WELCOME

Lanna Deamer l.deamer@hennikgroup.comPicture this: a symbolic baton is being passed from Joe Bush to Tom St John, and with a confident grasp, it's now in my hands. As the new bearer of this imaginary, yet symbolic torch, it's my turn to take the lead and kickoff this issue with some opening thoughts. The stage is set, the anticipation is high and I'm ready to deliver an engaging start that will hopefully leave you wanting more.

Firstly, a big thank you to those who joined us at our sixth Industrial Data Summit in Birmingham at the end of April. The day brought together a diverse group of experts from the sector for a day full of thought-provoking conversations. One of the highlights was a keynote delivered by Kat Dixon, Analytics Business Partner at Babcock International, on the importance of fostering a strong digital culture, where technology is harnessed to encourage collaboration, improve efficiency and enable data-driven decisions. As Kat reminded us, it’s ultimately people who will make the difference.

As so eloquently presented during Industrial Data Summit, by our Director, Henry Anson, we’ve a range of events coming up very soon; some of you may even be reading this at one of them. Manufacturing and Engineering Week 2023 is fast approaching and the week promises to be a festival of industrial innovation, with Design Engineering Expo, Drives & Controls, Maintec and of course, Smart Factory Expo all taking place under one roof. Not only will these be incorporated but The Manufacturer team will once again be delivering SME Growth Summit, Manufacturing Digitalisation Summit as well as celebrating ten years of The Manufacturer Top 100. Truly a week not to be missed!

In the ever-changing world of business, the adoption of digital technologies has become essential for manufacturers to succeed. By utilising these tools, manufacturers can improve their operational efficiency, increase customer satisfaction and foster innovation, thereby gaining a competitive edge. Ashley Oulton, Conference Programme Manager at The Manufacturer looks ahead to Manufacturing Digitalisation Summit taking place in Birmingham on June 7-8 as part of Manufacturing and Engineering Week 2023. See page 14.

As always, the editorial team has been out and about visiting the very best of UK manufacturers and we’ve got two more factory visits and a fun day out in South Wales to tell you about. In April, leading manufacturer of measuring and production systems, Renishaw, celebrated its 50th anniversary. The Manufacturer Editor, Joe Bush, paid a visit to the company’s Miskin site to find out more about the company’s evolution.

Long time supporters of The Manufacturer MX Awards, and winner of The Manufacturer of the Year 2021, we thought it was finally time to pay Lander Tubular Products a visit at their Birmingham site. With over 140 years of history and experience since William Lander started manufacturing household wire formed goods in his attic back in 1881, the company has grown and transformed beyond his wildest dreams. See page 32.

I look forward to seeing many of you at Manufacturing and Engineering Week, please do stop by The Manufacturer Studio and say hello!

D E C @TheManufacturer

Editorial Advisory Board

The Manufacturer’s editorial advisory board provides insight and guidance to the editorial team on a regular basis, helping maintain the relevance and quality of the magazine’s content, both in print and online. The board also provides diverse and expert comment on strategic developments in manufacturing.

Board members also advise on other The Manufacturer products and online publications, such as the Annual Manufacturing Report. Membership is by invitation only, but if you would like to be considered, please email j.bush@hennikgroup.com

Andrew Churchill EXECUTIVE CHAIRMAN

JJ Churchill and The Manufacturer Top 100, Exemplar 2014

Chris White

DIRECTOR OF INDUSTRIAL POLICY Manufacturing Technology Centre

Thomas d’Arcy INNOVATION LEAD

Rolls-Royce plc. Young Manufacturer of the Year, TMMX Awards 2017

Sarah Black-Smith

HEAD OF FACTORY OPERATIONS Siemens Digital Factory, Congleton

Deirdre Fox DIRECTOR OF STRATEGIC BUSINESS DEVELOPMENT Tata Steel

Christopher Greenough

CHIEF COMMERCIAL OFFICER SDE Technology, and The Manufacturer Top 100, Exemplar 2016

Dave Mooney MANAGING DIRECTOR Drallim Industries, and The Manufacturer Top 100, shortlisted 2014

Jan Ward CEO Corrotherm, and The Manufacturer Top 100, Exemplar 2014, current Judge

David Holmes

MANUFACTURING OPERATIONS DIRECTOR MAI BAE Systems and The Manufacturer Top 100, Exemplar 2017

Paul Gadd

DEPUTY DIRECTOR, LAND & MARITIME TRANSPORT, MANUFACTURING & MATERIALS Innovate UK

Roy Haworth ENGINEERING INTEGRATION MANAGER Airbus Defence and Space, and The Manufacturer Top 100, Member 2016

Laura McBrown MANAGING DIRECTOR G&B Electronics and The Manufacturer Top 100, Member 2016

What to expect

better, sooner

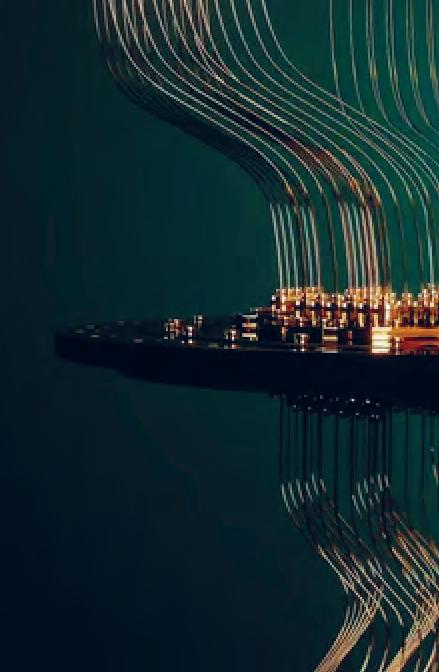

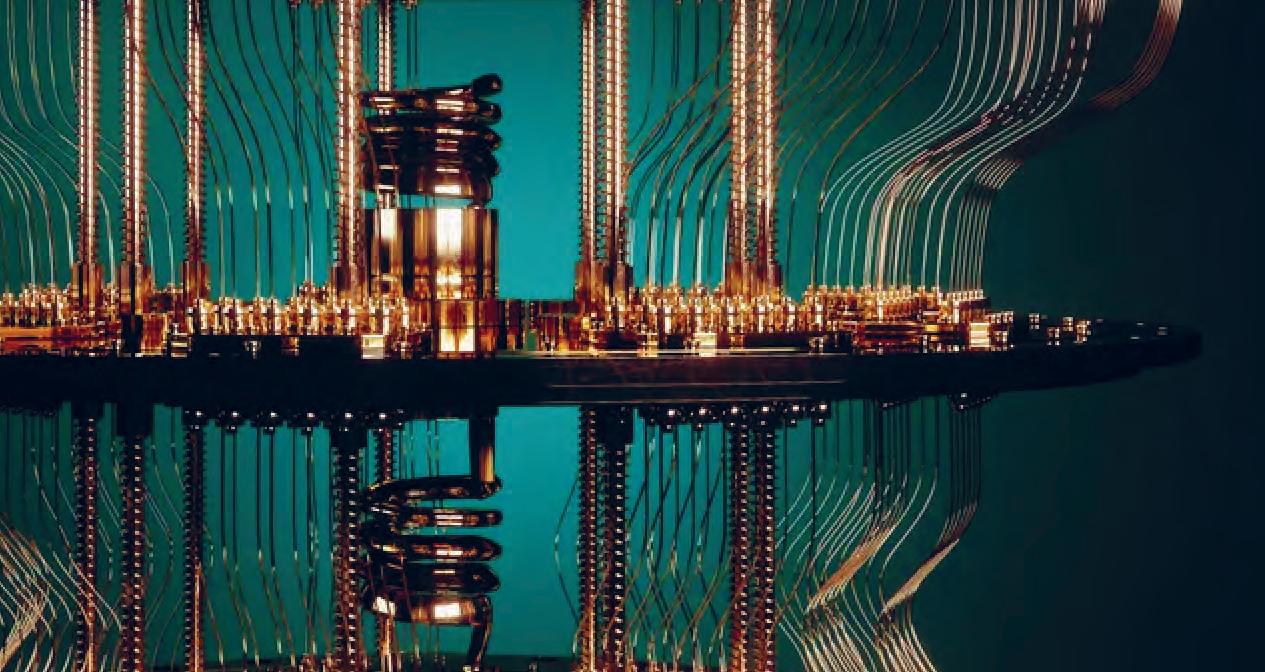

28 12 things you need to know about quantum computing Digital Catapult take a look at the technology benefits for manufacturing

32 Tubular sells The Manufacturer pays a visit to TMMX Manufacturer of the Year 2021

BIGGER, BETTER, SOONER

Smart Factory Expo is back for 2023 and if you’re thinking it seems like it came around fast, that’s because it has. From its new home at the NEC, Birmingham, as part of Manufacturing and Engineering (M&E) Week, Smart Factory Expo 2023 will take place on 7-8 June. And even though it’ll have only been six months or so since the last instalment, this year’s Smart Factory Expo is shaping up to be even bigger and better. The Manufacturer’s James Devonshire sat down with some key partners to learn more

What better way to kick off my Smart Factory Expo 2023 coverage than by finding out what we can expect from Innovate UK, the UK’s national innovation agency, at this year’s event.

