Have you tried our trade onl y print ser vice? Let us become your tr ade pr int pa r tner. F l ex B a n n e r S e l f Ad h es ive V i ny l CNC Cut ti n g S e r vic e S pe c i a lt y F i l m s Pu l l Up B a n n e r s Ac o u s tic P a n e l A Fr a m es ACP S tic ke r s B a n n e r Mes h We deliver high-quality, tr a de printin g se r vic es at competitive prices. www.propack.pro October 2023 People Technology Business A FOCUS ON: ALSO INSIDE... Helio by Orora Beverage Durst open house event at Brixen HQ Focus on an automated print quality inspection system Hawk Eye and new UV ink series range Labelexpo Europe returns to Brussels Spotlight on the latest innovations and label and packaging trends Wedderburn invests in labels Currie Group supplies HP and ABG solutions to expand label offering

All my clients are sooooo happy with the quality and turnaround times with your printing. Many thanks!

Kaz

Just a quick THANK YOU to you and your team in getting the report out so fast. Deadlines are often “self-imposed” by clients, but in this case it was a real and hard deadline. As usual, you guys nailed it.

John

Thanks for the iMag link. It looks great and has gone across to the client for inclusion on their website.

Massive thanks to the HP team for the work on this year’s publication. Couldn’t pull it off without you all.

Karina

My honest feedback with my experience is that I can’t fault any part of it.

Your team and yourself were extremely helpful and professional and very understanding when I had a late change due to a client decision.

Shipping was extremely fast and easy to track.

Luke

Thank you so much, my client was happy with both quality and high speed of turnaround/ delivery. Will definitely be ordering again.

Jacqui

I just had a call from our customer regarding the digital booklets. She’s absolutely wrapped and rang us to say a big thank you.

I thought I should pass that thanks on as we didn’t have much to do with it at all!

So... good job!

Sarah

YOU

OF OUR NEW CLIENTS ARE REFERRALS

CAN SEE WHY... AUSTRALIA’S BEST TRADE PRINTER

Big return of Labelexpo to Brussels

If you are surprised to see a different picture in this section of the ProPack.pro magazine, I hasten to explain that my editorial colleague, Hafizah Osman, is taking a few months of leave, but don’t fret; she will be back next year to take the steering wheel back in her hands. In the meantime, I will try to navigate the ship to the best of my abilities.

I travelled to Europe to report from Labelexpo, which was, figuratively and literally speaking, one of the hottest shows the ProPack.pro team has attended in recent years.

The excitement around this show has been building for the last four years. The industry has been teased with the impressive number of new technologies on display spread across nine halls at the Brussels Expo.

The official visitor numbers have not been released yet; however, it was one of the busiest shows, which, under The Modern Legends of Print motto, united 637 exhibitors, featured over 250 product launches and offered extensive educational programs.

Labelexpo shows are usually an excellent indication of where the industry is heading and its most significant trends. This year’s edition didn’t disappoint in this respect either.

After the lack of flexographic equipment on show at Labelexpo Americas last year, the European edition brought it back in abundance. It was not only present on the showfloor, but also featured a previously unseen amount of automation and innovation.

But I assure you, the digital printing market did not stay put in the last four years either and came back with a significant amount of innovation, more automation, faster presses and more digital embellishment options than ever before.

Add a few trends, such as automation, addressing the shortage of skilled labour worldwide, and sustainability, which adds competitive advantage, and you have one unmissable trade show.

Don’t worry; we have a detailed review of all trends and technologies at Labelexpo Europe 2023 on the following pages if you did not make it to Brussels this year.

Enjoy this magazine issue, and remember to follow us on LinkedIn at www.linkedin. com/company/propackpro/ for daily news.

ProPack Industry Supporters

been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2023 — Charted Media Group Pty Ltd

www.propack.pro 4 ProPack.pro October 2023 EDITOR’S LETTER Stay informed… visit www.propack.pro and subscribe to receive the latest packaging industry news and views

Piotr Wnuk

ProPack.pro is published by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication. Managing Director & Publisher: James Wells Editor: Piotr Wnuk News Editor: Piotr Wnuk Sales Manager: Carmen Ciappara Production Manager: Jacqui Cooper Pre-Press Manager: Tony Willson Design: Sarah Vella Printed by: Hero Print, Alexandria, NSW 2015 Mailed by: D&D Mailing Services DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have

IN THIS ISSUE...

The latest label and packaging market news

P6-7

ProPack’s comprehensive dive into the latest products launches, recent equipment installations and sales as well as the latest news from label and packaging associations in the region.

Currie Group brings HP Indigo and ABG solutions to Wedderburn

P8-10

Family-owned group Wedderburn, which has operated in New Zealand for 33 years and in Australia for more than 125 years, installed a new HP Indigo 6K Digital Press and a new AB Graphic International Digicon Series 3 finishing system to ramp up its label production and address demand for short runs, personalisation and batching data.

Labelexpo Europe spotlights market trends and innovations

P12-26

One of the most important labels and packaging market trade shows returned to

the Brussels Expo with The Modern Legends of Print motto. This year’s event featured 637 exhibitors, over 250 product launches and an extensive educational program. This special report delves into the latest trends on the show floor and features the major technical innovations.

A/NZ customer’s night during Labelexpo Europe 2023

P28-29

Australian and New Zealand-based label and packaging converters joined Jet Technologies, Currie Group, Rodden Graphics, Aldus Graphics, Rotometrics and GMS Pacific teams to bid farewell to Labelexpo Europe 2023 in Brussels. Our team was on-site to capture the essence of the evening.

Familiar faces spotted at Labelexpo Europe 2023

P30-32

Nearly 36,000 label and packaging converters flocked to Belgium for the latest edition of Labelexpo Europe, including almost 40 visitors from the region. The ProPack team spotted a few familiar faces in the crowd

THIS ISSUE SUPPORTED BY

Orora Beverage launches Helio can decoration technology

P34

In an exclusive interview, Orora Beverage general manager of cans Chris Smith explains the benefits of a new Helio by Orora, described as transformative packaging decoration and first-to-market high-speed digital printing technology developed for can design.

Durst Beyond event envisions the future of digital print

P36-37

Labels & Labeling report from Durst’s customer event dedicated to the labels and packaging market held at the company’s Brixen HQ, where the company highlighted the radical, new automated print quality inspection system Hawk Eye and new UV ink series range.

Pack diary

A guide to the upcoming events globally

P38

www.propack.pro October 2023 ProPack.pro 5 CONTENTS

P8-10

P34

P12-26

Durst Oceania confirms first LED label press sale at Labelexpo

Durst Oceania has confirmed the sale of an RSC-E label printer with LED curing at the recent Labelexpo exhibition in Brussels.

Durst Oceania managing director, Matt Ashman, said the sale to Steve Sheppard from PrintLounge in Auckland took place on the final day of the show following extended discussions.

“Durst is very excited to be bringing the first Tau RSC 340 E LED label press to the Oceania market complete with LED curing and the new Durst Hawkeye system delivering outstanding quality at 1200dpi.

“Durst as a business is immensely proud to have Steve and his team join the Durst family. Both family businesses share the same values and ethos and we are pleased to support the meteoric rise of the PrintLounge label business.

“Steve’s business will be ideal to utilise the Durst Tau platform to expand its evergrowing label business in New Zealand across multiple vertical markets.

“Our representative in New Zealand, Graham Blackall from Aarque, worked hard with Steve to develop a close relationship

Australia projected to be next go-to-market for digitally printed packaging

The latest Future Market Insights (FMI) report shows that the eco-friendly aspect of digitally printed packaging will drive this market for the next 10 years, with Australia expected to be the next go-to market, as players shift their base from matured markets like the United States and Europe.

The report, released in August 2023, titled ‘Unveiling the Future: Digital Printing Packaging Market’, forecasts a growth rate of CAGR 5.1 per cent in the next 10 years. In 2023 the industry’s size is predicted to reach a market value of US$18,666.50 million and is expected to be

worth US$30,696.4 million by 2033.

