Wayzgoose goes to Taranaki PrintNZ: the year in review

What to do about AI

Packaging gets a boost

Wayzgoose goes to Taranaki PrintNZ: the year in review

What to do about AI

Packaging gets a boost

Graphics industry veterans Leo Bult and Vicky Winslow recently founded a new company to supply high quality media to the local market. After getting off to a flying start, Chrome Grafixx is already distributing a comprehensive range of roll products and rigid media to the New Zealand market.

Despite being the new kid on the block, Chrome Grafixx offers its clients the advantage of decades of industry knowledge and expertise through Leo and Vicky, who had both taken a brief hiatus from the industry but found that they could not stay away.

Vicky says, “While it was good to have a break, we both found that we missed the industry and the amazing people who work in it. We have invested decades of our time in this sector and formed invaluable connections.”

After making the decision to incorporate their industry experience and product knowledge to seek out better solutions for customers, the Chrome Grafixx team set out to establish key relationships with local and international suppliers.

A focus on well-maintained inventory levels ensures Chrome Grafixx customers have reliable and consistent stock availability

Leo explains, “We could see the advantages of bypassing the middlemen and going directly to the source. It means that we can procure great products at fair prices and pass on these benefits to our customers through better products, better prices, and better support.”

The new company places its customers front and centre. He says, “From the outset, we have had a customer centric approach. We are a small and proficient team with a dedication to excellent customer service, quality support and product delivery. We understand the importance of delivering

high quality products, which is admittedly made easier with invaluable industry knowledge and connections.”

The team at Chrome Grafixx has a commitment to the print graphics market reflected in its dedication to supplying top-tier roll media and rigid products that drive creativity and excellence to the signage and print industry. Leo says, “We are devoted to providing a comprehensive range of high quality supplies, fair pricing, and outstanding service levels.

“Our offerings are designed to enhance the capabilities of our customers and elevate their projects, meeting the diverse needs of print professionals.”

Leo and Vicky’s impressive list of industry contacts enables Chrome Grafixx customers access to a diverse assortment of quality rigid and roll media. Leo says, “We are proud to collaborate with a network of esteemed suppliers who are leaders in the graphic media industry. Each of our partners are recognised for their innovation, quality, and market position, ensuring that we deliver only the best products to our customers.

“By partnering with these market leaders, known for their commitment to research

and development, we not only access a diverse range of superior materials and technologies but also benefit from their industry insights and advancements.

“This strategic alignment allows us to stay ahead of trends, offer state of the art solutions, and maintain a competitive edge in the ever evolving graphic media landscape. Together, we are dedicated to setting new benchmarks for quality and performance, ensuring that our customers receive the most innovative and reliable products.”

Leo and Vicky agree that simply offering a range of products will not cut it with discerning customers who know what they need. Leo says, “We understand that our customers have a diverse range of requirements, and we have tailored our offering to reflect those requirements.”

The Chrome Grafixx portfolio includes an extensive range of premium roll medias and rigid substrates that enhance efficiency and creativity.

Leo adds, “Our commitment to innovation ensures that we continually adapt to industry trends, helping our clients stay competitive and deliver exceptional results. With a focus on reliability and

performance, our products are designed to support every aspect of the printing process, from concept to final output.

“We prioritise sustainability, providing eco-friendly options that align with modern environmental standards. For example, we have a huge range of PVC free medias in both roll and rigid which offer an environmentally friendlier alternative to traditional print medias.”

Chrome Grafixx is excited to announce its partnership with Future Post, who recycle NZ waste plastic into NZ products – posts, rails, sleepers and bollards. Future Post’s Recycling Advocate (RAd) Partnership Programme provides a Kiwibased, sustainable recycling solution for commercial waste plastics. Chrome Grafixx will conveniently manage the recycling process for their customers who have opted into the recyclable programme, through a pick-up and drop-off service.

Vicky says, “We are proud to champion recycling as a core part of our commitment to sustainability. We believe in the power of small actions to create a big impact, which is why we are proud to partner with Future Post to actively promote responsible recycling and empower our customers to recycle

correctly and efficiently. This enables us to promote a positive outcome for end of life polypropylene products where traditionally this widely used product would otherwise end up in landfill.

“It is our aim to foster a culture of environmental responsibility, to lead by example and inspire our customers to make recycling a natural part of their everyday lives. Together, we can help protect our planet for future generations.”

Chrome Grafixx has specifically targeted a small but key product range which services a large part of the market but also allows Chrome Grafixx to focus on ensuring inventory levels are well maintained and that its customers have reliable and consistent stock availability.

The Chrome Grafixx product offering includes:

• Rigid Media: paper board, corrugated board, construction board, bubble PP, fluted PP, foam board, rigid plastics, and PVC foam.

• Roll Media: PVC free, synthetic, window, laminate, promotional, intermediate, and premium selfadhesive PVC. Wallpaper, floor graphics, vehicle wrap, backlit, poster UV paper, and magnets.

• Accessories: a range of blades and router bits suitable for Zünd, Esko, and Summa cutting tables.

Vicky adds, “Online ordering is a breeze. To make it even more fun, email us at sales@chromegrafixx.co.nz where we will

The attitude at Chrome Grafixx demonstrates how experience and knowledge makes a difference in the industry. Leo says, “At Chrome Grafixx, we are dedicated to driving innovation and excellence as a premier graphic media supplies specialist.

“With a collective 79 years of industry experience and knowledge, the Chrome Grafixx team combines expertise and insight to deliver top-quality solutions. Our customercentric approach combined with our culture of knowledge sharing gives us the capability to drive collective success and foster strong partnerships.

“It is not just business, it is personal. We are not just providing graphic media supplies; we are redefining the industry’s standards and possibilities through our mission and values.

“We have a simple mission: to provide top quality print supplies at fair and competitive pricing for all our customers without compromising quality.

“With our commitment to exceptional customer service and belief in building lasting relationships based on trust and integrity, we are dedicated to delivering innovative products. We have a big focus on environmental responsibility and sustainability, while offering personalised solutions that meet the distinctive and diverse needs of our customers. By prioritising customer satisfaction and affordability, we can help to empower individuals and businesses to achieve their creative goals.

“We want to revolutionise the print supplies industry by being the go-to source for innovative, high-quality products that empower creativity and sustainability.”

set you up with a website login and you will receive 10 per cent off your first order.

“We are old school and would love to chat with you and we look forward to discussing your requirements for rigid and roll media. Contact us on 09 883 5253.”

Cover Story p3-5

3-5 Cover Story: Industry veterans Leo Bult and Vicky Winslow recently founded a new company. Chrome Grafixx supplies a comprehensive range of high quality roll products and rigid media to the local market.

PrintNZ p10-14

10-12 Helping Hand: Iain MacIntyre recaps what happened in 2024, illustrating PrintNZ’s involvement across the industry.

14 Comment: The PrintNZ family continues to grow, making our industry stronger, says Ruth Cobb.

Features p16-26

16 Fujifilm Business Innovation: Skyline Print has installed an ApeosPro C750 digital press to boost its digital offering.

18-19 Bookbinding Press: Specialist knowledge and skills deliver high quality finishing for trade and retail customers.

20 Letterpress: Graham Judd reports from the third annual Wayzgoose held recently in Taranaki.

21 Epson: An Epson SD-10 has made colour management a breeze for the team at Dark Lab.

22 Konica Minolta: Taking the lead in promoting sustainability sees Konica Minolta revising its emission reduction goals.