Innovate UK is a non-departmental government body with a mission to drive sustainable economic growth through business-led innovation, by investing in innovation and giving businesses access to support.

At Smart Factory Expo 2023, all of Innovate UK’s services will come together to deliver two core aspects of the show: Made Smarter Innovation Alley and the Innovate UK Innovation Village.

To find out more about both offerings, I caught up with Innovate UK KTN’s AnnaMarie Taylor and Matt Wasley and James Crossling from HVM Catapult.

All the pillars of UK innovation under one umbrella

The most notable difference about Innovate UK’s presence at Smart Factory Expo 2023 is its structure. In previous years, the agency’s different streams have showcased the amazing work they are each doing to drive innovation, albeit usually via separate stands and showcases.

For 2023, all the organisational elements that make up the overall Innovate UK system will come together under one umbrella in the Innovate UK Innovation Village. This will

include Innovate UK KTN, Innovate UK Edge, the High Value Manufacturing Catapult (with all of its seven centres) and Made Smarter Innovation.

Showcasing leading edge innovation in low carbon advanced manufacturing, the Innovation Village and Innovation Stage will feature companies supported by Innovate UK, investment support and funding opportunities, as well as a series of speakers who are leaders in their industry.

At the Innovation Stage, exhibition visitors can learn from inspirational speakers and partners championing and demonstrating innovation in low carbon advanced manufacturing: from the Advanced Manufacturing Research Centre’s (AMRC) open-access smart factory framework,

DIGITAL TRANSFORMATION INNOVATION VILLAGE

The Innovation Village will demonstrate innovation across four areas that Innovate UK believes are fundamental to capitalise on the huge opportunity the UK has to become a world-class destination of choice for advanced low carbon manufacturing:

• Net zero: Materials and manufacturing will be technically advanced and play a vital role in achieving the UK’s net zero target by 2050 and meeting global sustainable development goals.

• Resilience in supply chains: Enabling companies to deal with uncertainty around changes to process, demand or supply, so the UK can create more resilient supply chains, creating more value with less cost and waste.

• Digitalisation: Innovate UK is working with manufacturing and digital industries to help the UK gain maximum advantage from the digital revolution.

• Skills and diversity: Courageous leadership, critical skills foresight, upskilling the current workforce and attracting diverse talent to drive UK manufacturing in all regions and nations.

Factory+, to the National Composite Centre’s (NCC) certification by analysis project. Apprentices from the HVM Catapult network will also talk about their careers and aspirations.

There will also be the opportunity to have your say on the Materials and Manufacturing Vision 2050, which looks at challenges and opportunities; it will outline a route to building on manufacturing capacity to make the UK a global centre for net zero sustainable production and reimagines the industry of the future.

Innovate UK’s Materials and Manufacturing Vision 2050 will be of significant importance for both our economy and society as the UK moves to establish itself as the destination of choice

for advanced low carbon manufacturing in a net zero focused world.

So why not come along and join the conversation on this crucial area of future manufacturing and learn about where Innovate UK funding will be directed going forward.

By providing access to inspiring talks, innovative companies, innovation and investment support, the Innovate UK Innovation Village represents a significant opportunity to progress your innovation aspirations.

Innovation that’s right up your alley

A regular feature at the heart of Smart Factory Expo, Made Smarter Innovation ...continued on Page 9.

ABOVE: In 2022, iov42 met with lots of different manufacturers on Innovation Alley – everyone from pharmaceutical manufacturers to companies manufacturing art

At Smart Factory Expo 2023, all of Innovate UK’s services will come together to deliver two core aspects of the show: Made Smarter Innovation Alley and the Innovate UK Innovation Village

Taylor, Innovate UK

Deloitte will focus on how digital engineering and smart manufacturing can enable your organisation to design, manufacture and operate products that are more sustainable

From seven smart factory sins to seven virtues

Deloitte’s ‘7 Sins of a Smart Factory Journey’ was a hit at last year’s Smart Factory Expo. The brilliant keynote by Deloitte’s UK leader for Industry 4.0, partner Nick Davis, and subsequent online article on The Manufacturer website garnered significant interest and traction.

Then there was Chip, the robot dog that captivated everyone who saw it at last year’s event, with its super-realistic movements, cute poses and book of tricks. To say we were excited to hear what Deloitte had planned for this year’s event is an understatement. We caught up with Nick (fresh back from Hannover Messe) to find out more.

Focus on sustainability

“The main theme that will run across all of our presentations and our stand this year will be sustainability”, Nick said.

“With Smart Factory Expo now a part of Manufacturing and Engineering Week, we will focus on how digital engineering and smart manufacturing can enable your organisation to design, manufacture and operate products that are more sustainable.”

The Deloitte stand will be the home of everything Deloitte. Stop by to learn about the breadth of expertise Deloitte offers; chat about your engineering and manufacturing transformation journey, experience immersive demos, hear about Deloitte’s project experience or just come to say hello and network.

Visitors to the Deloitte stand will discover how sustainability can be at the heart of product design and smart factory transformations. “We’ll cover sustainable

product design, circular ‘zero waste’ manufacturing, net zero workforce and sustainable transformation journeys,” Nick added.

Seven new sins

Deloitte will also be hosting four sessions in the Solutions Theatres over the two days. So, can we expect seven new smart factory sins, or has the focus changed for 2023?

Building on the success of last year’s ‘7 Sins of a Smart Factory Journey’, Deloitte will, on day one, reveal the ‘7 Virtues of Smart Factory’.

Nick said: “We will look at seven considerations for organisations on their sustainable engineering and manufacturing journeys and how to successfully navigate them. Later, we will talk about what product development will look like in the future as we embrace sustainability and the latest engineering practices. The session will cover material selection, circular design, durability and business models.

“On day two, we will share a client case study on reducing energy usage at a manufacturing facility, and how to get your smart factory to net zero.”

And finally, will Chip be returning?

Chip the dog will indeed be back this year and this time around he’ll have his own house. In 2022, poor old Chip was resigned to being charged in a cupboard – not exactly befitting a dog of such talent. This year, Chip will rest and charge in a bespoke dog house, further adding to the whole experience for visitors.

When it comes to innovation, as well as Chip, Deloitte will also have its virtual reality Metaverse experience, which will enable people to immersively explore its Dusseldorf, Wichita and Kyoto Smart Factories using a VR headset.

Meanwhile, a large screen will demonstrate some of Deloitte’s other innovative solutions. One such solution is GreenSpace Tech by Deloitte, which is a dynamic ecosystem that helps accelerate decarbonisation by enabling businesses to select the right technology to help to reduce investment risk.

Visitors can also expect some classic Deloitte demos on 5G, cyber security, digital transformation and more – everything you’d expect from the company’s Industry 4.0 offering.

The main theme that will run across all of our presentations and our stand this year will be sustainability

Nick Davis, partner and Industry 4.0 leader, Deloitte

Alley will be back once again this year, showcasing a host of the UK’s leading edge digital technology start-ups and scale-ups. These exciting, disruptive companies are ones to watch in the digital manufacturing space and will likely change the sector landscape over the next five to ten years.

Funded by Innovate UK and supported by Innovate UK KTN, Made Smarter Innovation Alley will feature no less than 30 game-changing innovators in the digital manufacturing space, each of which is younger than five years old or employs less than ten members of staff.

Confirmed Innovation Alley exhibitors (at time of writing) include:

• Sensor IT

• E-Nano

• TrackMyMachines

• Veribli

• FC Labs

• Clyde HSI

• iov42

• SMSTech

• Emerging Data Technologies

• CUEInterative

• DataFlowIQ

One Innovation Alley exhibitor that caught this reporter’s eye last year was FC Labs, with their incredibly powerful CoreTech technology which monitors fluctuations in mental attention. By tracking this data in real-time via two non-invasive sensors, CoreTech can flag when a potential workplace accident or incident due to human error might occur. This simple yet highly effective solution can empower individuals, teams and businesses to perform at their best, avoid accidents and injuries and improve overall health and wellbeing. Do check it out.

As well as getting to showcase their innovative solutions to manufacturers and other attendees, Innovation Alley exhibitors will also get access to Innovate UK experts, to help them hone their presentation skills and get the most out of their interactions with connections at the event. Furthermore, each Innovation Alley exhibitor will get the chance to pitch their solution(s) on the Innovation Stage to a select audience of interested individuals.

Scan the QR code to discover how iov42 found that Made Smarter Innovation Alley was a great testbed for their early stage blockchain technology.

If you’re going to be at Smart Factory Expo 2023, make sure you call in on Innovation Alley and see some of the amazing solutions on show first-hand.

Dr Megan Ronayne, Head of Industrial Technologies and Manufacturing at Innovate UK KTN said: “Made Smarter Innovation Alley is a key event in the manufacturing calendar, showcasing the most innovative, game-changing digital technology companies that are helping to advance the global manufacturing sector. At Innovate UK KTN, collaboration is core to what we do, and it is great to play such an essential role in connecting companies on the alley to potential partners, suppliers, customers and funders.”

