Visit Computaleta’s new showroom for the latest technology, demonstrations, expert advice, and training

Working with government Countdown to drupa Mainland Golf and pics

Visit Computaleta’s new showroom for the latest technology, demonstrations, expert advice, and training

Working with government Countdown to drupa Mainland Golf and pics

For over four decades, Computaleta has been New Zealand’s trusted supplier of self-adhesive films, consumables and cutting-edge print and hardware equipment for our sign and graphics customers.

Distributors since 1982, we are a team of experts renowned for our unparalleled service and support and are here to help you elevate your signage game.

Talk with one of our hardware experts today for tailored advice and discover why signage starts here.

Check out our extensive range of hardware options here

Visitors will have access to expert advice, demonstrations, and training sessions.

With a new purpose-built hardware showroom set to open in Auckland, the Computaleta team have geared up to demonstrate the company’s range of signage and print industry equipment.

Located in Computaleta’s latest facility at 9 Douglas Alexander Parade in Rosedale, the new showroom will highlight an impressive lineup of products including the latest innovations from industry leaders such as Canon, Summa, and HP.

Arlette Farland, director at Computaleta, says, “The addition of this new hardware showroom represents Computaleta’s commitment to providing cutting-edge solutions for the signage and print industry across New Zealand.

“Featuring a range of equipment specifically tailored to meet the needs of this dynamic sector, the showroom promises to be a valuable resource for businesses seeking to enhance their capabilities and stay ahead of the curve.”

The new showroom underscores Computaleta’s dedication to offering comprehensive solutions for every aspect of signage and print production. Arlette says, “The opening of the new hardware showroom represents an exciting development for Computaleta and the

wider signage community in Auckland. By providing access to the latest technologies and expertise, we continue to empower businesses to thrive in an ever-evolving market landscape.”

The company has a well-earned reputation for providing outstanding service and support to its customers. The team at Computaleta will utilise the new showroom to expand on this strong service and support ethic. Arlette explains, “We aim to serve as a hub for knowledge sharing and collaboration within the industry. Visitors can expect to benefit from expert advice, demonstrations, and training sessions tailored to help businesses optimise their operations and achieve their goals.”

Computaleta continues to expand its hardware portfolio and looks forward to demonstrating solutions that customers can use to grow their business.

Arlette says, “Among the range of bestin-class technology in the showroom, the highly anticipated new Canon Colorado M Series printer delivers exceptional quality and versatility in wide-format printing. This printer allows your customers to say, “Yes!” to more jobs. It offers speed and the ability to print white, gloss, and matte finishes simultaneously, while handling a wide variety of media. The versatility is

there for sign and print shops to produce outstanding and distinctive work.”

The new showroom will also house the Summa F Series flatbed cutter. Arlette says, “This finishing system offers the level of precision and efficiency that makes it ideal for a range of cutting applications. Complementing these printing solutions, the CWT Application worktable enables you to streamline workflow processes and maximise productivity.”

Computaleta has a mission to showcase the full gamut of equipment a sign and graphics printer needs to produce quality work at speed, enhancing workflow and creativity. She says, “In addition to the wider format equipment, Computaleta will also highlight equipment for smaller signage and print companies. The new HP 630W printer redefines the game for them, printing from the leading edge. Tied with the new HP Design and eCommerce software, the HP 630W printer allows you to go from web to print quickly.”

The new showroom will also be home to a new pneumatic vertical cutter from Inglet. Arlette says, “For over 70 years, Spanish brand Inglet has manufactured a complete range of cutting machines for the signage industry. Its cutters and saws make cutting roll media, ACM, foamboard, corflute, PVC foam, acrylic and glass easy.”

Arlette says that, as a cornerstone distributor to the New Zealand sign and graphics industry for over 40 years, family-owned and operated Computaleta’s legacy of support and service to the local graphics community will only grow with initiatives like the new showroom. She adds, “We are grateful to our clients for their ongoing support, and we appreciate the value of the relationships we have.”

Computaleta will announce a date for the official opening over the next few weeks. Arlette says, “So, watch this space. We are really looking forward to showing the value inherent in the solutions that we provide to the industry.

“In the meantime, join us in shaping the future of signage. Visit www.clgroup.co.nz to discover how Computaleta can help you grow your business.”

3 Computaleta: Family-owned Computaleta will open its new Auckland showroom next month, where it will demonstrate a range of solutions and welcome customers to talk about the latest innovations in the industry.

9 Think Laterally: Mick Rowan shares his tips on navigating the dynamics of small business entrepreneurship.

16 Fujifilm Business Innovation: The new iECHO digital cutting system removes the need for die-cutting, saving labour and time.

18 Currie Group: A recent visit by Horizon’s president has cemented the long-term partnership between Currie Group and the finishing specialist.

32 People in Print Awards: Take the opportunity to celebrate with and network on April 11 sustainability.

12-13 Helping Hand: Iain MacIntyre looks forward to the year ahead with PrintNZ working on strategies to deal with the new government and new policies.

14 Comment: Ruth Cobb reports from the Mainland Golf Day where all proceeds went to the Southern Colour Trust.

18 Introduction: With only two months until drupa opens the doors at Messe Düsseldorf, don’t miss your chance to book your place.

20 Design: Fabrice Peltier says that designers and printers can master the environmental impact of graphic creations using eco-inking.

21 Ricoh: Step into the HENKAKUVERSE at drupa 2024 to see the raft of innovations that Ricoh has ready for the giant show.

24 Packaging: Robert Seay discusses the options for digital print and corrugated packaging that will feature at drupa.

28 Wide Format News: Catch up with all the latest in wide format news.

30 Epson: The graphics giant is celebrating 40 years of providing solutions, service, and support to the local industry.

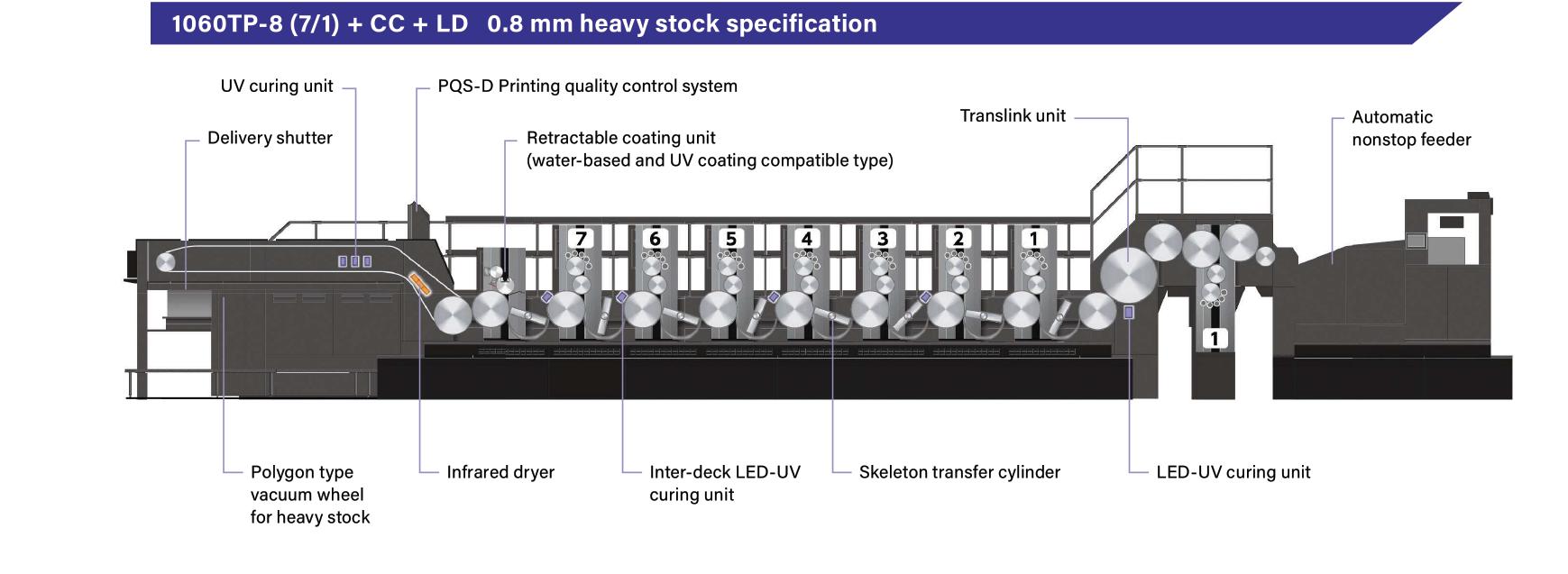

34-35 RMGT/Cyber: Packaging printing continues to expand globally and RMGT has the presses to meet the growing demand for high quality and speed to market.

