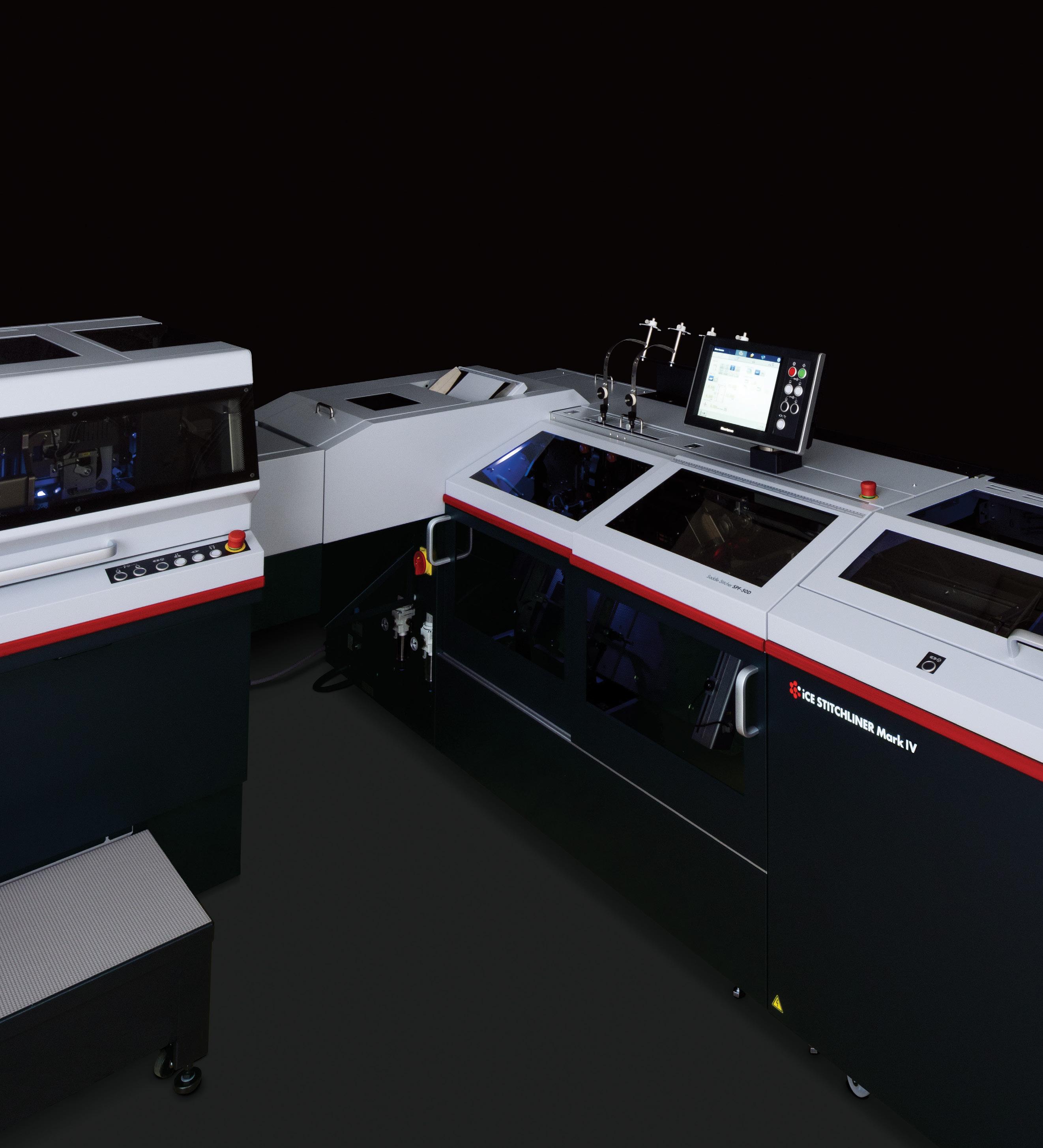

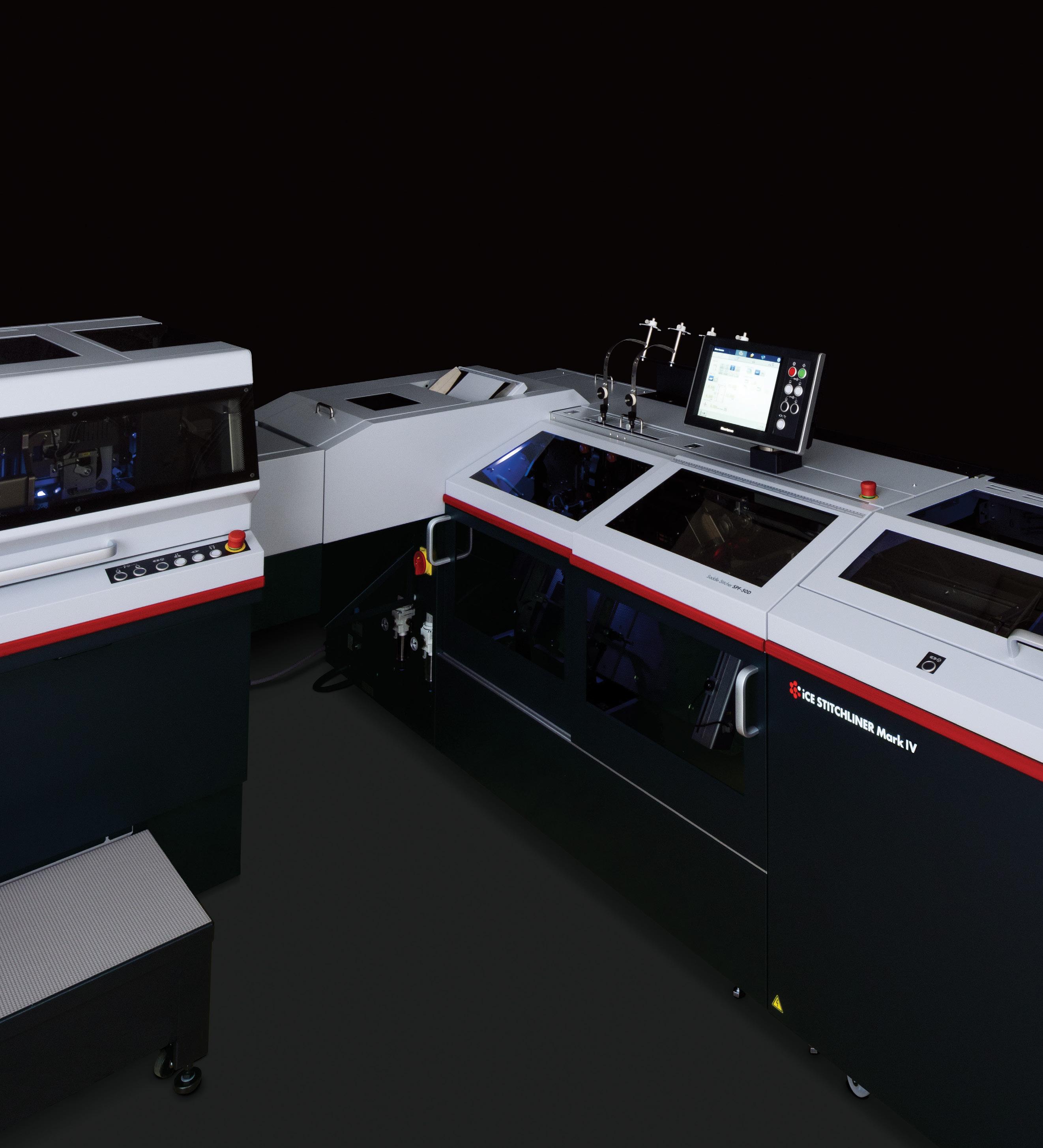

On the first Australian installation of the RMGT 970ST 7-colour offset press that includes a chamber coater, long delivery and a skeleton transfer system.

On the first Australian installation of the RMGT 970ST 7-colour offset press that includes a chamber coater, long delivery and a skeleton transfer system.

With the purchase of the new Ryobi RMGT 970 7 colour offset press with coater and Skeleton Transfer System, Sydney-based CCS Packaging has installed one of only two machines available in the world.

Waiting two decades for a sale requires patience and persistence, but this is precisely what Bernard Cheong from Cyber had to do to confirm his sale of a Ryobi RMGT 970 7 colour offset press with coater to CCS Packaging.

“I first visited Kevin from CCS Packaging over 20 years ago,” Cheong remembers.

