Epson fabric solutions let you say ‘yes’ to more work.

Enjoy more vibrant and accurate colour with better image quality and faster production speeds. Benefit from flexible media support, advanced management tools, and reduced operational costs with up to 5 years comprehensive service cover, including printheads. Whether it is dye sublimation, DTG or DTFilm, Epson offers superior solutions for your business.

Learn more at www.epson.co.nz/fabric

New printer addresses growing demand for fabric and merchandise customisation.

Epson has launched a new range, the SureColor G-Series and its first wide format printer designed exclusively for direct to film (DTFilm) production: the SureColor G6060.

Designed to meet the requirements of garment creators and merchandise manufacturers, the SureColor G6060 expands on Epson’s extensive range of fabric printers and is the first model dedicated to DTFilm production. Aimed at volume production, it has been designed to deliver consistent quality output with a low running cost, minimum maintenance, and a high duty cycle.

Epson says the SureColor G6060 opens new doors for fabric, apparel and merchandise production with enhanced quality, reliability, and efficiency. Gordon Kerr business marketing manager for Professional Print Solutions at Epson Australia, says, “Epson has many years of experience in the fabric market and has grown to be one of the world’s largest providers of print solutions. We understand that quality and consistency is important for customer satisfaction.

“We also understand maximising reliability while minimising parts and labour expenditure are key to profitable business. The new SureColor G6060 ticks all these boxes and complete with its new designation, is a perfect fit within our fabric line-up.

“In practical terms, by employing the DTFilm process, the SureColor G6060 makes adding images and logos to shirts, pants, and accessories simple and straightforward and thus enables imaging on a much wider range of material.

Epson will demonstrate the SureColor G6060 DTFilm printer at PacPrint25 in Sydney from May 20-23, 2025

“Garment manufacturers seeking a dedicated DTFilm production system can now easily and cost-effectively create custom workwear and teamwear. They can produce event and show merchandise alongside value-add clothing and a wide range of other items including coasters, umbrellas, notepads, and binders.”

The Epson SureColor G6060 features a compact design with all front loaded consumables. It supports film in rolls up to 900mm wide and 250mm in diameter. It incorporates an auto-cutter for sheet based production and can be used ‘inline’ with a range of third-party powder shaker/oven machines for roll-based production.

A 33mm eight-channel PrecisionCore Micro TFP printhead supports print speeds up to 17 metres per hour in colour + white and 32.6 metres per hour in white or colour only. Inkless nozzle status monitoring, auto-head cleaning, auto cap cleaning and continuous white ink recirculation ensure consistent high-quality output with maximum productivity and minimum waste.

The printer uses 1.6 litre UltraChrome DF ink packs that Epson describes as “cost-effective to order, easy to agitate, quick and mess-free to load”. The company says that Epson Precision Dot image processing ensures the SC-G6060 can produce accurate and consistent prints with bright colour and an enhanced gamut.

It adds, “Purpose-built for fast and efficient production, the SC-G6060

requires minimal operator oversight and minimum manual maintenance. It takes only a few minutes each week to ensure smooth and reliable operation and features a high duty cycle. It ships with a comprehensive warranty that includes the print head. Service cover can be extended with CoverPlus up to a total of five years for a low total cost of ownership.

The new printer features integrated support for Epson’s Cloud Solution PORT2 service, a free web-based service that you can access from desktop PCs for direct management as well as Android and iOS devices for remote monitoring. The PORT service provides advanced reporting and costing tools while facilitating enhanced support and service for maximum uptime.

Gordon concludes, “The SureColor G6060 is a terrific addition to Epson’s fabric range and should be well received by manufacturers with volume DTFilm production needs. For users with lower requirements and/or those who wish to produce a mix of DTG and DTFilm we will continue to recommend our SC-F1060, SC-F2260 and SC-F3000 models.”

Additional features of the SureColor G6060 include:

• Easy installation with a footprint of just 1.2 square metres.

• Uses a 240V power supply and consumes just 65W when printing.

• Equipped with Epson Edge Print PRO RIP software.

• Sheet-based prints are held for release via the control panel.

• UltraChrome DF ink is GOTS approved, OEKO-TEX Eco Passport certified, and has passed CPSIA Section 108.

The new SC-G6060 will ship with a comprehensive warranty that includes the printhead.

Epson will demonstrate the new SureColor G6060 on its stand at PacPrint25, which runs from May 20-23, 2025, at the Sydney Showground, Sydney Olympic Park.

For more on the new Epson SureColor G6060 go to: www.epson.co.nz

3 Epson: The Epson SureColor G6060 printer is the company’s first dedicated DTFilm wide format printer. Epson will demonstrate the new printer on its stand at PacPrint25 in May.

Features p8-40

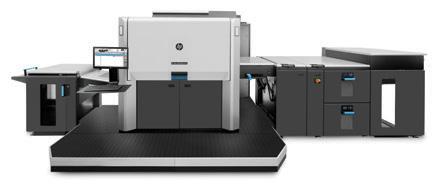

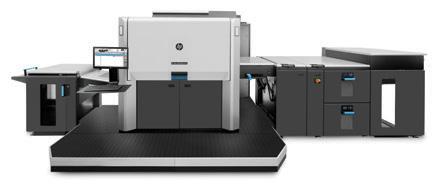

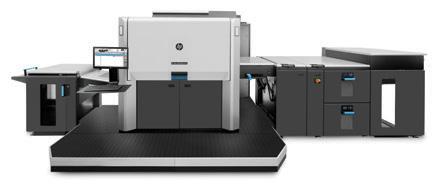

8 Fujifilm Business Innovation: Two new mid-range production presses in the Revoria Press series will shake up the digital print market this year.