24 Business: Charles Watson discusses technological and AI advancements affecting business.

26 Think Laterally: Reset, recharge, rejoice: Mick Rowan shares his Christmas holiday survival strategy.

Wide Format Plus p27-32

28 Aarque Group: The Big Picture recently installed an HP Latex R2000 at its Wellington site.

30 NZSDA Update: Mikayla Hopkins reports on the end of year activities that NZSDA members participated in.

31 NZSDA President: Shae Goom has some suggestions for planning a successful year in 2025.

32 NZSDA Innovation Champion: Dustin Brattle continually looks for new ideas to make the industry more environmentally friendly.

Labels & Packaging p34-40

34-36 Koenig & Bauer Durst: The Durst Delta SPC 130 offers a highly profitable opportunity for printers and converters.

38-40 Radio Frequency

Identification (RFID): Intelligent labels are having a profound impact on supply chains.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Shae Goom, Mikayla Hopkins, Graham Judd, Iain MacIntyre, Mick Rowan, Charles Watson.

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2024: Contents of this magazine are subject to copyright

materials.

Wayzgoose

Wayzgoose 2022

September 17, 2022

September 17, 2022

Napier

Napier

Heimtextil

APPEX and Auspack

January 14-17, 2025 | Frankfurt

www.inkianapress.co.nz

Foodtech Packtech

September 20-22, 2022

Auckland

Labelexpo Americas

March 12-15, 2024 | Melbourne Convention and Exhibition Centre

People In Print Awards

The Association of Handcraft Printers has a full day programme including visits to Havelock Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

September 13-15, 2022

Chicago, USA

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

February | Auckland

People in Print Awards

The global event for interior textiles, interior design and interior trends will feature new products and their applications. www.heimtextlmessefrankfurt.com

www.foodtech.packtech.co.nz

Foodtech Packtech

Foodtech Packtech

March, 2023 | Auckland

September 20-22, 2022

September 20-22, 2022

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise.

All in Print China

October 11-15, 2022

Shanghai

Send your nominations in for next year’s People In Print Awards and Rising Stars of Print Awards. Email bruce@newzealandpriner.co.nz

Auspack has transitioned into APPEX, the Australasian Processing and Packaging Expo. Organisers aim to truly represent all sectors of the industry: machinery, ancillary equipment, materials and packaging, food processing, and industry services. It will provide a comprehensive range of all processing and packaging equipment and services under one roof. www.appex.com.au

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

Auckland

Auckland

PrintNZ Golf Days

February 14, 2025 | Christchurch

Wayzgoose 2022

February 28, 2025 | Auckland

www.newzealandprinter.co.nz

Fespa Global Print Expo

March 19-22, 2024 | Amsterdam

Nominations will soon open for the People in Print Awards and Rising Stars of Print Awards. Do you know someone who is consistently achieving excellence in their work in this industry? Of course you do, so when the time comes, put their name forward for these awards so they can receive recognition for their efforts.

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

September 17, 2022

Napier

Fespa Global Print Expo 2025

May 6-9, 2025 | Berlin

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

Open to players of all abilities, PrintNZ Golf Days are all about fun and connecting with fellow industry professionals. www.printnz.co.nz

www.allinprint.com

Letterheads

4A/157 Stoddard Road, Mount Roskill, Auckland 1041.

All in Print China

All Print

October 21-23, 2022

Covering digital printing, screen printing, textile printing, garment decoration and signage, Fespa Global Print Expo will mix all the latest technology and solutions with events like the World Wrap Masters and Fespa Party Night alongside features such as its Sustainability Spotlight; Personalisation Experience, and Sportswear Pro.

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft.

October 11-15, 2022

October 11-15, 2022

www.fespaglobalprintexpo.com

Shanghai

Shanghai

Printopia

PacPrint 2025

www.inkianapress.co.nz

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Sign Foundry, Welling

The giant show brings hundreds of exhibitors to showcase their latest innovations across graphics, décor, packaging, industrial, and textiles. www.fespa.com/en

Foodtech Packtech

Foodtech Packtech

May 3-5, 2024 | Corbans Estate, Henderson

May 20-23, 2025 | Olympic Park, Sydney

Craig Paul 027 655 4267 sales@curriegroup.co.nz

September 20-22, 2022

Auckland

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

Now into its third year, the Printopia Festival of Original Print promises a fun, inspiring, print-filled weekend of artist talks, demos, workshops, live printing and of course our print fair. International artist Jenny Robinson will give the keynote presentation on May 4 and a masterclass the following day. www.printopia.nz

The show has moved from Melbourne to Sydney, where it will welcome around one hundred leading suppliers and manufacturers. www.pacprint.com.au

NZSDA Conference and Awards

drupa

June 12-14, 2025 | Nelson

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

May 28-June 7, 2024 | Dusseldorf, Germany

www.letterheads.co.nz

Interpack

May 4-10, 2023

Düsseldorf, Germany

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

Letterheads

Letterheads

• Consulting and Machine Recommendations Sourcing

October 21-23, 2022

Celebrating its 60th anniversary, NZSDA will combine its awards and conference under the theme: Tradition Meets Tomorrow. www.nzsda.org.nz

October 21-23, 2022

All in Print China

• Export/Import Sales

Sign Foundry, Welling

Sign Foundry, Welling

Pride In Print Awards

The world’s leading trade fair for printing technologies has opened registrations to again welcome the industry’s main players, and quite a few minor ones. All will show their latest solutions. Visitors can stay on trend with the technology and seminars featuring topics from sustainability to digitisation. www.drupa.com

July 4, 2025 | Cordis Hotel, Auckland

Visual Impact Brisbane Expo

July 17-19, 2023 | Brisbane

• Machinery Inspections & Valuations

October 11-15, 2022

Shanghai

Entries have opened. Mark the date for the Pride In Print Awards gala dinner in your diary. www.prideinprintawards.co.nz

Foodtech Packtech

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

• Plant Relocation OFFICE: 09 8367577, ALEX MOB. 021 975 477 sales@apm.co.nz www.apm.co.nz

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

September 2-4, 2025 | Auckland Showgrounds, Auckland

www.letterheads.co.nz

www.letterheads.co.nz

Visual Connections Australia will host visitors and exhibitors at the Brisbane Convention and Exhibition Centre. The Exhibition hopes to attract over 2,500 visitors interested in the signage, print, graphic and engraving industries and featuring digital printing, personalisation, signage, sublimation, design, routing, display solutions, and vinyl applications. www.visualimpact.org.au

Interpack

Interpack

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

newzealandprinter.co.nz

New Zealand’s largest food manufacturing, packaging, and processing technology trade show will attract more than 250 local and international exhibitors. www.foodtechpacktech.co.nz

May 4-10, 2023

May 4-10, 2023

Printing United

www.allinprint.com

National Wayzgoose

Düsseldorf, Germany

Düsseldorf, Germany

Las Vegas, USA | September 10-12, 2024

September 12-14, 2025 | Auckland

Letterheads

October 21-23, 2022

Labelexpo Europe 2025

September 16-19, 2025 | Barcelona, Spain

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

Letterpress and bookcraft will again feature in the fourth annual Wayzgoose. www.inkianapress.co.nz

Sign Foundry, Welling

Showcasing the latest innovations and applications in specialised printing, the event attracts thousands of visitors from across the printing industry, serving as an exhibition and as a knowledge hub, where experts share their expertise and stimulate discussions about the future of the industry. www.printingunited.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

Craig Paul 027 655 4267 sales@curriegroup.co.nz

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

The world’s biggest event for the label and package printing industry offers demonstrations of the latest technology and related seminars. www.labelexpo-europe.com

www.letterheads.co.nz

Interpack

May 4-10, 2023

Düsseldorf, Germany

Heimtextil features new products and trends for textiles and their applications

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

MÜLLER MARTINI has launched the Antaro perfect binder, available in two versions. Equipped with two spine preparation stations, the system uses EVA and PUR adhesives. It produces print on demand books at up to 2,000 cycles per hour and up to 4,000 cycles per hour for offset print applications. The Antaro accommodates all conventional types of book blocks, including signature stacks, pre-glued or thread-sewn book blocks, as well as single sheet stacks.

