MORE NEWS.

MORE MEDIA .

MORE INSIGHT.

MORE NEWS.

MORE MEDIA .

MORE INSIGHT.

The Manufacturer Digital Briefings are published twice weekly for the latest information, innovations & insights in manufacturing, sign up now.

j.devonshire@hennikgroup.com

The time has come for me to set the tone for the latest issue of The Manufacturer magazine. And having already heard from my colleagues, Joe, Tom and Lanna, in this column already this year, what big shoes I must now fill (quite literally in Tom’s case). But what should I talk about? Ah yes, how could I touch on anything other than Manufacturing and Engineering Week 2023, which I had the privilege of attending in person? But that’s not all… I also want to take the opportunity to tell you more about The Manufacturer Live coming up in November.

Even though it took me around 20 hours to travel the c. 6,500 miles from the Philippines (the place I call home) to the UK, I’d do it again tomorrow to attend Manufacturing and Engineering Week. This year’s event was A-mazing, with so many highlights that I couldn’t possibly do them all justice in 500 or so words. So, I’ll focus on a few that really stuck out.

First, SME Growth Summit, which I sat in on over the two days. Those of you who know me well will know that my father used to have a small engineering company in Somerset when I was a child. Some of my fondest memories were spent growing up there and I even did a week’s work experience on the factory floor (despite my hands being much more suited to writing than welding). So to say I’ve always had a soft spot for small businesses is an understatement.

We heard from Verve4Growth’s Ian Parker, Autodesk’s Asif Moghal and i3 Group’s Oliver Buhlinger, to name but a few of the esteemed speakers, each providing food for thought for the various SMEs in attendance. But what makes SME Growth Summit so special is its interactive discussions in between the keynotes. These sessions give SME leaders an opportunity to air their challenges and hear how businesses like theirs are working to overcome them.

It's this mix of insightful keynotes and intimate discussions that make SME Growth Summit so valuable. You can read more about this year’s event in my feature on page 6

Those of you who follow our LinkedIn account will likely have seen another highlight of mine: being force choked by Darth Vader on the Smart Factory Expo show floor. Darth’s presence at the event was to help promote another SME, Prove Anything, which was exhibiting on Made Smarter Innovation Alley.

But while Lord Vader was a very clever marketing gimmick, he was there to highlight how Prove Anything’s solution can help identify potential manufacturing flaws in products (like the first Death Star had). Co-founder Glenn Shoosmith explained to Tom and I how Prove Anything could have potentially prevented the Death Star’s demise (whether that’s a good or bad thing depends on your Star Wars allegiance).

Finally, we recently announced The Manufacturer Live, taking place in Liverpool this November. With Smart Factory Expo now a core component of Manufacturing and Engineering Week, The Manufacturer Live is the new brand under which several of our other key offerings now sit.

Taking place on 14-15 November at Exhibition Centre Liverpool, The Manufacturer Live will give delegates the opportunity to enjoy a series of award-winning events, including The Manufacturer Directors' Forums and the Manufacturing Leaders’ Summit. There are also two major celebrations of the best industry can offer, starting with The Manufacturer Top 100 Networking Party and finishing with The Manufacturer MX Awards. It’s already shaping up to be another amazing event. For further information, please visit info.themanufacturer.com/the-manufacturer-live.

DE C @TheManufacturer

Please note that points of view expressed in articles by contributing writers and in advertisements included in this journal do not necessarily represent those of the publishers. Whilst every effort is made to ensure the accuracy of the information contained in the journal, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrieval system or transmitted in any form or by any means without prior written consent of the publishers.

To receive your copy email: memberships@hennikgroup.com, telephone +44 (0)20 7401 6033 or write to the address here.

Hennik Research Limited (part of Nineteen Group), 1 Alwyne Road, Wimbledon, SW19 7AB

Tel: +44(0)20 7401 6033 Email: info@hennikgroup.com www.hennikgroup.com www.themanufacturer.com

The Manufacturer’s editorial advisory board provides insight and guidance to the editorial team on a regular basis, helping maintain the relevance and quality of the magazine’s content, both in print and online. The board also provides diverse and expert comment on strategic developments in manufacturing.

Board members also advise on other The Manufacturer products and online publications, such as the Annual Manufacturing Report. Membership is by invitation only, but if you would like to be considered, please email j.bush@hennikgroup.com

Andrew Churchill EXECUTIVE CHAIRMAN

JJ Churchill and The Manufacturer Top 100, Exemplar 2014

Chris White

DIRECTOR OF INDUSTRIAL POLICY Manufacturing Technology Centre

Thomas d’Arcy INNOVATION LEAD

Rolls-Royce plc. Young Manufacturer of the Year, TMMX Awards 2017

Sarah Black-Smith

HEAD OF FACTORY OPERATIONS

Siemens Digital Factory, Congleton

Deirdre Fox DIRECTOR OF STRATEGIC BUSINESS DEVELOPMENT Tata Steel

Dave Mooney

MANAGING DIRECTOR Drallim Industries, and The Manufacturer Top 100, shortlisted 2014

Jan Ward CEO Corrotherm, and The Manufacturer Top 100, Exemplar 2014, current Judge

David Holmes

MANUFACTURING OPERATIONS DIRECTOR MAI BAE Systems and The Manufacturer Top 100, Exemplar 2017

Christopher Greenough

CHIEF COMMERCIAL OFFICER SDE Technology, and The Manufacturer Top 100, Exemplar 2016

Paul Gadd

DEPUTY DIRECTOR, LAND & MARITIME TRANSPORT, MANUFACTURING & MATERIALS

Innovate UK

Roy Haworth ENGINEERING INTEGRATION MANAGER Airbus Defence and Space, and The Manufacturer Top 100, Member 2016

Laura McBrown MANAGING DIRECTOR G&B Electronics and The Manufacturer Top 100, Member 2016

The Manufacturer team is also proud to be acknowledged for the following…

SME Growth Summit 2023

10 100 years of improving life in the home We pay a visit to Whirlpool

14 Cloud data achieves clear visibility Kingspan explains how it is maximising its data

16 A company on its mettle when it comes to the environment We speak to Swedish steel manufacturer Ovako

20 Batteries included A key role in the future of industry

24 All you need is less Boosting carbon efficiency across manufacturing supply chains

28 Vaccine or virus? Your culture is crucial for recruitment and retention

SME Growth Summit, part of Manufacturing & Engineering Week 2023, saw the strategic leaders of UK SME manufacturers come together for two days of idea sharing and problem solving to drive development of strategy, product and the workforce. The Manufacturer's James Devonshire looks at some of the highlights from the event’s keynote speeches and discussion sessions

Manufacturing organisations are undoubtedly going to experience strong headwinds over the next two to three years (maybe longer). And while many larger companies will be able to successfully navigate these challenging conditions, smaller organisations may find themselves struggling.

If SMEs – often referred to as the lifeblood of the UK economy – are to weather the storm, they need to be focusing on areas such as talent, sustainability, digital transformation and supply chain resilience.

That’s why events like SME Growth Summit, which are designed to equip SMEs with the tools and knowledge they need, are so pivotal.

Asif

Moghal, Director for Market & Industry Development, Autodesk

One of the really great things about the work I'm privileged to do is I get to travel around and meet small to medium sized design and manufacturing companies and have conversations with them about how things are going. I think it's probably the greatest part of my job because I get to meet some innovative, ingenious, resilient people in companies who are doing something they really care about.

Now, despite a huge amount of diversity,

there are a few things most of these businesses have in common: they all want to make better products; they all want to sell more to new markets; and they all want to generate greater levels of value.

But something we've all observed recently are the challenges being faced. The conversations I've had with SME leaders have been about how they are coping. While all are trying (with success in some cases), others are struggling. And generally, this is where we see digital technologies as a potential route to overcome those challenges so we can get back to doing what we care about.