If you are interested in being a part of Made Smarter Innovation Alley in the future visit: bit.ly/InnovAlleySignUp.

Navigating the digital manufacturing space

As part of the High Value Manufacturing Catapult (HVMC), the Manufacturing Technology Centre (MTC) will have a presence in the Innovate UK Innovation Village. However, it will also have its own

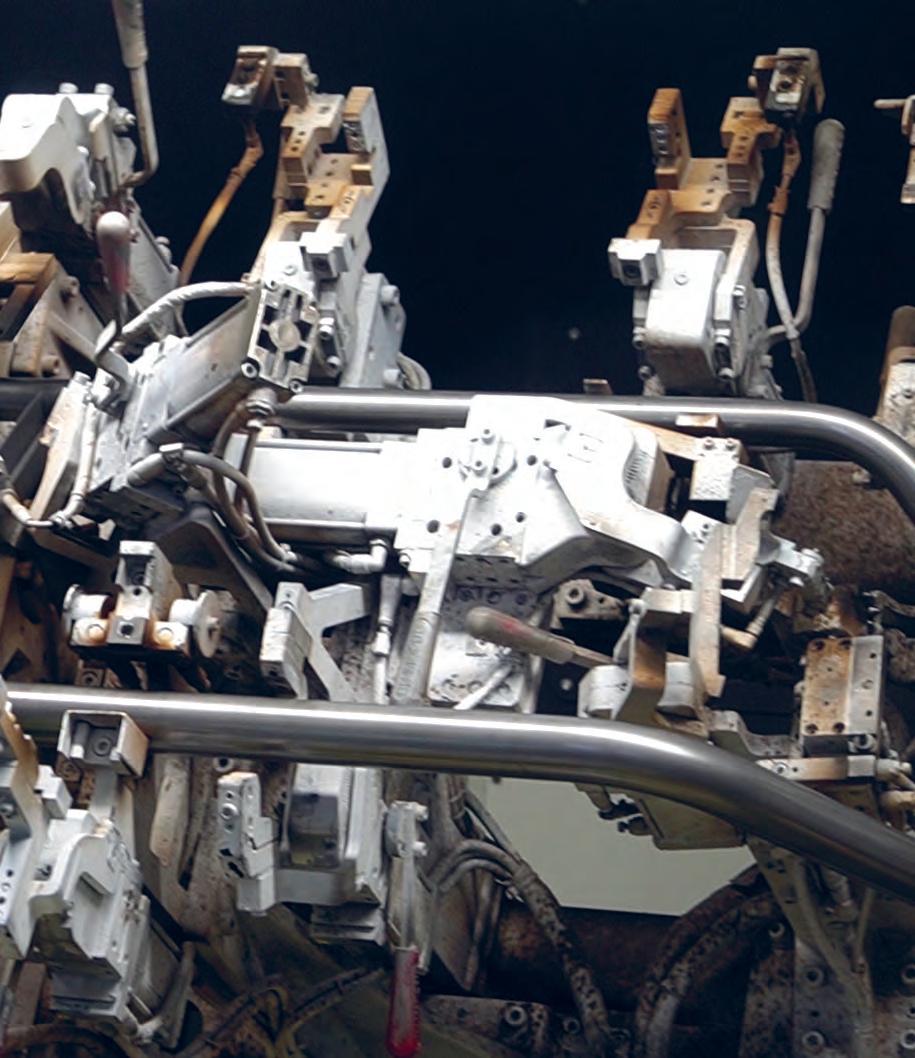

ABOVE: The MTC is seeing more and more businesses embarking on digital transformation journeys, driven by a number of potential benefits

separate stand outside in the main Smart Factory Expo arena to showcase the specific help it can provide manufacturing organisations.

MTC Director Andy Barnes gave us a flavour of what’s in store for MTC stand visitors this June.

A digital focus

The Manufacturing Technology Centre’s big focus for Smart Factory 2023 is digital transformation and, in particular, how organisations throughout the supply chain can learn to navigate the array of technologies and capabilities within Industry 4.0 in order to unlock new efficiencies within their manufacturing organisations, realise significant business outcomes and have a positive impact on society.

“The digital manufacturing landscape is very complex and that can be pretty daunting for many businesses”, said Andy. “One of the ways we can help is by guiding businesses through it using the frameworks and roadmaps we have developed, which can be applied to specific businesses and sectors.

“To help them on that journey from where they currently are – wherever that may be in terms of maturity or commitment –towards realising some of the benefits of smart manufacturing.”

Andy added that the MTC is seeing more businesses embarking on this journey, driven both by the traditional benefits, such

as productivity gains, as well as benefits which add value to their offerings. A good example of this is manufacturers using data to start taking advantage of and generating additional revenue from servitisation.

Such an approach not only adds value to customers but also to their own business. However, it requires a certain approach to data – both legacy and new – to ensure they are not only capturing the right information but getting genuine value from it. “That’s a lot of what we’re doing now,” Andy said.

Leveraging tech to get the best out of data

Andy told us that as well as supporting industry within the UK on routes to industrial digital transformation the MTC is also focused right now on leveraging new disruptive technology, such as Artificial

Intelligence

(AI) and Machine Learning

(ML) to help businesses maximise value from their data.

By using real-time data (providing it’s being captured), organisations can look to evolve and improve their machinery to make it work harder for them. Such an approach might include adding sensors to a piece of legacy equipment so that insights into its performance, availability and other metrics can be gleaned. Improvement plans can then be drawn up to boost the machine’s performance going forward. The MTC will be showcasing such sensors at Smart Factory Expo.

In a similar vein, technological advances like digital twins are making waves in the manufacturing industry. They enable organisations of all shapes and sizes to model various aspects of their businesses, both in design and operation, such as their production line, production facility and supply chain, so they can test changes to better determine their potential impact.

Through digital models, businesses can discover what a new product introduction might look like and also what it will entail, before they make any real-world changes. This allows organisations to effectively derisk their investments, as well as be more agile and adaptable.

Specific SME support Oftentimes, we see SMEs, in particular, reluctant to take the digital plunge, whether it be because of costs, lack of skills, etc.

How can the MTC help in that regard?

Andy continued: “With such a complex digital environment, there is a hesitancy for SMEs to step foot into the landscape. But where can they go for help? “SME’s are hesitant to reach out to one of the big consultancies, simply because of their size.

“Likewise, if you contact a software vendor, there’s a good chance they’ll sell you their solution, whether it’s a good fit for you or not.”

One of the roles the MTC plays is to provide independent support to SMEs who want to take advantage of digital and working with solutions providers who can help them do so. The experience and advice its experts can offer is so valuable and relatable because they simply understand manufacturers and their pain points.

Come along to the MTC stand and talk with experts, engineers and thought leaders who have decades worth of experience between them in specific manufacturing sectors such as aerospace, defence, automotive, construction, agritech, etc. You’ll be able to see from real world examples and demonstrators how the MTC has helped businesses like yours.

You can also discover more about the MTC’s Manufacturing Training Centre, which boasts a whole range of offerings designed to help businesses both big and small overcome their upskilling challenges.

Digital transformation doesn’t need to be difficult (or necessarily cost a fortune) For many manufacturing organisations –particularly the SMEs who are the lifeblood of British industry – digital transformation presents a number of challenges. Whether it’s having the right skills to proceed, or justifying the necessary investment, digital transformation is often prohibitive for SMEs.

However, digital transformation doesn’t need to be a one time, big time effort which costs hundreds of thousands of pounds and takes years to complete. Most companies can realise tangible benefits by making a few small changes and taking it from there. It’s a reality that RS Industria Founder and Managing Director, Richard Jeffers, knows all too well.

Start simple, grow smart

“There’s a lot of hype around digital transformation. A lot of the messages focus on how it’s got to be significant and enterprise-wide but even for large companies that can be challenging,” Richard said.

The Manufacturing Technology Centre’s big focus for Smart Factory Expo 2023 is digital transformation

Andy Barnes, Director, Manufacturing Technology Centre (MTC)

“One of our key messages will be how digital transformation can be for everyone and you shouldn’t be put off by the jargon. You don’t necessarily need to become a digital specialist or data scientist to realise results.”

Start simple, grow smart is the message the RS team wants to once again portray this year, highlighting to manufacturers that you don’t need to spend large amounts of time and money to start reaping some of the benefits associated with digital transformation.

An example of how a simple change can lead to significant cost savings can be seen in RS’s work with a food and beverage manufacturer to set up alerts. It became evident that the main bearing on a high-speed canning filler was vibrating abnormally. Upon further inspection, the cause was found to be a blocked lubrication feed. This simple alert, which led to more scrutiny, saved the manufacturer somewhere in the region of £100,000.

BELOW: For 2023, RS Industria will be teaming up with other parts of RS Group in the UK and Ireland to provide a more holistic overview of how it can support organisations

A unified approach for 2023

Last year, RS Industria’s stand at Smart Factory Expo was a spectacle. From the sea of red uniforms, to the massively insightful video case studies and literature (not to mention free coffee), the amount of value on offer was incredible.