HYBRID SOFTWARE and Highcon have partnered to integrate Hybrid’s PACKZ software into Highcon’s Digital Die Cutting Workflow Package (DWP). The companies say that by advancing artwork handling, high-quality previews, and automated XML export capabilities, this collaboration enables packaging converters to seamlessly integrate Highcon’s digital solutions into their workflows, simplifying setup while accelerating production timelines. The collaboration uses a custom designed version of the PACKZ Engine for Highcon, introducing a fully integrated PDF workflow.

CANON has unveiled the new LabelStream LS2000, for industrial scale label printing. The water-based inkjet label press prints CMYK plus white on self-adhesive substrates including paper and film with a new ink set designed to comply with food safety standards. Canon has aimed the new press at label converters serving industries such as food and beverages, personal care, household goods and electronics, and the manufacturing of bespoke or customised products.

Ligare’s New Zealand based book and education business is merging with Touchprint.

The merge will include the associated personnel and resources required to provide Ligare’s New Zealand customers with a seamless changeover and a wider service offering. Guy Phillips, chief executive officer at

Heidelberg says it is offering print shops the prospect of continued profitability thanks to hybrid production and Prinect Touch Free.

Dr David Schmedding, management board member for technology and sales at Heidelberg, says, “Heidelberg is a total solution provider and partner that can supply and integrate all the latest technologies on a technology neutral basis and in line with customer requirements. We offer the entire spectrum, from toner to inkjet and from offset to flexo printing, all controlled from a common Prinect workflow.”

Touchprint, says, “Touchprint operates a book business trading as Your Books and is looking forward to putting the strengths, and experience

of both businesses together for the benefit of our valued book clients throughout New Zealand.

“The combination of two strong book production businesses further enhances our ability to offer serious fire power for larger New Zealand professional publishers, as well as international publishers, big and small.”

Ligare New Zealand will change its name to Touchprint early in the new year and it will move to the Touchprint Auckland studio premises at 72 Dominion Road.

All contact details will remain the same.

In conjunction with Prinect Production Manager, Prinect Touch Free autonomously steers print orders through the workflow in a hybrid production environment. It automatically selects the most cost-effective production path.

Supported by AI, the Prinect Touch Free native cloud software calculates all possible layouts autonomously and decides iteratively based on the complete order backlog,

which method (offset or digital printing) represents the more efficient, more cost-effective production path that will also meet the delivery deadline.

The software analyses the order backlog and production key performance indicators on an ongoing basis, learns from this, and consequently optimises the decisions made for future jobs. Prinect Touch Free also takes account of postpress requirements.

Graph-Pak managing director Tom Ralph says there is nothing like the new NSK Zero packaging converting machine he is now distributing in Australia and New Zealand.

He says, “NSK makes on demand box making machines but at a completely different level. The companies I have been working with up until now do X-Y converting, but NSK does X-Y plus. So, you can actually get round shapes as well.

“Traditionally, for this type of packaging, companies would use a CNC router, and it is a very slow process to cut out the shape. With the NSK Zero, the shape is cut out and then needs to be mounted so it can stand up vertically or horizontally.

“This provides converters with the ability to create one single box, or 1000 boxes cut into various shapes from a CAD drawing ripped straight from a PDF. This will create bespoke packaging and promotional products for marketing purposes and point of sale which are very different from other machines in the market.

“The NSK Zero can do all of this in one pass, hole slitting, X/Y cutting, F (free)

PacPrint25 is inviting industry professionals to participate in the event’s education sessions, with the event’s organisers calling on thought leaders to share their knowledge, experiences, and perspectives on key industry topics.

Taking place at the Sydney Showgrounds Dome, Hall 2 and 3, from May 20-23, 2025, PacPrint25 will bring together leaders, innovators, and experts from all corners of the print industry, locally and globally.

The event is now accepting applications for speakers, industry panellists, and educational session leaders. Organisers say, “This is your chance to showcase your expertise, share insights, and engage with peers on the latest trends shaping our industry.

“Young, old, operational, sales, supplier, printer – you are all the individuals who make up the industry’s brains trust, and we want to include your voice into the seminars and industry panel sessions.”

Kirsten Taylor, PacPrint25 chair, says, “We believe that the future of the print industry depends on collaboration, dialogue, and continuous learning.

“Our seminars and panels are designed

stage, and round shaping and the product pops out at the end. There is nothing else like it on the market today.”

Nihon Seizuki Kogyo (NSK) describes the Zero digital converting machine as the first truly automatic, productionspeed digital cutting solution to the market. It says, “This is a new concept in automated production level finishing for the packaging and display industry. 80 per cent or more lines on most of today’s packaging and displays are on the X or Y axis. Cutting tables cannot cut

lines quickly enough to keep pace with modern printers. Zero focuses on this point by separating the X and Y line data into dedicated processing stages, which dramatically increases processing speed.

“For packages with a lot of straight lines and very few free lines (curves, circles, etc.), the software will instruct the F stage to assist in the cutting/creasing of the straight lines as well. This reduces the idle time of the knife/crease wheel at each stage, resulting in a faster processing time for each sheet.”

to facilitate these discussions, and we are inviting people from across the industry to join us in sharing their knowledge.

Whether you are an expert in sales, technology, AI, cybersecurity, HR/IR, or any other field relevant to print, we want to hear from you.”

PacPrint25 is interested in hearing from those with expertise in the following areas:

• Sales and marketing strategies: What are the latest trends in print sales? How can companies leverage digital marketing to reach new clients?

• Technological innovations: From digital printing advancements to automation, how can businesses stay ahead in a rapidly changing landscape?

• Artificial Intelligence (AI) and machine learning: How can AI optimise print production, streamline workflows, and enhance customer experience?

• Cybersecurity: As the print industry

becomes more digitally integrated, what steps should companies take to protect sensitive data and intellectual property?

• Human resources and industrial relations (HR/IR): How can print businesses attract and retain top talent in a competitive market? What are the best practices for managing remote teams?

Organisers are open to all ideas and encourage industry professionals to share their suggestions for other topics they would like to see covered. They add, “If there are specific speakers or experts you believe would add value to the discussion, we invite you to recommend them. Your feedback is essential in helping us curate a programme that is relevant, insightful, and beneficial to all attendees.”

PacPrint 25 will co-locate with Visual Impact Sydney and the Label and Packaging Expo.

A recap of 2024 shows PrintNZ involvement across the industry.

