchestrated by the HP Intelligent Automation Platform, PrintOS. Leveraging HP Site Flow, nearline intelligent automation with HP PageWide Smart Workcell Controller and partner technology from Hunkeler, Harris & Bruno, Müller Martini, IDEAL, Movigo and Spencer Metrics, the solution produced more than 750 books live but can produce up to 2,000 books per hour.

HP Indigo also introduced the next generation of consumable supplies designed to enhance print sustainability and boost productivity. The key innovations include the CMYK+ with new advancements such as a higher ink solid concentration, the Printing Imaging Plate (PIP+) with a new formulation in two key layers, and the Regenerated Imaging Oil (RIO), in-press recycling system for the ink carrier.

Hybrid Software highlights performance and quality

Hybrid Software, a full-stack supplier of all critical core technologies needed for industrial inkjet printing, took to Hunkeler Innovationdays 2025 to feature a full array of cutting-edge solutions for labels and packaging, software and hardware for inkjet press OEMs, and colour management.

Hybrid’s OEM business unit (formerly Global Graphics Software) highlighted SmartDFE, a digital front end for singlepass, high-speed digital presses.

SmartDFE’s capabilities include an AI-accelerated Harlequin RIP farm that drives data inline directly to the printhead electronics and OPC UA connectivity for industrial print environments, as well as integrated prepress workflow automation and advanced PDF editing tools.

Meteor Inkjet, an independent supplier of industrial inkjet printhead driving solutions under the Hybrid Software Group, was also at the show discussing printhead drive electronics and waveform development for inkjet printing devices.

In addition, Hybrid’s ColorLogic business unit demonstrated its latest colour management products that deliver superior colour accuracy, consistency, and flexibility for even the most complex print jobs.

“We regard Hunkeler Innovationdays as a very prestigious event in the industrial inkjet calendar,” Hybrid Software CEO Mike Rottenborn said.

“It’s always enjoyable – a gathering of like-minded people in a very focused setting – and provided an opportunity to connect with customers and OEM partners and listen to their challenges.”

Kodak showcases its “world’s fastest” inkjet press

Kodak demonstrated speed and versatility in inkjet production printing by running live demonstrations of the Kodak Prosper 7000 Turbo Press, calling it the world’s fastest web-fed full-colour inkjet press. The show was the Prosper 7000 Turbo Press’ first appearance in Europe.

Kodak demonstrated the Prosper 7000 Turbo Press printing with water-based Kodak Ektacolor Inks in a roll-to-roll configuration with an unwinder and a rewinder designed and manufactured by Kodak.

The Prosper 7000 Turbo Press is capable of printing at speeds of up to 410m/min. Its three print modes – Turbo, Performance and Quality – enable printers to easily fine-tune optimal speed and quality balance for each job.

The company said these capabilities make the Prosper 7000 Turbo Press an excellent solution for migrating larger direct mail,

commercial, transactional, and book printing jobs from offset to digital.

At the show, Kodak printed various applications at super-fast speeds on the Prosper 7000 Turbo Press several times a day. Along with scheduled demos, printers booked individual demonstrations of the press through Kodak sales representatives.

Visitors to the Kodak booth also had the opportunity to view a vast collection of print samples illustrating the high-quality output and the variety of applications that can be produced with the Kodak Prosper Ultra 520 Press, powered by Kodak Ultrastream Technology, and the new Kodak Prosper Print Bar, which incorporates Kodak Prosper Plus Imprinting Systems.

Kodak, in cooperation with partners Horizon International and Hunkeler, also demonstrated the efficient processing of paper rolls printed on Prosper Presses into finished printed products. A saddlestitched catalogue was produced on a Horizon iCE StitchLiner Mark V, and a Hunkeler paper processing line will handle a demanding direct mail application.

“We were excited to bring the Prosper 7000 Turbo Press to Europe for the first time and to raise the bar in terms of speed and production efficiency at Hunkeler Innovationdays. This cutting-edge inkjet press helps printers transition from offset to digital production and profitably serve their customers,” Kodak CEO and executive chairman Jim Continenza said.

“Our Prosper Presses, using high-speed continuous inkjet technologies and proprietary Kodachrome and Ektacolor Inks and Kodak Optimax Primers, help printers succeed in the ‘and’ era of print by providing ultra-productive, cost-effective printing of a wide range of applications.”