RS will be sharing a number of customer case studies, including ones involving Brompton Cycles where they’ve seen a tremendous amount of progress. Brompton spoke on RS’s behalf at Smart Factory Expo 2022; testimony to the great success the pair is realising together.

Measurement means money

As well as hosting a discussion session on advanced analytics at 11.00am on day one of the Manufacturing Digitalisation Summit (part of Smart Factory Expo), Richard will also be delivering a keynote speech. On the first day of the event at 10.25am, visitors can catch Richard’s presentation: 'Why Measurement means Money', to learn about the significant financial impact of using better information in managing factories, and the importance of communicating these high values to:

For 2023, RS Industria will be teaming up with other parts of RS Group in the UK and Ireland to provide a more holistic overview of how RS Group solutions can support organisations with numerous aspects of their digital transformation journeys and beyond.

Richard added: “In terms of the stand itself, we’ll be focusing on the practical application of digital transformation. Start with your number one problem, fix that and take it from there.”

• Gain the support of key stakeholders

• Create a sense of urgency to drive faster decision making

• Sharpen the focus on the rapid removal of barriers to implementation

Digital transformation is often so highly focused on the technology, that it can be easy to forget the core reasons for doing it.

Richard wrapped up our conversation by hinting that RS will likely make a significant announcement about their partnership with AWS. At present, RS is a certified AWS solutions provider for industrial IoT. Smart Factory Expo visitors can learn more about this partnership and find out how it can be beneficial to them.

7-8

If you’re attending Smart Factory Expo 2023, please visit the RS stand (C60) and talk with their experienced solutions engineers to discover how one simple change can begin a digital transformation journey which can deliver continuous improvement and reduce production losses – at a controlled pace and within a highly cost-effective budget.

Register for a free pass at www.mandeweek.co.uk/ manufacturing-expo-home

Education all areas

Readers of The Manufacturer cannot have failed to notice that Smart Factory Expo will be held at Birmingham’s NEC on 7-8 of June as part of Manufacturing & Engineering Week 2023 (www.mandeweek.co.uk)

n KEYNOTES

ABOVE: M&E Week promises to be a festival of industrial innovation

KEY TAKEAWAYS

• Manufacturing & Engineering Week will feature two Keynote Theatres and six Solutions Theatres

• Engineers Without Borders UK will be launching its Global Responsibility Competency Compass

• RS will be presenting findings from a recent survey of more than 1,000 maintenance professionals

• The Institute for Manufacturing (IfM) will be hosting its free educational Masterclass sessions

Smart Factory Expo (full preview article on page 6) will incorporate features such as Innovation Alley and associated events such as The Manufacturer Top 100, SME Growth Summit and the Manufacturing Digitalisation Summit. M&E Week also promises to be a festival of industrial innovation and in this article we look at some of the other elements taking place alongside Smart Factory Expo which readers might wish to plan in to their visit.

Education has always been a major part of the Smart Factory Expo experience, and this has only expanded through its integration into M&E Week. A major attraction of the show is the freeto-attend conference programme that will take place across two Keynote Theatres and six Solutions Theatres.

The first Keynote Theatre hosts a range of speakers and panel sessions on a wide range of relevant topics across both days of the event. The full programme can be viewed at www.mandeweek.co.uk/ conference-agenda. One keynote on 7 June that immediately catches the eye is from Katherine Bennett CBE, CEO of the HighValue Manufacturing Catapult. Speaking on the topic of Innovation as the Key to Business Transformation & Growth, the session discusses the importance of innovation to change manufacturing businesses for the better and includes examples of how Katherine has seen this working with companies that the HVMC are supporting. Also of great interest is the panel session on 8 June titled, The unstoppable rise of Digital Twins. This session, featuring Ben Wilkinson, Head of Digital Technology and Nipuni Karunaratne, Model Factory Manager, Rolls-Royce Civil Aerospace, covers Rolls-Royce’s introduction of a radical new business model in the 1990s that catalysed the development of early analytics. This grew over time into a connected ecosystem of digital twins and in this session, the panel will explore that journey and examine the cultural, behavioural and technological factors that enabled it.

The second keynote theatre is dedicated to the Maintec event. Maintec is the longest standing exhibition for the predictive maintenance, reliability and asset management industry and throughout its long history, the event has continued to focus on uptime and the tools, innovation, technology and people that support it - all topics that are dear to the hearts of The Manufacturer readers.

Delving into the Maintec Theatre agenda there are some real gems with everything from a session on the Commonwealth

SOLUTIONS THEATRES

Alongside the two keynote theatres there are, in addition, six Solutions Theatres. These theatres are again worth investigating by readers of The Manufacturer as the topics include key areas of interest: Automation & Robotics, Digital Transformation, IIoT & Connectivity, Industrial Data & AI, Innovation and Design Engineering. Additional free educational sessions are being hosted by the Institute for Manufacturing in the IfM Theatre. These Masterclasses are designed to challenge and extend the attendees' thinking in relation to some of the most pressing challenges and opportunities they face.

IfM uses research and frameworks developed at the University of Cambridge, so those attending the Masterclasses can gain practical insights and recommendations. IfM Industrial Practitioners have extensive expertise in supporting organisations across many sectors, and so are ideally placed to answer any questions and unpick problems.

The final timetable for this year’s Masterclasses will be released shortly

but previous strategic topics have included: Strategic Roadmapping, Technology and Innovation Management, Sustainability – Scope 3 Emissions, Sustainability - Reducing Energy Waste and Digital Strategy.

IfM Masterclasses require advance booking, and this can be done when registering for your ticket for Smart Factory Expo.

The week beginning 5 June 2023 is Manufacturing & Engineering Week with the centrepiece exhibitions, Smart Factory Expo, Design & Engineering Expo, Maintec and the Drives & Controls zone taking place at Birmingham’s NEC on 7-8 June. Other exhibitions are also taking place at the NEC during the week and these include Automechanika run by Messe Frankfurt, Med-Tech Innovation Expo and TCT 3Sixty from Rapid News Group, and Subcon from the Mark Allen Group.

ABOVE: Innovation Alley will feature as part of Smart Factory Expo (full preview on page 6)

Games titled, Keeping the Games

Running, to a session on the critical role of maintenance in achieving net zero. RS is sponsoring the Maintec Theatre and will be presenting findings from a recent survey of more than 1,000 maintenance professionals as well as the Founder of RS Industria, Richard Jeffers, presenting a thoughtprovoking session on predictive maintenance as a way of life – not a technology.

In addition to hosting presentations on perennially important topics such as eliminating downtime, the theatre will also see several case studies presented as well as looking to the future of maintenance with papers and panel discussions on the role of AI and machine learning.

One conference session to mention (which is taking place in the Maintec Theatre) is from Engineers Without Borders UK. The keynote session on the afternoon of Wednesday 7 June will see the launch of a Global Responsibility Competency Compass. This session is focused on those struggling to respond effectively to the complexity, uncertainty and challenges of the age.

The action-oriented tool, developed through extensive consultation and testing, articulates the essential skills, knowledge and mindsets that engineers increasingly need to deliver the most positive impact on the four principles of global responsibility: responsible, purposeful, inclusive and regenerative. For those in manufacturing businesses who want to achieve something regarding their sustainability challenges then this session is a ‘must see’.

To register for a free pass visit:

www.mandeweek.co.uk

Digitalisation

How is it revolutionising the manufacturing industry?

In today's rapidly evolving business landscape, digitalisation has emerged as a critical driver of success for manufacturers. By leveraging digital technologies and tools, manufacturers can gain a competitive advantage by enhancing operational efficiency, improving customer satisfaction and enabling innovation. The Manufacturer’s Conference Programme Manager, Ashley Oulton, looks ahead to Manufacturing Digitalisation Summit taking place in Birmingham on June 7-8

Digitalisation is the process of integrating digital technologies into manufacturing processes, products and services to improve efficiency, reduce costs and enhance customer satisfaction. It involves the use of technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics and cloud computing to automate and optimise manufacturing processes.

Key benefit 1: Improved operational efficiency and sustainability

By automating routine tasks and leveraging data analytics, manufacturers can streamline their operations, reduce waste and errors and increase productivity. For example, IoT sensors can be used to monitor equipment performance in real-time, enabling manufacturers to proactively identify and address issues before they cause downtime or disruption and make adjustments to reduce their environmental impact.

Key benefit 2: Enhanced customer satisfaction

By leveraging digital technologies, manufacturers can gain insights into customer preferences and behaviours, enabling them to develop more targeted and personalised products and services. Digitalisation can also improve the speed and accuracy of product delivery, leading to greater customer satisfaction and loyalty.

Key benefit 3: Enable innovation by facilitating the development of new products and services

By leveraging data analytics and machine learning algorithms, manufacturers can

identify patterns and insights that can inform the development of new products and services. Additionally, digitalisation can enable the rapid prototyping and testing of new products, allowing manufacturers to bring them to market more quickly and efficiently.

What are the challenges and barriers to digitalisation?

Despite the benefits of digitalisation, manufacturers may face several challenges and barriers when implementing it in their organisations.

