The

The

The packaging industry in Australia is going through a wave of disruption and if you don’t make it work for your business, you’re positioning yourself for a challenging journey ahead.

Ensuring your business is adaptable has bever been more crucial, and with many companies starting to reflect on their business needs and requirements for the new year, the timing couldn’t be more ideal.

But what are the issues causing this wave of disruption, you may ask. Discussing these topics was the key purpose of the recent ProPack Packaging Forum, where industry forward-thinkers brought their thought leadership to stage.

Meaningful discussions around AI in packaging, challenges and opportunities facing the sector, and future industry trends occurred – especially around the

role of technology in manufacturing, the future of sustainability, and how businesses can be better supported using smart packaging solutions.

It’s evident that technology is transforming packaging. From the adoption of emerging digital printing and production technologies, to improving business processes by investing in packaging optimisation tools and using AI in design – technological advancements are ripe for the picking.

All of these superior technologies support businesses in providing better customisation for clients, enhancing efficiency and reducing waste – things companies could be challenged with.

As for sustainability, it is a hot topic that’s on everyone’s radar – as it should be. It should no longer be an after-thought and packaging

companies must offer eco-friendly options to not only meet consumer demands but also adhere to stricter regulations.

Underpinning all of this is the need for collaboration and ensuring that a consumer’s experience remains top of mind. A functional and visually appealing package delivers the best unboxing experience, resulting in better brand perception. Collaboration between manufacturers, brands, suppliers and converters is also paramount to succeed.

All of the above and more is covered in this issue of ProPack.pro

This magazine is also the last issue for the year before we break for the silly season. On behalf of the team at ProPack, happy holidays and we look forward to bringing you more news, features, and thought leadership in the new year.

Pact Group has reported a loss in revenue for its FY24 full year financials

Mountain Blue and Opal partner for cardboard packaging trial P06

Collaboration on the brand Eureka sees the duo come together with Coles Group

VMA represents industry into govt across packaging reform P08

Says fibre-based packaging regulation should align with international standards reforms

Amcor releases 2024 Sustainability Report P08

Findings show continued progress in the company’s sustainability aspirations

New packaging marketplace to help SMEs recycle right P10

The ARL Marketplace aims to help SMEs navigate packaging sustainability

New kids on the block? Think again! P10

Kissel & Wolf has a pedigree stemming back some 35 years in A/NZ

Koenig & Bauer Au expansion P12

Koenig & Bauer Australia requires additional staff to support its recent growth

Koenig & Bauer Durst launches Delta SPC 130 in A/NZ P14-16

The printer delivers an innovative world-first sustainable solution for printers and converters

Unpacking the ProPack Packaging Forum in Sydney P18-25

The Forum brought together industry thought leaders and early adopters of technology

Gallery: Industry gathers at ProPack Packaging Forum P26-27

Suppliers and converters from all over A/NZ gather at the event

Pressnet expands its finishing with the Dapeng Rotacut 5575 P28

Dapeng Rotacut 5575 rotary die-cutter strips waste in one pass for Foyer Printing

Sinclair and Zespri join forces for new sustainable labelling P30

The Sinclair - T55 compostable label sets a new standard in produce packaging

Tweak refreshes Nerada Tea packaging in rebrand design P32

The redesign is a strategic brand evolution of Nerada Tea

Identifying pre-sale opportunities to build value P34

Areas of opportunity for improvement to enhance the value of your business

Shining the light on shady packaging P36-38

The good, the bad, and the ugly when it comes to brand packaging and design

The Future of Package Printing to 2029 Smithers’ study P40

Finds the packaging print market will hit US$604.0B in 2029 in the wake of drupa 2024

The Future of Biodegradable and Compostable Packaging P41

Sales value of sustainable compostable and biodegradable plastic will increase

Pack diary P42

A guide to the upcoming events locally and internationally

year revenue dips $91M from the prior year

Pact Group (ASX:PGH) has reported a loss in revenue for its FY24 financials, announcing revenue of $1.857 billion, which was $91 million below the prior year.

According to the company, this primarily reflected the loss of revenue from the Crates business, combined with some volume decline in Australia, New Zealand, and China.

However, Pact’s underlying EBIT of $154.6 million was above the prior year and reflected savings from the Transformation Program combined with margin growth in the materials handling and pooling, and in contract manufacturing segments on the back of efficiency gains.

Its underlying net profit after tax (NPAT) was $44.9 million, slightly ahead of the prior year. The reported NPAT was $74.9 million as a result of adding $30 million of after-tax

Berry producer Mountain Blue has announced a plastic free packaging trial in collaboration with packaging company, Opal, on the brand Eureka, and supermarket retailer, Coles Group.

As part of Mountain Blue’s ongoing commitment to sustainable practices, this initiative has introduced kerbside recyclable and FSC-certified cardboard punnets for blueberries across 34 Coles stores located in Northern NSW over a two-month period.

The punnets, which are an alternative to plastic containers, feature a unique transparent film produced from wood pulp.

By using FSC certified materials, the packaging further reinforces a commitment to sustainability, ensuring the materials come from responsibly managed forests.

The trial marks a significant step in packaging innovation within the fresh produce industry.

The kerbside recyclable punnets, developed in collaboration with Opal, aim to provide a plastic free alternative without compromising on the quality and freshness of Mountain Blue’s blueberries.

The punnets are made from recycled paper manufactured by Opal in Australia and feature

underlying adjustments which included the gain on sale of the Crates business.

The full year results contain five months of trading from the Crates business when it was wholly owned, and seven months of 50 per cent of the NPAT from the newly formed joint venture.

Pact Group CEO and managing director Sanjay Dayal said market conditions were challenging across the year as the business felt the impact of cost-of-living pressures in Australia and New Zealand, and subdued demand out of China.

“Despite these challenging conditions, we reported a growth in earnings. This was achieved on the back of a more stable and

predictable supply chain, a proactive cost reduction program – you will recall that I outlined the Transformation Program at our AGM last year – and significant efficiency gains across the business,” he said.

In addition, Pact Group chair Raphael Geminder revealed more information around the divestment of its non-core businesses, saying it has now reached an agreement to sell its Viscount roto-moulding business (VRM) in Carrum Downs, Victoria.

“VRM manufactures plastic infrastructure products such as underground pits and lids for telecommunications, electrical, road and rail applications, as well as water tanks, and other custom-made products,” he said.

“Under the agreement, the VRM business will be acquired by CRH, a building materials solutions company. Completion of the VRM transaction is expected later this year subject to the satisfaction of customary conditions and approvals.”

In addition, he mentioned that the unconditional off-market takeover offer for all the ordinary shares in Pact announced on 13 September 2023 closed on 7 June 2024, with Kin Group and associates increasing their share ownership in Pact to 88.04 per cent.

the robustness needed to protect fresh produce through supply chains and freight.

“We’re excited to trial kerbside recyclable cardboard punnets with Opal,” Mountain Blue managing director, Andrew Bell said.

“This innovation offers consumers sustainable packaging choices in Coles supermarkets.”

Chris Daly, executive general manager of Opal Packaging, said the company is heavily investing in research and development to test and commercialise products made from recycled and recyclable paper and cardboard.

“By partnering with Mountain Blue, we were able to understand their packaging needs and work together with our automation and machinery team, to deliver a punnet solution that is innovative, functional and sustainable,” Daly said.

Brooke Donnelly, Coles general manager of sustainability, said the large supermarket chain is continuously looking for ways to innovate and redesign its packaging, and this trial provides customers with a packaging alternative for a product they love to eat.

“Fresh produce packaging is ripe for innovation, and we’re excited to provide our customers with a plastic free alternative for much-loved and in season blueberries,” Donnelly said.

“This trial is about ensuring the new cardboard punnets keep blueberries as fresh and tasty as the conventional plastic packaging, and to see how our customers respond to the change.”

Mountain Blue added that it hopes this trial will pave the way for broader adoption of sustainable packaging.

CO-LOCATED

The Visual Media Association (VMA) and the Australasian Paper Industry Association (APIA) have worked with an industry-led Labels and Packaging Coalition to issue a submission on behalf of industry into the Federal Government’s packaging regulation reforms.

The position of the VMA’s Labels and Packaging Coalition, comprised of industry experts and stakeholders, is that fibre-based packaging regulation should align with international standards, rather than new government standards which may potentially over-regulate the print and visual media sectors.

The submission also advocates for the Department of Climate Change, Energy, The Environment and Water (DCCEW) to establish advisory working groups with representation from each relevant sector to ensure guidelines are adequate and successful, arguing that the current make-up of the Design Working Group (DWG), does not include manufacturers, who are critical technical advisors. With the department exploring the option of introducing the

Amcor has released its 2024 Sustainability Report, with the findings showing significant achievements and continued progress in the company’s sustainability aspirations.

In addition to having its safest year ever, more than 94 per cent of Amcor’s flexible packaging portfolio by area had a recycleready solution available, and 95 per cent of rigid packaging by weight was recyclable in practice and at scale.

Amcor also surpassed its goal of including 10 per cent post-consumer recycled plastic one year ahead of schedule and purchased more than 254,000 metric tons of recycled material for its solutions.

Amcor CEO Peter Konieczny said, “Amcor has led the way in making incredible progress designing our products to be recyclable and more efficient, but design alone is not enough.

“Society needs consumer participation and infrastructure development to make circularity real – to make sure used packaging is not left in nature but recycled to become new packaging. Sustainability is at the heart of our company and drives a sense of purpose, inspiration and energy in everything we do.”

Extended Producer Responsibility (EPR) scheme, the VMA highlighted the potential risks of increased costs and competitiveness issues for Australian businesses if regulations do not align with international standards and address the country’s unique market dynamics.

The association also maintained that fibre-based packaging is one of the most environmentally sound solutions available

and should be optioned into a selfregulated program.

“The fibre-based packaging sector is already leading the way in sustainability, which are compliant from forestry to mill to production to international best-practice standards. Burdening these suppliers, and in turn printers, with increased regulatory costs will have devastating consequences for the industry,” VMA CEO, Kellie Northwood said.

“Manufacturing in Australia already has high labour and energy costs – further government regulatory costs will impact local packaging manufacture and lose Australian jobs.

“A packaging product produced in another country without such regulatory costs will be produced and imported at a lower cost than a local manufacturer can provide and will reduce the very aim of securing more sustainable packaging outcomes for Australian products and consumers.”