Coming together as an industry to celebrate business success and recognise individuals and companies making a difference remains ever-more important given the recent challenging times.

Ruth Cobb, chief executive for PrintNZ, believes that despite ongoing economic issues and business challenges, it was uplifting to see the print and packaging industry continue to embrace excellence and seize opportunity to engage joyfully.

She says, “Over 50 People In Print Awards and 11 Rising Stars Awards were bestowed in our first industry awards event of 2024, held in conjunction with New Zealand Printer in Auckland back in April.

“An audience of over 100 recognised the wide range of talent, skills, knowledge,

experience, and diversity across our print and packaging community that is represented by these worthy winners.

It is important that we recognise the people that make our industry tick – we are nothing without them.

“Then an audience of about 400 enjoyed another fantastic Pride In Print Awards night in Wellington in July, where we recognised the world-class work that continues to be produced by our sector, as well as those excelling in training and sustainability areas.”

Among notable winners were:

• Pride In Print Supreme Award – MCC Albany

• PrintNZ Apprentice of the Year – Levi Lindsey (MCC Auckland)

• PrintNZ Trainer of the Year – Cheyne Lesa (Blue Star Jackson)

• PrintNZ Training Company of the Year – Inkwise Print Partners

• Pride In Print Business Awards Category – Gratpak

“And just recently, we had over 250 attendees across the two Women In Print events held in Auckland and Christchurch. Those were really good

numbers that show the continued importance of this initiative to provide a positive opportunity for women in our industry to network.”

Thanking her hard-working team for their ongoing commitment and diligence to best serve the needs of members, Ruth points out that a major focus during the year was a targeted career opportunities campaign officially launched with secondary schools.

She says, “The importance of the print and packaging industry continuing to attract and train its own workforce cannot be understated. Over the past 12 months PrintNZ has put substantial resources into educating school careers advisors and targeted groups of students about the industry and working with them to identify potential opportunities for a career in print and packaging.

“Our work in this space is continuing to develop, so that we can form our own pipeline of trainees who understand the role that print and packaging plays and the amazing opportunities the industry provides, particularly via the apprenticeship pathway.

“We have been successful in placing a number of students into print and packaging businesses already and look forward to continuing this in 2025.”

Ensuring the sector’s voice was heard by the new Government and officials on key issues remained another focal point for the team, with notable issues addressed including:

• Vocational education

• Immigration

• Energy

• NZ Post

Ruth continues, “Lobbying on behalf of our members is always an important role for PrintNZ, but these endeavours have taken on even great focus this year due to the late-2023 change in government.

“It had been hoped that with the change in power, positive policy developments would be seen promptly, but the complexities of a tripartite government as well as lingering economic factors have combined to stymie progress.

“We will remain diligent in our representation of the print and packaging sector to underscore its importance to the supply chain and role as a major employer in New Zealand, and therefore identify and address what impact potential policy moves may have.”

Although PrintNZ membership numbers saw a decline in 2024 for the first time in many years, Ruth says a “good number” of new members were also attracted to the association in 2024.

She says, “That decline was largely due to a number of businesses having either closed or merged as a consequence of the economic downturn and slow recovery. However, we still managed to sign up 20 new members over the course of the year.

“It is clear that print and packaging businesses continue to recognise the benefits of belonging to an industry association, particularly during difficult times.

“On behalf of PrintNZ, I sincerely thank our members for their ongoing, strong support of the association.”

Thank you to Tony Sayle

Ruth Cobb pays special tribute to immediate past president of PrintNZ, Tony Sayle, who recently retired from Jenkins Group and stepped down from the association’s Board.

She says, “Tony’s commitment to our industry has been outstanding. His passion for training, understanding of business and considered approach have made his contribution invaluable.

“He has steered the ship with a steady hand through some quite challenging times, notably the merger of the Communications and Media Industry Training Organisation (CMITO) into Competenz, and then the unprecedented challenges presented by the Covid-19 pandemic.

“On behalf of the industry I take this opportunity to wish Tony all the best in his retirement.”

She notes that Tony will nonetheless continue to keep a hand in the industry, having recently accepted an appointment as chair of Trust4Skills. She says, “The trust is responsible for allocating grants to PrintNZ members for training and providing opportunities for individuals and businesses to improve their skill base. Again, Tony’s sage advice, alongside the other trustees, will be well placed in ensuring that the fund continues to fulfil its purpose.”

A range of emerging positive indicators are raising hopes the New Zealand economy is finally on an upwards trajectory, but businesses should prepare for progressive rather than instantaneous gains.

Ruth says, “There is no doubt that we are seeing a number of good financial signs. We have had a couple of significant recent interest rates drops with another pending, and inflation has now returned to the Reserve Bank’s stated target range.

“The print and packaging sector is very much a barometer of the country’s overall economic state, given the reach of our members’ work in all manner of business activity.

“But given how weak the economy has been and where things currently stand for our members and businesses overall, the most pragmatic approach appears to be to continue to keep a firm hand on the tiller for now as a gradual improvement rolls out.”

In this vein, Ruth comments that a recent mantra for business of “Survive till ‘25” in order to navigate the weak economic environment and then thrive has in some quarters moved to “No fix till ‘26”.

Supporting the proposition, the Xero Small Business Insights (XSBI) update for July-September noted that when comparing the quarter year-on-year:

• Sales fell 2.7 per cent

• Jobs rose 6.6 per cent

• Wages rose 2.8 per cent

“Overall, the latest XSBI results are an early indication that the New Zealand economy remained weak in the September quarter, following the decline in GDP in the June quarter,” stated the update.

This is broadly in line with the Reserve Bank of New Zealand’s view that

economic growth is weak, in part because of low productivity growth, but mostly due to weak consumer spending and business investment. High-frequency indicators point to continued subdued growth in the near term.

Ruth adds it was good to see October’s ANZ New Zealand Business Outlook report a five point rise in confidence to a 10-year high of +66 but notes its counter observation that the pressure remains on.

She says, “Past activity and employment are still in negative territory economywide. The Outlook stated that there are still more firms saying activity and employment in the last month was lower than a year earlier than are saying it was higher. That is particularly true of the retail sector. This likely reflects that for consumers, the positive impact of lower interest rates is being offset by worsening job security.”

Ruth says, “The Business Outlook survey suggests the labour market will turn upwards too, but given the labour market lags activity considerably, there are still some hard yards to traverse before then.”

Ruth looks positively towards 2025. She says, “All of the economic issues and business challenges are not going to instantly disappear, but we can expect to continue on a gradual, upwards trajectory together. There is definitely cautious optimism coming through as things continue to improve.

“The print and packaging sector is a hardy industry, and we will continue to persevere and deliver the world-class products for which we are known. And rest assured that PrintNZ will continue to roll our sleeves up to deliver the bestpossible service to and representation for our valued members.”

www.printnz.co.nz

The PrintNZ family continues to grow, making our industry stronger.

As we sail towards the end of 2024 and make plans about what we might do during the holidays, it becomes a time when we think about our whanau: those we will see, those we won’t get to see, new additions during the year, and those no longer with us.

PrintNZ, as an industry association, is also a lot like a family (a really big one), and we too have seen some new additions during the year, but also the departure of too many familiar faces this year.

In our case, the bigger the PrintNZ family, the more we can do as a collective, so we continue to seek to grow - in numbers, in reach and in the services, we are able to offer. Despite the challenging times (or maybe because of them), we have secured a number of new members in 2024, and I wanted to take the opportunity to welcome them on board.