Challenge 1: The cost of implementing new digital technologies and systems

Digitalisation requires significant investment in hardware, software and training, which can be a significant financial burden for manufacturers, particularly small and medium-sized enterprises (SMEs).

Challenge 2: The need for a skilled workforce

Digitalisation requires a workforce with a range of skills, including data analytics, AI and machine learning. However, many manufacturers may not have the resources or expertise to recruit, train and retain such talent.

Challenge 3:

The need for a secure and reliable digital infrastructure

Manufacturers need reliable and high-speed internet connectivity, as well as robust cyber security measures, to ensure the safety and security of their digital systems and data. However, many manufacturers may not have access to such infrastructure or may lack the expertise to implement effective cyber security measures.

Challenge 4: Resistance to change among employees and stakeholders

Digitalisation requires a significant shift in mindset and culture, as well as new ways of working. Some employees may be resistant to these changes or may lack the skills or knowledge to adapt to new technologies and systems. Additionally, stakeholders such as suppliers and customers, may have their own preferences and systems, which may not align with the manufacturer's digitalisation strategy.

In conclusion, digitalisation is an essential driver of success for manufacturers in today's business landscape. By leveraging digital technologies and tools, manufacturers can improve operational efficiency, enhance customer satisfaction, enable innovation and make more sustainable decisions throughout their operations.

However, there are several challenges and barriers that organisations may face when implementing digitalisation, including the cost of implementation, the need for a skilled workforce, the need for a secure and reliable digital infrastructure and resistance to change among employees and stakeholders. Manufacturers must carefully consider these challenges and develop strategies to overcome them to fully realise the benefits of digitalisation.

Speaker's corner

Speakers and discussion leaders at Manufacturing Digitalisation Summit include:

Steve Penver, Group Head of Digital Integration, Babcock International

Clare Sibley, Head of Quality & Manufacturing Engineering, Williams Racing

Philip McNaughton, Head of Decarbonisation, British Sugar

Simon Martin, Head of Global Manufacturing, Yunex Traffic

Natalie Watson, Group Head of Sustainability, The Vita Group

Roy Pearson, NPI & Plant Engineering Manager, Gestamp

Paul Knight, Information Services & CISO, Turntide Technologies

Rashitha Jayasekara, Chief of Digital Manufacturing, Rolls Royce

Carl Haycock, UK Operations Director, Domino Printing Sciences

Alastair Henniker-Heaton, Manufacturing Systems Solution Architect, Johnson Matthey

The second annual Manufacturing Digitalisation Summit will be taking place in Birmingham on 7-8 June as part of Manufacturing and Engineering Week and several of the mentioned challenges will be discussed in our interactive roundtable discussion sessions.

Speakers and discussion leaders at the summit include senior digital, data, engineering and IT professionals from across the manufacturing industry.

Prasad Manorathna, Global Program Manager, Dover Corporation

Kallum Welch, Head of Manufacturing Engineering IS&S, Airbus

Suranjan Ghosh, Global Operations Director, Morgan Advanced Material

Steve Evans, Director of Research in Industrial Sustainability, IfM (University of Cambridge)

For more information on the Manufacturing Digitalisation Summit and to register your place please go to: manufacturing-digitalisation.com

Despite the benefits of digitalisation, manufacturers may face several challenges and barriers when implementing it in their organisations

SUSTAINABILITY

At Manufacturing Digitalisation Summit, taking place at the Birmingham NEC on 7-8 June, Phil McNaughton, Head of Decarbonisation at British Sugar, will be giving a keynote around the decarbonisation challenges for larger manufacturers with dispersed industrial sites and how digitalisation can help. The Manufacturer Editor, Joe Bush, caught up with him to find out more

The sweet smell of decarbonisa

With a history that goes back more than a century, British Sugar is the sole processor of sugar beet in the UK, and the leading producer of sugar into the UK market. The organisation has four manufacturing facilities in the UK - three in East Anglia and one in Nottinghamshire – and is contracted to over 2,500 growers of sugar beet crop. The processed crop produces a range of co-products in addition to the primary sugar product, ranging from animal feed to bioethanol and electricity which is then exported to the national grid.

Can you explain more about your role at British Sugar?

PM: My role was created towards the end of the last calendar year to lead our decarbonisation activity across all areas of our business and operations; from agriculture and how we reduce the environmental footprint of farming, our factory operations and Scope 1 carbon emissions, right through to the supply chain and distribution side of our manufacturing activity.

Our focus to date has specifically been on Scope 1, but we're continuing to develop and understand our emissions around Scope 3. Scope 2 emissions are really minor for us as it only accounts for a small amount of imported electricity. My role is essentially to drive activity, coordinate and prioritise when necessary.

How big is the decarbonisation challenge for British Sugar?

There’s no question that it is a challenge; but it's increasingly under the spotlight. Stakeholders have an increasing desire to understand how we drive our sustainability and ESG agenda, and carbon emissions are a big part of that. It's also become a much bigger question for investors in all sorts of organisations and businesses, us included.

In addition, it’s increasingly becoming a talking point with customers. The majority of the sugar that we produce goes into the industrial sector, but some does go through our sister retail business, Silver Spoon, and customers from both areas are increasingly wanting to understand firstly, what our carbon footprint is and secondly, what

we are doing to reduce our carbon and greenhouse gas emissions.

The focus on decarbonisation has increased to the point where we have included carbon reduction as part of our key strategic activities and workstreams when we reviewed them last September. And while we have activities around water reduction, packaging and plastics, carbon is seen, and has been agreed, as our priority around ESG.

How has the topic of decarbonisation changed for British Sugar over the past decade?

I've been with the business for almost 26 years and we've always had energy reduction and usage as a significant area of focus. Heat energy is a significant topic for us, driven by the fact that three quarters of sugar beet is water. Ultimately, to achieve the final solid product, that water needs to be evaporated and the product finished through a crystallisation process.

The heat energy required for that evaporation process is critical. We've made great strides over the last 40 years where we have reduced our energy demand by half. That’s been enabled through investment in new technology, efficiencies and continuous improvement activity. How's it changed more recently? Decarbonisation from a customer perspective has ramped up over the last two to three years which has been driven, ultimately, by our customers and consumers, and is only going to increase in the years to come.

Questions are now being asked in earnest around what our carbon and greenhouse gas emissions are, what do we measure? How do we measure?

And, importantly, are we improving and what are we doing to reduce emissions further? The landscape has certainly evolved, not only in terms of there being much more interest in the subject, but also around the need to articulate what our decarbonisation plan is, how it will be achieved and whether we’re on track to do so.

Head of Decarbonisation, British Sugar

We've seen ESG and related activities becoming more important right the way through the supply chain, to consumers and supermarkets etc. What marries that desire to improve company credentials in terms of performance around ESG, is how to achieve it in a financially neutral or positive way. Opportunities exist but we need to ensure that as a business we're

While we have activities around water reduction, packaging and plastics, carbon is seen, and has been agreed, as our priority around ESG

Phil McNaughton,

investing in the right long-term solutions. A vital balance has to be struck around how you can improve on your ESG, but also maintaining good bottom line profitability to encourage that reinvestment into improvement as you go forward. There’s a lot of desire, not just in our business, but in industry more broadly, but despite that good intent, after a while those goals can become more challenging from a financial point of view.

In terms of regulation, there are a number of areas that are governed by the Environment Agency. and understanding around climate change adaptation will need to be demonstrated. The main piece of regulatory or compliance pressure for us is around the UK Emissions Trading Scheme (UK ETS); accounting for and ensuring verification of greenhouse gas emissions annually from the burning of fossil fuels.

Additionally, the financial burden associated with regulatory compliance has increased significantly over the last decade. It was a relatively small amount of

expenditure eight to ten years ago. That’s certainly one driver to decarbonise, but clearly you can't do everything overnight.

Your keynote address at Manufacturing Digitalisation Summit will be around the decarbonisation of dispersed industrial sites. Can you give a flavour of the talk and some of the key takeaways?

All four of our sites are dispersed in nature in terms of classification (dispersed being a certain distance away from a track one or track two supported government cluster). All our sites are quite a significant distance from each respective nearest cluster, so we don't anticipate any direct benefit.

We try and lobby and advocate to a number of groups, including directly with government, around support for dispersed sites, from which around half of the industrial emissions in the UK are sourced.

The advent and deployment of Industry 4.0 will evolve British Sugar; we will embrace it and it will ultimately support improvement and efficiency in our existing operations

Phil McNaughton, Head of Decarbonisation, British SugarABOVE: British Sugar also has sites in Cantley (above) and Newark (bottom right)

Some of the challenges that we have, particularly in East Anglia, are around the strength of the electricity and gas networks. If we wanted to move to electrification on-site for example, and away from natural gas usage, with the intent of being able to import more green electricity from the grid, that's a real challenge as the infrastructure isn't sufficiently developed at this moment. And that'll be the same for other industrial operators in the region.

Furthermore, around infrastructure, if I was to highlight hydrogen as an example, the infrastructure isn't developed yet in this country, and we don't really know how it’s going to look. Hydrogen will come into track one and likely, track two government supported clusters, but in terms of deploying hydrogen into areas like East Anglia and other more remote regions where dispersed sites are operating, we’re probably 20 years away.