“I was joined two decades ago for the first meeting at CCS Packaging with my colleague George Williams who unfortunately didn’t live to see the final sale.

“We were unsuccessful on that occasion and since then Kevin has bought six offset presses from another company, so we feel very fortunate to have confirmed lucky number seven.

“We welcome CCS Packaging to the Cyber family and they join over 200 other RMGT 970 presses sold globally and the second RMGT 970 in Australia,” Cheong said.

Kevin Wilson from CCS Packaging purchased the machine almost a year before it was delivered and installed within his factory located at Silverwater in Western Sydney.

“As our business evolved we told ourselves that we needed a packaging press that was customised for use in the packaging industry. Previously we were using a commercial press for packaging production. Now that we have a customised machine, this is a serious packaging press that is built for purpose. We now have the ammunition to make a serious investment into the packaging category – whereas before we were

merely just assessing the segments in the packaging landscape. We expect this will provide substantial benefits and really open up opportunities for our business,” Wilson said.

The Ryobi RMGT 970 machine purchased by CCS Packaging has been customised with a Skeleton Transfer System and this is the second press in the world with this system – the only other machine is in Korea.

“This does an equally good job as a RMGT 10 Series, and will integrate perfectly into their workflow,” Cheong said.

For packaging printers, versatility is key. The 7 color Ryobi 970, configuration with the skeletal transfer system will provide the versatility we require. Allowing CCS packaging to take our company to the next level.

CCS Packaging CEO Gerry van Happen says the business has historically serviced the music and media industries, but is now diversifying into other categories.

“CCS built its reputation over 37 years in the very exciting media business producing packaging for vinyl, CD, DVD, Blu-ray and games categories. These industry segments have declined in the last seven years, but they are still a vital contribution to the business with CCS being the market leader for media packaging in Australia. Interestingly, over the last five years vinyl has been rediscovered and is now worth more than CDs in dollar terms. Vinyl is now a luxury product with high specifications representing both international and local artists.

“Our largest packaging segment is now represented by the cosmetic, personal health and loyalty card businesses. Our experience in producing high quality

products on short lead times has allowed us to grow this area. With in-house coating, rigid box, hard cover and finishing equipment we able to produce the vast majority of products without any outside operations. Further investments this year have also enhanced our position and we are always looking at ways we can offer our customers value options.

“CCS built its business on fast turn arounds and high quality. We have translated this knowhow into the packaging segment. The new Ryobi with its larger sheet size, will sit very nicely against our current eight colour with coater press. We have great fire power, superb finishing and complimentary equipment to offer to our customers,” van Happen said.

CCS Packaging works closely with its current and potential customers to encourage them to consider the benefits of onshoring their packaging work.

“Even before the recent epidemic we were asking our potential customers ‘what is the real cost of producing offshore?’. We found that by equating the cost of tying up capital in large order quantities we could offer faster deliveries more often. There is more to the real cost than just a cheaper off shore quote,” van Happen said.

CCS Packaging Operations Manager, Simon Studdert, is also very passionate about the benefits of keeping work in Australia and explaining the numerous benefits this presents for customers and plans to compete directly with overseas printers rather than local businesses.

“We have had success changing the views of several customers who can see the benefits by looking at the entire job as well as the advantages of printing onshore – and not just the unit price. We have taken our hard earned media knowledge to challenge the mindsets of potential customers regarding offshore print and packaging procurement. Are customers really getting a better price offshore

compared to onshore? Sure, the unit price may be better, but what about shipping cost and warehousing.

“With higher minimum quantities required for overseas printing, we have seen a number of customers run into problems after a large run when there is a change that needs to be made –particularly with ingredients for food packaging or out of date content for pharmaceutical packaging. All of that stock that has been brought in from overseas that is no longer usable needs to be destroyed. By offering a local solution with a faster turnaround time – customers also don’t need to order as many which can also be very beneficial to cashflow as well as the costs associated with storing a large amount of packaging. Real estate is also very expensive when used to store out of date packaging.”

Purchasing the Ryobi RMGT 970

As part of the extensive research leading up to the purchase of the machine, a trip to Japan was organised by Cyber NSW Account Manager Giorgio Rossi to test the Ryobi RMGT 970.

“Before we purchased the machine, we had a great experience travelling with Giorgio to Ryobi in Japan and we were very well looked after,” Studdert said.

“The professionalism of the team at Ryobi was brilliant and they couldn’t be any more accommodating. We went through the entire assembly plant as well as some of the other parts of the business including the die-casting facilities for the automotive industry.

“To test the machine, we trialled several technically difficult print jobs within the demonstration centre. We tried to push the machine past its limits with work printers have nightmares about. However, the Ryobi RMGT 970 passed with flying colours. We tested thin stock with very heavy ink coverage and fine reverse out type, followed by maximum thickness board at high speed with full solids. The press delivered mark free print with very clean screens. Metallics and fluoros with fine reverse out text remained open with no evidence of roller, gear marks or emulsification.

“During the testing, Ryobi RMGT 970 were very accommodating with their press time and access to the finer mechanical details of the machine. From the research I did, I was quietly confident that the machine would pass the tests, but I expected it to have some trouble with setting up – but that wasn’t the case – it went from one substrate to another with ease.

“Giorgio from Cyber was very helpful with providing us with specifications, configurations and information on all the machine’s systems answering any questions I had about the machine during the research process.”

This press features the Skeleton Transfer System which allows the wet side of the sheet to travel the length of the press without any contact. This also eliminates the need for regular IPC film cleaning and replacement. The new Ryobi RMGT 970 with a sheet size of 970mm x 650mm

complements the existing B2 eight colour press within CCS Packaging.

“This is the first installation in the southern hemisphere for this particular machine which is a 0.8mm spec machine that allows the printing of stock up to 800 micrometre boxboard.

“The Skeleton Transfer System means there is no IPC film that always needs to be cleaned by the operator. There is no build-up and then after a certain amount of impressions the cylinder on that film goes blind, so you have to replace it as it is a consumable. All of these issues are eliminated with this set-up – there is no marking and most importantly it creates better quality results. The side-lay on this machine is a new design – it is not just a pull side-lay, it also has a push from the opposite side that gives a more positive registration,” Rossi said.

“Purchasing this machine brings us into a different space in the market. It is also ready for us to embark on using the seven colours to produce the many special colour variants required in packaging. There will also be further technical opportunities that the Ryobi will be asked to achieve for our business and our customers.”

The installation of the Ryobi RMGT 970 was conducted by Cyber demonstrator John McCallum.

“John is based in Sydney and has worked with Cyber’s Ryobi machines for over 20 years. He has full factory training and is always on site when machines are installed,” Rossi said.

“Our installer and demonstrator John McCallum has been fantastic to work with,” said Studdert.

“His knowledge and experience was very thorough. John would stay back for hours each day to ensure the machine was 100 per cent and our operators had the support during the training stage. His enthusiasm and passion for what he does, shows in his work.”

Studdert said the graphical user interface (GUI) on the Ryobi RMGT 970 has been one of the key elements that has helped staff make the transition to the new machine during the training and installation process.

“Having mainly operated German presses, we found the iconology and operating system of the Ryobi to be very intuitive. This was also important, as it makes the transition from one press manufacturer to another a lot easier for our staff.”

No odor

No Ozone

No spray powder

No set-off

No loss time

• Instant dry

• Instant ON/OFF irradiation

Reduce CO2 emission

No large peripheral equipment

No need for overprint varnishing

Reduce electrical consumption

• Up to 91%

No VOC (Volatile Organic Compounds)

Reduce heat generation

Long life span

• Up to 15 times

Printing on film and cardboard

Just like your conventional offset press

...without the cons.

A skeleton transfer cylinder will be offered as an option for 970 model A1-plus size straight offset presses. The cylinder mechanism leverages the technology of RMGT’s flagship 10 series, which boasts a solid reputation in the packaging industry.

This newly added feature will enable the press to handle a wide range of sheet thicknesses from 0.04 to 0.8mm, expanding business opportunities by flexibly printing not only commercial and publication products but also packaging and speciality items.

Handles sheet thickness of up to 0.8mm to meet the demands of packaging printing.

Maximim sheet size of 650 x 965mm allows flexible handling of a wide variety of multi-up printing work.

Low-cost heavy-stock printing enhances competiveness (Approx. 20% lower plate costs and 18% lower power consumption versus a B1-size press)

2-4 Cyber: With the purchase of the new Ryobi RMGT 970 7 colour offset press with coater and Skeleton Transfer System, Sydneybased CCS Packaging has installed one of only two machines available in the world.