The Labels and Packaging Coalition will continue to provide industry feedback and offer expert advice on drafted policies and potential legislative recommendations at both federal and state levels.

“I extend my thanks to all participants in the Labels and Packaging Coalition. Your direction and expertise has been invaluable in shaping our submission and advancing sustainable packaging solutions,” Northwood said.

Amcor’s short-term and net-zero targets have been approved by the Science Based Targets initiative and the company published a Decarbonization Roadmap to share its approach to reach net-zero by 2050.

In addition, the company achieved a nine per cent reduction in absolute greenhouse gas emissions compared to FY23. Fourteen per cent of the electricity used was renewable, which represents a 64 per cent

increase compared to the previous year.

Amcor chief sustainability officer David Clark said, “Amcor is committed to leading the packaging industry toward a circular society. We are ramping up our efforts in advocating for consistent and effective regulations, encouraging infrastructure development, and educating both customers and consumers. We can all contribute to a more sustainable future”.

A new online packaging platform has launched in an effort to help customers of small businesses recycle right.

The ARL Marketplace aims to help SMEs get the support they need to navigate packaging sustainability and recycling, by providing access to Australia’s only evidence-based recycling label, the Australasian Recycling Label (ARL).

In 2022, the program was granted $4.5 million in funding from the Commonwealth government, to support SMEs to improve the sustainability of their packaging.

The ARL Marketplace enables SMEs to source packaging from registered suppliers like Pact Group, Zipform Packaging, and Labelmakers Group that is ready-to-label with the ARL.

“We understand that with so many competing responsibilities, it can be difficult for small businesses to prioritise sustainability,” Australian Packaging Covenant Organisation (APCO) CEO Chris Foley said.

“APCO is working to strengthen the recycling system and support SMEs through

the imminent packaging regulations that will come into place – and one of those ways is through the ARL Marketplace.

“The ARL Marketplace offers Australia’s small businesses an easy way to take action on packaging sustainability and reap the rewards.

“Small businesses have a major role to play in improving packaging sustainability in Australia – there are 2.5 million of them that make up more than 97 per cent of Australian businesses. By connecting them directly with packaging suppliers, we are making it easier than ever for small businesses to get the ARL on-pack.

“The ARL is a valuable tool for businesses to understand the environmental outcomes of the materials they are using in their packaging and plays a vital role in helping consumers recycle better. The Marketplace Directory supports industry to achieve packaging circularity in Australia,” Foley said.

The launch of the ARL Marketplace is the culmination of a two-year education campaign led by APCO, the Australian Institute of Packaging (AIP), the National Retail Association (NRA), and the Australian Food and Grocery Council (AFGC).

New kids on the block? Think again!

There are many in the digital packaging and sign and display segments who could perceive Kissel & Wolf Australia as being the “new kids on the block” – however, this is far from the case.

In fact, the company is one of the oldest and most trusted brands with a pedigree stemming back some 35 years in Australia and New Zealand. An incredible story of loyalty, family and a customer service level unrivalled even in today’s difficult climate.

From being the leading equipment and consumable supplier in the screen print market, they have steadily diversified whist never straying from core values. They also carefully and strategically build trusted supplier relationships, ensuring both old and new customers are supported and confident with any technology investment from Kissel & Wolf.

Kissel & Wolf packaging and sign and display A/NZ sales manager Bruce Caldwell said he was encouraged from day one, when managing director Jamie Weller suggested, “If we can’t support it, we won’t sell it”. This is the backbone of the service credo from Kissel & Wolf.

“With a myriad of world leading brands in the portfolio, we are well positioned in our offerings – including more recently being appointed to represent the Hanglory Group in the Australasian market,” Caldwell said.

“It’s another well planned and well executed strategy consistent with an already successful philosophy. Whether it’s a waterbased solution, UV, high volume single pass or an entry level requirement, it’s worth taking the time to evaluate these robust, well serviced, and well price positioned options. With a 135-year-old family-owned German parent company behind the A/NZ team, you can feel confident and secure in your

investment and long-term expectations. I would encourage you to scan the QR code and read the full company story; it’s not just compelling, it’s a fascinating Australian story that embraces the values many of us still hold, and how hard work, having a customer focus, and real experience brings success.

“I look forward to discussing with you the many options available when considering your next digital press investment.”

Scan the QR code to learn more about Kissel & Wolf’s packaging solutions

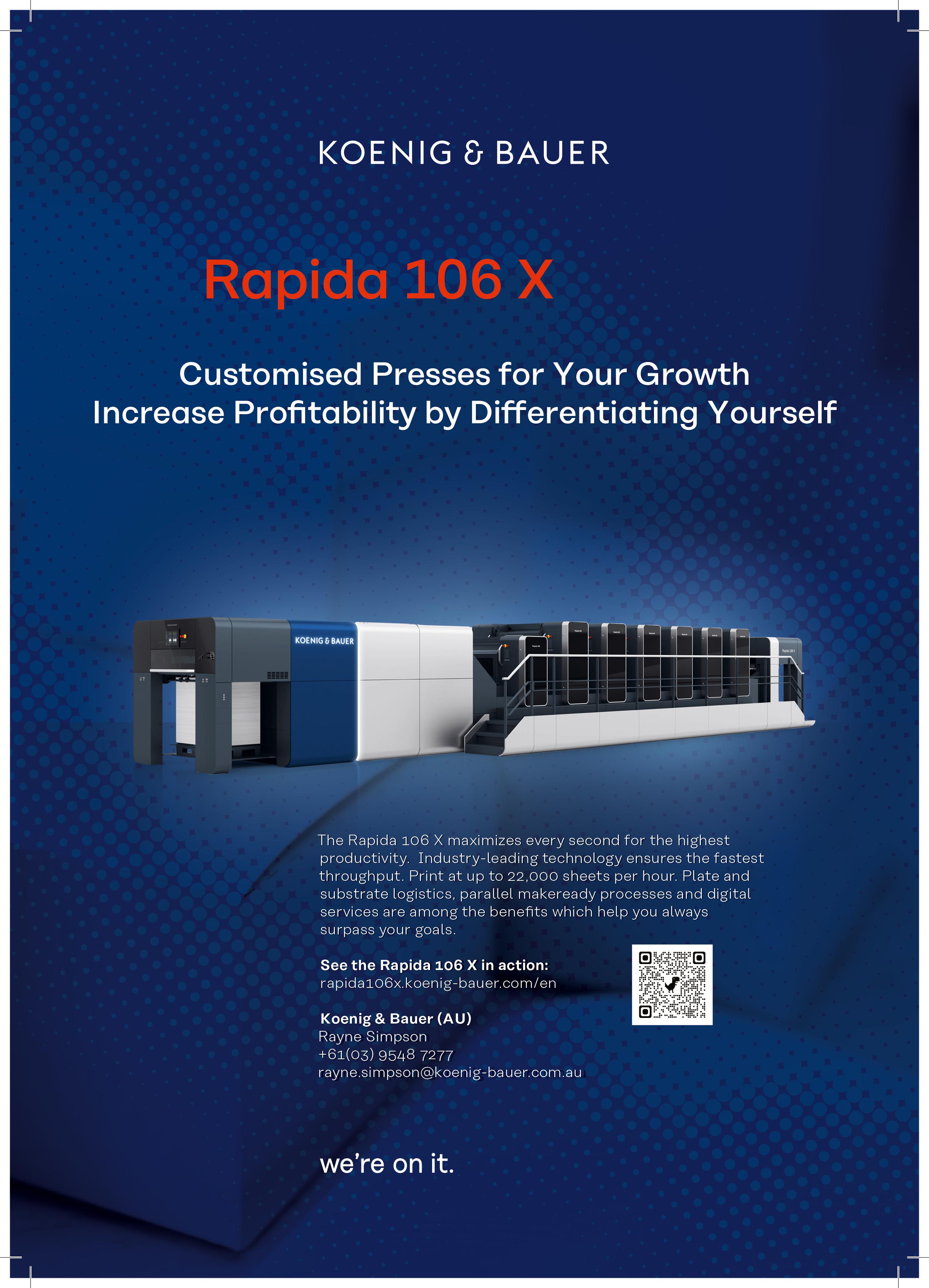

After its recent press sales and pending installations, Koenig & Bauer Australia has seen significant company growth and requires additional staff to support it

Koenig & Bauer’s Rapida 106 X has been hugely popular in the A/NZ region, resulting in company growth and the need for more staff

Newly appointed Koenig & Bauer Australia managing director Graham Harris has confirmed the Australian subsidiary requires additional staff after several successful press orders.

“This year has seen a rise in interest in the latest press technology from Koenig & Bauer,” Harris said.

“As a result of the recent installations, as well new orders scheduled for installation in late 2024 and early 2025, we are looking to expand our support team in Australia and New Zealand. We are looking for electrical and mechanical engineers to join the Koenig & Bauer team.

“The benefit of working for Koenig & Bauer Australia is that you are working directly for the manufacturer and not for an agency or distributor.

“All engineers will receive full factory training in Germany where we have a stateof-the-art customer experience and training facility with presses that are solely available for customer print demonstrations, print tests, operator training, and training of service and support staff.”

Earlier this year, Koenig & Bauer Australia managing director Dave Lewis announced his retirement and was replaced by Graham Harris in May, who has worked alongside Lewis for two decades as service manager.

Rayne Simpson recently joined Koenig & Bauer as sales manager for Australia and New Zealand. Simpson has more than 30

years of industry experience, including 13 years with CPI, seven years with Sicpa Graphics, and five years with Ferrostaal.

Simpson said, “Koenig & Bauer Australia thanks our customers for believing in Koenig & Bauer’s technology, innovation, and support. It’s the driving force behind our commitment to delivering quality and speed for our customers and their clients”.

Koenig & Bauer recently confirmed the sales of eight presses in Australia and New Zealand, including an unprecedented four presses to IVE Group in Australia and one to Blue Star in New Zealand.

The deal with IVE Group was a landmark order, which includes four cutting-edge Koenig & Bauer Rapida 106 X model presses. Details of the exact specifications remain confidential, underscoring the significance of this investment in response to the surging demand for high-quality printing solutions.

In addition to the partnership with IVE Group, Koenig & Bauer A/NZ confirmed a strategic collaboration with Bluestar NZ, one of New Zealand’s premier printing and marketing execution entities. This partnership was further underscored by the recent order of a Rapida 106 X, marking a significant milestone as it will be the inaugural installation of this advanced press in the A/NZ region.