However, these SME leaders tell me that as soon as they mention the word ‘digital’, they are bombarded with an absolute avalanche of jargon, terminology, buzzwords and theory. This means nothing and many SMEs are fed up with hearing this technical babble.

Digital transformation is a journey and it’s our belief that digital transformation doesn't need to be difficult. There are some repeatable steps that we've seen

time and time again, which will answer the question of where to start.

Firstly, don't start with technology. People don’t tend to come to us wanting to buy a data management, PLM or ERP system. They come to us because they have a problem.

So, rather than start with technology, it’s better to sit down with your leadership team and ask three questions: Where are we today on our digital journey? Where are we today in our ability to serve our market and our customers? And what's stopping us getting to where we want to be? This is a critical question because it feeds into step two.

Next, think about what capabilities would allow you to get to where you want to be and address those challenges. Is it the ability to flexibly customise your products or services for individual customers or segments of your market? If you can do that, you can charge a premium for it – up to 20% more.

Is it the ability to collaborate inside and outside of your business flexibly with increased speed, quality and effectiveness? Because that dramatically increases your chance of innovating.

Is it the ability to flexibly produce anything that comes in the front door of your offices, whether you do it in-house, through your supply chain or distributed?

Is it the ability to boost your engagement with your customers, so you have an elevated level of customer experience?

Or is it the ability to put data at the centre of your business and use it to create insight-based value-add services for your stakeholders?

We recommend you think about all these capabilities before you even consider technology. Connecting all these together is what can lead to digital transformation. And you don’t have to do them all at once; but you do have to understand where to start.

If you identify one of those five capabilities as being a game-changer for you, then focus on that and develop a strategy around it. But remember that you need to work with people - your employees, stakeholders and partners like us.

My call to action is to check out our British Manufacturing Initiative and all the resources that are there. We are looking for five SMEs that we are personally going to hand-hold through this process.

One of the biggest challenges for SMEs is competing on the national and global recruitment market, not only with each other, but with blue chips that have deep pockets and might be very attractive to talent. For SMEs to be competitive they have to think differently, innovate and point out what they have that others might not.

Diverse workforces and diverse teams breathe more innovation. That’s why we’ve focused on bringing a diverse team together and driving innovation that way. But while we’re still seeing under representation in manufacturing, for example, with the ratio of women in STEM roles, how do you attract more diverse talent into your organisation?

One of the keys is to be more inclusive; looking internally and externally at what we can do to attract different genders, people with disabilities, etc. as they will bring value to us.

The behaviour of people and what drives them is changing. If a role can be performed remotely, then why not consider offering hybrid working where possible. It’s a quick and easy way to differentiate yourself and make you more attractive than other companies – even the big blue chips.

SME leaders tell me that as soon as they mention the word ‘digital’, they are bombarded with an avalanche of jargon, terminology, buzzwords and theory... and they are fed up hearing all this technical babble

Asif Moghal, Director for Market & Industry Development, Autodesk

Adam Crowe, 3Dental

You might have three of four different pieces of software or technology in your business, and it can present a challenge pulling them together to create a holistic view of what’s going on.

One of the main reasons businesses want to build a digital transformation strategy is so they have information at their fingertips which allows them to make timely, impactful decisions.

Tim Lawrence, Made Smarter Innovation

We explored some of the challenges SMEs face when it comes to data. One of the most prominent was the vicious circle many encounter; I need the right data but how do I gather the data that I’ve captured and what is the value of that data?

This is particularly true if you have supply chain challenges and want to capture data relating to your customers and suppliers. The same goes for your factory where you want to take advantage of data but aren’t sure which sensors to utilise or where to get the data from so you can start analysing it.

James Crosby, Advantage Utilities

We looked at what sustainability means from both an individual standpoint (what it means to you) as well as what it means for your business, which can often be different. We then dived into some of the drivers for why you should look at being sustainable, which vary from simply doing the right thing to marketing purposes and demand from your customers and suppliers. And finally what are the barriers for SMEs achieving their sustainability goals?

Laura McBrown, G&B Electronics

We discussed some of the challenges of family businesses and culture. There was a lot on how you instigate change from the middle, particularly if you’ve got a director-level group that isn’t displaying the best example of what you want to achieve.

We also talked about the experiences people have had with family businesses and how they’ve created a safe learning environment to enable their people to grow.

Joe Walton, Michael Page

On the attraction piece, there was a big emphasis on process. Candidates are often looking for different things, so how do we adjust our processes to (a) get them through the door and (b) add to our culture, not remove from it.

The retention piece was inwardly focused. Once you’ve paid a recruitment fee, how do you keep the individual in your business for a period of time? A lot of the answers weren’t new, they were mainly about how do we get back to some proper leadership and management skill sets? Feel the pulse of your teams and understand what they want because people often don’t want the same things, which is where you can tailor your retention offerings.

Claire Turnbull, Seatriever International Holdings

Whether we are talking about automation from a machine or systems perspective, we mustn’t forget that people are still key to the success of any project and ensuring the business realises the gains. Automation often causes problems with people thinking it could take their jobs, and we discussed how to overcome these obstacles.

Diversity isn’t about division – despite what some people would have us believe – it’s about unity. And when we are looking to bring a diverse team together, we’re looking to create harmony (if we do it the right way), which breeds productivity.

It can also be powerful to bring more diversity into your leadership teams. That way, potential talent can see itself in senior positions and making a real difference to your business.

As with many aspects of business, if it gets measured, it gets managed; and the same goes for attracting talent. By adopting an approach that utilises data to inform your decisions and drive your efforts, you can achieve your vision.

Try to get your people on board with your vision and show them the role they will play in helping you achieve it. When people see how they can and will be making a difference to your organisations, it gives them a boost.

Ian Parker, Managing Director, Verve4Growth:

Back in 2012, I set up Verve4Growth to offer transformational services to manufacturing SMEs, generally under family, corporate or private equity ownership. And my introductions to businesses usually come

How can SMEs be competitive? Well, it's about thinking differently, innovating and pointing out what you have that others might not

Oliver Buhlinger, Head of Technology, i3 Group

via the banks, the advisory community and those interim providers that specialise in transformation, and there are a few of them.

The common thread is that the businesses all face challenges at the time of my introduction, and these challenges were unresolved and capable of putting the firm's viability at risk.

In the last ten years, I've undertaken 14 projects for clients as diverse as a familyowned custodial metering skid provider in Gloucestershire. Said business needed to ship an £8.5m skid on a certain day in August and if it didn’t, it would have gone bankrupt. Such a situation focuses the mind somewhat.

SMEs are very much the unsung heroes of the UK economy. According to national business statistics, there are 1.4 million SMEs with employees in the UK. Statistics will tell you there are 5.5 million SME businesses but only 1.4 million actually have an employee, an interesting fact in itself. And all those 1.4 million SMEs account for 53% of private sector employment and 47% of private sector sales. The vast majority of SMEs have fewer than 50 employees and only a resilient few make it into that medium gap of 50 to 249 employees.

There's no doubt that the last few years for all of us in industry have been extremely challenging. We've had to cope with Brexit, COVID and supply chain shocks. We're coping with war in Ukraine and what it's done for energy prices.

We’ve also had a fair amount of political turmoil in the last six months and if you've got a pension fund in your portfolio of assets, you'll see what will happen to the valuation of defined benefit pension schemes as a result of that new budget. And of course, we're living with high inflation at the moment.

The real question however, is whether we’re ready for what could happen next. We're all familiar with the classic business growth cycle. A firm starts, it survives and grows, and at some point reaches maturity. But in a fast-changing world it's inevitable that some will decline, get into difficulties and die. Turnover is always the driver in the launch and growth phases, and profit and cash generation are often thought of as being less important in those early stages of sales growth. And

sadly, many good compelling businesses runs out of cash in that dash for growth.