10 Fujifilm Business Innovation: Pukekohe Service Print has installed two new Revoria presses to boost production.

16 & 18 Konica Minolta: Programmatic printing can help you take your production to a new level.

20-21 Nekkorb: Marking a 15-year commitment to the labels, print, and packaging community, Nekkorb continues to innovate.

34 Durst: Technological innovation and commitment to the highest quality standards stand out as Durst Lienz celebrates its 25th anniversary.

36 Think Laterally: Work-life balance is a key driver of employee satisfaction and business success, says Mick Rowan.

12-13 Helping Hand: Iain MacIntyre catches up with two former Apprentice of the Year winners: Myra Anderson and Travis Jordan.

14-15 Comment: Ruth Cobb bids a sad farewell to five of our industry friends and colleagues who have recently passed away.

22 Supreme Winner: Wellington played host to the industry’s night of nights, which saw a tough to make label win the Supreme Award.

23 Apprentice of the Year: Meet Levi Lindsey from MCC Albany, the BJ Ball Print Apprentice of the Year.

24-32 Category and Process Winners: We hear from the winners and Pride In Print judges about this year’s winning entries.

33 Major Winners: Check out which companies collected the major prizes at this year’s Pride In Print Awards.

38 Aarque Group: 3M New Zealand has updated to a new HP Latex 700W printer, supplied through Aarque Group.

40 Computaleta: Summa cutters deliver efficiency and precision. Learn five benefits you can gain with these cutting systems.

42 Currie Group: The new EFI Pro 16h+ and EFI Pro 30f+ printers feature more capabilities, better image quality, and a performance boost over previous generations.

44 Visual Impact: Charly Blades, events manager for Visual Connections, reflects on the recent Brisbane show.

46 NZSDA Update: NZSDA members have come out of the cold to attend regional meetings, says Mikayla Hopkins.

47 NZSDA President: Shae Goom shares his thoughts on Visual Impact Brisbane and the recent NZSDA Conference.

48 NZSDA Apprentice of the Year: Mikayla Hopkins talks to this year’s winning apprentice.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Shae Goom, Mikayla Hopkins, Iain MacIntyre, Mick Rowan

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2024: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher. ISSN

Wayzgoose

Wayzgoose 2022

September 17, 2022

September 17, 2022

Napier

Napier

Printing United

APPEX and Auspack

www.inkianapress.co.nz

Foodtech Packtech

September 20-22, 2022

Auckland

September 10-12, 2024 | Las Vegas, USA

Labelexpo Americas

March 12-15, 2024 | Melbourne Convention and Exhibition Centre

September 13-15, 2022

Chicago, USA

Highlighting the latest innovations and applications in specialised printing, the event attracts thousands of visitors from across the printing industry, serving as an exhibition and as a knowledge hub, where experts share their expertise and stimulate discussions about the future of the industry. www.printingunited.com

Labelexpo Americas 2024

The Association of Handcraft Printers has a full day programme including visits to Havelock Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

September 10-12, 2024 | Chicago, USA

Foodtech Packtech

Foodtech Packtech

March, 2023 | Auckland

September 20-22, 2022

September 20-22, 2022

Auckland

Auckland

www.newzealandprinter.co.nz

National Wayzgoose

www.foodtech.packtech.co.nz

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise.

Auspack has transitioned into APPEX, the Australasian Processing and Packaging Expo. Organisers aim to truly represent all sectors of the industry: machinery, ancillary equipment, materials and packaging, food processing, and industry services. It will provide a comprehensive range of all processing and packaging equipment and services under one roof. www.appex.com.au

All in Print China

October 11-15, 2022

Shanghai

Going head-to-head with Printing United, America’s biggest label show promises something for everyone interested in labels including printers and label converters; flexible packaging and folding carton producers; brand owners; label and packaging designers; as well as industry suppliers. www.labelexpo-americas.com

Wayzgoose 2022

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

Fespa Global Print Expo

September 13-15, 2024 | New Plymouth

March 19-22, 2024 | Amsterdam

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

Nominations will soon open for the People in Print Awards and Rising Stars of Print Awards. Do you know someone who is consistently achieving excellence in their work in this industry? Of course you do, so when the time comes, put their name forward for these awards so they can receive recognition for their efforts.

September 17, 2022

Napier

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

www.allinprint.com

Programme highlights include visits to The Pioneer Village at Stratford with the ‘press gang’ and their print shop; bookbinder Jonathan Bennett; a printers fair; a buffet style Wayzgoose dinner with guest speaker; and an opportunity to see the Taranaki Aviation Technology and Transport Museum print shop in action.

Letterheads

www.abc-nz.org.nz

All Print

All in Print China

October 21-23, 2022

October 11-15, 2022

October 11-15, 2022

www.fespaglobalprintexpo.com

Tokyo Pack 2024

Shanghai

Shanghai

Printopia

October 23-25, 2024 | Tokyo Big Sight, Japan

Covering digital printing, screen printing, textile printing, garment decoration and signage, Fespa Global Print Expo will mix all the latest technology and solutions with events like the World Wrap Masters and Fespa Party Night alongside features such as its Sustainability Spotlight; Personalisation Experience, and Sportswear Pro.

May 3-5, 2024 | Corbans Estate, Henderson

Labelexpo South China 2024

December 4-6, 2024 | Shenzen, China

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

drupa

May 28-June 7, 2024 | Dusseldorf, Germany

Letterheads

Letterheads

October 21-23, 2022

October 21-23, 2022

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Sign Foundry, Welling

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Foodtech Packtech

Foodtech Packtech

September 20-22, 2022

Auckland

Craig Paul 027 655 4267 sales@curriegroup.co.nz

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

The 30th Anniversary show, which organisers call the ultimate event for Japanese packaging technology and science, Tokyo Pack showcases everything related to packaging including distribution, sales, consumption, and recycling. www.tokyo-pack.jp

www.letterheads.co.nz

Now into its third year, the Printopia Festival of Original Print promises a fun, inspiring, print-filled weekend of artist talks, demos, workshops, live printing and of course our print fair. International artist Jenny Robinson will give the keynote presentation on May 4 and a masterclass the following day. www.printopia.nz

Interpack

May 4-10, 2023

South China remains a significant market for the label and package printing industry and Shenzhen is a vibrant hub for business and innovation. Organisers promise visitors an inspiring three days where they will see the latest technology and machinery shaping the future direction of the industry. www.labelexpo-southchina.com

Sign Foundry, Welling

Sign Foundry, Welling

PacPrint 2025

May 20-23, 2025 | Olympic Park, Sydney

Visual Impact Brisbane Expo

July 17-19, 2023 | Brisbane

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise.

Düsseldorf, Germany

www.foodtech.packtech.co.nz

• Consulting and Machine Recommendations Sourcing

All in Print China

• Export/Import Sales

The world’s leading trade fair for printing technologies has opened registrations to again welcome the industry’s main players, and quite a few minor ones. All will show their latest solutions. Visitors can stay on trend with the technology and seminars featuring topics from sustainability to digitisation. www.drupa.com

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

www.letterheads.co.nz

October 11-15, 2022

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

• Machinery Inspections & Valuations

Shanghai

• Plant Relocation OFFICE: 09 8367577, ALEX MOB. 021 975 477 sales@apm.co.nz www.apm.co.nz

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

The most comprehensive and relevant business to business event serving the evolving needs of the print, sign and graphics industries in Australia, New Zealand and across the Asia-Pacific region, PacPrint will see around one hundred leading suppliers showcasing their latest products and services to thousands of industry professionals. www.pacprint.com.au

Interpack

Interpack

Printing United

May 4-10, 2023

May 4-10, 2023

Düsseldorf, Germany

Las Vegas, USA | September 10-12, 2024

Düsseldorf, Germany

Visual Connections Australia will host visitors and exhibitors at the Brisbane Convention and Exhibition Centre. The Exhibition hopes to attract over 2,500 visitors interested in the signage, print, graphic and engraving industries and featuring digital printing, personalisation, signage, sublimation, design, routing, display solutions, and vinyl applications. www.visualimpact.org.au

newzealandprinter.co.nz

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

www.allinprint.com

Letterheads

October 21-23, 2022

Sign Foundry, Welling

Showcasing the latest innovations and applications in specialised printing, the event attracts thousands of visitors from across the printing industry, serving as an exhibition and as a knowledge hub, where experts share their expertise and stimulate discussions about the future of the industry. www.printingunited.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com Craig Paul 027 655

newzealandprinter.co.nz organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

Craig Paul 027 655 4267 sales@curriegroup.co.nz

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

www.letterheads.co.nz

Interpack

May 4-10, 2023

Düsseldorf, Germany

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

EPSON has invested in a startup company that develops and manufactures microsatellites. Epson says Axelspace is a company that has demonstrated competitiveness in the expanding space data and technology utilisation business which has strong technological capabilities. Axelspace intends to explore the possibility of synergies with Epson’s sensing devices. Epson sees the space industry heading toward rapid commercialisation with the number of satellites launched globally expected to double in the next decade.