Further solidifying its presence in Australia, a large-format Rapida press is also on order. Earlier this year, United Print and Packaging embraced the future by

installing a B2 Rapida 76 press, augmenting Koenig & Bauer’s influence in the region.

“The mission for the new Rapida generation presses was simple: to develop the most efficient and sophisticated 740mm by 1,060mm sheetfed offset press ever built by Koenig & Bauer,” Harris said.

“The result is the new performance benchmark in industrial printing: the Rapida 106 X. It fulfils the highest demands in automation and productivity and is a pioneer in the industry when it comes to digitalisation.”

“This next-generation press is pioneering the future of industrial printing, offering significant advantages in economy and efficiency. Whether in commercial, packaging, or label printing, the Rapida 106 X sets a new standard for sheetfed offset,” Simpson said.

“The Rapida 106 X is packed with innovative solutions designed to meet individual requirements, excelling in automation and productivity. It promises remarkable profitability and efficiency, empowering businesses to confidently navigate the evolving landscape of the printing industry.

“As Koenig & Bauer A/NZ continues to lead the way in state-of-the-art printing technology, the company reaffirms its commitment to delivering exceptional after-sales support for the Australian and New Zealand printing, packaging, and label sectors.”

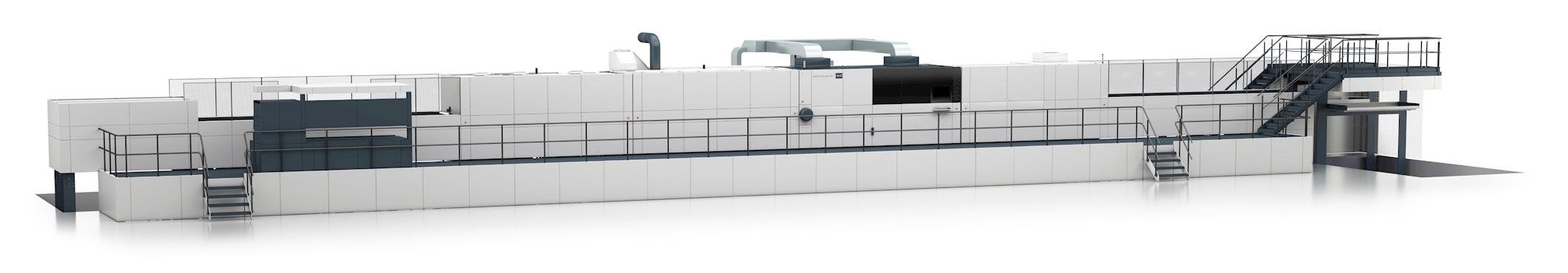

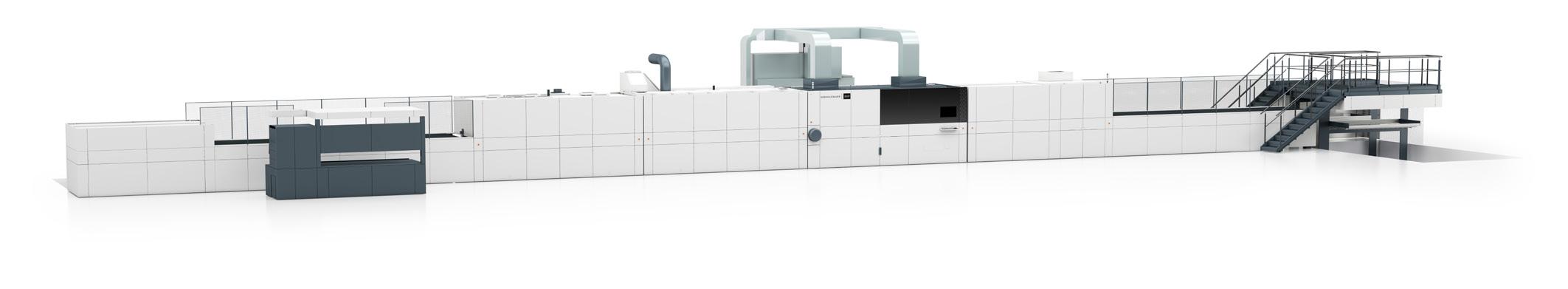

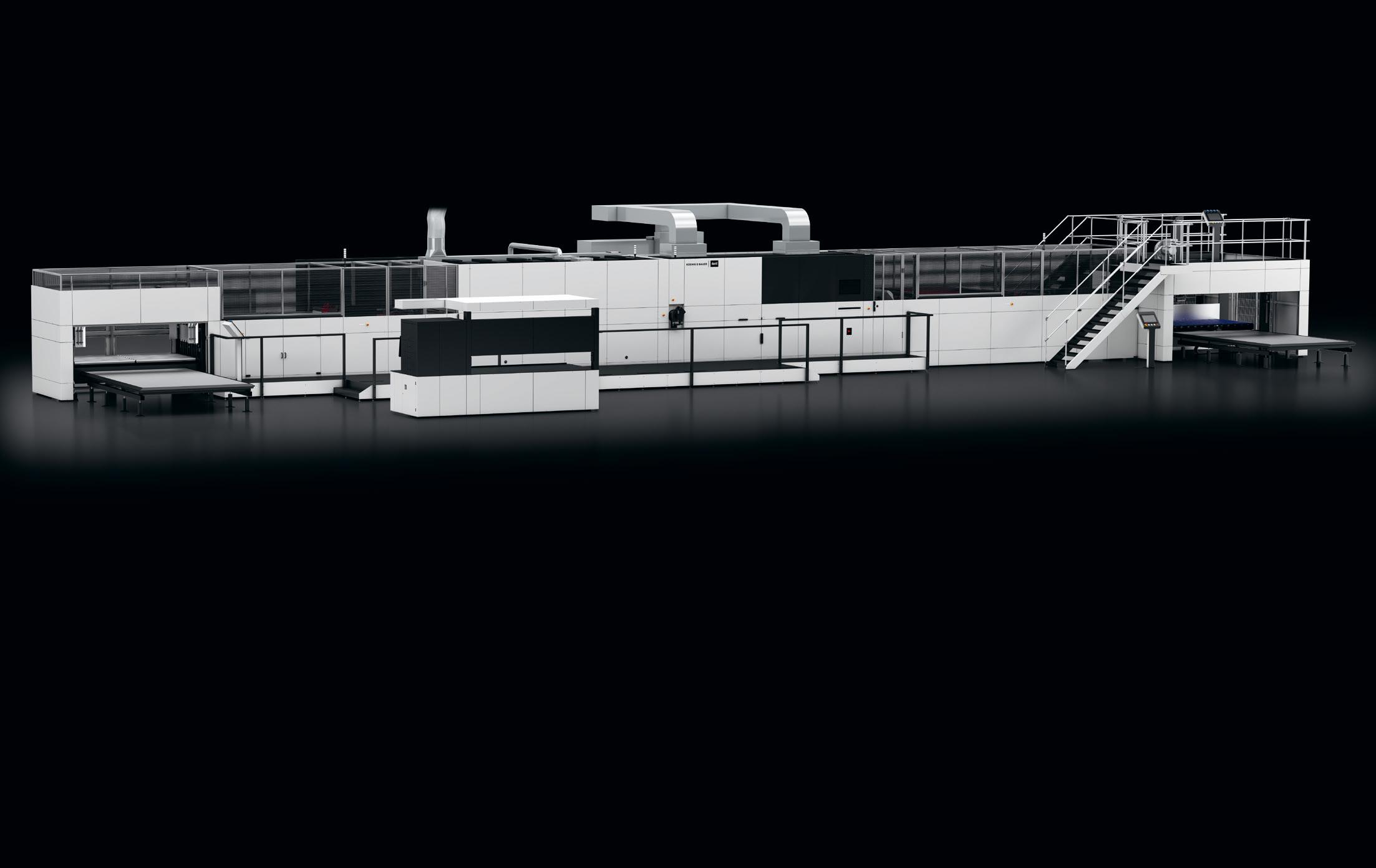

The Koenig & Bauer Durst Delta SPC 130 delivers an innovative world-first sustainable solution, as well as a highly profitable opportunity for printers and converters

The launch of the Koenig & Bauer Durst Delta SPC 130 in Australia and New Zealand represents a new opportunity for corrugated packaging converters to take advantage of worldfirst ink technology.

Koenig & Bauer and Durst, both world leaders in the manufacture of industrial printing machinery, signed a joint venture in 2019 to tap into the potential of digital production in the packaging industry.

The Delta SPC 130 single-pass press has been created for corrugated converters looking to migrate and embrace the benefits of digital production or upgrade from their current digital system.

The game-changing digital water-based white ink used with the Delta SPC 130 is

The Delta SPC 130 combines a well-engineered mechanical design with easily accessible sub-assemblies and selected components to guarantee durable quality and high performance

suitable for primary food packaging printing as it is food-safe, sustainable, and meets current and future regulatory as well as environmental standards, providing new application opportunities.

“Customers in Australia and New Zealand have been waiting for a product such as the Delta SPC 130 to deliver attractive, safe, and sustainable packaging,” Durst Oceania managing director Matt Ashman said.

“The Delta SPC 130 provides corrugated printers and converters with the latest digital printing technology that will play an ever-increasing role, complementing and optimising the operations for local printers and converters.

“Not only does the Delta SPC 130 deliver an innovative world first sustainable solution, it

also delivers a highly profitable opportunity for our printers and converters.”

Available with the possibility for in-field upgrades to increase throughput or provide additional applications, it is compatible with media sizes from 1.3 metres by 2.8 metres.

The machine is ideal for converters with annual production volumes between 3 million and 5 million square metres annually, by printing at 60m/min on coated and 90m/min on uncoated boards.

“The Delta SPC 130 is based on the latest generation of single-pass printing systems that Durst is already using successfully in the ceramics and label-printing segments. This single-pass technology has been continuously developed since 2005.

“Koenig & Bauer Durst has adapted and optimised this single-pass platform to the needs of the corrugated board industry,” Ashman said.

“The Delta SPC 130 combines a wellengineered mechanical design with easily accessible sub-assemblies and selected components to guarantee durable quality and high performance. It is a printing system that offers unrivalled versatility, low maintenance requirements and 24/7 reliability.

“The Delta SPC 130 is equipped with recirculating Durst Quadro Array printheads and water-based inks. It is equipped with Durst’s SPC drop-on-demand print head technology and has a non-hazardous ink system, and an IR/UV drying process designed for high productivity.