My version of the classic lifecycle is slightly different. Yes, we share the five stages of growth - creation, survival, take off, success and maturity - but I add five more stages which are known in my profession as the decline curve. A business is in trouble but not yet aware of its problems; is in trouble but is still in control; has completely lost control; has lost the business and is entering insolvency.

The first two stages of the decline curve are perhaps the most critical. The business is in trouble but all too often management is not yet aware or in control of the situation. And in the early stages of decline, it's much easier to change the trajectory, rescue the business and achieve a better outcome for all stakeholders.

When challenge strikes, outcome depends on management's willingness to recognise that the business is potentially in distress. My key message is keep an eye on your cash flow. Cash is the commodity in any business. Very few SME businesses, in my experience, have adequate cash flow forecasting processes. But when challenge strikes, a rolling 13 week cash flow forecast is vital.

Cast yourselves back to 2009 when Jaguar Land Rover (JLR) nearly went bankrupt. No one on the board at JLR understood cash and they had to bring in KPMG to run their daily cash management processes. Cash is one of those commodities that people in corporate life are used to turning to the treasury and saying, 'I need a bit more this month'. If you're an SME, and you've got to make the wages at the end of the week or month, that really does focus the mind on your cash availability.

SMEs today are operating in profoundly challenging times. Events happen faster and a business can be rapidly undermined. Be aware of the signs of trouble ahead. Understand your business's rolling 13 week cash flow forecast. What is driving the changes in business outlook? Are you seeing a trend or a blip, and if the business is in trouble, reach out for help. Talk to your bank and other key stakeholders. Time is a critical factor in finding a pathway to success. And lastly, leading turnarounds and transformation is a skill engaged with an experienced, accredited partner. We can provide management teams with help and support. Remember, it takes cash, time and help to find a pathway to success. l

In the early stages of decline, it's much easier to change the trajectory, rescue the business and achieve a better outcome for all stakeholders

Ian Parker, Managing Director, Verve4Growth

The Manufacturer’s Lanna Deamer paid a visit to Peterborough-based Whirlpool, one of the largest global manufacturers of kitchen and laundry appliances. The company’s journey began with the development of the first electric motor-driven wringer washer in 1911, marking the humble origins of Whirlpool

Over the years, the company has continued to pursue innovative ideas and create products that it believes will make a positive impact on the lives of users. With manufacturing and research centres spread across the globe, Whirlpool remains at the forefront of technological advancements.

The company has expanded its range of appliances to encompass every facet of the kitchen, including ovens, dishwashers, hobs, and of course, laundry appliances.

While you may not think you own any Whirlpool products, you probably do as the company is also home to the brands Hotpoint, Indesit and Kitchen Aid. More than 27 million kitchen appliances manufactured by Whirlpool are in homes across the UK. The white goods manufacturer is headquartered in Peterborough and houses a dedicated team of 1,000 staff members who undertake various crucial tasks related to customer interactions.

This includes handling customer enquiries, diagnosing issues with tumble dryers, washing machines or fridges, performing repairs either remotely through phone support or dispatching engineers for inperson assistance, as well as managing product deliveries and retrieval of old appliances.

Within the Peterborough site, there are specific areas designated for different operations. The site accommodates 350 call centre employees, a reprocessing and recycling centre, an engineer training academy and a factory outlet. The outlet offers repaired machines to both staff and the general public at significantly discounted prices.

Given the substantial presence of Whirlpool products in people's homes, it comes as no surprise that customer service is of utmost importance to the company. During my visit to the site, it was clear to see that Whirlpool is committed to prioritising exceptional customer service, ensuring that its customers receive the support they need when dealing with their appliances.

Ian Moverley, Head of Communications, Government Relations at Whirlpool UK said: “From a digital standpoint, we have observed significant transformations in how people purchase our products and engage with us, especially when they require customer service. There has been a substantial increase in individuals reaching out to us through various digital channels, extending beyond conventional

phone calls. We now utilise platforms such as WhatsApp, Facebook, and Twitter to provide assistance and information.

“Additionally, we have introduced a chatbot that effectively guides consumers, offering round-the-clock support for their enquiries and requirements. We understand that despite the presence of automated assistance, some customers may still prefer speaking directly with our team. In such cases, we are readily available to provide the necessary support and address their concerns. Our goal is to ensure that customers receive the assistance they need, precisely when they need it, leveraging the convenience and accessibility of digital channels while maintaining a human touch when required.”

The company’s vision is to be the world’s best kitchen and laundry company, in constant pursuit of improving life at home. Whirlpool believes that home includes the planet that we all live on.

And the manufacturer’s commitment to sustainability and environmental responsibility is shown through the actions it has taken in the UK.

Whirlpool has committed to reach net zero across all plants and operations by 2023.

• Single use plastic removed from all UK sites (bottles, cutlery etc.)

• Zero waste to landfill at the Yate manufacturing plant and Peterborough HQ

• Recycle every part of the old appliances collected as well as the packaging of new ones

• Partnered with Youreko to show the lifecycle cost of new machines, which enables consumers to make the most efficient choice for them

• Green energy used on all 14 UK sites

• Biofuel now used for on-site vehicles (such as forklift trucks)

• Started a journey to switch all delivery and service vehicles to electric power

• Safely remove all harmful gases from old refrigerators before recycling them

• Reduced emissions linked to the use of Whirlpool products by 60% since 2005 and committed to a further 20% reduction by 2030

Earlier this year, Whirlpool, with its brands of Hotpoint and Indesit, announced that in the last 15 years over 850,000 appliances have been refurbished or recycled through its on-site processes at the Peterborough site.

Ian commented: “In the last 15 years we have made great strides in moving towards a complete circular production process. Eighty-five percent of what has passed through the site has been given a second life, with the remaining 130,000 units recycled by our on-site partner.

“We have also collected a further 165,000 tonnes of appliances to be recycled since 2010, providing the opportunity for the materials to be reused in new products; as well as opening three in-house factory outlet stores that are open to the public in Peterborough, Gateshead and Yate. We hope to open our fourth by the end of the year.

“We have for many years responded and adjusted to the growing demand for right to repair and offered greater access to more cost-effective appliances. The 15 year WEEE

We have collected 165,000 tonnes of appliances to be recycled since 2010, providing the opportunity for the materials to be reused in new products

anniversary provided us with the perfect milestone to share just how responsive we have been, and will continue to be, to meet the demands of today’s consumer.”

Whirlpool is well on track to achieve its goal of becoming net zero by 2030, and is actively exploring opportunities to incorporate solar panels, wind power and other sustainable alternatives across all UK sites. Although the recent energy crisis has posed challenges, the white goods manufacturer remains committed to making consistent improvements year after year.

“For other manufacturers embarking on their own net zero journey, my foremost advice would be to engage your colleagues and foster their understanding of the path ahead. It is crucial to involve them, as their actions and contributions, no matter how small, can make a significant difference. Net zero progress is not solely driven by company decisions, but also by the collective efforts of every individual within the organisation,” suggested Ian.

The tech side of things

Touring the Whirpool showroom, we got to see some examples of the latest innovative tech on display. The new induction hobs, with CleanProtect technology, feature an innovative nanocoating that allows you to easily

clean your hob with just a spray of water, while protecting it from tough stains and still keeping a shiny finish over time.

We also got the opportunity to see the GentlePower technology in action which carefully sprays water onto your laundry (like a waterfall) but still giving a thorough wash, while optimising water and energy use by 65% and 59%.

As a manufacturer, one of Whirlpool’s primary focuses is the development of connected products. However, it is crucial to ensure that consumers can comprehend the tangible benefits offered by each product. It goes beyond the potential energy and water savings; connected products have the ability to provide guidance on maximising product performance and enhancing overall efficiency.

Ian went on to say: “The concept of serviceability is closely linked to this. By understanding when a product displays symptoms that may require a technician's assistance, consumers can make informed decisions. Key product innovations we are witnessing include continuous improvements in energy and water efficiency, as well as reduced noise levels. Our approach has been to diligently identify the consumer's priorities and develop innovations that meet those specific needs, rather than merely introducing new features for the sake of novelty.”