Countries in the Asia Pacific are expected to observe significant CAGR over the forecast period.

Australia’s digital printing and packaging industry is expected to be the next growth market in the assessment period as players look for alternative regions to matured markets they use currently.

The driving force behind the demand for digital printing is its eco-friendly aspect and the robust growth of commercial packaging. The use of digital printing lowers the

Ball & Doggett adds hubergroup Rapida Eco to its portfolio

Ball & Doggett has expanded its portfolio with hubergroup Rapida Eco, a range of sheetfed process inks, offering new sustainable alternatives for the regional offset printers.

The company relaunched the range under Rapida Eco, which is now mineral oil-free, combining fast setting with a sustainable formulation. The relaunch of the ink series was preceded by intensive research and development work.

Hubergroup sheetfed and UV product manager for Europe Josef Sutter said, “It was important to us that customers who place

great value on fast printing also have a sustainable option to choose from.

“We decided to reformulate our fastest sheetfed ink series. Not an easy task, but we are pleased that we took on this challenge and are now able to offer our customers one of the fastest vegetable-based inks for sheetfed printing available on the market.”

Like its predecessor, Rapida Eco allows the paper to be processed immediately after printing and is suitable for perfecting presses. Moreover, it offers a high ductfreshness which makes the series ideal for warmer regions too.

and understand his business needs. Graham is doing a great job growing the awareness of the Durst products in New Zealand.

“We look forward to working with Steve and the PrintLounge team from the first quarter of next year as they introduce to their customers the tremendous output of this the new machine utilising the latest technology launched globally at Labelexpo.”

environmental impact as it reduces the installation waste and requires no grids. The increasing need for digital printing in packaging is also driven by its cost-effective ability to generate short print runs.

According to FMI, on-demand printing plays a crucial role in waste reduction, guaranteeing that shifts in packaging and graphic designs do not lead to unused inventory.

Rapida has proven itself to have one of the fastest setting inks

The sustainability of printed products has been in the focus of hubergroup’s research activities for a long time so that the company has set ecological standards in the commercial market again and again in the past.

www.propack.pro 6 ProPack.pro October 2023 NEWS

According to FMI, personalised packaging is amongst the most critical trends in the market

Matt Ashman, Durst Oceania; Steve Sheppard, PrintLounge and Graham Blackall, Aarque Group

CMYKhub invests in ABG DigiLase 4.0

Trade print service provider CMYKhub has purchased the first DigiLase 4.0 with DigiJet 330 finishing solution from the A B Graphic International (ABG) portfolio to be installed in the Asia-Pacific region. The machine purchased through the A/NZ distributor Currie Group will be installed in the company’s Melbourne production facility.

CMYKhub launched its labels division in March after investing in an HP Indigo 6K Digital Press at PacPrint in 2022, which, according to CMYKhub manager for customer experience and communications Glen Francis, received “amazing” interest from customers.

Francis added, “I don’t think we’ve ever sent out so many sample kits to our resellers as we have done with labels, and orders have been growing steadily, month on month.

“As with any new product line at CMYKhub, we have introduced options slowly, building up the service as we better understand exactly what our customers want, but we confirmed almost immediately that the market for custom labels, particularly in short to medium runs, is where demand is really growing exponentially.

“Print buyers in this space demand creative solutions, produced to the highest standards, to achieve the cut-through and shelf appeal, and they want them fast.”

FPLMA calls for awards entries from Australia & New Zealand

Flexible Packaging and Label Manufacturers Association (FPLMA) has confirmed that the next edition of its Forum and Gala Dinner will be held in Melbourne at the end of August 2024.

The association already started accepting entries from label and packaging converters based in Australia and New Zealand for its popular awards.

The annual FPLMA Print Awards evening, which is a culmination of the association’s technical conference, recognises excellence in the packaging industry and is an important way to showcase outstanding work in the field. It represents a celebration of creativity, innovation and technical skill.

The Gala Dinner, with its awards ceremony, has become one of the most important events in the printing and packaging industry

The challenge for CMYKhub is to meet the demand from print service providers for an array of label options, but to do it profitably for its own business and provide good value and potential margin for resellers.

Francis added, “Quite clearly, the answer is digital print. CMYKhub already has a growing library of dies to finish standard and some regular and longer-run custom jobs. However, with short to medium runs making up a large and fast-growing proportion of orders, expanding our digital capacity made good commercial sense.”

According to Francis, that is where the new ABG DigiLase / DigiJet system comes in. It combines a DigiJet 330 digital embellishment model with DigiLase 4.0 digital laser cutting system. It provides a one-pass solution for a wide range of

embellishments and customised finishes in various sizes and formats.

Francis said, “We are always looking one step ahead, and with our label production, it was simply logical to investigate what would be on show at Labelexpo. The team from Currie Group were able to share with us what ABG had planned, and this combination solution immediately stood out to us for its flexibility and productivity.

“There was simply no question in our mind that modular systems like this are the future of finished labels.”

The DigiJet component of the new line has been configured to provide multiple high-quality embellishment options, including spot varnish, cold foil and tactile screen effects, all in a single pass and with absolutely no tooling.

professionals’ calendars. The 2022 edition, held in the Crown Melbourne attracted over 300 guests from 85 businesses.

FPLMA secretary and treasurer Tony Dalleore said, “The 2024 Print Awards brochure has been distributed and this year we are pleased to announce that the awards will be carried out in collaboration with the Lithographic Institute of Australia (LIA).

“This approach will signify the start of further collaboration with the LIA and Visual Connections and show a unified approach to all activities held within the scope of both associations.”

The entries will be categorised in several verticals, including flexo, offset, letterpress, gravure, digital, combination printing, booklets, screen printing and innovation.

www.propack.pro October 2023 ProPack.pro 7 NEWS

for all entries has been set for April 30, 2024

Trent Nankervis (CMYKHub), Mark Hyde (ABG), Mark Daws (Currie Group) and Paul Norton (CMYKHub)

Deadline

Currie Group brings HP Indigo and ABG solutions to Wedderburn

Wedderburn has operated in New Zealand for 33 years and in Australia for more than 125 years. The family-owned group, collectively employing more than 300 people, has earned a reputation for quality and integrity in everything it does.

Tony Reid, label production manager at Wedderburn New Zealand, says, “With a foundation in metrology, Wedderburn has enjoyed a somewhat natural progression into weighing, labelling and automated packaging. Our label manufacturing capabilities have grown from strength to strength alongside that progression.

“We are in the fortunate position to offer both long and short run printing, which is ideal for the New Zealand market. For many years, our label customers were predominantly in the food sector but more recently we have expanded into a much broader client base that includes industrial

manufacturers and wholesalers, household and personal care producers, logistics and distribution, and horticulture.”

In April this year, Wedderburn installed a new HP Indigo 6K Digital Press and a new AB Graphic International (ABG) Digicon Series 3 finishing system. Tony says, “We are seeing real growth in craft and boutique markets and with that comes a growing demand for short runs, label personalisation and batching data being included in custom labels. The addition of our new HP Indigo 6K Digital Press will help us serve that market even better than we have been doing.

“This is an entirely new machine for Wedderburn Labels. As mentioned, we have seen a real uptake in requests for short run, high-end and personalised custom labels. The HP Indigo 6K Digital Press enables us to serve these customers at a whole new level. It gives us flexibility

to compete with the smaller and more boutique print runs.

“The print quality is impeccable and is much sharper than conventional flexo label printing. We have printed a lot of promo stuff to showcase the press to some of our clients. We have tried silver, fluorescents, and whites, and we have printed on all our range of substrates, from standard face stocks, DT stocks, Silver PP to Clear PP for different effects. Clients like something that is different from the rest.

“So far, we have not run any work that would suit Enhanced Productivity Mode, but we have earmarked a few jobs for that process.