40 Konica Minolta: A new AccurioLabel 230 has taken Pumphouse Print’s label production to a new level.

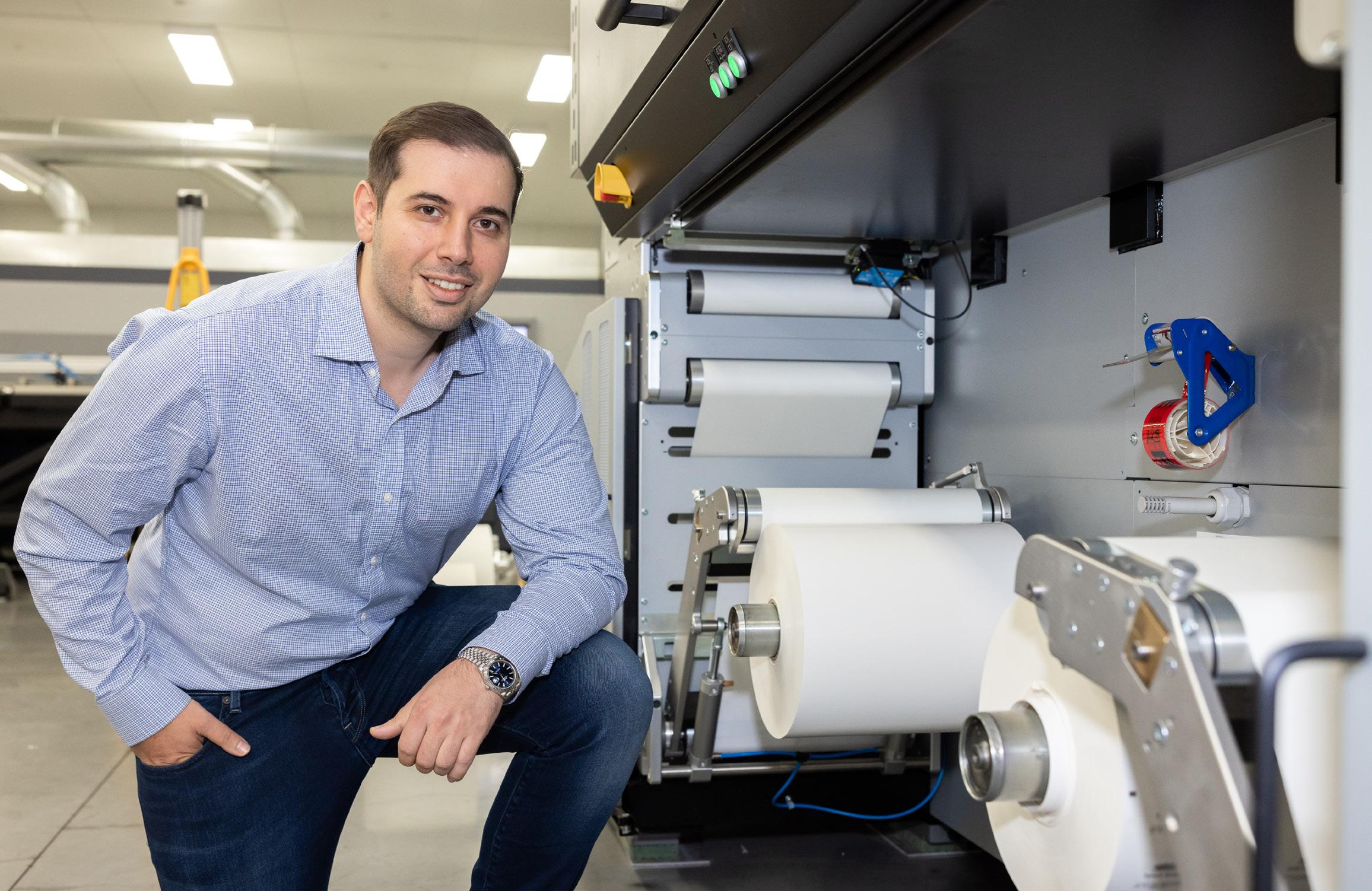

DURST OCEANIA has boosted the options for print across the region with the release of Durst Fluo Glow LED Inks. Matt Ashman, managing director at Durst Oceania, “This extraordinary addition to the Durst business enriches our existing ink portfolio for our valued customers. It provides printers with an opportunity to transform their work with a vibrant point of difference. The Durst Fluo Glow LED Inks are now available in yellow and pink and can be mixed endlessly to create red, orange, and green tones.

KOENIG & BAUER has announced that, on the basis of its preliminary figures, it has fulfilled its forecast for 2023. Despite a challenging global economic environment, exacerbated by a number of factors such as higher energy, material and personnel costs, Group earnings before interest and taxes (EBIT) reached €29.9m $52.9m). The company says it has significantly driven forward its transformation from a printing press manufacturer to a technology company, adding that it is headed in the right direction despite rising costs.

LANDA Digital Printing and Guangdong-based Chinese packaging giant, Zhongrong Printing Group have announced the installation of a second Landa S10 Nanographic Printing Press. The companies say the additional press meets the increased demand for short to medium-run digital packaging and supports the transition of more offset jobs to digital. Sharon Cohen, chief business officer for Landa Digital Printing, says, “This collaboration exemplifies our shared commitment to driving transformative change in the printing industry. ”

BJ Ball New Zealand has appointed Daniel Telfer to take on the role of chief executive officer. His appointment follows the recent departure of Richard Hislop.

Telfer possesses considerable experience in the industry going back to his time as managing director of Interpac packaging, which he says gave him the opportunity to cultivate BJ Ball as a customer. Most recently, he has worked as

general manager of Caspak Products. He has expressed his excitement about the industry and says that he

ICW supports creative design and content creation, reviews, revisions, approvals, and asset management within a tightly controlled, task-based process.

looks forward to playing a role in diversifying and securing BJ Ball’s future, “allowing it to continue to be a both supplier and employer of choice for customers and people.”

Richard Hislop’s move marks the end of an era for many at BJ Ball, who wish him a fond farewell. He worked for the company for over 20 years, leading it through its most recent stages of change, guiding through significant transformations, including the transition from a locally owned entity to a multinational corporation merger with Ball & Doggett, and joining the OVOL family. His tenure included BJ Ball acquiring Aarque Graphics in 2018 and Caspak Products in 2022.

Kodak has launched version 10.0 of web-based Kodak Prinergy Insite Portals.

The portals provide 24/7 access from anywhere. Kodak has upgraded the Kodak Prinergy Insite Prepress Portal (IPP) and the Kodak Prinergy Insite Creative Workflow (ICW) with multiple new enhancements. This includes improved usability thanks to collapsible job group lists in IPP to reduce the amount of scrolling.

The IPP allows printers and their customers to submit jobs, track progress, collaborate on changes, and proof and approve work. The

The newly implemented two-factor authentication at login safeguards data and personally identifiable information. The upgrade has integrated open authorisation for Microsoft Office 365 into IPP and ICW for greater security. Overall, the increased security within the IPP and ICW infrastructure helps to prevent malicious attacks.

The Insite Gateway plug in, which Kodak released in version 9.5, establishes a direct connection between the Adobe Creative Suite and the IPP. This allows you to transfer PDF files created with the creative software applications easily, quickly, and accurately to a job on

the IPP server. Jim Barnes, chief information technology implementation officer for Kodak, says, “The release of the Prinergy Insite Portals version 10.0 means all essential components and optional add-ons of the Kodak Prinergy Platform are now up to date and consistent.

“The new version provides printers with increased performance; helps them meet customer requirements faster and error-free; and makes the digital infrastructure for collaboration with customers and creative professionals more secure.

“The launch of Version 10.0 of Insite is further evidence that Kodak continues to support its customers in the printing industry with the continuous development of its software solutions as a trusted partner.”

Kale Print has officially become a Toitū Carbonzero certified organisation in line with ISO 14064-1.

Peter Lloyd, general manager at Kale Print says, “We’re thrilled with this achievement. It marks another pivotal moment in our journey, showcasing our dedication to responsible business practices, sustainability, and our commitment to meeting the highest social and environmental standards.

“As a family business that has operated for more than 35 years, we firmly believe it is the responsibility of each generation to leave things in better shape for the generation that follows.”

He adds that Toitū Envirocare provided all the tools that Kale Print needed to start its carbon reduction journey including tailored software and technical guidance through to independent audit and thirdparty certification.

In its second year of reporting under the Toitū net carbonzero programme, Kale Print achieved an absolute reduction in Category 1 and 2 emissions of 8.41 tCO2e. It achieved a reduction in its emissions intensity (for Category 1, 2 and mandatory Category 3 and 4 emissions) of 0.69 tCO2e/$M based on a two-year rolling average, adjusted for inflation.

As the largest commercial printer in the Bay of Plenty, Kale Print has taken a lead in sustainability. Peter says, “Kale Print is committed to doing no harm while working

Screen says it has finished developing its new Truepress JET 560HDX roll fed digital inkjet press.

The company believes the new press will drive further innovation in printing. It can operate in a variety of print modes, handling paper widths up to 560mm. Printing at speeds up to 150 metres per minute, it offers a maximum resolution of 1200dpi x 1200dpi. Compatible with Screen GA’s Truepress ink SC2, it prints directly onto offset coated papers without any pretreatment. Screen says the SC2 ink set’s special properties produce high vibrancy colours that pop with deep saturated hues as well as dense and neutral blacks for clearer printing of even fine text and line work.

on reducing emissions. Accordingly, we have offset our unavoidable emissions by investing in carbon credit projects to compensate for the Toitū mandatory emissions resulting from our operations this year.

“More than 50 per cent of our investment is supporting the Spray Point Native Forest Regeneration site located in Marlborough New Zealand. The remaining investment is supporting high quality international approved projects such as solar energy production to reduce fossil fuel and clean water programmes.”