The UK continues to face an enduring manufacturing skills shortage, which is a cause for concern. As an increasing number of schools prioritise higher education over vocational learning, there is a potential risk of inadequate training for highly skilled manufacturing roles. This not only results in skills shortages affecting various industries but also hinders overall economic growth.

While the UK boasts one of the highest university attendance rates globally, it also grapples with significant skills gaps in technical domains, including

Scan QR code for a video of the visit to Whirlpool

We have for many years responded and adjusted to the growing demand for right to repair and offered greater access to more cost-effective appliances

Ian Moverley, Head of Communications, Government Relations, Whirlpool UK

manufacturing. Addressing this disparity becomes essential to foster a well-rounded and thriving workforce capable of meeting the demands of the manufacturing sector and supporting the nation's economic progress.

Ian concluded: “Undoubtedly, we have encountered challenges when it comes to attracting the specific talent we desire. However, at Whirlpool, we have observed that once individuals join our organisation, they discover the numerous opportunities and potential for career growth available to them. As an example, I have been a part of this company for 27 years, and during my tenure, I have had

the opportunity to explore different areas, enabling me to develop new skills and expand my capabilities.

“When it comes to attracting the younger generation, we are actively highlighting the strength of our brands and our strong focus on sustainability. We recognise that these aspects hold significant importance for many individuals. Additionally, we are dedicated to assisting them in building a fulfilling career, as we understand the value of clear career development pathways and the ability to envision their professional growth within the organisation.”

• Whirlpool is focused on developing connected products that provide tangible benefits to consumers

• Whirlpool has taken various actions in the UK to reduce their environmental impact

• To address the skills shortage, the company emphasises attracting and retaining talent through highlighting the strength of its brands

Ireland-based materials manufacturer Kingspan has recently deployed AWS accelerator solution, AMP, from Storm Reply to help the company maximise its data. We caught up with John Neary, Automation Manager of the company's Insulated Panels Division, to find out more

Founded in 1965, Kingspan’s building materials business has grown into a €8.3bn revenue company with over 200 manufacturing sites worldwide. In 2019 the company also opened its IKON Global Innovation Hub, dedicated to finding innovative solutions for sustainability, performance and efficiency in construction.

Following a previous spell with the company, John got a call to return to Kingspan in 2019, rejoining in 2020 just prior to the outbreak of the COVID-19 pandemic. Despite the obvious upheaval, John explained that the lull around projects and deadlines caused by the pandemic, allowed the company to dedicate time on other areas of the business.

“We still implemented projects globally, but they were far less in number,” he

commented. “However, this helped us with the standardisation of operations across the business, something we're seeing the fruits of now. As a company, we want to develop not only our products, but also the environmental element of the business, and we have a large, growing team that are enabling us to do that.

“We want to be able to manufacture and deliver equipment built and designed by us. For example, our chemical systems, from a product perspective, are all built in-house to retain IP.”

John explained that as the business has grown, so data has become increasingly integral to Kingspan’s strategy. In the past, the limited amount of data generated by the company was tied to statistical process control (SPC) systems, which helped the company harvest and store the data onpremises, but little else.

He added: “Our data was quite scattered in the sense that the plant in Ireland would be completely different, from a data perspective, to one in England. Again, with the lull caused by COVID those systems subsequently became obsolete and we ended up with a number of old operating systems running in the background. For example, Flash became a security risk.”

It was then that Kingspan had the opportunity to invest with Storm Reply on using SPC obsolescence as a tool and pipeline to start harvesting data up to the cloud. The company is currently working with Storm Reply on building out that offering. In addition, Kingspan also engages

directly with Siemens and Mendix from an Amazon perspective.

From an infrastructure point of view, the company has removed on-premise servers and the requirement for their maintenance. This has been done by the deployment of a simple edge device connected to a PLC, and this can also be supported remotely through Amazon Web Services.

“By putting data into the cloud we can standardise our whole system,” continued John. “So, a transducer in Kingscourt, Ireland, will be the same as a transducer in Pennsylvania. This means we can start comparing the two. Beforehand that would have been extremely difficult and would have involved trying to use Excel spreadsheets downloaded from a database. The fact that it’s now in the cloud means our people can run a report on both transducers and compare them from two different plants; everything is a lot more interconnected and streamlined.”

Legacy historian, SCADA and statistical process control systems hold companies back from making data driven decisions, and while Kingspan has begun the journey to the cloud, it’s an issue the company is wrestling with.

The company still has legacy systems in place and is currently working through 22 ‘brownfield’ sites that have to be removed. These involve normal legacy IT issues where data is still being generated by those systems day-to-day, but running reports against that data is proving difficult.

“It’s only when we gather more data that we’ll really start to see the benefits,” John added. “And we're still very much in the infancy stage of this journey right now. We're starting to collect additional data from condition monitoring sensors etc that we didn't have with SPC systems, but we're also still running legacy servers to capture some of that data in some cases.”

With regards to data collection, Kingspan had many locations with a physical server on-site. That data had to be held for a certain amount of time which was proving a challenge in itself. The servers had to be kept stable and patched, and server downtime was taking up a lot of engineering resource.

“That resource has now been freed,” added John. “And we've also reduced our capital expenditure costs for those systems, because we're not having to buy them, (the servers, licencing etc). It's now more of an OPEX cost in terms of the data that we're

harvesting, and if the line goes down or we shut a plant. It means we haven't made an investment in a service which has then become redundant.

“Cloud has enabled me to see into my own team. I had two people in particular dealing with SPC; one has now moved into an automation lead role while the other is working with Storm Reply and AWS. I've theoretically reduced headcount in that area by moving onto the cloud-based system. We’re actually recruiting more people around the cloud piece so that we can bring the Amazon system to the next level ourselves. From a maintenance point of view, it's taken a huge headache away from us and freed up resources.”

To cloud or not to cloud

John explained that in terms of exactly what machine data is stored in the cloud, it is machine and company dependent. Currently, Kingspan’s flow, pressure and temperature data is stored on AWS cloud but there are set points from a machine perspective, that are on a HMI-based system for setups etc.

The company’s ultimate goal is to use its Amazon systems and AI to help predict failures and quality issues etc. Although it is a number of years away from that scenario, Kingspan is already working with Storm Reply on a proof of concept (POC) and Amazon on a profile system to make sure the company is heading in the right detection.

“At Kingspan, cloud, data and seeing what it can do is new for us,” said John. “We're very much a business that likes proof before we invest heavily in something. With those smaller investments we can start to answer those key questions around whether we implement predictive maintenance in the cloud; can we use the data from our machines to predict failures of pumps, motors, etc?

“Without Storm Reply we didn't have the expertise or the know-how to get these projects started; we had zero experience. Without them, we wouldn't be where we are now. They're going to work on the next POC with us to find a solution. And it's going to be based around the same developer master system that can then be rolled out to all of our plants without heavy investment thereafter.

“We want to start using our data in a meaningful way and want to make sure that if a piece of data goes out of spec, then we know what impact it has on our product. We’re working with Storm Reply on implementing a quality system in the cloud.

“From an engineering perspective, we would love the data to be able to tell us a product or piece of equipment is perfect, or when it needs a maintenance check. We also want it to develop into an MES system, using the data we're collecting, and link it to SAP and NetSuite. That will mean, from a production line perspective, if a global engineer installs a production line in any area, we ensure we’re offering the full package from an installation, engineering and operations point of view for the whole line. And that's where the cloud and Storm Reply will come in.” l

For more information visit: www.reply. com/storm-reply/en/amp-iot-solution

By putting data into the cloud we can standardise our whole system; everything is a lot more interconnected and streamlined

John Neary, Automation Manager, Kingspan

My alarm went off at 6.00am. Bleary eyed, initially confused at my surroundings, I squinted around the room that was filled with bright sunlight. In May, the sun stays high in the sky for most of the day in these parts. “Ouch,” I said forlornly, as a heavy, searing pain crept across my forehead and remained there all morning. I had woken up in a hotel room provided for us by our hosts at Ovako, who the night before had put on quite a show.