“These form the basis for the constant readiness for operation and reliability in industrial, multi-shift production environments. With our Flexline concept, we can offer the ideal solution based on the different customer needs.

“This technology is the future. It replaces such processes as litho-lam, where paper is printed on a litho press and then laminated onto corrugated. With this technology, the corrugated board can be printed directly, cutting out a process. The print quality also exceeds high quality litho.”

The Royal Group – one of the largest independent corrugated box and display manufacturers in the US – was one of the first companies to invest in a new Delta SPC 130 Automatic single-pass press from Koenig & Bauer Durst.

The six-colour Delta SPC 130 Automatic press – which is also available in Australia – was installed at The Royal Group’s MidAtlantic packaging site near Philadelphia in 2022, giving customers the flexibility to print unique versions of high-quality graphics for brands and brand extensions, allowing for mass customisation at a large scale.

The Royal Group specialises in industrial packaging, brown box shipping containers, plus high-end packaging, e-commerce, in-store displays and shelf-ready packaging. It serves a diverse range of customers including retail, food and beverage, pharmaceutical, health and beauty, agriculture, tech, and home goods.

“As both a producer and a converter of corrugated packaging, The Royal Group has

The Delta SPC 130 was demonstrated on the Koenig & Bauer Durst stand at drupa in Düsseldorf earlier this year.

According to Koenig & Bauer Durst managing director Daniel Velema, a large number of visitors at drupa were offered a closer look at the SPC Control Console and learned how the Delta SPC 130 is integrated into the production environment in conjunction with Durst workflow and analytics functionality.

made significant investments to acquire the best machinery available in the industry,” the company’s former CEO Bob McIlvaine said at the time of purchasing the machine.

“The investment in the Delta SPC 130 for our Mid-Atlantic site underpins our commitment to process improvement. It enables us to provide highly automated, world-class printing capabilities at speed, while remaining as flexible as

“Among the digital single-pass presses supplied by Koenig & Bauer Durst, the Delta SPC 130 is already well proven on the corrugated board market with several installations in major corrugated customers globally,” Velema said.

“As a world-leading supplier of digital sheetfed presses, single-pass printing systems and software services for the folding carton and corrugated markets – and with two giants of the packaging and printing industry as partners – we see enormous potential for significant growth in the coming years, enabling us to support and accelerate the digital journey of our customers.”

possible for our clients as we continue to grow our business.

“Digital packaging is the future – and we aim to satisfy our customers and meet their needs with innovative solutions.”

A more recent adopter of the Delta SPC 130 is Atlantic Packaging. The company was seeking a press that was durable and could run production speeds on corrugated.

As a vertically integrated corrugated company servicing the northeastern part of North America, Atlantic Packaging installed its first Koenig & Bauer Durst Delta SPC 130s using water-based inks at its Canadian factory earlier this year.

“Our journey in single pass digital corrugated started in 2018. At the time, our customers were asking us where they needed a smaller run size, flexibility, high quality graphics and speed to market as well as being sustainably focused,” Atlantic Packaging digital print manager Anthony Memme said.

“We chose the Koenig & Bauer Durst Delta SPC 130s as it was litho like, with the highest quality that we could achieve. We also felt there were synergies between Atlantic and Koenig & Bauer Durst. We are both family owned. Important, too, was the professionalism that we were presented with throughout the organisation, through the process, especially at the initial phases of our partnership, when we were looking and evaluating the different options for digital.

“Now brands are taking an interest in digital production – we see that especially

Food packaging certified

When paired with the Koenig & Bauer Durst Ink Set and suitable corrugated cardboard or cardboard material, the Delta SPC 130 is fully approved for all major certifications for the production of both primary and secondary food packaging.

Water technology

Koenig & Bauer Durst Water Technology inks allow high-quality, odour-free and non-fading end products to be produced in a single process, eliminating pre-treatment, interim drying and overprint varnish.

Configuration

The Delta SPC 130 can be configured with up to six colours, printing any length of corrugated cardboard or

in the Canadian market, and the flexibility that it gives them. The ability to print with the Koenig & Bauer Durst white ink allows them to achieve really good quality on uncoated and kraft substrates.

“Koenig & Bauer Durst’s digital white ink is revolutionary for us and our markets, especially with it being a water-based ink.

“We do a lot of food, food contact, food ready packaging, such as pizza and produce boxes. Being able to put down a white and get high-definition full colour graphics on a kraft substrate is going to be transformative in our industry.

“Up until now I have not seen any print method print this quality and vibrancy of colour on uncoated and kraft materials.”

Memme said the machine also improves the sustainability of a product, the look of it, and gives Atlantic Packaging the ability to react and pivot to market conditions.

“Sustainability is important to us as a company and our customers look to us to provide them with a sustainable product, with quality and speed to market as well,” he added.

• Media Type - Corrugated board

• Min. sheet size - 600mm by 600mm

• Max sheet size - 1300mm by 2800mm

• Min. sheet thickness - 1mm (F-flute)

• Max. sheet thickness - 12mm

• Max. stack height - 2000mm

• Max print resolution - 1000 dpi

• Printing speed (high quality)up to 90m/min

• Printing speed (high productivity) - up to 120m/min

• Length - 38m to 44m

• Ink type - Aqueous/water

Delta SPC 130 overview

This video provides a full overview, description, and demonstration of the major features and benefits of the Delta SPC 130.

Water-based white ink demonstration Koenig & Bauer Durst corrugated senior product manager Matthias Krautgasser demonstrates the clear benefits of printing world-first water-based white ink on corrugated using the Delta SPC 130.

paper media of up to 12mm in thickness. The printing system offers unrivalled versatility, low maintenance requirements and 24/7 dependability.

Resolution

The standard resolution for most of the production is 800 dpi. For printing of fine details and small text the Delta SPC 130 offers 1000 dpi as highest resolution. For very high productivity a 600 dpi mode is available too.

Media sizes

The Delta SPC 130 can print on a maximum sheet thickness of 12mm with a maximum sheet size of 1300mm by 2800mm.

Production volumes

This product is ideal for converters with annual production volumes between 3 million and 5 million square metres annually by printing at 60m/min on coated and 90m/min on uncoated boards.

Delta SPC 130 discussed at drupa Durst Oceania managing director Matt Ashman discusses the Delta SPC 130 at drupa in Düsseldorf.

World-first waterbased white ink

This demonstration shows how the worldfirst water-based white ink is applied to various substrates.

Benefits of the Delta SPC 130 to corrugated businesses

This video explains the benefits to business with the Delta SPC 130, and how it will transform operations for corrugated customers.

The inaugural ProPack Packaging Forum recently took place in Sydney, bringing together industry thought leaders and early adopters of technology

The inaugural ProPack Packaging Forum, which took place in Sydney, was one of the most important local packaging events of 2024, where suppliers and converters addressed a myriad of topics such as Artificial Intelligence (AI) in packaging, challenges and opportunities facing the sector, and future industry trends.

Headlining the event was a keynote presentation on IVE Group’s expansion into the packaging industry and its acquisition of JacPak, as it seeks to grow to $150 million in turnover within the next five years.

Peter Fotiadis from boutique commercial advisory firm Mattingly shared how IVE chose JacPak, and why the acquisition is an important part of the company’s packaging strategy into the future.

“JacPak and the IVE business generates about $45 million of turnover for folding cartons packaging. IVE has an ambition much bigger than that. The first thing that we did together as a group was a deep industry analysis, which was critical. Packaging extends well beyond folding cartons,” Fotiadis said.

“What emerged from that, for IVE, was that the folding cartons market was of high appetite and high interest, but specifically the small- and medium-run space would play most strongly to IVE’s strengths. Once we had a good look at where we were going to play, the second step was determining what we were trying to achieve.

“IVE wanted to bring scale to the business, was looking for sustainable returns, wanted to move forward in terms of sustainability, and bring in a business

that would be a strong foundation –unlock additional benefits across the balance of the business.

“The reason JacPak came through quite strongly after that exercise was, it predominantly focused on small to medium run, and over 90 per cent of its packaging produced was in FMCG. This was very attractive to IVE.

“JacPak also had a full, in-house packaging solution, which was important as IVE could see business right through from pre-press to printing, cutting, gluing, finishing, and logistics. Its people were great, the assets were well invested, and the culture was going to fit incredibly well with IVE.”

According to Fotiadis, the first thing that came out from the JacPak acquisition

was that there was still some additional capacity in the business for further sales. In fact, another $15 million of capacity was available.

“The JacPak footprint alone could get IVE to $60 million. Then, there’s the additional $30 million that JacPak will be able to leverage from IVE’s new Victorian and New South Wales investments,” he said.