ESKO is celebrating the 5000th sale of its CDI and XPS exposure unit platemaking equipment. Jan De Roeck, director of marketing at Esko, says, “For more than 25 years, we have worked to develop flexo platemaking solutions that help shorten lead times, maximise press uptime, and reduce operator interaction to improve overall efficiency. This milestone is testament to the innovation of the development team and to those customers who have embraced the technology all around the world.”

RICOH and its affiliates have received Gold Provider Partner status in the Asia-Pacific region by Cisco, following a comprehensive evaluation, where Ricoh showcased its expertise in implementing managed services, Cisco SD WAN, and Cisco Meraki solutions. Kei Uesugi, managing director of Ricoh Asia-Pacific, says, “This achievement reflects our team’s commitment and proficiency in delivering SD WAN services and Cisco Meraki solutions. We are excited to deepen our collaboration with Cisco and continue supporting SMB customers across the AsiaPacific region.”

Durst will host its biggest open house of the year in October, with New Zealand and Australian printers invited to attend the exclusive event that will showcase Durst’s latest innovations.

Building on the success of last year, Durst Beyond, is making a return with the theme ‘Performance High –Get the best out of people, products, and processes’.

Customers and partners from around the world, including Australia and New Zealand, are invited to meet at Durst Group’s state-of-theart headquarters in Brixen, South Tyrol, where attendees will get the chance to take a look beyond the surface and into the future of the printing world. Attendees

Heidelberg has started the new financial year 2024/2025 with growth in incoming orders following a successful drupa.

The company’s incoming orders of €701m ($1.287bn) in the first three months exceeded its expectations and rose from the previous year

will have the opportunity to meet successful Durst customers from Northern Italy, gain deep insights into Durst’s technologies and developments, listen to an engaging keynote, and explore various solutions through hands-on sessions and product demonstrations. These highly engaging sessions will be complemented by a programme highlighting South Tyrolean traditions.

Matt Ashman, managing director of Durst Oceania, says the event provides an opportunity to visit Durst’s home to see the latest developments in technology and meet the Durst team face

of €591m. The company says its best order value since 2016 forms a strong basis for the entire financial year with a high order backlog of €923m. Europe at plus 25 per cent, and the Americas at plus 30 per cent, recorded particularly strong growth. Asia delivered only slightly weaker growth as the previous year had been particularly strong due to Print China.

Jürgen Otto, chief executive officer of Heidelberg, says, “The strong recovery in our order intake allows us to look to the full financial year

to face. He says, “Durst has built a reputation in Australia and New Zealand for opening its doors to customers and prospects to come and see what we are made of and what our products are made of. It is very much in our DNA as a family company to open our doors and welcome likeminded people.

“Both myself and our chief executive officer and owner Christoph Gamper sincerely appreciate the journey that visitors make from New Zealand and Australia to enjoy the Durst hospitality and get to see and understand our ‘little big company’ located in mountains at Brixen.”

with great confidence. The pleasing order backlog from the drupa trade fair will lead to rising sales in the following quarters compared to Q1. At the same time, we are working on our cost situation and personnel costs, which are generally too high.”

As expected, sales in the first quarter fell below the previous year’s level due to the reluctance to invest ahead of drupa. The adjusted operating result fell by around €51m to €–9m compared to the adjusted figure for the same quarter of the previous year.

The annual national Printers and Bookbinders Wayzgoose will take place over the weekend of September 13-15 in New Plymouth.

Graham Judd of Inkiana Press, says, “This year, the programme includes visits to The Pioneer Village at Stratford with the ‘press gang’ and their print shop; bookbinder Jonathan Bennett; a printer’s fair, for those looking to buy or sell letterpress and bookbinders goodies; a buffet style Wayzgoose dinner with guest speaker; and an opportunity to see the Taranaki Aviation Technology and Transport Museum (TATATM) printshop in action.

“Many printers will know Graham O’Keeffe from his days with Heidelberg New Zealand. Graham will be involved with the activities over the weekend.”

With the interest of younger printmakers in letterpress print around the country, organisers are looking forward to a mix of ages and people from different print processes joining the Wayzgoose.

Graham adds, “The Wayzgoose Committee welcomes anyone with an interest in any and all areas of print, bookbinding, and what has become known as printmaking. If you have any old surplus letterpress equipment to dispose of, here is an opportunity to sell it to budding printers rather than see it going to the tip.”

The word Wayzgoose historically refers to an annual summer dinner or outing held by a printing house for its employees.

Some bookbinders believe that Wayzgoose was held on St Bartholomew’s Day because he was the patron saint of leather workers. The holiday, a break in printing, was traditionally also the day that papermakers took a break from making paper for the printers.

For more information go to the wayzgoose page on the Association of Book Crafts website, or contact graham@inkianapress.co.nz

Kodak has refreshed its Green Leaf programme for Sonora plate users. The company says that Kodak Sonora Process Free Plates help printers to reduce their environmental impact, as they eliminate processing equipment, chemistry and the consumption of water and energy from platemaking.

The new Green Leaf programme helps Sonora Plate users further educate their existing and potential customers about the sustainability benefits enabled by Sonora Process Free Plates.

More than 10 years after Kodak first introduced the Sonora Green Leaf Award, the refreshed Green Leaf programme provides a host of new tools and marketing items. These materials, which include a new Green Leaf marketing handbook, updated collateral, animations, and a Green Leaf certificate, are exclusively available to Sonora

Plate customers. After registering on a dedicated web portal, they have access to these materials.

Kodak says the programme reaffirms its commitment to its customers and the environment. It gives the company the chance to offer the printing industry numerous solutions to help improve sustainability.

Laura Cole, vice president for product management at Kodak, says, “Our new Green Leaf programme supports Sonora plate users in clearly demonstrating to print buyers and the market as a whole that their commitment to the environment and sustainability begins with Kodak Sonora Process Free Plates.

“By using the Green Leaf programme to communicate that they are doing their part to help the environment, printers using Sonora plates also improve their chances of gaining more business.”

Elevate your print projects with our finishing services

P (09) 444 5523

M 021 190 1305

E info@bookbindingpress.co.nz www.bookbindingpress.co.nz

Fujfilm Business Innovation has supplied a busy Auckland print company with a new Revoria Press EC1100 and a new Revoria Press E1110 to replace its old Versant 2100.

Since its inception in 2004, Pukekohe Service Print has established a reputation for high quality and service, values that the present directors Tim Kempton and Jason White continue to uphold.

Producing a comprehensive and diverse range of printing products and services, Pukekohe Service Print continually strives to produce something better for its customers as demand for quality grows.

Jason says, “Our aim is to exceed our client’s expectations, every time and we believe delivering high quality print work is only part of the process; it’s service that really sets us apart. Our experience and expertise, combined with the latest print technologies and an emphasis on quality, are the reasons Pukekohe Service Print has continued to grow.”

Two months ago, the company installed a Revoria Press EC1100 and Revoria Press E1110, supplied through Fujifilm Business Innovation New Zealand (FBNZ). The new presses replaced Pukekohe Service Print’s Versant 2100.

Tim says, “We needed to look at a solution that would work best for us and our customers, keeping the same quality and consistency. After much looking around and talking to various suppliers, we chose the best solution that would offer us both qualities and was cost-effective.

“With volumes increasing, we found we were doing considerably more black and white work of between 150,000 to 170,000 pages per month. So, with the ratio of colour vs black and white changing, we realised that we needed the versatility of two machines.

“The installation provided a seamless crossover that took two days of de-installation and then installation. We had the Revoria EC1110 Press up and running within a day to keep production

going on a weekly job without missing any deadlines.”

The Revoria Press EC1100 (100ppm) and Revoria Press E1110 (110ppm) offer high productivity across a range of media jobs, handling paper weights from 52gsm to 350gsm for the E1110 and from 52gsm to 400gsm for the EC1100, which also prints long sheets of 330mm x 1200mm with the banner unit.

Tim says, “We find using the Revoria Flow RIP very user friendly. The training that we received from Glen Greenhill of FBNZ took place over a day and it was a simple process giving us options like hot folders and auto imposing. All these innovations speed our processes up.”