Slowly, flashbacks of the night before entered my brain, and I remembered what had caused me to lay here unable to move. “Schnapps!” Shouted Patrik Olund, Group Head of R&D at Ovako. “Every time we sing a song, we take some schnapps.” And there were a lot of songs. A couple were in Swedish, one was in Finnish and was impossible to sing and others were to the tune of ABBA songs, but with the lyrics changed.

Example: The CEO and I, to the tune of The Winner Takes It All. First line: “I don’t want to talk, about administration.”

Before the starter had even arrived, we’d sung at least six songs, with Patrik taking the lead with incredible vigour. Looking back, I think he may have written the lyrics to a lot of these songs himself.

Sat to my right was my colleague, Lanna Deamer. “What is actually in Schnapps?” she asked, looking tentatively at the size of the shot glasses in front of us. I took a sip of mine: “Bad stuff,” I replied. “You can have mine,” said Lanna.

It turns out you can pick up quite a lot from a two-day trip to Hofors in Sweden. A boozy three-course meal complete with schnapps and a sing-along; a full and thorough explanation of world class sustainable manufacturing; a tour of the world’s first hydrogen steel plant; and this article you’re about to read, written by The Manufacturer’s Tom St John

Then the lady sat to my left passed me her schnapps and announced, “I’m driving.” In a bid to immerse myself in the culture and to not appear rude, I saw off the schnapps from either side of me… it was a poor decision.

Still lying in bed, knowing I’d eventually have to attempt sitting up, I thought back to the start of the night. Sitting out on a balcony enjoying conversations with members of Ovako as well as a handful of UK press that had come along on the trip, John Larsson, Vice President Marketing & Sales at Ovako announced: “As well as being great at making steel, we are really good at refilling drinks.” Several times, the man dashed to grab me another beer upon noticing I didn’t have one in my hand.

Then, after dinner, and after singing our way through what felt like most of Abba’s back catalogue, we ended up in a downstairs room with loud music where I had some Swedish whiskey. Just after the point of talking utter gibberish, but slightly before offering to break dance for everyone, I decided it was time to leave the party and stumble across the road to my room.

The following morning’s walk from our hotel across to Hofors Bruk, the name of the site where the Ovako steel plant is situated, was only 15 minutes or so. John Larsson had said goodbye to us at the hotel – he was very much around for the drinking, but left when it came to the sensible stuff, a decision I had great respect for.

However, Patrik was on hand to show us around and eagerly informed the group that we were in an area of engineering heritage. Evidence has been found that manufacturing was taking place in Hofors around 2,000 years ago, with some highquality forged iron being uncovered close to the site.

“This was a steelmaking facility as early as the 1500s. The Hofors Bruk site was founded in the 1600s. From then on, we’ve had a very long and continuous steelmaking tradition here,” said Patrik, whose ability to get a party going was matched only by his knowledge and passion for Ovako.

“We are a steel company, specialising in what we call engineering steel, used for demanding applications. We’re perhaps most famous for the bearing steels that we produce, which we supply to companies all around the world.

“Bearings is a very important market for us, but we’re also involved across the whole of the automotive industry, plus we’re very active in the mining and rock processing industries.”

The site was enormous. The Hofors facility is the company’s hub, with production in steel and billet rolling mills and in tube and ring mills.

Demands on high-performance steel components have increased over the years, having to cope with higher loads for everincreasing periods. Ovako’s clean steel, produced at this site, has evolved to meet these tougher requirements.

You’re probably wanting to hear more about the ‘hydrogen steel plant,’ mentioned at the top of this article. The clean steel is a product of this, but we’ll get to that shortly. It’s important to set the scene when it comes to Ovako’s sustainable credentials as this is a company that has always had circularity at its core, going back hundreds of years.

Due to the very material manufactured by the company, it realised early on that it could do more with less. Steel is 100% recyclable, which means that you can continuously remelt it while keeping the same quality. For every newly produced tonne of steel using recycled material, 1,100kg of iron ore and 600kg of coal can be conserved as well as energy savings of 74%, compared with the same process using raw materials. “It’s an amazingly unique material,” said Vendela Stenuis, Sustainability and Communication Specialist at Ovako.

“Sustainability has been with us for our entire history,” she said. “We were using the circularity process - remelting steel scrap

Sustainability was being practiced at Ovako before it even became a word in the dictionary Vendela Stenuis, Sustainability and Communication Specialist, OvakoABOVE: Patrik Olund, Group Head of Research & Development, Ovako

to make steel - here in Hofors 500 years ago. Sustainability was being practiced at Ovako before it even became a word in the dictionary.”

The same steel scrap process is used today. Of course, in 500 years the process has been refined and improved upon. In 2012, Ovako started the conversion from fossil fuels to electricity in the heat treatment process.

Vendela continued: “We have a carbon neutral operation, but we do still have emissions, we know that. A year and a half ago, we decided to counterbalance our emissions with carbon offsets. We are the first steel company in the world that is carbon neutral in our operations.”

When asked what has spurred the company on to become so sustainably minded, she answered: “First of all, there is regulation. Much like UK companies, we have legislation to think about in Sweden.” The environmental policy in Sweden contains several climate goals, with companies actually having to act a bit faster than those in the UK. By 2045, Sweden is aiming to have zero net emissions of greenhouse gases in the atmosphere; five years sooner than the UK’s 2050 target.

“That makes us want to push sustainability even harder to stay ahead of that legislation,” explained Vendela. “Our success comes from a need to continually improve because we constantly want to push ourselves to be as environmentally friendly as possible.”

Ovako, like every other big manufacturer globally, is building all of its sustainable practices towards the end goal – net zero. It was interesting to hear from Vendela that Ovako’s time frames are pretty similar to most others. “We want to reach zero emissions. Of course, that's our long-term target. We're looking at 2030 to reduce them by 80% and in 2040 to reduce them by 90%.”

It gave me the sense of measured, sensible expectations. Ambitious, of course, but not overly so. The targets aren’t flashy, just for the sake of a headline. This will be done gradually, through continuously

improved processes. There is another key driver in this of course, as Vendela mentioned: “The hydrogen project will allow us to make a big step towards our targets.”

Hydrogen pioneers

That leads us on to the main event. First, we were taken to see Sweden's largest electrolyser for the production of fossil-free hydrogen. Then, we were taken into the furnace to see the manufacturing process up close. Not too close though or your face will melt off. It was absolutely roasting in there. I mean, of course it was, but I can’t stress enough just how hot it was. Anxiety inducingly hot. On the bright side, it went a long way to knocking the hangover out of my system.