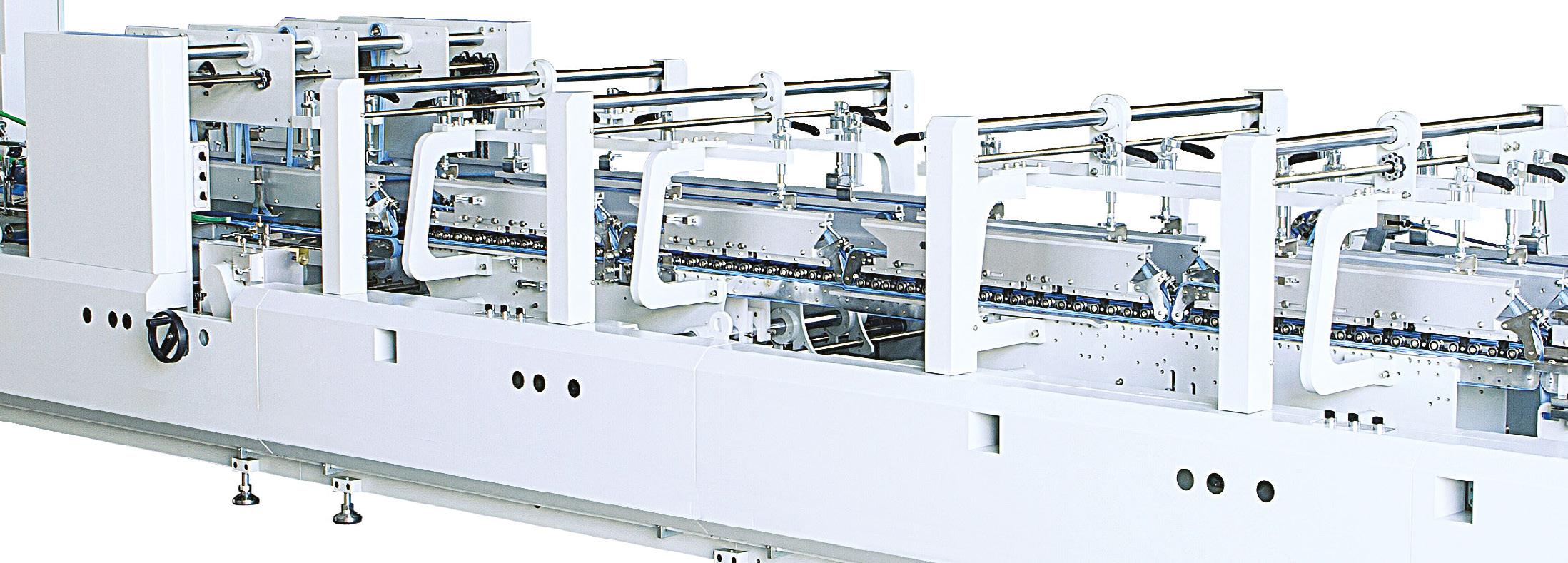

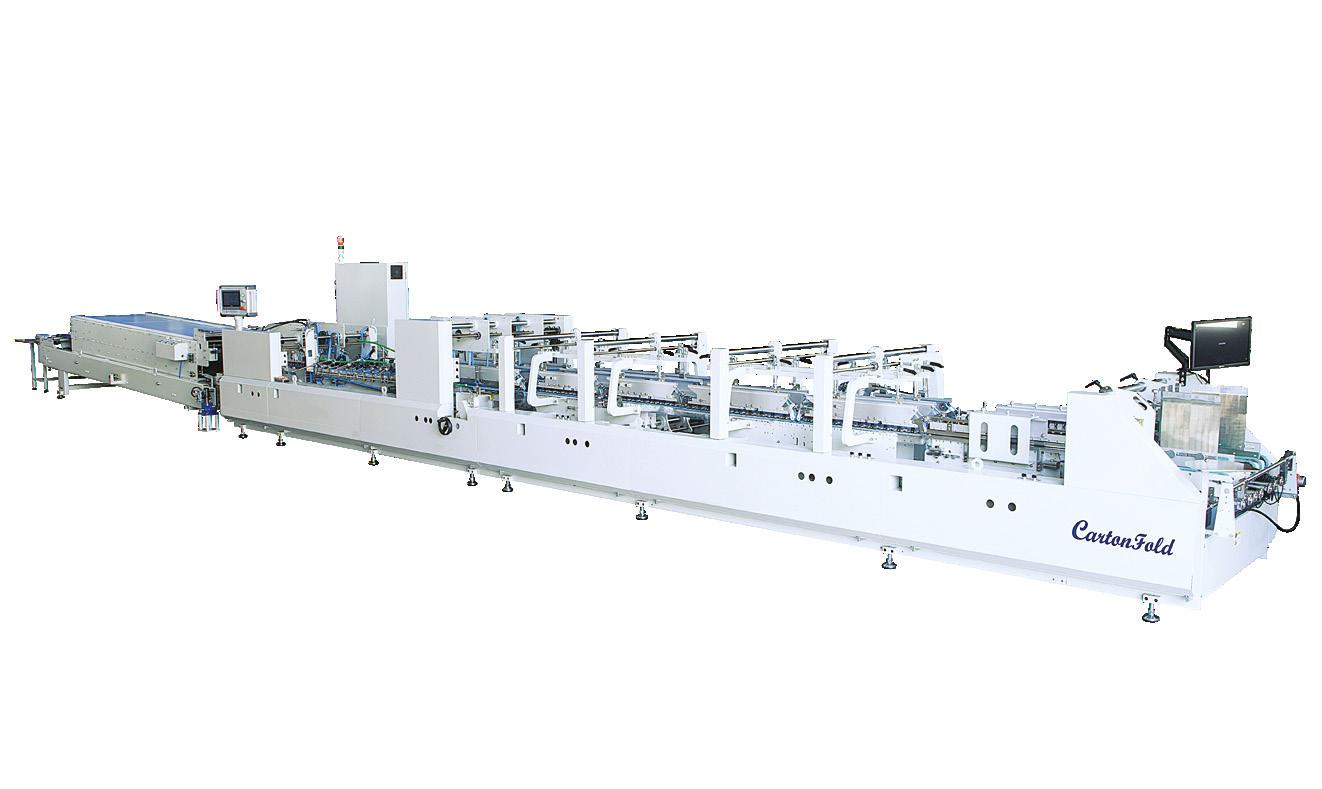

IVE recently announced it has invested into renewing its printing and press assets. According to Fotiadis an investment in cutting and gluing equipment to complement the press investment is due to follow so that it can have a full in-house solution and help deliver on the additional $30 million.

“That’s something that IVE will be targeting over the next three years. It also has plans, towards the medium-term, of a further $60 million of revenue that would only be available and unlocked with further investment,” Fotiadis said.

“I don’t think further bolt on acquisitions are out of the question and IVE sees a pathway to grow organically in any case. IVE will be, in my opinion, a formidable competitor in this space.”

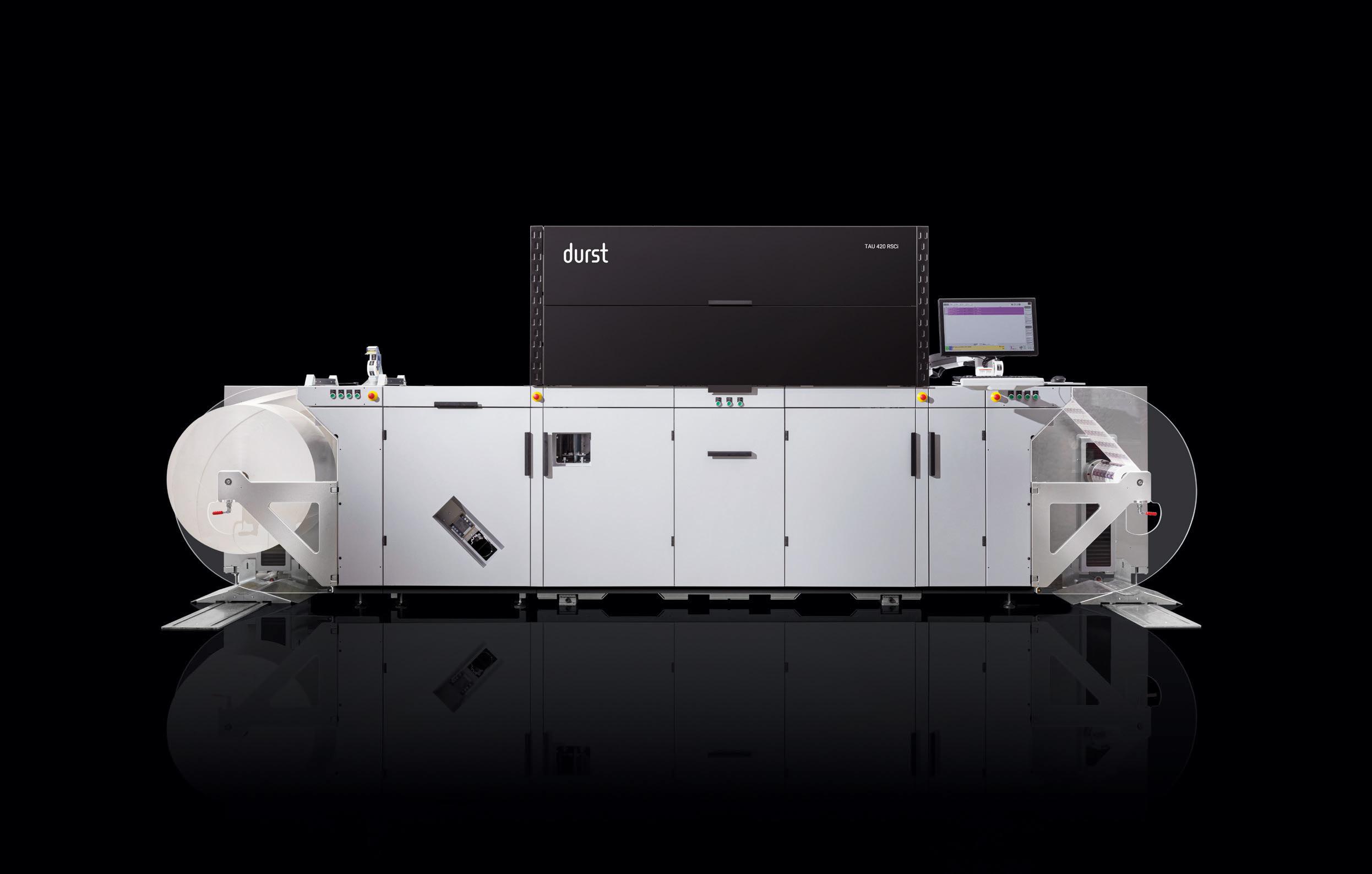

Mediapoint goes ‘back to the future’ with labels

Mediapoint co-owner Jamie Xuereb discussed his journey and re-entry into the labels and packaging sector after 11 years. Known primarily as a trade printer for the wide format category, Mediapoint recently invested in a Durst Tau label printer and is deploying the same customer service and fast turnarounds into the growing packaging market.

Victoria-based Mediapoint has become a well-known name in the industry, having grown year-on-year since its inception almost two decades ago.

“In 2006, my brother and I bought a machine that could cut stickers in the signage space. We only got into printing as a hobby, but our mum got us into the signage game and we started getting paid for our work. After about 12 months of having that machine, it broke down,” Xuereb said.

“We then found a large format press that could print and cut. That’s what started us in the large format game.”

Known primarily as a trade printer for the wide format category, Mediapoint then bought a Durst Tau RSC E machine a couple of years ago which returned the business back into the labels category.

“When we started business in the sticker space, we found that there weren’t any

companies offering custom shaped and sized labels. So, at the time, we bought an entry level printer and entry level cutting machine with a plotter-based cutter, but it totally failed for us because the technology wasn’t where it needed to be,” Xuereb said.

“But now, things have changed. We saw the opportunity to create custom shaped labels that can be machine applied while eliminating the whiteness on the edge, and the Durst Tau RSC E was the perfect fit for us.”

Mediapoint is now deploying the same customer service and fast turnarounds into the growing packaging market that has in its key business in wide format.