Joining us in 2024, welcome to:

• All About Design & Print, East Tamaki, Auckland, commercial print

• Annex Group, Hamilton, commercial print and signage

• BPAC Services, Auckland,

packaging, point-of-sale, and project management

• Canon Production Printing, Australia, production printing equipment and consumables

• CCGNZ Group, Albany, Auckland, screen and digital printing equipment and consumables

• Computer Signs 1999, Palmerston North, signage, and digital print

• Dash Engineering, Coatesville, Auckland, maintenance, and engineering

• Documents Unlimited, Ponsonby, Auckland, digital print, and plan printing

• Durst Oceania, Auckland, digital printing equipment and consumables

• Epson New Zealand, Auckland City, digital printing equipment and consumables

• Flint Group, Auckland/Wellington/ Christchurch, printing inks and coatings

• Hi-Tec Ink 2024, Christchurch, screen/ digital print equipment and inks

• Indigo Print Services, New Lynn, Auckland, digital printing

• INX, Auckland, printing inks and coatings

• Miniature Folding, Henderson, Auckland, specialist print finishing

• Point Paper, Otahuhu, Auckland, carton board supplier

• Signature Press, East Tamaki, Auckland, commercial print

• Strokers Screen Printing, Napier, screen printing

• Times Media, Howick, Auckland, publishing, and promotional print

• True North, Mt Wellington, Auckland, print management services

• Uniscreen Group, East Tamaki, Auckland, screen/digital printing equipment and consumables

Each of these businesses has recognised the value of being part of a like-minded family and being able to take advantage of the opportunities that provides both as an individual business and as an industry.

We have also sadly farewelled some great people from our print family this year and we pass on our condolences to their families and colleagues, many of whom are still connected to the industry.

• Patricia Pedersen, Lochiel Print

• John and Ann McQuarrie, Past President, PrintNZ

• Laurie Pilling, Admark Visual Imaging

• Teresa Bews, Universal Print

• Mark Burgess, Ricoh

• Denyse McCoid, Contact Labels

• Alan Williams, PrintLounge

• John Bell, CJ Phoenix Engineers

• Jeremy Gibson, Ellar Graphics

• Jon Sprague, Lamatex

• Mark McFadden, Toltech Print

I am sure there are others who have gone from your businesses, and I take this moment to acknowledge their contribution to the industry – they will all be missed.

Wherever you are these holidays, take the time to enjoy your family – the ones you were born with and the ones you have chosen to be part of your life.

From the family at PrintNZ –Happy Holidays.

From its site in Albany on Auckland’s North Shore, Skyline Print produces a range of retail printed products and trade services for the printing industry.

In August, Skyline Print installed an ApeosPro C750 digital press, supplied through Fujifilm Business Innovation New Zealand (FBNZ). Company founder and director Ray Beacham says, “The ApeosPro C750 was an excellent choice. It is easy to operate and gives us good print quality and good colour work. Our operators are experiencing improved turnover with few issues when operating this machine.

“With the ApeosPro C750, we can create a variety of products from business cards and flyers to posters and booklets. It prints well.”

Printing at up to 75 pages per minute, the ApeosPro C750 supports a wide range of paper sizes and thicknesses, printing at 330mm x 1,300mm simplex and 330mm x 762mm duplex. Using Super EA Eco toner, which has the industry’s smallest toner particles for smoother gradation, the ApeosPro C750 printer handles stock weights from 52gsm to 350gsm.

Skyline Print specialises in carbonless NCR printing; book stitching, padding

and finishing; die-cutting and embossing; CTP platemaking and supplying offset blankets; as well as digitally printed booklets and variable data printing.

When Ray and Susan Beacham established Skyline Print in 1988, they did not envisage being directors working in the business 44 years later. Ray says, “It started in a Skyline garage, hence the name. As the business grew over the years, we had to move it into larger premises. We now employ two staff members.”

Skyline has partnered with FBNZ for six years. Ray says, “Our contract with FBNZ has been excellent, especially with the service we receive. Our account manager Paul Thomas has kept us well informed and is available and easy to talk with.”

Over the years, Skyline Print has helped four apprentices qualify as printers including their son Mike, who is Skyline Print’s main point of contact as sales manager. The company has begun expanding into other sectors, such as packaging.

Mike says, “We enjoy supplying trade services to the printing industry but we

can also see the benefits in broadening our offering, especially using our digital capability with the ApeosPro C750.

“We also find that keeping as much work as possible in house makes everything easier. We can control the quality and turnaround times.”

The ApeosPro C750 printer has the world’s first LED printhead to achieve 2400 dpi x 2400 dpi high resolution. These compact printheads deliver high image quality, having evolved to be sharper and higher definition.

The ApeosPro C750 printer also handles textured stock with ease. By adjusting the force applied to the paper, according to the paper thickness, it performs a stable paper feed even with cardstock paper.

Offering ease of operation, the ApeosPro C750 printer comes standard with Simple Image Quality Adjustment (SIQA). This enables you to maintain print quality by scanning dedicated charts to automatically calculate the appropriate adjustment values. This quick and simple user operation removes the need to remember fine calibration values.

Paul Thomas, graphic arts account manager for FBNZ, says, “The ApeosPro C750 Graphic Print (GP) Controller provides high image quality and productivity with 1200 dpi × 1200 dpi high-resolution RIP processing and 10-bit smooth gradation correction for reproducing text, thin lines, and gradations. It also has a 3D calibration that allows for colour adjustment of CMYK single colours and for a mixture of colours. It automatically detects if RGB images, such as photos, are ‘Portrait’ or ‘Scenery’ and corrects them to match the characteristics.”

ApeosPro C750 Series

High performance multifunction printers that are perfect for creating beautiful, professional output quality in-house promotional material.

To find out how to print like a pro, scan here to contact one of our sales managers or visit our website at fujifilm.com/fbnz

From its Glenfield base, on Auckland’s North Shore, Bookbinding Press completes a range of finishing work.

Owner, director, and man of all trades at Bookbinding Press, Gary Horsbrough, is a qualified Bookbinder and Print Finisher. He has owned the business since 2010.

He says, “It was established in 1976, and I purchased it off the founder. I was his very first tradesman; I started here after finishing my apprenticeship with Trade Ruling and Binding. I have had a few hiatuses with things like the Big OE, but 95 per cent of my time since 1989 has been working in this industry.

“We currently employ seven staff members, and they perform the full range of print finishing and bookbinding tasks. They are a great group of people so I can confidently tell customers that they will receive the best quality work. I work on

the floor as well as running the sales side and manage the company.”

Bookbinding Press’s work covers:

• Bookbinding

• PUR binding

• Case binding

• Line Mounting

• Foiling

• Ring binders

• Menus

• Bespoke boxes

• Section sewing

• And sail/singer sewing

Gary adds, “We also offer a consultation service. It is important that, prior to printing, the customer understands what we can do to obtain the best result for their job. We often provide one-off samples for sign off.

“Our customers come from all sorts of places. Obviously print companies and

advertising agencies feature here. There are fewer companies with real expertise in bookbinding and finishing, so when companies realise that we can help them deliver a top quality outcome for their work, they can make the most of our services. We have rate cards for the trade, and we are always happy to help with advice and recommendations.