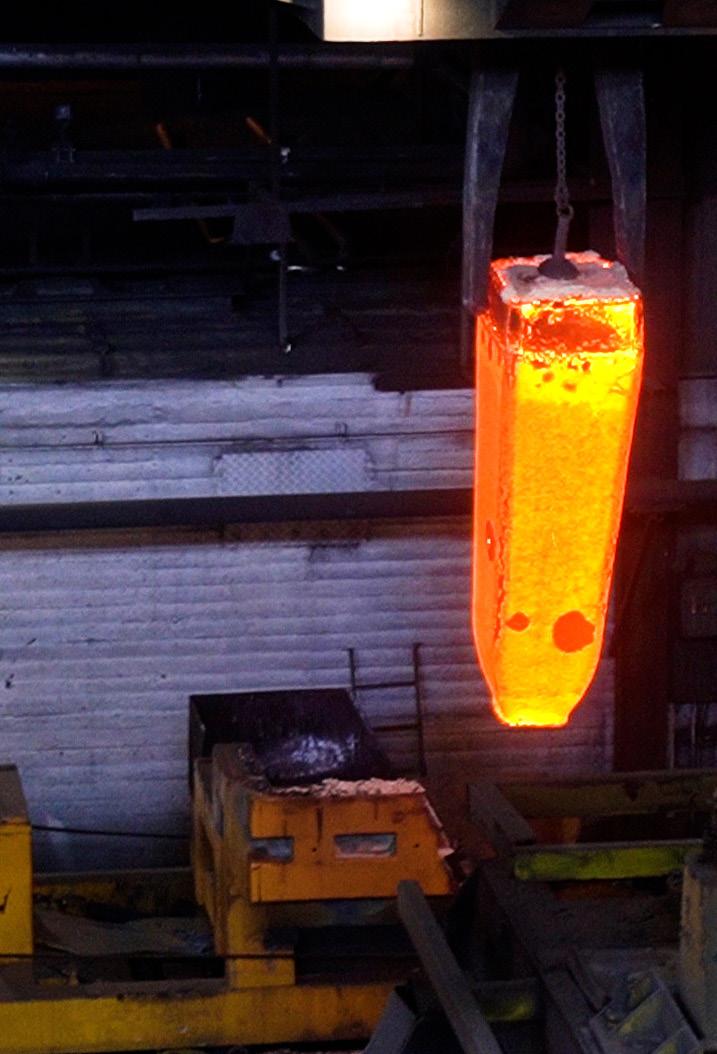

Large steel billets, so hot they were turned a molten lava shade of orange, were being lifted mechanically from the furnace across to the factory to be rolled. This is the most visually and physically exciting part of the manufacturing process.

After the scrap steel is melted down in the electric arc furnace that we were standing in, it’s then cast into ingots of about four tonnes each. The ingots are heated up before being rolled. This is the part of the process where hydrogen is introduced, making Ovako the first producer in the world to use this technology. “Once the ingots are rolled, they are then cut into pieces, before being taken further downstream in the process,” explained Mikael.

“We send some of these to the rolling mill in Hällefors, (a municipality to the southwest of Hofors) where we produce smaller sized steel bars. Others we convert into hot rolled rings and tubes. The tubes can also be cold in order to have even smaller dimensions and other mechanical properties.”

Every stage of the manufacturing process is electrified. The heating of the billets before rolling, the smelting part and also the reheating that takes place after rolling. Mikael added: “We have converted almost all furnaces worldwide to electrical heating.

LEFT: The hydrogen plant in Hofors will make Ovako the first manufacturer in the world to heat steel with hydrogen prior to rolling

We’re showing the world that you can exclude carbon dioxide from certain stages of the steel manufacturing process

Mikael Persson, Project Manager, Ovako

But to heat up the billet before rolling, you need to go to incredibly high temperatures, which is almost impossible to do directly with electricity.”

He continued: “So now, via electricity, we can switch from propane to hydrogen, which gives us a carbon dioxide-free fuel for the heating before rolling phase. We can now say that we’ve electrified all the steps in the steel manufacturing process and that it is fully fit for purpose. We’re not using any fossil fuels in our end products.”

Mikeal told us that trials for this project were first undertaken in March 2020. Lanna, recovering from the heat of the furnace, asked Mikael: “Did COVID slow this down?”

“Yes,” he replied, “COVID was picking up at this point, for sure. But still, we were able to continue the project. It felt slow, but that said, I don't know if we could have progressed any quicker, even without COVID, because there's a lot of preparation that needed to be done during testing.”

When quizzed on the tag of ‘hydrogen pioneers’, Mikeal added: “Have we been called hydrogen pioneers!? That’s a good one. The technology for producing hydrogen and oxygen is no secret. Electrolysers are used everywhere. The pioneering element of this is we’ll produce enough with hydrogen to supply all our furnaces. We also won’t have any storage.”

He added: “There are other hydrogen factories in the world, some big ones too. But they combine other processes which use fuels like petrol and so on. This is a big hydrogen factory within a steel plant, which uses hydrogen at the same time as it’s produced; no one has done that before.”

This is a project that has gained a lot of traction in Sweden, with partnerships from key players in Nordic industry such as Volvo Group, Hitachi Energy, H2 Green Steel and Nel Hydrogen. They are supplying Ovako with different components and technical solutions for the plant. The plan is to use local hydrogen production in all Ovako’s units where steel is rolled by 2030, provided there is a good supply of fossil-free electricity.

“By doing this,” concluded Mikael, “We can show the world that you can exclude carbon dioxide from this stage of the steel manufacturing process.”

This was a lesson in sustainable excellence, although, Ovako is still faced with a conundrum that UK manufacturers also regularly report – the management of Scope 3 emissions. “Scope 1 and 2 is easy,” said Vendela, chuckling. “They belong to us, but capturing and managing the upstream and downstream emissions of our customers and our suppliers is harder.

“We have a great relationship with them but getting that information and then working out a calculation of those emissions is tricky. They know what their Scope 2 is, but how much of their Scope 2 is our Scope 3?”

She continued: “We’ve committed to science-based targets, and this fall, (autumn) we need to get those targets approved and that includes Scope 3 emissions. So, we have planned for that, and we will manage to capture that data.”

This was almost reassuring to hear. No company is completely infallible when it comes to sustainability, how could they improve if they were? Words we heard often on this trip were ‘improve processes’, and there’s a clear trail of that when you look down the timeline of Ovako’s sustainability journey.

We bid adjö to our hosts, collected our belongings and were taken on the two-hour drive back to Arlanda Airport in Stockholm. This was an eye-opening trip to one of Europe’s genuinely inspiring examples of environmental progress. These guys make first class steel, but truly dangerous schnapps - I for one, would visit again.

• This is a genuine world-first technology for the heating of steel before rolling.

• Despite the metal’s recyclable qualities, the steel industry is a historically large carbon emitter. Ovako is one of the companies bucking that trend.

• Not touched on in the article, but Ovako has similar industry-wide problems when it comes to attracting diverse talent.

• Sweden is a beautiful country to visit during the spring and summer months. Just don’t drink the schnapps.

One only has to look at the meteoric rise in electric vehicles to know the role the humble battery is playing in our daily lives and in wider society. However, this is certainly not something you have to tell the team at Philadelphia Scientific. From battery handling and monitoring to watering and cleaning, the manufacturer provides a plethora of advanced technology solutions to the industrial battery industry.

The company specialises in the research, design, development and manufacturing of products for motive power, standby and automotive batteries, in addition to tools that maximise battery performance. Philadelphia Scientific serves a global marketplace from multiple locations around the world and are holders of an extensive patent inventory.

On arrival we were greeted by the wonderfully named Andy NapoleonHill, Philadelphia’s Sales and Marketing Manager, who showed us into the company’s Bolton factory, a former cotton mill. “We know if batteries are maintained properly and used as they're supposed to be, then they perform better and last longer, and we've been developing and manufacturing products that make that happen for nearly 40 years,” he said. “Typically, customers using our technologies tend to see an improvement in battery performance of around 25- 40%.”

It just got interesting!

Once settled in, the company’s Duncan Jones introduced himself, sporting a full cast on his leg and accompanying walking stick (the result of a baseball

injury). “It’s healing pretty well considering it only happened five weeks ago,” he told us optimistically. When he’s not trying to steal second base, Duncan is Philadelphia’s Founder and Managing Director, heading up the company during what has become a fascinating and exciting period.

Duncan explained that simply, batteries have traditionally been thought of as boring; a necessary set of products and technologies for many industries, but not one that elicited any kind of interest or passion from those that had to deal with them.

However, in the current climate, with the push towards renewables and energy reduction, all of a sudden, it’s a technology that people are becoming more familiar with. For example, there has been a recent push from industry towards lithium batteries, as they can boast fantastic energy density and can be charged very quickly. The drawback is that they are expensive and hard to recycle.