Pukekohe Service Print has a long association with FBNZ. Tim says, “We have been with FBNZ for coming up 20 years.

“We are grateful to Greg O’Shannassy from FBNZ, who did a lot of work in figuring out of which machines and solutions would work for our situation, including the space where the machines were to be housed.

“We are still finding new things about the two new machines. When we don’t know

something and where needed, we make a quick phone call to Glen to help us out.

“We also belong to PrintNZ and have used them on occasions when we have some questions and have found them very helpful.”

With the installation of the Revoria Presses, Pukekohe Service Print has enabled higher productivity. Like others in the industry, the company is operating in a sluggish economic environment but using its strong work ethic to maintain its position. Tim says, “Although there has been a downturn in the market, at this stage we haven’t been too affected because of all our packaging work. We just have to keep doing what we are doing right.

“It is all about quality and service, don’t over promise and under deliver. Enjoy the things you do, take pride in everything that goes out the door as it is your name that your clients remember. They trust you to do your very best and don’t take shortcuts.

“What gets us through each week is having a laugh together, even when things are tough. Brainstorming a potential problem all together to get the best result.”

Immerse yourself in the world of exceptional printing with our versatile production printer, engineered to fulfill your high-resolution printing demands with remarkable speed and precision. The customizable feeding and finishing options unlock a realm of limitless creative opportunities.

Whether you seek intricate graphics, precise text, or compatibility with various media types, rest assured that the Revoria Press EC1100 has everything you need.

We bid a sad and respectful farewell our beloved friends and colleagues: Mark Burgess, Denyse McQuoid, Teresa Bews, Laurie Pilling, and John McQuarrie.

Over the last couple of weeks, we have said farewell to five industry legends, and I wanted to take the time to acknowledge them and ensure that their contributions are honoured in print.

Each of these people was a huge part of the business they owned and worked in. They touched many people in our industry and each one of them possessed an incredible technical knowledge of the industry which they were happy to share. Their bright personalities and love of people means we will remember them for a long time to come.

Mark Burgess

Mark’s involvement in the digital print sector of the industry spanned across more than 30 years. He spent the last 17 of those at Ricoh.

He took a particular interest in the development of the digital print industry and was heavily involved in setting up the Ricoh Commercial and Industrial Print Division in New Zealand.

Mark took great pleasure in converting even the most steadfast of offset fans over to the world digital print and showing them just what it has to offer.

Outside of work, Mark was a devoted sportsperson. He was heavily involved with rugby, lawn bowls, cricket and softball as well as having a mad passion for motor racing.

He dedicated many hours to those sports, not just on the field but on the administration side of things at his local clubs including serving as President of both the Tawa Rugby Club and the Victoria Bowling Club.

Denyse McQuoid

Denyse started in the industry at age 15 and by 20, she had completed a lithographic printing apprenticeship at Auckland Copy Centre; one of the first females to do so.

She worked in several businesses in the industry including West Plaza Copy Centre and Tasman Westside. She spent the last 14 years of her career managing Contact Labels, where she used her vast knowledge to deliver exacting work to their clients.

Denyse combined an infectious personality with an incredible work ethic, and an absolute willingness to help others across the industry. These attributes meant that she gained the respect and admiration from both customers and other printers.

In April of this year, Denyse received a People In Print Award, reflecting her commitment to the industry.

Multi-talented, she could achieve anything she set her mind to, with a real eye for design that spread much wider than her work in the printing industry. Her love of the industry was exceeded only by her love of her family.

Teresa Bews

Teresa was the co-owner of Universal Print which was established in 1991 and grew from a small premise in Papatoetoe to their current factory in East Tamaki. She worked in the business alongside her husband David while raising their two children Ben and Angus. Family was hugely important to her and that extended to their employees as well with the business run very much as a family, borne out by the longevity of their staff (or maybe that was her fabulous baking).

Teresa was a jack of all trades and a master of many and would turn her hand to anything that needed doing in the business to get the job done and out to the customer.

Teresa was an absolute adventure seeker and took every chance she could to get out there and live her life to the fullest, never shying away from things that

would make many of us cry. She fought ferociously until the end driven by her love for her family, in particular her three grandchildren whom she adored.

Laurie Pilling

Laurie was the owner of Admark Visual Imaging in Hamilton from 1991 until he retired in 2019. Laurie spent the first 20 years of his working life in the military, rising to the rank of Lieutenant Colonel. He was decorated for his service in Vietnam and in 1977 was awarded a Member of the British Empire at the Queen’s Birthday Honours List.

Following his departure from the army he set himself a goal to make $1 million in 12 months and he achieved that by investing in some now iconic Waikato businesses including Waingaro Hot Springs, and the Waipa Delta Paddle Steamer. In 1991

he bought into Admark and the rest is history. Admark was the recipient of one of only 16 gold medals given out at the first Pride In Print Awards in 1994, and they have continued to excel over the last 31 years achieving a total of 65 gold and 43 highly commended awards, along with a number of category and process wins.

Laurie was presented with a Special Recognition Award at the 2019 Pride In Print Awards and was also made a Life Member of the Self Adhesive Label Manufacturers Association in the same year. Laurie understood the importance of people and was a strong supporter of industry training, investing heavily not only in his own staff but in others as well.

The single word most commonly used to describe Laurie was “gentleman” and he will forever be an Officer and a Gentleman.

John McQuarrie

John was a Past President (1990-1992) and Life Member of PrintNZ. He started in the industry in 1952 at Whitcome and Tombs in Dunedin, commencing a print apprenticeship at the age of 17.

One of the last colour blind apprentice in the training system, John cleverly managed things by having other tradespeople help when inks needed to be mixed.

With the gift of the gab, John transitioned from the presses into a sales role. He then progressed up through the ranks into management roles. In 1986, he became the group operations manager for the Print Division of the newly formed Printpac which came from a merger between Whitcoulls Production and Alex Harvey Industries. That company morphed into Norton Opax, Bowater and Rexham.

During the 1980s, John took on the role of chief negotiator, working on behalf of the industry at the annual industrial Award negotiations. He found himself involved in a number of stand-offs and a national strike, but somehow a conclusion was always reached through the negotiation process, sometimes over a beer.

John was a judge at the Pride In Print Awards for many years, including Convenor of Judges for four years from 2000 to 2003, completing 50 years of giving back to the industry he loved so much.

We thank you all for choosing print as your career and for your contributions to our industry.

Kia tau Rangimarie - Rest in Peace.

The winning experiences and career pathways of two former Apprentice of the Year winners.

Orangebox senior account manager

Myra Anderson recalls feelings of “excitement, energy, nerves and pride” flooding through her on the 2017 Pride In Print Awards Evening. She says,

“I was nervous to be in front of so many people from the industry, anxious to find out who would win and trying my best to remember my talking points if my name was called.

“I had dreamed of becoming Apprentice of the Year since my first assessment in 2013. I was with printing.com for four years before I took on the apprenticeship, so I knew that the print industry was for me.

“It’s been nearly 16 years now since I started as a pretty green print finisher

and I’m proud to reflect on how far I’ve come.”

Encouraging apprentices to fully “lean into” the knowledge and experience available within their companies, she says, “The wisdom that you can receive from your colleagues and mentors is invaluable. Don’t be afraid to ask questions and seek feedback. Also, try to embrace every challenge as a learning opportunity. The more you put into your apprenticeship, the more you’ll get out of it.

“Being named Apprentice of the Year is one of, if not the, proudest moment of my career. It boosted my confidence and opened new opportunities within the industry. It also reinforced my commitment to continuous learning and professional development.”

Myra was a web and graphic designer at printing.com at the time of winning the award. She has since explored different roles at different companies. She says, “I have had roles as production manager at a design agency; marketing producer at an accounting software company; a print buyer for a procurement/third-party logistics company. Working as a print buyer gave me the opportunity to work with a wide range of printers and finishers around New Zealand.

“My current role is all about looking after our clients and finding the best solutions for them through our datadriven, direct marketing services. My apprenticeship provided the skills, knowledge and confidence to be able to discuss prepress and print in a range of methods and finishing, and the entire production process with ease.

“One of the most fulfilling aspects of my role is the ability to combine my technical knowledge with client relationship management, ensuring that each project is delivered to the highest standard possible and exceeds client expectations. The apprenticeship honed my problem-solving skills and improved my financial decision-making, which are crucial in my role.

“I am especially proud to work for a New Zealand-owned and operated company. I also love working alongside so many longstanding Orangebox team members. The length of their service is a real testament to how great a company Orangebox is to work for.”