“We use the ILP unit on every job we print to improve the transfer and adhesion of HP Indigo ElectroInks. The intelligent colour automation with inline spectrophotometer and a shorter colour

LABELS www.propack.pro 8 ProPack.pro October 2023

Label production ramps up with HP Indigo 6K Digital Press and ABG Digicon Series 3 finishing system supplied by the regional distributor, Currie Group

Tony Reid with the HP Indigo 6K Digital Press, which delivers “impeccable” print quality

calibration makes it fast and easy to hit brand colours with extreme accuracy, consistency, and repeatability from the first print to the last.

“The HP Indigo One-Shot Color technology for colour registration feature means we have no registration issues as all the colour separations are transferred simultaneously to the blanket in one pass for accurate and repeatable registration.

“We use PrintOSX Production Pro all the time with the DFE (Digital Front End). It enables us to monitor and drive continuous operational improvements. We are starting to use the HP SmartStream feature that comes with the press; we have run a few VDP (variable data print) jobs; and we are also using a colour correction programme, HP Colour Pilot.”

Smart finishing with ABG

Choosing its first ABG Digicon Series 3 as the finishing system to complement the HP Indigo 6K Digital Press made good sense to the Wedderburn team. Tony says, “We like the concept of the modular finishing unit. We can add more features to it in the future, especially if the market dictates. Plus, we know ABG as we have some of their gear already and it is good equipment.

“We use it for finishing all the work that comes off the HP Indigo 6K Digital Press. This is a very versatile machine, and it has finished all that work with ease, no matter how complex the job.

We take advantage of the automation features that we have on the ABG Digicon Series 3. These include a servo-driven full rotary quick change flexo print unit; a semi-rotary die cutting station; an over lamination unit; I-Score, which is an auto-set back scorer; and an upper web advance unit. It also offers super easy user-friendly software.”

“We have seen a real uptake in requests for short run, high-end and personalised custom labels. The HP Indigo 6K Digital Press enables us to serve these customers at a whole new level. It gives us flexibility to compete with the smaller and more boutique print runs.”

Tony Reid, label production manager at Wedderburn

With 32 years’ industry experience, predominantly in commercial web offset and heatset, Tony is enjoying his more recent move to full on labels production.

He says, “I moved to New Zealand in 2005 to take up a shift supervisor position at APN in Manukau. After six years, I moved to Ovato, formerly PMP, as the print manager, where I stayed for 12 years until they closed the heatset division of

the business in April 2022. Looking for a new challenge but wanting to stay in the industry, I accepted this role at Wedderburn.”

Service and support

Currie Group has supported Wedderburn for the last 10 years, since the company installed an eight-unit OMET X4 press. Tony says, “I have gotten to know Craig Paul, country manager — NZ Currie Group, and the team over the past year but Vernon Herbert, our NZ managing director, has known Craig for a long time.

“Currie Group has always been there for Wedderburn: for all our training needs, press upgrades and machine breakdown support. We have HP and ABG trained staff inhouse who perform all press maintenance.”

Mark Daws, director — Labels & Packaging ANZ Currie Group says, “We are honoured to be the partner of choice on this exciting journey for Wedderburn. Vernon, Tony and their team have embraced the digital mindset head-on and Currie Group have already rolled out local Business Development training to their Sales and Production teams.

He concludes, “The complementary tools Wedderburn now has to offer its customer base will give them not only production gains but also a competitive edge. We wish them all the success as they grow on this journey.”

LABELS www.propack.pro October 2023 ProPack.pro 9

The modular ABG Digicon Series 3 finishing system is the perfect complement to the HP Indigo 6K Digital Press

HP Indigo 6K Digital Press offers a raft of innovations

The latest model iteration in the 6000 series of presses, the HP Indigo 6K Digital Press, seven-colour machine delivers up to 97 per cent of the Pantone spectrum. Among its key inks, the new premium high opacity white ink offers numerous new applications such as print sleeve applications. The powerful RIP is five times faster than the previous model.

Offering a range of modes, it prints at speeds of up to 30 metres per minute in four-colour mode; up to 40 metres per

minute in Enhanced Productivity Mode; and up to 60 metres per minute in one or two-colour mode.

Special inks available for use include Premium White for Sleeves, Spot Colours, Silver, Fluorescent Pink, Green, Yellow and Orange, Transparent, Digital Matte, Invisible Yellow and Red, plus two White ink cans on press.

Its advanced features include Enhanced Productivity Mode, Inline Priming Unit,

Intelligent colour automation (media fingerprint with new inline spectrophotometer), HP Indigo OneShot Color technology for perfect colour registration, and PrintOSX Production Pro, the world’s first cloud integrated Digital Front End.

Mark Daws adds, “With the HP Indigo 6K, any colour can be reached consistently through its unmatched versatility of media, inks, and applications. Its combination of tools, support, technical breakthroughs, and continuous improvement add up to a proven formula of long-term success, with an installed base of thousands of presses worldwide.”

ABG Digicon Series 3 offers versatile finishing

ABG’s flagship Digicon Series 3 offers a modular design so you can tailor this finishing system to suit your requirements.

It offers a choice of web widths 330mm and 430mm. You can use it roll-to-roll or roll-to-sheet. Incorporating intuitive controls and lowcost maintenance, the Digicon Series 3 keeps pace, inline, with the latest digital print engines.

Innovations and options include:

• Full automation: enables quick job changeovers and simple prepress setups.

• Reliability: using high quality components, intelligently designed for consistent production.

• Intelligence: Digicon Series 3 integrates with any Management Information System (MIS).

• Multiple web widths: available in two different web widths: 330mm and 430mm.

• Modularity: simple to configure modules and options to allow you to have the machine you need.

• Flexibility: working across a range of print applications, from roll to roll and

roll to sheet, foil, embossing to screen varnish; its screen module runs at twice the speed of its predecessor.

• Foil and embossing: the Big Foot 50 Tonne Hot Foil & Embossing features applies 50 tonnes of pressure allowing foil stamping across and along the web.

• Fast track die: a semi-rotary die that runs up to 180 metres per minute.

• Automatic die plate mounting and removal: every time you change jobs, flexible dies are mounted accurately and precisely using high resolution cameras.

www.propack.pro 10 ProPack.pro October 2023

Wedderburn has enjoyed a 10-year relationship with Currie Group that began when the major industry supplier installed this eight-unit OMET X4 press

LABELS

Mark Daws, director — Labels & Packaging ANZ, Currie Group

Labelexpo Europe spotlights market trends and innovations

The paramount labels and packaging market event, Labelexpo Europe, returned to Brussels in full force with The Modern Legends of Print motto, 637 exhibitors, over 250 product launches and an extensive educational program

In addition to nine exhibition halls filled with innovations, visitors to Labelexpo 2023 could attend an expert-led masterclasses organised by The Label Academy covering sustainable labels and packaging.

Major Labelexpo Europe 2023 features included the Automation Arena and Flex Pack Trail.

The Automation Arena, which was put together by Cerm, Esko, Xeikon, KURZ, Grafotronic and Fedrigoni SelfAdhesives featured a full “lights out” production workflow, from file creation to turret rewind, with automated inspection and MIS integration without any manual intervention.

The show also offered the Flex Pack Trail, where visitors could learn about digital and conventional press technologies, flexible packaging material constructions, coating, laminating, ink and curing requirements, in-line and near-line decoration options, quality control and migration testing.

A new feature for this year’s edition of Labelexpo Europe was Flexo’s Future – ECG, a series of presentations and guided tours on Expanded Colour Gamut (ECG) printing with daily presentations by renowned ECG

expert Dr Kai Lankinen who examined all aspects of fixed palette printing, where up to seven inks (CMYK+OGV) are used to reproduce spot colours.

The Dieline Forum, a two-day design conference, which ran alongside the Labelexpo Europe show, explored the

latest trends and innovations shaping tomorrow’s brands, focusing on sustainable branding.

Labelexpo Global Series managing director Jade Grace said, “The volume of exhibitors participating at this year’s show has been truly incredible, not only in the

LABELEXPO EUROPE 2023 www.propack.pro 12 ProPack.pro October 2023

The official visitor numbers have not been released yet, but Labelexpo Europe 2023 was one of the busiest trade shows ProPack team visited in the recent years

number of returning companies but also the number of new exhibitors joining us for the first time.