“Just going off the technologies showcased at drupa, for example, you could see that there was a lot more packaging equipment – it tells you where the industry is moving towards,” Xuereb added.

The Pakko story stemmed from an idea in horticulture

Also speaking at the Packaging Forum was Pakko founder and CEO Nina Nguyen, who shared the Pakko story and how she built the business from the ground up, in addition to addressing the issue surrounding the sustainability messaging of companies.

The Pakko story started as a result of a dream to start business in horticulture –this wasn’t Nguyen’s dream, but that of her parents. After migrating to Sydney from Vietnam in the late 1980s, Nguyen’s parents saw the potential to create for themselves a niche market by growing and selling Asian produce. In 2009, when on holidays in Lockyer Valley in Queensland, they fell in love with the rural area and decided to start business there.

At that time, Nguyen herself was finding her feet in deciding on a career.

She wasn’t interested in the usual nineto-five jobs and wanted to do something more. At the time, she was living in Fairfield, NSW, and ventured into various businesses, including a beauty salon, a clothing store, and a tattoo studio, all located in South Windsor, NSW.

“There was opportunity, but they were all lacking something. A year or two after my parents started up their horticulture business, they found it hard because by the time they grew the produce, packed them in a box, stacked them, and sent them to Sydney or Melbourne, the bottom box collapses by the time it gets to the destination. They were just not strong enough,” she said.

“The different weather conditions, the moisture, it was affecting the boxes. So, I decided to help and found some overseas manufacturers. But with external factors like currency exchange, control quality, fluctuation, and customs clearance coming into play, it wasn’t sustainable. So, I created Pakko as a manufacturing company in 2017 for the sole purpose of helping my parents.

“The first few months were challenging, but it has become an industry that I’ve fallen in love with. We now focus on custom packaging. We help brands share their story, share their message, and make their packaging stand out.”

Nguyen spoke about Pakko’s recent acquisition of Boxes R Us, saying the move wasn’t on the radar and was unforeseen.

“It wasn’t something we were looking at, but when the opportunity arose, I looked at Boxes R Us and found it to be a unique company. The way it operated was, storing a lot of pre-cut items stored on the shelf, which a customer selects from, and using a foiling machine to foil on corrugated boxes. It complemented Pakko so well as it’s short-run bespoke packaging for emerging startup businesses,” she said.

Nguyen also addressed the issue around sustainability – corporations wanting to be fully sustainable, but not knowing what that entails – and business longevity.

“Corporations have an idea of what they want, but then they don’t know how it can be delivered. So, we’re there, in a way, to guide them through that whole process,” she said.

“You have to balance product sustainability with business sustainability. You need to look at all the materials that are sustainable and meet ESG requirements, but you also must look at how you’re going to sustain your business for the next three to five years. And this is where technology steps in – streamlining your front-end, optimising your back end, and making sure your team is on board.”

Making a cold call resulted in Said Khoury purchasing UPP

United Printing & Packaging (UPP) managing director and owner Said Khoury shared his story after making the decision to leave his job in the labels category to buy a business in Sydney, which is now a specialist in the premium end of the folding carton category. Khoury saw the opportunity in folding cartons, even though he had an extensive background in the labels space.

“In 2013, after about 17 years working for a major labels company, I felt like I needed to challenge myself and make a move in a different direction in my career. After thinking about it for a little bit, I realised the only way that I was going to be able to utilise my skills, learn new things, and get my career to the next level was to go out on my own,” he said.

“I felt like there was a major opportunity in folding cartons. I basically looked for a small sheet-fed printer to buy, which then, over time, I could convert into a folding carton manufacturing facility.”

However, Khoury’s wishes didn’t come true as there were no businesses that suited what he was looking for, for sale at that point in time. So, he started looking around and found a small company, UPP, and reached out to its owner.

“I made a cold call, set up a meeting with the owner, and within 15 minutes, asked him if he was interested in selling the business. He was turning 65 the year I met him and had no exit strategy. I said, ‘so what if the right offer came around? Would you consider it?’ He said he might. Four months later, I ended up buying the business from him,” Khoury said.

According to Khoury, the first 12 months were crucial in taking the business to the next level.

“The previous owner had been in business for just over 30 years and the business’ turnover was about $2.5 million at that time. That was comfortable for him. But, I had to double the turnover within the first 12 to 18 months to make it work. That was very challenging with a small business that only employed eight people,” he said.

“I really wanted to focus on the folding carton market, and as a starting point gear up the company to supply the pharmaceutical market segment. So, we made the announcement to the staff that we were going to let go of commercial print work – which was roughly half the sales of the company (folding cartons was probably about a third of the sales).

“The majority of the equipment was suitable as a starting point.”

Fast forward to today, the company has a full in-house capability, and has for the past eight years, been doing everything – from structural design to pre-press, printing, die cutting and gluing – within its premises.

Khoury invested heavily in multifunction gluing equipment that suits the needs of the pharmaceutical market for unique cartons. Its latest acquisition, and biggest investment to date, is a Koenig & Bauer Rapida 76.

“While we offer no minimum order quantity, the additional productivity and efficiency from the Rapida 76 and its ability to run at 16000 sheets an hour means we can tap into medium to high volume work where we could not compete previously,” Khoury said.

“The Koenig & Bauer Rapida 76 was the right press for us as it allows us to deliver folding carton work with precision and consistency which is paramount for our premium and boutique clients. A huge part of our decision was also with support first and machine second.

“The technology on the press was important, but we chose Koenig & Bauer because of the service and support we receive from local engineers based here on the ground in Sydney.”

Technologies support NZ’s PrintLounge’s business plans

PrintLounge (NZ) general manager Greg Daniel spoke about his recent investments in technology, including a Durst Tau 340 RSC E LED label press and AB Graphic finishing equipment, and how the company’s embrace of new business opportunities from digital diversification resulted in a shift away from its two decades as an offset printing specialist.

Daniel said the company recently installed an AB Graphic finishing equipment, with another unit on the way.

“Brands themselves were telling us of the importance of good finishing. We decided to go down the AB Graphic route with the Digicon. We never looked back from that point. It’s a great piece of equipment, the engineering is superb, the service is

amazing, and the accuracy and speed of the equipment is fantastic,” he said, via Zoom.

“We’ve just purchased another unit – the Digicon Lite 3 Series – that will soon be on its way over to us.”

Modular in design, the AB Graphic Digicon can be designed to meet a business’ needs, enabling them to create a clear and competitive advantage.

PrintLounge is a family-owned business that has been in operation since 2000. It was known to be a sheet-fed operation up until 2016 when it purchased its first Komori H-UV press, following which it also moved into the LED-UV space.

Also, within that time, it upgraded its digital machinery and moved into the labels space.

“Now, we’ve ended up as a commercial packaging with digital printing company that also does roll labels,” Daniel said.

“When we first started in roll labels, we were only dipping our toes in this space and used a basic CMYK toner-based machine. However, we soon realised we required quite a bit more – we needed white, we needed a wider colour gamut.

“We did a lot of research and decided on the Durst Tau RSC 340 E LED label press with LED curing and the new Durst Hawkeye system in 2023.

“What it has done is changed the way we work here. The software drives the machine and within minutes, we have got ink usage for a quote, we’ve got the team in pre-press able to make colour correction or whatever else needs to be done with the click of a button. It’s amazing how fast that is, and that flows on to the actual machine itself. That has changed

everything from the high resolution that it prints at, to the amazing white that it puts down, all at 50 metres per minute. And to think that we can still upgrade that to 80 metres a minute.

“All we are focussing on now is getting jobs out the door.”

Convergence of the industry is reshaping print segments

NAPCO Research vice-president Nathan Safran took a deep dive into future industry trends, stating that by entering the packaging space, companies can make use of the lucrative opportunities it presents. Over a video presentation, he said the barriers are breaking down between print segments.

“From our state of the industry panel research, we found 68 per cent, or close to 600 panel members, now tell us they have diversified beyond their primary segment. There is a wide range of implications about what that means and where opportunities lie,” he said.

“Some of the things driving convergence include maintaining profitability, ‘stickiness’ for clients, and an added investment into R&D which is lowering barriers to entry.”

NAPCO Research identified the segments within the packaging space that package printers are looking at expanding into, with 40 per cent of package respondents saying they’re looking at expanding into labels and 70 per cent of respondents saying they have invested in new equipment in the past five years to expand into new applications.

“Packaging printers are concerned about that – you have your customer base, and you can grow your customer base.

It’s certainly important to be aware of competition and others that are looking to get into the space, but I wouldn’t panic too much. I would focus on growing your own business and looking at whether expansion is right for you,” he said.

“Convergence is happening because diversification is a must in order to stay relevant.”

Safran said for those who are unable to expand their business into other segments, partnering with trade printers and outsourcing work to them is an option to consider.

Safran also explored key trends that are driving change in packaging, the top two being sustainability and the demand for customisation.

“Sustainability is arguably the number one priority within the packaging segment.

A third of brand owners place sustainability in their top five challenges,” he said.

“Those that are looking to enter or already in the market should be aware of sustainability implications for applications. There’s so much to talk about when we look at the importance of sustainability, but many give it lip service.

“It represents an opportunity for you, as you’re having those conversations with your clients, to have a conversation about sustainability, how your products, offerings, capabilities, and technology supports their sustainability initiatives.

“As for the demand for customisation, when you personalise corrugated with your digital press, you show off your printing capabilities. There are some amazing things that can be done with packaging, and it is definitely a marketing opportunity.”

Safran also echoed the sentiments of many other speakers at the event, mentioning that AI is poised to be the next big industry disruptor.

“Printers are telling us that they are looking to utilise AI for operations –to become more efficient and reduce costs, whether it’s in predictive maintenance, quality control, supply chain, or logistics. They’re also looking at using it around hiring, in performance evaluation, and customer service,” he said.

The question to ask is, what do we all want from AI?

Technology expert and Byteside founder and head of content Seamus Byrne delivered his keynote speech around the topic on everyone’s minds – generative AI.

“It’s important to be asking ourselves the right questions to know what we want to achieve with it,” he said.

“Sometimes, we can get really focussed on the cool, shiny new toy. But we need to make sure we’re focussed on what’s the actual outcome we’re looking for. What is it we want to achieve with these tools? Do we want a white-collar workhorse? Do we want the trusted confidante or the analytical genius here? What exactly is it we think is going to add value to our business to push things forward?”