Kale Print’s commitment to managing and reducing its emissions has seen the company review its greenhouse gas emissions reduction targets and plans so they fall in line with Toitū net carbonzero programme requirements.

Additionally, a new high-efficiency, intelligent drying system enables substrates with high ink densities to dry efficiently, supporting superior quality and wide gamut printing on a wide range of papers. In addition, a new fast-start operating system ensures flawless integration of all internal hardware, software, and finishing equipment, according to Screen.

Screen will show the new system at drupa 2024. The company says the commercial printing market requires flexible print solutions with high value economics. It requires more complex work with faster turnaround times, shorter print runs, multiple versions, latestage revisions, and variable information. It says these requirements have created new business opportunities for high productivity digital inkjet presses offering offset-like economics.

Screen adds that, in the publishing market, aggressive economics and high quality and flexible format sizes enable a

growing number of companies to benefit from the capabilities of high-speed, rollfed digital inkjet presses. It says that, while facing the increasing shortening of production runs and demand for book of one requirements, book production systems need to be optimised for extremely low to mid-volume production.

The direct mail market’s needs for high productivity and flexibility when running lightweight uncoated papers and thick, attention-getting high-gloss self-mailers at low fixed and variable costs are needed to help offset the rising cost of postage. Driving direct mail production costs as low as possible will encourage marketers to continue to utilize the valuable medium.

In response to these changing market realities, Screen says it has introduced the Truepress JET 520HD with the Truepress SC and SC+ ink sets as a practical inkjet solution for printing directly onto offset coated papers without the need for an inkjet treatment.

Heidelberg has launched the company’s first fully-digital label press, the Gallus One inkjet press, into the Asia Pacific market.

The launch follows a four-day label printing open house at Heidelberg Indonesia’s showroom in Jakarta. Heidelberg welcomed 230 delegates from the Asia Pacific region at the open house event. Dario Urbinati, chief executive at Gallus and Thomas Frank, Heidelberg’s regional director for Asia Pacific attended.

At the open house, guests saw live demonstrations of the Gallus One inkjet press and the Gallus Labelmaster 440 flexo press.

Equipped with a range of automation features, Gallus One offers high print quality, consistency, and reliability, according to Heidelberg. The company adds that the press takes ease of operation to a new level by including a newly developed automated print head cleaning method, eliminating the need for manual cleaning, and extending the lifespan of the print heads.

Gallus One can print 70 metres per minute, even with high opacity white of up to 85 per cent. With a printing width of 340mm, it handles a variety of selfadhesive materials such as papers and plastics, as well as unsupported materials.

Gallus One fully integrates into Heidelberg’s Prinect workflow. Heidelberg and Gallus developed the system jointly. It combines Heidelberg’s digital printing and software knowhow Gallus’s expertise in label printing.

At the open house, Frank spoke about

Global packaging giant Amcor is closing 10 plants across the globe as post-Covid destocking continues. It has implemented significant workforce reductions. Amcor says this in response to a substantial decline in customer demand for beverages, meat, and destocking by pharmaceutical customers.

The company’s net profit witnessed a nearly 60 per cent drop in the first half of the financial year, prompting the cutting of 2000 jobs, approximately five per cent of its workforce. Amcor’s sales figures experienced a nine per

the label printing as an increasingly important area of focus for the Heidelberg Group in the region. He said, “For this reason, we have opened the new showroom here in Jakarta, right in the centre of our region, in a country where packaging and label production are growing well above the global average.

“The Gallus One digital inkjet press launch in the Asia Pacific market follows successful installations in Europe and the US. Frank added, “This is a sound basis

cent decline, from US$7.35bn ($11.9bn) to US$6.69bn, resulting in a recordbreaking 10 per cent drop in volumes. Net profit plummeted to US$286m, a sharp decrease from US$691m in the corresponding period of the previous year.

Amcor attributes the challenging market conditions to continued postCovid destocking, particularly in healthcare. In addition, cost of living pressures has led consumers to opt for value pack beverage cans over Amcor’s PET bottles. Ron Delia, chief executive officer of Amcor acknowledged the adverse market conditions, highlighting a 17 per cent decrease in net income, an eight per cent decline in EBITDA, and a 10 per cent drop in EBIT.

In North America, consumers scaled back on soft drinks and PET bottled

for our regional launch here. We have the infrastructure in Asia to handle press hardware, software, and consumables.”

Urbinati and Gallus Group head of global sales Thomas Schweizer also discussed the rise of smart, connected printing and the future of the label and packaging industry during the event.

At drupa 2024, the companies will show further extensions to the Gallus One. drupa takes place in Düsseldorf, Germany, from 28 May to 7 June.

beverages Amcor specialises in. Also, pharmaceutical, and medical device customers contributed to the sales decline by reducing their inventories. Eco-conscious consumers in the US, grappling with cost of living pressures shifted packaging preferences towards value-packs of 24 cans rather than single PET bottle versions, impacting Amcor’s sales.

Amcor’s exit from Russia contributes to the company’s focus on cost management leaving it operating 210 factories in 43 countries.

Despite a slight improvement in volumes in January, Delia expressed caution, stating, “We’re not expecting any rebound in consumer spending.”

In addition, he has an expectation that pharmaceutical customers will not repeat the destocking of the past.

UMICK ROWAN

UMICK ROWAN

nleashing success in the dynamic realm of small business entrepreneurship necessitates a profound understanding of the transformative power that innovative thinking holds.

In an era where adaptability and creativity are paramount virtues, entrepreneurs realise that embracing innovation is not merely a strategic option; it has become an indispensable necessity in the journey towards success.

The foundation of innovative thinking signifies a paradigm shift from the days when entrepreneurship relied solely on tried and tested methods. Today, it involves a departure from the conventional to the extraordinary. Those interested in running small businesses increasingly recognise that staying ahead in the competitive landscape requires more than just offering a good product or service; it demands cultivating a mindset that welcomes change and thrives on ingenuity.

Culture is crucial

Adapting to change emerges as a cornerstone of entrepreneurial success, particularly for small businesses facing a myriad of challenges, from resource constraints to intense competition. However, those with an innovative mindset don’t perceive challenges as insurmountable roadblocks but rather as opportunities for growth. Their ability to adapt swiftly becomes a cornerstone, enabling them to pivot in response to evolving circumstances and capitalise on emerging trends in the market.

Crucial to this paradigm shift is fostering a culture of innovation within the business. Recognising that entrepreneurial success extends beyond the leader, organisations must adopt transformative strategies to encourage innovation at all levels. This includes creating an environment where employees are empowered to share ideas freely, promoting experimentation with new approaches, and instilling a mindset

Collaborative networks open doors to fresh perspectives and opportunities helping to fuel innovation

that views failure not as a setback but as a valuable stepping stone to success. This culture of innovation becomes an essential component, shaping the ethos of the entire business.

The marriage of innovation and technology provides enormous benefits for small businesses navigating the intricacies of the modern market. Entrepreneurs increasingly leverage the power of digital advancements, from embracing e-commerce solutions to adopting data analytics for informed decision-making. Understanding the significance of staying tech-savvy positions these companies for growth in a rapidly evolving landscape. Technology becomes a tool for efficiency, market insight, and enhanced customer experiences, underlining the symbiotic relationship between innovation and technological integration.

Innovative thinking and risk-taking become inseparable companions on the entrepreneurial journey. Entrepreneurs willing to step out of their comfort zones and take calculated risks often find themselves at the forefront of industry transformation. Whether introducing groundbreaking products or venturing into new markets, these calculated risks propel them towards innovation driven success. This is not about reckless decision-making, but rather a strategic approach that balances uncertainty with calculated foresight.

Connect to collaborate

Collaboration and networking emerge as potent catalysts for innovation in the small business landscape. Recognising the

power of shared insights and experiences, entrepreneurs actively engage with their peers, industry experts, and even competitors. Collaborative networks open doors to fresh perspectives and opportunities, creating a melting pot of ideas that fuel innovation and benefit all parties involved. It’s a recognition that innovation often thrives in interconnected ecosystems.

Educational initiatives that nurture entrepreneurial skills and promote innovative thinking play a crucial role in shaping the landscape of small businesses. Workshops on design thinking, courses on emerging technologies, and initiatives that provide aspiring entrepreneurs with the tools to think innovatively contribute significantly to the overall growth of the small business ecosystem. It’s an investment in the future, sowing the seeds of innovation early on.

Looking ahead, the future of small business entrepreneurship will undoubtedly be shaped by continual innovation. Adapting to change, thinking creatively, and embracing a culture of innovation will remain pivotal for success. Small businesses that seamlessly integrate innovative thinking into their DNA will survive and thrive in an ever-evolving marketplace. The ability to foresee trends, adapt swiftly, and consistently innovate becomes the bedrock upon which sustained growth is built.

As we celebrate the success stories of innovative small businesses, it becomes evident that the entrepreneurial journey is not just about navigating challenges but turning them into stepping stones for a brighter, more innovative future. It’s a journey where resilience, adaptability, and the constant pursuit of innovative solutions become the hallmarks of enduring success.

Are you ready to take the first step toward innovation-driven success by embracing change, fostering a culture of creativity, and leveraging collaborative networks?

The time has come to join the ranks of visionary entrepreneurs shaping the future. Your success story awaits. Start innovating today.