“We delivered an exciting show across nine halls where visitors could see a burst of new technology and products, everything from pre-press to materials, sustainable products as well as digital and conventional printing and converting technologies.

“Add to this a world-leading series of educational events, a focus on automation, flexible packaging, sustainability and expanded colour gamut for label converters, and you had an unmissable Labelexpo experience.”

Label and packaging converters flocked to Belgium to see what innovations have been waiting for them during the last four years of Labelexpo Europe absence. The actual visitor numbers have been confirmed at 35,889 and it was indeed, one of the busiest trade shows the ProPack team visited in the recent years.

The Australia and New Zealand delegation in attendance was also strong, with nearly 40 visitors from the region present at the event.

QLM Label Makers manager of people and culture Morag Pugh said, “It is my second visit to Labelexpo and it is fantastic. The first really large print exhibition in four years. The vibe there was awesome. Everyone has such an amazing passion and energy for our industry. And it’s great that all the big brands and the smaller ones come to represent and to showcase their products and talk about the latest innovations in print.”

Mediapoint founder Jamie Xuereb added, “It is my first time at Labelexpo and it has been amazing to be able to come here and learn about label industry, which is fairly new to us. It was great to be able to see the supply chain and see what’s happening around the industry. This is the first big show in the label industry since COVID, so it is great to see everyone here enjoying it, learning, networking and getting to know each other a lot better.”

essence of the evening, reconnect with familiar industry peers and provide comprehensive coverage of this memorable event. (See pages 26-27)

The return of flexo

This year’s edition of the show was the first time that the European label and packaging converters community had a chance to get together since the last Labelexpo Europe in 2019. There has been a significant amount of innovation and new products launched since then.

Those who were lucky to have visited the Americas edition of Labelexpo last year, noticed the absence of the flexo technology on the show floor in Chicago. The industry was then predicting the digital print was overtaking analogue printing techniques. Some were even envisaging the imminent disappearance of flexo.

The visitor to Labelexpo Europe 2023 however, saw a completely different show floor to that one in Chicago. The halls were filled with flexo technology, which was not only proving it is far from dying but was also showcasing how it competes with digital machines.

Tarsus Group strategic director Andy Thomas-Emans commented, “The boundary between the digital print and flexo is constantly shifting, but the key technology trend is automation. We could see several highly automated machines, automated pressure setting, automated register control and more use of extended colour gamut printing. We have even seen automated job change on a Bobst machine.”

Flexo was not only very prominent at the show, but it featured wider machines. We have seen the premiere of the new Nilpeter FA-26 targeted at short run, valueadded flexible packaging and unsupported film applications.

Lombardi was showing its 26-inch Invicta press and Bobst showcased the M6 press, which according to the company is the most automated in-line flexo press on the market, featuring the entirely automatic flexo job changeover with the patented Bobst V-Flower technology.

Digital gets faster and smarter

Digital print manufacturers also proved that the last four years were filled with intense research and development and showcased a wide array of innovations.

HP used its display at Labelexpo Europe 2023 to demonstrate how to achieve outstanding efficiency and substantial business growth thanks to LEPx-based HP Indigo V12 and HP Indigo 200K digital presses – both showcased for the first time in Europe.

The Brussels Expo show floor was also filled with digital machines offering higher print resolution and higher opaque whites printed in-line. There was a definite trend for digital varnish and embellishment. We saw a high-build digital varnish, digital metallization and a significant amount of laser die-cutting, with highly developed automation, running with speeds of up to 160 metres per minute.

A B Graphic International (ABG), for instance, prepared the biggest presence yet at this year’s Labelexpo Europe to unveil its automation technology and showcase 13 of its cutting-edge finishing machines. Automated solutions streamline the print and finishing process by connecting all stages into one workflow.

Digital finishing has shown the use of modern technologies, such as AI (Artificial Intelligence) to manage the entire production process from the file through to the converting machine without any manual intervention.

Advantageous sustainability

As much as the last edition of Labelexpo Europe 2019 has been focused very heavily on sustainability, this year’s show proved how much can change in just four years. Sustainability is no longer a trend throughout the industry but the necessity and the advantage many converters use to win business.

Labelexpo exhibitors have brought a wide range of materials which are responding to the consumers’ demand for more eco-friendly and environmentally conscious production.

Regional converters joined Jet Technologies, Currie Group, Rodden Graphics, Aldus Graphics, Rotometrics and GMS Pacific for an exclusive Customer’s Night. Our team was on-site at the O’Reilly’s Pub in Brussels to capture the

Thomas-Emans added, “There is a trend for wider machines, which are really packaging printing presses as they are able to print flexible packaging and unsupported film materials. I think we probably won’t see much more of the simple 8-colour flexo presses. Inkjet and the other digital technologies will take that market. But on the wider and more specialist machines flexo is becoming a key technology.”

We have seen increasing use of postconsumer recycled plastics and more use of post-consumer waste in response to ambition of reaching closer to the circular economy models.

UPM Raflatac was showing plastic packaging developed entirely from wood, labels made from ocean-bound plastics and specific adhesives allowing unrecyclable labels to be cleanly released from PT or glass bottles to enable circular reuse of those containers.

LABELEXPO EUROPE 2023 www.propack.pro October 2023 ProPack.pro 13

Scan the code to see the full gallery of familiar faces we found at Labelexpo Europe 2023.

Thomas-Emans added, “In terms of linerless labels we are seeing the first pushes towards prime label linerless systems, that have core developed many years ago and now are being picked up by Avery Dennison in combination with Bobst to develop machine systems in terms of the applicator.”

Work flows automatically

This year’s edition of Labelexpo Europe featured the Automation Arena, which is a confirmation of yet another important trend surfacing in the labels and packaging market.

Industry suppliers, such as Cerm, Esko, Xeikon, KURZ, Grafotronic and Fedrigoni Self-Adhesives worked together to feature a fully automated production workflow. Presentations during the show proved that the entire production process is, from file creation by the brand owner through to finishing, inspection and MIS integration and sending ready product to the brand owner is possible without any manual intervention.

Thomas-Emans added, “In terms of workflow automation we see many ways in which it is being implemented by several suppliers at Labelexpo. It is making the printing press and equipment work together on the automated network. We are no longer going to have job bags with proofs. This is going to be driven by factory automation systems and automated colour management in the cloud. We can see end to end colour management.

A designer knows exactly what the press is going to print with its profiles digitally available.”

INNOVATION ON SHOW

A B Graphic International (ABG)

ABG showcased 13 of its cutting-edge finishing machines and ABG Connect, an automated workflow solution that streamlines the print and finishing process.

ABG also promoted its latest product innovations, including advancements in non-stop winding technology and the new turret rewinder model.

The stand visitors could see Converter, a new fully modular converting line with higher speeds, new flexo technology and a smaller footprint.

Scan the code to see Mark Daws from Currie Group demonstrating the ABG Digicon Series 3 with DigiLase and DigiJet at Labelexpo

Other products on show included a Digicon with screen and EcoLeaf unit for sustainable foiling, DigiLase 4.0, DigiJet 330, DigiLite, SRI3 430 with monochrome inkjet, shrink sleeve seaming, doctoring solutions and an entry-level SRI.

ABG also featured ABG Connect, a groundbreaking automated workflow solution that streamlines the print and finishing

automated workflow.

The company has also collaborated with HP to demonstrate its non-stop unwind and rewind system. It integrates into the HP Indigo V12 production line as a single platform. It has been designed with state-of-the-art guarding measures, ensuring operator safety, ease and comfort during operation.

It can reach speeds of up to 120 metres per minute. It delivers the best tension control, making it highly reliable for various applications.

ABG global sales director Matt Burton said: “Key to ABG’s leadership in the print

process by connecting all stages into one

www.propack.pro 14 ProPack.pro October 2023 LABELEXPO EUROPE 2023

Scan the code to watch Mark Hyde, sales manager at ABG explaining ABG Connect at Labelexpo.