She has also pursued additional qualifications and other educational experiences. She says, “Studying part-time taught me that I’m a pretty driven person. Once I finished studying, I felt a little lost with all that spare time! I found I needed something to always work towards outside of work.

“After completing my New Zealand Certificate in Print – Digital Print Processes, I completed my Diploma of Print Management in 2020, completed a 21-day course through Outward Bound and I’m currently working towards a Certificate of Project Management through Open Polytechnic. I believe that continuous education is key to staying relevant and successful in any industry.”

Gratitude and pride

Currie Group New Zealand account manager Travis Jordan remembers the 2021 Pride In Print Awards Evening as an incredibly overwhelming and emotional experience. He says, “The nerves on stage were intense. I felt incredibly grateful and proud of the achievement that myself and Soar Print (now Soar Communications Group (SCG)

had accomplished. I don’t think that feeling has ever left me. It remains one of my biggest personal achievements.

“We were very fortunate to have BJ Ball Papers host a generous morning tea for our company the following week.”

Travis retains a drive to strive for excellence. He says, “I am passionate and proud of the work myself and those around me have been able to produce and ultimately learn from. I think those successes big and small are worthy of celebrating – after all our industry is a craft and I bloody love it.

He advises apprentices to enjoy the highs and learn from the lows. He says, “We work in a fast-paced industry, mistakes will be made. But how you choose to react to those mistakes is what will make you. Some of my best work or learnings have come from failures. Problem solving and understanding how to find solutions is where you will build integrity and thrive when future technical challenges arise.”

He completed his apprenticeship during the Covid-19 pandemic. He says, “It was strange and challenging year for all. As a digital print and finishing operator for SCG’s labels and flexibles division, Rocket Print, I had the opportunity to work within an amazing team and some incredibly-talented individuals and mentors, I moved into a position as production manager where I was able to cover all technical advances as

well as plan and train staff to ensure we were able to work in an enjoyable, yet lean, environment.

Currie Group

“In late 2023 I took on the role of account manager for Australia and New Zealand print trade equipment and service provider, Currie Group New Zealand. This role has brought great new challenges and learnings and has exposed me to another technical avenue in the industry. I feel fortunate to be surrounded by yet another great team, as well as a great customer base here in New Zealand.

“In my current role, I focus on ensuring clients receive support across the entire Currie Group portfolio, as well as keeping the market informed of the leading technologies that we have available here. I also stress the importance of sustainability and the recycling programmes behind our products and their consumables, ensuring everyone can recycle efficiently.

“The most enjoyable aspect of my role is learning more about our clients’ businesses and seeing the shared passion they have for their trade, wanting to stay educated and keep up to date with new innovations and technologies. I love being able to help find new solutions to help a company add value to their business.”

Although not currently involved in additional external training, he says he receives “immense support and continued training internally” within Currie Group to remain abreast of both portfolio and overall market developments.

Looking ahead, he would like to see greater exploration from the market of the value-add proposition of Currie Group’s products and “what they can do to enhance business capabilities and efficiencies”.

He adds, “I would also love to see the industry flourish and entice the younger generation to join the world of print. There are so many aspects of our industry to be excited about and market trends to be explored. I want to continue to support our existing clients and build new relationships within the wider market.

“I want to support PrintNZ and Competenz and their efforts to expose the younger generations to what our industry has to offer. Technology within print is having rapid growth and it’s exciting.

“We need to remain proud of our craft and what we achieve day to day and continue to celebrate our trade. The younger generation is a greatly important investment to the future of this industry.”

In this article, Konica Minolta discusses the benefits of programmatic printing.

Programmatic printing, also known as automated printing, refers to the process of computer programming and automation to control and manage various aspects of the printing workflow. The combination of modern printing presses, intelligent algorithms, and database technology enables the programmatic personalisation of the attention grabbing print channel.

What lies behind the buzzword programmatic printing? Anyone who produces printed products such as catalogues or advertising letters for a broad target group and sends them out according to the scattergun principle enjoys little success. As a result, many customers now consider doing without printed brochures altogether and others have already taken that step. This is a mistake because you cannot surpass the haptic experience of a catalogue. In addition, everything that you can personalise online, you can also personalise in print, and you can achieve that relatively effortlessly thanks to digital technologies.

Tailormade print

Personalised print products have evolved into so much more than cover letters with a personal address.

Today, you can create print mailings that you can tailor to the individual interests and behaviour of your clientele and you can have them delivered at the right time with the appropriate address: For example, when a potential buyer has not completed his online purchase; when an order for consumables was placed some time ago; or when interesting offers have become available for a special target group.

Recipients receiving individualised print products enjoy the experience. The combination of automation and personalisation makes programmatic printing an unbeatable tool in modern dialogue marketing.

Personalised, data-driven advertising in the form of letters, postcards and self-mailers is ending the era of impersonal mass mailings and putting the customer at the centre.

To get started with this new and very promising form of address, printers’ customers first need comprehensive advice.

It is no longer enough to simply process incoming print jobs. It is much more a matter of informing customers about the possibilities of programmatic printing. It is advisable to start talking to customers at

an early stage. This means a fundamental change in the traditional way of thinking, both for printers and for their customers.

In this process, the printer becomes a competent partner who enables a new and different type of print campaign that involves flexible scalable highspeed digital printing processes for an individual customer journey and more customer loyalty.

This places new demands on the job profile of the specialist staff of printing companies. Today, specialist knowledge and consulting expertise are in demand, as well as the ability to understand the customer’s problems and requirements and to solve them together with him.

Programmatic printing is basically possible with any press. This means that investments in new hardware are not mandatory.

Programmatic printing involves the integration of software, hardware and data to streamline and optimise the printing process. It can be applied to different printing technologies, for example digital printing, offset printing and large format printing. Specific software tools and scripts are applied

The digital revolution continues with the highly evolved AccurioPress C14000 series, designed to ensure you never stop printing. These high speed digital colour presses offer next level automation for ultra-efficient, high volume colour printing. Packed with an array of impressive features, powerful inline finishing options for high pr oductivity and with in-built technology, they offer unparalleled quality and consistency print after print.

To rethink efficiency, simply visit: konicaminolta.co.nz/AccurioPressC14000series

to automate tasks such as file preparation, pre-press, colour management, imposition, printing and finishing.

For its customers, Konica Minolta analyses which solutions are already available inhouse and which software they require. Often, many tools can be further used if the customers have the right idea about the software and the work steps. For example, if the goal is to address a smaller customer segment of 100 to 500 recipients, AccurioPro Variable Data (VDP) from Konica Minolta is the right solution. This suite stands for performance and flexibility and can be integrated via a switch for automation. A first possible step towards programmatic printing is, for example, also an InDesign plug-in.

Our showrooms demonstrate the possibilities and concrete solutions for programmatic printing and show which new paths printers can take today. Members of the Konica Minolta team will happily advise you on site.

The result for you is the integration of the print channel into the marketing automation software reduces the effort involved in planning and implementing classic print campaigns many times over.

Programmatic printing offers many advantages

• Greater efficiency.

• Fewer human errors.

• Improved consistency.

• Shorter turnaround times.

• The ability to meet complex printing requirements.

• It is particularly valuable in print environments with long runs, tight deadlines and the need for customisation or personalisation.

Konica Minolta’s workflow software

AccurioPro Flux Ultimate integrates easily into a programmatic printing solution. It will automate and manage the printing process. This software offers advanced features for file processing, colour management, variable data printing and collaboration between different printing devices.

With AccurioPro Flux Ultimate, you can programmatically create and manage print job queues, automate file preparation and colour correction, implement variable data printing and control output from multiple print devices. It helps streamline the print workflow and optimise efficiency.

AccurioPro Flux Ultimate offers advanced automation features and integration with multiple print devices. These are the essence of programmatic printing: using

automation and computer programming to control and optimise the printing process, and to achieve greater efficiency.

Programmatic printing gives innovative marketers the tools they need to run more efficient, personalised marketing campaigns in close collaboration with printers. Full automation enables cross-media, customer-centric print products that impress, increase sales and retain customers.

Konica Minolta describes the advantages and most important aspects of programmatic printing:

Programmatic printing enables the automation of file preparation tasks such as image processing, colour correction and file conversion. Software tools can be programmed to automatically process incoming files and optimise them for printing.

Programmatic printing makes it easier to incorporate variable data into printed materials. This creates personalised or customised printed pieces with unique information such as names, addresses as well as personalised offers.