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

Leading supplier Currie Group and finishing specialist Horizon, have marked another milestone in their long-term partnership with the visit of Horizon’s new generation of leadership to Australia.

Recently, Hideharu Hori, executive director of the company and grandson of its founder Hachiro Hori, and managing director, Sam Miyazaki, spent a week in the country meeting with Currie Group’s operational team, and visiting customers. During Hori’s first visit to the region since taking over the reins from his father, Ejiro Hori, he reinforced Horizon’s commitment to its long-term channel partner for the ANZ market. He says, “The relationship between Horizon and Currie Group is a long and close one built on similar values and a shared understanding that partnership delivers the best outcomes for everyone.

“As island nations, Australia and New Zealand are similar to Japan in that the vast majority of work produced here is done for the domestic market. We understand this type of market very well, but our partnership with Currie Group has always been vital to ensure we are up to date with what is going on here, and what print service providers in the ANZ region need.”

For Currie Group, too, the partnership is pivotal. Established under its chairman, David Currie, in 1981, it fills an important role in the company’s ‘complete solutions’

approach. Currie Group CEO Rob Mesaros, says, “Over many years, Currie Group has grown its stable of brands through partnerships with pioneering manufacturers like Horizon – in this case, enabling us to provide innovative, reliable finishing solutions to complement print production.

“It is more than a supply arrangement, however; we are close at all levels. We have open access to Horizon’s technical experts and regularly factory-train our service technicians, so that we can continue to meet our commitment to outstanding service and support as markets develop and Horizon technology continues to evolve.”

Horizon anticipates and reflects evolving market needs, now responding to an increased demand for systems solutions with higher levels of automation and integration.

Hori says, “Here in Australia and New Zealand, like Japan, I can see for myself that businesses are facing significant skilled labour challenges.

“Everywhere in the world, too, the pandemic highlighted the need to optimise the use of staff resources by supporting production teams with systems that streamlined workflows, reduced touchpoints, and made crossskilling easier. This is not to say that

we are moving away from supplying stand-alone solutions, but we recognise the need for automation for businesses to streamline their operations and maximise profitability. Horizon has responded, driving its future development under three pillars: Usability, Workflow and Automation.”

Myazaki adds, “Those who are familiar with Horizon equipment will already know that our interfaces are not only easy to use and intuitive but are similar across all our systems and equipment.

“They operate seamlessly on a single platform, and if an operator needs to switch from one machine to another, it is an easy transition. In terms of workflow, we know that good solutions demand not only machines which integrate seamlessly, but the right platform to ensure smooth operation and optimise performance. This is where our commitment to developing our workflow management software iCE Link and collaborations with all leading print engine manufacturers ensures our customers can maximise the value of their systems.

“As visitors to drupa will see in May, we are increasingly optimising production through automation, and incorporating complementary technologies like robotics and automated guided vehicles (AGV) to further enhance workflow efficiencies. These are our priorities and, because all our systems are fully modular, businesses can invest in the solutions which meet their needs today, and then scale up as required.”

He continues, “We have invested in a large stand of more than 1600 square metres, featuring 16 systems in total, including at least five new products, with end to end, highly-automated workflows incorporating features like robotic arms and AGVs taking centre stage.

“You will see our systems and equipment in action, both on our booth and in the booths of our collaboration partners. In total, we will take over 450 pieces of equipment to Germany. We will also showcase our new, predictive AI technology, currently under development and already piloted at three Japanese sites, to test its benefits for set-up and production optimisation.”

PrintNZ envisages an intensive year of liaison and lobbying with the new National Party-led coalition government, with several early policy announcements potentially having notable impacts on the print sector.

The main aspects of the 100-day and 49-point plan announced by the government on November 29 with immediate relevance to the print industry are:

1. Stop work on the Income Insurance Scheme.

2. Stop work on industry transformation plans.

16. Repeal the Fair Pay Agreement legislation.

17. Introduce legislation to restore 90day trial periods for all businesses.

40. Begin disestablishing Te Pūkenga and Workforce Development Councils.

as well as environmental and waste issues are absolutely the main focuses for her team going into 2024.

She explains, “Many of the new government’s policy announcements appear favourable to business. We particularly support the abolition of fair pay agreements and a return to 90-day trial periods.

“But there can often be some devil in the detail, with well-intentioned ideas inadvertently having unintended consequences which can lead to negative impacts on industry. So, PrintNZ’s focus will be on steadfastly reviewing proposed policies and liaising to ensure our members’ interests are best represented.”

To expedite matters, PrintNZ has assisted the development of Briefings to Incoming Ministers (BIMs) across a number of portfolios. Ruth says, “One of those, developed through our membership of the eight-organisation New Zealand Manufacturing Alliance, was targeted at the Minister of Trade.

The subheadings for these entailed:

• Empowering New Zealand’s manufacturers to succeed in a world where domestic subsidies and other measures increasingly threaten their global competitive position.

• Clear and consistent policy settings for a secure supply of energy at a stable cost.

• Access to capital for growth and productivity improvement,

• Innovation support that is fit for purpose.

• Removal of the constraints on the supply of suitably skilled labour.

She adds, “That particular BIM was also further personalised for and sent to the portfolios for Immigration, Workplace Relations and Safety, Energy, Tertiary Education and Skills.”

Another BIM developed for the Minister for the Environment through PrintNZ’s association with Packaging New Zealand stated priorities as entailing:

• Develop a Packaging Action Plan focused on providing certainty, in collaboration with industry.

• Use the Waste Minimisation Fund to achieve the actions in the Packaging Action Plan.

• Anticipate what changes will be needed to keep pace with New Zealand’s trading partners and make the necessary adjustments.

• Ensure that policies are aligned and cohesive.

Among key industry events confirmed for the year thus far by PrintNZ, with dates yet to be finalised:

Mainland Regional Charity Golf Day in Christchurch – this event raises funds for the Full Colour Trust which supports people in the print and graphics industries in the South Island that may not qualify for assistance and cannot afford to pay for help they need, which is commonly, but not exclusively, health-related.

Ruth Cobb, chief executive PrintNZ, Cobb says advancing workplace relations

People In Print Awards and Rising Stars of Print – these awards recognise the people that have made a contribution PrintNZ

“To complement the quest by manufacturing businesses for further growth in domestic and international markets, five main policies and measures were outlined.”

Seminars – these will take place across the regions. They serve to update members on both legislative changes and information across industry campaigns.

to either the printing industry or their community during the previous 12 months. It also recognises those on their way up: our future leaders.

Wellington/Manawatu Charity Golf Day –raises funds for Wellington Free Ambulance and the Reg Dixon Memorial Trust which helps with education in the industry.

Training Graduation Ceremonies in Christchurch and Auckland – these events provide opportunities for every person in the industry that has received a qualification during 2023 to have their mahi acknowledged in front of their peers and families.

Apprentice of the Year – acknowledging the Top 10, Top 5 and overall outstanding print apprentice to graduate during 2023.

Pride In Print Awards - our industry showcase of excellence in product and people: ‘The Big One’.

Women In Print – providing opportunities for women in the industry to network and listen to inspiring stories from some of New Zealand’s great ladies.

Ruth adds, “These events continue to deliver key opportunities for members to learn, network, reward excellence and raise funds for charity.”

As businesses review the worth of every dollar spent in the current cost-of-living crisis, buyers need continuous reminders of the benefits that the print sector provides across a wide range of outcomes. Ruth says, “These notably include integrity, sustainability, and effectiveness.

“PrintNZ will continue to expand on the programmes it already subscribes to and in 2024 will broaden the reach of the audience with additional investment to support the messaging of such vital campaigns as Printed In New Zealand, Value of Paper and Print (VoPP), Two Sides and Love Paper. Placing the Printed In New Zealand ‘stamp’ on the work that members produce emphasises they have been proudly printed in this country.

“In 2023, we localised this initiative, allowing members to regionalise the logo and use it to promote their businesses locally. The logo carries a member identity number which highlights that the printer is a member of their national trade association while also authenticating the use of the logo.

“VoPP focuses on effectiveness, raising awareness of the power of paper, print and mail marketing in today’s ‘noisy’ communications world. VoPP is a unified voice for the paper, print and mail industry and supports members with quality marketing collateral, PR and media representation, and targeted consumer research.”

A well-established global campaign, Two Sides focuses on the sustainability of print. She adds, “It incorporates companies in the communications value chain including forestry, pulp, paper, inks and chemicals, pre-press, press, finishing, publishing, printing and distribution.”

Love Paper, a global initiative, is a two pronged campaign. Ruth says, “Brands are encouraged to use the Love Paper logo on their marketing/packaging material, with valuable advertising space also being gifted by major publications around the world to run Love Paper advertisements.

The Love Paper logo is now a registered trademark that reaches over 10 million consumers every month through newspapers and magazines.”

PrintNZ will undertake an industry specific benchmarking survey during the year. This will provide exclusive data on wage rates, charge out rates and financial benchmarks.

Ruth says, “The surge in inflation experienced over the last two years has affected all of these, so information will be invaluable for companies to understand their place in the market, risks to the business, and opportunities for change.

“But the output will only be as good as the input and that means we rely on enough members contributing accurate data to ensure meaningful analysis and results. PrintNZ asks our members to take the time to participate.”