Along with 13 machines ABG showcased the popular Digicon Series 3

Asahi Photoproducts was helping visitors how to switch to water-wash plates

Embrace Automate

finishing market is our ability to create solutions for the market as the market evolves. With the addition of ABG’s nonstop winding technology, label printers can maximise the potential of the V12 press.”

Contact Currie Group, the ANZ distributor of ABG equipment for more information.

Asahi Photoproducts

Asahi Photoproducts promoted a variety of ways that the future of sustainable label and flexible packaging production is available today and how the company can work with flexo operations to help converters along their road to Solvent Zero.

Printing with expanded gamut process colours allows for a broader colour gamut and typically includes CMYK plus orange, green and violet. By adding these three additional base inks into the process, producers can achieve a much closer match to traditional formulated spot ink colours as well as eliminate the need to wash up the press between jobs.

Minimising or eliminating solvent use in the plate production process is a key step for many flexo operations in reducing their carbon footprint and offering a more sustainable flexo operation and a cleaner, more enjoyable working environment.

detergent usage by 40 per cent. In a standard 10-hour-per-day plate processing operation, the system can process plates up to 38 square metres.

Jet Technologies is the regional Asahi Photoproducts distributor.

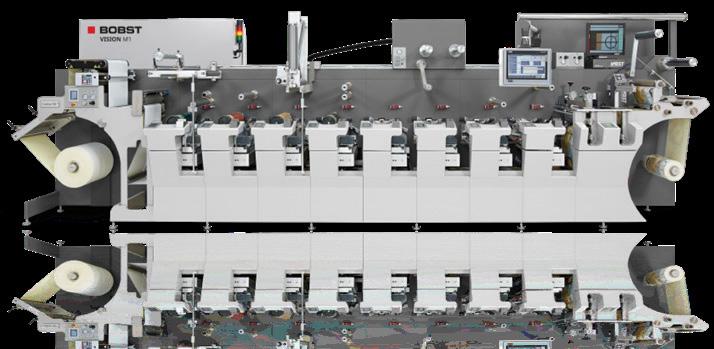

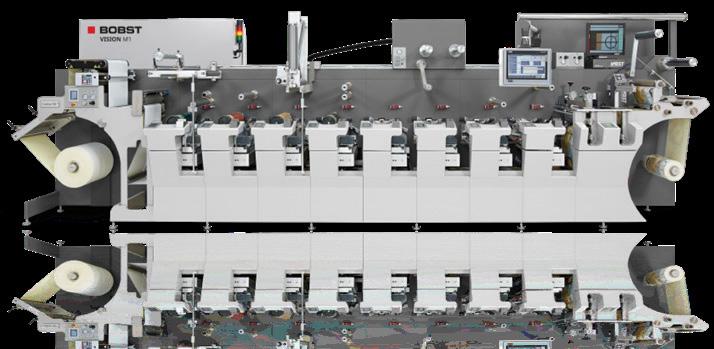

Bobst

In line with its industry vision based on the four key pillars – connectivity, digitalization, automation, and sustainability – Bobst has demonstrated its dedicated approach to label innovation, addressing the need for precision at full production speed with cutting-edge solutions. These included a digital label press and an inkjet module for rapid, high-opacity white printing.

The company showcased the Digital Master Series, which features a built-in digital front end (DFE) connected to a fully automated printing module to independently handle calibration and cleaning routines. It connects to flexo modules equipped with features such as automated pressure and register settings. For finishing, Bobst showcased the latest automated and easy-to-operate cutting solutions.

Based on Bobst Accucheck technology, the new quality control system ensures meticulous label inspection, from colour stability to print errors. If any mistakes are detected, the machines’ prompt action minimises waste.

The company showcased its Asahi AWP CleanPrint plates, which are water-washable, supporting the company’s Solvent Zero approach to product development.

The AWP-DEW plates are already certified Carbon Neutral in collaboration with the Carbon Trust and the AWP-CleanFlat plates are currently in the final stages of the Carbon Neutral approval program. Both plates are designed with sustainability in mind.

The company has also highlighted the importance of industry collaborations as a critical driver for growth.

Bobst head of narrow mid-web printing and converting product line Matteo Cardinotti said, “With our large presence at Labelexpo Europe 2023, we aim to demonstrate how Bobst has the most compelling solutions to narrow web challenges not just for today, but for the future.

“Our technology is strategically designed to combine automation, digitalization, and connectivity with the sustainability-driven needs of an ever-evolving market.

“By leading innovation across these four key pillars, Bobst is simplifying label production and empowering converters to unlock greater possibilities.”

According to the company, the Bobst M6 press also showcased at Labelexpo, is the most automated in-line flexo press on the market. A key feature is the entirely automatic flexo job changeover possible thanks to the patented Bobst V-Flower technology.

In combination with DigiFlexo registration, pressure adjustment, and Bobst oneECG colour management, changing a job can be performed in under one minute with minimal ink, material and electricity waste, making it the most sustainable conventional solution.

In addition to Bobst gravure and CI flexo presses, the Master M6 is suitable for mainstream short-to mid-run flexible packaging and shrink sleeve applications.

Asahi Photoproducts introduced its updated AWP wastewater recycling unit for use with AWP plate processing systems. The unit features proprietary filtering technology developed by Asahi Kasei that reduces wastewater by 75 per cent and

Following a surge in installations, Bobst has added more than 100 narrow-mid-web presses for labels and packaging to its installed base over the last 12 months.

Bobst also showcased various sustainable options at its booth, including AD LinrSave solution, new substrates, most waste and energy-efficient conventional printing solutions, quality control systems like Accucheck and automation systems like DigiFlexo.

www.propack.pro 16 ProPack.pro October 2023 LABELEXPO EUROPE 2023

Scan the code to watch Jet Technologies product manager for print and finishing Darryl Wilson speaking about Asahi’s road towards Solvent Zero print environment

Scan the code to watch Asahi Photoproducts general manager of sales and marketing Takumi Saito speaking about the new AWP Loop technology

Under the motto “Simplifying label production” Bobst demonstrated its innovation in labels and flexible packaging production

Durst

At Labelexpo Europe, Durst Group set the benchmark in digital printing with the introduction of its Durst Hawk Eye technology. This innovative technology utilises camera vision systems with the aim of automating print quality, resulting in significantly reduced waste and overall improved print quality.

The Durst Hawk Eye is not only an inspection system – it goes one step further as it is correcting print mistakes, such as missing nozzles, inline and in real-time, without any setup needed and without any operator intervention.

thrilled to introduce this innovative solution to the market and provide exclusive information during Labelexpo.”

Durst Group also unveiled the next generation of the Tau RSC UV ink set at Labelexpo. This new ink set, available in the colours CMYK OVG and white, will meet the latest regulatory requirements and expands the converters’ application range even further.

On the showfloor, alongside a new digital printing press, the successful Tau 510 RSCi was showcased. This press demonstrated its capabilities in real-time, printing at a remarkable speed of 80 metres per minute at a printing width of 510mm, leading to productivity of over 3,000 square metres per hour.

The Tau 510 RSCi brings powerful advantages to production: material and application versatility and excellent print quality even at highest productivity and

extremely aggressive TCO. These are a few reasons why label converters are using the Tau 510 RSCi to switch their flexo production to digital.

Durst has equipped the Tau 510 RSCi with new automation features, making the life of the operator easier and increasing the overall high efficiency of the machine. The press on the showfloor will be equipped with the powerful double white feature, allowing to print white ink at excellent opacity levels.

Epson

Epson showcased the L-4733AW, a major upgrade to the SurePress 4000 series, which made its first appearance at a trade show in Europe.

According to Epson, building on the renowned success of its industry-leading predecessor, the SurePress L-4733AW short-run label press offers a combination of quality, consistency, repeatability, and higher speed print modes.

Using Epson’s newly improved AQ4 ink-set (CMYK with green, orange, and white), it delivers a wider colour gamut and precise colour matching on a greater variety of substrates.