“Our retail customers include the likes of real estate agents, textile and construction companies, and stationery suppliers. We also do a solid amount of archival work for one-off clients. We have a variety of requests such as wedding albums, thesis binding, baby books, memorial books, recipe books and so on.”

At the beginning of 2023, lethal atmospheric rivers flooded the Wairau area where Bookbinding Press sits. The flooding almost destroyed the business.

Gary says, “The atmospheric rivers had a massive effect on us. The building flooded and we lost most of our equipment and stock. We were able to save some of the machinery. Fortunately, our insurance company did the right thing, and we have worked hard to rebuild the business.

“We have replaced the equipment that could not be saved, and we have fortified the building against further flooding. Importantly, we have managed to retain customers.”

The flooding wasn’t the only issue Bookbinding Press faced. Its recently acquired case binding machine caught fire, but Gary and his team were able contain the blaze. He says, “It was timing. We were closing up the factory when we saw the smoke. If it happened a couple of hours later, we might have lost the whole building.”

If you are superstitious, you would be expecting a third misfortune and sure enough, Bookbinding Press had part of its roof come off during a storm.

Currently, Gary says the biggest challenge Bookbinding Press faces is the lack of industry skills. He says, “Finding qualified bookbinding tradespeople is

getting more difficult. Another issue is the ongoing cost increases that most businesses are having to cope with.

“One of the best aspects of this business is the incredible people I get to meet. It is truly rewarding to know that the skills we bring can make a real difference to their projects. Whether it is a quick chat with a customer or going the extra mile to get the job done, it always makes for a fulfilling week. Ultimately, we are proud to assist people in creating exactly what they want.”

The Association of Handcraft Printers recently hosted The third annual Printers’ and Bookbinders’ Wayzgoose in New Plymouth and Stratford.

This Wayzgoose was a weekend event, starting with a meeting of attendees at Puke Ariki to view the Fred Butler Archive with archivist Lucy MacFarlane. Some of us had no idea of what we were going to be viewing, and were intrigued by the huge number of books that Fred Butler had put together. This included newspaper clippings and handwritten letters, covering various aspects of New Plymouth life and events.

The clippings spanned from 1880 to 1970, organised into themes like air, crime, births and so on. Fred Butler was a local eccentric and avid collector in Taranaki, though he later moved to Thames and Tauranga. He collected second-hand

books and reused them as scrapbooks for his clippings archive. Every second page of the book was cut out to accommodate the large number of clippings pasted in.

A comprehensive index card catalogue accompanies the archive. A different wallpaper sample covers each book’s spine, which gives the collection its distinctive aesthetic.

“We were also lucky enough to be welcomed into the Glass Case collection at Puke Ariki. ‘Glass case’ refers to the glass fronted cabinets the books are kept in, but it is also the collection of rare and treasured books in the archive. We saw a 1780s printing of a map book of Devon brought to New Zealand in the 1840s, and the earliest extant Taranaki phone directory from the 1920s, among many other interesting treasures.

A wet Saturday morning could have been miserable for out-of-town visitors, but no, the trip to the Stratford Pioneer Village was most enjoyable watching the ‘Press Gang’, a team of local printers, showing off the presses rolling at their print shop.

“The village bookbinder, Jonathan Bennett, also came in especially to tell the story of his work at the village and locally. A talented binder, Jonathan completes a lot

of gold leafing in his restoration work and new books that he binds. I didn’t know egg whites is the glue used in gold leafing.

The Saturday evening dinner is the highlight of any Wayzgoose, this time at the Devon Hotel. We sat down to a delicious buffet meal, and our speaker for the occasion was Dickon Lentell.

Dickon told us of his life in the printing trade, starting in Cape Town, and some time in London in the 1980s, before coming to New Zealand in 1988. His print career started in prepress work, moving into offset and then digital printing.

He has been involved with the Pride in Print Awards for the last decade as a judge, and for three years as Convenor of Judges. He continues to be involved in judging. He shared his thoughts on where he sees the printing industry heading, with some areas in decline such as newspapers and business stationery, but other areas growing, such as packaging and label printing. It was easy for some of us who are retired printers to identify with much of his story, and I think for some of the younger folk there to learn where their letterpress craft had come from and where it is heading.

A sunny Sunday morning gave us the chance to appreciate the beauty of Taranaki. Attendees wound up the weekend with a site visit to the Taranaki Aviation Transport and Technology Museum (TATAM).

The Press Gang returned to show and tell the vast collection of print equipment they have in their print shop. Graham O’Keeffe, ex-Heidelberg legend and team leader of the Ministry of Transport and Technology (MOTAT) printing volunteers is part of the volunteer team. Graham is a great spokesperson for both the Stratford and TATATM printshops, and printing in general.

All the attendees appreciate the Press Gang members. Their enthusiasm, and generosity in giving up their weekend for the Wayzgoose provided a huge boost for all who attended.

We continue to build on our excellent Wayzgoose events year on year, next year’s will be even bigger and brighter. Make sure you organise to attend the BIND25 Wayzgoose in Auckland, September 12-14, 2025.

In 2016, business partners Dave Cooper and Mark Hobson founded Dark Lab, after having worked together for another company in the sign and display industry.

Mark joined the sign and display industry after leaving school, completing an apprenticeship from back in the days of brushes and paint. Dave is a qualified graphics designer but says he “wanted something more hands-on, so he shifted into signage”.

In April, Dark Lab installed an Epson SD-10 spectrophotometer alongside an Epson SC80600 printer. Dave says, “Our sales rep from Aarque Group mentioned the SD-10 and we thought it would be ideal for when we need to match colours for shopfitting. We complete a lot of specialised shopfitting work, often requiring vinyl colours to match specific paint or product samples. We also do a lot of vinyl work for panel beaters, which requires us to match existing damaged vinyl on vehicles.

“With most solid vinyl colours being pretty limited, we have had to come up ways to print vinyl to match certain PMS

colours or paint finishes. Previously, this involved a lot of guess work, generally starting with eyeballing and coming up with a base CMYK colour; printing a bunch of sample swatches, then visually narrowing it down and selecting one; taking that again and guessing what to add/remove in terms of CMYK; printing more sample swatches; then rinse and repeat as many times as needed until we got it close.

“Now, with the SD-10, we can simply scan a colour or swatch and print a sample as well as varying swatches to match. It makes things easier when we have to match a specific colour. We are impressed with its ability to scan a specific colour and either send it to Adobe design programmes for file setup, or straight over to the Epson SC-80660 for printing.

“It also makes workflow and colour matching easier, saving a lot of time and guess work from the process, especially compared to what we used to do.

“The SD-10 is super simple to use for all base functions, requiring virtually no need for training to scan colours, understanding the values and getting the colour

management right takes a bit of practice/ patience, but once you have the whole system setup and running it makes basic colour matching very easy. It is easily portable and simple for anyone to take a colour measurement, so one of the guys can take it with them to a site and scan any existing vinyl graphic colours we might require for reproducing the graphics.

“Before the SD-10, the only option was to take our Pantone books on site and visually match up the closest colour, then print sample swatches based on the Pantone colour and manually print/adjust swatch charts to create the best match we could.

“The SD-10, combined with the Epson Cloud Solution PORT and the SC-80660, allows us to easily print and reproduce almost any colour we need, including most solid vinyl colours which we wouldn’t have even been able to get close to before switching to the Epson large format print solutions.