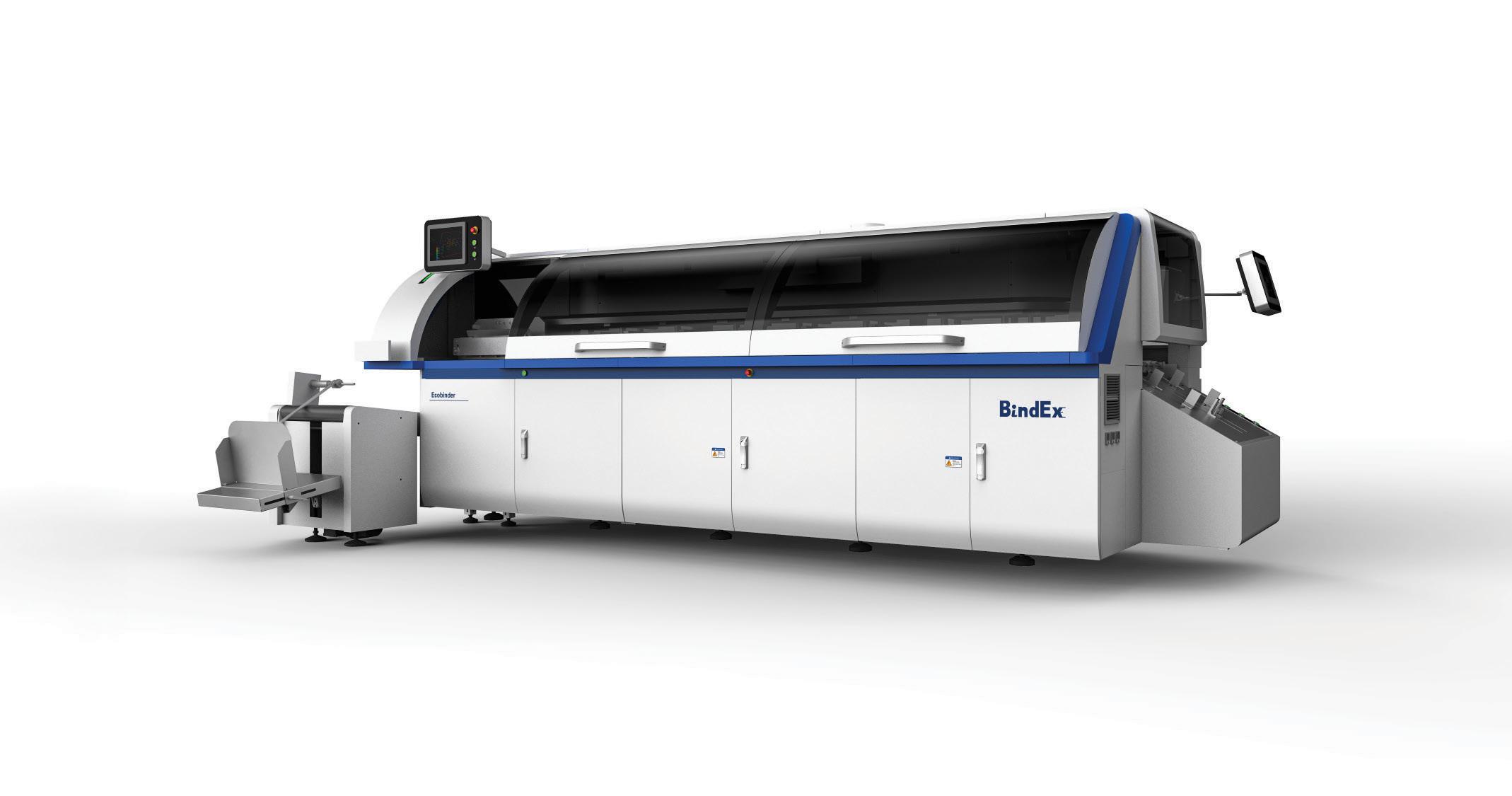

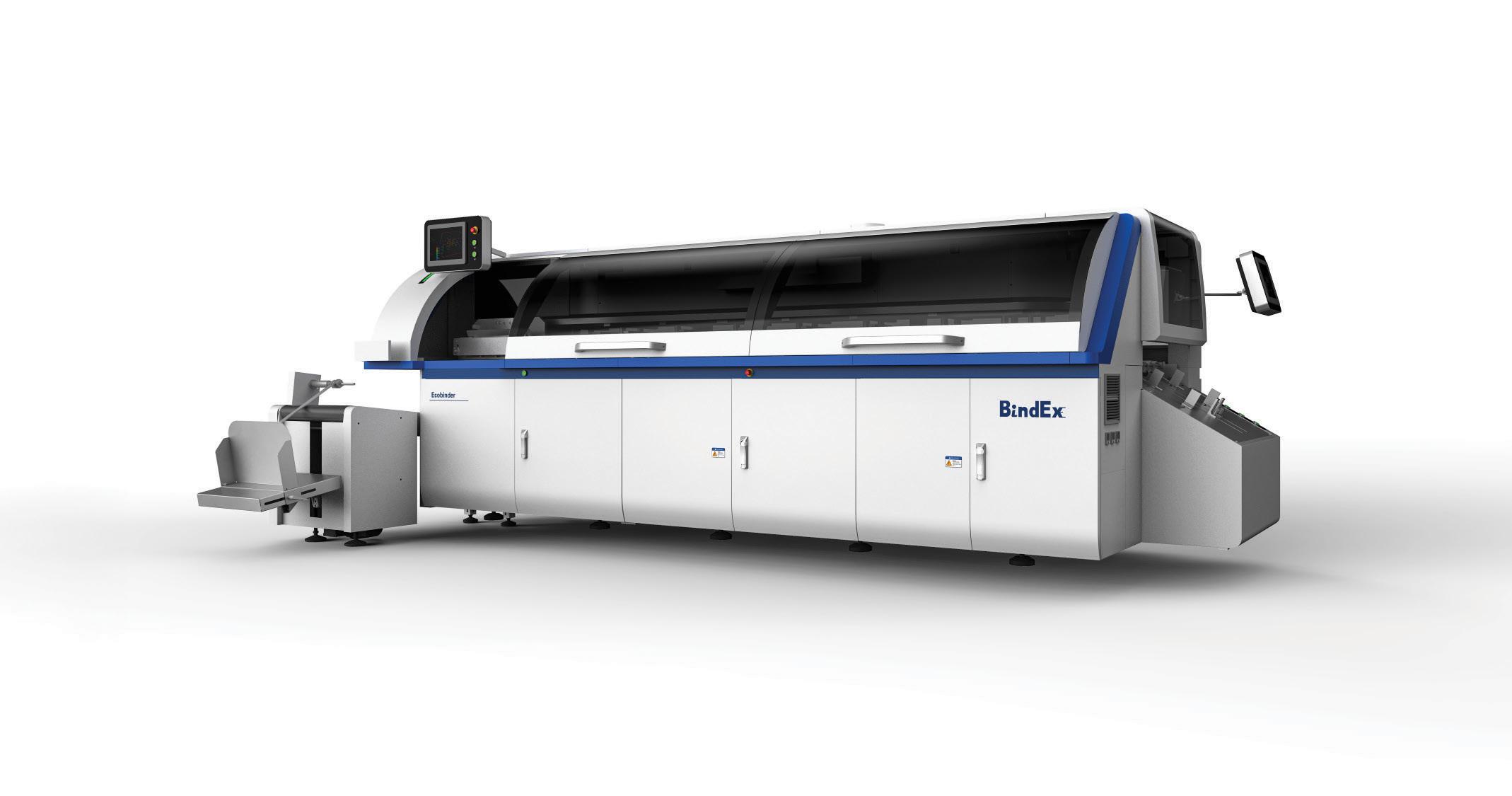

14 Graph-Pak/Pressnet: Bindex finishing solutions are now available in New Zealand through Graph-Pak and Pressnet.

16 Konica Minolta: Chris O’Hara discusses print’s future and its importance in everyday life.

30-31 Fujifilm Business Innovation: Industry professionals enjoyed a leisurely afternoon at the recent New Zealand (FBNZ) Bowls Tournament.

40 PacPrint25: Driving success across the industry is just one of the aims for the upcoming PacPrint25 show in Sydney.

PrintNZ p10-13

10 Helping Hand: PrintNZ kicks off the year with a campaign aimed at strategically raising awareness of the effectiveness and sustainability of print, reports Iain MacIntyre.

13 Ruth Cobb: show how you can get the most out of your PrintNZ membership.

18 AI: At the ProPack Packaging Forum, technology expert Seamus Byrne delivered the keynote speech on generative AI.

20-21 Nekkorb: Tash Brokken details the advantages of the Dantex and MPS ranges of label solutions, supplied exclusively through Nekkorb.

22 Aarque Group: Epson’s new flagship label press, the SurePress L-6534VW is available now through Aarque Group.

24 Jet Technologies: Jack Malki reveals the top three trends redefining the printing industry for 2025.

26-28 Shady Packaging: Vicki Strull explores the good, the bad, and the ugly of brand packaging

34 Durst: Industry veteran Brett Addison has joined Durst Oceania as the new sales manager.

36 NZSDA President: Shae Goom sees a mix of challenges and opportunities for signees in 2025.

37 NZSDA Update: Mikayla Hopkins has the latest from NZSDA, including the new National Sign Making Day.

38 Fespa: The giant wide format show returns to Berlin in May.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS: Ruth Cobb, Shae Goom, Mikayla Hopkins, Iain MacIntyre, Jack Malki, Hafizah Osman, Vicki Strull, Steve Wilton-Jones

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2025: Contents

www.labelexpo-americas.com

Wayzgoose

Wayzgoose 2022

September 17, 2022

September 17, 2022

Napier

Napier

APPEX and Auspack

www.inkianapress.co.nz

Foodtech Packtech

September 20-22, 2022

Auckland

Labelexpo Americas

March 12-15, 2024 | Melbourne Convention and Exhibition Centre

September 13-15, 2022

Chicago, USA

The Association of Handcraft Printers has a full day programme including visits to Havelock Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

People in Print Awards

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise.

www.foodtech.packtech.co.nz

All in Print China

October 11-15, 2022

Shanghai

Auspack has transitioned into APPEX, the Australasian Processing and Packaging Expo. Organisers aim to truly represent all sectors of the industry: machinery, ancillary equipment, materials and packaging, food processing, and industry services. It will provide a comprehensive range of all processing and packaging equipment and services under one roof. www.appex.com.au

Foodtech Packtech

March, 2023 | Auckland

Foodtech Packtech

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

September 20-22, 2022

September 20-22, 2022

Auckland

Auckland

Wayzgoose 2022

www.newzealandprinter.co.nz

Fespa Global Print Expo

March 19-22, 2024 | Amsterdam

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

All Print

All in Print China

September 17, 2022

Napier

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

www.allinprint.com

Nominations will soon open for the People in Print Awards and Rising Stars of Print Awards. Do you know someone who is consistently achieving excellence in their work in this industry? Of course you do, so when the time comes, put their name forward for these awards so they can receive recognition for their efforts.