It also offers simplified, automated maintenance features designed to maximise uptime with minimal operator intervention to offer faster, more efficient, reliable workflow and shorter turnaround times.

Additionally, it aims to significantly reduce setup time and waste, resulting in enhanced efficiency and an even more competitive total cost of ownership (TCO) for the Tau RSC platform printers.

“The Durst Hawk Eye is a game-changer for the digital printing industry,” Durst Group product manager Martin Leitner said.

“This technology will greatly increase productivity and efficiency, but more importantly, it will reduce waste and the carbon footprint of our customers. We are

www.propack.pro October 2023 ProPack.pro 17

Scan the code to watch Durst Oceania managing director Matt Ashman talking about Durst innovations at Labelexpo Europe 2023

Scan the code to watch Durst Group product manager Martin Leitner discussing Durst Hawk Eye at Labelexpo

Scan the code to watch the Epson SurePress L-4733AW demonstration by Epson product manager, labels and packaging solutions for print production EMEAR, Trish Jones

The spotlight on the Durst booth was on three primary themes – more applications, more automation and less waste

Epson debuted its recently extended range of SurePress label presses

LABELEXPO EUROPE 2023

Labelexpo visitors could also experience the SurePress L-6534VW in combination with an in-line GM DC330 Mini all-in-one compact label finisher. The press delivers print speeds of up to 50 metres per minute for high-volume production. Being able to finish in-line offers a complete end-to-end, high-quality solution which can reduce overall production time on longer runs.

Also debuting at Labelexpo were Epson’s new cloud enabled ColorWorks label printers. This follows a partnership announcement between Epson and Loftware, the world’s largest cloud-based enterprise labelling and artwork management provider. By connecting to the systems of enterprise businesses across multiple locations, cloud enabled ColorWorks printers are meeting the rise in demand for high-productivity colour labelling solutions in the chemical, pharmaceutical, electronics, automotive, aerospace and retail sectors.

Epson demonstrated an automated labelling application using two ColorWorks printers, a smart camera, and an Epson robot. It showcases a medical industry application requiring bespoke labelling of different size drug containers. The automated process eliminates human handling, which is necessary for certain medications and any potential human labelling errors.

consistent digital flexo plates while minimising waste.

AVT Helios System, demonstrated at the show, automatically inspects printed labels or packages for defects and imperfections, delivering quality results and eliminating customer rejections.

The company also brought its latest Esko Software version to Brussels. It delivers a combination of prepress editing and cloudbased workflow automation solutions, now more integrated and connected throughout the entire prepress workflow.

Fujifilm highlighted the Jet Press FP790 digital flexible packaging press via a live demonstration from Fujifilm’s beta customer in the UK. It features water-based inkjet technology, making it suitable for food packaging production.

It has been developed as a digital alternative to flexo production for mainstream applications and print runs and to help packaging businesses deal with a widening variety of products, resulting in a proliferation of SKUs, and shorter delivery times.

Other stand highlights included a demonstration of Epson’s new prototype RFID printer. The first of its kind, the printer produces colour, on-demand RFID labels which offer significant benefits over black and white counterparts, such as easy differentiation between products and the ability to clearly highlight information.

Esko and X-Rite Pantone have partnered to showcase how an ecosystem of automated workflow, colour management, flexo platemaking, digital printing, and print inspection tools can deliver consistent performance and accelerate business growth.

The stand highlights included Phoenix, Esko’s AI-based tool that unlocks planning and imposition productivity improvements, with a seamless interface between pre-press data and production data in Esko applications.

Esko also showcased the award-winning CDI Crystal XPS 4835, utilizing UV main and back exposure to produce highly

X-Rite joined in Brussels with its eXact 2, a connected and easy-to-use handheld spectrophotometer that can measure colour across various substrates, including flexible film and paper, in a single device while verifying customer standards.

Coupled with X-Rite ColorCert Suite, the eXact 2, which works with Esko

Fujifilm also showcased its flagship tonerbased production press in the Revoria range, the Revoria PC1120. Progressively launched throughout Europe over the past two years, it features an advanced print engine with ten colours, including gold, silver, white, pink, clear, easily configurable in six before and after CMYK stations.

Fujifilm says it offers industry leading print quality, incredible media and finishing versatility, and the largest colour gamut on the market.

WebCenter and AVT’s Spectralab, provides printers with an overall view of print quality and colour performance in a single number score to confirm compliance with brand specifications.

Finally, Labelexpo visitors could see PantoneLIVE digital colour libraries for the creation and sharing of accurate brand colour standards that are achievable across various printing technologies and substrates.

Esko products are available in the region via Jet Technologies.

The press uses Super EA-Eco Toner, with micro scale particles which are 20 per cent smaller and have a 20 per cent lower melting temperature than typical alternatives. This lets it print a broader range of media including plastics and synthetics, offering access to the packaging and labelling markets.

Fujifilm

Labelexpo visitors could also see the single pass 42K Printbar System on the Fujifilm stand. It is built to the desired print width

Esko

Fujifilm

Labelexpo visitors could also see the single pass 42K Printbar System on the Fujifilm stand. It is built to the desired print width

Esko

www.propack.pro 18 ProPack.pro October 2023 LABELEXPO EUROPE 2023

Scan to watch a video of Trish Jones demonstrating the Epson SurePress L-6534VW at Labelexpo

Scan the code to watch Jet Technologies product manager for print and finishing Darryl Wilson talk about Esko’s ecosystem

Esko showcased one connected workflow across the label and packaging supply chain

Scan the code to watch Fujifilm Europe category manager for digital packaging Raynald Barillot speak about the company’s message for Labelexpo Europe

REACH & SVHC COMPLIANT HEAVY METAL FREE VOC FREE BS5609 SECTION 3 COMPLIANT For more information, please visit durst-group.com/label Industrial scalability 330 / 420 / 510 m m print width Jumbo winders Flexo-like productivity Competitive ink pricing Low ink consumption Print quality 1200 x 1200 dpi @ 2 pl Up to 95 % P antone coverage BEST IN CLASS COMPETITIVE EDGE SCALABILITY TAU RSCi INNOVATES YOUR BUSINESS

by using as many Fujifilm Samba printheads as needed to meet production needs.

The system’s flexible print width enables customers to print anywhere they desire across the press web. As a result, there is no need to reposition individual printbars or manage stitch zones as jobs change.

The 42K imprinting bar system is suitable for folding carton, corrugated packaging and other industrial applications.

Fujifilm was also promoting its Flenex FW live on the stand to demonstrate the speed with which these water-wash plates can be made. Utilising a Luscher XPose! 330L platesetter and C-Touch processor, Flenex FW plates have been developed to provide the highest print quality and productivity, while significantly lowering the cost-in-use compared to thermal, solvent or other water-wash plate technologies, with total platemaking time under 40 minutes.

Gallus

Heidelberg and Gallus have utilised Labelexpo Europe 2023 to emphasise its commitment to smart, connected printing by introducing a trio of systems addressing the shortage of skilled labour, increasing productivity and reducing waste.

Heidelberg CEO Dr Ludwin Monz said, “The new solutions that Heidelberg and Gallus have developed together address the most important challenges that stakeholders market-wide are facing every day, such as the shortage of skilled labour and the demand for more productivity.”

Labelexpo marked the European trade show debut of the new Gallus One digital label press.

Launched in August 2022, the Gallus One was designed to remove the total cost of ownership (TCO) barrier for adopting reelto-reel digital labels with the highest level

of automation and cloud-based technologies. For the first time, it aims to provide brands with access to costeffective, sustainable, high-quality digital labels.

Further optimising the TCO benefits, Gallus recently launched the new Gallus One with Converting bringing the entire production in-line, featuring a digital printer with an in-line flexo station, a semi-rotary die-cutter that can change a job within one minute and process up to 70 metres per minute, and vision inspection systems to ensure the highest level of quality and minimise waste.