Given changes that the new government has commenced in the vocational education space, Ruth emphasises that PrintNZ’s commitment to training will prove more important now than ever to the sector. She says, “Last year, PrintNZ committed to working directly with schools to promote print and establish a conduit to our industry.

“As well as continuing to educate careers teachers and open the eyes of students to the many exciting career paths print offers, this year we will be looking to provide work experience opportunities and broaden the programme in general.

“Particularly given there are so many unknowns with the new government, this work – alongside print firms maintaining their own training commitments – will be another key focus of PrintNZ’s agenda for 2024.

“While we remain closely linked to Competenz and other industry training organisations, it is vital that we continue to develop our own workforce.”

While this represent the big-ticket items in mind for the start of the New Year, the PrintNZ team will continue with its everyday work across a broad range of additional services. Ruth adds, “Our core activities remain the interactions we have with our individual member companies in understanding their business; supporting their business practices; and amplifying the opportunities they have to promote the strength and vitality of the industry.”

Annual Golf Day goes off on a perfect Canterbury day.

BJ Ball

PrintNZ kicked off its calendar of events for 2024 with the Mainland Golf Day, when 64 players took to the greens at Waitikiri Golf Club on a perfect Canterbury day to raise funds for the Full Colour Trust.

The Full Colour Trust is a charitable organisation serving the print and graphics industries in the South Island by providing funding to individuals and families who may not qualify for assistance through the usual channels, and who can’t afford to pay for the help they need.

Since its inception 16 years ago, the Trust has assisted many in their time of need in a variety of ways. Over the past 12 months alone it has generously gifted thousands

of dollars to families in the industry and PrintNZ is proud to be able to contribute to their funding.

On the day, the weather and the golf course combined to produce some spectacular scores on the day and a record number of twos potted across any of the golf days we have run.

Thank you to everyone that contributed to the funds raised – the players, and in particular the sponsors: BJ Ball Papers, Custom Cutting Formes, Coural, Fujifilm, Servicom and Spicers Paper/Total Supply.

Best Gross

1st BJ Ball #3

2nd Servicom

Chris Thomas, Mark Richardson, Simon Delany, Andrew Thompson

Johnny Main, Gary Eyre, Tom Sevier, Leon Yee

3rd BJ Ball #2

Richard Cooke, Guy Noble, Dan Bushby, Andrew Carver

Best Nett

1st Spicers #1

2nd Spicers #2

3rd Custom Cutting

Nathan Pene, Dean Godfrey, Simon Jones, Brent Libeau

David White, Nigel Williams, Simon Osikai, John Moimoi

Paul Robinson, Clint O’Loughlin, Jared Booth, Sarah McPherson

Dale Hopkins Memorial Cup – awarded for the longest drive.

Mark Kelly, Coural

Russell Taylor Memorial Cup – awarded for closest to the pin.

Guy Noble, BJ Ball

Fujifilm Business Innovation New Zealand (FBNZ) has signed on as a distributor for iECHO, a global manufacturer of automated digital cutting machines.

Founded in 1992, iECHO has grown from producing CAD software to a company that exports technology and solutions to 100 countries. The advent of computer aided manufacturing has seen the evolution of a new type of digital cutting technology that combines most of the benefits of die cutting with the flexibility of computer controlled precision cutting of highly customisable shapes. By 2006, more than 2,000 iECHO customers were benefiting from the company’s expertise in digital cutting systems.

Glen Greenhill, national production print specialist at FBNZ, says, “We are excited about the possibilities that iECHO digital cutting systems offer our customers, who have avoided the likes of die-cutting and kiss-cutting jobs because of the time and expense involved in having to get dies made.”

“Unlike die cutting, which uses a physical die of a specific shape, digital cutting uses a cutting tool (which can be a static or

“The iECHO is a powerful addition to any print or signage shop that wants to add short run die-cutting and or kiss-cutting to their services giving them the freedom to create some amazing die-cut work.

“You can cut, crease, and kiss-cut a range of products in a matter of minutes, all in-house, without the need to purchase expensive die forms that you might only use once after the job is completed. The iECHO offers New Zealand print companies a broader range of options for die-cutting and kiss-cutting. For example, you have the option to tweak the artwork if the cut is not quite right and recut it easily, which you can’t do with a traditional die form.

“The range of materials this solution can handle includes D-Board, Foam Board, Sticker, Reflective Material, Cardboard, Plastic Sheet, Corrugated Board, Grey Board, Corrugated Plastic, ABS Board, and Magnetic Stickers, to name a few.”

oscillating blade, or a mill) that follows a computer programmed path to cut out the desired shape. The big advantage of digital cutting is the absence of shape specific dies, ensuring shorter turnaround times compared to die-cutting machines, as it removes the need to switch between die shapes, reducing overall production time. In addition, it removes the costs associated with the manufacture and use of dies, making the process more cost effective.

“Computer controlled digital flatbed or conveyor cutters can easily integrate registration mark detection on the sheet with on the fly control of the cut shape, making digital cutting machines ideal for highly customisable automated manufacturing processes.”

Recently, FBNZ placed an iECHO PK0604 cutting system into its Print Technology Centre at Landing Drive in Auckland. Glen says, “We have just started to do customer demonstrations on the iECHO PK0604 and the positive feedback we are getting from our customers indicates that the time is right to introduce this technology to the local market.

The team at FBNZ has already used the iECHO PK0604 to create several “cool things”. Glen says, “You can produce a wide range of products. We have already made money boxes, tealight candle holders, display boxes, wedding invites, Christmas present tags, birthday invites, gift card holders just to name a few. The options are endless.

“The iECHO comes pre-installed with all the tools you need to cut a wide range of products versus other manufacturers that require you to purchase extra tooling and an extra cost to the customer. FBNZ provides national support and service. We give customers the peace of mind that if anything goes wrong, there is a team behind them to help, unlike other vendors that might not have anyone in their area that can help them.”

Initially, FBNZ will supply the iEcho PK models and the iECHO PK4 in New Zealand. Glen says, “We will look at other models in the future that can cut larger sheets and thicker media. In the past, customers wanted to do short-run die-cutting but found it too costly and time-consuming to take that type of work. They could not offer it to their customers, so they missed out on a potential revenue stream. That is no longer the case.

“We look forward to welcoming you to the Print Technology Centre to show how iECHO can add to your business offering.”

Introducing the iECHO PK 0604 - your shortcut to perfect packaging! Combining the fully automated feeding platform with multiple creasing and cutting options, get creative with customised packaging in no time.

Another reason to have a spring in your step this Easter

Contact your local sales representative to find out more

Time is running out to book your spot for the world’s leading print fair.

With less than two months to go, more than 1400 exhibitors have booked their stands for drupa 2024.

The world’s leading trade fair for print technologies runs from May 28 to June 7 in Düsseldorf, Germany. It gives industry professionals from across the world an opportunity to discover the future of print technologies and graphic communication.

Organisers say drupa stands for inspiration, innovation, top-class knowledge transfer and intensive networking. It is a must attend event for everyone involved in the printing, packaging, and graphics industry.

Robert Laing, managing director of Messe Reps – the local representative for Messe Düsseldorf, says, “No other event offers the breadth and depth of solutions and

trends that drupa provides. When you come to drupa you can:

• Connect with industry leaders – professionals from all over the world.

• Get informed about the latest developments – innovative technologies and equipment.

• Take advantage of a varied programme – including forums where specific topics are focused on and discussed in depth.

• Discover new products and services – materials, equipment, software and more.

“Messe Reps. & Travel is your contact for drupa. Information on trade fairs and on Düsseldorf is available at www.messereps.co.nz. If you are planning to travel to drupa we can assist you with booking accommodation in Düsseldorf.

“If you have any questions about drupa or Düsseldorf, please do not hesitate to contact me, phone 09 212 6200 or email robert@messereps.co.nz.”

Thank our generous sponsors for Celebrating Kiwis in Print Platinum Sponsor Gold Sponsors

We can master the environmental impact of graphic creations.

The common factor in many graphic creations, especially in packaging design, is that they are usually printed in large quantities to meet consumer demands. However, amid the focus on reducing packaging material consumption, we have overlooked one crucial aspect: the environmental impact of printing inks. Often deemed insignificant, the inks used in graphic creations play a more substantial role than we might realise, both in terms of their ecological implications and economic considerations.

Understanding the composition of ink reveals its complex nature, which consists of several components. The pigments, or colorants, provide the vibrant hues that capture attention and differentiate brands. The vehicle, or binder, acts as the carrier, enabling the ink to adhere to various surfaces effectively. Additionally, we use adjuvants to enhance ink properties, ensuring quick drying times or improved resistance to wear and tear.

Each graphic element, typographic character, shape, and colour thoughtfully chosen to convey the intended message represents a specific quantity of ink required for reproduction. Embracing an eco-friendly approach known as ecoinking or ink saving process, designers can craft top quality graphic designs while managing ink consumption during the printing process.

The eco-inking approach is best incorporated during the initial stages of design development, providing an intermediary step based on a wellconceived graphic proposal. However, forward thinking designers may also consider eco-inking as an integral part of the entire design process, even at the conception of a brand’s graphic identity and guidelines.