Letterheads

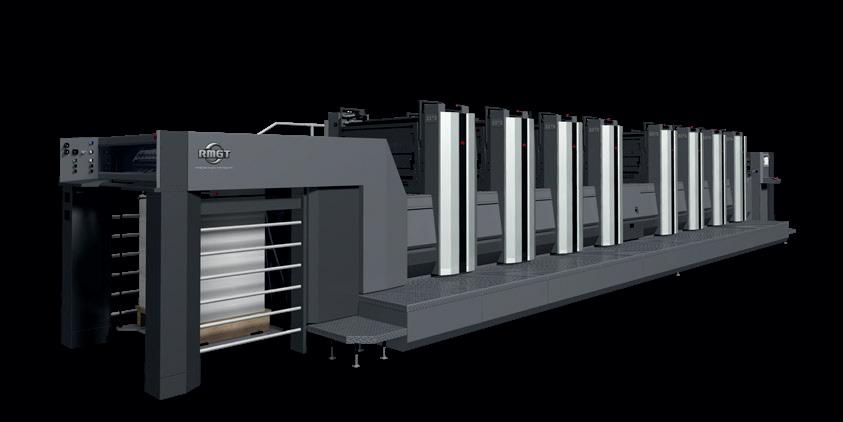

RMGT won the award for high productivity and energy efficiency

October 21-23, 2022

October 11-15, 2022

October 11-15, 2022

Shanghai

Shanghai

Printopia

Covering digital printing, screen printing, textile printing, garment decoration and signage, Fespa Global Print Expo will mix all the latest technology and solutions with events like the World Wrap Masters and Fespa Party Night alongside features such as its Sustainability Spotlight; Personalisation Experience, and Sportswear Pro. www.fespaglobalprintexpo.com

May 3-5, 2024 | Corbans Estate, Henderson

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Sign Foundry, Welling

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Foodtech Packtech

Foodtech Packtech

drupa

The RMGT 1060AX-6+CC+LD press has received the ‘2024 Users’ Prize’ from Printing & Printing Equipment Industries Association of China, recognizing it as one of the most valuable printing products at the 2024 China Printing Association Entrepreneur Forum held in Chongqing, China. Cyber distributes RMGT presses in New Zealand.

Perfector, which won the same award in 2022. We would like to take this

September 20-22, 2022

Craig Paul 027 655 4267 sales@curriegroup.co.nz

Auckland

Now into its third year, the Printopia Festival of Original Print promises a fun, inspiring, print-filled weekend of artist talks, demos, workshops, live printing and of course our print fair. International artist Jenny Robinson will give the keynote presentation on May 4 and a masterclass the following day. www.printopia.nz

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

May 28-June 7, 2024 | Dusseldorf, Germany

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

www.letterheads.co.nz

May 4-10, 2023

Letterheads

Letterheads

October 21-23, 2022

October 21-23, 2022

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

Düsseldorf, Germany

• Consulting and Machine Recommendations Sourcing

All in Print China

• Export/Import Sales

The 1060AX is the model name used in Chinese market for the 1060LX series equipped with the 17,100 sheets per hour high-speed option.

The world’s leading trade fair for printing technologies has opened registrations to again welcome the industry’s main players, and quite a few minor ones. All will show their latest solutions. Visitors can stay on trend with the technology and seminars featuring topics from sustainability to digitisation. www.drupa.com

Sign Foundry, Welling

Sign Foundry, Welling

Visual Impact Brisbane Expo

July 17-19, 2023 | Brisbane

October 11-15, 2022

• Machinery Inspections & Valuations

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

The Printing & Printing Equipment Industries Association of China made the award in recognition of the press’s high productivity and energy efficiency. Earning admiration from the industry, RMGT said, “We are proud to follow in the footsteps of the RMGT 10 Tandem

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

Shanghai

• Plant Relocation OFFICE: 09 8367577, ALEX MOB. 021 975 477 sales@apm.co.nz www.apm.co.nz

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

Visual Connections Australia will host visitors and exhibitors at the Brisbane Convention and Exhibition Centre. The Exhibition hopes to attract over 2,500 visitors interested in the signage, print, graphic and engraving industries and featuring digital printing, personalisation, signage, sublimation, design, routing, display solutions, and vinyl applications. www.visualimpact.org.au

Interpack

Interpack

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

newzealandprinter.co.nz

May 4-10, 2023

May 4-10, 2023

Printing United

www.allinprint.com

Düsseldorf, Germany

Düsseldorf, Germany

Las Vegas, USA | September 10-12, 2024

Letterheads

October 21-23, 2022

Sign Foundry, Welling

Showcasing the latest innovations and applications in specialised printing, the event attracts thousands of visitors from across the printing industry, serving as an exhibition and as a knowledge hub, where experts share their expertise and stimulate discussions about the future of the industry. www.printingunited.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

Fujifilm Business Innovation and Konica Minolta have announced further details and an establishment date of January 31 for their joint venture.

Craig Paul 027 655 4267 sales@curriegroup.co.nz

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

www.letterheads.co.nz

The companies have completed all review and approval procedures under overseas competition laws.

newzealandprinter.co.nz

newzealandprinter.co.nz

In addition, they have named the joint venture company Global Procurement Partners Corp, which they have located in Yokohama, Japan with capital of ¥50m ($575,000). Fujifilm Business Innovation will have a 75 per cent share ratio and Konica Minolta 25 per cent.

President Masaharu Furukawa, corporate vice president and director at Fujifilm Business Innovation will oversee 192 employees, which will

Interpack

May 4-10, 2023

Düsseldorf, Germany

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

EPSON has achieved more than 100 million units in cumulative global sales for its high capacity ink tank inkjet printers. Currently, the company sells these printers in about 170 countries and regions. Yoichi Yamada, chief operating officer for the Office & Home Operations Division at Epson, says, “The values of high capacity ink tank printers, of low printing costs, minimal hassle with ink replacement, and low environmental impact, have led to their widespread acceptance around the world.”

DSCOOP has appointed Angie Mohni, vice president of marketing at Nobelus, a new addition to its global board as its first partner council chair. The new position recognises the pivotal role partners play in fostering innovation, education, and growth opportunities for the print industry. Peter van Teeseling, executive director at Dscoop, says, “Partners are critical to the success of our ecosystem, and Angie’s leadership will help us elevate the collaboration between partners and printers.”

BOBST and ESKO have created smartGravure a new tool that enables gravure printers to benefit from a fully digitalised workflow. The companies say the new tool optimally produces exceptional and consistent quality; minimising waste of substrates and ink; more than halves colour matching time, reduces downtime by 70 per cent and supercharges efficiency. They add that the new technology can be implemented in a gravure press to deliver fully controlled output.

Canon and Heidelberg top management have signed off on the contract for a global cooperation agreement in sheetfed inkjet. The companies announced the agreement at drupa 2024.

The signing took pace at Heidelberg’s Wiesloch-Walldorf site. Heidelberg will sell the new Jetfire 50 B3 inkjet printing system with Prinect connection worldwide and incorporate it into an ecosystem for a hybrid

production environment that also includes offset printing solutions. The company will add a B2 version, the Jetfire 75 and says the market launch of Jetfire 50 B3 inkjet printing system is going completely to plan.

At the contract signing, Heidelberg chief executive officer Jürgen Otto and chief sales officer Dr David Schmedding gave the Canon representatives an overview of

the new Jetfire 50 industrial B3 inkjet printing system’s market launch.

Otto said, “The digital printing collaboration with Canon marks a milestone in the growth strategy for our core business. Besides selling the Jetfire 50 itself, we will also benefit from recurring sales from services and consumables throughout the press’s lifetime.”

In the latest blow to the media industry, NZME has closed 14 community newspapers citing a decline in advertising revenue and significant increases in distribution costs making the newspapers no longer financially viable.

The 14 NZME titles closed are the Hauraki-Coromandel Post, the Katikati Advertiser, the Te Puke Times, the Te Awamutu Courier, the Taupō & Tūrangi Herald, the Napier Courier, the Hastings Leader, the CHB Mail in Hawke’s Bay, the Stratford Press, the Bush Telegraph in Tararua, the Whanganui Midweek,

the Manawatū Guardian, the Horowhenua Chronicle and the Kāpiti News.

Michael Boggs, chief executive officer at NZME, said the decision came after consultation with the NZME team, taking on external feedback from MPs, mayors, local businesses and readers. In an internal email, he said, “This is a sad day for NZME and it’s not news I want to be sharing. However, it is the right decision to ensure we continue to operate a sustainable media business and to put NZME in the best possible position for ongoing financial growth

into the future. On behalf of everyone at NZME I want to say a heartfelt thanks to our exceptional team who has served our community network and thank them for their commitment, efforts and dedication to serving their local communities. Thank you also to our loyal customers and readers for their support.”

NZME owns the New Zealand Herald; nzherald. co.nz; six other daily newspapers; a suite of radio stations including Newstalk ZB; and the property website OneRoof.

Several parties interested in buying individual community mastheads have already approached NZME, which has said it “will liaise with those people”.

Pantone 17-1230 Mocha Mousse is the Pantone Colour of the Year selection for 2025.

The company describes Mocha Mousse as “a trend led fashion colour with a rich neutrality that extends our perception of brown, crossing from the humble and earthbound to the luxury and aspirational”.

Leatrice Eiseman, executive director at the Pantone Color Institute, says, “Underpinned by our desire for everyday pleasures, Pantone 17-1230 Mocha Mousse expresses a level of thoughtful indulgence. Sophisticated and lush, yet at the same time an unpretentious classic, Pantone 17-1230 Mocha Mousse, extends our perceptions of the browns from being humble and grounded to embrace aspirational and luxe.