Labelexpo visitors could also see how to turn a Gallus ECS 340 into a hybrid system with the help of the newly available digital printing unit (DPU). Launched this year as part of the inaugural Gallus Experience Days, the DPU transforms a traditional Gallus ECS 340 into a Gallus Labelfire 340 hybrid press without the additional platform investment.

The trade show also provided a platform to showcase the new Heidelberg Customer Portal (HCP), which was recently unveiled at the opening of the Gallus Group’s landmark new industry facility – the Gallus Experience Center – and which automates almost every customer touchpoint.

The future iterations of the HCP will also provide predictive capabilities utilising artificial intelligence (AI) to provide recommendations to drive productivity, reduce maintenance, and boost profitability. The new platform is expected to save customers, on average, up to 35 per cent in both time and money.

For high-volume applications, experts from Heidelberg also showcased a complete production workflow for in-mould label production.

HP Indigo

HP demonstrated how to achieve outstanding efficiency and substantial business growth thanks to LEPx-based HP Indigo V12 and HP Indigo 200K digital presses – both showcased for the first time in Europe.

With these solutions, HP showcased its commitment to the market and offered a complete portfolio that allows converters to shift the majority of their label jobs to the HP Indigo 6K, HP Indigo V12, or HP Indigo 200K digital presses.

www.propack.pro 20 ProPack.pro October 2023 LABELEXPO EUROPE 2023

Scan the code to watch Currie Group director for labels and packaging in ANZ Mark Daws presenting HP Indigo V12 Digital Press during Labelexpo Europe 2023

Fujifilm demonstrated its growing range of analogue, digital and sustainable print solutions

Gallus showcased its Gallus One digital label press

Completing the main display with the well-established, industry standard HP Indigo 6K Digital Press, the Patio Hall in Brussels Expo was humming with a suite of presses that accommodate every need of converters and brands in the label and flexible packaging industry.

The HP Indigo V12 Digital Press, currently ending a successful beta phase, is now available for early release.

HP Indigo holds 65 per cent of the worldwide digital label and packaging market value, and more than 2,600 active presses in the field, enabling converters to become Future Ready for the everchanging market needs.

For even greater productivity, ABG’s nonstop winding solution – specifically developed to run with the HP Indigo V12 Digital Press, and also demonstrated at the booth, can be added.

Completing the portfolio on the booth floor was the HP Indigo 6K Digital Press demonstrating E2E complete order-tolabel automation with the Web2Pack e-commerce solutions for small brands, combining the ABG Digicon Series 3 – a fully digital line with no setup; the Storefront solution from Infigo; and digital embellishment and laser die-cutting finishing from ABG.

PrintOS Spot Master is now available on the HP Indigo 6K and 200K digital presses, enabling converters to reach spot colours in minutes, to keep them consistent throughout the run, and to share the results with their brands.

The 200K Digital Press is now commercially available, after completing a beta phase. The field-proven mid-web solution for flexible packaging print is designed for seasoned industry players, or for label converters who wish to diversify their business to include flexible packaging, increase their label productivity or print wider format labels and shrink sleeves.

The HP Indigo 200K Digital Press drives on-demand delivery with no minimum orders, and enables spectacular variable designs, and minimal waste vs conventional printing processes. It is the heart of the Digital Pouch Factory which along with HP Indigo partners offers a complete lamination, slitting, and pouch-making production line.

Partners at the show included Karlville Pack Ready for thermal lamination, Karlville Swiss for pouch making, and JetFX for digital embellishment.

Printing live at the booth, HP Indigo and partners demonstrated how to help meet brand sustainability expectations by printing on a full range of HP-recommended sustainable media including compostable, recycled and FSC certified paper, as well as a recyclable paper pouch.

HP Indigo also demonstrated a newly designed Carbon Footprint Calculator which helps converters and brands to assess the carbon footprint of a printed job.

Currie Group is the A/NZ distributor of HP Indigo presses.

Hybrid Software

The company returned to help converters face the challenging times and a perfect storm of high prices for energy and substrates, a shortage of skilled labour, and higher interest rates that make capital equipment purchases more difficult.

Hybrid’s CloudFlow software is used for workflow automation by thousands of label printers and converters worldwide.

According to the company, the industry consolidation has resulted in many printers with multiple printing locations, so centralising pre-press automation in the cloud provides a real advantage.

MyCloudFlow delivers all the power of CloudFlow in a multi-tenant workflow solution hosted in the AWS cloud and managed by Hybrid Software to provide ease of use and extreme performance scalable on demand.

It has been developed not only for multisite printers; even smaller label companies can benefit from lower infrastructure costs, with no servers to purchase or local IT support required, and implementation taking just a few hours.

Hybrid Software highlighted MyCloudFlow’s turnkey integrations with Cerm, Label Traxx and Radius, the leading MIS systems used in labels and packaging.

The company also demonstrated a significant release of Packzimizer for automated lane planning of label repetitions for digital print production as well as stacked label imposition for sheet-fed, cut-and-stack label production.

Hybrid says that with many label converters producing shrink sleeves and in-mould labels, 3D modelling has become an essential pre-press tool for the label industry. Therefore, the company integrated recently acquired iC3D technology into Proofscope for highquality 3D-rendering of labels and shrink sleeves, including photorealistic ray tracing and visualisation of embellishments.

Hybrid’s variable data printing (VDP) software has also been enhanced for easier preparation of variable data labels for digital printing. Its output format is standard PDF, compatible with any RIP, but optimised for its Harlequin RIP.

For analogue printing, Hybrid showcased a variety of print samples from its new Velvet Screening, the next-generation

www.propack.pro October 2023 ProPack.pro 21 LABELEXPO EUROPE 2023

Scan the code to watch HP industrial print general manager APJ Arnon Goldman introducing the new Indigo 200K Digital Press at Labelexpo

Scan the code to watch an interview with Mike Rottenborn CEO of Hybrid Software

Hybrid Software demonstrated its continued innovation to boost productivity and improve the competitiveness

hybrid AM/FM screening technology for flexo, which provides unprecedented control of highlight dots and smoother gradations on all types of flexo plates, even at lower output resolutions.

Karlville Converting

Converting and packaging machines supplier Karlville put its K3 Plus shrink sleeve seaming machine on display. The new Plus series is one of the most advanced seamers in the industry.

Karlville said this is the third generation of seamers which eliminates the forming tool.

This new design makes the most operator friendly machine available, facilitating training with an automated machine. The difference between a K2 and a K3 model is that the K2 utilises a brake on the unwind, while the K3 is motorised.

Konica Minolta teamed up with a Denmarkbased finishing equipment expert Grafisk Maskinfabrik (GM) to showcase the full production workflow for the label converting and packaging industry.

The company, which shared its stand with its longstanding partner MGI Digital Technology, was running live demonstrations of five systems.

Konica Minolta presented the AccurioLabel 400 single-pass digital press to a broad, global audience at Labelexpo for the first time. Launched last year, it delivers a new level of enhanced print quality for converters, as well as benefits such as running cost reductions and the ability to expand applications with white toner. The toner press offers improved productivity with speeds of up to 40 metres per minute and is available in 4- and 5-colour configurations.

Konica Minolta and MGI showcased endto-end Industry 5.0 Ecosystems with

several partners, including ePS, OneVision, IIJ, GM and more.

To enable customers to produce variable data printing with high visual impact labels, Konica Minolta combined pre-and post-press solutions provided as turnkey offerings.

The second machine on show was the tonerbased entry-level AccurioLabel 230 press being configured with GM’s DC330Mini, connected in-line with the label press. This exhibit also includes an innovative art inkjet customisation project in combination with partner Industrial Inkjet Ltd (IIJ).

The equipment line up completed MGI’s JETvarnish 3D Web Compact, Octopus Web machine and Konica Minolta’s PKG-1300, designed for corrugated manufacturers, converters, printers and brand owners looking for short-run digital inkjet box printing.

As part of showcasing the full label production cycle, Konica Minolta’s also promoted comprehensive software suites, including Accurio Pro Flex and Accurio Pro Dashboard, as well as service capabilities together with partner solutions on large screens.