Kurz sets new standards and redefines digital embellishment

Kurz presented its latest technologies and solutions at Hunkeler Innovationdays, where it demonstrated how digital embellishment is setting new standards with outstanding productivity, speed and efficiency.

Visitors also saw some of its machines, applications and solutions, including the

DM-MAXLINER 2D, a highly industrialised solution for digital sheet embellishment that was shown live in action using high-quality substrates from its cooperation partner Sappi. Following its successful premiere at drupa 2024, the machine was presented again in an exclusive setting.

The DM-MAXLINER 2D combines patented cutting-edge technology with versatility and enables high-quality metallisation on a wide range of substrates, including openstructured, uncoated papers. Thanks to the patented inkjet-on-transfer technology, the machine sets new standards in precision, print quality, and reliability.

As an interactive state-of-the-art exhibit, the DM-UNILINER 3D offered a technology deep dive into 3D inkjeton-substrate technology for label and roll applications. Event participants experienced how this technology produces fascinating effects and exciting creations in just one work step, through digital metallisation and coating. The flexibility of the machine enables flat and tactile effects from four to 100 μm with impressive quality on an industrial scale.

With the ultra-compact MCUBE complete solution, Kurz subsidiary MPRINT presented economical and easy-to-integrate solutions for variable data printing. These are ideal for latestage four-colour printing on labels with QR or barcodes and batch numbers.

Kurz also presented a wide range of applications and exhibits for hot, cold and digital embellishment as well as security solutions for brand protection.

Ricoh puts end-to-end automation on display

Ricoh demonstrated highly automated end-to-end processes that enhance the productivity of print operations.

Ricoh’s expansive high-speed inkjet and sheetfed production portfolio, represented by Ricoh Pro VC80000, Ricoh Pro VC40000, and Ricoh Pro C9500 technologies, as well as an interactive presentation of the Ricoh Pro Z75 B2 inkjet press, demonstrated how everyday capabilities can be elevated to create a highly productive concept to completion environment.

The company said efficient and profitable end-to-end production begins with software solutions including the Ricoh TotalFlow BatchBuilder, that simplifies and automates many steps in short run digital production, and Ricoh ProcessDirector, that captures, transforms and manages production information and print processes with precise tracking.

Ricoh Predictive Insight, first introduced on the Pro VC80000 high speed inkjet press, provided data driven insights into device utilisation and operator productivity. Ricoh said by using Artificial Intelligence and machine learning capabilities, processes and operations are monitored to help optimise hardware uptime and throughput while minimising maintenance interruptions.

Completing the highly connected approach was a new automation protocol called Print Line and Finishing Interface (PLF-I). This open-source interface enables a step change in communication between web fed printers such as the Pro VC80000 and pre- and post-processing equipment, resulting in enhanced automation.

Elevating print production automation further, Ricoh executives said the Ricoh Auto Color Adjuster provides easy, fast and accurate colour management capabilities, and ensures consistency from system to system and job-to-job.

Ricoh Europe Graphic Communications vice-president Eef de Ridder said, “Automation has the power to positively enhance every stage of the print production process. The increased role of AI and machine learning provide levels of understanding, operational improvements and touchless workflows that help reduce pressures and increase productivity.

“Building on the ‘Connect’ theme of Hunkeler Innovationdays 2025, Ricoh demonstrated how automation also continues to elevate hardware and software capabilities and allows commercial, transactional, and enterprise printers greater freedom to competently and confidently expand their service offering.”

At the tradeshow, Screen showcased innovative inkjet printing solutions under the theme “Powering Print Connections”. Visitors to the Screen booth experienced a range of solutions designed to elevate print production to new levels, such as: Truepress JET 560HDX with Hunkeler finishing integration: The flagship Truepress JET 560HDX combines printing precision with seamless finishing equipment integration. Regular live demonstrations illustrated how the new Truepress SC2 Ink produces high-resolution 1200 dpi full

colour output at productive speeds of 150m/min, without primers and on offset-coated papers.

The new Truepress JET 520NX AD: Engineered for transactional and direct mail printing, the Truepress JET 520NX AD was unveiled at Hunkeler Innovationdays 2025 with live demonstrations – printing at 225m/min. This press sets a new standard in high-speed performance for the transactional printing market as it can bring dense, high-contrast designs and legible text on thin 40 gsm substrates.