“Infused with subtle elegance and

Opal Cartons New Zealand has invested in a Koenig & Bauer printer for its Christchurch site. The company says this demonstrates its commitment to innovation and high-quality print for local manufacturing in the South Island.

Terri Smith, general manager of Opal Cartons New Zealand, says this investment offers significant advantages, using the latest

Markus Weiss takes over Koenig & Bauer packaging sheetfed

Koenig & Bauer has appointed Markus Weiss as chief executive of its paper and packaging sheetfed system segment. He succeeds Ralf Sammeck.

Dr Andreas Pleßke, chief executive of Koenig & Bauer, says, “Ralf Sammeck has succeeded in continuously establishing the sheetfed segment as a complete solution provider and expanding market leadership in the packaging sector. In doing so, he has positioned the division

earthy refinement. Pantone 17-1230 Mocha Mousse presents a discrete and tasteful touch of glamour. A flavourful brown shade, Pantone 17-1230 Mocha Mousse envelopes us with its sensorial warmth.”

The company sees “a growing movement to align ourselves more closely with the natural world. It says that, characterised by its organic nature, Pantone 17-1230 Mocha Mousse honours and embraces the sustenance of our physical environment. Imbued with

technology to create additional capacity through efficiencies and high-quality printed products for Opal’s valued customers.

She says, “This investment shows our commitment to integrate advanced technology into our South Island Carton site and deliver the best quality products for our customers. The press’s technological features will enhance our production capabilities and set new benchmarks in efficiency and quality, allowing us to continue offering unmatched services to customers not only in the South Island, but across New Zealand.

“This investment furthers our commitment to ensuring carton packaging for New Zealand is made in New Zealand by those on the ground

for the future. With his instinct for customers and markets, he is a role model for the sales team worldwide.”

Markus Weiss will take up his new position on February 1, 2025, and will be a member of the Group Management reporting to the Executive Board. Sammeck says, “Markus Weiss is a strong, international leader who has built up an excellent network over the past almost 20 years and brings enormous experience in

authenticity Pantone 17-1230 Mocha Mousse finds harmony and balance between the demands of modernity and the timeless beauty of artful creation”.

Laurie Pressman, vice president of the Pantone Color Institute, adds, “The everlasting search for harmony filters through into every aspect of our lives including our relationships, the work we do, our social connections and the natural environment that surrounds us.

“Harmony brings feelings of contentment, inspiring a positive state of inner peace, calm, and balance as well as being tuned in with the world around us. Harmony embraces a culture of connection and unity as well as the synthesis of our mental, spiritual, and physical wellbeing. With that in mind, for Pantone Colour of the Year 2025, we look to a colour that progresses our embrace of the feeling of our Pantone Colour of the Year, Pantone 13-1023 Peach Fuzz into another dimension, extending further into our desire for comfort, and the indulgence of simple pleasures that we can gift and share with others.”

at our South Island site.”

Opal Cartons Christchurch has manufactured cartons for more than 40 years, supplying a range of key industries including FMCG, Seafood, Dairy and Beverages.

The business won gold in the Structural Design Packaging category at the Pride in Print 2024 Awards for the design of a cookie bucket sleeve developed in collaboration with wellknown New Zealand brand and Opal Cartons customer, Cookie Time. Terri says, “Our structural designer cleverly created a sleeve that featured Cookie Time’s fun, colourful branding and was also functional and strong enough to hold more than one kilogram of cookies.”

our industry. I am particularly pleased about this because our customers are very important to me.”

Koenig & Bauer claims to be the only manufacturer that can print on almost all substrates using almost all technologies. Weiss says, “Offset printing will remain the leading technology in packaging and commercial printing in the long term, complemented by innovative solutions in the prepress and postpress areas. At the same time, digital printing is becoming increasingly important.

“The optimal combination of both technologies opens new growth opportunities for our customers and shows that their joint use will shape the future of the printing industry. I am delighted to be able to contribute my knowledge and experience in this exciting field to the leading packaging manufacturer with a great team.”

Fujifilm Business Innovation has announced the global launch of two new mid-range production presses in the Revoria Press series: the Revoria Press EC2100S and the Revoria Press SC285S. The new presses made their debut at drupa 2024.

Equipped with a specialty toner station in addition to the four-colour toners, the new presses enable five-colour printing in one pass. They are compact in size, offering high print quality and speed. Worldwide sales began in January 2025.

The Revoria Press EC2100S prints at a high speed of 100 pages per minute and is ideal for commercial printing and quick printing. The Revoria Press SC285S has a printing speed of 85 pages per minute for quick printing and in-house printing. The company says the new presses offer a compact machine size through the newly developed Vertical Toner Development Technology.

It has designed them to incorporate the same technology that enables high image quality printing, a feature of the flagship model, the Revoria Press PC1120.

The new presses handle an expansive range of paper weights from lightweight 52gsm to heavyweight 400gsm and paper sizes, from a minimum of 90mm x 146mm up to 330mm x 1300mm without reducing printing speed.

A new feature, Smart Monitoring Gate D1, detects colour variation and front to back misalignment during printing, enabling automatic correction in real time to maintain high print quality without compromising on productivity. To generate high quality images and smooth workflows, the company will offer two choices of Revoria Flow and Fiery print servers. With the newly developed vertical toner development system that can contribute to maintaining compact machine size, the company says you can now produce premium quality printed materials, even when working with a wide variety of products, small lots, and short delivery times, such as catalogues, brochures, manuals, and sales promotion materials.

Main features of the new presses:

Equipped with a one pass five-colour print engine, one specialty toner can be used in addition to the CMYK toners. A

full range of support functions is available for easy utilisation of specialty colours.

• A variety of specialty toners are available in Clear, Pink, Custom Red, Gold, Silver and White. A variety of metallic colours can be expressed by mixing highly brilliant Gold and Silver toners with CMYK toners.

• The image data is automatically divided into five colours of CMYK and Pink on the Revoria Flow and Fiery print servers.

• Designs can be created while checking the expression of specialty colours with the preview function. Users can save time and effort for test printing.

• Quick toner change. You can easily change the specialty toner in about 10 minutes.

Efficient space utilisation: with compact LED printhead and high-resolution print at 2400 dpi.

High speed printing: The Revoria Press EC2100S prints at 100 pages per minute, while the Revoria Press SC285S prints at 85 pages per minute.

Versatile media handling: for a wide range of applications.

Compact belt roll fuser: enables highquality printing on textured paper.

Air Suction Feeder: ensures reliable feeding of coated paper, which tends to stick to the paper. The Static Eliminator removes static electricity from film paper and other static-sensitive printing paper, enabling reduction of adhesion between sheets of paper for work efficiency.

Media support: for paper output such as envelopes, water-resistant paper, and cardboard for packaging.

Print Inspection System: inspects printed materials automatically and in real time to detect printing defects such as dots, stains, pinholes, streaks, and paper folds. The system inspects readability of characters and barcodes, numbering information continuity and front/back characters and numbering continuity.

Server compatibility: Both new presses are compatible with Revoria Flow and Fiery EC21 and EC22 servers. Customers can choose from several options of print servers to meet their needs.

Aimed at strategically raising awareness of the effectiveness and sustainability of print, an enterprising new marketing campaign will headline a full programme of initiatives planned for PrintNZ members in 2025.

Leading branding and marketing firm Strategy will launch the campaign this month. Ruth Cobb, chief executive officer at PrintNZ, says the campaign will

significantly raise the profile of print with targeted stakeholders throughout the country.

She says, “The Board of PrintNZ is investing substantially into this campaign, which will strive to improve the visibility of print while turning off negative messaging and highlighting our many positives.

“Complementing the current collateral available to members through the Two Sides and Value of Paper and Print and other initiatives, the campaign will leverage a range of marketing channels.

“The target audience will include marketing and brand managers (client side); marketing and advertising agencies; corporates/print buyers; and government agencies.

“Ultimately, we aim to develop a broader understanding of the effectiveness of printed media with the target audience and the outcomes it can achieve for their own campaigns, as well as improve engagement with those key stakeholders.

“The message will be heard again that print remains a powerful, cost-effective and sustainable form of communication.”

Necessarily put on hold during the pandemic, the annual PrintNZ benchmarking survey is set to return to publication again this year.

Ruth says, “The industry has been through a period of substantial change with highs and lows over the last few years, and the new benchmarking data will provide

insights into where our wages, charge-out rates, and financial data currently sit.

“The survey is one of the most valuable benefits of PrintNZ membership and is referred to as they complete a variety of business tasks throughout the year.

“For example, having this up to date data helps members understand where they are positioned in the market, as well as providing broad industry oversight and forecasting that is useful when working with banks and financial institutions.