Programmatic Printing makes it easier to manage print jobs through automation. Print job queues can be created and managed programmatically to ensure that jobs are processed in the desired order and with the correct settings.

Colour management

Precise colour control is critical in printing. Programmatic Printing

enables automated colour management that ensures consistent colour reproduction across different print runs and devices. Colour profiles can be applied automatically, and colour calibration can be scheduled and performed at regular intervals.

Programmatic printing enables automation of imposition tasks, such as page reordering, imposition template selection and trim settings.

Print verification and quality control

Automated quality control tools can be integrated into Programmatic Printing workflows. These tools automatically check for common printing issues such as image resolution, colour accuracy and font embedding, ensuring that the final printed output meets the desired quality standards.

Integration with production equipment

Programmatic printing can be integrated with a variety of printing systems. These include digital presses, offset presses and finishing equipment. This integration enables seamless communication between software and hardware, reducing manual intervention and increasing productivity.

With a commitment to the labels, print, and packaging community, Nekkorb continues to innovate.

Starting Nekkorb Solutions in April 2009, on the back of the largest global financial crisis since the great depression, seemed to some like a crazy and brave move but Frank and Claire Brokken were up for the challenge.

Frank has ink in his veins, having started in the printing industry in 1975 as a flexographic printing apprentice. He subsequently moved to technical sales positions at leading ink manufacturer Morrison Printing Inks and flexographic printing plate giant (DuPont). His time working for these companies gives him the knowledge that enables him to add value to all printing and converting companies as well as supply partners that Nekkorb has had the pleasure of working with over the years.

Since 1996, MPS has only made servo driven machines. Designed with an operator focused process in mind, they feature slide out printing units that can be easily set up safely outside the machine while it is still running; ink curing on the chill roller rather than the impression roller to reduce material wastage and downtime cleaning cured ink; and extensive data collection capabilities.

• Ease of

• Highest quality

• Significant foil saving

• For budget flexibility

Through his process knowledge and extensive travelling around the world, he created a strong portfolio of foundation products for Nekkorb to start trading. Some of those initial supply companies like 3M, Zecher, TKM and WINK remain Nekkorb partners today. He says, “It goes to show great products and good working relations stand the test of time.

“Other great companies that make up Nekkorb’s product portfolio today include industry leading recognised manufactures, MPS, Dantex, Vinfoil, Gietz, DuPont, AVT, x-rite and Esko.”

Nekkorb’s commercial manager Tash (Natasha) Brokken, Frank and Claire’s eldest daughter, has worked in the business for the past 12 years. She will eventually take over the running of the business continuing its founding values of respect, trust, innovation, and sustainability. Nekkorb’s great product portfolio is full of gems, among them:

Frank calls the MPS Narrow and Mid web label and packaging machines the most advanced machines in their category today.

The new Dantex Pico Technology allows printers to test, tweak and turn around custom label orders fast. The modular designed Pico range offers numerous options for inline finishing; die-cutting, lamination, backlit/edge trim, slitting and rewinding. You can personalise every label, create short runs for A/B testing or simply trial label alternatives for a product launch. Frank says, “The Picocolour and PicoJet machines accelerate the time to market and maximise your return on investment. They achieve outstanding whiteness and extremely high print quality in a single pass.”

This market leader shines in the design and manufacture of label finishing, die cutting slitter rewinders, digital label converting finishing systems and flexible packaging finishing equipment. Frank says, “In-house technical innovation has been the driving force behind BGM with constant product development to meet the changing needs and requirements of customers. Offering a three-year guarantee on all in-house manufactured parts, BGM delivers outstanding after sales service and product support.”

One of the world’s leading manufacturers of cutting tools for the graphic industry with the motto “You Cut We Care”, Wink makes precision tools for printers, and converters all over the world. Frank says,

“We are surrounded by products, that acquire final shape through die-cutting. Wink’s flawless quality in its die-cut products is crucial for our customers’ success. Depending on the sector and material involved, Wink must meet very different requirements, when it comes to specifications for its cutting tools. From kiss-cutting to cutting-through, perforating, creasing, and embossing. Wink tailors its tools perfectly to meet the requirements of the individual.”

Zecher, founded in Germany 75 years ago, focuses solely on the manufacture of anilox. Frank says, “For the highest quality and engraving consistency Zecher

Building for the future:

continues to deliver on its promises and develop new ‘First in industry’ technologies that others try to copy.”

For a full closed loop and secure process solution Nekkorb has partnered with Esko, X-Rite and AVT. From design software, plate production, process measuring and control to 100 per cent inspection of the finished print this partnership deliver the highest quality print, faster and consistent with less downtime and wastage.

Frank treasures his place in the business, using his 49 years’ experience in the industry to help Tash build her team for the future.

Bring new life back into your old printing machine

• Save money

• Ink

• Paper

• Energy

• Best in class colour consistency

• Seamless intergration with most rips

This closed loop colour measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

Ready or considering the upgrade?

Contact us now

Get in touch with our partner

Labels stars as MCC grabs the Supreme Award and Apprentice of the Year Award.

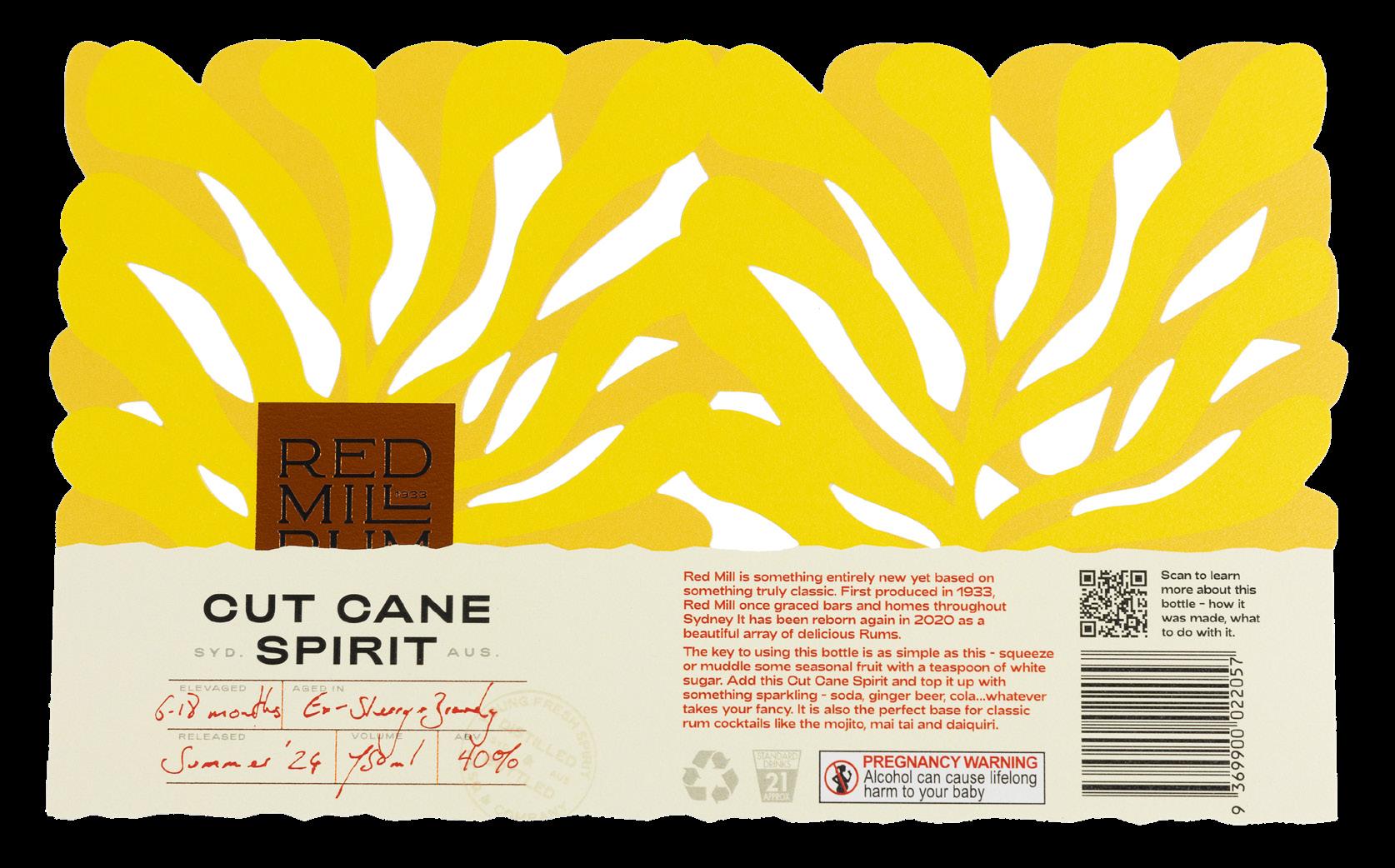

Several companies had turned down the Red Mill Rum job that MCC Albany turned into a Pride In Print Supreme Award winner

The Pride In Print Supreme Award for 2024 has gone to MCC Albany for its Red Mill Rum label.