Kocher+Beck

Kocher+Beck showcased its GapMaster EM and TecScreen processing units. The interactive stand, built using sustainable materials, will be reused over several shows in a bid to reduce the company’s carbon footprint.

The machine has three tension zones, which allows for a dedicated tension zone for the forming section for better lay flat control. The unwind tension zone is now free to add innovations like laser integration or pin hole perforation while the film is flat.

The Plus also offers a long list of advantages that aims to solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionise the way shrink sleeves are converted.

Karlville has support facilities in the US, Europe, and Asia, servicing a global customer base. It is available locally from Currie Group.

Konica Minolta

www.propack.pro 22 ProPack.pro October 2023 LABELEXPO EUROPE 2023

Scan the code to watch an interview with Konica Minolta head of industrial printing Sasha-Vittorio Paolucci at Labelexpo

Scan the code to watch Karlville director of global sales Ben Cunningham demonstrating the K3

Karlville presented the third generation of seamers

Konica Minolta ran live demonstrations of five systems

The GapMaster EM (Electronic Move) was one of the highlighted technologies at Kocher+Beck’s stand. The company showcased a servo-driven system, the only system on the market to offer both adjustments by a rotary dial and digital input with haptic feedback for the operator.

From TecScreen, advancements have been made to the ever-popular processing unit, which now offer functionality to store and recycle water, another example of the company’s strides towards sustainability.

For flexible dies, a new generation of antistick coating provides a revolutionary nonstick result with less adhesive residue on the cutting edges. The new coating is certified in all applications such as pharma/ medical applications (FDA-Certified) and is environmentally compliant.

Kocher+Beck also featured advancements in die-cutting with a new Industry 4.0-ready digital KMS Pressure Gauge System equipped with a variety of sensors and offering higher stability under changes of load.

Further highlights at the stand included the Quick-Change die-cutting station with magnetic cylinders pre-mounted during the current job and can easily swapped in seconds.

The company has partnered with Inspired Print Solutions (IPS) to create its stand for Labelexpo 2023 using sustainable materials. The stand will be reused over several shows in a bid to reduce the carbon footprint of the company. At Labelexpo all materials on the Kocher+Beck stand are either FSC forestry accredited, recyclable, or manufactured from recyclable content. Fixtures that are not manufactured from sustainable materials will be repurposed for 2025 and 2027.

Kocher+Beck products are available in the region via Jet Technologies.

Mark Andy

Mark Andy has returned to premiere its new fully servo-driven PRO Series flexo press and showcased modern technologies developed to help converters succeed in the highly competitive label and packaging market.

Mark Andy is marketing the new PRO Series machine as the first fully servo-driven CE certified flexo press at an affordable price point, providing an efficient and effective workflow, low machine operating costs and offering an upgradable design that allows converters to expand their flexo capabilities or easily transition into digital with a toner-based engine.

PRO Series shares the award-winning Performance Series printhead design, resulting in time and material savings while maximising profits and productivity. It is compatible with sMArt link for production monitoring and analytics.

PRO Series is also the flexo platform for Digital PRO Max, a toner-based digital press with a low cost to print and exceptional white.

Rounding out the Mark Andy press offering was its top-of-the-range hybrid press, the Digital Series HD, featuring a unique combination of Mark Andy’s flexo print stations and a UV Ink Jet engine.

Mark Andy’s premier hybrid press, Digital Series HD (DSHD), equipped with the proprietary digital and flexo print technologies, was printing on the stand at speeds up to 73 metres per minute.

It combines high-resolution digital print and best-in-class production capability into a single pass workflow. The Digital Series HD is equipped with value added print features and an automatic turret rewinder, demonstrating Mark Andy’s ability to provide end of line automation solutions.

Its European debut also made the Digital PRO Max, a toner-based hybrid press built on the new PRO Series platform. It is a result of Mark Andy’s long experience in digital technology combined with significant feedback from users of previous Digital PRO models. The Digital PRO Max is faster, has lower cost-to-print, includes toner white, and can be available in configurations from roll to roll up to full hybrid. The combination of this digital engine on the future-proof PRO Series platform yields higher speeds, more productivity and increased profitability.

www.propack.pro October 2023 ProPack.pro 23 LABELEXPO EUROPE 2023

Scan the code to watch Aldus Graphics national sales manager Chris Bodger talking about new Mark Andy equipment and the recent market trends

Mark Andy premiered PRO Series flexo press

Kocher+Beck embraced sustainability in Brussels

Premiering at Labelexpo was ProWorx Label Suite, an exclusive imposition tool. This new software streamlines and automates label production setup, including inline printing and embellishment processes.

ProWorx Label Suite is an Adobe Creative Cloud extension tailored to Mark Andy’s hybrid presses. It provides job defining and imposition for printing and postprocessing, including die-cutting, and allows for more efficient and sustainable label production.

Mark Andy equipment is available in the region via Aldus Graphics.

OMET

OMET, which is celebrating its 60th anniversary this year, showcased new machinery and solutions for the global labels and packaging market by running live demonstrations of its XJet and KFlex machines at its stand.

The press is also designed to handle a range of jobs – from wraparound, shrink sleeve labels to lids, self-adhesive labels to wet glue and multi-layer.

In addition, OMET presented its proven capability to print from 12 microns mono films such as PET, PVC/PET shrink, BOPP, IML and foils to 600 microns paperbased packaging such as cartons, paper cups and liquid packaging, covering the widest gamut of packaging materials on the market.

The KFlex flexo printing machine is a modular platform press that can handle substrates from 12 microns up to aluminium lidding and light carton board. It comes in two web widths – 16-inch and 20-inch – and boasts a maximum print speed of 200 metres per minute.

The machine is targeted at end-use applications in markets including food and beverage, industrial, household, healthcare, cosmetics and wine and spirits.

With 60 years on the market and proudly serving market leaders across 100 countries, OMET demonstrated its ability to provide optimised solutions in the areas of flexo, digital, offset and gravure printing technologies with the capability to provide all these printing technologies in single pass combination printing solutions.

OMET equipment is available in the region via Currie Group.

Pulse Roll Label Products

Visitors to the Pulse booth could learn more about the benefits of using a single anilox volume for their print jobs, made possible thanks to Pulse’s PureTone ink range.

Since its launch last October, Monolox Fixed Anilox Printing has been helping converters worldwide to maximise their uptime and reduce ink consumption by standardising the flexographic process.

Pulse also showcased the new, highperformance ink, PureTone DC, which can be cured with UV LED lamps, using just a fraction of the power of traditional UV lamps.

Pulse MD Gary Seward said, “Being fully Food Packaging Compliant, new PureTone DC is suitable for label converters supplying industry sectors that require compliance to food packaging regulations and guidelines. What’s more, the range also includes CMYK+OGV for extended colour gamut printing.”

LED lamps used with PureTone DC can deliver a more stable light, ensuring consistency of curing and print. Unlike traditional UV lights, they can also be switched on and off instantly.

www.propack.pro 24 ProPack.pro October 2023 LABELEXPO EUROPE 2023

Scan the code to watch Currie Group technical product manager for labels and packaging Jon Murray presenting the new KFlex press

Scan the code to watch Omet CEO Antonio Bartesaghi talking about the company’s 60th anniversary

Ink specialist Pulse showcases its Monolox Fixed Anilox Printing and PureTone DC dual cure inks

OMET brought XJet and KFlex machines to Brussels

PureTone DC’s dual-cure formulation means printers can use just one set of inks with both UV and LED curing presses, delivering further efficiency gains by avoiding unnecessary inventory and ink management complexity, as well as being able to convert across press by press.

The new ink also matches the impressive strength of others in the Pulse range, making it easy to compare and match colours as necessary.

Pulse Roll Label Products technologies are distributed by Jet Technologies in the region.

Screen

Screen and Nilpeter introduced an innovative in-line solution to meet the increasing demand for integrated digital printing and embellishment. Showcasing the latest generation technology, the two companies partnered up to meet the requirements of the label and packaging industry with stable and high-quality combination printing.