“This is the first Epson hardware and software we have used. We are very happy with both the hardware solutions and ongoing support they have provided.

“We also complete a fair bit of high end retail work, with quite demanding clients. Colour matching was a big issue for us, especially with brighter Pantone and pastel colours, Upgrading to Epson has given us a massive boost in both our colour matching capabilities and large format image print quality.

“As a small business, we are a close-knit team that collaborates well together. Everyone ends up taking on a variety of roles and responsibilities through the whole process, so there is always a unique sense of satisfaction in seeing any project come to life, transforming an idea or concept into reality and following it through to a successfully finished product always leaves a smile on the face.

“Innovation is at the heart of our industry, and we believe staying ahead with the latest technology and print solutions is key to surpassing client expectations. We are committed to delivering exceptional quality, as we know it speaks volumes and can only lead to a stronger, more successful future for our business.”

Graphics giant revises its environmental goals to reduce CO2 emissions.

In the midst of growing environmental awareness, Konica Minolta has emerged as a leader in promoting sustainability within the printing industry.

Chris O’Hara, national production print manager for Konica Minolta New Zealand, says, “With a firm dedication to eco-friendly practices, Konica Minolta is reshaping printing technology to prioritise responsible production and consumption.”

At the core of Konica Minolta’s environmental initiatives lies its ambitious ‘Eco Vision 2050’. Originally aiming for an 80 per cent reduction in CO2 emissions, the company has since revised its goal to achieve net zero emissions for the entire product life cycle by 2050. Chris says this reflects Konica Minolta’s recognition of the importance of addressing climate change and minimising its ecological footprint.

A key strategy in Konica Minolta’s sustainability efforts is the promotion of digital printing over traditional analogue methods in commercial printing. Chris explains, “Unlike analogue printing, which relies on various consumables such as printing plates, blankets, rollers, fountain solutions, and cleaning chemicals, digital printing eliminates the need for these components.

“Printing plates, typically made of metal like aluminium, and printing blankets, made of rubber, are integral parts of analogue printing processes. The production of these materials often involves resource-intensive processes, including mining metals or producing rubber through petrochemicals, contributing to environmental degradation and CO2 emissions.

Chris O’Hara, national production print manager for

“Additionally, analogue printing requires significant water consumption for washing up these components after each use. By transitioning to digital printing, Konica Minolta reduces its environmental footprint by minimising the use of these materials and resources, thereby promoting a more sustainable and ecofriendly approach to printing.”

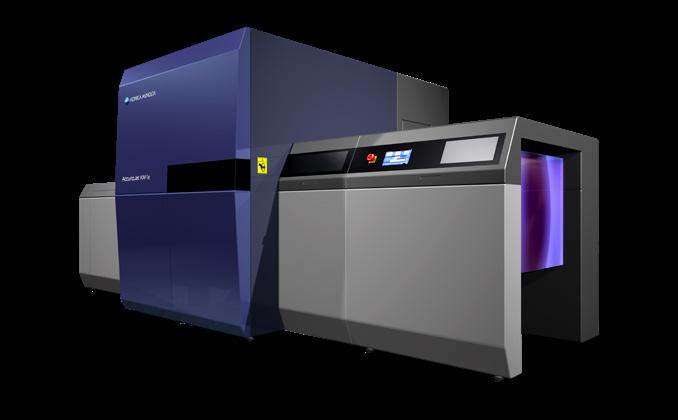

An example of Konica Minolta’s commitment in this area is its AccurioJet KM-1e inkjet press. Chris says, “The AccurioJet KM-1e inkjet technology is certified by INGEDE for de-inking, It ensures that ink can be efficiently removed from the paper, facilitating the recycling process and contributing to resource conservation.

“Furthermore, the AccurioJet KM-1e emits no volatile organic compounds (VOC), setting it apart from other digital B2 platforms. This not only enhances environmental friendliness but also makes it compliant with stringent regulations. Additionally, the AccurioJet KM-1e’s adherence to emission standards makes it suitable for industries with strict regulations such as food safety (certified by FDA) and toy manufacturing, further demonstrating Konica Minolta’s commitment to sustainability and safety.

“The AccurioJet KM-1e offers several environmental advantages over traditional offset printing methods. By streamlining the production process and minimising paper waste, this innovative technology helps reduce CO2 emissions and conserve resources. Moreover, Konica Minolta’s proprietary HS UV ink ensures a clean working environment by emitting no Volatile

Organic Compounds (VOCs), promoting employee health and well-being.”

In addition to technological innovations, Konica Minolta actively collaborates with its customers and suppliers to promote sustainability throughout the printing supply chain. By sharing knowledge and best practices, the company empowers others to adopt eco-friendly solutions and reduce their environmental footprint.

Chris says that despite many people feeling a sense of hopelessness about the ongoing deterioration of the environment, it is still important to set realistic targets to reduce our carbon footprint.

He says, “As part of its commitment, Konica Minolta is continuing to push for a more sustainable print industry through initiatives like these:

• Konica Minolta has revised its ECO vision target to achieve 100 per cent emissions reduction by 2050.

• The AccurioJet KM-1e receives the highest rating from JFPI for its ecofriendly attributes.

• Konica Minolta’s HS UV ink minimises waste and emits no VOCs, contributing to a cleaner environment.

• The environmental benefits of the AccurioJet KM-1e include its capability to reduce CO2 emissions by up to 80 per cent compared to other UV ink press technologies.

• Konica Minolta will continue to highlight the importance of sustainable printing solutions in meeting customer demands and driving business growth.

Chris adds, “Konica Minolta’s commitment to sustainability sets a precedent for the printing industry, demonstrating that eco-friendly practices can lead to both environmental preservation and business success.

“As the world continues to prioritise environmental responsibility, Konica Minolta remains at the forefront, pioneering innovative solutions for a greener future.”

Our new AccurioShine 3600 is a precious gem that adds value to your print business. It creates beautiful digitally varnished and embellished print that makes customers smile and workflows more efficient. This compact digital spot UV coater uses the latest MGI varnish technology to add stand out 2D and 3D effects across short run work. Digital varnishing eliminates screens, plates or dies, while the AccurioShine 3600 AI driven registration system sets up and adjusts each page for you. Eco friendly LED curing system cuts out drying delays and simplifies post-press processes. When optioned with the iFoil system, foil can be added to the print and varnish layers to add sparkle.

To rethink embellishment, simply visit: konicaminolta.co.nz/AccurioShine3600

Charles Watson considers the benefits and pitfalls of business in the fast moving world of technological and AI advancements.

In our industry, staying competitive means embracing cutting edge technologies to optimise operations and boost efficiencies. However, technology can assist in other areas of your business, and AI platforms are emerging as invaluable tools. Particularly advantageous for smaller businesses without dedicated HR departments, these platforms can greatly assist in recruitment and performance management processes. However, caution is warranted against over reliance, as human oversight remains essential to ensure accuracy and mitigate errors, much like proofing of printed materials.

AI platforms are already being used in recruitment processes across many industries. The larger the employer or recruitment firm, the more likely they are to use them to review and assess candidates. Related AI platforms rapidly sift through resumes, looking for patterns from data inputs, which result in recommendation and prediction outputs. These platforms use advanced algorithms to analyse resumes and identify candidates that closely match the job requirements. If the inputted search parameters are clear and detailed, the platform can ensure promising candidates do not slip through the cracks by focusing solely on qualifications and skills. Further, and if used appropriately, AI based assessments can provide valuable insights into a candidate’s skills and aptitudes.