In terms of our decarbonisation plans, our priority is to try and reduce our energy usage, primarily through steam reduction, to as low a point as we can get. Then, when we do find the right opportunities to change from natural gas, we'll do so at a point where we’re using the minimum amount of fuel possible. We've got a number of steam reduction projects which we’re progressing and developing within the business across all four sites.

We’re also looking further out at the different technologies and fuel options that will enable us to change from natural gas in the future. My position, and British Sugar’s, would be that it's likely to be a blend of fuels and technologies that we’ll need to deploy across the four sites, and maybe within the same site, in order to get to the point where we can ultimately decarbonise.

For manufacturers operating multiple and dispersed sites, what are some of the challenges when it comes to decarbonisation?

To an extent it depends on where your sites are located and if they are genuinely dispersed. For those that are, there are challenges around availability through networks of alternative fuels. So, if you are a dispersed site, and you're getting

on with fuel switching today, and in the years to come, you're likely to be doing it off grid. And you're probably tying up with a third-party who is offering that deployment for you on a variety of different levels of ownership.

That again depends on location, appetite and whether you've got other significant energy users in the same area that might join forces with you to make that type of investment and project more attractive for yourself and any thirdparties you may be working with.

Quite frankly, the more remote you get, the more challenging this becomes. And while there are end of pipe technologies, such as carbon capture and storage, we're fairly agnostic on that, because it doesn't genuinely reduce the burning of fossil fuels and emitted carbon.

Our position would be that, as a first port of call, we want to try and reduce the quantity of fossil fuels we're burning to reduce our greenhouse gas emissions at source, rather than having to adopt a technology that might capture the carbon and put it into storage.

What part can technology and digitalisation play to help address this?

We’re just starting to discover some of the options and opportunities that Industry 4.0 may offer and we’re collaborating with an external partner to help us do that.

We've identified six areas of work activity and assigned leaders to each one. Through the increasing level of automation that we've deployed across our sites in recent years, providing operators the ability to control the plant remotely on digital equipment, we're now set up with a much better infrastructure. We're now trying to test and work out how we take maximum advantage of that to improve the consistency of site operations, and look for opportunities that can be deployed across all sites that gives us the best options for repeatability and consistency.

We're learning in this space, but I think there’s a massive opportunity both in terms of generating better data and how we use it to improve, but also, how that data is used specifically for energy performance. We will identify opportunities, we just don't know what they are yet, but we're fairly confident they will come.

How is the company using renewable energy sources?

It’s currently quite limited because of the size of energy demand that we have. However, there are a couple of areas that are worth highlighting. We have a 5MW anaerobic digestion plant at our Bury St Edmonds site. Pressed pulp, which is what remains after we’ve extracted sugar out of the sugar beet, is then fed into that anaerobic digestion plant. The green electricity generated is injected directly into the network.

The majority of our pressed pulp is dried, pelleted and then sold into the animal feed market in the UK, and therein lies one of our internal conflicts. That actually generates revenue for us with one of our sister businesses. However, going forward, if we want to put that material into anaerobic digestion instead, we will have to give up that revenue and find how that imbalance is addressed elsewhere.

We also have a couple of small solar PV installations. Again, solar PV is one of the areas and potential projects that we are currently reassessing because technologies change in terms of their viability and what’s available.

It is also worth underlining the credentials that we have around good quality, combined heat and power (CHP) plants. All of our sites have a CHP scheme, and obviously, for an overall electricity and heat supply, that maximises the efficiency and utilisation of that input fuel.

A standalone power station generating electricity would be at a much lower overall efficiency than our CHP schemes deliver in terms of useful heat and electricity, which is pushing around 80%.

What does British Sugar’s decarbonisation and digitalisation future look like?

The advent and deployment of Industry 4.0 will evolve at British Sugar; we will embrace it and it will ultimately support improvement and efficiency to a greater level in our existing operations and our continuous improvement. That will help us from an energy utilisation point of view.

I think it might also help identify opportunities where we can look for investment and highlight areas where there is lower performance. In terms of marrying that with a decarbonisation future, I think there's lots of known technology, particularly within the sugar arena, that we might consider deploying that will help us ultimately reduce energy and decarbonise.

I can see that Industry 4.0 will also help support alternative, lower carbon emitting fuels. When we start to look at alternatives, I would expect digitalisation to be a part of that process. I can also see us having to be much more flexible in terms of switching between different

fuels, particularly as we transition from a carbon emitting business in terms of the fossil fuel that we're burning, to ultimately one where we're using clean fuels and we've decarbonised.

That's clearly a few years and decades away but digitalisation will help us through that period and to optimise the decarbonisation aspect of the business. It will also help us to marry that with the commercial and financial side of balancing what fuel to use, when and how to generate electricity, and potentially continue to export some of that energy to the grid.

It's a challenge, because we're not quite sure how we’re going to get there but I'm absolutely certain that digitalisation will have a part to play in how we go forward and we will understand that better over the next two or three years.

KEY TAKEAWAYS

• British Sugar is a significant user of natural gas and there is a high heat and electricity demand from each of its four sites in the UK

• Carbon reduction is now a part of British Sugar’s key strategic activities and workstreams

• Over the last 40 years British Sugar has reduced its energy demand by half via investment in new technology, efficiencies and continuous improvement activity

• The importance of decarbonisation from a customer perspective has increased over the last two to three years

• Industry 4.0 technologies have created an improved infrastructure for decarbonisation at British Sugar

Manufacturing digitalisation Summit will take place at the NEC, Birmingham on 7-8 June. To register your place visit: manufacturingdigitalisation.com

In terms of decarbonisation, we're not quite sure how we’re going to get there yet, but I'm absolutely certain that digitalisation will have a part to play in how we go forward

Phil McNaughton, Head of Decarbonisation, British Sugar

DISCOVER TECHNOLOGY BREAKTHROUGHS AT THE MADE SMARTER INNOVATION ALLEY

MADE SMARTER INNOVATION ALLEY:

Located at the very heart of Smart Factory Expo (7-8 June 2023, NEC, Birmingham), Made Smarter Innovation Alley is the largest showcase of leading edge digital technology start-up and scale-up in the UK that will change the landscape of manufacturing over the next 5-10 years.

Funded by Innovate UK and supported by Innovate UK KTN, the Alley is open to university spin-outs, start-ups and scale-ups who are less than 5 years old, employ less than 10 members of staff and have an innovative digital product or service targeting manufacturers.

Meet 40+ companies with innovative digital manufacturing technologies in AI, machine learning, additive manufacturing, sensors and blockchain, robotics, immersive technologies and IIOT across multiple industry sectors including medtech, chemistry, defence, nuclear, automotive, aerospace, food and drink and others.

DON’T ALSO MISS:

Visit the Innovation Village to connect with the Innovate UK innovation ecosystem and be inspired through funding, collaboration, investment, and leading-edge research to support the aspirations of the UK’s manufacturing industry.

Meet and engage with early-stage companies and their founders to uncover bleeding-edge disruptive technology that could be gamechanging for you, your product and your business in the future.

REGISTER A FREE PASS TO ATTEND www.mandeweek.co.uk

Funded by:

Supported by:

A PERFECT 10 FOR THE

This year sees The Manufacturer celebrate the tenth anniversary of the Top 100; the awards programme which celebrates the inspiring individuals who are shaping the manufacturing sector in the UK

From Young Pioneers and Unsung Heroes to Inspiring Leaders and Innovators, the Top 100 is a showcase of the very best talent the sector has to offer, as judged by an esteemed panel featuring leaders of industry, academic institutions and manufacturing associations.

In this article, The Manufacturer Editor, Joe Bush, takes a trip down memory lane for a catch up with three of the original 20 Exemplars from the very first Top 100 intake in 2014: Jan Ward CBE, Founder of Corrotherm, a supplier of seamless pipes, tubes, fittings and flanges; Richard Lloyd, General Manager of wines and spirits company, Accolade Wines; and Adrian Maxwell, Managing Director of cappuccino and espresso coffee machine manufacturer, Fracino.

What was it like to be named as an Exemplar in the first ever Top 100?

JW: It was a lovely surprise because I wasn't expecting it. There's a sense of achievement because you've been recognised for the work you do, but being named in the Top 100 is also a really good way to link up with other people.

You've got something in common with others named in the same cohort. You get talking and it actually leads to business opportunities and access to information that you can use to improve your business. It was also great to see manufacturing acknowledged and the profile of the sector being raised in the public domain.

RL: To be in the first year to be selected in the Top 100 was amazing, but to then be named in the Exemplar group was incredibly flattering; it's something I've always cherished. I've attended most years since and seen the calibre of people that have been added. It was just magical to be there from the start.

It’s always good to have some external recognition as a verification of your standing. Being an Exemplar in the Top 100 also gives you an air of credence when you’re in a group of people and part of dynamic business discussions.