“The data is also referred to during wage negotiations, strategic planning and as an information source when compiling reports for management in New Zealand and offshore.

“Furthermore, survey results are used extensively by PrintNZ to support our lobbying efforts and assist communications with Government, other industry groups and the wider printbuying community.”

Ruth confirms PrintNZ has been working diligently to put the industry’s position strongly forward on a number of topical legislative and national policy developments, and will continue to “make noise” this year through lobbying focused on:

• NZ Post

• Energy – including mill closures

• Education/Training Bills

• Immigration

• Employment relations – including a number of Bills underway and major reforms proposed to the Holidays Act.

Mail prices have gone postal

Ruth says, “In our view, the extraordinary price increases and drastic service contractions introduced by NZ Post, which hugely impacts circulation of print volume, are in direct conflict with its service-defining Deed of Understanding with the government.

“Following our extensive lobbying across the political spectrum, the Deed is now under active review. We are calling on NZ Post to provide a sustainable and signalled strategy over increasing costs, a return to meeting its social obligations and a refocus on being accountable to the principles of the Deed.

“The letterbox remains the only channel that provides a communication pathway to every household in New Zealand, and it is an important network for our industry, but only if it works for all parties.”

With “substantial concern” mounting over the price and availability of energy, she adds that PrintNZ recently joined with the Manufacturers’ Alliance to make representations to the Minister for Energy.

She explains, “This situation is having a negative impact on the manufacturing sector – including some large businesses, which are a direct part of our industry’s supply chain, having had to pause production and/or close down. Escalating energy prices have become a significant threat to the global competitiveness of New Zealand manufacturers, and this is affecting exports and those competing with imports in the domestic market.

“The Minister acknowledged there needs to be a clear pathway to ensure long term, affordable pricing and surety of supply. The government is working to remove barriers and is undertaking a review of the market to deliver globally competitive energy prices, alongside its commitment to Net Zero by 2050.”

An “enormous collaborative effort” within the short six-week timeframe allocated saw PrintNZ complete a submission to the government’s proposal to overhaul the vocational education system.

Ruth says, “Work-based learning is vital to our industry – the print, packaging and print finishing trades’ training takes place fully in the workplace. The training programmes are designed by industry, for industry and we need to ensure that there is no weakening of that standard.

“We need to be sure that the Minister of Education understands what this means.”

Immigration remains another hot topic, with pandemic-granted Accredited Employer Workplace Visas ending as the government turns its focus on building local talent and reducing the ratio of skilled versus unskilled migrants.

Ruth says, “This directly impacts some of our members and we are working with them and Immigration New Zealand to try and ensure that staff they have employed, and spent considerable resource training, are able to remain.

“The Skilled Migrant Category is also not fit for purpose, and we are lobbying to ensure that trades are recognised with a pathway to residence for those migrants that come in under this system.

“In an industry where technology is continuously evolving, we are often reliant on being able to bring in skilled migrants to both work and in turn train Kiwis, and those people need reassurance they can build a life here with their families.”

laws changing

Employment relations is additionally expected to consume lobbying space in 2025 as a number of Bills work their way through the system.

These include a maximum income threshold of $180,000 per annum for unjustified dismissal personal grievances –reducing an employee’s rights to remedies where they have contributed to a situation which gave rise to a personal grievance, as well as pay deductions for partial strikes; protected negotiations for termination of employment by agreement; and of course,

the Holidays Act Reform which has been five-plus years in the process.

Key 2025 events

Notable industry events confirmed for the year at the time of publication (most dates yet to be finalised) include:

• Mainland Regional Charity Golf Day (Christchurch) – February 14, Waitikiri Golf Course – raising funds for the Full Colour Trust which supports people in the print and graphics industries in the South Island that may not qualify for regular channels of assistance and cannot afford to pay for help they need (which is commonly, but not exclusively, health-related)

• Auckland Golf Day – February 28, Huapai Golf Club – returning after a 10-year hiatus

• People In Print Awards and Rising Stars of Print Awards – recognising the people that have made a contribution to either the printing industry or their communities during the previous 12 months (also recognising the sector’s upcoming future leaders)

• Training Graduation Ceremonies (Christchurch/Auckland) – providing an opportunity for every person in the industry that has received a qualification during 2024 to have their mahi acknowledged in front of

their peers and families

• Apprentice of the Year –acknowledging the Top 10, Top 5 and overall outstanding industry apprentice to graduate during 2024

• Pride In Print Awards on July 4, Cordis Hotel, Auckland – the industry showcase of excellence in product and people and the premier event for our industry.

• Seminars – held across the regions and this year predominantly focused on a “hefty” legislative agenda, while also providing members with updates on the new marketing campaign and other initiatives

• Women In Print – providing opportunity for women in the industry to network and listen to inspiring stories from “some of New Zealand’s great ladies”

Emphasising that training “isn’t always about apprenticeships”, Ruth points out that PrintNZ will strive to generate a new round of education grant applications to Trust4Skills.

She says, “The fund has around $20,000 available for grants to PrintNZ members each year and trustees are keen to see this spread across a broad range of learning opportunities.

“Investing in staff helps demonstrate their value to the business and the Trust can help fund this – a win/win for everyone.”

The team at PrintNZ looks forward to delivering these vital services to members and much more during the year.

Ruth says, “There is also of course, ongoing emphasis on our business-asusual activities that the membership values. This includes the work we do with individual members on employment issues, health and safety, compliance, and business referrals, and working with schools to secure a talent pipeline.

“As a team we very much enjoy the interaction with our members and knowing we are helping make a difference. We always welcome and invite members to reach out directly to us with any queries or issues that arise, or on other areas where we may be able to develop services to assist the industry.

“As we are all aware, things have not been the easiest economically and mentally for businesses, families, and individuals over recent years. But we are in this together, and the horizon is brightening with expectations of a progressive lift through the course of this year.”

Looking at the many ways you can get great value out of your PrintNZ membership.

There was much talk in 2024 that all we had to do was Survive to 25. We have done that, but what’s next?

We are all aware that the new year did not bring with it a magic switch and if we are looking for rhymes – “More of 24” might be with us for a wee bit yet.

While we proceed with caution, it is important to make the most of what is available to you and maximise how you spend your money.

As an industry association, we are here to help our members navigate their way through a variety of issues and it continues to surprise us the number of members that pay for external services that we provide as part of our membership.

In a bid to help you make the most of your membership and avoid some unnecessary costs, here is a start of year reminder of

a couple of things that would ensure you more than get your money’s worth.

The single biggest space we see additional costs incurred is in the employment relations arena. There is a substantial amount of help we can provide from templates and documented processes to individual guidance through situations such as disciplinary action, restructuring and redundancy, to name a few.

Documents such as an Individual Employment Agreement can be expensive to purchase and often this single document alone would cost you more than the cost of an entire year of membership of PrintNZ. We can help adapt these to your specific circumstances and ensure that they comply with current legislation and provide the protections you need as an employer.

The employment relations field is fraught with potholes and loopholes, and it is expensive when you get it wrong. For example, the 90 day trial period is a great tool for employers to use and sounds simple. In fact, it is complex in the way it needs to be implemented, administered and actioned. Getting any part of that process

wrong leads to an automatic unjustified dismissal and that is an expensive mistake; in nearly all cases it will cost well in excess of $10,000 in compensation.

On the back of a challenging year, we have seen an increase in restructuring and redundancy activity and this is another area that is complex to negotiate. There is no defined “perfect process” you can follow, and as employment law is all based on case law, what is “right” this week could be overturned next week. There are so many parts to the process that can trip you up, and while you may have the most legitimate reason to take the actions you are taking, if you don’t get the process right it will cost you.

We can guide you through these processes, which often have to be adapted on the way through and provide the documentation to minimise the risk. No business can afford the fines and lost wages that can be awarded if you make a mistake.

On the disciplinary front, while a situation might be unique to your business, we have often seen it before and can give you guidance on how to work your way through that to reach a satisfactory and fair outcome.

The second area we often see contracted external help is Health and Safety. In many cases, this is a good thing where you have additional regular support that keeps your health and safety planning and implementation on track.

Again, where PrintNZ can help, particularly with smaller businesses, is providing templates, advice and assistance to set up a system. This is such an important part of your business and one you cannot ignore. We can help ensure you have a system that is fit for purpose, reduces workplace risks and most importantly, protects your employees.

Finally, we will be releasing the PrintNZ Survey in 2025. This will provide data on wages, salaries, charge-out rates and financial benchmarks. Make sure you participate – the data out will only be as good as what we get in, and if you want to get the results, you will have to provide answers. This will cost you nothing more than a bit of your time.

Make the most of us so you can make the most of 2025.

emerging inkjet web market. Tom adds, “We are excited about bringing this technology to the local market and we look forward to discussing with you how these solutions can help your business.”