Collaborative partnerships for innovative digital inkjet solutions: With Hunkeler Innovationdays 2025 highlighting the importance of a smooth, integrated print production workflow, Screen showcased its partnerships with various industryleaders in print finishing, workflow solution developers, and MIS systems.

IBIS Bindery Systems’ saddle stitch binding system was on the Screen booth, providing visitors with a window into digital print production, processing printed rolls from various digital inkjet presses as they are saddle stitched and bound, ready for packing and shipping to clients.

Screen also supplied rolls printed on its Truepress JET 520HD+ system with SC+ inks to the Hunkeler and Horizon booths and provided support during both companies’ demonstrations using control barcodes generated by EQUIOS workflow, and showing in real-time, the smooth transitions between different jobs within rolls during postprocessing.

Screen Australia managing director Peter Scott, who was on the ground, said, “The great thing about this event is its focus on highest-volume digital print and finishing. It’s definitely ‘big end of town’ for digital printing, both reel and sheetfed and Hunkeler bookends the amazing technology on show with its excellent feeding and finishing technologies covering books, direct mail, pharma, transactional and now even magazine and commercial print thanks to advances in ink and drying.”

*Photos courtesy of LinkedIn and attendees of Hunkeler Innovationdays.

Müller Martini and Hunkeler continue to innovate and pave the way for a new era of printing excellence, which was recently demonstrated at Hunkeler Innovationdays

Müller Martini recently demonstrated its industry leading innovation at Hunkeler Innovationdays 2025. The three smart factory solutions presented revolutionise production processes in the digital printing industry for the long-term.

With 6,800 participants and 120 exhibitors presenting 40 live solutions, the event grew once again year on year.

“We are proud that together with our partners, we were able to present pioneering solutions during the four days of the trade fair that will shape the future of the digital printing industry,” Müller Martini CEO, Bruno Müller said.

Impressive smart factory solutions

For the first time, Müller Martini presented a significantly larger booth, integrating technologies from multiple vendors. This setup reflected the broader global industry trend toward collaboration, where printing presses, finishing equipment, and workflow solutions are no longer isolated systems but part of a cohesive production line.

“This is what we face these days. When we talk about ‘Smart Factories’, we talk about combined lines with presses from different vendors, and we add the finishing to it. On top of that, we have our workflow solutions. This approach allows for greater efficiency and flexibility, ensuring that print jobs are seamlessly processed from start to finish,” Müller Martini Australia country manager Ian Sampson said.

All three Smart Factory applications on display captivated countless visitors to the Müller Martini booth and demonstrated how Müller Martini can set new standards for end-to-end production processes in collaboration with its partners.

Visitors also experienced how a finished softcover book was produced inline from both the white roll and the white sheet – from the digital web-fed or sheet-fed printing machine to the cutting robot with subsequent sorting line, fully automated and without manual intervention.

Customers from across the globe were particularly impressed, stating, “Müller Martini has networked everything that can

be networked on its booth. From the white roll to the finished book – it’s fantastic to see how everything works seamlessly”.

Highlights included the showcase of the Vareo PRO perfect binder and the InfiniTrim cutting robot, which are ideal for digital printing productions, especially due to the elimination of changeover times.

“The ability to implement individual customer requirements quickly and efficiently with these networked solutions is a decisive advantage in today’s fastmoving printing industry. Müller Martini is heading in the right direction with these innovations,” Sampson said.