“People have therefore, been looking for alternative methods of making traditional lead acid batteries perform better,

as they are far more recyclable,” said Duncan. “We've been involved with this type of technology for a long time and our products help make those batteries applicable to new markets."

In addition, Duncan explained that nowadays consumers expect that high value products are also intelligent e.g., the average washing machine now comes with an app and a new car will have certain digital control systems. “Likewise, when people buy a battery, they expect it to have digital capabilities too. That's been very useful for us as we make tools that make that possible.”

One such tool is Philadelphia’s online data portal, batterymanagement.net. This online hub takes all of the data captured and uploaded by Philadelphia’s range of products, such as the iBOS and eGO!, and translates it into easy-to-understand information and reports.

These data-charged reports, provide managers with the hard facts to run their battery rooms, save resources, verify savings and assure continued efficiencies into the future.

The devil is in the data and batteries and chargers that service a fleet of forklift trucks, for example, comprise a technology investment possessing a huge amount of data that can be analysed and compared to reveal even more powerful ways to cut costs on all fronts.

Philadelphia Scientific has eight product categories with thousands of different variants designed for specific customers, regions or uses. “We try and pre-manufacture as many of the sub-assemblies as we can,” said Andy. “However, because we manufacture regional or customer specific products, we can't manufacture to stock.

“Therefore, we try and work with local suppliers as much as we can. This means that for any components that we use, we have a reliable source and supply chain to make sure we can meet the demand of our manufacturing processes and keep everything all in one place.”

Andy believes that the ‘everything inhouse’ mantra was a key factor behind Philadelphia Scientific’s victory in the Product Innovation and Design category at last year’s TMMX Awards.

He said: “We essentially run an end-toend closed loop manufacturing process, from working with our customers and industry to establish the concept, and bringing it in-house to our R&D team (who we've invested heavily in). We believe that's a really strong area for growth.

“We can take a product from design all the way through to manufacturing and sales, and then loop it back into the process. So, if anything needs to be tweaked or improved, we have that capability and are small and agile enough to carry it out quickly - having a small, bespoke team that can take an idea from concept in month one to shop floor in month six, is something that can’t be achieved anywhere else.”

Duncan added that a key element to innovation and design is firstly establishing that there is a target market. “I see over and over again, particularly in our industry, products being developed that nobody asked for. Until you've figured out that there's a need for the product, don't start that journey,” he said.

He also stressed the importance of understanding value. The industrial world doesn't have an ego, so a product isn’t going to be designed for style. Therefore, value and ROI is crucial, and if you don’t have those two key elements the product won’t be successful.

A third, and equally key element, is ownership; having someone that is responsible for the product. When a Philadelphia design engineer develops a product, they become the owner and get a commission on sales, now and in the future. “That gets them engaged and makes them eager to ensure the product gets to market and stays valid, rather than just staying in development. I think that's quite unique in the R&D world.” Duncan added.

We know if batteries are maintained and used as they're supposed to be, they perform better. Our products help make this possible

Andy Napoleon-Hill, Sales and Marketing Manager, Philadelphia Scientific

• Philadelphia has eight different product categories with thousands of different variants

• Batteries and battery systems are now expected to include digital capabilities

• Philadelphia Scientific customers are experiencing an improvement in battery performance of around 25- 40%

• Batteries will form a key component of industry’s future decarbonisation strategy

• In-house capabilities were key to Philadelphia Scientific winning the Product Innovation and Design Award at TMMX Awards 2022

Like all manufacturers, Philadelphia Scientific has had to react and adapt to a number of different issues over recent years.

One that is ongoing is the drive towards sustainability and increased efficiency.

It’s here that the company is embracing digital technology via the use of robotics to take over mundane worker tasks. It is also decreasing waste by replacing all paper-based instructions with dynamic QR codes that can be updated remotely.

“Some of our challenges are fundamentally connected to resistance to change,” Duncan added. “Many traditional customers around the world have managed to get by for the last 20 years without digital technology in their batteries, and so often question why they need it now. Getting them to change that mindset is difficult.

“And then from an employer perspective in manufacturing, it’s also a challenge to eliminate the fear that robotics and digital technologies are going to replace people. On the contrary, they're there to make workers’ lives more efficient, and that way we can sustain the growth in the business and make workers’ jobs more valuable.”

Since the company purchased its current building, which dates back to 1888, it has been renovated and

ABOVE: Philadelphia’s online data portal, batterymanagement.net, takes all of the data captured and uploaded by Philadelphia’s range of products, such as the iBOS and eGO!, and translates it into easy-to-understand information and reports

insulated, has had low loss glass installed as well as a digital heating control system, all of which help reduce the building’s impact on the environment.

In addition, six half kilowatt solar arrays have been installed on the outside of the building which are used for charging EVs and have been active for the last year. The next stage will be the installation of a 50kW array which will run the entire length of the building, with the

Scan QR code for a video of the visit to Philadelphia Scientific

objective of taking Philadelphia’s entire manufacturing off grid.

Andy added that the company has experienced slight knock-on effects from the COVID pandemic and over the past two years, have had to increase component stock by 50% to ensure customer demands are met.

Jones,

Jones,

“The situation is improving slightly,” Andy continued. “We are seeing an ease in the supply chain and it’s getting easier to source the microchips and silicon-based modules that we use in our components, for example.

“To mitigate this challenge and help secure the supply chain and the process of how we go to market, we redesigned some of our products to have a more uniform fit in some components. That means if we have a rush on a certain product, we have the components already in-house and in stock, enabling us to meet customer demand as quickly as possible.”

What does the future look like?

Duncan concluded that, like it or not, batteries are going to be an essential part of everyone’s decarbonisation

BELOW: Since 1983, Philadelphia Scientific has brought advanced technology solutions to the industrial battery industry

strategy. “What we want to do is make sure that the batteries that are out there perform as well as they can.

“We want to have our monitoring technology on every industrial battery. From an environmental perspective, that's going to help reduce the number of batteries that are needed and help them last longer. And obviously, from a manufacturing perspective, that means more products being made here, which will mean more jobs and more innovation. l

Nowadays, when people buy a battery, they expect it to have digital capabilities. That's been very useful for us

Duncan

Managing Director, Philadelphia ScientificLEFT TO RIGHT: Andy Napoleon-Hill, Sales and Marketing Manager and Duncan Jones, Managing Director, Philadelphia Scientific at last year’s The Manufacturer MX Awards 2022 ABOVE: Philadelphia Scientific’s Bolton home dates back to 1888

on partners and supply chains for Scope 3 or embodied carbon, which typically means all materials used that contribute to the operation and comprise the major contribution to emissions by any organisation.

However, Gordon added that as long as the overall direction of travel is focusing on reducing materials use wherever possible, then reusing everything you can and looking to recycle the remainder, as an organisation you're helping reduce contributions to the increase of CO2 equivalent emissions in our atmosphere.

The approach can work even when you cannot get full transparency of your overall supply chain.

"Reducing at Gripple has been based around using less energy and less materials, and we've designed product solutions that use 25% less material. If you use 25% less material broadly, you're going to cut those emissions," he explained. "The same applies to packaging."

Gripple also looks at where business opportunities can align. The company has already spawned a new business making returnable packaging, further increasing the share of materials reused. Already, it's "really viable", turning over around £20m a year.

With so much analysis reporting that numbers on carbon emissions aren't adding up and even technology and manufacturing giants accused of greenwashing to boot, it can be hard not to feel that fighting off the climate crisis might be unrealistic or even impossible.

However, Gordon Macrae, Special Projects Manager at Yorkshire-based wire joining and tensioning systems provider Gripple,

said the overall picture is what's important. Having accurate numbers to hand is not necessarily critical to an organisation's success in carbon reduction.

"What every business should be doing today, irrespective of having the correct data or not, is reduce, reuse, recycle," said Gordon. He added that many manufacturers have cottoned on to the benefits of data collection and data strategy for reducing emissions in-house.