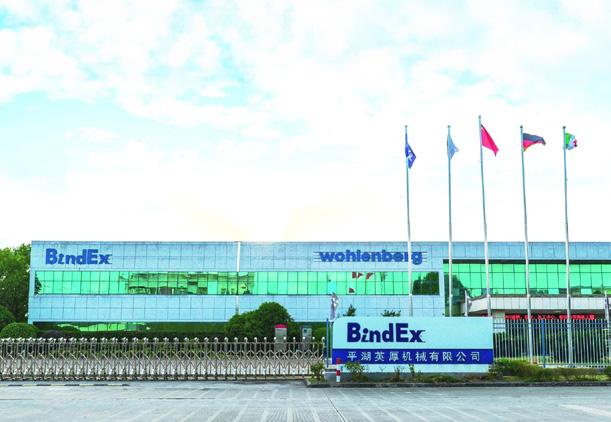

Industry suppliers Graph-Pak and Pressnet share a common interest in supplying high quality solutions that help their customers improve their bottom lines.

Industry veterans Charlie Scandrett, managing director of Pressnet and Tom Ralph, manging director of Graph-Pak have a massive depth of knowledge and experience, which they are only too happy to share with customers.

Recently, the companies entered into a marketing and sales arrangement to provide Bindex PUR binders, HXCP folders, HPM guillotines and Bin Bao sheeters.

Charlie had previously visited Bindex and became its Australasian agent. He says, “Over a decade ago, the Chinese binding machine manufacturer Bindex entered into a manufacturing and licensing agreement with Wohlenberg of Germany.

“Now, every Wohlenberg book clamp and Sprinter s or s XL gathering machine in the world is manufactured at Bindex in Pinhu, in the Hengzhou district of China.

“Wohlenberg’s name is on the main factory front, and Wohlenberg have supplied technology and reviews of Bindex technology to the Li father/son team who own Bindex.

“Bindex have a range of machines from the single clamp Explore at 500 books per hour, through to the 12,000 books per hour Galaxy 12,000e.

“All Bindex machines are automatic setup with servo motors.”

Also in the range, the Ecobinder offers speeds of up to 2,000 books per hour. Charlie says, “This PUR model is ideally suited for the on demand market.

Graph-Pak and Pressnet have already sold the first Eco binder model to a printer in Melbourne. Charlie says, “We immediately found problems with safety lights, stacker speed and the integration of the Nordson PUR supply unit with the Bindex Ecobinder.

“Mr Ang Li, the general manager and part owner of Bindex, then flew to Melbourne himself, with his engineers, to supervise the rectification. Nordson in China ran some tests at the Bindex factory, and the problem was resolved.

“This first installation is running well now. Although we had this initial issue, the subsequent actions from Bindex have proved how very responsive the company is with its technical support.

“We have a bilingual engineer’s support chat group, where we can talk to Bindex engineers in English, and they read Chinese at their end.”

Tom and Charlie have four proposals for Galaxy 6000e machines out in the Australian market already.

Tom says, “We are confident these affordable and technically excellent machines will achieve significant market share.”

Pressnet is also co-operating with Bindex to design roll-to-bind solutions for the

The Bindex Ecobinder, a fully automated five-clamps perfect binder is an ideal solution for flexible and quick binding of small and medium book quantities.

Equipped with an automatic book delivery, which ensures that the book falls smoothly from the clamp, the Ecobinder can connect to the digital three knife trimmer, forming a digital perfect binding line to meet various production need.

Ecobinder features:

• Automatic thickness measuring device.

• Book clamps, opening and closing automatic adjustment.

• Professional independent notching section for superior spine preparation, width automatic adjustment.

• Double Spine glue units with independent temperature control; and an automatic spine glue cutoff with a PUR glue unit option.

• Side glue section, width automatic adjustment.

• Cover guides/scoring on the cover feeding section, width automatic adjustment.

• Cover guides (both front and side) on the nipping section, width automatic adjustment; and heavy duty double cam mechanism for superior spine nipping quality.

• Book positioning guides, automatic adjustment.

• Delivery channel, width automatic adjustment.

• Integral casting and strong rigidity.

Adaptation holds the key to print’s successful evolution.

In a world where smartphones, tablets and social media have become ubiquitous, industry professionals have expressed concern that print will become obsolete. Chris O’Hara, national production print manager for Konica Minolta New Zealand, says, “With so many businesses going paperless, newspapers moving online, and e-books increasing in popularity, such fears seem reasonable. However, the truth is that print is more than alive, it is essential.

“Print remains an integral part of business operations, from marketing collateral and point of sale materials to labels and packaging. Industries like healthcare, education, manufacturing, and retail all rely heavily on print to communicate with customers, meet regulatory requirements, and enhance brand visibility.

“Companies using modern printing techniques and sustainable practices have significantly reduced print’s environmental impact. Paper and cardboard are biodegradable and recyclable, making them a more environmentally sustainable option compared to digital devices that require electricity, data centres, and create e-waste.

“The key to print’s survival and its longevity lies in its ability to adapt and evolve. From marketing materials to packaging, print continues to play an essential role in both business and daily life. Print retains its relevance in our commercial and cultural worlds and its ongoing positive impact improves peoples’ lives in many ways.”

One of print’s most significant advantages over digital media is its physicality. The value of a person holding a printed piece in their hands comes from more than just its appearance. Our brains receive feedback from when we touch something. Whether it’s a glossy brochure, a beautifully designed magazine, or luxury product packaging, the tactile experience creates a sense of authenticity and permanence that digital formats simply can’t match.

Chris says, “For brands, print’s inherent tactility can translate to greater customer engagement and trust. Designed well, any printed product can evoke emotions, create lasting impressions, and serve as

a physical reminder that remains with the person holding it. We live in a time where digital advertisements appear and disappear in seconds. However, a printed brochure, direct mail piece, or even a business card can make the difference between a customer remembering or forgetting the product.”

Welcome screen breaks

Increasingly, consumers regard print as a premium medium that delivers exclusivity and a more personal touch than digital. Although digital content is instantly accessible and easily consumed, print gives people a welcome break from screens.

Chris says, “In marketing campaigns, we see luxury brands leveraging highquality print for the likes of limitededition catalogues, stunning direct mail campaigns, and upscale packaging that elevates their brand image.”

According to a study completed by researchers at Temple University in Philadelphia, USA, print advertisements activate more brain activity related to value and desire than digital advertisements. Chris says, “This leads to a higher likelihood of purchasing and it is not confined to luxury items. Print’s appeal as a tangible, personal, and premium medium resonates with consumers across demographics.

“Digital fatigue has become a growing challenge for consumers and businesses. People confront screens at work then face more screens at home for entertainment and social interaction. Away from this environment, print offers a refreshing escape from the relentless digital noise.

Chris says, “Print gives us the chance to unplug our devices and enjoy moments of calmness.

“A magazine on a coffee table, or a wellcrafted direct mail campaign, gives readers a chance to slow down, engage deeply, and appreciate the content without distractions. This undivided attention is something that people find more difficult to capture in the fast-paced digital world.

“This doesn’t mean that we should disregard the digital medium. Rather, we can see enormous value in integrating print with digital. For example, using QR codes and augmented reality with variable data printing enables marketers and print businesses to bridge the gap between print and digital. A printed brochure with a QR code can lead customers to a brand’s website for more information, special offers, or interactive content. Variable data printing allows businesses to personalise their print materials for individual customers, making each piece more relevant and engaging.

“Furthermore, integrating AI with print technology will help us to deliver smarter and more personalised solutions. AIdriven tools enable businesses to analyse customer data and create highly targeted print materials tailored to individual preferences. AI can power dynamic design adjustments, optimise content for specific audiences, and predict trends for more effective print campaigns.

He concludes, “Print’s ability to evolve, personalise, and engage in a world flooded with digital content means it will continue to thrive.”

The digital revolution continues with the highly evolved AccurioPress C14000 series, designed to ensure you never stop printing. These high speed digital colour presses offer next level automation for ultra-efficient, high volume colour printing. Packed with an array of impressive features, powerful inline finishing options for high pr oductivity and with in-built technology, they offer unparalleled quality and consistency print after print.

To rethink efficiency, simply visit: konicaminolta.co.nz/AccurioPressC14000series

Asking the right questions when considering AI in business.

THAFIZAH

OSMAN Contributing Editor

echnology expert and Byteside founder and head of content

Seamus Byrne delivered his keynote speech at the inaugural ProPack Packaging Forum in Sydney around the topic on everyone’s minds: generative AI.

He said, “The big thing with AI is that it’s important to be asking ourselves the right questions to know what we want to achieve with it.

“Sometimes, we can get really focused on the cool, shiny new toy. But we need to make sure we are focused on the actual outcome we are looking for. Consider these questions:

• What is it we want to achieve with these tools?