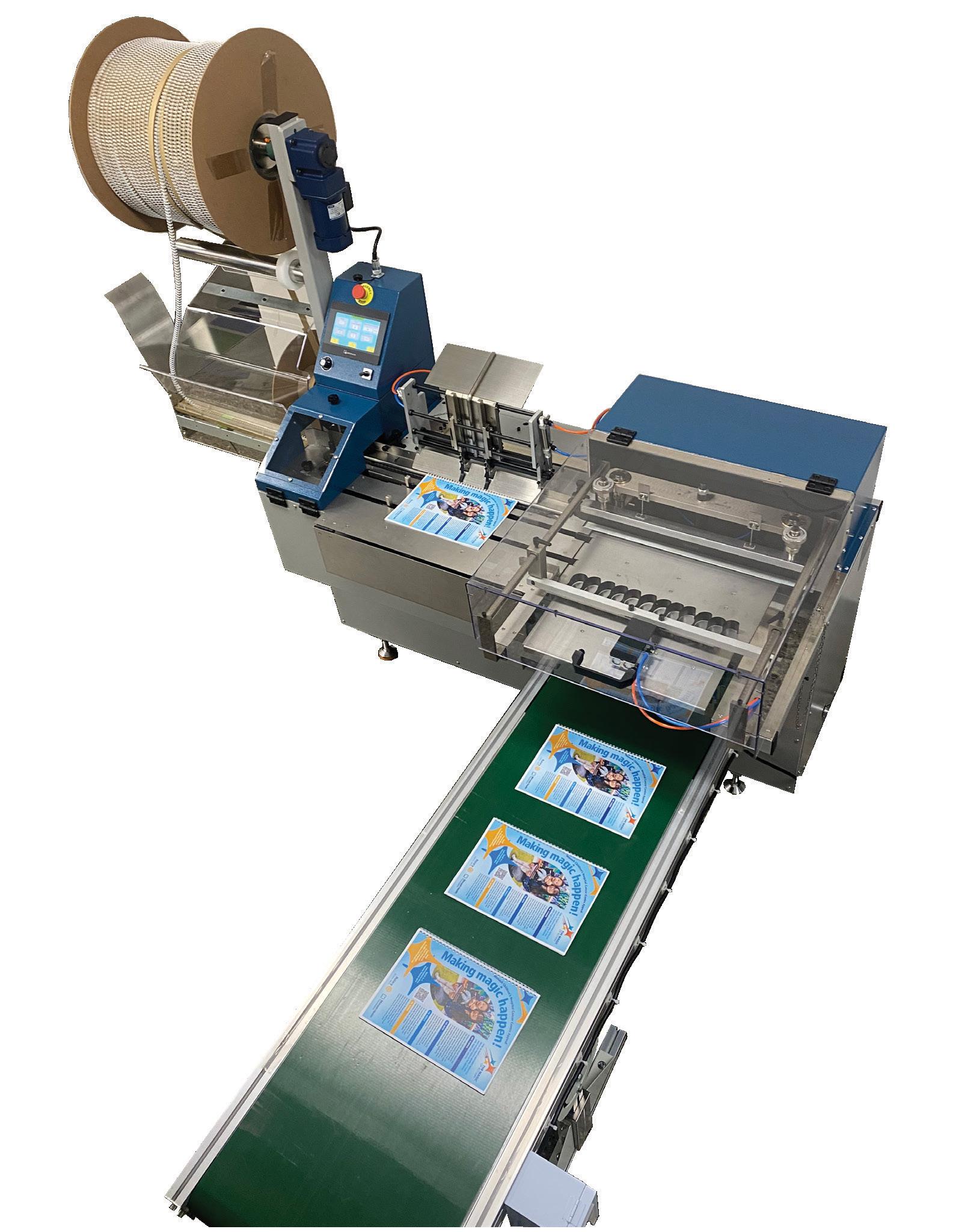

The Prinova Digital saddle stitcher on show also produced eight different saddle-stitched products in very short runs from the roll in a continuous process.

By integrating finishing solutions such as Hunkeler Unwinding, Folding and Cutting High Precision Binding and Trimming, Müller Martini demonstrated a nearly ‘lights-out’ production environment.

“We needed to be able to demonstrate that such machines can run independently with as little personnel as possible as we know finding skilled operators is challenging,” Sampson said.

“I believe, one of the major challenges in modern print production is handling diverse job specifications on a single roll of paper – there could be 100 different jobs, all variable in content. These jobs may have varying page counts, sizes and cut lengths. Our Connex Workflow ensures every job is

tracked and finished correctly, even when dealing with complex, mixed format jobs.”

Müller Martini also showcased connectivity at its stand. The Connex workflow system, a key technology to produce individualised print products, controlled all three lines from the digital printing press to the finished sorted product stack. The seamless integration of all production steps, from impositioning the print data to sorting the finished products, fascinated the trade visitors.

The printing industry is in a digital revolution, with requirements for shorter print runs and an increasing demand for customisation, according to Sampson.

“To embrace the digital transformation is to remain competitive. Print runs are shrinking globally and the companies that can handle this shift require the right equipment. Müller Martini and Hunkeler demonstrated this at HID25,” Sampson said.