Traditionally, performance reviews occur annually, resulting in employers reviewing

In the new AI world, businesses are cautioned not to lose sight of human value

a worker’s performance using potentially outdated metrics that fail to provide meaningful insights in real time for both the business and the worker. By contrast, and if used appropriately, AI platforms can be used to analyse worker performance metrics such as productivity, engagement and achievements in real time. This has the potential to help identify issues that need to be addressed earlier than an annual performance review. Further, AI platforms can be used to create personalised development plans for workers based on their individual strengths and those areas requiring improvement.

Implementing AI in the workplace necessitates a comprehensive policy and compliance framework, and that includes related authorisation or approval requirements for their use. Regular reviews of these policies is essential due to the rapid evolution of AI technology.

It is not recommended to use AI platforms for critical issues and decisions if you don’t understand the platform. Adequate training is crucial to ensure proper understanding and appropriate utilisation of the platform. Like with all computational related processes flawed or poor quality inputs and questions will result in less than optimal outputs.

Businesses must also consider data protection and privacy implications, especially when using open-source AI platforms. Businesses should understand that inputted data is going to be used

by that platform for machine learning purposes, as well as for use in answering similar queries from other businesses. If your business uses a paid service, consider the commercial terms and conditions carefully.

In addition, compliance with employment laws is paramount, as any decisions based on AI recommendations must be justifiable and legally sound. If an employer is challenged over a recruitment or performance management decision based on a recommendation from using an AI platform, they must be able to explain how AI was utilised and that the recommendations and other outputs were not biased and were considered by the business prior to implementation. Also, if the use of an AI platform causes legal exposures, liability will most likely land on your company rather than the AI software company.

Despite the challenges that accompany the adoption of AI platforms, their transformative potential in recruitment and performance management practices, and other areas are significant. These platforms offer a myriad of potential benefits, from streamlining processes to enhancing decision-making efficiency. However, to fully capitalise on these advantages while minimising associated risks, businesses must adopt a strategic and ethical approach to their implementation and utilisation.

This entails striking a balance between automation and human intervention, recognising that while AI can offer unparalleled speed, human oversight is indispensable for ensuring accuracy, trust, fairness, and ethical conduct.

Charles Watson

GM – IR, Policy and Governance Visual Media Association

This article is of a general nature and guidance only and does not constitute legal advice.

Taking a break from work means more than not physically being there.

Let’s be honest, if you’re reading this and you work in the print industry, the word holiday probably sounds more like a mythical concept than an actual break. Between end of year client rush jobs, stocktaking, and trying to squeeze in those last minute projects before the shutters come down, the Christmas period can feel more like a marathon than a rest.

But here’s the thing: you can’t run your business, or yourself at full throttle forever. Like any machine that needs regular maintenance, your body and mind need genuine downtime. And I’m not talking about the kind of break where you are half answering emails from your in-laws’ dining room or scrolling through work notifications while pretending to watch the cricket.

Real recovery is an art, and in the print world, it requires some strategic planning.

First up, let’s talk boundaries. In our hyper-connected world, it’s tempting to be perpetually ‘on’. But those work emails can wait. Set up an out of office message that is clear and firm. Something like: “Thanks for your message. I am recharging until [date]. For urgent matters, contact [designated backup]”. And mean it. Put the work phone in a drawer, or better yet, give it to a trusted family member to hide.

Physical recovery isn’t just about sleep, though that is crucial. For those of us who spend hours standing near presses or hunched over computers, the holiday is a chance to reset those muscles. Consider activities that are the opposite of your work routine. If you’re usually indoors, get outside. Beach cricket, coastal walks, or even just sitting in the sun with a good book can do wonders.

In New Zealand and Australia, we’re blessed with incredible summer landscapes during the Christmas break. Whether you’re in Auckland’s stunning harbourside spots or on Burleigh’s golden sands, use this environment. Nature has an extraordinary way of recalibrating our stress levels. An easy jog, a morning dip, or even just watching the waves can be more restorative than any fancy wellness retreat.

Nutrition matters, too, and I’m not just talking about avoiding a second slice of pav on Chrissy day. Your body needs real, nourishing food after a year of quick lunches and caffeine-fuelled afternoons. Local summer produce is a gift. Think fresh seafood, crisp salads, and fruits that actually taste like fruit, not something that’s travelled halfway around the world.

Mental recovery is just as important as physical. This might mean different things for different people. For some, it’s spending uninterrupted time with family. For others, it might be a solo project or hobby completely unrelated to work. For me, it’s exploring the beautiful back roads of Northern NSW on my Guzzi (That’s Mick’s classic Italian motorcycle – Ed). But it could be surfing, painting, jamming with mates, or getting lost in woodworking during their break. The key is finding something that lets your brain shift gears completely.

Speaking of shifting gears, be kind to yourself about productivity. The print industry demands high performance, but a holiday is not the time to maintain that pace. If you spend a day doing absolutely nothing productive, that’s not wasted time, that’s essential maintenance.

Technology can be both a blessing and a curse during breaks. Use it wisely. Set up technology-free zones or times. Maybe breakfast is a device-free meal, or evenings are for actual conversation, not scrolling. Your mental bandwidth will thank you.

For those running print businesses, this advice extends to your team. Encourage genuine disconnection. A truly rested team returns more innovative, more resilient. Those who feel they can genuinely switch off are the ones who bring fresh energy when January rolls around.

So, this Christmas, power down those mental processors. Lock away the work phone. Swap spreadsheets for sunscreen, client proofs for cold bevies, and deadline stress for beach cricket.

Your print shop will survive without you for a few weeks. Geez, it might even miss you, but not as much as you’ll miss these precious moments of pure, uninterrupted downtime. Think of it as preventative maintenance for the most important machine in your business: you.

Merry Christmas, print legends. May your days be merry, your seafood fresh, your beers cold, and your out of office message firmly switched on. See you in the New Year – restored, recharged, and ready to make some serious print magic happen.

Stay golden. Stay sane. And for the love of all that is holy, put down that work phone.

P.S. If you find yourself thinking about colour calibration while watching the sunset, seek immediate help. Or another beer.

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

Recently, innovative print company

The Big Picture installed an HP Latex R2000 wide format printer into its Wellington headquarters, supplied through Aarque Group.

Managing director Hamish Woulfe says, “Wide format and rigid media printing makes up approximately 50 per cent of our revenue, so this installation is significant.

“We have had a few UV flatbeds over the years, and we really wanted to move to a different ink technology. For us, the HP Latex R2000 ticks all the boxes. The installation went smoothly, with a senior HP technician flying in for the week from Korea to oversee everything.

“We have run a number of Latex printers over the years, dating all the way back to the L25500, so the platform was familiar to us. Our operators had a couple of days of initial training, then hit the ground running with a large project. There will be continuous learning as we profile different stocks. We will have some more advanced operator training in another couple of months.

“Our workload fluctuates, with some months heavy on rigids, while others have more roll to roll work. The hybrid platform of the R2000 allows us to respond to this, giving us flexibility with

whatever direction the market takes us. There are lots of cool features like white ink and multi-layer printing, but we’ve been flat out with our standard rigid work since installing it so have not had a chance to experiment with these yet. We’re looking forward to developing into some new markets with these capabilities next year.”