The nation’s print community gathered in Wellington in July for the annual Pride In Print Awards and the Print Training Awards.

On a near freezing capital city evening, a capacity crowd filled the Tākina Wellington Convention & Exhibition Centre for the awards celebration. Emcee Hilary Barry kept the audience in tune with the tone of the night, telling the winners and their supporters to “celebrate loudly and celebrate proudly”. While the born and bred Wellingtonian who resides in Auckland proclaimed her love for her hometown, she also admitted that the weather had blown her horizontal at the airport.

Craftmanship wins

MCC Albany’s Supreme Award winner job showed “mastery of a job so complicated that other label converters had turned it down”. The work also won the Labels category.

Marco Adriaanse, sales director for MCC New Zealand, accepted the Supreme Award, expressing his gratitude for

the team at MCC. He said, “I feel overwhelmed, to be honest. For MCC, it is recognition of decades of craftmanship. The level of technicality and innovation involved in this job goes beyond what most people understand when they look at a label.

“It is a high end product, niche and bespoke. We had a connection with the designer Ben Galbraith, who has a habit of always pushing the envelope. The customer was over the moon with the job and said we had exceeded the brief they had given us.

“Several companies had turned down the job before we accepted it. Most label converters are going to say, ‘No thank you, we simply can’t do it’, because in the process of trying to remove the cutouts, they end up ripping the label. MCC Albany is the only company, based on my knowledge, who can produce this.”

“From a business perspective, to go back and pass on this acknowledgement from industry, that this has been peer reviewed; it is massively satisfying.”

Judges impressed

Pride In Print judges said, “The Red Mill Rum label, printed two-up, featured

beautifully enhanced sheets of stock run simultaneously with 23 precise die line cut-outs apiece removed across a print run of 6500 – this job presented significant technical challenges.

“Being a self-adhesive label, the backing liner needed to remain intact for application, which eliminated the usual efficient option of ‘punching’ or ‘blowing’ out the cut-outs. After much collaboration and trialling, a cost-effective solution was found to complete the tricky removal process on the press.

“Furthermore, with the heavily-textured stock to feature large solid areas as well as fine text and lines, the job required considerable make-ready and precise application of gold foiling and high-build spot varnish. These processes needed to be mastered across three passes on two different presses.”

The Pride In Print Awards receive invaluable support from its generous patron, Fujifilm as well as the sponsors: Avery Dennison, B&F Papers, BJ Ball, Currie Group (NZ), DIC New Zealand, Kurz New Zealand, Nekkorb, Paper Source, Reproflex3, Ricoh New Zealand, Spicers NZ and UPM Raflatac. The media sponsor is New Zealand Printer Magazine

PrintNZ has named MCC Auckland flexographic printer Levi Lindsey as the BJ Ball Print Apprentice of the Year.

Ruth Cobb, chief executive of PrintNZ, announced the Apprentice of the Year and other Training Awards winners at the gala 2024 Pride In Print Awards Evening, hosted by Hilary Barry at Tākina Wellington Convention and Exhibition Centre. She said, “This truly is the highlight of my job – recognising the people that will be the future of our industry and the businesses that encourage them.

“Some, uninformed, people might say you don’t need skill to be a printer anymore, but there is a lot more to print than pushing an on and off switch. If we are going to continue to stretch the

boundaries and wow our customers, we need to continue to master the dynamics of inks, substrates, colour management and finishing, to say nothing of the complexities of the front end.”

The five Apprentice of the Year finalists were Levi Lindsey, MCC Albany; George Cunningham, Allied Press; Anna Hodge, Be My Guest Design; Amit Shankar, Labelmakers; and Kathryn Wheeler, Freedom Plus. The final selection took place after the candidates’ interviews earlier on the day of the awards evening.

Ruth said, “They were all so passionate. Every one of them spoke with such technical detail about the work they brought along – highlighting again that print is a craft. A comment from one of them today summed this up when they said: ‘The fundamentals only get you so far’.

“And a point to note about this particular group of people, who all graduated last year, is they pretty much completed their entire apprenticeship under the auspices of the Covid-19 pandemic and the disruptions that brought to workplaces, families, and businesses.

“I know this is just the beginning of their journeys. The learning does not stop here. They all have aspirations to go further and do more and we are so glad they are doing that in our industry.”

Levi Lindsey said, “I am truly honoured to receive the award. “I want to thank MCC Auckland, formerly known as Adhesif Labels, my colleagues and my mentors for their unwavering support and guidance. This achievement is a testament to their dedication and belief in me.

“To my fellow apprentices: keep striving for excellence and never stop learning. Together, we can shape the future of the industry.”

Haydn Mitchell, technical manager at MCC Auckland, said, “Levi’s first role at Adhesif Labels was working in our post-press cleaning area. Having shown a keen interest in printing, he progressed to the role of flexo printer assistant. Having excelled at this he was offered a flexo printing apprenticeship.

“His proactive approach, combined with consistently delivering top-notch quality work and keeping that positive attitude, speaks volumes about his dedication and work ethic.

“I was not surprised at all to see Levi excel in his apprenticeship. With his commitment and upbeat demeanour, it was pretty much a given.”

Stuff claimed the 2024 Pride In Print Publications Category for its production of The Post Weekend Te Upoko O Te Ika, Saturday December 9th Edition 2023.

Andy Brown, Stuff Petone printing plant day shift printing supervisor, stated the importance of timely production for The Post Weekend, the Saturday edition of Wellington’s daily metropolitan newspaper. He said, “We printed it at Stuff’s print production plant in Petone on a Manroland Geoman double-width press on Norske Skog 40gsm newsprint using Huber coldset inks and Kodak Sonora plates.

“What is impressive about this entry is the size of the paper: a 40-page broadsheet newspaper. We printed it on three of the four printing towers of our press. “It is a time-critical job. To be able to produce a copy with the quality of registration and consistency of colour throughout with the pressures of deadlines to be met is quite an achievement.”

Judges said, “Boasting strong colour depth and almost faultless registration, this was a very well printed newspaper. Such high quality was achieved despite

Blue Star Jackson won the Print Category and Sheetfed Offset Process Award for the Riddet Institute Annual Report.

Tim Upton, Blue Star Jackson account director, said, The job was created for internal and external stakeholders as a snapshot of the progression into real world, potential application of world class, food-based science research.

“Careful attention to detail was crucial to this print job. It contained a number of challenging aspects with full black print, white borders, reversed type, as well as split spreads.

“The cover of the report required innovation, with discussions taking place well before the files were handed over, to create the perfect embellishment to complement the design, this year being a spot UV to draw attention to the title ‘Focus and support elements’. The report is also printed on a Forest Stewardship (FSC) and Elemental Chlorine Free (ECF) accredited paper stock.

“Our client said, ‘We have such faith in Blue Star to take our vision for the report and produce it with such care and expertise that we consider them a key

the short lead time and presses running at speeds of 40,000 copies per hour, with operators having just 30 minutes from the start of production to providing the first batch of completed editions for waiting delivery trucks.

“With Stuff needing to complete the

entire print run within just three hours, there was also little opportunity to make corrections on the press. To consequently produce such a colourful, vibrant, and clean publication is testament to the quality of the machinery and personnel involved.”

partner in this job, now and in the future.’”

Judges said, “The outstanding printing and finishing in this annual report excelled in delivering on the full potential of a superb design. Printed at A1 and folded down to landscape A4, the folios were in a near perfect position throughout and the binding was faultless.

“There was great consistency in the registration and colour, with the rich blacks standing out on the uncoated stock, and a spot UV was applied to the cover to provide an eye-catching finish. This is one of the best offset printed annual reports we have seen in a long time.”

Gravure Packaging won the Flexible Packaging Category (Joint) and the Gravure Process Award for the Joyhana Whipping Cream Sleeve.

Grant Amelung, technical director at Gravure Packaging, said, “The job uses photo-realistic images, reproduced perfectly with the colours nicely saturated. It maintains realistic vignettes and depth and solid colours. It features detailed and petite Chinese characters and background dual vignettes of twospot colours merging seamlessly.”