To meet these evolving needs the teams at Müller Martini and Hunkeler have integrated transactional and trans promotional applications expanding their finishing capabilities. With the acquisition of Hunkeler, the Müller Martini portfolio now includes additional applications that further streamline ‘print to finish’ workflows.

As Innovationdays concluded, those that made the effort to travel to Lucerne to witness these efforts were demonstrated to a show of fully integrated, automated print factories that to some was just a vision.

“Seeing was believing. Once visitors and customers see how seamlessly our systems work together, the complexity fades away. With Smart Factories, connected Workflows and Automated finishing solutions, the future of print production is clear – it is faster, more efficient and highly adaptable to market demands,” Sampson added.

Müller Martini and Hunkeler, together, continue to innovate and pave the way for a new era of printing excellence.

Müller Martini is the leading provider of system solutions for digital transformation processes in the printing industry, catering to both smart factory and conventional manufacturing customers. mullermartini.com

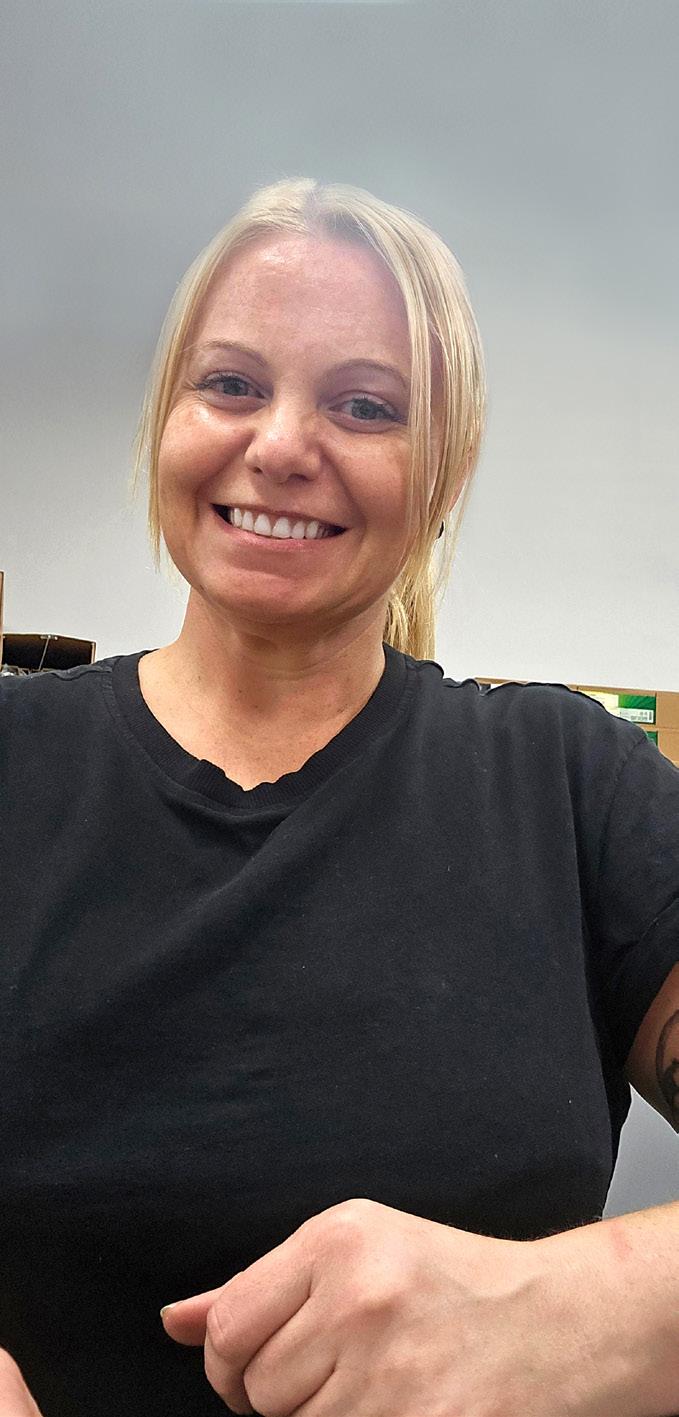

When Sharna Beck started her career in print, she quickly realised it was not just a job but an art form that required precision, creativity, and technical skill

Sharna Beck, HP Indigo digital press operator from Southern Impact, has had a steady, upward trajectory in her performance and personal development.