The core objective of eco-inking is to optimise ink consumption without compromising the quality and visual impact of the creations. It seeks to achieve a harmonious balance between resource efficiency and creativity. Although changes made to ink usage might not be immediately apparent to consumers or readers, successful eco-inking initiatives have demonstrated their potential to bolster a brand’s environmental credibility and resonate positively with the intended target audience.

Adopting an eco-design philosophy in graphics goes beyond reducing ink consumption; it encompasses a holistic approach to environmental stewardship. By implementing eco-friendly practices in materials selection and production processes, designers can significantly reduce the environmental footprint of their work.

Eco-inking also presents a compelling advantage when it comes to recycling. Graphic papers, extensively used for packaging and marketing materials, undergo a deinking process during recycling to ensure the purity of the resulting paper. By minimising the quantities of ink used in printing, eco-inked papers facilitate the deinking process, reducing the consumption of chemicals and energy required to remove inks from the recycled material. This, in turn, minimises waste production and contributes to a more sustainable circular economy.

For brand owners aiming to reduce costs, eco inking offers a potential source of savings. Using fewer inks directly impacts expenses, and opting for CMYK, or even CMY, printing can deliver outstanding results at even lower costs and with a reduced environmental impact.

The practical application the ecoinking approach has proved its

efficiency. Developed over a decade ago, this innovative technique has been meticulously tested on over 250 consumer product packages in France. The results have been nothing short of remarkable, consistently achieving an average reduction of ink consumption by up to 25 per cent while preserving the visual appeal and message impact of the original creations.

I believe in sharing knowledge and expertise for the collective betterment of our environment. In this spirit, I have chosen to disseminate the eco-inking technique as an open-source resource through comprehensive guides and training materials. I encourage fellow designers, manufacturers, and businesses to embrace eco-inking and unlock the potential for positive change in our creative industries. Feel free to reach out and while you visit drupa, not only assume new substrates, new machinery and innovative technologies will help you to reduce the environmental impact of packaging, also consider new ways to conceive and produce packaging.

Embracing eco-inking offers a means to enhance the environmental sustainability of graphic creations and an opportunity for designers to stand as pioneers of change in the evolving landscape of design and consumer consciousness. Together, we can make a meaningful contribution to safeguarding our planet’s resources and ensuring a greener, more promising future for generations to come.

Fabrice Peltier, an expert in packaging design and a pioneer in eco-design, works towards more environmentally responsible packaging solutions. He serves as a consultant and a catalyst for creativity in eco-design for the entire packaging industry, including packaging manufacturers, market players, and eco-organisations.

Ricoh has a raft of innovations ready for the giant show.

When you visit Ricoh’s drupa stand, you will receive an invitation to experience the HENKAKUVERSE, a virtual production environment where you can learn about how Ricoh’s leading-edge technologies can be harnessed for the benefit of their print operations.

You will find the Ricoh stand at drupa 2024 in Hall 8a of the Messe Düsseldorf, Germany, May 28 to June 8.

An array of applications will showcase the production possibilities of Ricoh’s broad technology portfolio.

Ricoh will bring together a host of new technologies for the first time including the Ricoh Pro Z75 B2 sheetfed digital inkjet press. Shaking up the B2 sheetfed space, the first B2 perfecting (autoduplexing) sheetfed inkjet platform using aqueous ink, accelerates the shift from offset to digital with higher print quality, faster turnaround times, and fewer demands on staff.

The new Ricoh Pro VC80000 digital colour high speed inkjet webfed press offers AI capability; new generation Ricoh printheads; and high level of integration with finishing equipment. It enables commercial, book, and direct mail printers to enjoy breakthrough performance in terms of its consistently

high print quality and new levels of productivity, shift after shift.

A new digital colour sheetfed press, the next generation 135ppm Ricoh Pro C9500 gives give commercial printers a chance to expand revenue streams and enhance operational efficiency with its laboursaving automation. On the stand, the five colour Ricoh Pro C7500 digital colour sheetfed press will complement it with the latest in agile, versatile flexible and responsive toner-based technology.

Designed for speed, precision, and durability, Ricoh’s market leading printheads deliver optimum print quality while minimising downtime. Visitors can explore Ricoh’s latest generation printheads and some selected applications on the stand as well as gain insights into the inkjet printhead roadmap.

Last month, Ricoh’s commitment to sustainable and responsible operations achieved a double A score from global environmental non-profit organisation CDP for climate change and for water security. Ricoh also secured its 12th inclusion among the Global 100 Most Sustainable Corporations list. The company has built all of its technologies on this commitment to sustainability.

Ricoh’s automation technologies support print businesses’ drive to reduce their

impact on the planet. All the production technologies on display are built on Ricoh’s commitment to sustainable and responsible operations that last month achieved a double A score from global environmental non-profit organisation CDP for climate change and for water security. Ricoh also secured its 12th inclusion among the Global 100 Most Sustainable Corporations list.

Ricoh’s software area will focus on production automation, combining cloud based and on premise solutions that aid maximum production efficiency.

High quality and consistent results are ensured by an array of specially developed solutions including the award winning, trailblazing Ricoh Auto Color Adjuster which provides precise colour management and matching capability without the need for a colour specialist.

An immersive theatre experience at the heart of the stand will see the HENKAKUVERSE and its opportunities presented. It will show some of the many ways Ricoh technologies can prove transformative for forward thinking businesses, from data driven, book, and commercial printers to enterprise operations.

The Ricoh stand will house another feature to spark creativity and new approaches, firing up your imagination. The Print Bar and Applications Garden will feature inspiring client cases that illustrate how Ricoh’s co-innovation approach can help different types of print companies to future proof their business. It will show printed samples from across the technologies as well as those from Ricoh’s versatile large format systems.

Michael Laursen, national manager –Ricoh Graphic Communications, says, “Ricoh helps print professionals unlock opportunities to broaden their offering and expand their business through a range of strategies and initiatives. With HENKAKU, we have the chance to truly partner with you and ‘co-innovate’ together. Our focus on sustainable production allows you to shape your business success to suit your needs and that of your customers. At drupa, you can join our team of specialists as they help you explore ways that you can transform your business.”

In Japanese, HENKAKU means transformational innovation – and at Ricoh, it means everything to us.

But to truly unlock the power of HENKAKU, we need to work with you our partners and ‘Co-innovate’ –taking on your real world challenges and finding solutions, together.

At drupa 2024, join us to discover what Co-innovation could mean for you and the future of your business.

We’ll be unveiling our latest inkjet technology, alongside our incredible sheetfed and software developments.

You’ll also be able to enter The House of HENKAKU and experience an immersive theatrical show that will bring the spirit – the magic – of Co-innovation to life.

May 28 – June 7, 2024 Düsseldorf, Germany

REGISTER FOR MORE INFORMATION

There are real options for digital print and corrugated packaging.

Digital print has promised broad transformation in corrugated packaging for a long time. While it has made significant progress, digital print today still only represents and addresses a small subset of corrugated print needs.

New approaches are needed to broaden the reach and value of digitally printed corrugated packaging.

Digital print transformation in the corrugated industry has been a promise waiting to happen for many years. Part of the reason for the delay could be the industry has been perceived as having one monolithic set of needs and digital print has been promoted as one generic solution to fit all those needs. However, all corrugated needs and digital print solutions are not the same.

The reality is much more nuanced. Indeed, there has been some progress in several use cases and sub-markets including high quality graphics, samples, mock-ups, displays, short-run, large format, double-sided print, and supply chain efficiency including turn-around time, but there are still a few other use cases like personalisation and variable data that have not yielded transformation.

Regardless, digital print still only addresses a fraction of the overall market for printed corrugated packaging. For this to change, we must ask why and eventually address the many gaps that exist today with the overall solution set.

As suggested, the various digital print capabilities are nuanced. Digital print solutions generally do not adequately address all substrate, board combinations, and form factors. Specific requirements of the printed product like ink holdout, colour, overprint varnish, coefficient of friction, durability, and gluability all play a part in what can or cannot be done by any given digital print solution. Specific press limitations might mean something can be done in limited quantities or certain situations but cannot be done at scale and remain cost-effective.

Digital print was and still is supposed to simplify, streamline, and accelerate the overall graphics, print process, and product development for the corrugated industry. Digital print in corrugated has been most successful in areas in need of disruption including samples, mock-ups, displays, and ultra short runs. However, to get at the bulk of the market, digital needs to contend with what analogue printing does well day in and day out.

It has been incrementally fine-tuned to provide the quality, productivity, reliability, equipment life expectancy, and cost structure that the market recognises today. Different production workflows have evolved to meet various product requirements with various levels of efficiency. Digital print must do something better or different to provide more value than analogue.

Finally, digital printing must consider the macro trends and what the needs of tomorrow will be. These macro trend requirements include fast turnaround, short run lengths - for

many different reasons - supply chain efficiency, eCommerce, lightweighting, sustainability, and automation that could make digital solutions more compelling in the future.

The predominant issue with digital print is the production costs for a given run length compared to the analogue alternative. For digital to win more broadly, it must look beyond just consumables cost and look at reducing overall value chain costs including running costs, maintenance, capital, useful life, and any other steps or parts that can be streamlined. It is encouraging to see a next generation of solutions that will hopefully help make some of the necessary improvements to expand the segments of the market where digital can add value. With these solutions, they are addressing the broader value chain, reducing steps, and improving overall economics rather than just addressing print.