However, Seamus warned that generative AI is at the stage where language does not actually equal intelligence – that a good command over putting together ‘cool paragraphs’ and ‘cool ideas’ isn’t the same as being truly intelligent.

“There’s this concept of the stochastic parrot. I don’t necessarily agree with it in full, but the idea is like, an incredibly advanced version of teaching a parrot to say some words which it does not understand the meaning behind. So, we may have to be careful about using AI for decision making if it doesn’t fully understand what it’s meant to do,” he said.

A way to mitigate this is through prompt engineering, which Byrne said is about knowing how to ask for what you want.

“When you add that little extra ‘oomph’ in the message that you’re asking it to solve, somehow you can just encourage it to give you something better than it would have if you didn’t offer that little bit of extra encouragement,” Byrne said.

“Generative tools can also help to elevate somebody who doesn’t know much about a space to learn a lot more. But, once you’re in the industry, you’ll very quickly start to see the difference between what these tools are capable of to help you without them

becoming trained on the expert details that you need in this industry.”

The other big question for businesses, according to Byrne, is what to do with data.

“There’s so much data coming off systems. Therefore, you need to work out how to enable that data to be fed into AI systems. The data can exist but are you able to unlock it to start feeding it into AI tools that can bring that data to light and give you the extra intelligence you need,” he said.

“On top of that, we have governance issues around data, security issues, privacy issues and getting the guardrails right on this. That’s a big consideration for the long-term. The key, right now, is experimentation – to start exploring some of these tools and to start learning lessons on them. Maintain flexibility, unless you absolutely know there is a specific reason why we need to make that commitment right now.”

Byrne said the future is heading towards agentic AI, where it starts to manage

complex problems for users and independently does things on the internet for them.

Durst Group CEO and co-owner Christoph Gamper spoke about the possibilities around digital for the packaging industry, and how the company’s joint venture with Koenig & Bauer has resulted in unique innovations that are unseen elsewhere in the world.

Gamper said digital is no longer wearing its ‘baby shoes’ and will not replace offset.

“Digital will not substitute offset; it depends on the application, and nothing is all digital on a label press. The discussion around offset versus digital is no longer applicable anymore – you just have to do what makes sense for your business,” he said.

“We have been working within the digital space for more than 25 years across different industries and for packaging, with the new machines shown at drupa 2024, we have

seen that digital is the primary technology. It’s reliable, it’s 24/7, and it’s highly versatile. We see ourselves as an enabler in digital and have partnered with companies such as Koenig & Bauer to support this space.”

Gamper delved into Durst’s joint venture with Koenig & Bauer, and the launch of its latest VariJET 106 single pass press at the recent drupa 2024 tradeshow. The VariJET 106 is a fully digital machine that targets the folding carton and corrugated markets.

He also pointed out the new Delta SPC 130 used in corrugated markets – another family member in Koenig & Bauer Durst’s single pass digital sheet-fed press portfolio.

The Delta SPC 130 is a corrugated printer using water-based inks, resulting in converters being able to deliver on sustainability and meeting food safe standards. In addition, as the Delta SPC 130 is digital, makeready times are eliminated and wastage is zero.

Gamper said Koenig & Bauer Durst is the first company in the world to offer digital white ink for corrugated substrates in primary food packaging, which creates new possibilities in packaging, for example printing on plain brown or lower grade white boards.

Hybrid Software product manager Pascal Wybo addressed the role of AI in revolutionising the industry and domains in packaging production that will benefit from the technology. According to Wybo, from a technology point of view, AI is just a logical evolution of statistics and analytics.

However, he said AI is actually AI when technology tries to simulate human intelligence and is descriptive, diagnostic, predictive, prescriptive and generative.

“It should be able to interpret tons of data today in every label and packaging company. You should get business intelligence out of it. Artificial Intelligence can only be called AI if it’s able to learn –your workflow automation that you have today, is not AI,” he said.

“In addition, AI should be able to generate business improvements without a human being involved.

“AI is going to reshape the packaging industry. It will help companies improve efficiency, reduce costs, enhance quality, and create new opportunity.

“From design and pre-press automation to predictive maintenance, AI will be the catalyst for innovation and operational excellence at the production floor.”

Wybo said AI will help solve current challenges converters may be currently facing, such as labour-intensive designs, staff working long hours, high material waste, inefficiency in print runs, downtime due to equipment failures, a lack of predictive maintenance, as well as rising demands for personalised labels and short-run jobs.

“As a software technology provider, we see AI as the catalyst for development, end user excellence, and innovation in software creation. AI can monitor your workflows, your software, and your hardware. Hybrid Software uses AI for internal product and solution problem solving. We want to guarantee you quality,” he said.

Wybo also spoke about an AI label and packaging project Hybrid Software was involved in. The Johnnie Walker Diageo Blue Label personalised bottles was a generative AI-powered experience that allows guests to co-design a personalised bottle of Johnnie Walker Blue Label. The experience prompted visitors to answer three simple questions that influenced key themes in Scottish artist Scott Naismith’s work, ultimately impacting their bottle design. The simple prompts generated various colours, locations, artistic styles, and times of day, resulting in a unique bottle that was printed in a matter of minutes.

Wybo said projects such as this comes as consumers increasingly search for unique experiences and products that signal belonging, status, and personality. He said consumers are going beyond the most up-to-date cultural movements, seeking things that feel entirely original, with personalisation now a necessity.

“AI is going to be everywhere – even in basic packaging processes, in pre-flight, colour management and your production floor. It is all about guaranteeing the quality of your label and package,” he said.

As a first step, he suggested businesses adopt an AI directive involving five steps –identifying strategic challenges in the business, exploring the possibilities with AI solutions, selecting what you want AI to do, prioritising things that are important for your business, and validating your choices using the technology.

The big issues in packaging

Kissel & Wolf A/NZ sales manager Bruce Caldwell addressed the topic of the biggest challenges in printing and packaging. He said the costs involved in manufacturing is one of the biggest issues.

“The production and servicing costs in our industry are extremely high by comparison

to many other manufacturing segments, and the margins are not improving despite technology and resource investment. We all struggle with rising costs; however, we rely very heavily on the core ingredients of print, paper, ink and freight – all of which are predicted to increase substantially in the coming year,” he said.

“The skyrocketing of cost and access to paper and pulp is something that we will have to watch. This is going to change and distort areas in printing and packaging quite dramatically in terms of the way we go to market, and the conversations we need to have with our print buyers. How that will affect volume when considering run lengths and how we best approach product or equipment positioning will be a consideration. Brands and print buyers will require astute relationship management and honest conversations on how “the partnership” may be benefit from different strategies. Inventory control, variable and mosaic-based data may be a valuable sales tool as we move forward, particularly in the digital realm.”

The other challenges that Caldwell identified include: finding and retaining good staff, the need to get micro in technology investments, the potential of AI, getting more help from the Federal and State governments, and being aware of environmental footprints. Caldwell also spoke about the quality of Chinese-made equipment, especially that of Hanglory Group (Shenzen Hanway), which Kissel & Wolf represents in Australia.

“I mentioned in a forum previously that to succeed, we need to shift the paradigm on attitudes to digital press technologies out of China and greater Asia. What I saw at the Hanglory manufacturing site in Shenzen, was almost career defining,” he said.

“Apart from the impressive and large portfolio, it was the attitude and research

it had invested to play in the larger markets outside of China. The company had to change its ways to get into the US, European and A/NZ markets. It invested heavily on quality control, sourced the best technology and resources available (in or outside of China), and started using channel partners like Kissel & Wolf to improve local serviceability,” he said.

“It’s genuinely exciting to see what it’s doing. Its single-pass presses in waterbased technology are well ahead of the game and it’s producing robust devices that are very well price positioned. Its goal of disrupting the US and European markets is already surpassed with more installations of single and multi-pass presses than any other manufacturer.”

CCS Media Packaging recently installed its new RMGT Ryobi 970 seven-colour press with aqueous coating through Cyber Australia, bringing in the final piece of the jigsaw in its 12-month, multimillion dollar investment, which also included a Rollem and state-of-the-art gluing line with Robatech hot and cold glue.

Cyber Australia NSW state manager George Rossi was at the recent ProPack Packaging Forum, telling attendees how CCS improved its business processes following the install of the RMGT Ryobi 970.

“CCS has been in the packaging market for some time. It realised that, over the years, the commercial press it had wasn’t quite reaching some of the expectations of its packaging clients and therefore, started to investigate about what packaging press it needed to run alongside its existing commercial press,” Rossi said.

“CCS produces packaging for clients in gaming, pharmaceutical, as well as highend cosmetics and perfume, so it needed

a press that could deliver on unique packaging jobs. That led to a trip to Japan with a client that owned a Ryobi 970. They liked the speed, quality and environmental capacity of the machine and invested in it.”

“The Ryobi 970 is ideal for medium capacity packaging, enabling CCS to match over 90 per cent of PMS colours using the four-colour process. The machine gives the business enormous scope to meet clients’ special colours and finishing requirements, all while being printed in one pass.

“This printer represented another expansion of CCS’ capabilities. Some of the products it now produces are very high-end and boutique.”

Cyber Australia is also the agent for SBL in the region and Rossi used the ProPack Packaging Forum to announce that Immij Print & Packaging has purchased a 1050 die cutter, to be installed early next year.

“When Immij went to drupa, it did an extensive amount of research on what

die cutter to buy. SBL isn’t a high-end machine, nor is it a cheaper Chinese manufactured machine. It sits somewhere in the middle. SBL is manufactured in Taiwan and the bed of the machine is made in Japan,” Rossi said.

How to deliver on ‘modern flexo’ in the industry

Miraclon regional lead Steve Smith took to the forum to explain the importance of ‘modern flexo’ and referenced a case study from Sri Lanka where a customer decided on Miraclon’s ‘modern flexo’ technology.

Miraclon is a company that produces flexographic plates, and it was spun out of Kodak five years ago.

‘Modern flexo’ describes print production where:

• Flexo can achieve visual parity with gravure, offset and digital

• Results are consistent and predictable enough to enable printing by numbers

• Jobs are printed with as few colours as possible (more process, less spots)

• Print conditions offer wide print latitude and facilitate clean printing

• Outcomes can be optimised in more challenging environments, including with more sustainable materials.

“Sustainability is an unfortunate word that gets thrown around a little too much. A lot of brands are undertaking what we call greenwashing, in trying to convince people that what they’re doing is sustainable. We look at sustainability as how we can reduce waste,” Smith said.