• Do we want a white-collar workhorse?

• Do we want the trusted confidante or the analytical genius here?

• What exactly is it we think is going

to add value to our business to push things forward?

Stochastic parrot

However, Seamus warned that generative AI is at the stage where language does not actually equal intelligence. A good command over putting together ‘cool paragraphs’ and ‘cool ideas’ isn’t the same as being truly intelligent.

He explained, “There’s this concept of the stochastic parrot. I don’t necessarily agree with it in full, but the idea is like an incredibly advanced version of teaching a parrot to say some words which it does not understand the meaning behind. So, we may have to be careful about using AI for decision making if it doesn’t fully understand what it’s meant to do.”

He added that one way to mitigate this situation is through prompt engineering, which he said is about knowing how to ask for what you want. He commented, “When you add that little extra ‘oomph’ in the message that you are asking it to solve, somehow you can just encourage it to give you something better than it would have if you didn’t offer that little bit of extra encouragement.

“Generative tools can also help to elevate somebody who doesn’t know much about

a space to learn a lot more, but once you are in the industry, you will very quickly start to see the difference between what these tools are capable of to help you without them becoming trained on the expert details that you need in this industry.”

The other big question for businesses, according to Seamus, is what to do with data.

He said, “There’s so much data coming off systems, so you need to work out how to enable that data to be fed into AI systems. The data can exist but are you able to unlock it to start feeding it into AI tools that can bring that data to light and give you the extra intelligence you need.

“On top of that, we have the governance issues around data, the security issues, the privacy issues and getting the guardrails right on this. That’s a big consideration for the long-term.

“The key, right now, is experimentation; to start exploring some of these tools and to start learning lessons on them. Maintain flexibility, unless you absolutely know there is a specific reason why we need to make that commitment right now.”

He added that he sees the future heading towards agentic AI, where it starts to manage complex problems for you and independently do things on the internet for you. He said, “It will use applications on your behalf to go and get other things done.”

As a starting point, Seamus also suggested businesses explore the following tools depending on their areas of expertise: ChatGPT, Google Gemini, Mistral AI, Claude by Anthropic, Perplexity AI, Runway, Arc Browser and NotebookLM.

The inaugural ProPack Packaging Forum would not be possible without the support from its sponsors:

Platinum Sponsor – Durst Oceania

Gold Sponsor – Cyber

Gold Sponsor – Miraclon

Bronze Sponsor – Hybrid Software

Bronze Sponsor – Kissel & Wolf

Bronze Sponsor – Koenig & Bauer

Reel to reel high-definition digital label printing machines with hybrid options available Upgrade your existing/new offset m/c with revolutionary cost saving cold transfer technology

machines, standalone or integrated into existing machinery

Stop playing the piano

•

• Paper

•

• Save money

machine

Bring new life back into your old printing machine

• Energy

• Ink

• Save money

• Paper

• Save money • Ink

• Best in class colour consistency

• Energy

• Ink • Paper

• Energy

• Best in class colour consistency

• Energy

• Best in class colour consistency

• Seamless integration with most rips production quicker than ever before. Ready or considering the

• Seamless integration measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

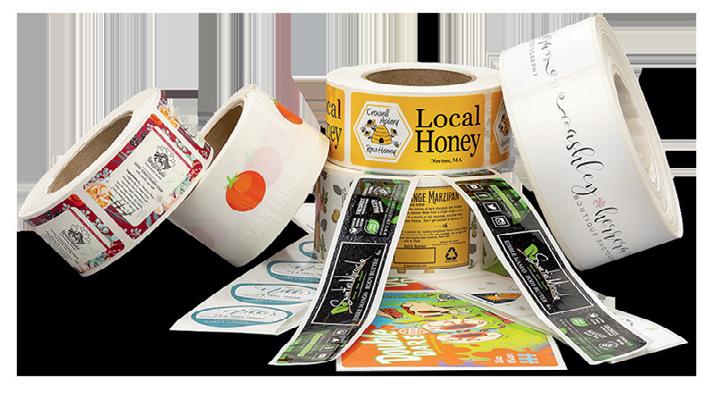

Dantex has announced the launch of the PicoColour HD and PicoJet 1200 models.

Ru

Ru

Built on a modular platform, the Picojet 1200 is a true hybrid system, available as a reel-to-reel press with a print width to 350mm and speeds of up to 75mpm, as a bespoke hybrid system where a variety of base and additional colour stations can be custom configured to incorporate features such as full or semi-rotary die cutting and a variety of flexo station options.

The PicoColour HD is built on and benefits from advanced Picojet technology, providing print width to 254mm with speeds of up to 50mpm, and compact inline finishing. Offering excellent printed results and suitable for short and long run jobs, the HD press provides all the benefits of digital printing for today’s demanding production environment.

Nekkorb Solutions commercial manager Tash Brokken said, “Pico offers highly productive, affordable label printing; no minimum run quantity; minimal waste; super-fast turnarounds; and it makes label production fast and easy. Modular station options can include flexo, die cut, cold foil, lamination, edge trim, back scoring and rotary or shear slitting.

In addition, PicoCenta and PicoPilot workflow automation software with touchscreen interface adds to a userfriendly experience. Other features

include SuperWhite ink, offering an opacity of 92 per cent in a single pass; SuperText, which delivers super fine text; and DecoTactile for a wide range of textured embellishments.

“PicoJet’s Digital Resolution System (DRS) significantly increases print quality and detail, positioning the PicoJet DRS as groundbreaking in the label and flexible packaging space. Featuring eight grey levels and providing 2400 dpi, this proprietary technology, owned exclusively by Dantex, marks the first time in the industry that a digital inkjet system has reached this level of precision.

“Pico technology also boasts advancements in colour gamut, setting a new benchmark for digital UV inkjet printing, ensuring unparalleled colour accuracy and consistency. With a Delta E of 2, it continues to push the boundaries of colour precision, covering 97.5 per cent of the colour gamut. Utilising CMYK WOVG, Dantex’s eight-colour printing press achieves the highest colour accuracy due to the combination of its incredibly powerful software suite with Dantex’s printing technologies.

“Dantex’s Pico presses have passed a stringent 150-point requirements list which guarantees that the manufacturing supply chain is ‘truly British’. Only those products that pass this test are permitted to carry the Made In Britain mark. The Made in Britain accreditation is an international seal of excellence.”

In the evolving landscape of label printing, the MPS EF Symjet hybrid machine, with its Domino inkjet print engine, sets a new benchmark for efficiency, versatility, and print quality, according to Tash Brokken, commercial manager at Nekkorb Solutions. She said, “This cutting-edge machine combines the strengths of flexographic printing with state-of-the-art digital technology, offering label manufacturers unparalleled flexibility and productivity.

“At its core, the MPS EF Symjet is built on the robust MPS EF platform, renowned for its precision and userfriendly operation. The addition of Domino’s inkjet technology elevates this press to a hybrid marvel, seamlessly integrating traditional and digital workflows. This hybrid capability enables printers to handle short-run, variable data jobs alongside longer production runs without the need for multiple machines, reducing operational complexity and maximising return on investment.

“One of the standout features of the MPS EF Symjet is its high speed performance. The Domino engine delivers impressive digital speeds of up to 70 metres per minute, ensuring that even the most demanding production schedules are met with ease. Combined with MPS’s advanced web control system, the Symjet guarantees consistent quality and accuracy, even at top speeds.

“The machine’s ability to switch effortlessly between flexo and digital printing is another game-changer. Users can apply spot colours, varnishes,

or cold foils through flexo units, while the digital module provides vibrant full-colour printing with up to seven UV-curable ink colours, including opaque white. This flexibility enables the production of complex, high-value labels in a single pass, reducing waste and time while enhancing creative possibilities.

“Sustainability is another key benefit of the MPS EF Symjet. By enabling ondemand printing, it minimises waste associated with overproduction and setup. Domino’s environmentally friendly UV ink system further supports greener production practices, aligning with the growing demand for sustainable solutions in the printing industry.

“In addition to its technological prowess, the Symjet boasts an intuitive operator interface, ensuring ease of use and reduced downtime. The machine is designed for quick setup and changeovers, further enhancing efficiency for businesses handling diverse print jobs.

“For label manufacturers seeking a future-proof solution, the MPS EF Symjet represents a transformative investment. By blending the reliability of flexo with the agility of digital, it delivers unmatched performance, empowering businesses to meet market demands while staying ahead of the competition.”

For more information and a confidential appraisal of your printing requirements contact Frank or Tash at Nekkorb Solutions. Frank +64 277138987, Tash +64 21423464 or email; info@nekkorbsolutions.co.nz.