The pace of progress is both encouraging and disappointing. There are pockets of great success, but there is also a lot of work to do to get us to the full transformation that all members of the value chain need.

These improvements and new solutions cannot get here fast enough. It will be exciting to see what is announced and shown at drupa 2024 to further drive the industry’s digital transformation.

Robert Seay, vice president of Digital Print Strategy and Growth at GeorgiaPacific, has over 20 years of digital print innovation and implementation experience including time at both HP and GP with the last 14 years focused on packaging.

Digital print can work in packaging, and it can add value

Epson Australia and New Zealand managing director Craig Heckenberg and Epson global president Yasunori Ogawa

At Aarque we offer solutions tailored specifically for your business.

All from top industry brands...

Quality used equipment with 3 months parts warranty and a free set of inks with each printer sold

ONLY$31,000

ONLY$26,000

ONLY$26,000

Roland lef2-200

ONLY$25,000

ONLY$18,000 Roland LV290 laser engraver

ONLY$21,000

Scan here to view our full range of quality used equipment and related terms and conditions

Total Supply has announced a new partnership with Kongsberg Precision Cutting Systems (Kongsberg PCS).

Gareth McGrail, general manager of Total Supply, says, “With a focus on delivering quality products and providing the highest quality service to our customers in New Zealand, we are delighted to be further strengthening our relationship with Kongsberg PCS, the leader in its markets, and to be adding the renowned Kongsberg range of digital finishing solutions to our offering.

Total Supply takes responsibility for management of the full complement of sales, distribution, and servicing of Kongsberg PCS’s range of digital finishing

Agfa has relaunched and redesigned the Anapurna H3200 hybrid printer.

The Anapurna H3200 hybrid wide format printer will replace the existing H3200i LED.

Phillip Burns, sales manager for Agfa in Australia and New Zealand, says, “The first generation of Anapurna products was launched almost 20 years ago. This latest generation offers higher speed and higher resolution with a reassuringly well-known platform that will make local printers and more productive while also offering lower cost and Greenguard certified printing inks.

“This new version of the Anapurna H3200 delivers a 70 per cent increase in speed compared to its predecessor in production mode.

Out of Home media company JCDecaux New Zealand is the exclusive Out of Home partner of the New Zealand Olympic Committee, for the Paris 2024 Olympics.

Phil Eastwood, general manager of JCDecaux New Zealand, says, “The excitement and team spirit could best

New partnership, from left: Morgan John, general manager Spicers NZ; Geoff Milliken, business manager Total Supply; Stuart Fox, chief executive Kongsberg PCS; and Gareth McGrail, general manager Total Supply

solutions, including spare parts and consumables.

David Preskett, vice president of Kongsberg PCS, EMEA and APAC, says, “This new agreement is part of our ongoing commitment to moving towards a more efficient and effective way to meet the evolving needs of our customers. This distribution partnership strengthens the existing channel we have available for our customers in New Zealand. In addition,

“Equipped with a new protective closure, the new design of the Anapurna H3200 has also been specifically created to provide printers with a safer working environment.”

Philip Van der Auwera, product manager – sign and display at Agfa, says, “The Anapurna H3200 gives a boost in productivity and improved quality. This step underscores Agfa’s commitment to innovation and delivering top-notch solutions that align with the evolving needs of our customers.”

be captured by this line from the New Zealand Olympic Committee manifesto: Ko Tātou Te Kapa o Aotearoa ~ We are the New Zealand Team.”

“There’s nothing like the Olympics to capture a true sense of pride in the talented athletes representing New Zealand overseas. And there’s nothing like Out of Home to help share the emotion and excitement with the nation. We will use our large format and airport networks to keep Kiwis updated with the latest near real-time results, medal tally, athlete updates and more. The Paris 2024 Olympics will see our partnership with the New Zealand Olympic Committee deliver

it enables us to give our customers across the country the level of attention they deserve and live up to our ethos of ‘global presence, local service’.

“With its sixty-plus years of history in the industry, this agreement with Total Supply ensures that Kongsberg digital finishing solutions can now be accessed by more customers and in more countries than ever before. This is about Kongsberg PCS focusing on improvements where we can really make a difference, to deliver the best levels of service to our customers.”

McGrail adds, “With over 60 years of industry presence, Total Supply stands poised to enhance the New Zealand sign industry’s landscape. We are proud to fortify our relationship with Kongsberg PCS, a recognized leader in its markets, by incorporating their renowned digital finishing solutions into our product portfolio.

“This partnership marks a significant step forward in the distribution of cuttingedge digital finishing solutions to sign and display customers throughout New Zealand. From Auckland, Wellington, to Christchurch, we’ve got you covered.”

“Like its predecessor, the Anapurna H3200 features a six-colour plus white ink set and UV LED curing. However, both the print shuttle and print engine itself have been redesigned to achieve a significant productivity increase. Its fast-firing print heads ensure rapid throughput, up to 66 square metres per hour in production mode, and superior print quality on flexible and rigid materials alike.

“Additionally, the printer’s newly implemented continuous board feeding capacity enables efficient printing on rigid materials, with the capability to print up to four boards printed simultaneously.”

“The enhanced print shuttle also contributes to improved image quality, particularly noticeably in darker solid tones. The Anapurna excels in delivering high-quality prints across a spectrum of applications, from uncoated rigid media like corrugated boards and plastics.”

a bigger and more creative campaign than ever before.”

JCDecaux New Zealand has been a New Zealand Team partner since 2017. Nicki Nicol, secretary general of the New Zealand Olympic Committee, says, “As a charity we rely heavily on commercial and other key partnerships to help us promote sport and the Olympic values and help create New Zealand history. JCDecaux is an amazing supporter, helping send our teams to compete overseas and bringing the excitement and spirit of the Games back home. Our partners, some of New Zealand’s biggest supporters, are as inspired by our athletes as we are.”

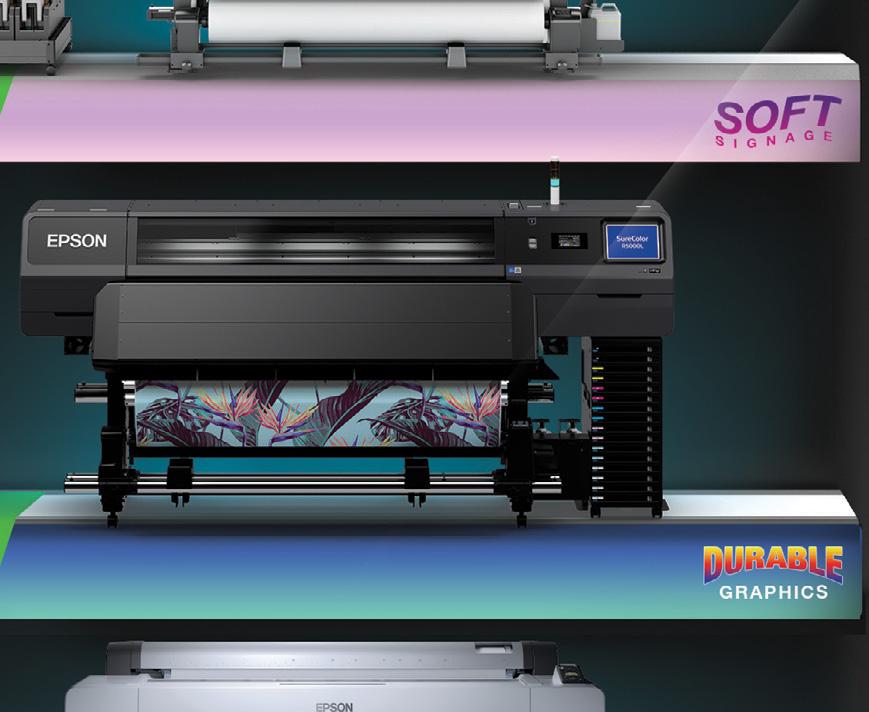

Reflecting on four decades of industry leadership.

Epson Australia, a leader in imaging technology, has announced its 40th anniversary of operations in Australia and New Zealand. The company will use its 40th year to continue its legacy and introduce exciting new products in large format printing, projectors, office, and industrial printing.

Epson Australia says it has achieved numerous milestones over the last 40 years which include currently being recognised as the number one brand in Australia for projectors, large format printers, thermal receipt printers and consumer ink tank printers.

Craig Heckenberg, managing director Epson Australia and New Zealand, says, “We are thrilled to commemorate this significant milestone in our company’s history.”

Epson Australia started out in November of 1983, with a small team of 20 people in Sydney. Three to four years later, it began in New Zealand. The wholly owned subsidiary of Seiko Epson Corporation represents over 80 years of Japanese craftmanship, engineering and environmental excellence.

Since its inception, the company has been at the forefront of advancements in print

and projection, delivering the highest quality, reliability, and service to its Australian and New Zealand customers.

Throughout its journey, Epson Australia has played a central role in transforming industry and improving the way people and businesses communicate their creativity, craftmanship, ideas and messages.

The company’s recent environmental initiatives include partnering with Earth Hour, the world’s biggest movement to protect our planet, sponsoring the Royal Botanic Gardens of Sydney and transitioning to 100 per cent renewable energy across its entire operation in Australia and New Zealand.

Mr Yasunori Ogawa, Seiko Epson Global President, said, “I would like to congratulate Epson Australia for their 40th anniversary and offer my thanks for the dedication and support of all the employees, partners and customers who have made this possible.