Beck, who was named by Women in Print Australia as the winner of last year’s HP Dscoop giveaway, travelled to APJ Dscoop in Cebu, Philippines, where she joined a global community of HP Graphic Arts users, industry leaders, and innovators for a unique opportunity to network, learn, and grow alongside some of the brightest minds in the printing industry.

But Beck’s initial transition into print was purely coincidental. With a background in hairdressing and business administration, alongside her personalised apparel merchandise and signs side hustle, Cre8, she never anticipated taking the path in print.

Beck’s digital print journey began in 2018 in the mail room at Southern Impact in Victoria, where she trained on several digital presses before later joining the company’s digital department as an HP Indigo digital press operator.

“It turned out to be a pivotal moment in my professional journey,” Beck said.

“As I began working in the mailing department, I quickly realised that print was not just a job but an art form that required precision, creativity, and technical skill,” she said.

“My early days involved learning the intricacies of mailing processes, and I became proficient in operating various machines. This fundamental experience was critical as it instilled a deep understanding of the workflow in print production.

“Through hands-on practice, I evolved from a beginner to someone capable of troubleshooting and diagnosing machine issues, which helped me gain respect among my peers. As my interest in printing grew, I sought further knowledge and skills.”

Within a year, Beck completed training on the HP Indigo Series 3 and Series 4 digital presses, making her the only digital operator at Southern Impact with the ability to run all four digital presses, which includes three Indigo presses –

an HP Indigo 7600, HP Indigo 7800 and B2-sized HP Indigo 15K digital presses.

“Pursuing certifications like the HP Indigo Series 3 and 4 level 1 further solidified my expertise in the field. I also worked with Xerox and Konica Minolta machines, which allowed me to delve deeper into the mechanics of printing. The experience of producing variable data jobs like flyers and postcards ignited my passion for digital printing,” Beck said.

“Being part of a team that values collaboration and mentorship has been a rewarding experience. The wealth of knowledge shared among colleagues has been an indicator of how integral teamwork is in achieving success within the industry.”

Beck also received the Printers Award at APJ Dscoop, which she said is a testament to the collective efforts and unwavering support from her colleagues.

As a woman in the print industry, Beck draws inspiration from several industry figures including Southern Impact commercial digital print general manager, Wendy Coss.

“I find motivation in trailblazing women in our industry, who have shattered glass ceilings and challenged stereotypes. Their stories are a powerful reminder that perseverance and dedication can lead to significant changes in an otherwise traditional field,” Beck said.

“Wendy has been a significant mentor in my career, not only in giving me the opportunity to pursue a new direction but also opening the doors to a new set of possibilities as a digital printer.

“Additionally, I am inspired by colleagues like Indigo guru Marcus Cafolla, lead digital printer at Southern Impact, who has equipped me with valuable tools by sharing insights, providing constructive feedback, and encouraging me to push my boundaries.

“My mentors have played a critical role in equipping me with the tools I need to learn and print effectively. They provided not just industry-specific skills but also essential leadership qualities, such as confidence, resilience, and effective communication.

“Their guidance helped me navigate challenges and taught me the value of networking and collaboration. With their support, I’ve learned to embrace my unique perspective and use it to drive innovative solutions within the business.”

Looking ahead, Beck’s aims include not only advancing her professional skills but also contributing to a more sustainable and equitable print industry.

“I envision a future where diversity is not just an initiative but a fundamental aspect of our business operations. By engaging in continuous learning and advocating for women’s leadership roles, I aim to cultivate an environment where everyone can succeed,” she added.

“My journey in print has been filled with continuous learning and growth, and I look forward to what the future holds in this exciting field.”

2024 was another year filled with contrasts and transformation for the print industry. While economic conditions remained unpredictable, businesses that stayed agile and invested in the right technology found opportunities for growth. The most successful businesses focused on adaptability.

The biggest challenge remained the cost of doing business, with rising wages, material costs, and supply chain pressures requiring smarter investment decisions.

We witnessed a strong appetite for automation and efficiency-driven solutions as companies focused on streamlining operations and improving profitability. A real shift towards low-touch workflows also emerged, reducing manual labour and increasing efficiency.