Yes, it's still hard to get accurate figures

Gripple has also built up a product group for anchoring systems for matting that allows vegetation to be planted on, for example, defensive levees against flooding and constructions to prevent soil erosionanother cause of emissions.

"These are all the sorts of things you can do today, and it is beholden on manufacturers. But, I am quite critical of the government not putting enough money into the knowledge base to give us a better understanding of using alternative materials and recycling," Gordon added.

"Our products are often all about having to meet performance requirements, and that's often one of the reasons why you have to use virgin material."

How manufacturers can boost carbon efficiency across their full supply chain - even if they can't accurately trust supplier estimates

He conceded that Gripple is fortunate because it's vertically integrated, enabling the manufacturer to take components used when building machines and redeploy them in a different machine, or somewhere else. "A big challenge is that 80% of our products go into construction which is much more difficult to deal with. There's some work to do there," he added.

Instead of focusing on the latest numbers, manufacturers can make progress by becoming more open, sharing peer-to-peer information about experiences, providers and collaborative efforts to develop more collective thinking and innovation, for instance among users of heavy metals based in Sheffield in Gripple's case.

"Manufacturers aren't very good at sharing information and best practice. Yet this is a much bigger challenge than individual companies. It should be to everyone's benefit if we can find better ways of doing things," he continued.

Organisations such as the Sustainable Digital Infrastructure Alliance (SDIA) have been hammering home the point that stepping outside the office to speak to local people beyond the business can help find synergies. By sharing information and collaborating on practical solutions, even

RIGHT: Trees and forests can help counteract some emissions although reduction is key overall IMAGE: Landon Parenteau /Unsplash

more resource use can be reduced and materials reused or recycled.

The pros and cons of current transport infrastructure can restrain manufacturing efforts to cut emissions. Why not work together to lobby for or apply for funding for better cycling and pedestrian facilities? Or employees at different businesses might club together to reduce emissions from their work commute through car-pooling, for example. Can materials, water or energy used by a factory be redeployed for cooling assets at some other operation or even in residential areas?

Work with what and who you know Tasha Lyth, Sustainability Manager at Gripple, recommended the approach of stepping outside the door and talking to people. If a business can figure out what's going on locally, there can be a real chance to develop mutually beneficial solutions.

"If instead you spend 12 months trying to establish your starting point with data, by then your information is probably no longer

relevant for the current business position," she pointed out.

People you have in-house also often have knowledge that isn't leveraged, including in relation to where resources are wasted. When cost savings can be coupled up, the result can be "environmental savings all day long" and you are almost certainly reducing your environmental impact.

Lyth added: "Ultimately, if you've got experienced people who know your business, then they will also know what material means to the business. If I sit down with our senior leadership team and ask

BELOW: Facilities can benefit from taking an overall 'big picture' view IMAGE: Marcin Jozwiak/Unsplash

Reducing at Gripple has been around using less energy and less materials, and we've designed product solutions that use 25% less material

Gordon Macrae, Special Projects Manager, Gripple

where they think our carbon hotspots are, they might not have the numbers in front of them, but they will certainly be able to identify those areas," she said.

Tasha went on to highlight that the need to calculate emissions or perform weightings of carbon can feel like "some kind of dark art" when actually it's just conversion factors that are manageable by a "fairly savvy" Excel user without significant training. Simply identify the right people and show them what's needed, and you can be well on the way to figuring out your emissions.

"If you are wanting to set a net zero or carbon neutrality target, you need to have numbers to back it up. So if you want to embark on that public commitment, there is probably a reasonable amount of data work to do for a couple of months," added Tasha.

"However, if you just want to do the right thing, there's absolutely no requirement to make that public commitment and reducing emissions can just be part of your business culture. It's about making a start and being bold."

Gripple does its key data collection as part of its reporting period at the start of the year. By each March the company aims to have the full carbon emissions account and set for the previous year. That gives the organisation enough good information to figure out whether its reductions and savings are on track and to scope out the next steps to keep the momentum going.

Tasha added: "We also have dashboards and information currently live within the business that's used internally. We don't share that information but we use it to drive behaviour and change."

To achieve a fully data-driven and compliance approach, Mike Hardisty, Head of Environmental Sustainability at EngineeringUK, said it can become essential to tackle supply chain partners directly. Actually ask the supplier about its environmental achievements and initiatives, and consider whether they sound substantive or more like window-dressing.

"Check if the supplier has an environmental management system that meets ISO 14001 or similar," Mike said. Product claims can often be independently verified by a respected third-party. Construction products and materials, for

ABOVE: Technology and e-waste are major contributors to Scope 3 embodied emissions

- IMAGE: John Cameron/ Unsplash

example, can come with an Environmental Product Declaration (EPD) of the environmental impact associated with each unit of product.

"EPDs cover a pre-defined scope to avoid suppliers under-calling the impact by choosing to ignore certain areas. As an example, at EngineeringUK we only use paper that has been certified by the Forestry Stewardship Council (FSC)," said Hardisty.

Manufacturers can also request that their supplier submits their corporate emissions data to the CDP (formerly the Carbon Disclosure Project) and sets a carbon reduction target through the Science Based Targets Initiative (SBTi).

• Scope 3 (embodied carbon) emissions from partners and across supply chains are the toughest to calculate

• There's no need to wait for accurate data - what matters is to head in the right direction

• Reduce materials use everywhere you can, working with what you know and can learn

• Reuse materials wherever reduction isn't possible, and recycle what's left

• Innovate internally and externally to create approaches to increase the overall amounts you reduce, reuse and recycle.

Consider developing environmental product declarations (EPDs) for your own products, to see how they compare

Mike Hardisty, Head of Environmental Sustainability, EngineeringUK

"Adopt an internationally recognised carbon reporting framework, such as the Greenhouse Gas Protocol (GHG Protocol) or ISO14064-1. EngineeringUK adopted the former," he continued. "The basic [carbon emissions] calculations are quite straightforward although getting the right data often isn't."

He warned that all 13 Scope 3 categories of emissions must be considered if nothing significant is to be missed. This suggests that many manufacturers may need to invest in special training for one or two people and a potential investment in third-party computer software - such as Emitwise for automotive, FMCG or packaging, OneClick LCA for construction projects or Watershed for consumer goods and supply chains.

"Consider developing EPDs for your own products, both to see how they compare and to better understand how you can reduce the impact of your products. This will require specialist software or outsourcing to specialist carbon consultancies," Hardisty added.

Luke Walsh, Managing Director at Liverpool industrial communications specialist Brainboxes, commented that the firm has been accredited with ISO 140001 for years and for sustainability via EcoVardis. "However, internally we see this as a small step, validating where we currently are and setting a pathway to demarcate future improvement."

He added that smaller manufacturers especially, can struggle to impose supply chain compliance and restraints, with suppliers not necessarily offering transparency when asked and as a result, like Gripple, the company is focusing on internal transparency first and aiming to influence the supply chain by example.

"Brainboxes now monitors and exposes all energy consumption data to all staff within the organisation," Luke said.

At Brainboxes, sharing is caring Brainboxes is using its own industrial communication and monitoring expertise in-house alongside a view of cost and the carbon footprint. "We display this data in our foyer, next to the coffee machine. When taking a break, staff will often review the data and suggest improvements to management," Luke revealed. For example, sequencing start-up of the machines each morning on the production line, turning the compressor off during stocktake when not required or turning the air-con up 1oC.

Brainboxes also made the tools it uses to do this open source and are available

TOP: Brainboxes' Luke Walsh says it can be tough as an SME asking for more transparency ABOVE: ABB's David Lowen says that manufacturing facilities reduce energy costs and carbon emissions using its own tech

on its website, so customers and suppliers alike can implement this for themselves for a low investment. "However, let's not forget this is just the beginning of the journey; no business has cracked this yet. It's a multidecade process," Luke noted.