“In this market, most people will print four colour, plus one or two spot colours in flexo. In ‘modern flexo’, what we are doing is eliminating spot colours.

“By doing that, you’re looking at sustainability improvements. By reducing or eliminating spot colours, you’re going to increase the efficiency of your press. You’re also going to reduce the amount of VOCs caused by solvents when you wash down the decks each time you change a spot colour. This is the same as digital printing.”

Smith also spoke about visual parity, saying that in packaging, an end customer doesn’t pick up a package from the shelf based on if it was printed using digital, offset, gravure or flexographic technology. Smith added that ‘modern flexo’ requirements are about selfstandardisation, process optimisation, commitment to process control and a change in mindset.

“Miraclon’s FLEXCEL NX technology is all about precision from the start. It is an integrated solution that completes more jobs in less time, at lower cost,” he said.

Smith also spoke about one of Miraclon’s customers in Sri Lanka that decided on FLEXCEL NX technology in 2022. This customer, ALFT Packaging, has been able to standardise the production process and get the maximum efficiency and productivity from the press after adopting Miraclon technology.

“The best day they had over the past 12 months was, they did 21 job changeovers in two shifts. That’s phenomenal for flexo,” Smith said.

The inaugural ProPack Packaging Forum would not be possible without the support from its sponsors:

Platinum Sponsor – Durst Oceania

Gold Sponsor – Cyber

Gold Sponsor – Miraclon

Bronze Sponsor – Hybrid Software

Bronze Sponsor – Kissel & Wolf

Bronze Sponsor – Koenig & Bauer

The inaugural ProPack Packaging Forum in Sydney saw suppliers and converters from all over Australia and New Zealand gather to address the trends shaping the industry

The inaugural ProPack Packaging Forum recently took place in Sydney, bringing together more than 50 people in the industry.

Suppliers and converters from all over Australia and New Zealand

gathered at the Shangri-La to learn about opportunities and challenges facing the industry, as well as key trends that are shaping the space.

Here are some pictures from the event:

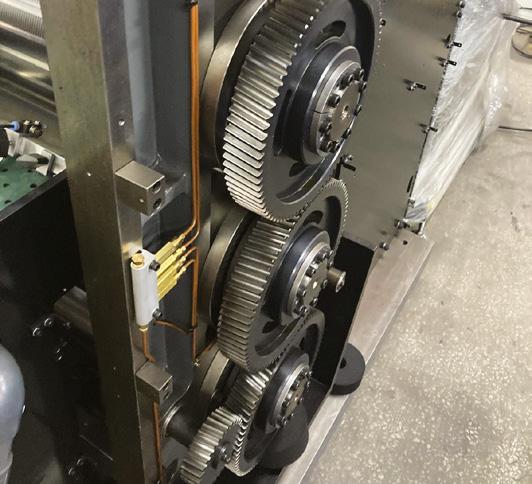

Pressnet offers an extensive range of products encompassing printing machines, die-cutting equipment, paper cutting machines, binding solutions, laminating machines, and more, catering to diverse requirements across various sectors.

The leading provider of cutting edge machinery solutions for the printing and packaging industry has expanded its portfolio with a new rotary die cutting solution from manufacturer Dapeng.

Charlie Scandrett, managing director at Pressnet, said, “Dapeng, situated in Rui’an China, is primarily a paper guillotine manufacturer. However, 11 years ago, Dapeng began to develop rotary die-cutters”.

Pressnet suggested to Dapeng that it could increase its machine’s sheet size to 550mm x 750mm to suit the medium printer die cutting market and “to replace the ageing Heidelberg SBGs”.

Scandrett said, “The result is the Dapeng Rotacut 5575, which is a servo-motor setup machine capable of die-cutting

and stripping the waste in one pass. Its gearing and side frames are as heavy duty as an SBG”.

Suitable for small batch and long-run production, the integrated Rotacut 5575 rotary die cutting machine uses a flexible die forme which is easy to replace.

Features include automatic paper lifting, automatic paper feeding, double sheet detection, chasing mark alignment die cutting, automatic deviation correction, automatic waste discharge and other functions.

The separator section can be directed to blow away waste, and adjustment does not require tools. The separator section and collection section can be pushed away as a whole for changing the die forme.

The wheel of the separator section is electrically controlled, timed up and down to deliver the final product to the receiving table smoothly

Applications include stickers, tags, wine labels, playing cards, small boxes and so on. It handles coated paper, cardboard, PE film, and other media. It handles sheet

sizes from 240mm x 280mm up to 550mm x 750mm at speeds of between 1,000 and 6,000 cycles per hour. It handles a range of media from 0.15mm to 1.0mm in thickness.

Recently, Pressnet completed its first Dapeng Rotacut 5575 regional installation at Foyer Printing on the Gold Coast.

Scandrett said, “It is already die cutting and stripping drink coasters at about 100,000 pieces per hour”.

Foyer Printing director Ron Rankin said, “We have run the Dapeng Rotacut 5575 for about two months. It is the first in the country, so we are the guinea pigs for the machine, which is proving to be a good workhorse. Obviously, there is a learning curve when you have a new machine, but we have smoothed it out and the Rotacut 5575 is ploughing on. There is still more refinement to come as we want to get it to its full potential.

“At the moment, we are die-cutting, but we are looking forward to using the other capabilities that it has such as scoring and kiss-cutting. We do have plans for that later down the track. As yet, we haven’t run it at its maximum speed of 6,000 cycles per hour, but it is handling everything we can throw at it.

“Charlie and his engineer have helped us sort out any teething problems and concerns that we had. For instance, they gave us advice on getting the correct angles for the feeding suckers. We were also initially concerned that we might not get good longevity from the knives, but they are also performing. The Rotacut 5575 is quite gentle on the knives.”

Foyer Printing has had a long relationship with Pressnet.

Rankin said, “I have known Charlie for a long time and over the past 12 to 15 years he has supplied us with several machines. He is very knowledgeable, and he is a man of his word. We wanted some custom elements added to our Rotacut 5575 and he managed to get those done at a fair rate. Charlie always does his best to make sure we are happy. If we need anything, he is only an hour away,”

The affordable future of general die-cutting, using rotary, flexible, magnetic dies

SPECIFICATIONS:

Size: 240 x 280mm to 550 x 750mm

Speed: 1,000 - 6,000 sph

Thickness: 0.15 mm to 1.0 mm stock

Waste: Automatically stripped into bin underneath

Swing Tags: Holes stripped on the run

OPTIONS:

• Programmable individual product stacker

• Ladder conveyor of waste to a large wheelie bin

• Sheet stacker for the unstripped sheet

• Magnetic lower cylinder for embossing die

Installed in Australia die-cutting drink coasters

Built with heavy side frames like a cylinder die-cutter, all Western electronics and very user-friendly.

The Sinclair - T55 compostable label sets a new standard in produce packaging, reducing plastic waste and helping create a more sustainable future

Sinclair, a global leader in fruit labelling technology, and Zespri, the world’s largest kiwifruit marketer, have joined forces to launch their newest and most innovative compostable fruit label.

The companies said the new label, named the Sinclair - T55 fruit sticker, marks “a significant step forward” in produce packaging and environmental responsibility.

The compostable sticker provides a minimal packaging solution that reduces consumer waste compared to other packaging. It can be disposed of in-home compost bins along with fruit peels and other organic waste, simplifying consumer waste management.

It breaks down and fully biodegrades to become part of usable compost within 365 days. This demonstrates that the Sinclair - T55 fruit sticker is safely compostable, without leaving harmful residues in the environment.

With certification for its end-of-life performance – it has received the home and industrial ‘Finished Products’ certification from TÜV Austria and the home composting certification from ABA and DIN CERTCO – the fruit sticker also maintains Sinclair’s high standards for automated, high-speed application in the packinghouse and throughout the supply chain.

According to Sinclair and Zespri, this is the highest-performing compostable label available, with application performance equivalent to conventional

plastic stickers. It provides exceptional conformity to adhere securely to fruits and vegetables, allowing essential product information – origin, variety, PLU and barcodes – to be displayed with branding.

Sinclair senior marketing manager Duncan Jones told ProPack.pro, “The label is constructed from a certified compostable film. A fruit label has three components – adhesive, label material, and inks. Sinclair - T55 has home compost certification for the finished label construction, not just components.

“Our goal for a home compostable label began about 15 years ago, and we are on our 5th generation, which finally meets all current global composting standards and has ABA, DIN CERTCO, and TÜV Austria home compost certification.

“It also meets composting standard AS 5810, making it a minimal packaging alternative that can help reduce plastic packaging waste. Certification from the Australasian Biobased Association (ABA) demonstrates its environmental performance and suitability as an environmentally conscious choice to remove plastic packaging from the supply chain.

“Its performance is equivalent to conventional labels, which in the past has been a challenge due to the nature of compostable materials.”

Jones said the Sinclair - T55 fruit sticker offers the fresh produce industry and retailers with the opportunity to reduce plastic packaging.

“It’s a significant achievement as it currently meets single-use plastics legislation globally. We now offer a proven packaging solution to help reduce reliance on plastic packaging, but still provide the benefits consumers and retailers require,” he said.

“As a certified compostable label, it also provides essential consumer point of sale information – produce variety, origin, brand, etc. – as well as ensures retailer information – PLU, barcode, etc. – can be displayed for checkout efficiency and/or product traceability.

“Our business has been focused on fresh produce labels for more than 40 years and this remains our focus. We are already receiving other enquiries from the packaging industry due to the uniqueness of this achievement in developing this certified compostable label.”

Zespri CEO Jason Te Brake said, “Our collaboration with Sinclair reflects our commitment to embracing more sustainable practices across our global supply chain. Exploring more sustainable fruit label options has been an area of considerable focus for Zespri over a number of years, with our labels providing an important assurance to consumers that the fruit they are purchasing is authentic, safe and high-quality Zespri kiwifruit”.

Sinclair - T55 is available in Australia and New Zealand, with Zespri confirming it is transitioning to label all its kiwis to Sinclair - T55 in the next 12 months.

durst-group.com/label

The redesign is a strategic brand evolution of Nerada Tea, bringing together the clever blend of heritage from Nerada and the contemporary graphic elements from Tweak

Nerada tea is a reputable brand in Australia with over 50 years of expertise and celebrated for its premium tea and herbal infusions. The introduction of an English Breakfast blend called for a refresh that would not only introduce the new tea blend but re-establish Nerada expertise in the category.