AM: It is very prestigious to be in the Top 100; it has helped us win other awards and market the company. Before being nominated we were fairly unknown, now we’re being consulted around policy, which is absolutely incredible – government are actually looking to us. Being recognised by The Manufacturer was a catalyst for that and it really helped us promote the business and push it forward.

In addition, it’s really helped us from the perspective of being in a global market. Recognitions like this give us extra kudos and credibility with potential customers. We didn’t export a single product until 2009; now our export market represents around 35-40% of our turnover.

JW: The Top 100 programme is more important to the sector now than ever before. It's absolutely vital as we can see all too clearly how unstable the UK economy can become if it’s totally reliant on services, which it has been. The Top 100 is key to promoting the industry and encouraging youngsters to get involved; to show that working in manufacturing can be successful and enjoyable.

What impact has The Top 100 had on your career?

RL: There have been some big milestones that have come about from our relationship with The Manufacturer. We always attend their events as a group because it’s really important to hear different views, ideas and see different technology; we can discuss, meet people and discover what works for us.

We’ve introduced 3D printing of our spare parts, AI and machine learning, totally off the back of being at The Manufacturer events and meeting other suppliers and likeminded businesses. Our business has evolved with technology and for me, The Manufacturer and The Manufacturer Top 100 has provided the platform to help us grow.

JW: Being in the Top 100, using the network and attending events hosted by The Manufacturer has opened up a number of opportunities for me to meet and talk to other people and companies. That collaboration is really useful.

As manufacturers, we're naturally curious, but that is enhanced by being part of the Top 100 as there’s nothing like the face-toface sparking of ideas across platforms and people. The other huge bonus of being a Top 100 Exemplar is that it has enabled me to see other factories, which is my favourite thing to do.

The programme brings you together with people that you wouldn't necessarily have met under normal circumstances. It enables you to get involved and understand more about what others are doing in areas beyond your sector, but which can still influence what you do.

I also like the fact that the Top 100 puts forward people that wouldn't necessarily be acknowledged – the Young Pioneer and Unsung Hero categories for example; the people that work in the

Our business has evolved with technology and for me, The Manufacturer Top 100 has provided the platform to help us grow

Richard Lloyd, General Manager, Accolade Wines

background to keep production rolling, doing the jobs that are not necessarily high profile. It's not all about the chief executives and members of the board.

When you get the title of being in the Top 100, it puts you on the same level as everyone else in that year’s intake. People from a large automotive OEM, for example, wouldn't necessarily be speaking to a small manufacturer from the Midlands. But when you're in the Top 100, you all come together.

AM: I still like to be very hands-on, although I don’t have as much time to do so as I once did. I oversee and run the business, and I have a core team that run each department and report into me. I’ve constantly learned new skills as the business has grown,

and I always listen. That’s something my father taught me. You don’t have to agree with what’s being said, but as long as you’re listening, you’re always learning.

RL: I’ve become more of a generalist since being included in the Top 100. I’m lucky now that I have full supply chain end-to-end responsibility. The huge advantage of that is having the skill set to be able to bring a group of different functions together and make sure they are optimised as a whole.

When looking after just one function, you’re very focused on optimising that one area, and rightly so. But my career has now become one of building a leadership team and making sure we provide that end-to-end supply chain offering for our customers.

The Top 100 has really helped us from the perspective of being in a global market. These recognitions give us extra kudos and credibility with potential customers

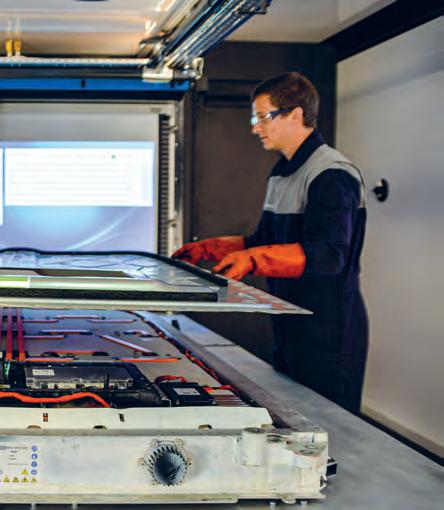

Adrian Maxwell (above left), Managing Director, FracinoBELOW: The fabrication of copper tubing at Fracino

How has the landscape of manufacturing changed in the last decade?

JW: Automation and digitalisation have been huge. However, in truth I'm disappointed it hasn't come further. But I am aware of the barriers that exist for small businesses and how hard it is to find the necessary skills to enable the rollout of such technology. That demographic of people and the infrastructure that will enable this to happen, is not going to grow quickly, and perhaps the two years of the pandemic and the aftermath has caused further delays. Small businesses know that it's something they should be doing but they can sometimes get overwhelmed. So again, talking to other Top 100 members helps to gauge some perspective and see what can be done. And there are offers of help as well.

The bigger companies will try to assist smaller businesses or introduce them to people that can. There’s certainly a desire for digital transformation by most small manufacturers, and they are aware of the fact, particularly with labour shortages, that automation and digital is the way to go.

There's also a very robust discussion being had around what can be achieved with net zero. There are lots of things that people can do, but they all cost money. So sharing information about how this can be done cheaper and more incrementally is key.

It's a case of trying to work out what's affordable for you so you can take those small steps, because it's not possible for everyone to leap into it and convert everything straightaway, especially if you have inherited assets that are quite old. However, the Top 100 gives you the opportunity to sit down and talk with people who are perhaps further along the journey and offer ideas of what you can be doing yourself.

RL: Sustainability has grown massively. That’s why we’re now a carbon net neutral facility; we have the country’s largest wind turbine, we 3D print machine parts using one of our waste streams and we move all our vehicles around the site on hydrated vegetable oil (HVO).

We have had to evolve our offering and the way we work. The cost pressures that have grown recently have meant that productivity improvements are more important than ever. Our ability to embrace technology and take cost out where we can has been critical, but the core purpose of delivering value for our customers has ultimately, remained unchanged.

We embraced sustainability and found it has had an economic benefit. Our 2.5MW wind turbine, which was put up in 2019, provides 50% of our electricity for the site. And when you compare the cost of that electricity against the grid, it’s about a quarter of the price.

There’s been a number of different pressures but, if you keep embracing new technology and partner with businesses that help you optimise and drive forward, you can stay ahead of the game. The initiatives we’ve rolled out mean we are more resilient to some of the external factors impacting the sector.

AM: We’ve been working on environmental issues for quite a long time. We installed solar panels around eight years ago, and at the time were able to take advantage of the buy-intariffs. That means we can use all the power we generate and get paid for it, which is absolutely wonderful.

That was a 25 year contract so it is still ongoing. The solar panels are paid for following our initial outlay of around £40,000. That demonstrated foresight on our part and you can’t underestimate the importance of reinvestment; it really is a no brainer – particularly at the moment with the current energy

The Top 100 programme is more important to the sector now than ever before. It’s key to promoting the industry and encouraging youngsters to get involved; to show that working in manufacturing can be successful and enjoyable

Jan Ward CBE, Founder, Corrotherm

crisis – so the measures we implemented a few years ago have been an absolute godsend.

We also recycle all our metal and our machines themselves are 96% recyclable. We recycle all our own cardboard and reuse all our own waste. We recycle everything we possibly can, even down to our own oil.

A key purpose of the Top 100 is to raise awareness of the sector and help reduce the skills gap. How has this particular problem shifted since 2014?

AM: We see evidence of the huge skills shortage across many facets of the industry. If we need something done that’s physical or practical, we’re finding that the vast majority of people available are from an older age group.

We do have young people but we find that we really have to pull them along as often, they’re not that keen on the work. I blame the education system to a certain extent as young people are pushed into and coached for exams, which doesn’t provide them with the practical skills needed for a career in manufacturing - they can't think around a problem and often don't know how to communicate.

Of course, we find some young people who aren't very good at school and struggle with academia, but they've got great practical skills. They’re the ones we try and get hold of quickly because they are unusual. The education system needs to recognise that we’re not going to be able to fill the skills gap unless we have those practical courses.

CNC machinists are so hard to find. We have someone who’s semi-retired that's running our machines; we are struggling and are just managing with what we've got. Something needs to change. And I think it probably needs to start at school, because education tends to portray ‘engineer’ as a dirty word.

It’s a completely different sector now. You can be working with some pretty high-tech pieces of equipment and machinery, producing some amazing finished products. However, there’s still not the right links between school and industry to bring the two together.

JW: Unfortunately, I don't think that the skills gap has changed much in terms of the volume of people coming into the sector. We haven't had the big influx into the industry that would have been desirable. And we’ve also had the retirement issue that we knew was coming and is still ongoing.

COVID certainly made that worse – an estimated half a million early retirees left the labour force due to the pandemic and I suspect quite a high number of those came from manufacturing.

The sector is performing a lot better than it was a decade ago and I don't think the gender gap is as big a problem as it once was. However, the main issue is still around attraction and the pull of other sectors has made it harder to recruit young people.

I don't think the industry has done a bad job of putting itself out there, but the skills piece is still not where it needs to be and we're not getting the feed of people with the right level of skills coming into the sector, particularly in mathematics and physics. So companies are having to take pretty raw recruits and train them themselves.