“Epson is committed to achieving sustainability and supporting the community and no group company embodies this commitment more than

Epson Australia. I look forward to working with everyone to achieve even greater success both for Epson Australia and the wider community.”

These achievements underscore the company’s commitment to excellence and its pivotal role in driving innovation and growth in Australia.

Craig says, “We are very proud of our achievements and success over the last 40 years. As such, I must thank all Epson staff both past and present, our channel partners and customers for contributing to this success. We now focus on the next 40 years and on creating continued growth through providing innovative products and services that make a positive impact to the lives of our customers, their businesses, and their communities.”

Today, the company’s product portfolio consists of home and office printers, scanners, thermal receipt printers, projectors, large format printers, industrial print solutions and a wide range of software tools that enhance the productivity and usability of its products and provide more value to customers.

The company has also expanded its team to over 150 people across Sydney, Melbourne, Brisbane, Adelaide, Perth and Auckland with offices and showrooms in each location. Its service coverage and remote support capabilities ensure minimal disruption and quick turnaround times, even in remote locations.

Craig adds, “Again, it’s the hard work and dedication of our team, their proven track record of providing the highest level of customer service and the support from our customers which has led to our success. Whether it be at home or work, we pride ourselves on helping our customers get the most out of our products and services and to be there for them when it really matters.

“Looking ahead, we have a lot more to accomplish and we pledge to continue to play our part to protect the environment by working with our customers and industry to help solve societal issues, strive for sustainability and improve quality of life.”

Total Signage Solutions from the Vendor You Can Trust.

Epson’s signage and décor printers deliver higher image quality with superior colour and gradation. They offer wide media support and cost-effective production backed with on-site CoverPlus extendable up to 5 years. From indoor POS, outdoor signs, back-lit displays, window decorations, banners and vehicle wraps to wall coverings, floor stickers, custom cabinetry, flags and merchandise, Epson has the selection for you.

www.epson.co.nz/prographics

Durst Oceania returns as Platinum Sponsor for the event.

Set for April 11, this year’s People in Print Awards and Rising Stars of Print Awards will take place at Sorrento in the Park in Auckland on April 11, with a 4.30pm start.

New Zealand Printer and Print NZ have again partnered to give you a chance to celebrate our printing industry talent at the event.

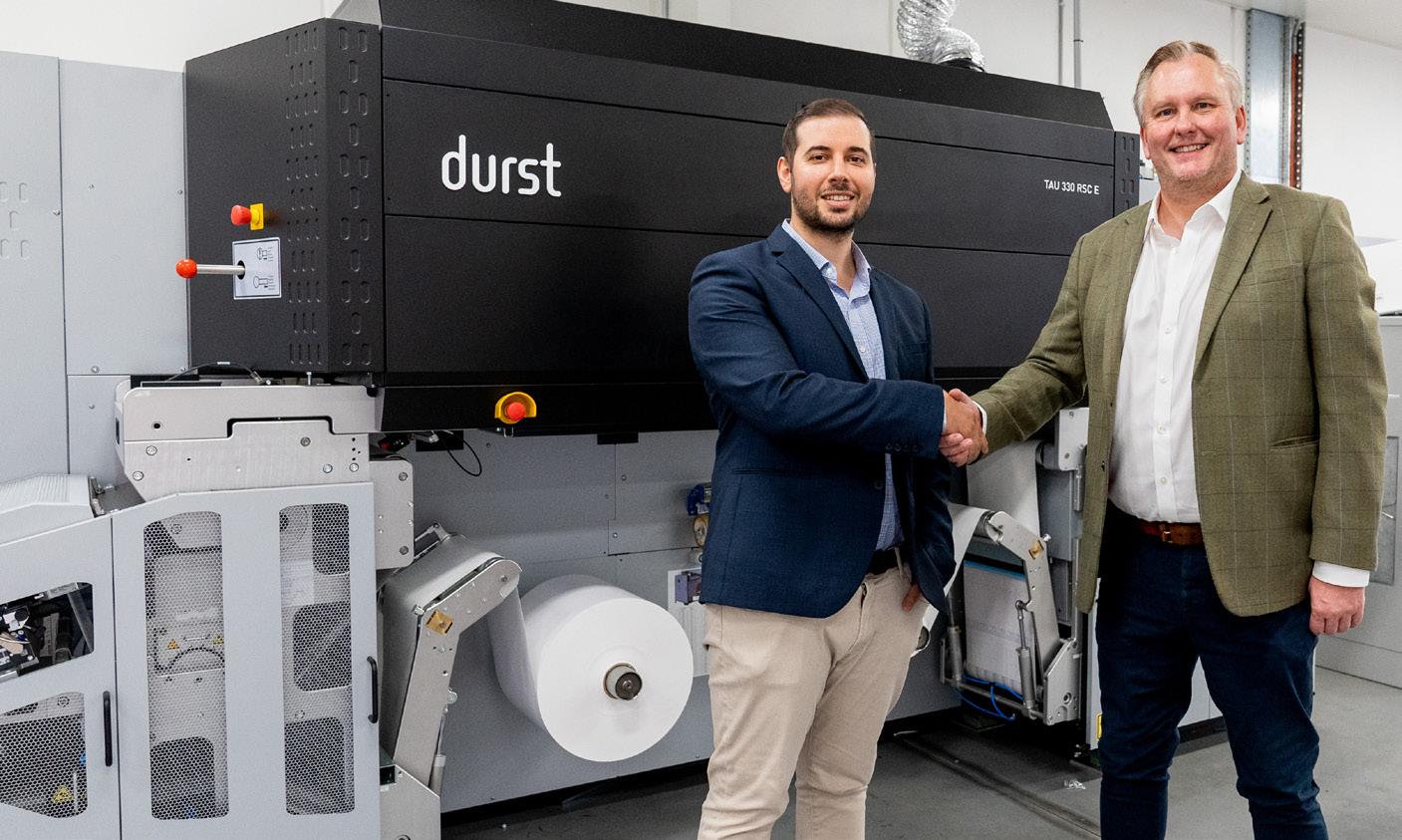

This year, Durst Oceania returns as Platinum Sponsor for 2023. For the past three years, Durst has also been the Platinum Sponsor of the prestigious ProPrint Awards, which New Zealand Printer’s sister publication ProPrint organises in Australia.

Brian Moore, publisher at New Zealand Printer, says, “It is a great privilege to again welcome Durst as Platinum Sponsor for the Awards. The other confirmed sponsors are Computaleta, Cyber, Konica Minolta, and Wholesale Print. Their support for this event shows their strong commitment to the industry.”

Matt Ashman, managing director of Durst Oceania, comments, “Durst is very happy to return as the Platinum Sponsor of the People In Print Awards and support the New Zealand printing community.

“Durst has seen massive growth in the New Zealand market over the last 12 months. The Durst footprint is growing

month on month in both the large format and labels hardware markets as well as in the software category.”

As in previous years, guests at the awards can look forward to a smart casual, stand-up affair with delicious finger food and drinks. The evening provides an ideal opportunity to network with and celebrate the people in our industry.

Ruth Cobb, chief executive at PrintNZ, says, “We are pleased to support the People In Print Awards and Rising Star Awards. Recognising members of our industry who have made an extraordinary contribution during the year gives us a chance to appreciate those who go above and beyond. We look forward to celebrating their achievements as we take the time to acknowledge them.”

Lawrence Evans, managing director of Wholesale Print, says, “What a timely reminder that people still make the industry exciting, vibrant, and motivational.

“Print has shifted with astonishing speed toward a hi-tech manufacturing industry, so it feels right that we acknowledge the visionaries, the determined, and the straight up survivors that populate our market. It has not been easy for anyone, which may be why I get the feeling that there is a high level of mutual respect for

competitors, suppliers and of course the faithful end customers to us all. I hope to see you at the People in Print Awards for 2024.”

Chris O’Hara, national production print manager for Konica Minolta Business Solutions New Zealand, says, “Konica Minolta is privileged to stand as a steadfast sponsor of the People in Print Awards. At Konica Minolta, we recognise the importance of celebrating the remarkable individuals who define and enrich the print industry. Their unwavering dedication and ingenuity serve as the cornerstone of our collective success.

“We look forward to uniting with fellow professionals at People in Print Awards, to honour the exceptional talents and contributions that continue to elevate the print industry in New Zealand.”

Arlette Farland, director at Computaleta, adds,” We are thrilled to be part of an event that celebrates the incredible talent and innovation within the printing industry. This event not only recognises the achievements of individuals who have made extraordinary contributions but also provides a valuable opportunity for networking and collaboration.

“As Gold Sponsor we are committed to fostering growth and excellence within the New Zealand printing community. We look forward to an inspiring evening of recognition and celebration on April 11 at Sorrento in the Park.”

What: People In Print and Rising Stars of Print Awards

When: April 11, from 4.30pm

Where: Sorrento in the Park, One Tree Hill, Auckland

Contact Phone: 021 631 559

Contact email:

bruce@newzealandprinter.co.nz

Register online: https://form. jotform.com/72270835215857

organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

Wayzgoose 2022

September 17, 2022

September 17, 2022

Napier

Napier

April 11, 2023

Auckland

www.inkianapress.co.nz