Sustainability also became a more urgent priority, with customers demanding real action rather than just conversation.

Diversification was another major subject, with many printers expanding their offerings into adjacent markets –whether through labels and packaging, sign and display, or large format. Those who leaned into personalisation and customisation also set themselves apart, taking advantage of digital print’s flexibility. Above all, businesses that stayed relevant had one thing in common: they embraced change rather than resisting it.

2025 will be about efficiency, innovation, and sustainability.

The industry has started shifting towards leaner, smarter, and more connected operations. AI and automation will continue to reshape workflows, while robotics will play an even bigger role in reducing manual intervention.

Opportunities in automation and workflow optimisation will result in speed to market becoming an ever-increasing differentiator. The demand for short-run,

high-value applications continues to grow, and those who embrace it will thrive.

Sustainability will no longer be an option – it will be a business imperative. We also expect more convergence between digital printing, with datadriven print campaigns becoming more personalised and interactive.

Most notably, the sign and display segment is seeing increased demand for highimpact, high-quality short-run applications, with businesses seeking versatile, durable, and cost-effective solutions – especially in interior decor applications.

Labels and packaging remains a large opportunity, especially as brands look for more sustainable and short-run solutions.

We’re seeing increasing demand for high-end embellishments and finishing, as brands invest in premium-quality print. All these opportunities and innovations will present themselves during this year’s events and tradeshows. We can expect to see major breakthroughs in robotics and AI-driven workflow automation. Print technology will continue to push boundaries in speed, quality, and sustainability, with more hybrid solutions combining analog and digital strengths.

New finishing technologies will also be a highlight, giving businesses more ways to differentiate their output. Sign and display innovations will focus on versatility, with further developments in UV printing delivering enhanced durability and sustainability benefits.

Additionally, we expect to see more consolidation in the industry, as businesses either scale up or struggle to keep pace. The biggest challenge though will be navigating rising operational costs while maintaining profitability.

Labour shortages also remain an ongoing concern, driving automation

as a necessity, rather than a luxury. And of course, keeping up with changing customer demands – particularly around sustainability and speed to market will be critical.

For Currie Group, 2025 is about deepening our partnerships, driving innovation, and expanding our capabilities. We’ll continue to bring the latest technology to market, helping customers unlock new revenue streams.

Investment in service remains a top priority, as we know that the best equipment is only as good as the support behind it. We’re also looking at key strategic growth areas, particularly in labels and packaging, sign and display, automation, and finishing solutions.

We are also actively working with our partners to bring more energy-efficient solutions to market, alongside materials and processes that reduce waste.

A major focus for us is our partnership with the HP Planet Partners Program and Close the Loop initiatives committed to reducing waste by recycling and repurposing printing hardware and consumables.

Beyond these efforts, we are actively supporting our customers on their own sustainability journeys, providing education and customised strategies to help them implement more responsible and efficient printing practices.

To conclude, the industry needs to embrace change to thrive. The businesses that will succeed in 2025 and beyond are those that invest in the future, stay agile, and focus on value creation.

The industry is evolving at an incredible pace. AI, automation, and sustainability are no longer trends, they are business imperatives. Continue to innovate, invest for the future, and push the boundaries with trusted partners. The future is filled with opportunities.

In 2024, the industry experienced drupa for the first time in a long time, with everyone returning to Düsseldorf for the largest print event on the planet with high expectations.

It was great to experience the largest exhibition booth that Durst has constructed anywhere in the world, that was expanded even further with the impressive products featured on the adjacent from the joint venture with Koenig & Bauer.

The products showcased at drupa in 2024 represented the latest digital platforms that now provide solutions for businesses who previously would not have considered Durst as their primary partner of choice. But as Durst CEO Christoph Gamper said at the inaugural ProPack Packaging Forum in Sydney in October 2024 – “Digital is no longer wearing its baby shoes”.

Durst now has a broad range of digital platforms that offer versatility, speed and quality that are now attracting businesses not only from the wide format sector, but also more traditional print categories including lithographic, flexographic and packaging.

Coming into 2025, this momentum has continued with Durst’s client base expanding beyond its traditional sectors with new customers who have embraced the opportunities from digital technology die to the changes in market demands, order sizes, turnaround times and versioning.

We have continued to see the packaging sector growing exponentially and we will