All of that said, I do think that going digital and the adoption of automation has helped to recruit more young people by

quashing that image of the sector being all about oily rags and overalls, and showing youngsters that are training now and thinking about degrees, the truth about the industry.

We need the universities to step up and show what is possible in manufacturing. Unfortunately, teachers and parents are often way behind the times when it comes to knowing what manufacturing is about. Parents generally don't understand what real, modern manufacturing means in terms of a career and it's up to the institutions to get that message across.

However, I’m afraid that many universities are behind the curve. Many of the engineering departments are not well funded, don't have the necessary equipment, and are therefore, not up to speed with what's going on. The universities are also failing to recruit the right sort of people. Former manufacturers need to be doing the teaching; giving it to professors that have only ever been in academia is not good for manufacturing.

In the past, I’ve found resistance to modern methods when I've visited universities (3D printing for example). If it’s a technology that’s not understood, then it’s not going to be wanted in the university department. There are notable exceptions of course - places like Brunel, Manchester and some of the Scottish universities especially. But I think in general, there's a very big gap between what the lecturers know and want to do, and what's actually needed by industry.

2023

The Manufacturer Top 100 Awards ceremony will take place on 7 June as part of Manufacturing & Engineering Week. Visit www.mandeweek.co.uk/ manufacturing-expo-home to register.

MORE NEWS.

MORE MEDIA .

MORE INSIGHT.

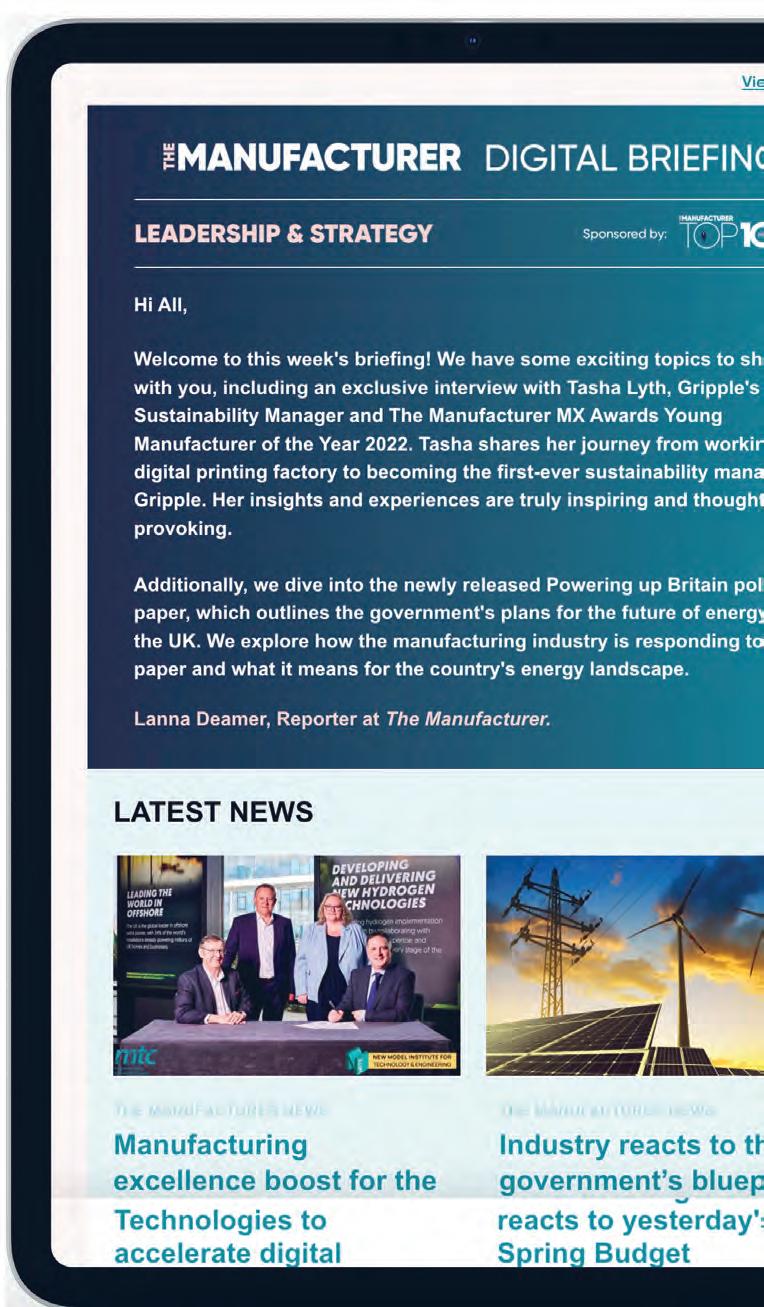

DIGITAL BRIEFING

The Manufacturer Digital Briefings are published twice weekly for the latest information, innovations & insights in manufacturing, sign up now.

For many, quantum computing may appear to have parallels with nuclear fusion: a technology with great potential but with no provable benefits despite decades of costly research.

However, beyond the hype and the theory, there will be plenty of real-life, tangible opportunities for manufacturers to solve critical business challenges more quickly and cheaply, and it is important to be aware of the threat that quantum computing offers to some encryption schemes. There’s already lots to read online and plenty of organisations, including Digital Catapult, that can help manufacturers dip their toes into the quantum water.

1. Why do we need quantum computing? Despite the massive increase in computing power which defines our modern world, there are still some tasks classical computers can’t handle well. For example, developing a room temperature

things you need

to know about quantum

LEFT: Despite the massive increase in computing power which defines our modern world, there are still some tasks classical computers can’t handle well

superconductor would help solve the world’s energy problems yet research is blocked, in part, because classical computers can’t simulate quantum systems with many entangled particles.

Medical research also suffers because classical computers can’t simulate large molecules accurately. Optimisation and machine learning algorithms are sometimes limited by computing resource constraints. Quantum computers will, it’s believed, solve some of these difficult problems in the future, due to their fundamentally different computing paradigm.

2. How will quantum computing affect my industry?

Today’s Noisy Intermediate Scale Quantum (NISQ) devices have, at most, a few hundred qubits, and these are very error prone. In the current NISQ era, Variational Quantum Algorithms (VQA), where a quantum computer is ‘trained’ by a classical computer, are likely to be used for a wide range of functions:

• Optimisation: Solving a wide range of real-world problems such as finding the best configuration for telecoms networks, optimal vehicle routing for last mile delivery, optimising supply chains and factory flows.

• Machine learning: Particularly for anomaly detection to find manufacturing faults.

• Computational fluid dynamics: Calculating fluid flows around vehicles to make them more aerodynamic.

The ‘holy grail’ of modern research is to build a large, universal, error corrected quantum computer, which could in principle run any quantum algorithm; with many positive societal impacts including revolutionising the challenge of climate change by discovering new materials for solar cells, batteries and even room temperature superconductors.

3. Which industries will benefit the most in the short-term?

Multiple industries with complex supply chains will benefit from the ability to carry out better optimisations than are possible classically, and these are likely to be the first commercial use cases, with quick and significant paybacks.

At Digital Catapult, we’re supporting sectors including energy, construction, automotive, transportation, advanced manufacturing, material science and telecoms to determine how companies in those sectors will gain a competitive advantage by understanding the future benefits and applications of secure quantum computing for their industry, upskilling their employees and encouraging innovation. For example, quantum computers are being used to develop next-generation batteries, and the aerospace industry will benefit from digital twins enabled by quantum fluid dynamics simulations.

4. How does quantum translate into economic opportunity?

Many businesses will benefit from improved quantum chemistry, fluid dynamics, machine learning and optimisation. These businesses will need to purchase not just a quantum computer, or cloud access to a quantum computer, but ‘the complete product’. They may need to purchase consultancy, to understand which problems are amenable to quantum computing, quantum software and the rights to use quantum algorithms.

The quantum computer manufacturer will themselves need to source essential supply chain components such as dilution refrigerators, lasers, semiconductor nanostructure design and manufacture and microwave generators, and depend on scientific research. All of these transactions provide an economic opportunity and build a quantum eco-system.

5. What is a quantum computer?

Quantum computers depend on quantum effects only relevant at small scales, that we don’t see in our day-to-day lives. For example, a normal egg-timer starts off full, and then gradually empties as the sand drains out. The quantum equivalent, at the atomic scale, is completely different. A radiation pulse will cause an atom to transition between excited and ground quantum states, like the egg timer.

Because in quantum mechanics energy comes in lumps, or ‘quanta’, after a pulse of appropriate length, the atom is found with equal probability in the excited state or in the ground state. The pulse has placed the atom in a ‘quantum superposition’ where it is in both the excited and ground states at the same time. The atom can be considered to be a ‘qubit’ - the quantum equivalent of the classical computing bit.

6. How is quantum computing different from normal computing?

A bit used on normal, or ‘classical’ computing, is only ever in one of two binary states, 0 or 1. Because of superposition, a qubit holds much more information. In a quantum computer, parallel processing over many qubits in superposition can give huge benefits over classical computers for some computations problems.

7. What is quantum supremacy and why does it matter?