BGM Elite Label-i Automatic Inspection Slitter Rewinder

Free-standing label inspection slitter rewinder suitable for paper labels, transparent clear-on-clear & films

BGM Elite Comflex Compact Digital Converting Finishing System

A fully offline entry level digital converting finishing solution suited for any digital print house

BGM Elite Digiflex Digital Converting Finishing System

Use as a spot register station or a simple flood coating station. Available in both full or semi-rotary die cutting versions

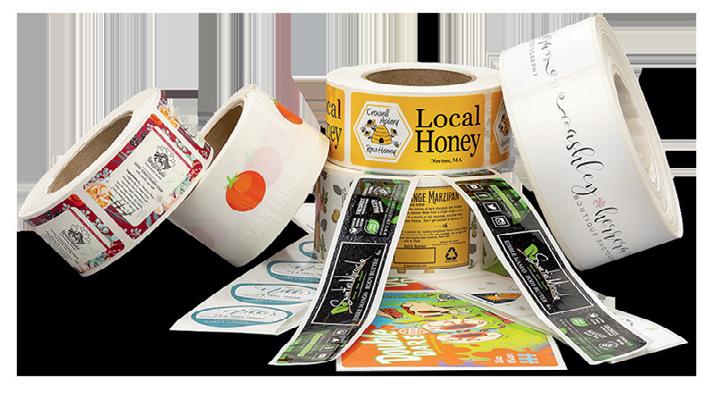

Steve Wilton-Jones discusses the benefits of installing Epson’s flagship label press into your business.

The Epson SurePress L-6534VW delivers ultrahigh-resolution printing with stunning clarity and vibrant colours

ISTEVE WILTON-JONES

National Equipment Sales

Aarque Group

n the fast-evolving world of label printing, staying ahead of the curve means investing in technology that delivers unparalleled performance, quality, and flexibility.

Meet the Epson SurePress L-6534VW, the state of the art solution that is setting new standards in digital label printing. High opacity white and high-build digital varnish in satin and gloss finishes deliver premium tactile and visual experiences, captivating consumers and enhancing your customer’s brand.

Precision and quality you can trust

Designed with Epson’s proprietary PrecisionCore printhead technology, the Epson SurePress L-6534VW delivers ultra-high resolution printing with stunning clarity and vibrant colours. Whether you’re printing complex graphics, detailed text, or vibrant images, the SurePress L-6534VW ensures every label looks sharp and professional.

One of the standout features of the SurePress L-6534VW is its versatility. It supports a wide range of label media, including clear film, metallic substrates, and standard paper, making it perfect for various applications from food and beverages to cosmetics and industrial products.

The flexibility to switch between different types of media without compromising on quality means you can meet diverse customer needs with ease.

Epson is committed to sustainability, and the Epson SurePress L-6534VW reflects this commitment. With reduced waste and energy consumption compared to conventional printing methods, this digital press helps you minimise your environmental footprint while maintaining exceptional print quality, making it an environmentally responsible choice for your printing operations.

Speed and productivity

Time is money in the label printing industry, and the Epson SurePress L-6534VW is engineered for speed and productivity. Capable of printing at speeds up to 50 metres per minute, this press

ensures you can handle high volume print jobs efficiently without sacrificing quality.

Seamless integration and a userfriendly interface

The Epson SurePress L-6534VW will integrate seamlessly into your existing workflow, whether that’s adding finishing in-line, or simply taking advantage of its intuitive touchscreen interface makes operation straightforward, reducing the learning curve for your team.

Plus, with Aarque’s comprehensive support and service network backed by Epson, you can be confident that help is always at hand when you need it.

The Epson/Aarque advantage

When you choose the Epson SurePress L-6534VW, you’re not just investing in a printing press; you’re gaining a trusted partner in Epson and Aarque, providing local industry leading expertise and unwavering support, you can be assured your business is equipped for success.

The future of label printing starts today

Investing in the Epson SurePress L-6534VW means equipping your business with the technology to meet today’s demands and future challenges. With its unmatched quality, versatility, eco-friendly design, and productivity, the SurePress L-6534VW is the smart choice for businesses looking to excel in the competitive world of label printing.

At Aarque Group, we love helping our customers to discover more about how the Epson SurePress L-6534VW can transform their label printing business. For further information, please contact us at Aarque Group to arrange a demonstration of this exciting technology, phone 0508 22 77 83. We look forward to hearing from you. Steve Wilton-Jones | 021 719 634.

Scan the QR Code to learn more about the Epson SurePress L-6534VW

Featuring an exceptionally wide colour gamut, opaque white ink, and inline one-pass matte and gloss varnish, the SurePress L-6534VW delivers print detail that truly stands out. Elevating digital label printing with stunning tactile effects, this press sets a new standard of quality.

Unlock new revenue opportunities with this reliable, proven platform, backed by Epson’s trusted inkjet technology, industry expertise, and worldclass service and support to ensure your business reaches its full potential.

Jack Malki discusses how the top trends will redefine the printing industry in 2025.

As the Australasian printing industry faces evolving consumer expectations, rising costs, and increasing environmental pressures, Jet Technologies, an industry leader in print and packaging supply, has pinpointed three key trends that are shaping the path toward a smarter and more sustainable future: print on demand, automation, and sustainability.

Precision, Efficiency, and Opportunity

Print On Demand (POD) will become more prominent in the local printing industry in 2025, offering businesses the ability to produce materials in exact quantities required.

This approach eliminates the inefficiencies of overproduction, reduces storage costs, and significantly minimises waste, addressing both environmental concerns and bottom-line pressures.

Jack Malki, director at Jet Technologies, says, “The need for custom, on-demand solutions are escalating as businesses work to minimise overproduction and deliver on the growing consumer expectation for personalisation.

“At the same time, challenges like labour shortages and rising costs are pushing the industry toward smarter solutions, like POD, which emphasises waste-free production, eco-friendly materials, and automated workflows to unlock new growth in a competitive marketplace.”

Jack says the rise of POD is particularly impactful in the packaging sector, where short run production and rapid turnaround times are critical. For example, beverage companies using POD can create tailored, region specific packaging for limited edition products tailored towards local events. This strategy can not only help move stock, it can also create lasting impressions with consumers and help build brand loyalty.

POD also offers businesses new ways to connect with customers through integration with cross-media marketing campaigns. This capability allows businesses to print and distribute personalised marketing collateral such

Jack Malki, director, Jet Technologies

as QR code-enabled flyers on a just in time basis for limited offers, creating a seamless bridge between physical and digital customer interactions.

Automation transforms workflows

Changing every phase of the printing process, automation drives efficiency and improves margins in an increasingly competitive market. From automated job submissions and scheduling to AI-driven quality control, businesses are leveraging technology to reduce manual intervention and error rates while optimising output.

Jack says, “Automation is critical in addressing the dual pressures of labour shortages and escalating operational costs. By streamlining processes, it empowers printing businesses to deliver superior results faster, with greater accuracy, and at a lower cost, transforming the way the industry operates and meets customer expectations.

“For instance, automated finishing equipment can help print shops significantly reduce production timelines. A printer could integrate automated binding and trimming systems, enabling shorter turnaround times for high-volume book production, while maintaining impeccable quality standards.

“Additionally, cloud-based workflow management systems are allowing businesses to operate seamlessly across multiple locations. These platforms provide real-time visibility into job status, inventory levels, and maintenance

schedules, empowering teams to make informed decisions and address potential issues proactively.”

Sustainability has evolved from an industry buzzword to an operational necessity. In 2025, printing businesses will lean into eco-conscious innovations such as recyclable, biodegradable, and non-plastic materials. At the same time, energy-efficient technologies, like LED UV curing, are reducing resource consumption without compromising on quality.

Jack says, “In 2025, we expect an even stronger emphasis on sustainability, with environmental, social, and governance (ESG & SDG) initiatives becoming central to printing and management practices.

“Print manufacturers and their partners have a unique opportunity to lead in sustainability, helping businesses reduce emissions while ensuring operational excellence.

“Printers who embrace water-based inks and carbon-neutral production processes are strategically positioning themselves to forge partnerships with environmentally conscious retail brands. This approach not only reduces their carbon footprint but also enhances their appeal as a preferred vendor for clients prioritising ESG alignment.

“Further innovation is occurring in material reuse, with advancements in circular economy models enabling used packaging materials to be repurposed into new products. This trend is fostering collaborations between the printing and recycling industries, creating a closedloop system that benefits both the planet and profitability.”

As the printing industry moves into 2025, trends such as POD, automation, and sustainability are key factors shaping its future. Jack adds, “With these innovations at the forefront, New Zealand and Australian printing businesses are uniquely positioned to meet evolving demands, improve efficiency, and lead in environmental responsibility.”

Labels & Labeling’s branding and design columnist Vicki Strull explores the good, the bad, and the ugly when it comes to brand packaging and design

lettuce packaging that